engine coolant CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 356 of 2438

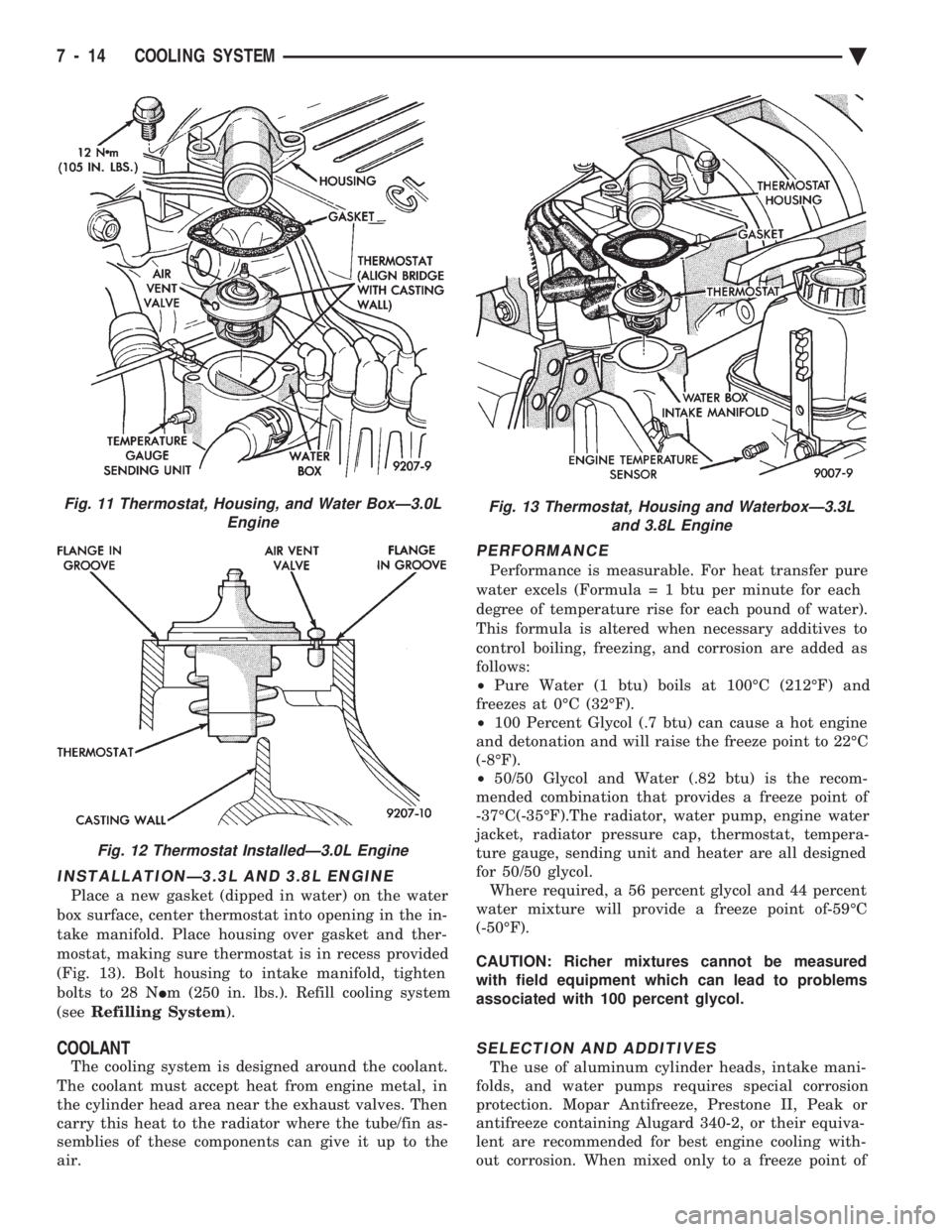

INSTALLATIONÐ3.3L AND 3.8L ENGINE

Place a new gasket (dipped in water) on the water

box surface, center thermostat into opening in the in-

take manifold. Place housing over gasket and ther-

mostat, making sure thermostat is in recess provided

(Fig. 13). Bolt housing to intake manifold, tighten

bolts to 28 N Im (250 in. lbs.). Refill cooling system

(see Refilling System ).

COOLANT

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves. Then

carry this heat to the radiator where the tube/fin as-

semblies of these components can give it up to the

air.

PERFORMANCE

Performance is measurable. For heat transfer pure

water excels (Formul a = 1 btu per minute for each

degree of temperature rise for each pound of water).

This formula is altered when necessary additives to

control boiling, freezing, and corrosion are added as

follows:

² Pure Water (1 btu) boils at 100ÉC (212ÉF) and

freezes at 0ÉC (32ÉF).

² 100 Percent Glycol (.7 btu) can cause a hot engine

and detonation and will raise the freeze point to 22ÉC

(-8ÉF).

² 50/50 Glycol and Water (.82 btu) is the recom-

mended combination that provides a freeze point of

-37ÉC(-35ÉF).The radiator, water pump, engine water

jacket, radiator pressure cap, thermostat, tempera-

ture gauge, sending unit and heater are all designed

for 50/50 glycol. Where required, a 56 percent glycol and 44 percent

water mixture will provide a freeze point of-59ÉC

(-50ÉF).

CAUTION: Richer mixtures cannot be measured

with field equipment which can lead to problems

associated with 100 percent glycol.

SELECTION AND ADDITIVES

The use of aluminum cylinder heads, intake mani-

folds, and water pumps requires special corrosion

protection. Mopar Antifreeze, Prestone II, Peak or

antifreeze containing Alugard 340-2, or their equiva-

lent are recommended for best engine cooling with-

out corrosion. When mixed only to a freeze point of

Fig. 11 Thermostat, Housing, and Water BoxÐ3.0L Engine

Fig. 12 Thermostat InstalledÐ3.0L Engine

Fig. 13 Thermostat, Housing and WaterboxÐ3.3Land 3.8L Engine

7 - 14 COOLING SYSTEM Ä

Page 357 of 2438

-37ÉC (-35ÉF) to -59ÉC (-50ÉF). If it looses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed solution.

SERVICE

Coolant should be changed at 52,500 miles or three

years, whichever occurs first, then every two years or

30,000 miles.

ROUTINE LEVEL CHECK

Do not remove radiator cap for routine coolant

level inspections. The coolant reserve system provides a quick visual

method for determining the coolant level without re-

moving the radiator cap. Simply observe, with the

engine idling and warmed up to normal operating

temperature, that the level of the coolant in the reserve

tank (Figs. 5 and 6) is between the minimum and

maximum marks.

ADDING ADDITIONAL COOLANT

The radiator cap should not be removed. When

additional coolant is needed to maintain this level, it

should be added to the coolant reserve tank. Use only

50/50 concentration of ethylene glycol type antifreeze

and water.

SERVICE COOLANT LEVEL

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator. When servicing requires a coolant level check in the

radiator, the engine must be offand notunder pres-

sure. Drain several ounces of coolant from the radiator

drain cock while observing the Coolant Recovery Sys-

tem (CRS) Tank. Coolant level in the CRS tank should

drop slightly. Then remove the radiator cap. The radia-

tor should be full to the top. If not, and the coolant level

in the CRS tank is at the MIN mark there is a air leak

in the CRS system. Check hose or hose connections to

the CRS tank, radiator filler neck or the pressure cap

seal to the radiator filler neck for leaks.

LOW COOLANT LEVEL AERATION

Low coolant level in a cross flow radiator will equal-

ize in both tanks with engine off. With engine at

running operating temperature the high pressure inlet

tank runs full and the low pressure outlet tank drops.

If this level drops below the top of the transmission oil

cooler, air will be sucked into the water pump:

² Transmission oil will become hotter.

² High reading shown on the temperature gauge.

² Air in the coolant will also cause loss of flow through

the heater.

² Exhaust gas leaks into the coolant can also cause the

same problems.

