wheel CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2300 of 2438

(6) Pull trim panel forward and separate from ve-

hicle. (7) Remove bolt holding lap belt anchor to floor

and push end of belt through access hole in trim

panel.

INSTALLATION

Reverse the preceding operation.

REAR SHELF TRIM PANEL

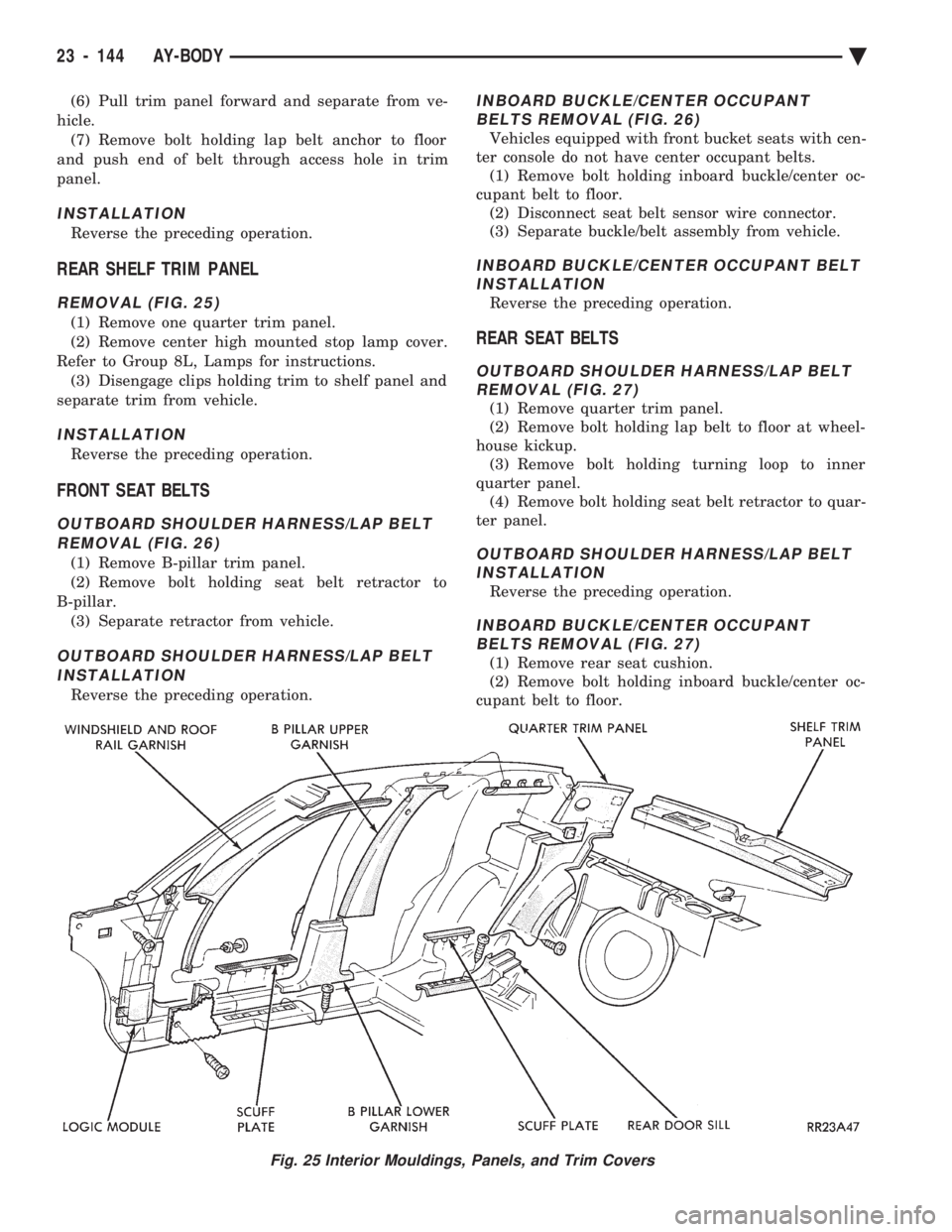

REMOVAL (FIG. 25)

(1) Remove one quarter trim panel.

(2) Remove center high mounted stop lamp cover.

Refer to Group 8L, Lamps for instructions. (3) Disengage clips holding trim to shelf panel and

separate trim from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT SEAT BELTS

OUTBOARD SHOULDER HARNESS/LAP BELT REMOVAL (FIG. 26)

(1) Remove B-pillar trim panel.

(2) Remove bolt holding seat belt retractor to

B-pillar. (3) Separate retractor from vehicle.

OUTBOARD SHOULDER HARNESS/LAP BELTINSTALLATION

Reverse the preceding operation.

INBOARD BUCKLE/CENTER OCCUPANT BELTS REMOVAL (FIG. 26)

Vehicles equipped with front bucket seats with cen-

ter console do not have center occupant belts. (1) Remove bolt holding inboard buckle/center oc-

cupant belt to floor. (2) Disconnect seat belt sensor wire connector.

(3) Separate buckle/belt assembly from vehicle.

INBOARD BUCKLE/CENTER OCCUPANT BELT INSTALLATION

Reverse the preceding operation.

REAR SEAT BELTS

OUTBOARD SHOULDER HARNESS/LAP BELTREMOVAL (FIG. 27)

(1) Remove quarter trim panel.

(2) Remove bolt holding lap belt to floor at wheel-

house kickup. (3) Remove bolt holding turning loop to inner

quarter panel. (4) Remove bolt holding seat belt retractor to quar-

ter panel.

OUTBOARD SHOULDER HARNESS/LAP BELT INSTALLATION

Reverse the preceding operation.

INBOARD BUCKLE/CENTER OCCUPANTBELTS REMOVAL (FIG. 27)

(1) Remove rear seat cushion.

(2) Remove bolt holding inboard buckle/center oc-

cupant belt to floor.

Fig. 25 Interior Mouldings, Panels, and Trim Covers

23 - 144 AY-BODY Ä

Page 2302 of 2438

(3) Remove cushion from vehicle.

REAR SEAT CUSHION INSTALLATION

Reverse the preceding operation.

REAR SEAT BACK REMOVAL

(1) Remove rear seat cushion assembly.

(2) Remove bolts holding seat back to rear floor

kick-up. (3) Lift seat back upward to disengage upper hooks

from shelf support panel. (4) Separate seat back from vehicle.

REAR SEAT BACK INSTALLATION

Reverse the preceding operation.

BODY MOULDINGS

STICK-ON BODY SIDE MOULDING REMOVALAND INSTALLATION

(1) Warm the effected stick-on moulding and body

metal to approximately 38ÉC (100ÉF) using a suitable

heat lamp or heat gun. (2) Pull stick-on moulding from painted surface.

(3) Remove adhesive tape residue from painted

surface of vehicle. (4) If moulding is to be reused, Remove tape resi-

due from moulding. Clean back of moulding with Mo-

par, Super Kleen solvent or equivalent. Wipe

moulding dry with lint free cloth. Apply new body

side moulding (two sided adhesive) tape to back of

moulding. (5) Clean body surface with Mopar, Super Kleen

solvent or equivalent. Wipe surface dry with lint free

cloth. (6) Apply a length of masking tape on the body,

parallel to the top edge of the moulding to use as a

guide, if necessary. (7) Remove protective cover from tape on back of

moulding. Apply moulding to body below the mask-

ing tape guide. (8) Remove masking tape guide and heat body and

moulding, see step one. Firmly press moulding to

body surface to assure adhesion.

FRONT WHEEL OPENING MOULDING REMOVAL

(1) Remove screws holding wheel opening mould-

ing to front fender. (2) Separate moulding from fender.

FRONT WHEEL OPENING MOULDINGINSTALLATION

(1) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (2) Install screws around wheel opening.

