power steering fluid CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1758 of 2438

INSTALLATION

WARNING: FUEL TANKS DESIGNED FOR GASO-

LINE ONLY VEHICLES CANNOT BE USED ON

FLEXIBLE FUEL AA-BODY VEHICLES. WHEN SER-

VICING THE FUEL SYSTEM OF A FLEXIBLE FUEL

VEHICLE, ONLY USE ORIGINAL EQUIPMENT OR

EQUIVALENT REPLACEMENT COMPONENTS. (1) Position fuel tank on transmission jack. Con-

nect vapor separator/rollover valve hose and position

insulator pad on fuel tank. Position vapor vent so

that it is not pinched between tank and floor pan

during installation. (2) Raise tank and fuel filler tube carefully into

position. Use a light coating of power steering fluid

to ease fuel filler tube installation. Ensure filler tube

grommet is not damaged. Verify that the tube is in-

stalled correctly. (3) Tighten fuel tank strap nuts to 23 N Im (250 in.

lbs.) torque. Remove transmission jack. Ensure

straps are not twisted or bent. (4) Lubricate the metal tubes on the fuel pump

with clean 30 weight engine oil. Install the quick

connect fuel fittings. Refer to Quick Connect Fittings

in the Fuel Delivery section of this Group. (5) Attach electrical connector to fuel pump mod-

ule and level sensor unit. (6) Lower the vehicle.

(7) Attach filler tube to filler neck opening in

quarter panel. Tighten quarter panel screws to 2

N Im (17 in. lbs.) torque.

(8) Fill fuel tank, install filler cap, and connect

battery cable.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(9) Use the DRBII scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

FUEL PUMP MODULE

Refer to the Fuel Delivery section of this group.

METHANOL CONCENTRATION SENSOR

Refer to the Fuel Delivery section of this group.

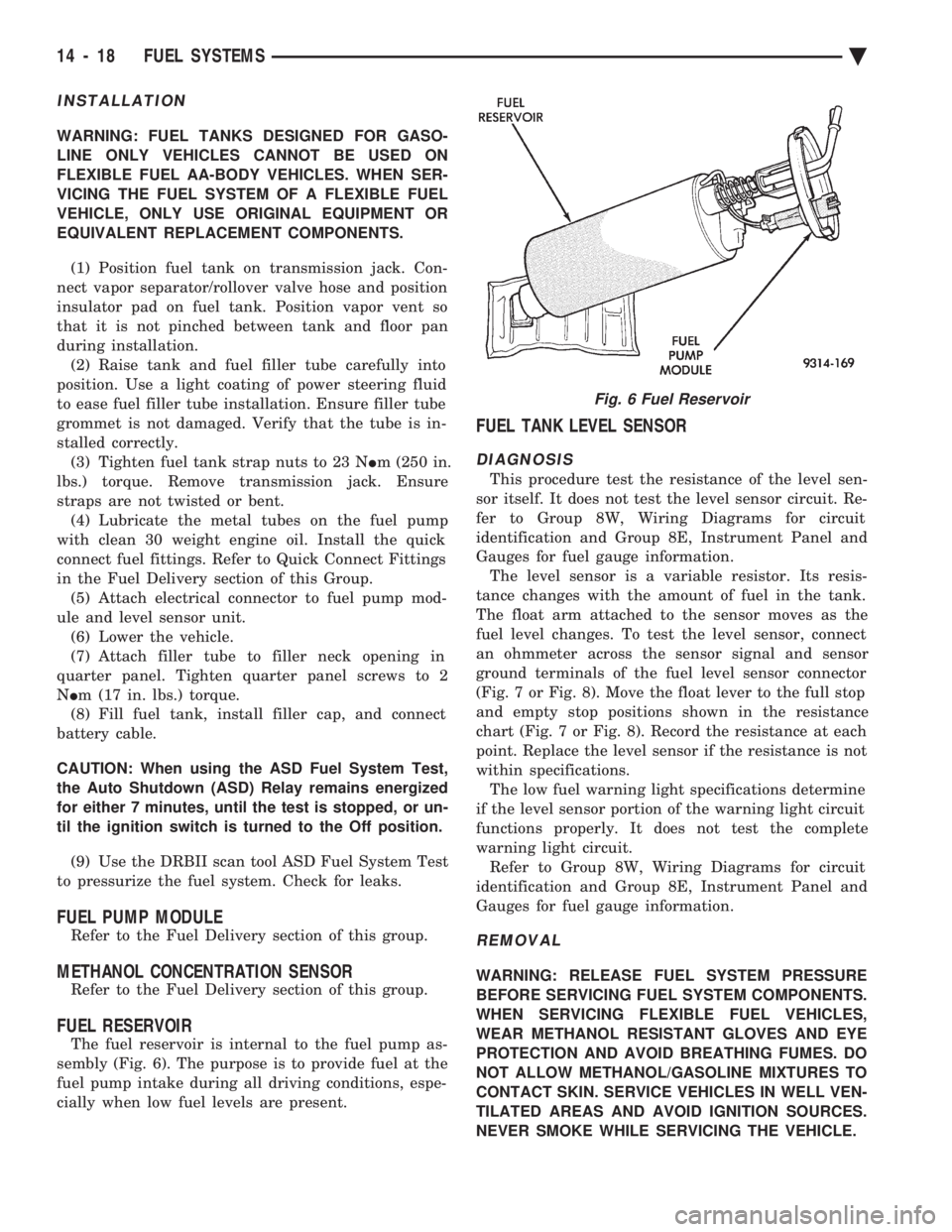

FUEL RESERVOIR

The fuel reservoir is internal to the fuel pump as-

sembly (Fig. 6). The purpose is to provide fuel at the

fuel pump intake during all driving conditions, espe-

cially when low fuel levels are present.

FUEL TANK LEVEL SENSOR

DIAGNOSIS

This procedure test the resistance of the level sen-

sor itself. It does not test the level sensor circuit. Re-

fer to Group 8W, Wiring Diagrams for circuit

identification and Group 8E, Instrument Panel and

Gauges for fuel gauge information. The level sensor is a variable resistor. Its resis-

tance changes with the amount of fuel in the tank.

The float arm attached to the sensor moves as the

fuel level changes. To test the level sensor, connect

an ohmmeter across the sensor signal and sensor

ground terminals of the fuel level sensor connector

(Fig. 7 or Fig. 8). Move the float lever to the full stop

and empty stop positions shown in the resistance

chart (Fig. 7 or Fig. 8). Record the resistance at each

point. Replace the level sensor if the resistance is not

within specifications. The low fuel warning light specifications determine

if the level sensor portion of the warning light circuit

functions properly. It does not test the complete

warning light circuit. Refer to Group 8W, Wiring Diagrams for circuit

identification and Group 8E, Instrument Panel and

Gauges for fuel gauge information.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

