ABS CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1912 of 2438

(12) Remove the fuel hose quick connect fittings

from the chassis tubes. Refer to Fuel Hoses, Clamps

and Quick Connect Fittings in the Fuel Delivery

Section of this Group. Place a shop towel under the

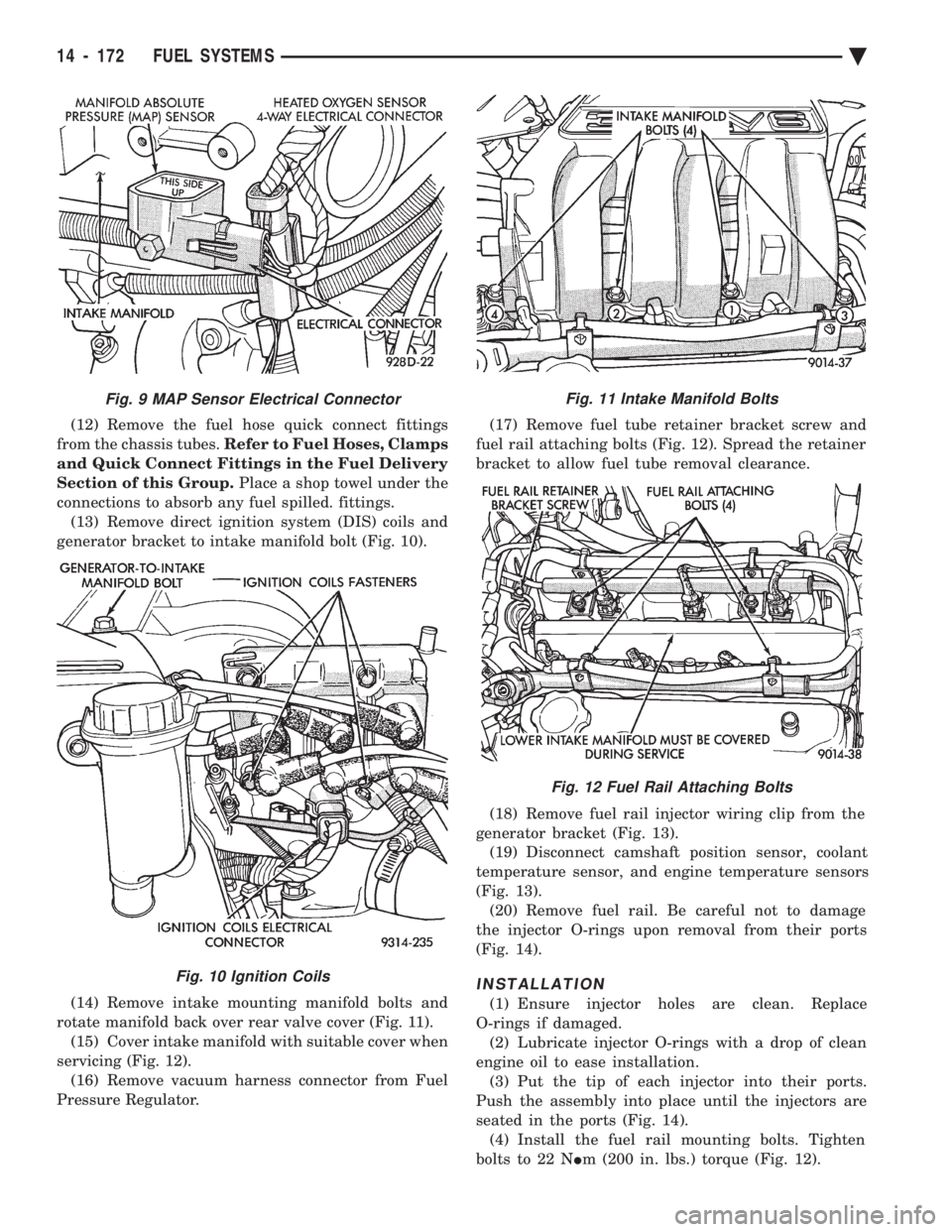

connections to absorb any fuel spilled. fittings. (13) Remove direct ignition system (DIS) coils and

generator bracket to intake manifold bolt (Fig. 10).

(14) Remove intake mounting manifold bolts and

rotate manifold back over rear valve cover (Fig. 11). (15) Cover intake manifold with suitable cover when

servicing (Fig. 12). (16) Remove vacuum harness connector from Fuel

Pressure Regulator. (17) Remove fuel tube retainer bracket screw and

fuel rail attaching bolts (Fig. 12). Spread the retainer

bracket to allow fuel tube removal clearance.

(18) Remove fuel rail injector wiring clip from the

generator bracket (Fig. 13). (19) Disconnect camshaft position sensor, coolant

temperature sensor, and engine temperature sensors

(Fig. 13). (20) Remove fuel rail. Be careful not to damage

the injector O-rings upon removal from their ports

(Fig. 14).

INSTALLATION

(1) Ensure injector holes are clean. Replace

O-rings if damaged. (2) Lubricate injector O-rings with a drop of clean

engine oil to ease installation. (3) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports (Fig. 14). (4) Install the fuel rail mounting bolts. Tighten

bolts to 22 N Im (200 in. lbs.) torque (Fig. 12).