REAR WHEEL OPENING MOULDING REMOVAL

(1) Remove screws holding wheel opening mould-

ing to quarter panel. (2) Separate wheel opening moulding from quarter

panel.

REAR WHEEL OPENING MOULDING INSTALLATION

(1) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (2) Install screws around wheel opening.

VINYL ROOF BONNET

REMOVAL (FIG. 30)

(1) Remove quarter panel trim covers.

(2) Remove head lining.

(3) Remove nuts holding transverse roof moulding

to roof panel and separate moulding from vehicle. (4) Remove nuts holding vinyl top bonnet to roof.

(5) Remove rear deck filler panel.

(6) Remove screws holding rear window opening

lower valance to body. (7) Disengage clips holding vinyl top bonnet to

quarter panel. (8) Pull vinyl top bonnet away from top panel to

separate bonnet from anti-flutter sealer holding bon-

net to roof.

INSTALLATION

(1) Clean anti-flutter sealer from roof surface and

inside of vinyl roof bonnet. (2) Apply a 20 mm (0.75 in.) bead of anti-flutter

sealer across the roof panel at the mid point between

the front of the bonnet and rear of roof. (3) Apply a 20 mm (0.75 in.) by 150 mm (6 in.)

bead of anti-flutter sealer down each roof side panel

at mid point between the door opening and rear of

roof. (4) Place the bonnet into position on the roof panel

and align to proper fit. (5) Reverse the removal operation.

REAR DECK FILLER PANEL

REMOVAL (FIG. 31)

(1) Raise truck lid to full up position.

(2) Remove screws holding rear deck filler panel to

body in the front trunk opening gutter. (3) Close trunk lid, do not latch.

(4) Lift filler panel upward and separate from ve-

hicle.

INSTALLATION

Reverse the preceding operation.

23 - 146 AY-BODY Ä

Page 2312 of 2438

REFRIGERANT SERVICE PROCEDURES INDEX

page page

Adding Partial Refrigerant Charge ............ 10

Charging Refrigerant SystemÐEmpty System . . . 11

Discharging Refrigerant System .............. 11

Evacuating Refrigerant System .............. 11

Manifold Gauge Set Connections ............. 9 Oil Level

............................... 12

R-12 Refrigerant Equipment ................. 8

Refrigerant Recycling ...................... 9

Sight Glass Refrigerant Level Inspection ........ 8

Testing for Refrigerant Leaks ............... 10

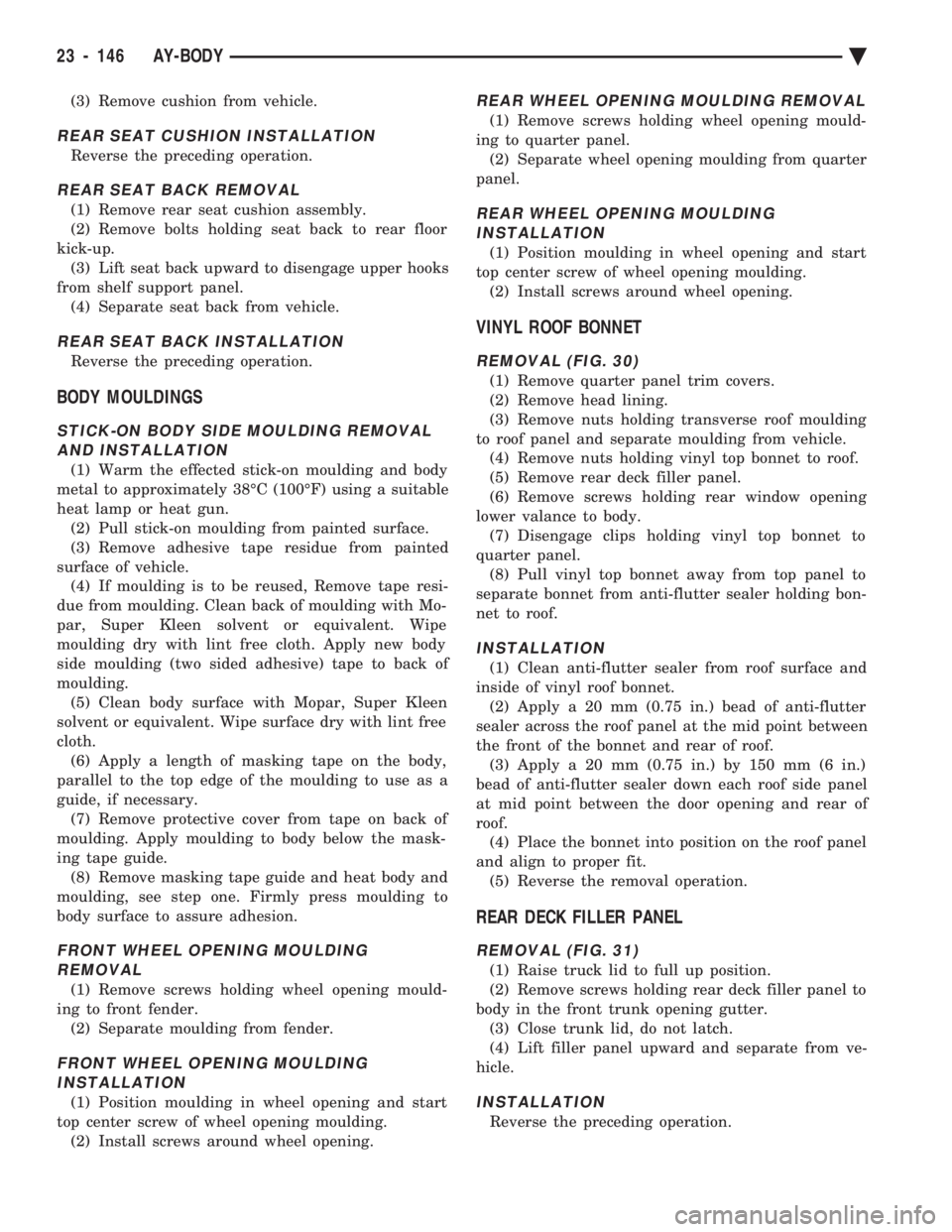

SIGHT GLASS REFRIGERANT LEVEL INSPECTION

The filter-drier is equipped with a sight glass (Fig.

1) that is used as a refrigerant level indicator only.

This sight glass is not to be used for A/C perfor-

mance testing. To check the refrigerant level re-

move the vehicle jack. Then clean the sight glass,

start and warm up engine, and hold rpm slightly

above idle (1100 rpm). Place the air conditioning con-

trol on A/C, RECIRC and high blower. The work

area should be at least 21ÉC (70ÉF). If a Fixed Dis-

placement type compressor does not engage, the re-

frigerant level is probably too low for the Low

Pressure Cut-Off switch to detect. Or, with a Vari-

able Displacement compressor, for the Differential

Pressure Cut-off to detect. If compressor clutch does

not engage, test the refrigerant system for leaks. If

compressor clutch engages, allow approximately one

minute for refrigerant to stabilize. View refrigerant

through sight glass. The suction line should be cold

to the touch and the sight glass should be clear.

If foam or bubbles are visible in sight glass, the re- frigerant level is probably low. Occasional foam or

bubbles are normal when the work area temperature

is above 43ÉC (110ÉF) or below 21ÉC (70ÉF). If suction

line is cold and occasional bubbles are visible in the

sight glass, block the condenser air flow. This will in-

crease the compressor discharge pressure. Do not al-

low engine to over heat. Bubbles should dissipate.

If not, the refrigerant level is low.

CAUTION: Do not allow engine to over heat while

blocking the condenser air flow.

WARNING: R-12 REFRIGERANT IS DETRIMENTAL

TO THE ENVIRONMENT WHEN RELEASED TO THE

ATMOSPHERE. DO NOT ADD R-12 REFRIGERANT

TO A SYSTEM THAT HAS A KNOWN LEAK.