Fig. 6 Fuel Reservoir

14 - 18 FUEL SYSTEMS Ä

Page 1761 of 2438

INSTALLATION

WARNING: FUEL PRESSURE RELIEF/ROLLOVER

VALVES DESIGNED FOR GASOLINE ONLY VEHI-

CLES CANNOT BE USED ON FLEXIBLE FUEL AA-

BODY VEHICLES. WHEN SERVICING THE FUEL

SYSTEM OF A FLEXIBLE FUEL VEHICLE, ONLY

USE ORIGINAL EQUIPMENT OR EQUIVALENT RE-

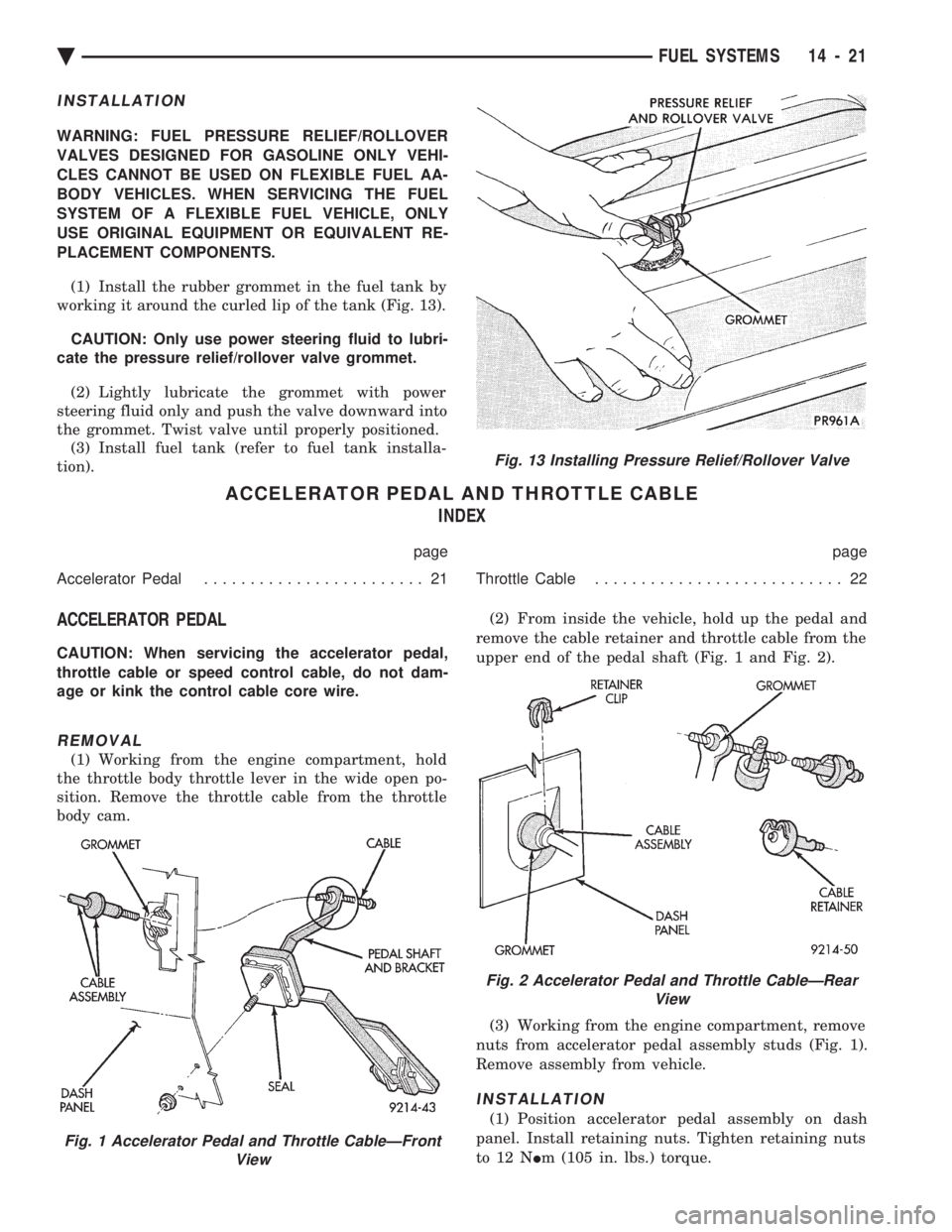

PLACEMENT COMPONENTS. (1) Install the rubber grommet in the fuel tank by

working it around the curled lip of the tank (Fig. 13).

CAUTION: Only use power steering fluid to lubri-

cate the pressure relief/rollover valve grommet.

(2) Lightly lubricate the grommet with power

steering fluid only and push the valve downward into

the grommet. Twist valve until properly positioned. (3) Install fuel tank (refer to fuel tank installa-

tion).

ACCELERATOR PEDAL AND THROTTLE CABLE INDEX

page page

Accelerator Pedal ........................ 21 Throttle Cable........................... 22

ACCELERATOR PEDAL

CAUTION: When servicing the accelerator pedal,

throttle cable or speed control cable, do not dam-

age or kink the control cable core wire.

REMOVAL

(1) Working from the engine compartment, hold

the throttle body throttle lever in the wide open po-

sition. Remove the throttle cable from the throttle

body cam. (2) From inside the vehicle, hold up the pedal and

remove the cable retainer and throttle cable from the

upper end of the pedal shaft (Fig. 1 and Fig. 2).

(3) Working from the engine compartment, remove

nuts from accelerator pedal assembly studs (Fig. 1).

Remove assembly from vehicle.

INSTALLATION

(1) Position accelerator pedal assembly on dash

panel. Install retaining nuts. Tighten retaining nuts

to 12 N Im (105 in. lbs.) torque.

Fig. 1 Accelerator Pedal and Throttle CableÐFront

View

Fig. 13 Installing Pressure Relief/Rollover Valve

Fig. 2 Accelerator Pedal and Throttle CableÐRearView

Ä FUEL SYSTEMS 14 - 21

Page 1919 of 2438

STEERING

CONTENTS

page page

ACUSTAR STANDARD AND TILT STEERING COLUMN ............................ 28

AUTOMATIC TRANSMISSION SHIFTER/IGNITION INTERLOCK .......................... 36

GENERAL INFORMATION .................. 1 POWER STEERING GEAR

................ 25

POWER STEERING PUMPS ................ 1

SPECIFICATIONS AND TIGHTENING REFERENCE .......................... 42

GENERAL INFORMATION

Safety goggles should be worn at all times

when working on any steering gear or pump. Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual. The power steering system consists of these four

major components. Power Steering Pump, Power

Steering Gear, Pressure Hose, and Return Line.

Turning of the steering wheel is converted into lin-

ear travel through the meshing of the helical pinion teeth with the rack teeth. Power assist steering is

provided by an open center, rotary type control valve.

It is used to direct oil from the power steering pump

to either side of the integral steering rack piston. Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As steering ef-

fort increases as in a turn, the torsion bar twists,

causing relative rotary motion between the rotary

valve body and valve spool. This movement directs

oil behind the integral rack piston, which in turn,

builds up hydraulic pressure and assists in the turn-

ing effort.