DEAERATION

Air can only be removed from the system by gather-

ing under the pressure cap. On the next heat up it will

be pushed past the pressure cap into the CRS tank by

thermal expansion of the coolant. It then escapes to the

atmosphere in the CRS tank and is replaced with solid

coolant on cool down.

COOLING SYSTEM DRAIN, CLEAN, FLUSH AND

REFILL

Drain, flush, and fill the cooling system at the

mileage or time intervals specified in the Maintenance

Schedule in this Group. If the solution is dirty or rusty

or contains a considerable amount of sediment, clean

and flush with a reliable cooling system cleaner. Care

should be taken in disposing of the used engine coolant

from your vehicle. Check governmental regulations for

disposal of used engine coolant.

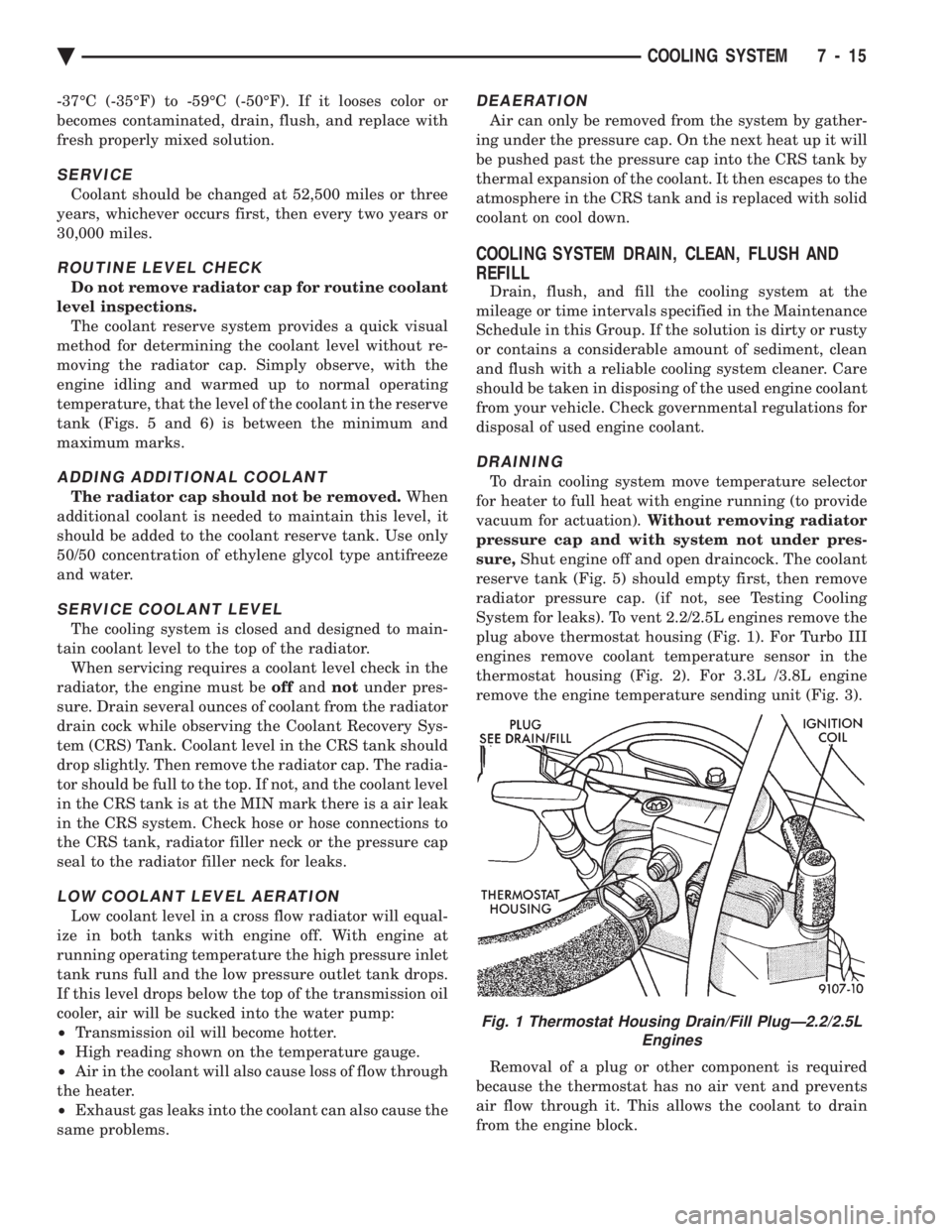

DRAINING

To drain cooling system move temperature selector

for heater to full heat with engine running (to provide

vacuum for actuation). Without removing radiator

pressure cap and with system not under pres-

sure, Shut engine off and open draincock. The coolant

reserve tank (Fig. 5) should empty first, then remove

radiator pressure cap. (if not, see Testing Cooling

System for leaks). To vent 2.2/2.5L engines remove the

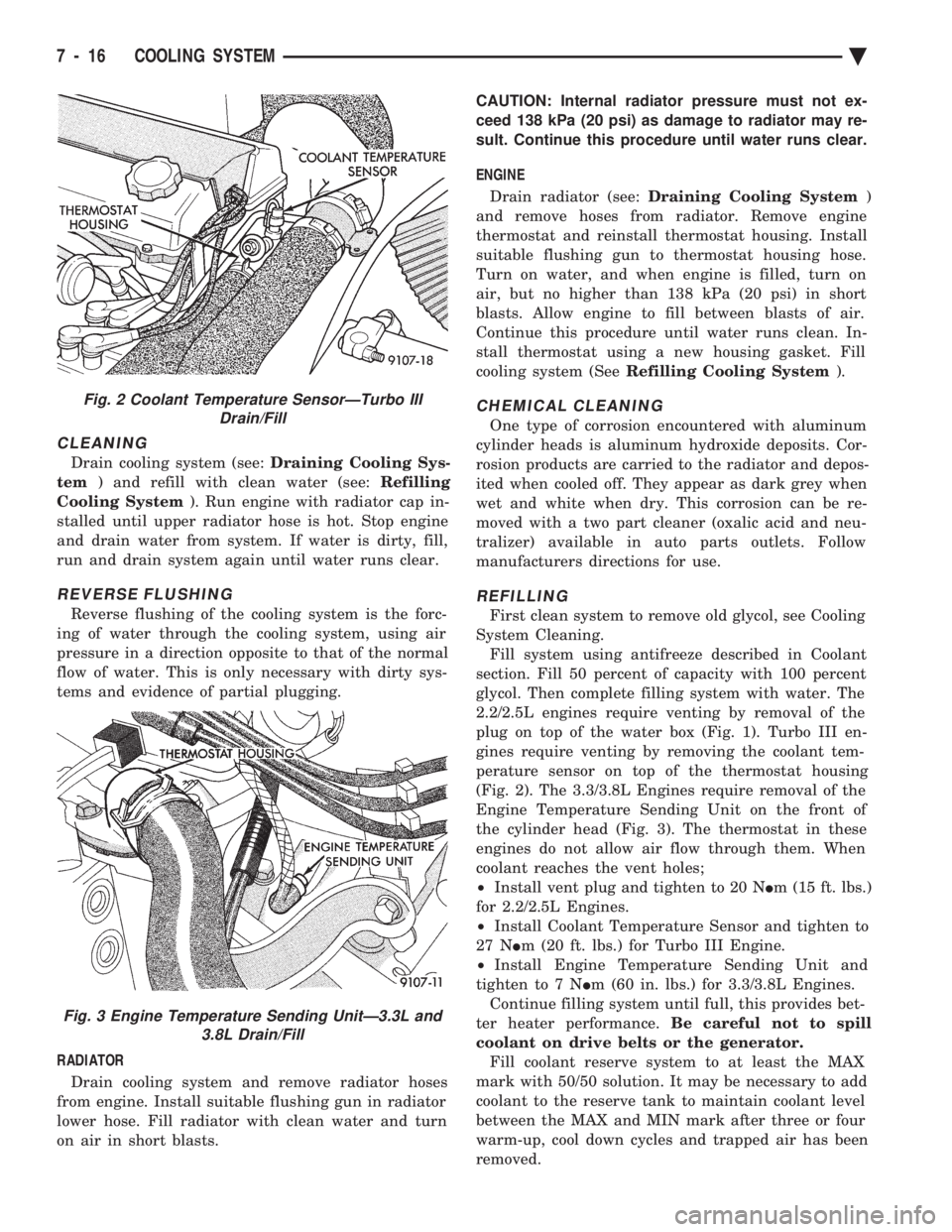

plug above thermostat housing (Fig. 1). For Turbo III

engines remove coolant temperature sensor in the

thermostat housing (Fig. 2). For 3.3L /3.8L engine

remove the engine temperature sending unit (Fig. 3).