Fig. 11 Intake Manifold Bolts

Fig. 12 Fuel Rail Attaching Bolts

Fig. 9 MAP Sensor Electrical Connector

Fig. 10 Ignition Coils

14 - 172 FUEL SYSTEMS Ä

Page 1914 of 2438

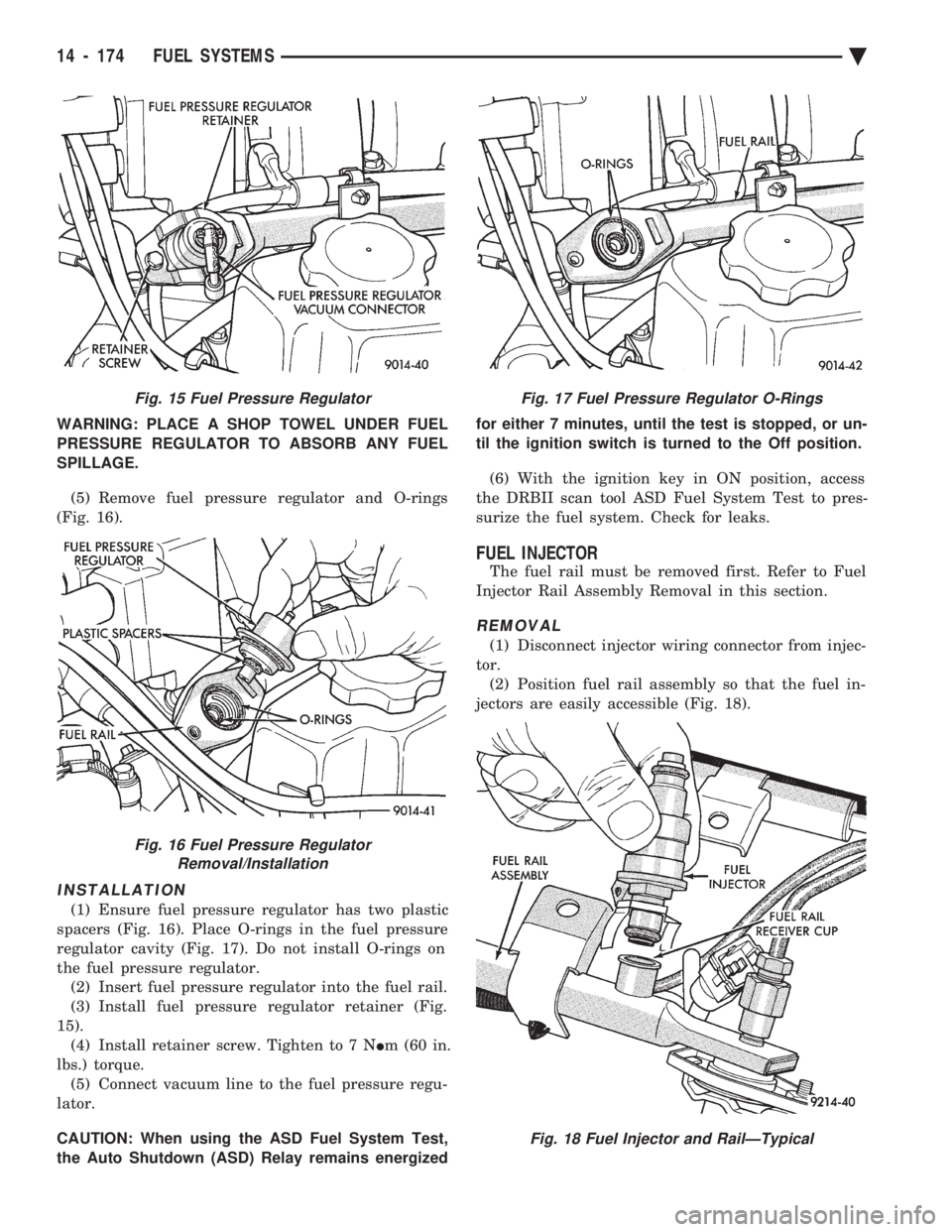

WARNING: PLACE A SHOP TOWEL UNDER FUEL

PRESSURE REGULATOR TO ABSORB ANY FUEL

SPILLAGE.

(5) Remove fuel pressure regulator and O-rings

(Fig. 16).

INSTALLATION

(1) Ensure fuel pressure regulator has two plastic

spacers (Fig. 16). Place O-rings in the fuel pressure

regulator cavity (Fig. 17). Do not install O-rings on

the fuel pressure regulator. (2) Insert fuel pressure regulator into the fuel rail.

(3) Install fuel pressure regulator retainer (Fig.

15). (4) Install retainer screw. Tighten to 7 N Im (60 in.

lbs.) torque. (5) Connect vacuum line to the fuel pressure regu-

lator.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(6) With the ignition key in ON position, access

the DRBII scan tool ASD Fuel System Test to pres-

surize the fuel system. Check for leaks.

FUEL INJECTOR

The fuel rail must be removed first. Refer to Fuel

Injector Rail Assembly Removal in this section.

REMOVAL

(1) Disconnect injector wiring connector from injec-

tor. (2) Position fuel rail assembly so that the fuel in-

jectors are easily accessible (Fig. 18).

Fig. 15 Fuel Pressure Regulator

Fig. 16 Fuel Pressure Regulator Removal/Installation

Fig. 17 Fuel Pressure Regulator O-Rings

Fig. 18 Fuel Injector and RailÐTypical

14 - 174 FUEL SYSTEMS Ä

Page 1915 of 2438

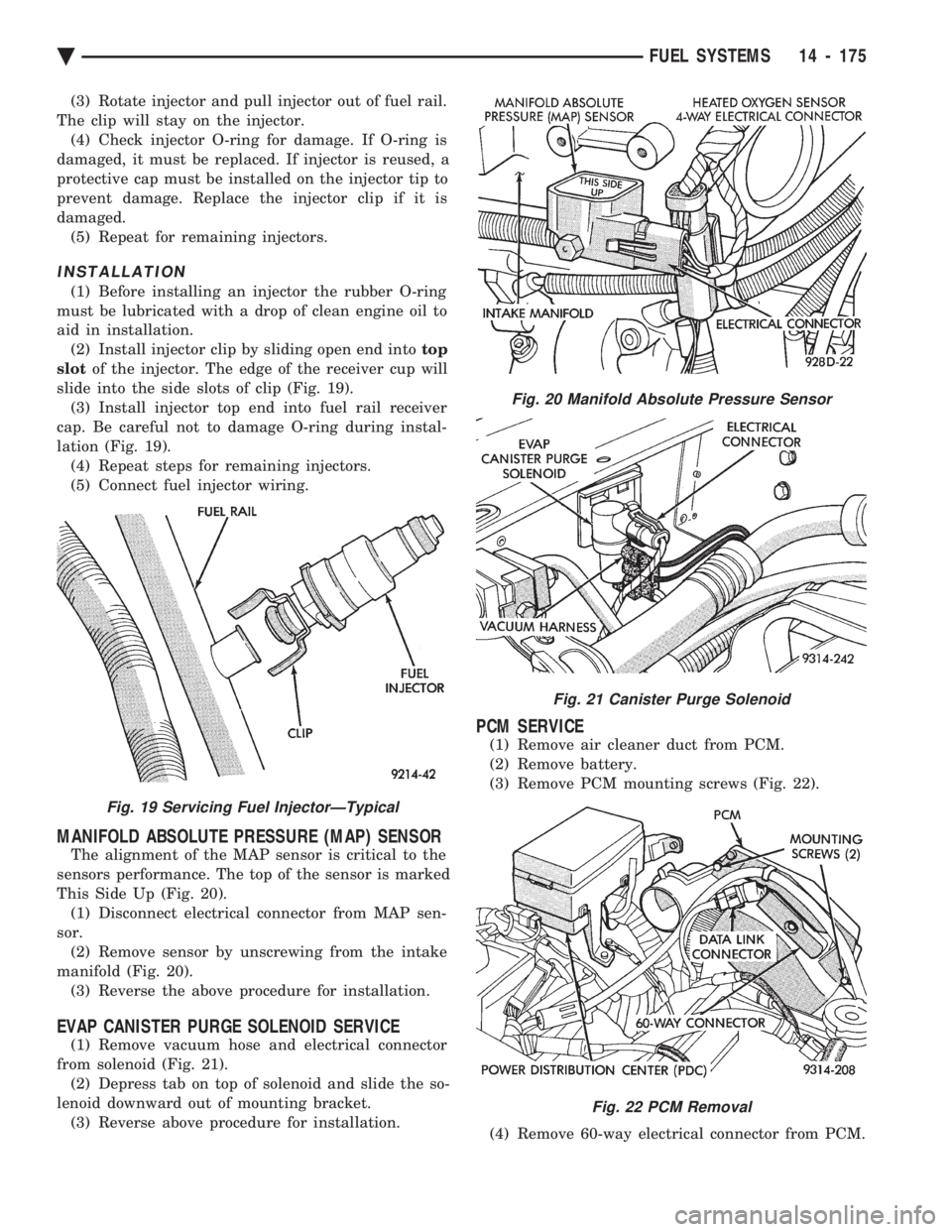

(3) Rotate injector and pull injector out of fuel rail.

The clip will stay on the injector. (4) Check injector O-ring for damage. If O-ring is

damaged, it must be replaced. If injector is reused, a

protective cap must be installed on the injector tip to

prevent damage. Replace the injector clip if it is

damaged. (5) Repeat for remaining injectors.