POWER STEERING PUMPS

INDEX

page page

Checking Power Steering Fluid Level .......... 9

Flow Control Valve Fitting O-Ring Seal ........ 23

General Information ........................ 1

Power Steering Hoses ..................... 11

Power Steering Pressure Switch ............. 10

Power Steering Pump Fluid Reservoirs ........ 22 Power Steering Pump Pressure Test

........... 9

Power Steering Pump Pulley Service .......... 20

Power Steering Pump Removal .............. 12

Power Steering Pump Service ................ 2

Power Steering PumpÐInitial Operation ....... 24

Steering Components Service Diagnosis ........ 2

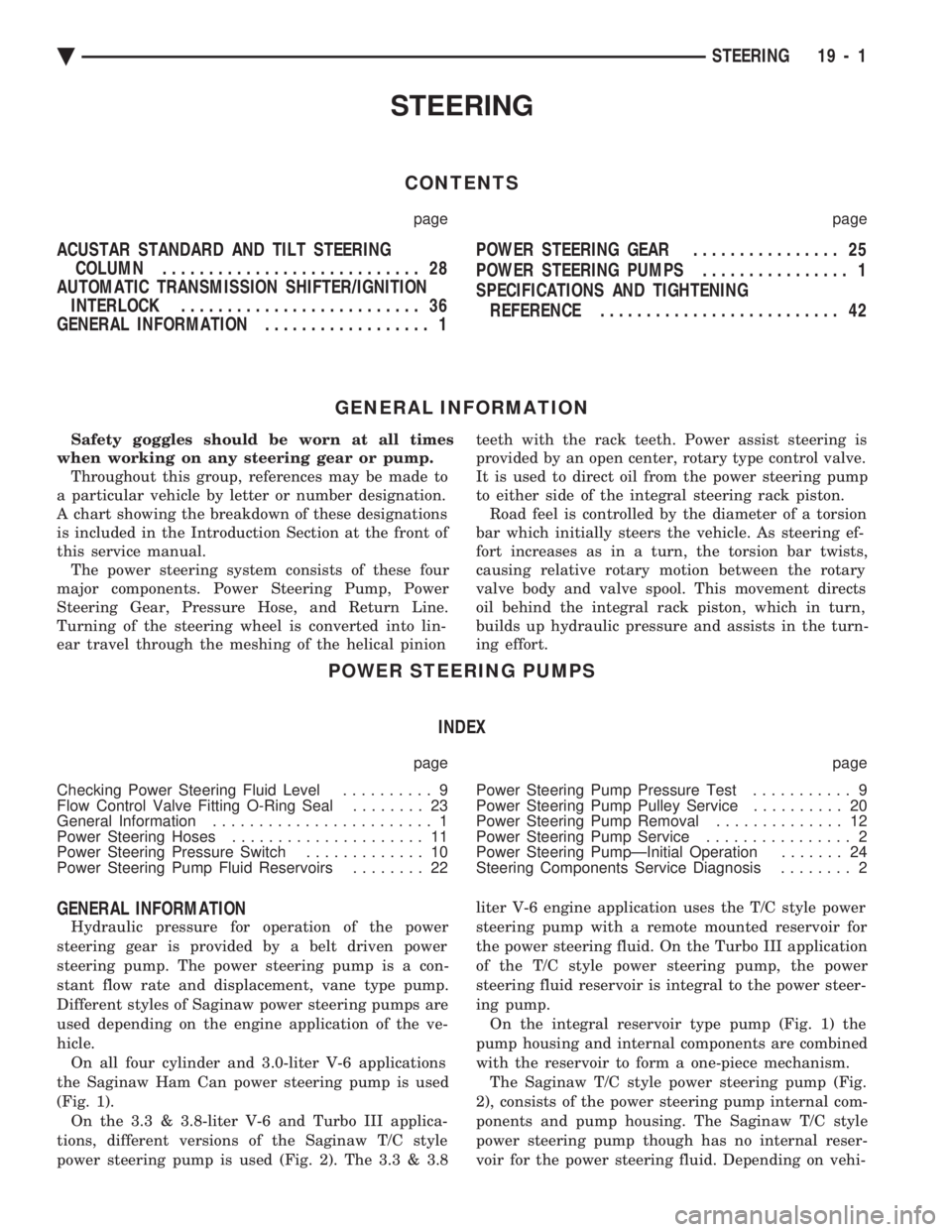

GENERAL INFORMATION

Hydraulic pressure for operation of the power

steering gear is provided by a belt driven power

steering pump. The power steering pump is a con-

stant flow rate and displacement, vane type pump.

Different styles of Saginaw power steering pumps are

used depending on the engine application of the ve-

hicle. On all four cylinder and 3.0-liter V-6 applications

the Saginaw Ham Can power steering pump is used

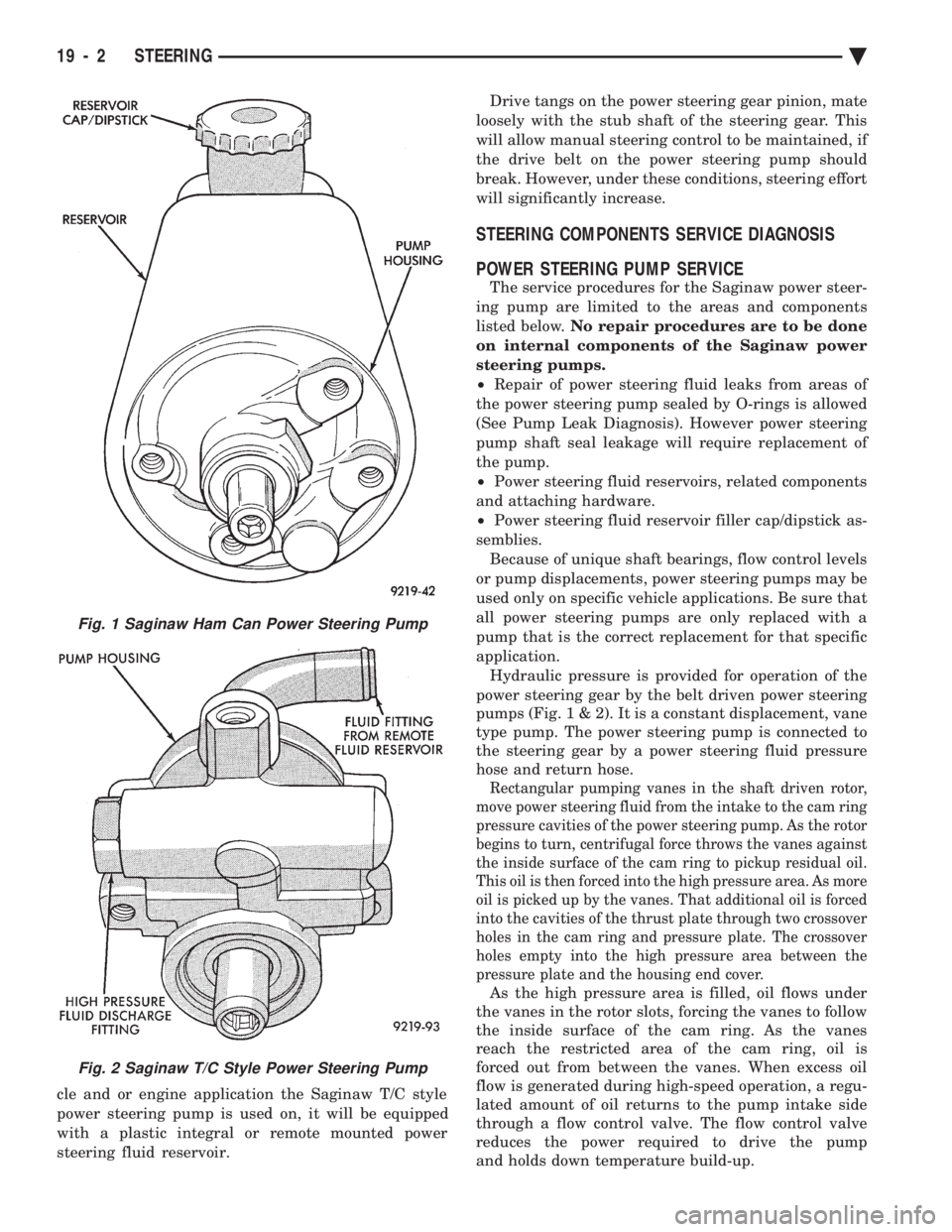

(Fig. 1). On the 3.3 & 3.8-liter V-6 and Turbo III applica-

tions, different versions of the Saginaw T/C style

power steering pump is used (Fig. 2). The 3.3 & 3.8 liter V-6 engine application uses the T/C style power