Removal of a plug or other component is required

because the thermostat has no air vent and prevents

air flow through it. This allows the coolant to drain

from the engine block.

Fig. 1 Thermostat Housing Drain/Fill PlugÐ2.2/2.5L Engines

Ä COOLING SYSTEM 7 - 15

Page 358 of 2438

CLEANING

Drain cooling system (see: Draining Cooling Sys-

tem ) and refill with clean water (see: Refilling

Cooling System ). Run engine with radiator cap in-

stalled until upper radiator hose is hot. Stop engine

and drain water from system. If water is dirty, fill,

run and drain system again until water runs clear.

REVERSE FLUSHING

Reverse flushing of the cooling system is the forc-

ing of water through the cooling system, using air

pressure in a direction opposite to that of the normal

flow of water. This is only necessary with dirty sys-

tems and evidence of partial plugging.

RADIATOR Drain cooling system and remove radiator hoses

from engine. Install suitable flushing gun in radiator

lower hose. Fill radiator with clean water and turn

on air in short blasts. CAUTION: Internal radiator pressure must not ex-

ceed 138 kPa (20 psi) as damage to radiator may re-

sult. Continue this procedure until water runs clear.

ENGINE

Drain radiator (see: Draining Cooling System )

and remove hoses from radiator. Remove engine

thermostat and reinstall thermostat housing. Install

suitable flushing gun to thermostat housing hose.

Turn on water, and when engine is filled, turn on

air, but no higher than 138 kPa (20 psi) in short

blasts. Allow engine to fill between blasts of air.

Continue this procedure until water runs clean. In-

stall thermostat using a new housing gasket. Fill

cooling system (See Refilling Cooling System ).

CHEMICAL CLEANING

One type of corrosion encountered with aluminum

cylinder heads is aluminum hydroxide deposits. Cor-

rosion products are carried to the radiator and depos-

ited when cooled off. They appear as dark grey when

wet and white when dry. This corrosion can be re-

moved with a two part cleaner (oxalic acid and neu-

tralizer) available in auto parts outlets. Follow

manufacturers directions for use.

REFILLING

First clean system to remove old glycol, see Cooling

System Cleaning. Fill system using antifreeze described in Coolant

section. Fill 50 percent of capacity with 100 percent

glycol. Then complete filling system with water. The

2.2/2.5L engines require venting by removal of the

plug on top of the water box (Fig. 1). Turbo III en-

gines require venting by removing the coolant tem-

perature sensor on top of the thermostat housing

(Fig. 2). The 3.3/3.8L Engines require removal of the

Engine Temperature Sending Unit on the front of

the cylinder head (Fig. 3). The thermostat in these

engines do not allow air flow through them. When

coolant reaches the vent holes;

² Install vent plug and tighten to 20 N Im (15 ft. lbs.)

for 2.2/2.5L Engines.

² Install Coolant Temperature Sensor and tighten to

27 N Im (20 ft. lbs.) for Turbo III Engine.

² Install Engine Temperature Sending Unit and

tighten to 7 N Im (60 in. lbs.) for 3.3/3.8L Engines.

Continue filling system until full, this provides bet-

ter heater performance. Be careful not to spill

coolant on drive belts or the generator. Fill coolant reserve system to at least the MAX

mark with 50/50 solution. It may be necessary to add

coolant to the reserve tank to maintain coolant level

between the MAX and MIN mark after three or four

warm-up, cool down cycles and trapped air has been

removed.

Fig. 2 Coolant Temperature SensorÐTurbo III Drain/Fill

Fig. 3 Engine Temperature Sending UnitÐ3.3L and 3.8L Drain/Fill

7 - 16 COOLING SYSTEM Ä

Page 359 of 2438

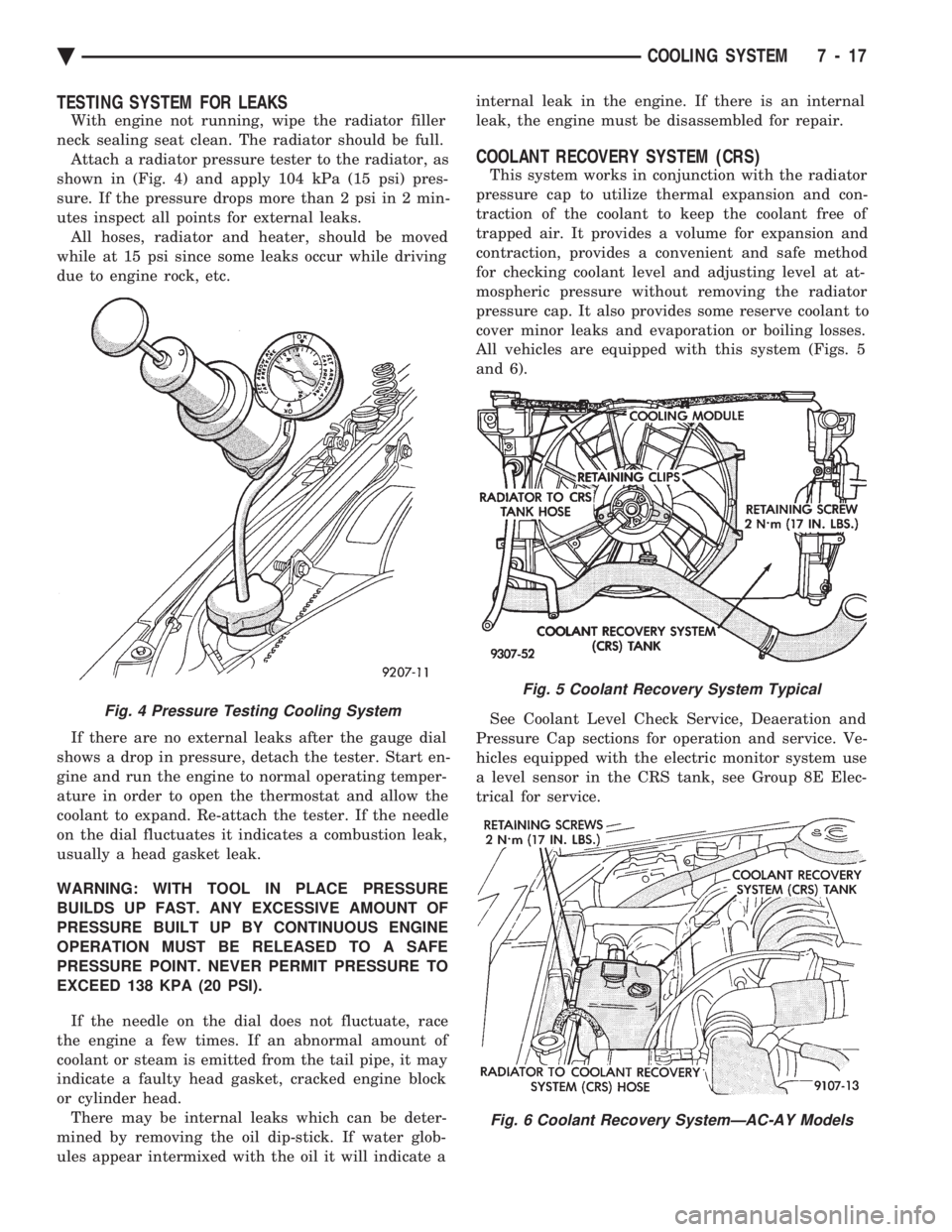

TESTING SYSTEM FOR LEAKS

With engine not running, wipe the radiator filler

neck sealing seat clean. The radiator should be full. Attach a radiator pressure tester to the radiator, as

shown in (Fig. 4) and apply 104 kPa (15 psi) pres-

sure. If the pressure drops more than 2 psi in 2 min-

utes inspect all points for external leaks. All hoses, radiator and heater, should be moved

while at 15 psi since some leaks occur while driving

due to engine rock, etc.