INSTALLATION

(1) Before installing an injector the rubber O-ring

must be lubricated with a drop of clean engine oil to

aid in installation. (2) Install injector clip by sliding open end into top

slot of the injector. The edge of the receiver cup will

slide into the side slots of clip (Fig. 19). (3) Install injector top end into fuel rail receiver

cap. Be careful not to damage O-ring during instal-

lation (Fig. 19). (4) Repeat steps for remaining injectors.

(5) Connect fuel injector wiring.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The alignment of the MAP sensor is critical to the

sensors performance. The top of the sensor is marked

This Side Up (Fig. 20). (1) Disconnect electrical connector from MAP sen-

sor. (2) Remove sensor by unscrewing from the intake

manifold (Fig. 20). (3) Reverse the above procedure for installation.

EVAP CANISTER PURGE SOLENOID SERVICE

(1) Remove vacuum hose and electrical connector

from solenoid (Fig. 21). (2) Depress tab on top of solenoid and slide the so-

lenoid downward out of mounting bracket. (3) Reverse above procedure for installation.

PCM SERVICE

(1) Remove air cleaner duct from PCM.

(2) Remove battery.

(3) Remove PCM mounting screws (Fig. 22).

(4) Remove 60-way electrical connector from PCM.

Fig. 19 Servicing Fuel InjectorÐTypical

Fig. 20 Manifold Absolute Pressure Sensor

Fig. 21 Canister Purge Solenoid

Fig. 22 PCM Removal

Ä FUEL SYSTEMS 14 - 175

Page 1951 of 2438

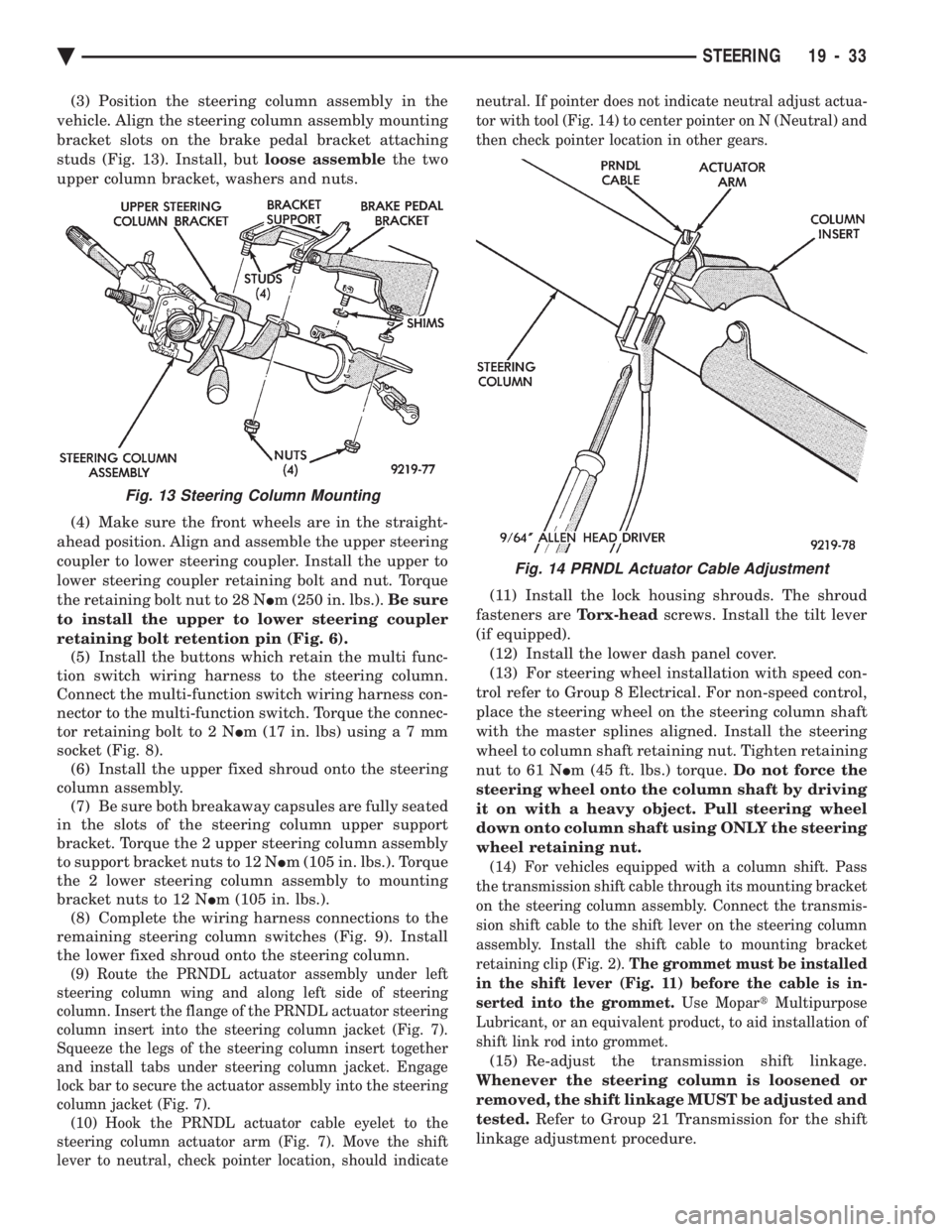

(3) Position the steering column assembly in the

vehicle. Align the steering column assembly mounting

bracket slots on the brake pedal bracket attaching

studs (Fig. 13). Install, but loose assemblethe two

upper column bracket, washers and nuts.

(4) Make sure the front wheels are in the straight-

ahead position. Align and assemble the upper steering

coupler to lower steering coupler. Install the upper to

lower steering coupler retaining bolt and nut. Torque

the retaining bolt nut to 28 N Im (250 in. lbs.). Be sure

to install the upper to lower steering coupler

retaining bolt retention pin (Fig. 6). (5) Install the buttons which retain the multi func-

tion switch wiring harness to the steering column.

Connect the multi-function switch wiring harness con-

nector to the multi-function switch. Torque the connec-

tor retaining bolt to 2 N Im (17 in. lbs) usin ga7mm

socket (Fig. 8). (6) Install the upper fixed shroud onto the steering

column assembly. (7) Be sure both breakaway capsules are fully seated

in the slots of the steering column upper support

bracket. Torque the 2 upper steering column assembly

to support bracket nuts to 12 N Im (105 in. lbs.). Torque

the 2 lower steering column assembly to mounting

bracket nuts to 12 N Im (105 in. lbs.).

(8) Complete the wiring harness connections to the

remaining steering column switches (Fig. 9). Install

the lower fixed shroud onto the steering column.

(9) Route the PRNDL actuator assembly under left

steering column wing and along left side of steering

column. Insert the flange of the PRNDL actuator steering

column insert into the steering column jacket (Fig. 7).

Squeeze the legs of the steering column insert together

and install tabs under steering column jacket. Engage

lock bar to secure the actuator assembly into the steering

column jacket (Fig. 7). (10) Hook the PRNDL actuator cable eyelet to the

steering column actuator arm (Fig. 7). Move the shift

lever to neutral, check pointer location, should indicate neutral. If pointer does not indicate neutral adjust actua-

tor with tool (Fig. 14) to center pointer on N (Neutral) and

then check pointer location in other gears.

(11) Install the lock housing shrouds. The shroud

fasteners are Torx-headscrews. Install the tilt lever

(if equipped). (12) Install the lower dash panel cover.

(13) For steering wheel installation with speed con-

trol refer to Group 8 Electrical. For non-speed control,

place the steering wheel on the steering column shaft

with the master splines aligned. Install the steering

wheel to column shaft retaining nut. Tighten retaining

nut to 61 N Im (45 ft. lbs.) torque. Do not force the

steering wheel onto the column shaft by driving

it on with a heavy object. Pull steering wheel

down onto column shaft using ONLY the steering

wheel retaining nut.