steering pump with a remote mounted reservoir for

the power steering fluid. On the Turbo III application

of the T/C style power steering pump, the power

steering fluid reservoir is integral to the power steer-

ing pump. On the integral reservoir type pump (Fig. 1) the

pump housing and internal components are combined

with the reservoir to form a one-piece mechanism. The Saginaw T/C style power steering pump (Fig.

2), consists of the power steering pump internal com-

ponents and pump housing. The Saginaw T/C style

power steering pump though has no internal reser-

voir for the power steering fluid. Depending on vehi-

Ä STEERING 19 - 1

Page 1920 of 2438

cle and or engine application the Saginaw T/C style

power steering pump is used on, it will be equipped

with a plastic integral or remote mounted power

steering fluid reservoir. Drive tangs on the power steering gear pinion, mate

loosely with the stub shaft of the steering gear. This

will allow manual steering control to be maintained, if

the drive belt on the power steering pump should

break. However, under these conditions, steering effort

will significantly increase.

STEERING COMPONENTS SERVICE DIAGNOSIS

POWER STEERING PUMP SERVICE

The service procedures for the Saginaw power steer-

ing pump are limited to the areas and components

listed below. No repair procedures are to be done

on internal components of the Saginaw power

steering pumps.

² Repair of power steering fluid leaks from areas of

the power steering pump sealed by O-rings is allowed

(See Pump Leak Diagnosis). However power steering

pump shaft seal leakage will require replacement of

the pump.

² Power steering fluid reservoirs, related components

and attaching hardware.

² Power steering fluid reservoir filler cap/dipstick as-

semblies. Because of unique shaft bearings, flow control levels

or pump displacements, power steering pumps may be

used only on specific vehicle applications. Be sure that

all power steering pumps are only replaced with a

pump that is the correct replacement for that specific

application. Hydraulic pressure is provided for operation of the

power steering gear by the belt driven power steering

pumps (Fig . 1 & 2). It is a constant displacement, vane

type pump. The power steering pump is connected to

the steering gear by a power steering fluid pressure

hose and return hose.

Rectangular pumping vanes in the shaft driven rotor,

move power steering fluid from the intake to the cam ring

pressure cavities of the power steering pump. As the rotor

begins to turn, centrifugal force throws the vanes against

the inside surface of the cam ring to pickup residual oil.

This oil is then forced into the high pressure area. As more

oil is picked up by the vanes. That additional oil is forced

into the cavities of the thrust plate through two crossover

holes in the cam ring and pressure plate. The crossover

holes empty into the high pressure area between the

pressure plate and the housing end cover.

As the high pressure area is filled, oil flows under

the vanes in the rotor slots, forcing the vanes to follow

the inside surface of the cam ring. As the vanes

reach the restricted area of the cam ring, oil is

forced out from between the vanes. When excess oil

flow is generated during high-speed operation, a regu-

lated amount of oil returns to the pump intake side

through a flow control valve. The flow control valve

reduces the power required to drive the pump

and holds down temperature build-up.

Fig. 1 Saginaw Ham Can Power Steering Pump

Fig. 2 Saginaw T/C Style Power Steering Pump

19 - 2 STEERING Ä

Page 1927 of 2438

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops. The pressure built up in

the steering gear exerts pressure on the spring end of

the flow control valve. The high pressure lifts the re-

lief valve ball from its seat and allows oil to flow

through a trigger orifice located in the outlet fitting.

This reduces pressure on the spring end of the flow

control valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level. Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to re-

main closed.

CHECKING POWER STEERING FLUID LEVEL

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH ENGINE OFF TO PREVENT INJURY FROM

MOVING PARTS. DO NOT USE AUTOMATIC TRANS-

MISSION FLUID IN THE POWER STEERING SYS-

TEM. DO NOT OVERFILL THE POWER STEERING

SYSTEM.

Wipe reservoir filler cap free of dirt, before check-

ing power steering fluid level. The dipstick should in- dicate FULL COLD when fluid is at normal ambient

temperature, approximately 21ÉC to 27ÉC (70ÉF to

80ÉF). In all pumps add fluid as necessary to obtain

proper level, using only MopartPower Steering

Fluid, or equivalent. DO NOT USE ANY TYPE

OF AUTOMATIC TRANSMISSION FLUID.

POWER STEERING PUMP PRESSURE TEST

The following procedure can be used to test the op-

eration of the power steering system on the vehicle. (1) Check power steering pump drive belt tension

and adjust as necessary. (2) Disconnect power steering fluid pressure hose,

at steering gear or power steering pump. Use a con-

tainer for dripping fluid. (3) Connect Pressure Gauge, Special Tool C-3309-E

(Fig. 1) to both hoses using adapter fittings. Connect

spare pressure hose to gear or pump. (4) Completely open valve on Special Tool

C-3309-E (Fig. 1). (5) Start engine and let idle.

(6) Check power steering fluid level, and add fluid

as necessary. (7) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the

range of 345-552 kPa (50-80 psi).

PUMP LEAKAGE DIAGNOSIS

Ä STEERING 19 - 9

Page 1929 of 2438

INSTALL

(1) Install power steering pressure switch into fit-

ting on power steering pressure hose by hand until

fully seated. Then torque power steering pressure

switch to 12 N Im (106 in. lbs.).

(2) Install vehicle wiring harness connector onto

power steering pressure switch. Be sure latch on wir-

ing harness connector is fully engaged with locking

tab on power steering pressure switch.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(3) Fill power steering pump reservoir to correct

fluid level. (4) Connect negative cable back on negative post of

battery. (5) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

POWER STEERING HOSES

Service all power steering hoses with the vehicle

raised on a hoist. Cap all open ends of hoses, power

steering pump fittings and steering gear ports to pre-

vent entry of foreign material into the components.