If there are no external leaks after the gauge dial

shows a drop in pressure, detach the tester. Start en-

gine and run the engine to normal operating temper-

ature in order to open the thermostat and allow the

coolant to expand. Re-attach the tester. If the needle

on the dial fluctuates it indicates a combustion leak,

usually a head gasket leak.

WARNING: WITH TOOL IN PLACE PRESSURE

BUILDS UP FAST. ANY EXCESSIVE AMOUNT OF

PRESSURE BUILT UP BY CONTINUOUS ENGINE

OPERATION MUST BE RELEASED TO A SAFE

PRESSURE POINT. NEVER PERMIT PRESSURE TO

EXCEED 138 KPA (20 PSI).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam is emitted from the tail pipe, it may

indicate a faulty head gasket, cracked engine block

or cylinder head. There may be internal leaks which can be deter-

mined by removing the oil dip-stick. If water glob-

ules appear intermixed with the oil it will indicate a internal leak in the engine. If there is an internal

leak, the engine must be disassembled for repair.

COOLANT RECOVERY SYSTEM (CRS)

This system works in conjunction with the radiator

pressure cap to utilize thermal expansion and con-

traction of the coolant to keep the coolant free of

trapped air. It provides a volume for expansion and

contraction, provides a convenient and safe method

for checking coolant level and adjusting level at at-

mospheric pressure without removing the radiator

pressure cap. It also provides some reserve coolant to

cover minor leaks and evaporation or boiling losses.

All vehicles are equipped with this system (Figs. 5

and 6).

See Coolant Level Check Service, Deaeration and

Pressure Cap sections for operation and service. Ve-

hicles equipped with the electric monitor system use

a level sensor in the CRS tank, see Group 8E Elec-

trical for service.

Fig. 4 Pressure Testing Cooling System

Fig. 5 Coolant Recovery System Typical

Fig. 6 Coolant Recovery SystemÐAC-AY Models

Ä COOLING SYSTEM 7 - 17

Page 360 of 2438

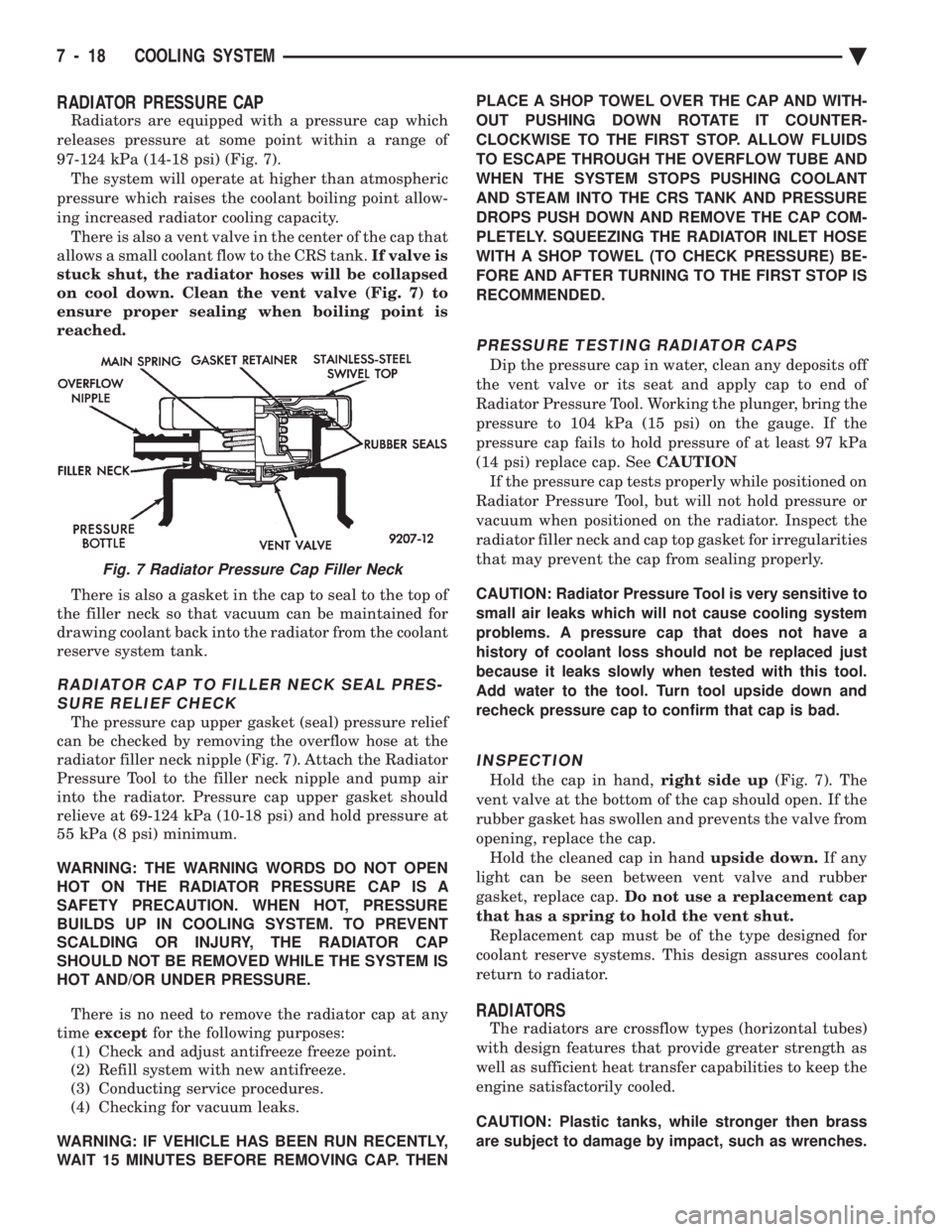

RADIATOR PRESSURE CAP

Radiators are equipped with a pressure cap which

releases pressure at some point within a range of

97-124 kPa (14-18 psi) (Fig. 7). The system will operate at higher than atmospheric

pressure which raises the coolant boiling point allow-

ing increased radiator cooling capacity. There is also a vent valve in the center of the cap that

allows a small coolant flow to the CRS tank. If valve is

stuck shut, the radiator hoses will be collapsed

on cool down. Clean the vent valve (Fig. 7) to

ensure proper sealing when boiling point is

reached.

There is also a gasket in the cap to seal to the top of

the filler neck so that vacuum can be maintained for

drawing coolant back into the radiator from the coolant

reserve system tank.

RADIATOR CAP TO FILLER NECK SEAL PRES- SURE RELIEF CHECK

The pressure cap upper gasket (seal) pressure relief

can be checked by removing the overflow hose at the

radiator filler neck nipple (Fig. 7). Attach the Radiator

Pressure Tool to the filler neck nipple and pump air

into the radiator. Pressure cap upper gasket should

relieve at 69-124 kPa (10-18 psi) and hold pressure at

55 kPa (8 psi) minimum.

WARNING: THE WARNING WORDS DO NOT OPEN

HOT ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM IS

HOT AND/OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

time except for the following purposes:

(1) Check and adjust antifreeze freeze point.