The refrigerant system will not be low on (R-12)

unless there is a leak. Find and repair the leak be-

fore charging.

R-12 REFRIGERANT EQUIPMENT

WARNING: EYE PROTECTION MUST BE USED

WHEN SERVICING AN AIR CONDITIONING REFRIG-

ERANT SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED

BEFORE PROCEEDING WITH THIS OPERATION.

PERSONNEL INJURY CAN RESULT.

When servicing an air conditioning system, an A/C

charging station is recommended (Fig. 2). An (R-12)

refrigerant recovery/recycling device (Fig. 3) should

also be used. This device should meet SAE standards.

Contact an automotive service equipment supplier

for refrigerant recycling/recovering equipment. Refer

to the operating instructions provided with the

equipment for proper operation. A manifold gauge set (Fig. 4) must also be used in

conjunction with the charging and/or recovery/recy-

cling device. The service hoses on the gauge set be-

ing used should have manual (turn wheel) or

automatic back flow valves at the service port con-

nector ends. This will prevent refrigerant from being

release into the atmosphere.

Fig. 1 Filter Drier and Sight Glass

24 - 8 HEATING AND AIR CONDITIONING Ä

Page 2342 of 2438

FIXED DISPLACEMENT COMPRESSORÐMODEL SD709P INDEX

page page

Compressor ............................. 38

Compressor Clutch/Coil Assembly ............ 38

Compressor Shaft Seal .................... 41 Cylinder Head/Valve Plate

.................. 44

Description ............................. 38

Refrigerant System Diagnosis ............... 45

DESCRIPTION

The Sanden compressor is a 7 piston design. Sys-

tem lubrication is provided by 135 ml 615 ml (4.6 oz.

6 0.5 oz.) of 500 viscosity refrigerant oil.

The clutch used on the compressor consists of 3 ba-

sic components:

² The pulley

² Front plate

² Field coil

The pulley and field coil are attached to the front

head of the compressor with tapered snap rings. The

hub is keyed to the compressor shaft and is retained

on the shaft with a self-locking nut. Special service

tools are required to remove and install the clutch

plate on the compressor shaft.

COMPRESSOR

The A/C compressor may be removed and posi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the A/C

compressor clutch/coil assembly, engine, cylinder

head, or generator.

WARNING: REFRIGERANT PRESSURES REMAIN

HIGH EVEN THOUGH THE ENGINE MAY BE

TURNED OFF. BEFORE REMOVING A FULLY

CHARGED COMPRESSOR, REVIEW THE SAFETY

PRECAUTIONS AND WARNINGS SECTION IN THIS

GROUP. DO NOT TWIST OR KINK THE REFRIGER-

ANT LINES WHEN REMOVING A FULLY CHARGED

COMPRESSOR. SAFETY GLASSES MUST BE

WORN.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Loosen and remove drive belts (refer to group

7, Cooling System) and disconnect compressor clutch

wire lead. (3) Remove refrigerant lines from compressor (if

necessary). (4) Remove compressor attaching nuts and bolts.

(5) Remove compressor. If refrigerant lines were

not removed, lift compressor/clutch assembly and tie

it to a suitable component. To install, reverse the removal procedure.

COMPRESSOR CLUTCH/COIL ASSEMBLY

The magnetic clutch consists of a stationary elec-

tro-magnetic coil and a rotating pulley and plate as-

sembly. The electromagnetic coil is retained on the com-

pressor with a snap ring and is dimpled to maintain

its position. The pulley and plate assembly are mounted on the

compressor shaft. When the compressor is not in operation, the pul-

ley free wheels on the clutch hub bearing. When the

coil is energized the plate is magnetically engaged

with the pulley and turns the compressor shaft.

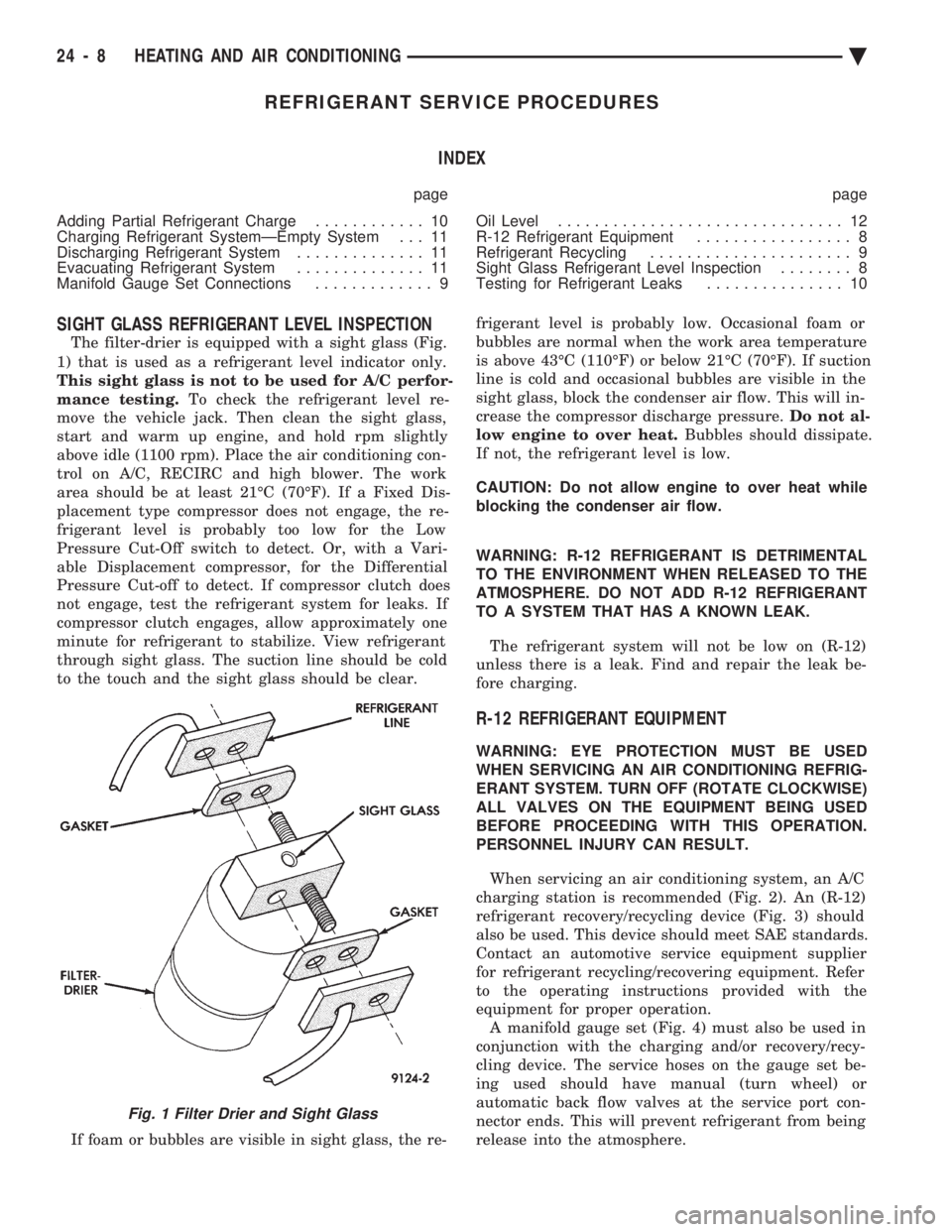

REMOVAL

(1) Insert the 2 pins of the front plate spanner into

any 2 threaded holes of the clutch front plate (Fig.

1). Hold clutch plate stationary. Remove hex nut

with 19 mm (3/4 inch) socket.