(14) For vehicles equipped with a column shift. Pass

the transmission shift cable through its mounting bracket

on the steering column assembly. Connect the transmis-

sion shift cable to the shift lever on the steering column

assembly. Install the shift cable to mounting bracket

retaining clip (Fig. 2). The grommet must be installed

in the shift lever (Fig. 11) before the cable is in-

serted into the grommet. Use MopartMultipurpose

Lubricant, or an equivalent product, to aid installation of

shift link rod into grommet.

(15) Re-adjust the transmission shift linkage.

Whenever the steering column is loosened or

removed, the shift linkage MUST be adjusted and

tested. Refer to Group 21 Transmission for the shift

linkage adjustment procedure.

Fig. 13 Steering Column Mounting

Fig. 14 PRNDL Actuator Cable Adjustment

Ä STEERING 19 - 33

Page 1958 of 2438

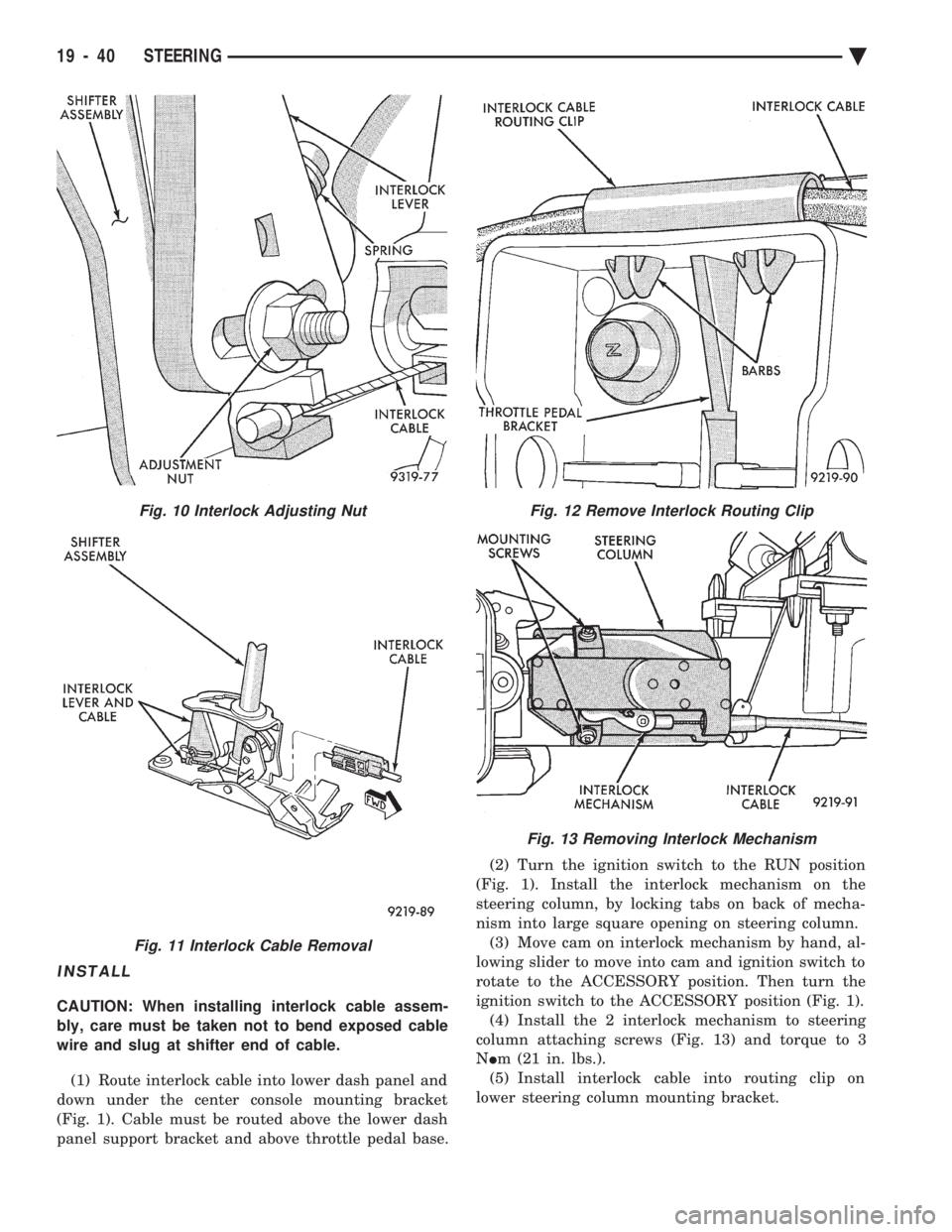

INSTALL

CAUTION: When installing interlock cable assem-

bly, care must be taken not to bend exposed cable

wire and slug at shifter end of cable.

(1) Route interlock cable into lower dash panel and

down under the center console mounting bracket

(Fig. 1). Cable must be routed above the lower dash

panel support bracket and above throttle pedal base. (2) Turn the ignition switch to the RUN position

(Fig. 1). Install the interlock mechanism on the

steering column, by locking tabs on back of mecha-

nism into large square opening on steering column. (3) Move cam on interlock mechanism by hand, al-

lowing slider to move into cam and ignition switch to

rotate to the ACCESSORY position. Then turn the

ignition switch to the ACCESSORY position (Fig. 1). (4) Install the 2 interlock mechanism to steering

column attaching screws (Fig. 13) and torque to 3

N Im (21 in. lbs.).

(5) Install interlock cable into routing clip on

lower steering column mounting bracket.

Fig. 10 Interlock Adjusting Nut

Fig. 11 Interlock Cable Removal

Fig. 12 Remove Interlock Routing Clip

Fig. 13 Removing Interlock Mechanism

19 - 40 STEERING Ä

Page 2006 of 2438

so that pump housing and case front may be covered

with soapy solution or water. Leaks are sometimes

caused by porosity in the case or pump housing.If a leak source is located, that part and all associ-

ated seals, O-rings, and gaskets should be replaced

with new parts.

GEARSHIFT LINKAGE ADJUSTMENT

Normal operation of the Park/Neutral Position

Switch provides a quick check to confirm proper

manual linkage adjustment. Move the selector level slowly upward until it

clicks into the ``P'' Park notch in the selector gate. If

the starter will operate the ``P'' position is correct. After checking ``P'' position, move selector slowly

toward ``N'' Neutral position until lever drops in the

``N'' stop. If the starter will also operate at this point

the gearshift linkage is properly adjusted. If the

starter fails to operate in either position, linkage ad-

justment is required.

CAUTION: When it is necessary to disassemble

linkage cable from levers, which use plastic grom-

mets as retainers, the grommets should be replaced

with new grommets. Use a prying tool to force rod

from grommet in lever, then cut away old grommet.

Use pliers to snap new grommet into lever and rod

into grommet.

(1) Set parking brake.

(2) Place gearshift lever in P(PARK) position.

(3) Loosen clamp bolt on gearshift cable bracket.

(4) Column shift: Insure that preload adjustment

spring engages fork on transaxle bracket. (5) Pull the shift lever by hand to the front detent

position (PARK) and tighten lock. Tighten screw to

11 N Im (100 in. lbs.). Gearshift linkage should now

be properly adjusted. (6) Check adjustment as follows:(a) Detent position for neutral and drive should

be within limits of hand lever gate stops. (b) Key start must occur only when shift lever is

in park or neutral positions.