(2) Refill system with new antifreeze.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN PLACE A SHOP TOWEL OVER THE CAP AND WITH-

OUT PUSHING DOWN ROTATE IT COUNTER-

CLOCKWISE TO THE FIRST STOP. ALLOW FLUIDS

TO ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COM-

PLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE) BE-

FORE AND AFTER TURNING TO THE FIRST STOP IS

RECOMMENDED.

PRESSURE TESTING RADIATOR CAPS

Dip the pressure cap in water, clean any deposits off

the vent valve or its seat and apply cap to end of

Radiator Pressure Tool. Working the plunger, bring the

pressure to 104 kPa (15 psi) on the gauge. If the

pressure cap fails to hold pressure of at least 97 kPa

(14 psi) replace cap. See CAUTION

If the pressure cap tests properly while positioned on

Radiator Pressure Tool, but will not hold pressure or

vacuum when positioned on the radiator. Inspect the

radiator filler neck and cap top gasket for irregularities

that may prevent the cap from sealing properly.

CAUTION: Radiator Pressure Tool is very sensitive to

small air leaks which will not cause cooling system

problems. A pressure cap that does not have a

history of coolant loss should not be replaced just

because it leaks slowly when tested with this tool.

Add water to the tool. Turn tool upside down and

recheck pressure cap to confirm that cap is bad.

INSPECTION

Hold the cap in hand, right side up(Fig. 7). The

vent valve at the bottom of the cap should open. If the

rubber gasket has swollen and prevents the valve from

opening, replace the cap. Hold the cleaned cap in hand upside down.If any

light can be seen between vent valve and rubber

gasket, replace cap. Do not use a replacement cap

that has a spring to hold the vent shut. Replacement cap must be of the type designed for

coolant reserve systems. This design assures coolant

return to radiator.

RADIATORS

The radiators are crossflow types (horizontal tubes)

with design features that provide greater strength as

well as sufficient heat transfer capabilities to keep the

engine satisfactorily cooled.

CAUTION: Plastic tanks, while stronger then brass

are subject to damage by impact, such as wrenches.

Fig. 7 Radiator Pressure Cap Filler Neck

7 - 18 COOLING SYSTEM Ä

Page 361 of 2438

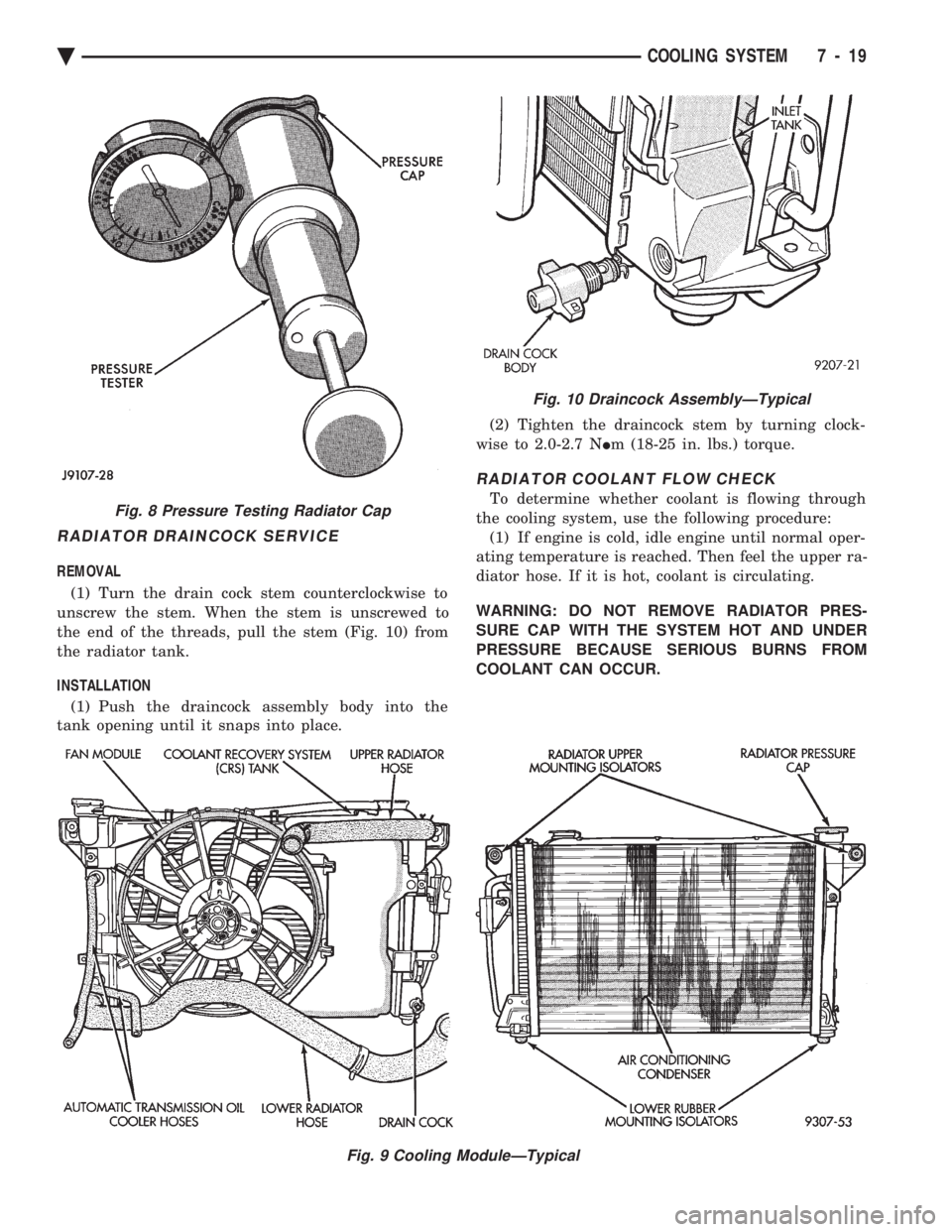

RADIATOR DRAINCOCK SERVICE

REMOVAL (1) Turn the drain cock stem counterclockwise to

unscrew the stem. When the stem is unscrewed to

the end of the threads, pull the stem (Fig. 10) from

the radiator tank.

INSTALLATION (1) Push the draincock assembly body into the

tank opening until it snaps into place. (2) Tighten the draincock stem by turning clock-

wise to 2.0-2.7 N Im (18-25 in. lbs.) torque.

RADIATOR COOLANT FLOW CHECK

To determine whether coolant is flowing through

the cooling system, use the following procedure: (1) If engine is cold, idle engine until normal oper-

ating temperature is reached. Then feel the upper ra-

diator hose. If it is hot, coolant is circulating.

WARNING: DO NOT REMOVE RADIATOR PRES-

SURE CAP WITH THE SYSTEM HOT AND UNDER

PRESSURE BECAUSE SERIOUS BURNS FROM

COOLANT CAN OCCUR.

Fig. 9 Cooling ModuleÐTypical

Fig. 8 Pressure Testing Radiator Cap

Fig. 10 Draincock AssemblyÐTypical

Ä COOLING SYSTEM 7 - 19

Page 362 of 2438

(2) Remove radiator pressure cap when engine is

cold, Idle engine until thermostat opens, you should

observe coolant flow while looking down the filler

neck. Once flow is detected install radiator pressure

cap.