WARNING: POWER STEERING OIL, ENGINE PARTS

AND EXHAUST SYSTEM MAY BE EXTREMELY HOT

IF ENGINE HAS BEEN RUNNING. DO NOT START

ENGINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

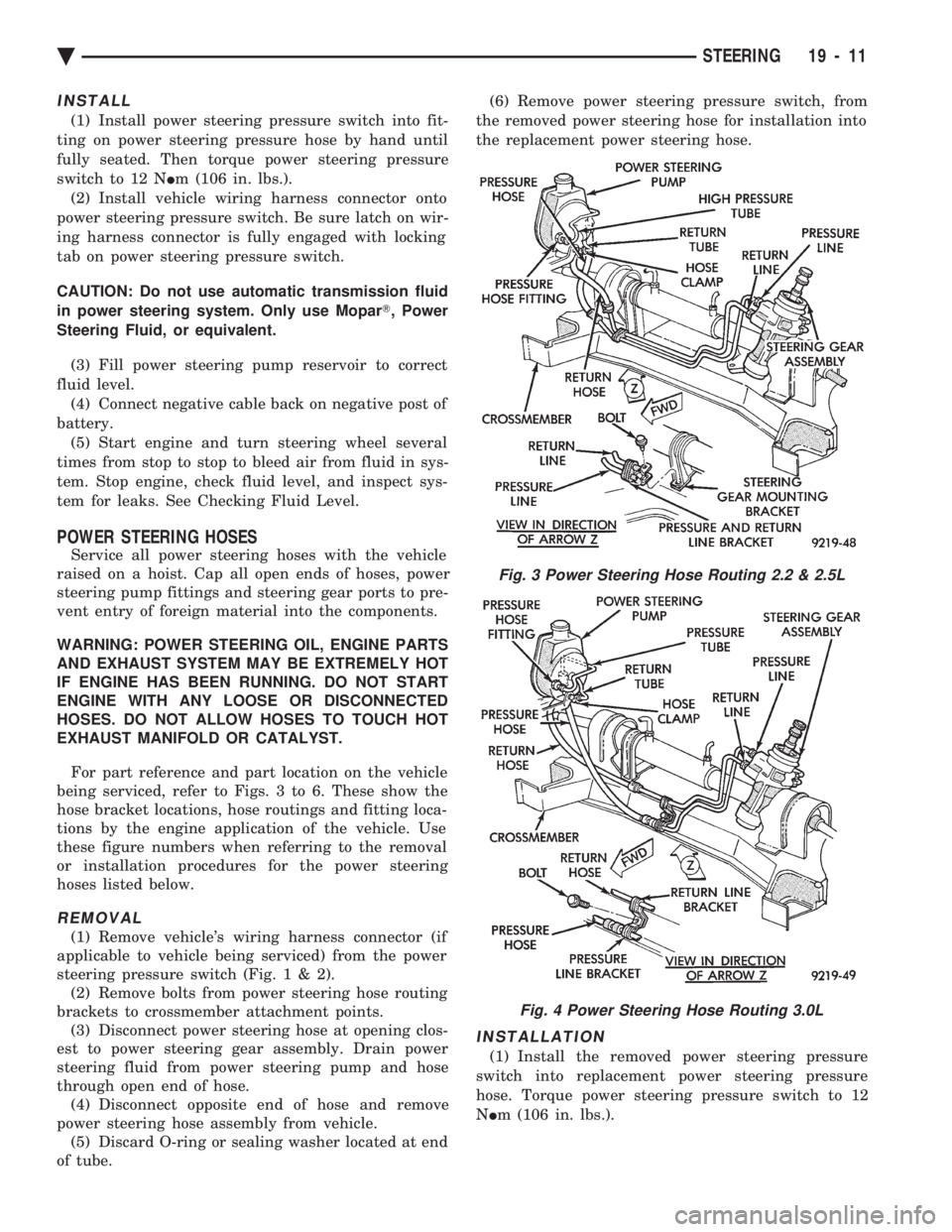

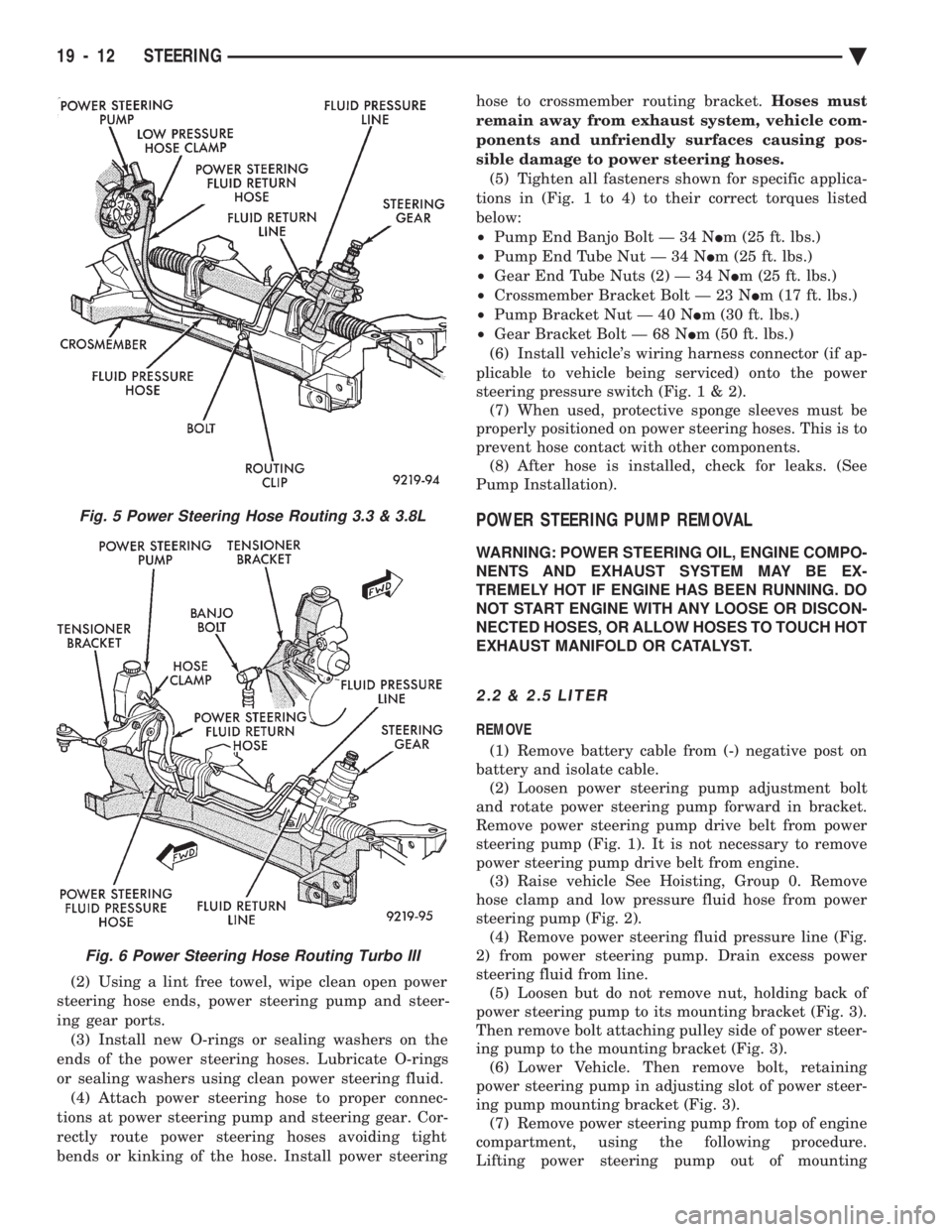

For part reference and part location on the vehicle

being serviced, refer to Figs. 3 to 6. These show the

hose bracket locations, hose routings and fitting loca-

tions by the engine application of the vehicle. Use

these figure numbers when referring to the removal

or installation procedures for the power steering

hoses listed below.