(2) Remove clutch front plate using puller. Align

puller center bolt to compressor shaft (Fig. 2). Thumb

tighten the puller bolts into the threaded holes. (3) Turn center bolt clockwise with 19 mm (3/4

inch) socket until front plate is loosened. (4) Remove shaft key by lightly tapping it loose

with a slot screwdriver and hammer (Fig. 3). (5) Remove the external front housing snap ring

by using spread type snap ring pliers (Fig. 4).

Fig. 1 Hex Nut Removal

24 - 38 HEATING AND AIR CONDITIONING Ä

Page 2351 of 2438

COMPONENT SERVICE PROCEDURES INDEX

page page

Air Distribution Duct ...................... 50

Air Distribution Duct ...................... 52

Ambient Switch .......................... 47

Blend-Air Door .......................... 64

Blower Motor ............................ 58

Blower Motor Wheel Assembly .............. 58

Blower Resistor Block ..................... 49

Condensate Drain Tube ................... 64

Condenser Assembly ...................... 57

Condenser Fan Control Switch .............. 47

Defroster Duct ........................... 51

Defroster Duct Adapter .................... 51

Defroster Ducts/Demister Ducts and Hoses ..... 52

Differential Pressure Cut-Out Switch Diagnosis . . 48

Evaporator Coil .......................... 64 Expansion Valve

......................... 55

Filter-Drier Assembly ...................... 57

Fin-Sensing Cycling Clutch Switch ............ 53

Heater Core ............................ 64

Heater Hoses ........................... 51

Heater-A/C Unit AssemblyÐRemoval and Installation ............................ 61

Heater-A/C Unit Recondition ................ 63

Low or Differential Pressure Cut-Off Switch ..... 54

Temperature Control CableÐAA,AP,AG and AJ Models ............................ 49

Temperature Control CableÐAC/AY Models .... 48

Vacuum ActuatorÐFresh/Recirc Door ......... 50

Vacuum ActuatorsÐMode Doors ............. 52

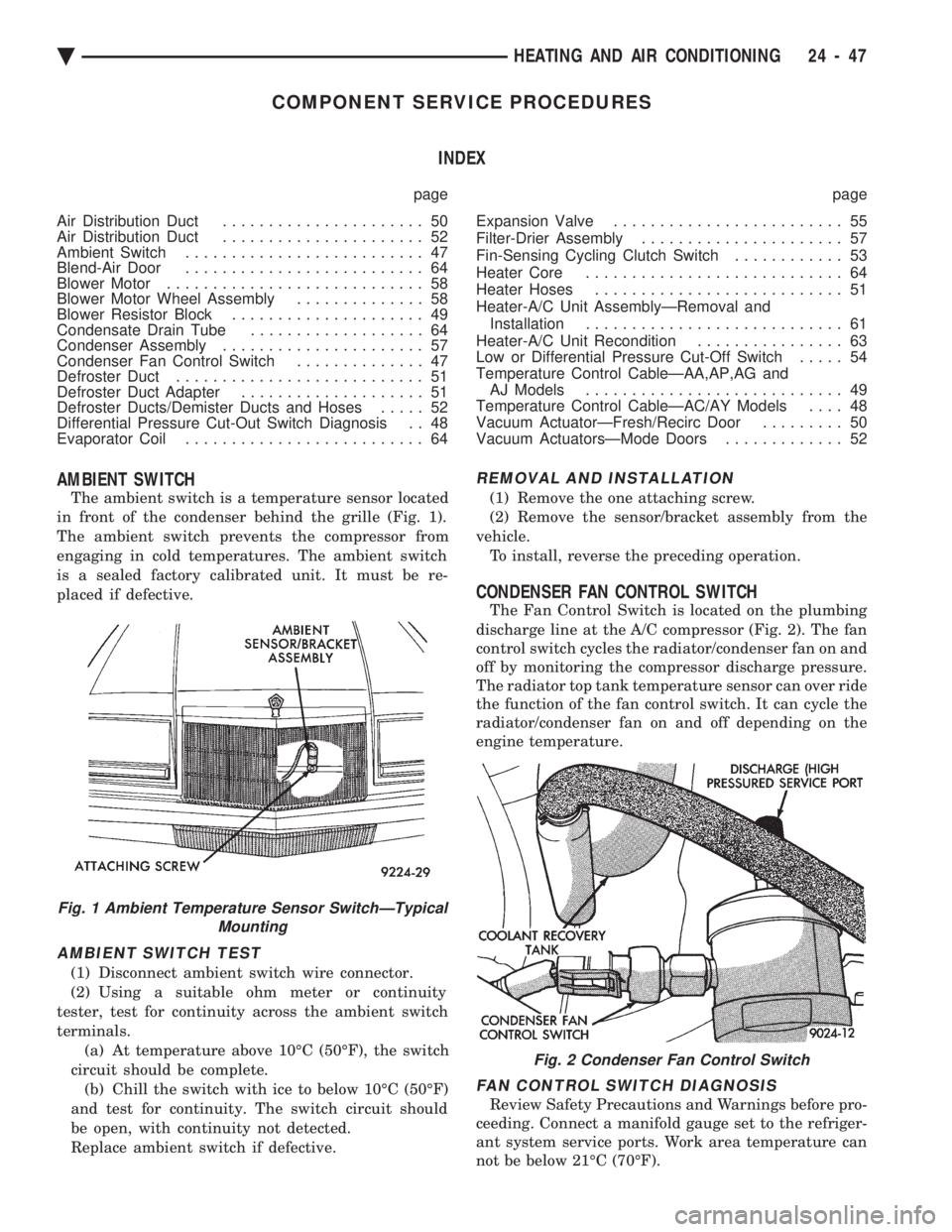

AMBIENT SWITCH

The ambient switch is a temperature sensor located

in front of the condenser behind the grille (Fig. 1).

The ambient switch prevents the compressor from

engaging in cold temperatures. The ambient switch

is a sealed factory calibrated unit. It must be re-

placed if defective.

AMBIENT SWITCH TEST

(1) Disconnect ambient switch wire connector.

(2) Using a suitable ohm meter or continuity

tester, test for continuity across the ambient switch

terminals. (a) At temperature above 10ÉC (50ÉF), the switch

circuit should be complete. (b) Chill the switch with ice to below 10ÉC (50ÉF)

and test for continuity. The switch circuit should

be open, with continuity not detected.

Replace ambient switch if defective.

REMOVAL AND INSTALLATION

(1) Remove the one attaching screw.

(2) Remove the sensor/bracket assembly from the

vehicle. To install, reverse the preceding operation.

CONDENSER FAN CONTROL SWITCH

The Fan Control Switch is located on the plumbing

discharge line at the A/C compressor (Fig. 2). The fan

control switch cycles the radiator/condenser fan on and

off by monitoring the compressor discharge pressure.

The radiator top tank temperature sensor can over ride

the function of the fan control switch. It can cycle the

radiator/condenser fan on and off depending on the

engine temperature.

FAN CONTROL SWITCH DIAGNOSIS

Review Safety Precautions and Warnings before pro-

ceeding. Connect a manifold gauge set to the refriger-

ant system service ports. Work area temperature can

not be below 21ÉC (70ÉF).