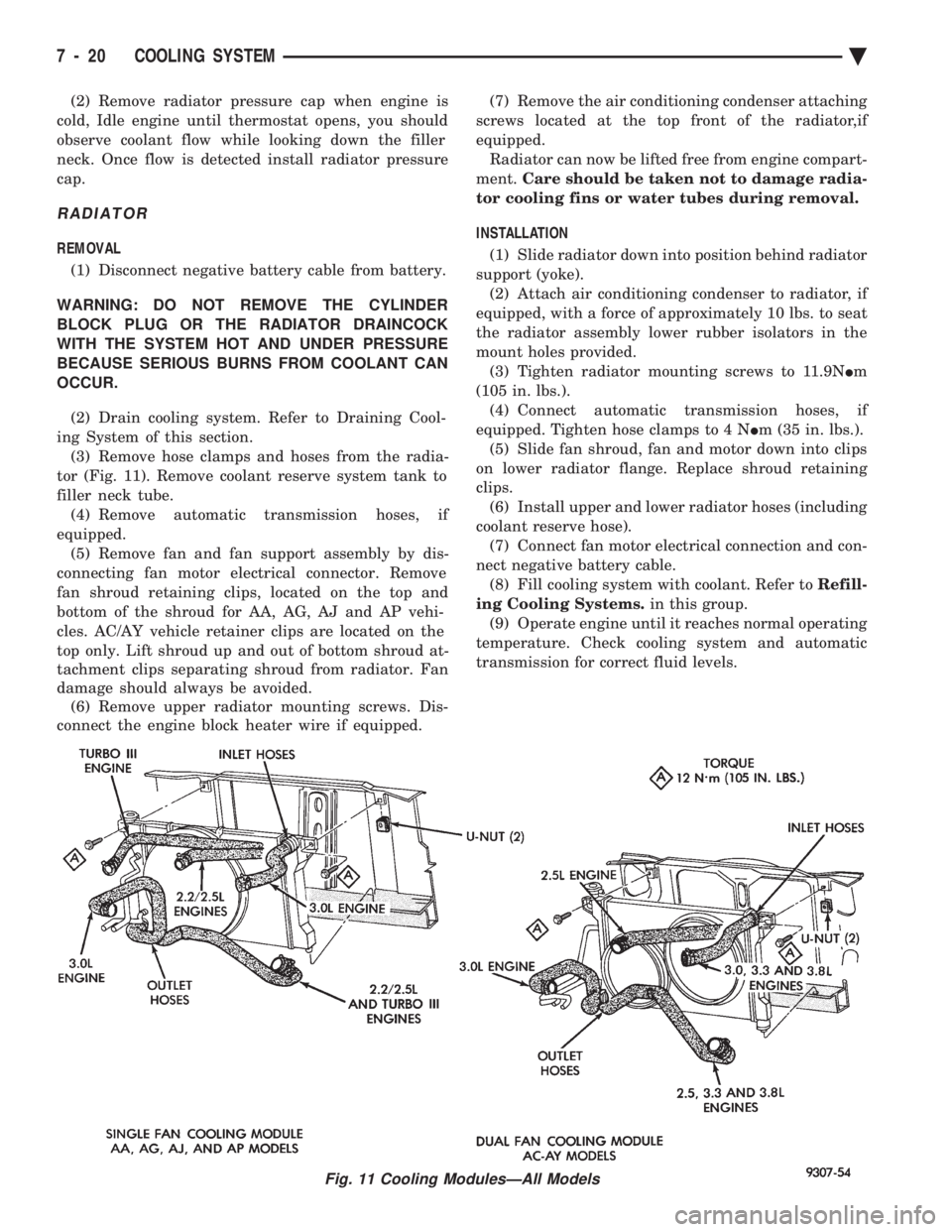

RADIATOR

REMOVAL

(1) Disconnect negative battery cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(2) Drain cooling system. Refer to Draining Cool-

ing System of this section. (3) Remove hose clamps and hoses from the radia-

tor (Fig. 11). Remove coolant reserve system tank to

filler neck tube. (4) Remove automatic transmission hoses, if

equipped. (5) Remove fan and fan support assembly by dis-

connecting fan motor electrical connector. Remove

fan shroud retaining clips, located on the top and

bottom of the shroud for AA, AG, AJ and AP vehi-

cles. AC/AY vehicle retainer clips are located on the

top only. Lift shroud up and out of bottom shroud at-

tachment clips separating shroud from radiator. Fan

damage should always be avoided. (6) Remove upper radiator mounting screws. Dis-

connect the engine block heater wire if equipped. (7) Remove the air conditioning condenser attaching

screws located at the top front of the radiator,if

equipped. Radiator can now be lifted free from engine compart-

ment. Care should be taken not to damage radia-

tor cooling fins or water tubes during removal.

INSTALLATION

(1) Slide radiator down into position behind radiator

support (yoke). (2) Attach air conditioning condenser to radiator, if

equipped, with a force of approximately 10 lbs. to seat

the radiator assembly lower rubber isolators in the

mount holes provided. (3) Tighten radiator mounting screws to 11.9N Im

(105 in. lbs.). (4) Connect automatic transmission hoses, if

equipped. Tighten hose clamps to 4 N Im (35 in. lbs.).

(5) Slide fan shroud, fan and motor down into clips

on lower radiator flange. Replace shroud retaining

clips. (6) Install upper and lower radiator hoses (including

coolant reserve hose). (7) Connect fan motor electrical connection and con-

nect negative battery cable. (8) Fill cooling system with coolant. Refer to Refill-

ing Cooling Systems. in this group.

(9) Operate engine until it reaches normal operating

temperature. Check cooling system and automatic

transmission for correct fluid levels.

Fig. 11 Cooling ModulesÐAll Models

7 - 20 COOLING SYSTEM Ä

Page 363 of 2438

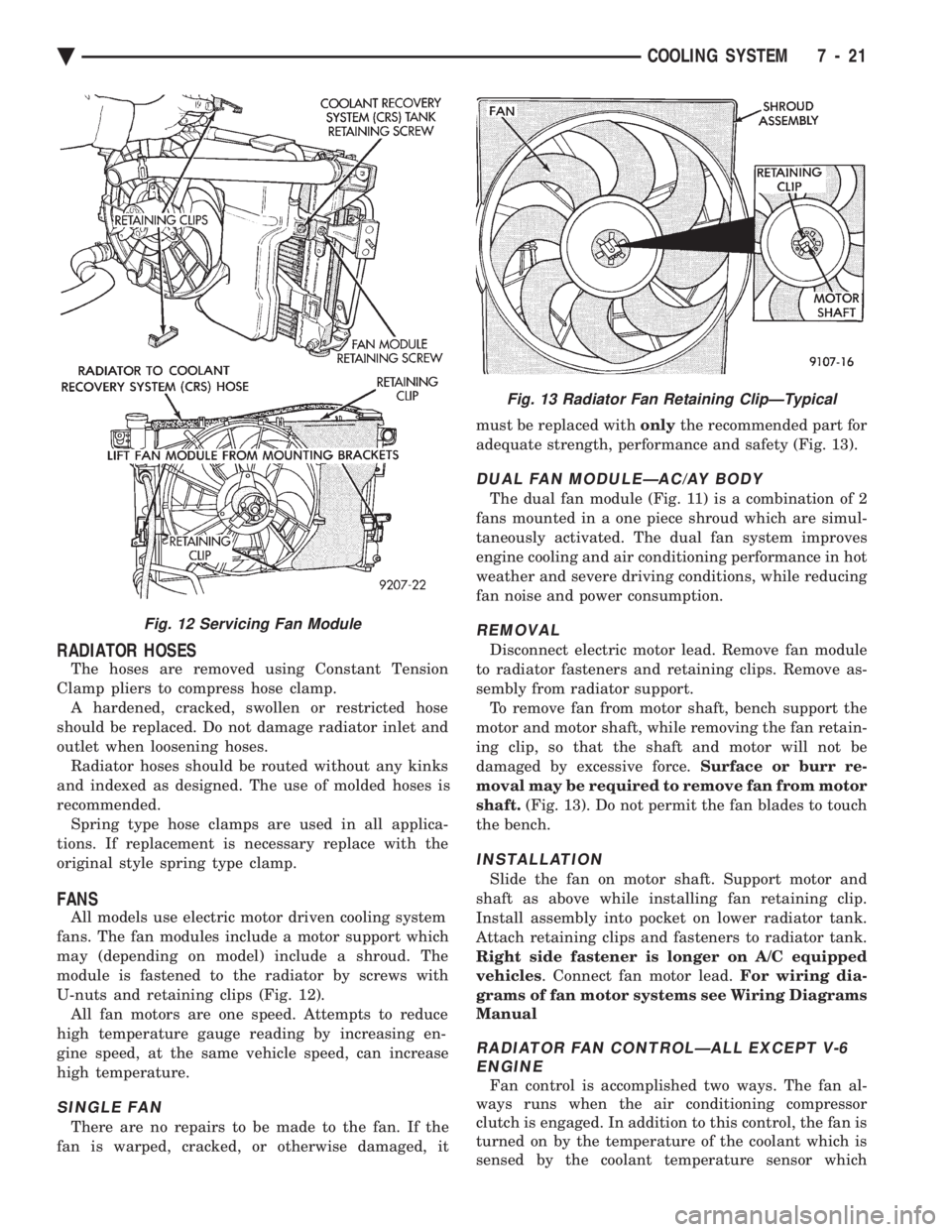

RADIATOR HOSES

The hoses are removed using Constant Tension

Clamp pliers to compress hose clamp. A hardened, cracked, swollen or restricted hose