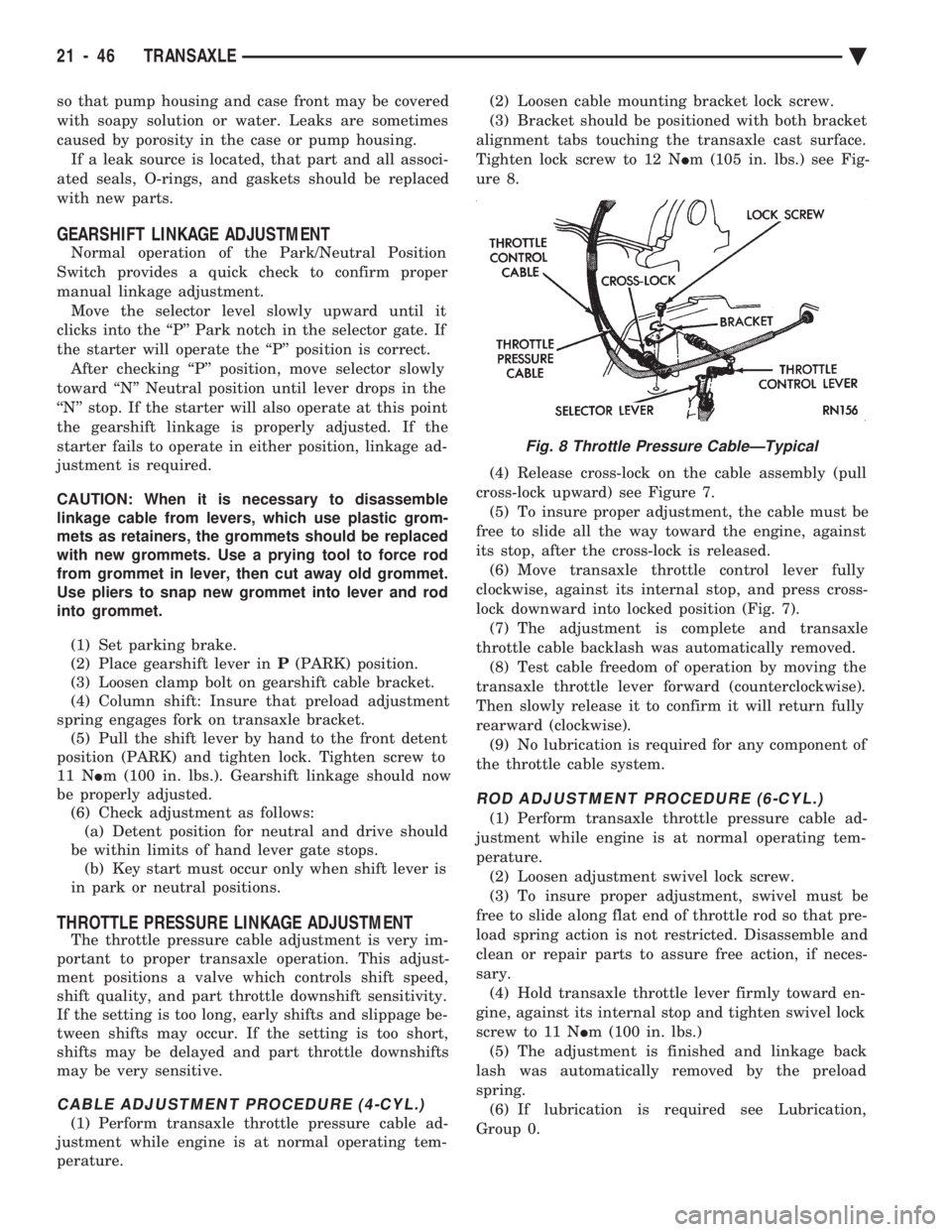

THROTTLE PRESSURE LINKAGE ADJUSTMENT

The throttle pressure cable adjustment is very im-

portant to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too long, early shifts and slippage be-

tween shifts may occur. If the setting is too short,

shifts may be delayed and part throttle downshifts

may be very sensitive.

CABLE ADJUSTMENT PROCEDURE (4-CYL.)

(1) Perform transaxle throttle pressure cable ad-

justment while engine is at normal operating tem-

perature. (2) Loosen cable mounting bracket lock screw.

(3) Bracket should be positioned with both bracket

alignment tabs touching the transaxle cast surface.

Tighten lock screw to 12 N Im (105 in. lbs.) see Fig-

ure 8.

(4) Release cross-lock on the cable assembly (pull

cross-lock upward) see Figure 7. (5) To insure proper adjustment, the cable must be

free to slide all the way toward the engine, against

its stop, after the cross-lock is released. (6) Move transaxle throttle control lever fully

clockwise, against its internal stop, and press cross-

lock downward into locked position (Fig. 7). (7) The adjustment is complete and transaxle

throttle cable backlash was automatically removed. (8) Test cable freedom of operation by moving the

transaxle throttle lever forward (counterclockwise).

Then slowly release it to confirm it will return fully

rearward (clockwise). (9) No lubrication is required for any component of

the throttle cable system.

ROD ADJUSTMENT PROCEDURE (6-CYL.)

(1) Perform transaxle throttle pressure cable ad-

justment while engine is at normal operating tem-

perature. (2) Loosen adjustment swivel lock screw.

(3) To insure proper adjustment, swivel must be

free to slide along flat end of throttle rod so that pre-

load spring action is not restricted. Disassemble and

clean or repair parts to assure free action, if neces-

sary. (4) Hold transaxle throttle lever firmly toward en-

gine, against its internal stop and tighten swivel lock

screw to 11 N Im (100 in. lbs.)

(5) The adjustment is finished and linkage back

lash was automatically removed by the preload

spring. (6) If lubrication is required see Lubrication,

Group 0.