REMOVAL

(1) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig .1&2).

(2) Remove bolts from power steering hose routing

brackets to crossmember attachment points. (3) Disconnect power steering hose at opening clos-

est to power steering gear assembly. Drain power

steering fluid from power steering pump and hose

through open end of hose. (4) Disconnect opposite end of hose and remove

power steering hose assembly from vehicle. (5) Discard O-ring or sealing washer located at end

of tube. (6) Remove power steering pressure switch, from

the removed power steering hose for installation into

the replacement power steering hose.

INSTALLATION

(1) Install the removed power steering pressure

switch into replacement power steering pressure

hose. Torque power steering pressure switch to 12

N Im (106 in. lbs.).

Fig. 3 Power Steering Hose Routing 2.2 & 2.5L

Fig. 4 Power Steering Hose Routing 3.0L

Ä STEERING 19 - 11

Page 1930 of 2438

(2) Using a lint free towel, wipe clean open power

steering hose ends, power steering pump and steer-

ing gear ports. (3) Install new O-rings or sealing washers on the

ends of the power steering hoses. Lubricate O-rings

or sealing washers using clean power steering fluid. (4) Attach power steering hose to proper connec-

tions at power steering pump and steering gear. Cor-

rectly route power steering hoses avoiding tight

bends or kinking of the hose. Install power steering hose to crossmember routing bracket.

Hoses must

remain away from exhaust system, vehicle com-

ponents and unfriendly surfaces causing pos-

sible damage to power steering hoses. (5) Tighten all fasteners shown for specific applica-

tions in (Fig. 1 to 4) to their correct torques listed

below:

² Pump End Banjo Bolt Ð 34 N Im (25 ft. lbs.)

² Pump End Tube Nut Ð 34 N Im (25 ft. lbs.)

² Gear End Tube Nuts (2) Ð 34 N Im (25 ft. lbs.)

² Crossmember Bracket Bolt Ð 23 N Im (17 ft. lbs.)

² Pump Bracket Nut Ð 40 N Im (30 ft. lbs.)

² Gear Bracket Bolt Ð 68 N Im (50 ft. lbs.)

(6) Install vehicle's wiring harness connector (if ap-

plicable to vehicle being serviced) onto the power

steering pressure switch (Fig .1&2).

(7) When used, protective sponge sleeves must be

properly positioned on power steering hoses. This is to

prevent hose contact with other components. (8) After hose is installed, check for leaks. (See

Pump Installation).

POWER STEERING PUMP REMOVAL

WARNING: POWER STEERING OIL, ENGINE COMPO-

NENTS AND EXHAUST SYSTEM MAY BE EX-

TREMELY HOT IF ENGINE HAS BEEN RUNNING. DO

NOT START ENGINE WITH ANY LOOSE OR DISCON-

NECTED HOSES, OR ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

2.2 & 2.5 LITER

REMOVE

(1) Remove battery cable from (-) negative post on

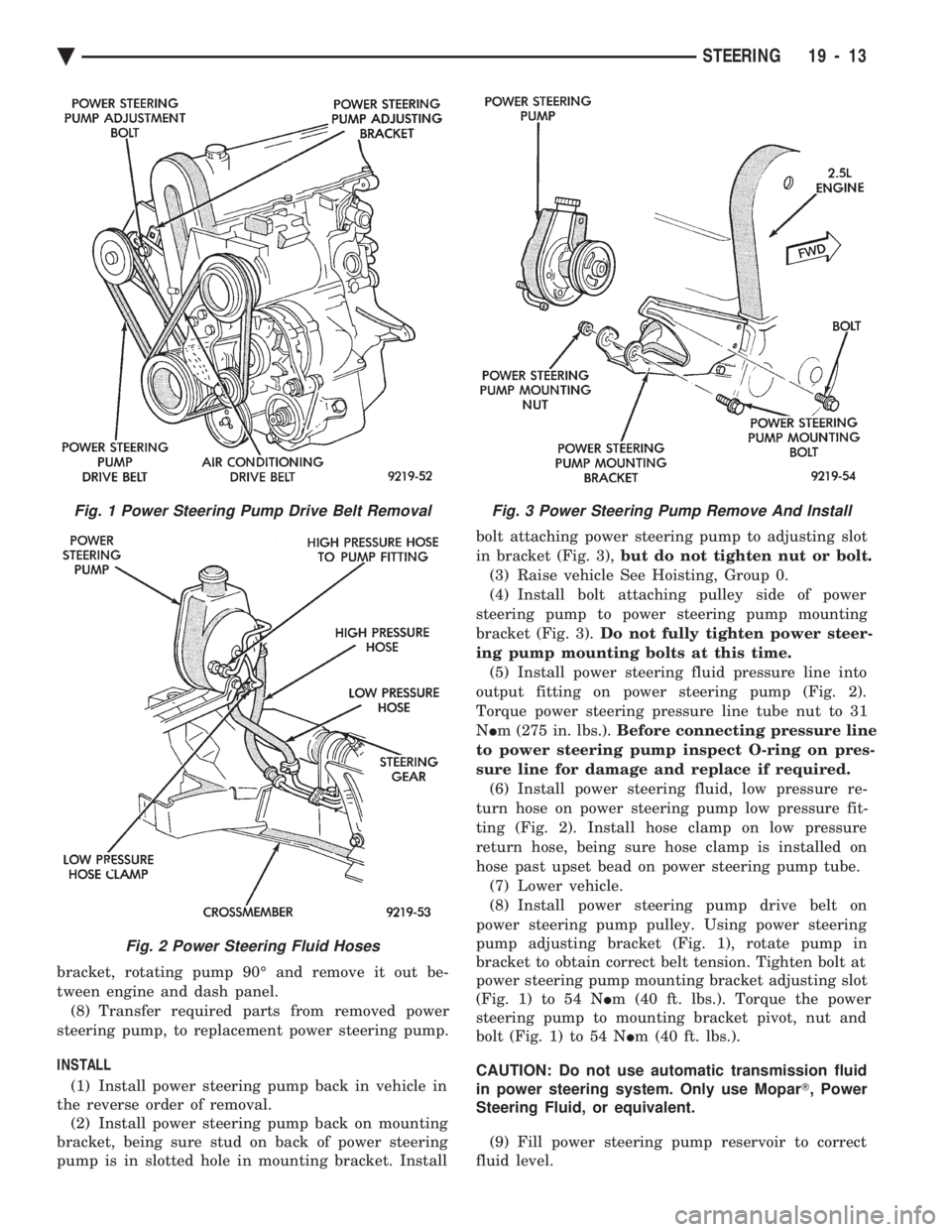

battery and isolate cable. (2) Loosen power steering pump adjustment bolt

and rotate power steering pump forward in bracket.

Remove power steering pump drive belt from power

steering pump (Fig. 1). It is not necessary to remove

power steering pump drive belt from engine. (3) Raise vehicle See Hoisting, Group 0. Remove

hose clamp and low pressure fluid hose from power

steering pump (Fig. 2). (4) Remove power steering fluid pressure line (Fig.

2) from power steering pump. Drain excess power

steering fluid from line. (5) Loosen but do not remove nut, holding back of

power steering pump to its mounting bracket (Fig. 3).