Fig. 1 Ambient Temperature Sensor SwitchÐTypical Mounting

Fig. 2 Condenser Fan Control Switch

Ä HEATING AND AIR CONDITIONING 24 - 47

Page 2357 of 2438

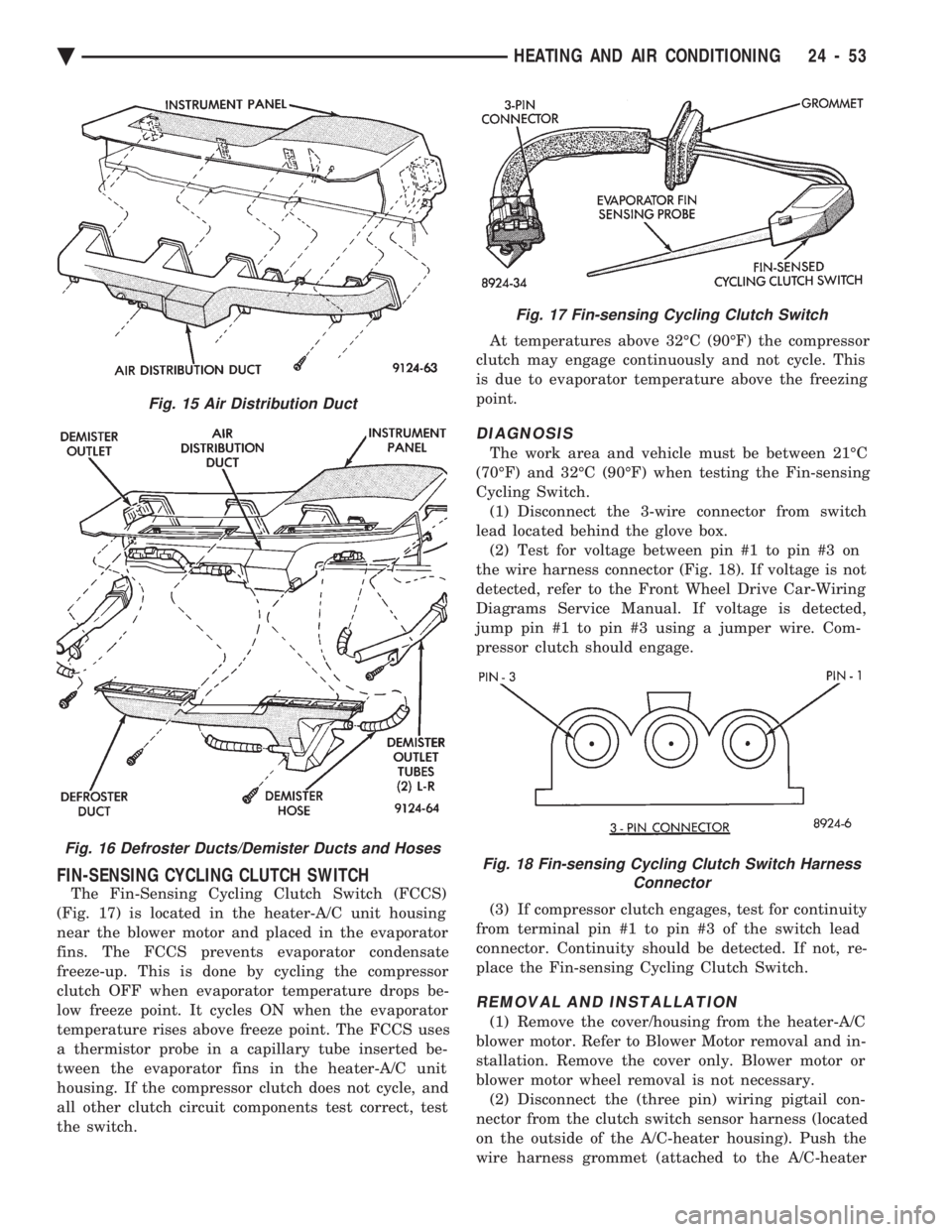

FIN-SENSING CYCLING CLUTCH SWITCH

The Fin-Sensing Cycling Clutch Switch (FCCS)

(Fig. 17) is located in the heater-A/C unit housing

near the blower motor and placed in the evaporator

fins. The FCCS prevents evaporator condensate

freeze-up. This is done by cycling the compressor

clutch OFF when evaporator temperature drops be-

low freeze point. It cycles ON when the evaporator

temperature rises above freeze point. The FCCS uses

a thermistor probe in a capillary tube inserted be-

tween the evaporator fins in the heater-A/C unit

housing. If the compressor clutch does not cycle, and

all other clutch circuit components test correct, test

the switch. At temperatures above 32ÉC (90ÉF) the compressor

clutch may engage continuously and not cycle. This

is due to evaporator temperature above the freezing

point.

DIAGNOSIS

The work area and vehicle must be between 21ÉC

(70ÉF) and 32ÉC (90ÉF) when testing the Fin-sensing

Cycling Switch. (1) Disconnect the 3-wire connector from switch

lead located behind the glove box. (2) Test for voltage between pin #1 to pin #3 on

the wire harness connector (Fig. 18). If voltage is not

detected, refer to the Front Wheel Drive Car-Wiring

Diagrams Service Manual. If voltage is detected,

jump pin #1 to pin #3 using a jumper wire. Com-

pressor clutch should engage.

(3) If compressor clutch engages, test for continuity

from terminal pin #1 to pin #3 of the switch lead

connector. Continuity should be detected. If not, re-

place the Fin-sensing Cycling Clutch Switch.

REMOVAL AND INSTALLATION

(1) Remove the cover/housing from the heater-A/C

blower motor. Refer to Blower Motor removal and in-

stallation. Remove the cover only. Blower motor or

blower motor wheel removal is not necessary. (2) Disconnect the (three pin) wiring pigtail con-