Fig. 8 Throttle Pressure CableÐTypical

21 - 46 TRANSAXLE Ä

Page 2164 of 2438

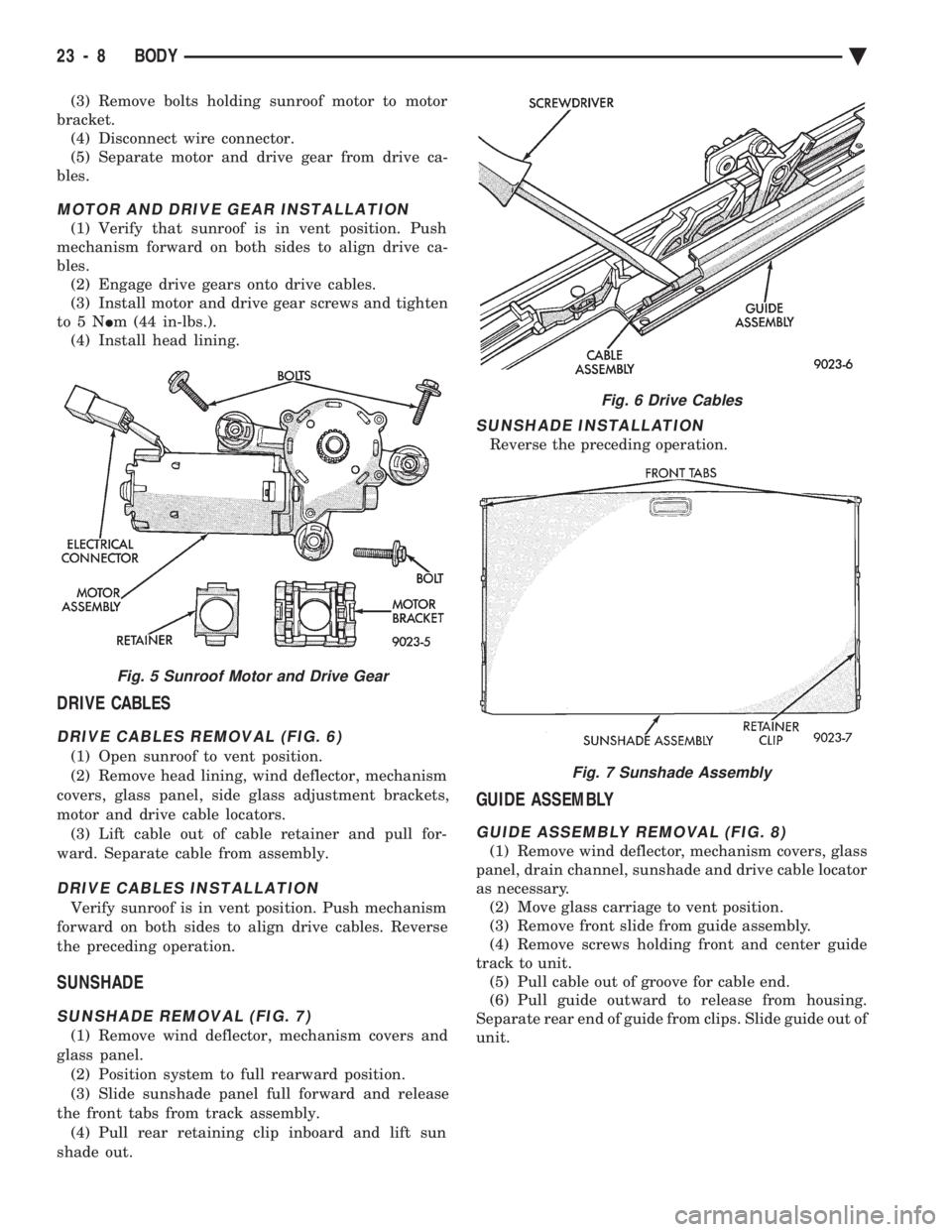

(3) Remove bolts holding sunroof motor to motor

bracket. (4) Disconnect wire connector.

(5) Separate motor and drive gear from drive ca-

bles.

MOTOR AND DRIVE GEAR INSTALLATION

(1) Verify that sunroof is in vent position. Push

mechanism forward on both sides to align drive ca-

bles. (2) Engage drive gears onto drive cables.

(3) Install motor and drive gear screws and tighten

to5N Im (44 in-lbs.).

(4) Install head lining.

DRIVE CABLES

DRIVE CABLES REMOVAL (FIG. 6)

(1) Open sunroof to vent position.

(2) Remove head lining, wind deflector, mechanism

covers, glass panel, side glass adjustment brackets,

motor and drive cable locators. (3) Lift cable out of cable retainer and pull for-

ward. Separate cable from assembly.

DRIVE CABLES INSTALLATION

Verify sunroof is in vent position. Push mechanism

forward on both sides to align drive cables. Reverse

the preceding operation.

SUNSHADE

SUNSHADE REMOVAL (FIG. 7)

(1) Remove wind deflector, mechanism covers and

glass panel. (2) Position system to full rearward position.

(3) Slide sunshade panel full forward and release

the front tabs from track assembly. (4) Pull rear retaining clip inboard and lift sun

shade out.

SUNSHADE INSTALLATION

Reverse the preceding operation.

GUIDE ASSEMBLY

GUIDE ASSEMBLY REMOVAL (FIG. 8)

(1) Remove wind deflector, mechanism covers, glass

panel, drain channel, sunshade and drive cable locator

as necessary. (2) Move glass carriage to vent position.

(3) Remove front slide from guide assembly.

(4) Remove screws holding front and center guide

track to unit. (5) Pull cable out of groove for cable end.

(6) Pull guide outward to release from housing.

Separate rear end of guide from clips. Slide guide out of

unit.

Fig. 5 Sunroof Motor and Drive Gear

Fig. 6 Drive Cables

Fig. 7 Sunshade Assembly

23 - 8 BODY Ä

Page 2307 of 2438

SAFETY PRECAUTIONS AND WARNINGS

WARNING: WEAR EYE PROTECTION WHEN SER-

VICING THE AIR CONDITIONING REFRIGERANT

SYSTEM. SERIOUS EYE INJURY CAN RESULT

FROM EYE CONTACT WITH REFRIGERANT. IF EYE

CONTACT IS MADE, SEEK MEDICAL ATTENTION

IMMEDIATELY. DO NOT EXPOSE REFRIGERANT TO OPEN

FLAME. POISONOUS GAS IS CREATED WHEN RE-

FRIGERANT IS BURNED. AN ELECTRONIC TYPE

LEAK DETECTOR IS RECOMMENDED. LARGE AMOUNTS OF REFRIGERANT RELEASED

IN A CLOSED WORK AREA WILL DISPLACE THE

OXYGEN AND CAUSE SUFFOCATION. THE EVAPORATION RATE OF (R-12) REFRIGER-

ANT AT AVERAGE TEMPERATURE AND ALTITUDE

IS EXTREMELY HIGH. AS A RESULT, ANYTHING

THAT COMES IN CONTACT WITH THE REFRIGER-

ANT WILL FREEZE. ALWAYS PROTECT SKIN OR

DELICATE OBJECTS FROM DIRECT CONTACT

WITH REFRIGERANT.

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with equipment being used.

COOLING SYSTEM PRECAUTIONS

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT STORE IN OPEN OR UNMARKED CON-

TAINERS. WASH SKIN AND CLOTHING THOROUGHLY AF-

TER COMING IN CONTACT WITH ETHYLENE GLY-

COL. KEEP OUT OF REACH OF CHILDREN AND PETS.

DO NOT OPEN A COOLING SYSTEM WHEN THE

ENGINE IS AT RUNNING TEMPERATURE. PER-

SONAL INJURY CAN RESULT.

The engine cooling system is designed to develop

internal pressure of 97 to 123 kPa (14 to 18 psi). Al-

low the vehicle 15 minutes (or until a safe tempera-

ture and pressure are attained) before opening the

cooling system. Refer to Group 7, Cooling System.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the ca-

pacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil will

absorb moisture readily out of the air. This moisture

will convert into acids within a closed system. The following precautions must be observed:

The system must be completely empty before open-

ing any fitting or connection in the refrigeration sys-

tem. Open fittings with caution even after the

system has been emptied. If any pressure is noticed

as a fitting is loosened, allow trapped pressure to

bleed off very slowly. A good rule for the flexible hose lines is to keep the

radius of all bends at least 10 times the diameter of

the hose. Sharper bends will reduce the flow of re-

frigerant. The flexible hose lines should be routed so

they are at least 3 inches (80 mm) from the exhaust

manifold. Inspect all flexible hose lines to make sure

they are in good condition and properly routed. Unified plumbing connections with aluminum gas-

kets cannot be serviced with O-rings. These gaskets

are not reusable and do not require lubrication be-

fore installing. The use of correct wrenches when making connec-

tions is very important. Improper wrenches or im-

proper use of wrenches can damage the fittings. The A/C system will remain chemical stabile as

long as pure-moisture-free R-12 and refrigerant oil is

used. Abnormal amounts of dirt, moisture or air can

upset the chemical stability. This condition could

cause operational troubles or even serious damage if

present in more than very small quantities. When it is necessary to open the refrigeration sys-

tem, have everything needed to service the system

ready. The system should not be left open any longer

than necessary. Cap or plug all lines and fittings as

soon as they are opened to prevent the entrance or

dirt and moisture. All lines and components in parts

stock should be capped or sealed until they are ready

to be used. All tools, including the refrigerant dispensing man-

ifold, the manifold gauge set, and test hoses should

be kept clean and dry.