Then remove bolt attaching pulley side of power steer-

ing pump to the mounting bracket (Fig. 3). (6) Lower Vehicle. Then remove bolt, retaining

power steering pump in adjusting slot of power steer-

ing pump mounting bracket (Fig. 3). (7) Remove power steering pump from top of engine

compartment, using the following procedure.

Lifting power steering pump out of mounting

Fig. 5 Power Steering Hose Routing 3.3 & 3.8L

Fig. 6 Power Steering Hose Routing Turbo III

19 - 12 STEERING Ä

Page 1931 of 2438

bracket, rotating pump 90É and remove it out be-

tween engine and dash panel.(8) Transfer required parts from removed power

steering pump, to replacement power steering pump.

INSTALL

(1) Install power steering pump back in vehicle in

the reverse order of removal. (2) Install power steering pump back on mounting

bracket, being sure stud on back of power steering

pump is in slotted hole in mounting bracket. Install bolt attaching power steering pump to adjusting slot

in bracket (Fig. 3),

but do not tighten nut or bolt.

(3) Raise vehicle See Hoisting, Group 0.

(4) Install bolt attaching pulley side of power

steering pump to power steering pump mounting

bracket (Fig. 3). Do not fully tighten power steer-

ing pump mounting bolts at this time. (5) Install power steering fluid pressure line into

output fitting on power steering pump (Fig. 2).

Torque power steering pressure line tube nut to 31

N Im (275 in. lbs.). Before connecting pressure line

to power steering pump inspect O-ring on pres-

sure line for damage and replace if required. (6) Install power steering fluid, low pressure re-

turn hose on power steering pump low pressure fit-

ting (Fig. 2). Install hose clamp on low pressure

return hose, being sure hose clamp is installed on

hose past upset bead on power steering pump tube. (7) Lower vehicle.

(8) Install power steering pump drive belt on

power steering pump pulley. Using power steering

pump adjusting bracket (Fig. 1), rotate pump in

bracket to obtain correct belt tension. Tighten bolt at

power steering pump mounting bracket adjusting slot

(Fig. 1) to 54 N Im (40 ft. lbs.). Torque the power

steering pump to mounting bracket pivot, nut and

bolt (Fig. 1) to 54 N Im (40 ft. lbs.).

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(9) Fill power steering pump reservoir to correct

fluid level.

Fig. 1 Power Steering Pump Drive Belt Removal

Fig. 2 Power Steering Fluid Hoses

Fig. 3 Power Steering Pump Remove And Install

Ä STEERING 19 - 13

Page 1932 of 2438

(10) Connect negative cable back on negative post

of battery. (11) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

3.0 LITER

REMOVE

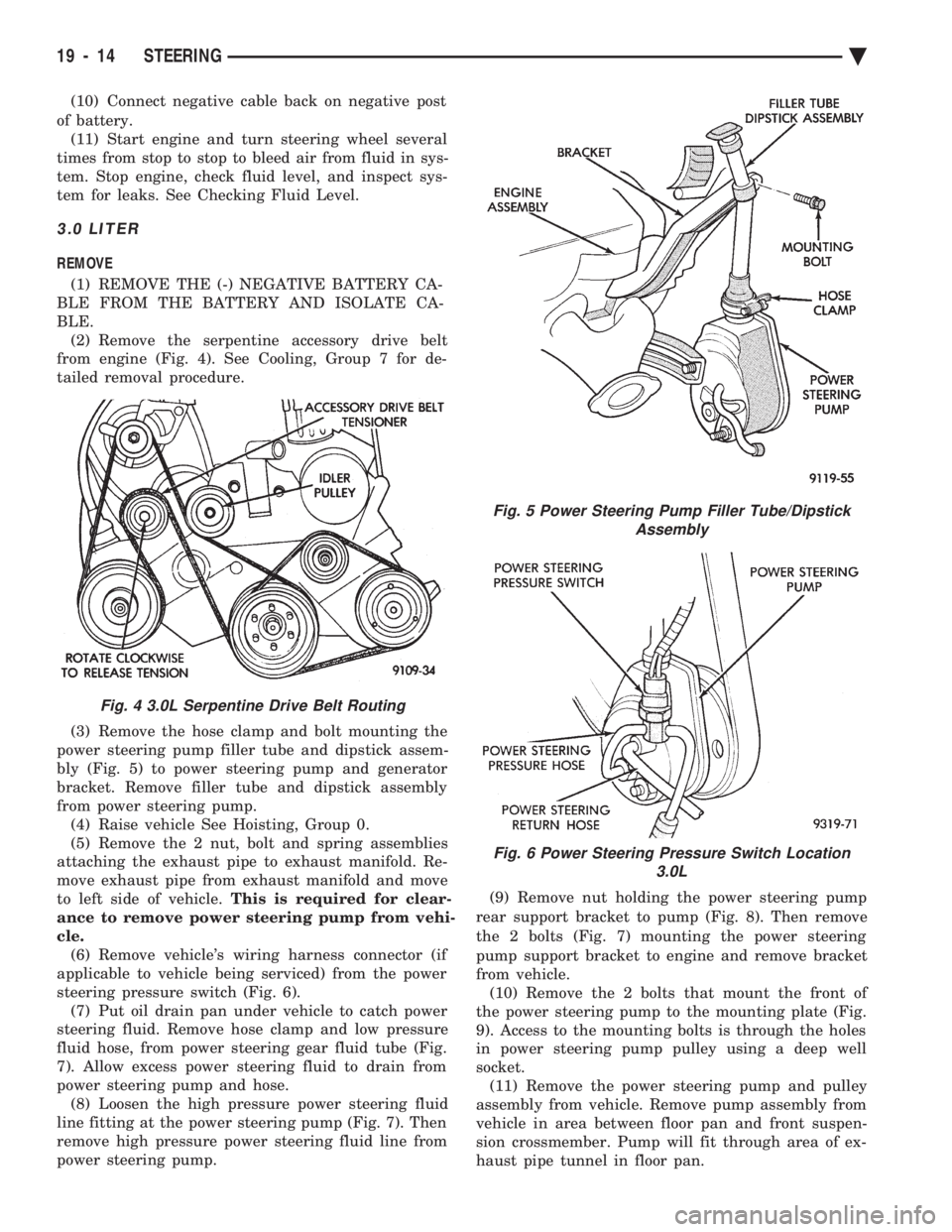

(1) REMOVE THE (-) NEGATIVE BATTERY CA-

BLE FROM THE BATTERY AND ISOLATE CA-

BLE. (2) Remove the serpentine accessory drive belt

from engine (Fig. 4). See Cooling, Group 7 for de-

tailed removal procedure.

(3) Remove the hose clamp and bolt mounting the

power steering pump filler tube and dipstick assem-

bly (Fig. 5) to power steering pump and generator

bracket. Remove filler tube and dipstick assembly

from power steering pump. (4) Raise vehicle See Hoisting, Group 0.

(5) Remove the 2 nut, bolt and spring assemblies

attaching the exhaust pipe to exhaust manifold. Re-

move exhaust pipe from exhaust manifold and move

to left side of vehicle. This is required for clear-

ance to remove power steering pump from vehi-

cle. (6) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig. 6). (7) Put oil drain pan under vehicle to catch power

steering fluid. Remove hose clamp and low pressure

fluid hose, from power steering gear fluid tube (Fig.