nector from the clutch switch sensor harness (located

on the outside of the A/C-heater housing). Push the

wire harness grommet (attached to the A/C-heater

Fig. 15 Air Distribution Duct

Fig. 16 Defroster Ducts/Demister Ducts and Hoses

Fig. 17 Fin-sensing Cycling Clutch Switch

Fig. 18 Fin-sensing Cycling Clutch Switch Harness Connector

Ä HEATING AND AIR CONDITIONING 24 - 53

Page 2358 of 2438

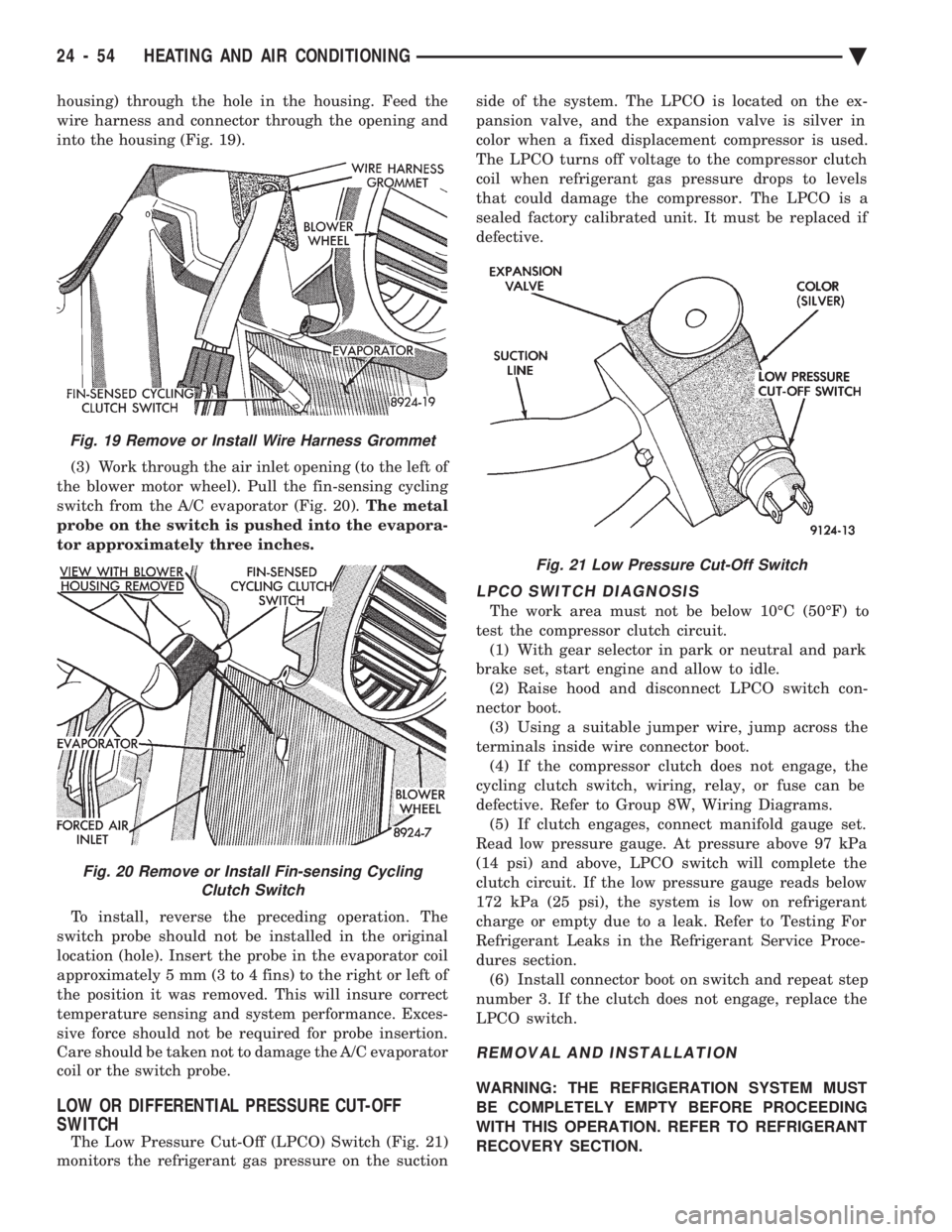

housing) through the hole in the housing. Feed the

wire harness and connector through the opening and

into the housing (Fig. 19). (3) Work through the air inlet opening (to the left of

the blower motor wheel). Pull the fin-sensing cycling

switch from the A/C evaporator (Fig. 20). The metal

probe on the switch is pushed into the evapora-

tor approximately three inches.

To install, reverse the preceding operation. The

switch probe should not be installed in the original

location (hole). Insert the probe in the evaporator coil

approximately 5 mm (3 to 4 fins) to the right or left of

the position it was removed. This will insure correct

temperature sensing and system performance. Exces-

sive force should not be required for probe insertion.

Care should be taken not to damage the A/C evaporator

coil or the switch probe.

LOW OR DIFFERENTIAL PRESSURE CUT-OFF

SWITCH

The Low Pressure Cut-Off (LPCO) Switch (Fig. 21)

monitors the refrigerant gas pressure on the suction side of the system. The LPCO is located on the ex-

pansion valve, and the expansion valve is silver in

color when a fixed displacement compressor is used.

The LPCO turns off voltage to the compressor clutch

coil when refrigerant gas pressure drops to levels

that could damage the compressor. The LPCO is a

sealed factory calibrated unit. It must be replaced if

defective.

LPCO SWITCH DIAGNOSIS

The work area must not be below 10ÉC (50ÉF) to

test the compressor clutch circuit. (1) With gear selector in park or neutral and park

brake set, start engine and allow to idle. (2) Raise hood and disconnect LPCO switch con-

nector boot. (3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot. (4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams. (5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, LPCO switch will complete the

clutch circuit. If the low pressure gauge reads below

172 kPa (25 psi), the system is low on refrigerant

charge or empty due to a leak. Refer to Testing For

Refrigerant Leaks in the Refrigerant Service Proce-

dures section. (6) Install connector boot on switch and repeat step

number 3. If the clutch does not engage, replace the

LPCO switch.

REMOVAL AND INSTALLATION

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION. REFER TO REFRIGERANT

RECOVERY SECTION.

Fig. 21 Low Pressure Cut-Off Switch

Fig. 19 Remove or Install Wire Harness Grommet

Fig. 20 Remove or Install Fin-sensing Cycling Clutch Switch

24 - 54 HEATING AND AIR CONDITIONING Ä

Page 2362 of 2438

new condenser, refer to Oil Level in the Refrigerant

section. Tighten the refrigerant line mounting nut to

23 N Im (200 inch pounds).

Evacuate and recharge system.

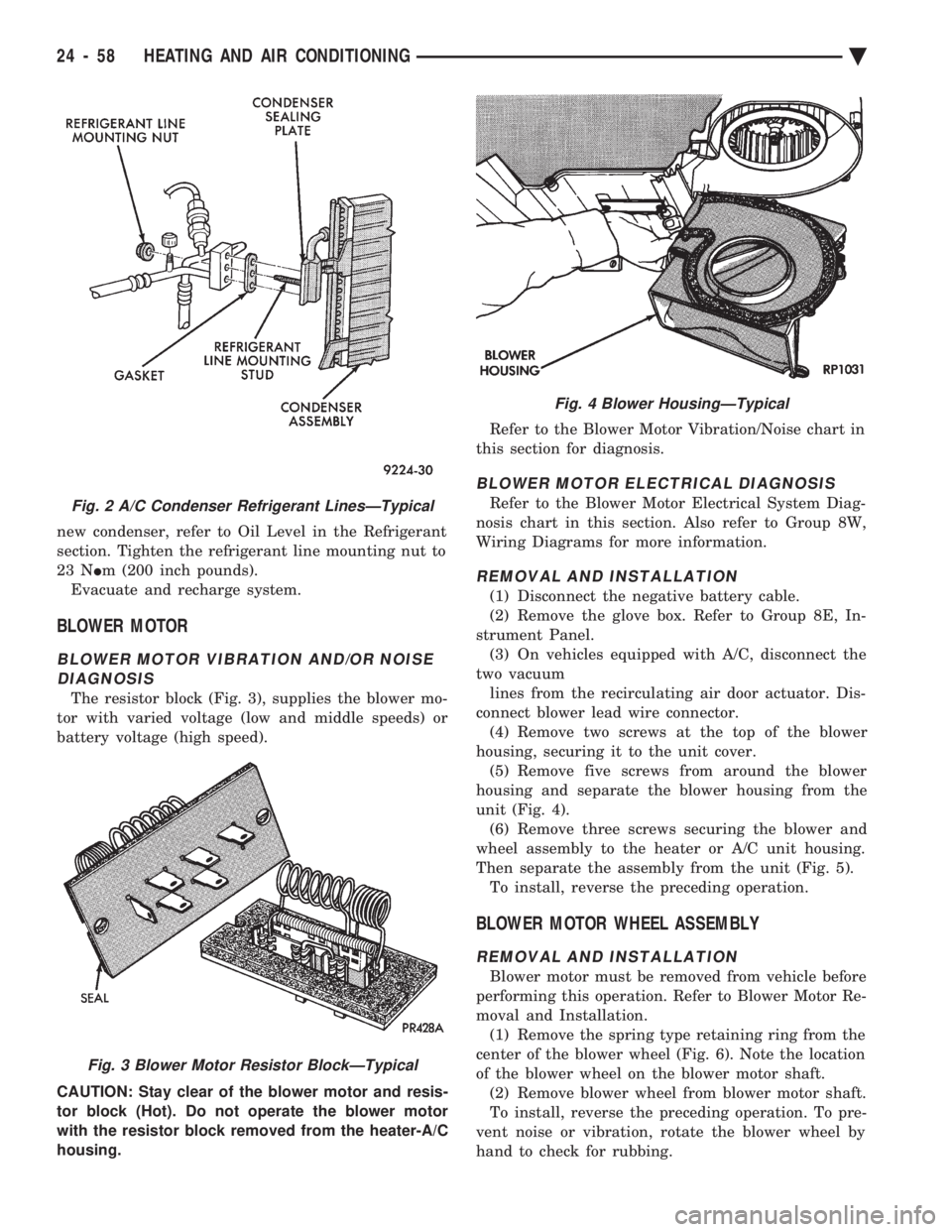

BLOWER MOTOR

BLOWER MOTOR VIBRATION AND/OR NOISE DIAGNOSIS

The resistor block (Fig. 3), supplies the blower mo-

tor with varied voltage (low and middle speeds) or

battery voltage (high speed).