Fig. 6 Heater only or HeaterÐA/C Controls

Ä HEATING AND AIR CONDITIONING 24 - 3

Page 2310 of 2438

HEATER AND A/C PERFORMANCE TESTS

HEATER OUTPUT TEST

PRE-DIAGNOSTIC PREPARATIONS

Review Safety Precautions and Warnings before

performing the following procedures. Check the radiator coolant level, drive belt tension,

and engine vacuum line connections. Also check ra-

diator air flow and radiator fan operation. Start en-

gine and allow to warm up to normal operating

temperature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing cap. Place a rag over the cap and

turn it to the first safety stop. Allow pressure to es-

cape through the overflow tube. When the system

stabilizes, remove the cap completely.

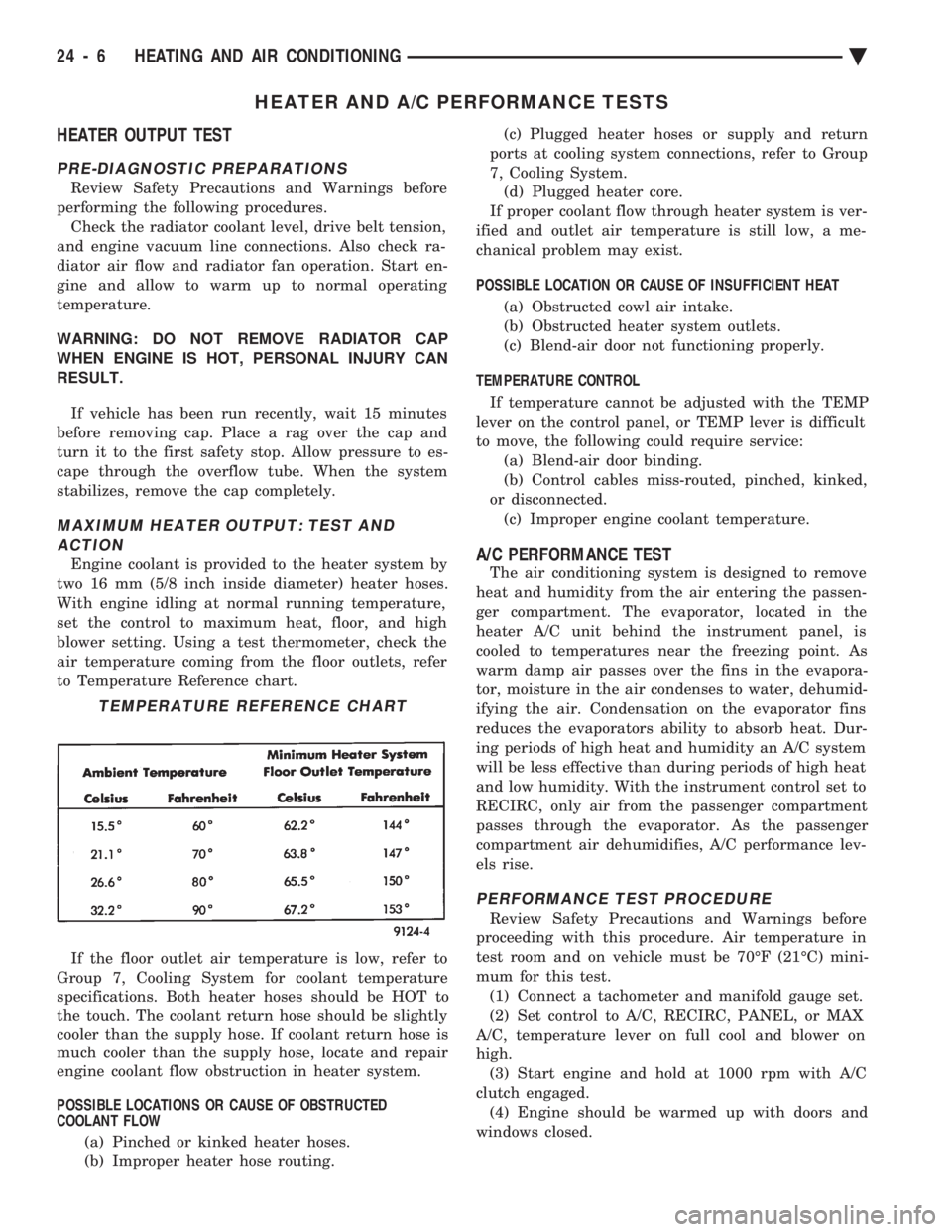

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference chart.

If the floor outlet air temperature is low, refer to

Group 7, Cooling System for coolant temperature

specifications. Both heater hoses should be HOT to

the touch. The coolant return hose should be slightly

cooler than the supply hose. If coolant return hose is

much cooler than the supply hose, locate and repair

engine coolant flow obstruction in heater system.

POSSIBLE LOCATIONS OR CAUSE OF OBSTRUCTED

COOLANT FLOW

(a) Pinched or kinked heater hoses.

(b) Improper heater hose routing. (c) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group

7, Cooling System. (d) Plugged heater core.

If proper coolant flow through heater system is ver-

ified and outlet air temperature is still low, a me-

chanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF INSUFFICIENT HEAT

(a) Obstructed cowl air intake.

(b) Obstructed heater system outlets.

(c) Blend-air door not functioning properly.

TEMPERATURE CONTROL If temperature cannot be adjusted with the TEMP

lever on the control panel, or TEMP lever is difficult

to move, the following could require service: (a) Blend-air door binding.

(b) Control cables miss-routed, pinched, kinked,

or disconnected. (c) Improper engine coolant temperature.A/C PERFORMANCE TEST

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

heater A/C unit behind the instrument panel, is

cooled to temperatures near the freezing point. As

warm damp air passes over the fins in the evapora-

tor, moisture in the air condenses to water, dehumid-

ifying the air. Condensation on the evaporator fins

reduces the evaporators ability to absorb heat. Dur-

ing periods of high heat and humidity an A/C system

will be less effective than during periods of high heat

and low humidity. With the instrument control set to

RECIRC, only air from the passenger compartment

passes through the evaporator. As the passenger

compartment air dehumidifies, A/C performance lev-

els rise.

PERFORMANCE TEST PROCEDURE

Review Safety Precautions and Warnings before

proceeding with this procedure. Air temperature in

test room and on vehicle must be 70ÉF (21ÉC) mini-

mum for this test. (1) Connect a tachometer and manifold gauge set.

(2) Set control to A/C, RECIRC, PANEL, or MAX

A/C, temperature lever on full cool and blower on

high. (3) Start engine and hold at 1000 rpm with A/C

clutch engaged. (4) Engine should be warmed up with doors and

windows closed.

TEMPERATURE REFERENCE CHART

24 - 6 HEATING AND AIR CONDITIONING Ä

Page 2316 of 2438

WARNING: REVIEW SAFETY PRECAUTIONS AND

WARNINGS BEFORE CHARGING THE REFRIGER-

ANT SYSTEM.