7). Allow excess power steering fluid to drain from

power steering pump and hose. (8) Loosen the high pressure power steering fluid

line fitting at the power steering pump (Fig. 7). Then

remove high pressure power steering fluid line from

power steering pump. (9) Remove nut holding the power steering pump

rear support bracket to pump (Fig. 8). Then remove

the 2 bolts (Fig. 7) mounting the power steering

pump support bracket to engine and remove bracket

from vehicle. (10) Remove the 2 bolts that mount the front of

the power steering pump to the mounting plate (Fig.

9). Access to the mounting bolts is through the holes

in power steering pump pulley using a deep well

socket. (11) Remove the power steering pump and pulley

assembly from vehicle. Remove pump assembly from

vehicle in area between floor pan and front suspen-

sion crossmember. Pump will fit through area of ex-

haust pipe tunnel in floor pan.

Fig. 4 3.0L Serpentine Drive Belt Routing

Fig. 5 Power Steering Pump Filler Tube/Dipstick Assembly

Fig. 6 Power Steering Pressure Switch Location 3.0L

19 - 14 STEERING Ä

Page 1933 of 2438

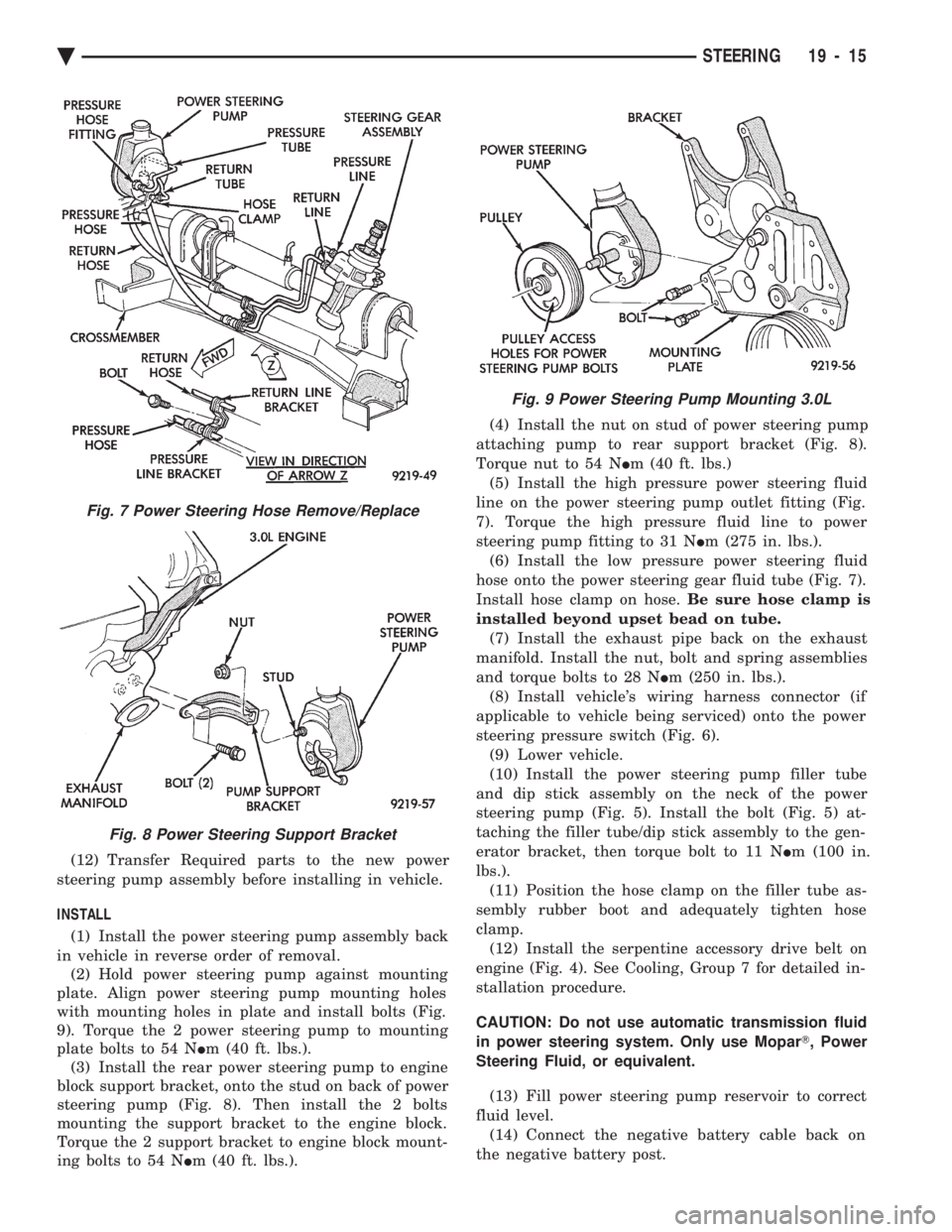

(12) Transfer Required parts to the new power

steering pump assembly before installing in vehicle.

INSTALL

(1) Install the power steering pump assembly back

in vehicle in reverse order of removal. (2) Hold power steering pump against mounting

plate. Align power steering pump mounting holes

with mounting holes in plate and install bolts (Fig.

9). Torque the 2 power steering pump to mounting

plate bolts to 54 N Im (40 ft. lbs.).

(3) Install the rear power steering pump to engine

block support bracket, onto the stud on back of power

steering pump (Fig. 8). Then install the 2 bolts

mounting the support bracket to the engine block.

Torque the 2 support bracket to engine block mount-

ing bolts to 54 N Im (40 ft. lbs.). (4) Install the nut on stud of power steering pump

attaching pump to rear support bracket (Fig. 8).

Torque nut to 54 N Im (40 ft. lbs.)

(5) Install the high pressure power steering fluid

line on the power steering pump outlet fitting (Fig.

7). Torque the high pressure fluid line to power

steering pump fitting to 31 N Im (275 in. lbs.).

(6) Install the low pressure power steering fluid

hose onto the power steering gear fluid tube (Fig. 7).

Install hose clamp on hose. Be sure hose clamp is

installed beyond upset bead on tube. (7) Install the exhaust pipe back on the exhaust

manifold. Install the nut, bolt and spring assemblies

and torque bolts to 28 N Im (250 in. lbs.).

(8) Install vehicle's wiring harness connector (if

applicable to vehicle being serviced) onto the power

steering pressure switch (Fig. 6). (9) Lower vehicle.

(10) Install the power steering pump filler tube

and dip stick assembly on the neck of the power

steering pump (Fig. 5). Install the bolt (Fig. 5) at-

taching the filler tube/dip stick assembly to the gen-

erator bracket, then torque bolt to 11 N Im (100 in.

lbs.). (11) Position the hose clamp on the filler tube as-

sembly rubber boot and adequately tighten hose

clamp. (12) Install the serpentine accessory drive belt on

engine (Fig. 4). See Cooling, Group 7 for detailed in-

stallation procedure.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(13) Fill power steering pump reservoir to correct

fluid level. (14) Connect the negative battery cable back on

the negative battery post.

Fig. 7 Power Steering Hose Remove/Replace

Fig. 8 Power Steering Support Bracket

Fig. 9 Power Steering Pump Mounting 3.0L

Ä STEERING 19 - 15