should be replaced. Do not damage radiator inlet and

outlet when loosening hoses. Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended. Spring type hose clamps are used in all applica-

tions. If replacement is necessary replace with the

original style spring type clamp.

FANS

All models use electric motor driven cooling system

fans. The fan modules include a motor support which

may (depending on model) include a shroud. The

module is fastened to the radiator by screws with

U-nuts and retaining clips (Fig. 12). All fan motors are one speed. Attempts to reduce

high temperature gauge reading by increasing en-

gine speed, at the same vehicle speed, can increase

high temperature.

SINGLE FAN

There are no repairs to be made to the fan. If the

fan is warped, cracked, or otherwise damaged, it must be replaced with

onlythe recommended part for

adequate strength, performance and safety (Fig. 13).

DUAL FAN MODULEÐAC/AY BODY

The dual fan module (Fig. 11) is a combination of 2

fans mounted in a one piece shroud which are simul-

taneously activated. The dual fan system improves

engine cooling and air conditioning performance in hot

weather and severe driving conditions, while reducing

fan noise and power consumption.

REMOVAL

Disconnect electric motor lead. Remove fan module

to radiator fasteners and retaining clips. Remove as-

sembly from radiator support. To remove fan from motor shaft, bench support the

motor and motor shaft, while removing the fan retain-

ing clip, so that the shaft and motor will not be

damaged by excessive force. Surface or burr re-

moval may be required to remove fan from motor

shaft. (Fig. 13). Do not permit the fan blades to touch

the bench.

INSTALLATION

Slide the fan on motor shaft. Support motor and

shaft as above while installing fan retaining clip.

Install assembly into pocket on lower radiator tank.

Attach retaining clips and fasteners to radiator tank.

Right side fastener is longer on A/C equipped

vehicles . Connect fan motor lead. For wiring dia-

grams of fan motor systems see Wiring Diagrams

Manual

RADIATOR FAN CONTROLÐALL EXCEPT V-6 ENGINE

Fan control is accomplished two ways. The fan al-

ways runs when the air conditioning compressor

clutch is engaged. In addition to this control, the fan is

turned on by the temperature of the coolant which is

sensed by the coolant temperature sensor which

Fig. 12 Servicing Fan Module

Fig. 13 Radiator Fan Retaining ClipÐTypical

Ä COOLING SYSTEM 7 - 21

Page 364 of 2438

sends the message to the Engine Controller. The En-

gine Controller turns on the fan through the fan re-

lay. See Wiring Diagrams Manual for circuity and

diagnostics provided.Switching through the Engine Controller provides

fan control for the following conditions.

² The fan will not run during cranking until the en-

gine starts no matter what the coolant temperature

is.

² Fan will run when the air conditioning clutch is

engaged and low pressure cutout switch is closed.

² For 4 cylinder application the fan will run at ve-

hicle speeds above about 40 mph only if coolant tem-

perature reaches 110ÉC (230ÉF). It will turn off when

the temperature drops to 104ÉC (220ÉF). At speeds

below 40 mph the fan switches on at 102ÉC (215ÉF)

and off at 93ÉC (200ÉF).

² This is to help prevent steaming. The fan will run

only below 16ÉC (60ÉF) ambient. Between 38ÉC

(100ÉF) to 97ÉC (195ÉF) coolant temperature, at idle

and then only for three minutes.

RADIATOR FAN CONTROLÐAC/AY BODY V-6 ONLY

For this application, fan control is accomplished

based on coolant temperature, and on A/C head pres-

sure. These vehicles receive the variable displace-

ment compressor. The fan will go on when;

² Coolant temperature reaches 102ÉC (215ÉF) and off

at 93.4ÉC (200ÉF) regardless of vehicle speed.

² When the head pressure reaches 1516.9 kPa (220

psi) and turn off when the pressure reaches 1103 kPa

(160 psi).

TEMPERATURE GAUGE INDICATION

At idle the temperature gauge will rise slowly to

about 5/8 gauge travel. The fan will come on and the

gauge will drop to about 1/2 gauge travel, this is nor-

mal.