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater-A/C

housing. Refer to the Blower Motor Vibration/Noise chart in

this section for diagnosis.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

Refer to the Blower Motor Electrical System Diag-

nosis chart in this section. Also refer to Group 8W,

Wiring Diagrams for more information.

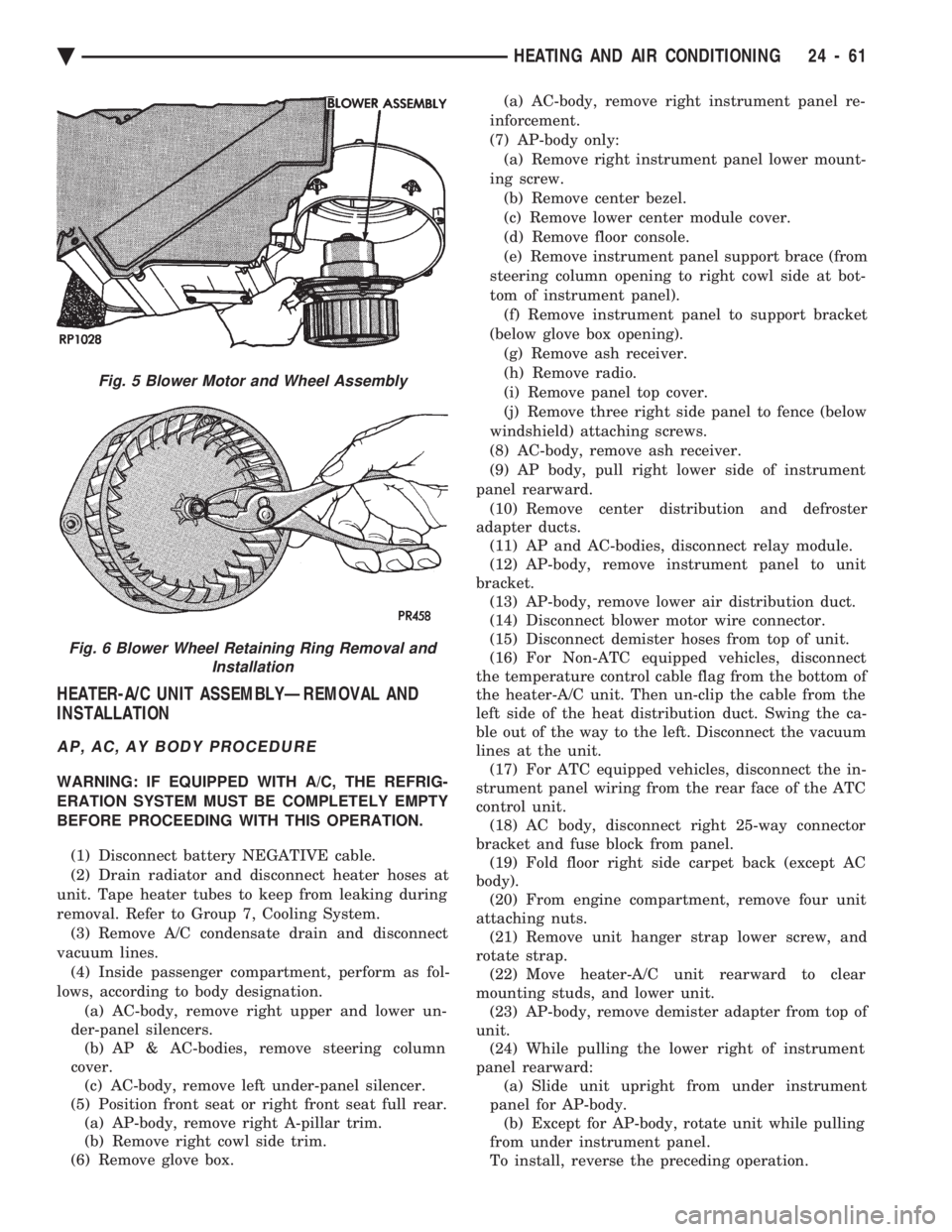

REMOVAL AND INSTALLATION

(1) Disconnect the negative battery cable.

(2) Remove the glove box. Refer to Group 8E, In-

strument Panel. (3) On vehicles equipped with A/C, disconnect the

two vacuum lines from the recirculating air door actuator. Dis-

connect blower lead wire connector. (4) Remove two screws at the top of the blower

housing, securing it to the unit cover. (5) Remove five screws from around the blower

housing and separate the blower housing from the

unit (Fig. 4). (6) Remove three screws securing the blower and

wheel assembly to the heater or A/C unit housing.

Then separate the assembly from the unit (Fig. 5). To install, reverse the preceding operation.

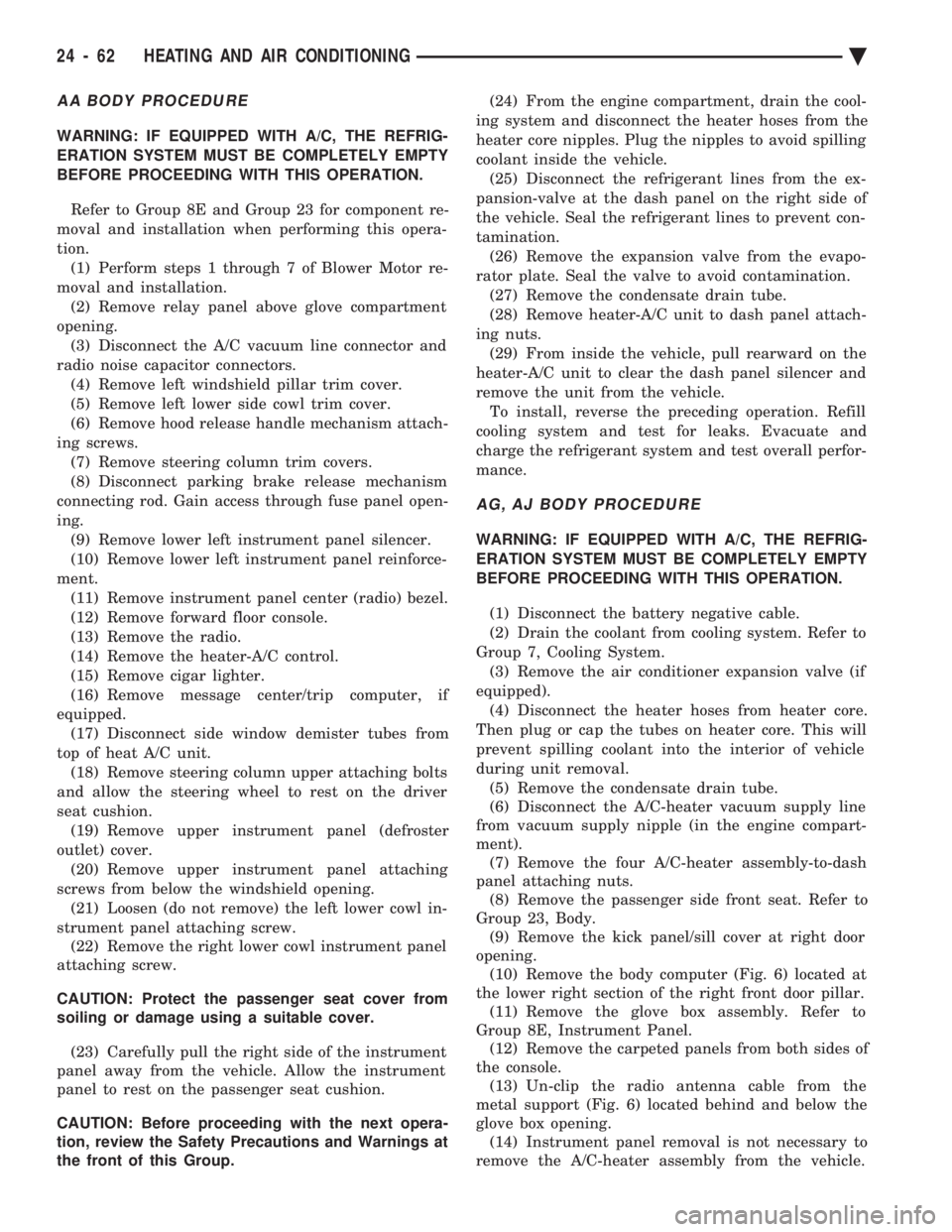

BLOWER MOTOR WHEEL ASSEMBLY

REMOVAL AND INSTALLATION

Blower motor must be removed from vehicle before

performing this operation. Refer to Blower Motor Re-

moval and Installation. (1) Remove the spring type retaining ring from the

center of the blower wheel (Fig. 6). Note the location

of the blower wheel on the blower motor shaft. (2) Remove blower wheel from blower motor shaft.