After the system has been tested for leaks and

evacuated, a refrigerant charge can be injected into

the system. (1) Connect manifold gauge set.

(2) Measure refrigerant (refer to capacities) and

heat to 52ÉC (125ÉF) with the charging station. Refer

to the instructions provided with the equipment be-

ing used.

REFRIGERANT CAPACITIES:

² Without Rear A/C = 907 g (32 oz.)

² With Rear A/C = 1219 g (43 oz.)

(3) Open the suction and discharge valves. Open

the charge valve to allow the heated refrigerant to

flow into the system. When the transfer of refriger-

ant has stopped, close the suction and discharge

valve. (4) If all of the refrigerant charge did not transfer

from the dispensing device, start engine and hold at

idle (1400 rpm). Set the A/C control to A/C, low

blower speed, and open windows. If the A/C compres-

sor does not engage, test the compressor clutch con-

trol circuit and correct any failure. Refer to Group

8W, Wiring Diagrams. (5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance. Refer to Heater and A/C Performance Tests

in this Group. (7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

OIL LEVEL

It is important to have the correct amount of oil in

the A/C system to ensure proper lubrication of the

compressor. Too little oil will result in damage to the

compressor. Too much oil will reduce the cooling ca-

pacity of the system. The oil used in the compressor is a 500 SUS viscos-

ity, wax-free refrigerant oil. Only refrigerant oil of

the same type should be used to service the system.

Do not use any other oil. The oil container should be

kept tightly capped until it is ready for use, and then

tightly capped after use to prevent contamination

from dirt and moisture. Refrigerant oil will quickly

absorb any moisture it comes in contact with. It will not be necessary to check oil level in the

compressor or to add oil unless there has been an oil

loss. This may be due to a ruptured line, shaft seal leakage, leakage from the evaporator, condenser

leak, filter drier or loss of refrigerant due to a colli-

sion. Oil loss at a the leak point will be evident by

the presence of a wet, shiny surface around the leak.

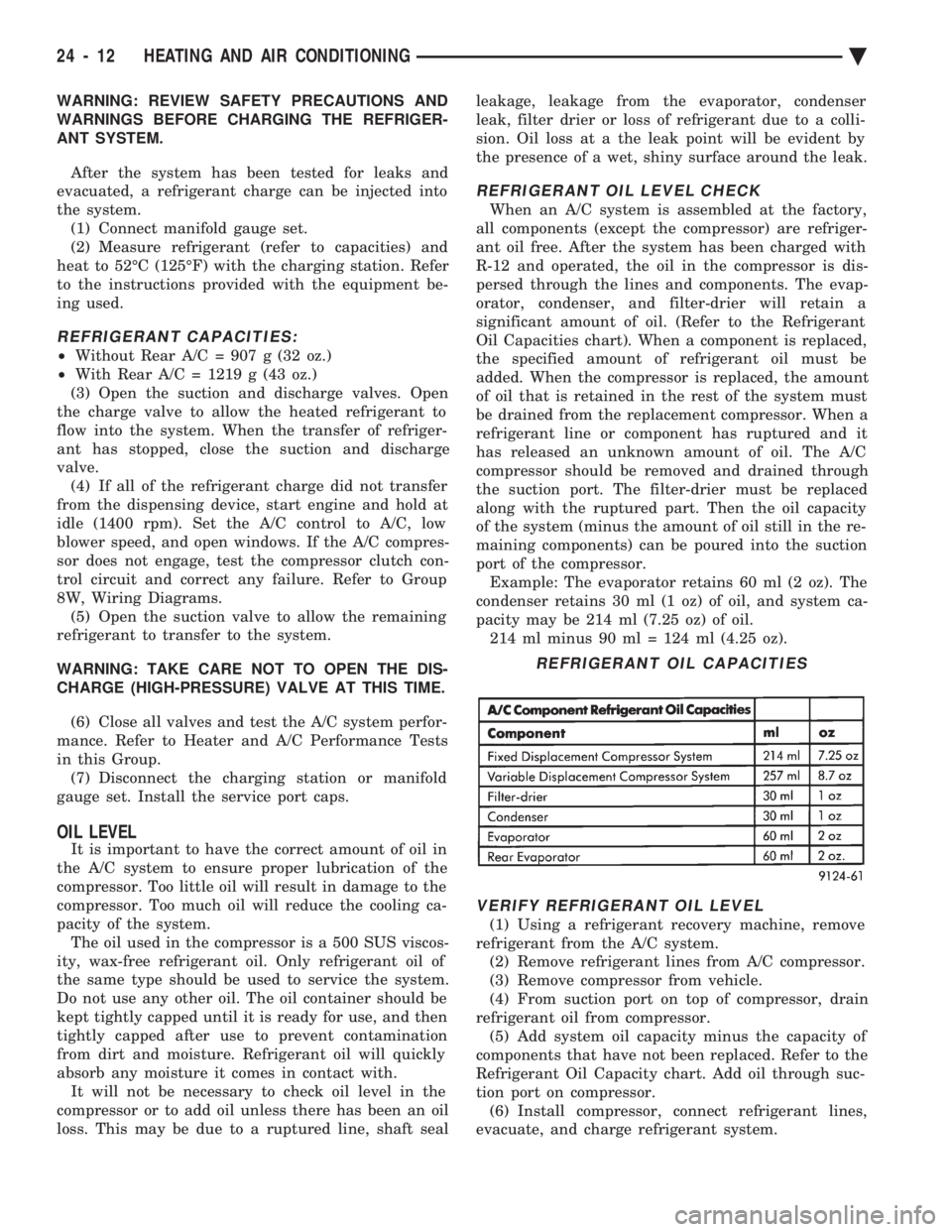

REFRIGERANT OIL LEVEL CHECK

When an A/C system is assembled at the factory,

all components (except the compressor) are refriger-

ant oil free. After the system has been charged with

R-12 and operated, the oil in the compressor is dis-

persed through the lines and components. The evap-

orator, condenser, and filter-drier will retain a

significant amount of oil. (Refer to the Refrigerant

Oil Capacities chart). When a component is replaced,

the specified amount of refrigerant oil must be

added. When the compressor is replaced, the amount

of oil that is retained in the rest of the system must

be drained from the replacement compressor. When a

refrigerant line or component has ruptured and it

has released an unknown amount of oil. The A/C

compressor should be removed and drained through

the suction port. The filter-drier must be replaced

along with the ruptured part. Then the oil capacity

of the system (minus the amount of oil still in the re-

maining components) can be poured into the suction

port of the compressor. Example: The evaporator retains 60 ml (2 oz). The

condenser retains 30 ml (1 oz) of oil, and system ca-

pacity may be 214 ml (7.25 oz) of oil. 214 ml minus 90 ml = 124 ml (4.25 oz).

VERIFY REFRIGERANT OIL LEVEL

(1) Using a refrigerant recovery machine, remove

refrigerant from the A/C system. (2) Remove refrigerant lines from A/C compressor.

(3) Remove compressor from vehicle.

(4) From suction port on top of compressor, drain

refrigerant oil from compressor. (5) Add system oil capacity minus the capacity of

components that have not been replaced. Refer to the

Refrigerant Oil Capacity chart. Add oil through suc-

tion port on compressor. (6) Install compressor, connect refrigerant lines,

evacuate, and charge refrigerant system.

REFRIGERANT OIL CAPACITIES

24 - 12 HEATING AND AIR CONDITIONING Ä