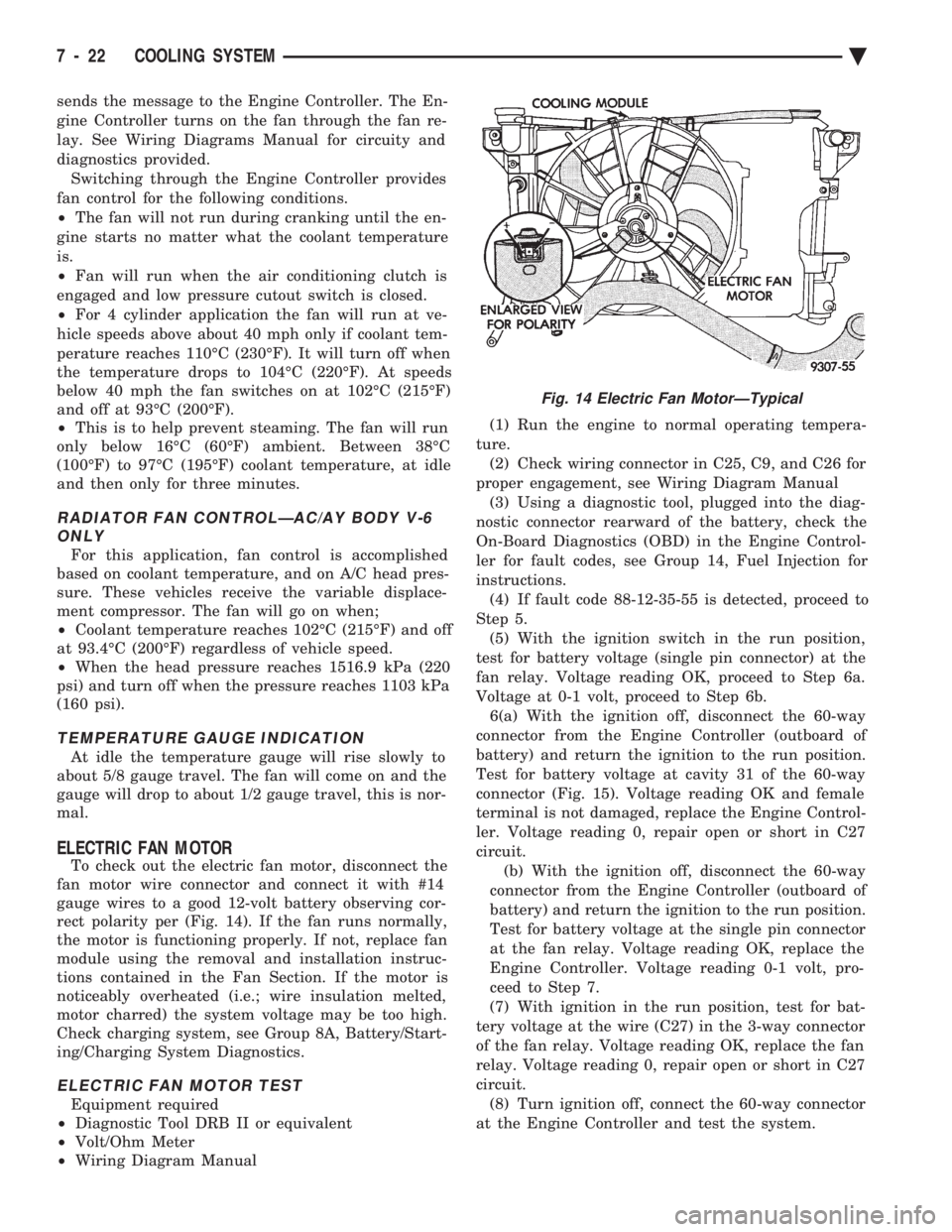

ELECTRIC FAN MOTOR

To check out the electric fan motor, disconnect the

fan motor wire connector and connect it with #14

gauge wires to a good 12-volt battery observing cor-

rect polarity per (Fig. 14). If the fan runs normally,

the motor is functioning properly. If not, replace fan

module using the removal and installation instruc-

tions contained in the Fan Section. If the motor is

noticeably overheated (i.e.; wire insulation melted,

motor charred) the system voltage may be too high.

Check charging system, see Group 8A, Battery/Start-

ing/Charging System Diagnostics.

ELECTRIC FAN MOTOR TEST

Equipment required

² Diagnostic Tool DRB II or equivalent

² Volt/Ohm Meter

² Wiring Diagram Manual (1) Run the engine to normal operating tempera-

ture. (2) Check wiring connector in C25, C9, and C26 for

proper engagement, see Wiring Diagram Manual (3) Using a diagnostic tool, plugged into the diag-

nostic connector rearward of the battery, check the

On-Board Diagnostics (OBD) in the Engine Control-

ler for fault codes, see Group 14, Fuel Injection for

instructions. (4) If fault code 88-12-35-55 is detected, proceed to

Step 5. (5) With the ignition switch in the run position,

test for battery voltage (single pin connector) at the

fan relay. Voltage reading OK, proceed to Step 6a.

Voltage at 0-1 volt, proceed to Step 6b. 6(a) With the ignition off, disconnect the 60-way

connector from the Engine Controller (outboard of

battery) and return the ignition to the run position.

Test for battery voltage at cavity 31 of the 60-way

connector (Fig. 15). Voltage reading OK and female

terminal is not damaged, replace the Engine Control-

ler. Voltage reading 0, repair open or short in C27

circuit. (b) With the ignition off, disconnect the 60-way

connector from the Engine Controller (outboard of

battery) and return the ignition to the run position.

Test for battery voltage at the single pin connector

at the fan relay. Voltage reading OK, replace the

Engine Controller. Voltage reading 0-1 volt, pro-

ceed to Step 7.

(7) With ignition in the run position, test for bat-

tery voltage at the wire (C27) in the 3-way connector

of the fan relay. Voltage reading OK, replace the fan

relay. Voltage reading 0, repair open or short in C27

circuit. (8) Turn ignition off, connect the 60-way connector

at the Engine Controller and test the system.

Fig. 14 Electric Fan MotorÐTypical

7 - 22 COOLING SYSTEM Ä

Page 365 of 2438

FAN SHROUD

All vehicles have fan shrouds to improve fan air

flow efficiency. These fan shrouds cover less than full

radiator frontal area to prevent the shroud from re-

stricting air flow at high speeds. The shroud supports the electric fan motor and fan.

For removal and installation see Radiator Section.

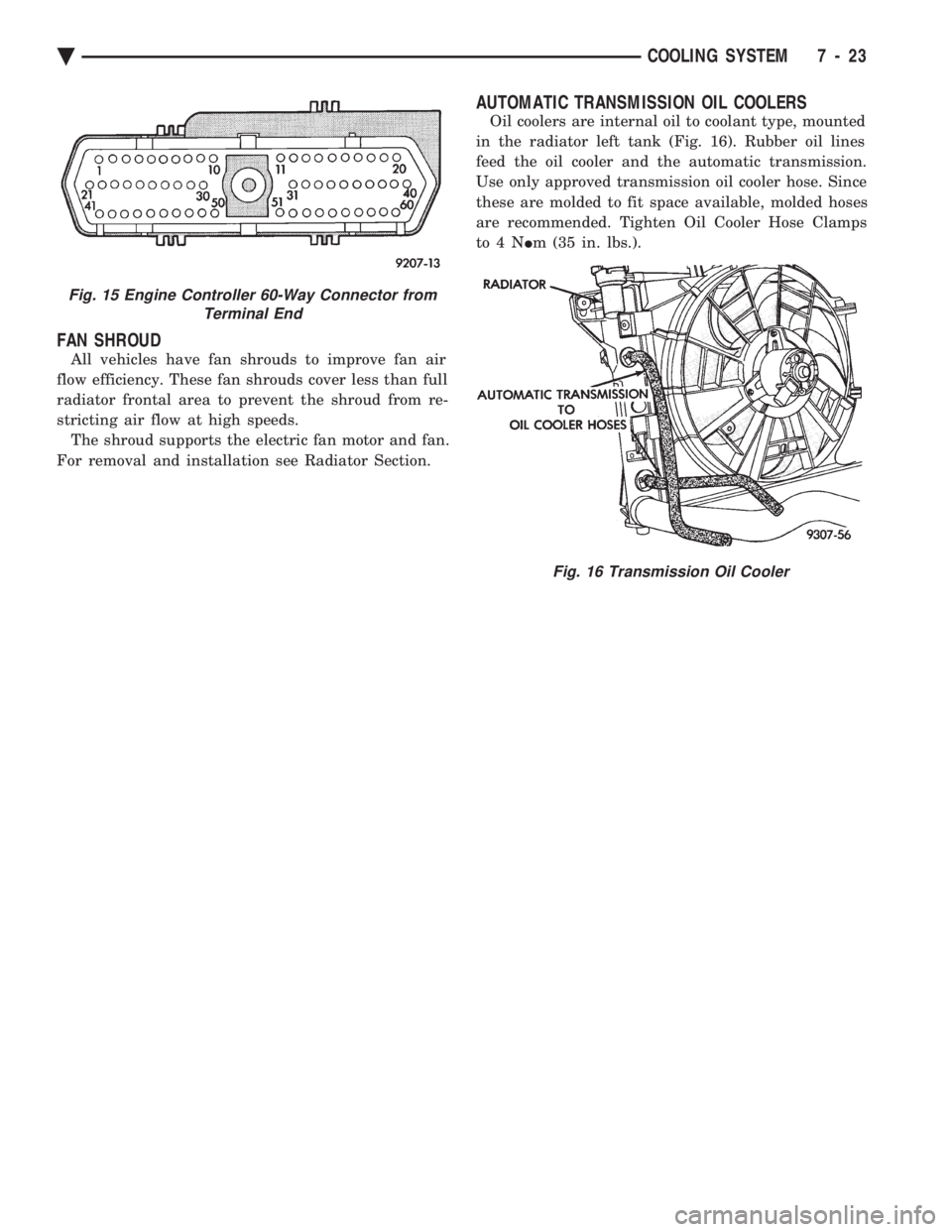

AUTOMATIC TRANSMISSION OIL COOLERS

Oil coolers are internal oil to coolant type, mounted

in the radiator left tank (Fig. 16). Rubber oil lines

feed the oil cooler and the automatic transmission.

Use only approved transmission oil cooler hose. Since

these are molded to fit space available, molded hoses

are recommended. Tighten Oil Cooler Hose Clamps

to4N Im (35 in. lbs.).

Fig. 15 Engine Controller 60-Way Connector from

Terminal End

Fig. 16 Transmission Oil Cooler

Ä COOLING SYSTEM 7 - 23