To install, reverse the preceding operation. To pre-

vent noise or vibration, rotate the blower wheel by

hand to check for rubbing.

Fig. 2 A/C Condenser Refrigerant LinesÐTypical

Fig. 3 Blower Motor Resistor BlockÐTypical

Fig. 4 Blower HousingÐTypical

24 - 58 HEATING AND AIR CONDITIONING Ä

Page 2365 of 2438

HEATER-A/C UNIT ASSEMBLYÐREMOVAL AND

INSTALLATION

AP, AC, AY BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION.

(1) Disconnect battery NEGATIVE cable.

(2) Drain radiator and disconnect heater hoses at

unit. Tape heater tubes to keep from leaking during

removal. Refer to Group 7, Cooling System. (3) Remove A/C condensate drain and disconnect

vacuum lines. (4) Inside passenger compartment, perform as fol-

lows, according to body designation. (a) AC-body, remove right upper and lower un-

der-panel silencers. (b) AP & AC-bodies, remove steering column

cover. (c) AC-body, remove left under-panel silencer.

(5) Position front seat or right front seat full rear. (a) AP-body, remove right A-pillar trim.

(b) Remove right cowl side trim.

(6) Remove glove box. (a) AC-body, remove right instrument panel re-

inforcement.

(7) AP-body only: (a) Remove right instrument panel lower mount-

ing screw. (b) Remove center bezel.

(c) Remove lower center module cover.

(d) Remove floor console.

(e) Remove instrument panel support brace (from

steering column opening to right cowl side at bot-

tom of instrument panel). (f) Remove instrument panel to support bracket

(below glove box opening). (g) Remove ash receiver.

(h) Remove radio.

(i) Remove panel top cover.

(j) Remove three right side panel to fence (below

windshield) attaching screws.

(8) AC-body, remove ash receiver.

(9) AP body, pull right lower side of instrument

panel rearward. (10) Remove center distribution and defroster

adapter ducts. (11) AP and AC-bodies, disconnect relay module.

(12) AP-body, remove instrument panel to unit

bracket. (13) AP-body, remove lower air distribution duct.

(14) Disconnect blower motor wire connector.

(15) Disconnect demister hoses from top of unit.

(16) For Non-ATC equipped vehicles, disconnect

the temperature control cable flag from the bottom of

the heater-A/C unit. Then un-clip the cable from the

left side of the heat distribution duct. Swing the ca-

ble out of the way to the left. Disconnect the vacuum

lines at the unit. (17) For ATC equipped vehicles, disconnect the in-

strument panel wiring from the rear face of the ATC

control unit. (18) AC body, disconnect right 25-way connector

bracket and fuse block from panel. (19) Fold floor right side carpet back (except AC

body). (20) From engine compartment, remove four unit

attaching nuts. (21) Remove unit hanger strap lower screw, and

rotate strap. (22) Move heater-A/C unit rearward to clear

mounting studs, and lower unit. (23) AP-body, remove demister adapter from top of

unit. (24) While pulling the lower right of instrument

panel rearward: (a) Slide unit upright from under instrument

panel for AP-body. (b) Except for AP-body, rotate unit while pulling

from under instrument panel.

To install, reverse the preceding operation.

Fig. 5 Blower Motor and Wheel Assembly

Fig. 6 Blower Wheel Retaining Ring Removal and Installation

Ä HEATING AND AIR CONDITIONING 24 - 61

Page 2366 of 2438

AA BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION. Refer to Group 8E and Group 23 for component re-

moval and installation when performing this opera-

tion. (1) Perform steps 1 through 7 of Blower Motor re-

moval and installation. (2) Remove relay panel above glove compartment

opening. (3) Disconnect the A/C vacuum line connector and

radio noise capacitor connectors. (4) Remove left windshield pillar trim cover.

(5) Remove left lower side cowl trim cover.

(6) Remove hood release handle mechanism attach-

ing screws. (7) Remove steering column trim covers.

(8) Disconnect parking brake release mechanism

connecting rod. Gain access through fuse panel open-

ing. (9) Remove lower left instrument panel silencer.

(10) Remove lower left instrument panel reinforce-

ment. (11) Remove instrument panel center (radio) bezel.

(12) Remove forward floor console.

(13) Remove the radio.

(14) Remove the heater-A/C control.

(15) Remove cigar lighter.

(16) Remove message center/trip computer, if

equipped. (17) Disconnect side window demister tubes from

top of heat A/C unit. (18) Remove steering column upper attaching bolts

and allow the steering wheel to rest on the driver

seat cushion. (19) Remove upper instrument panel (defroster

outlet) cover. (20) Remove upper instrument panel attaching

screws from below the windshield opening. (21) Loosen (do not remove) the left lower cowl in-

strument panel attaching screw. (22) Remove the right lower cowl instrument panel

attaching screw.

CAUTION: Protect the passenger seat cover from

soiling or damage using a suitable cover.

(23) Carefully pull the right side of the instrument

panel away from the vehicle. Allow the instrument

panel to rest on the passenger seat cushion.

CAUTION: Before proceeding with the next opera-

tion, review the Safety Precautions and Warnings at

the front of this Group. (24) From the engine compartment, drain the cool-

ing system and disconnect the heater hoses from the

heater core nipples. Plug the nipples to avoid spilling

coolant inside the vehicle. (25) Disconnect the refrigerant lines from the ex-

pansion-valve at the dash panel on the right side of

the vehicle. Seal the refrigerant lines to prevent con-

tamination. (26) Remove the expansion valve from the evapo-

rator plate. Seal the valve to avoid contamination. (27) Remove the condensate drain tube.

(28) Remove heater-A/C unit to dash panel attach-

ing nuts. (29) From inside the vehicle, pull rearward on the

heater-A/C unit to clear the dash panel silencer and

remove the unit from the vehicle. To install, reverse the preceding operation. Refill

cooling system and test for leaks. Evacuate and

charge the refrigerant system and test overall perfor-

mance.

AG, AJ BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION.

(1) Disconnect the battery negative cable.

(2) Drain the coolant from cooling system. Refer to

Group 7, Cooling System. (3) Remove the air conditioner expansion valve (if

equipped). (4) Disconnect the heater hoses from heater core.

Then plug or cap the tubes on heater core. This will

prevent spilling coolant into the interior of vehicle

during unit removal. (5) Remove the condensate drain tube.

(6) Disconnect the A/C-heater vacuum supply line

from vacuum supply nipple (in the engine compart-

ment). (7) Remove the four A/C-heater assembly-to-dash

panel attaching nuts. (8) Remove the passenger side front seat. Refer to

Group 23, Body. (9) Remove the kick panel/sill cover at right door

opening. (10) Remove the body computer (Fig. 6) located at

the lower right section of the right front door pillar. (11) Remove the glove box assembly. Refer to

Group 8E, Instrument Panel. (12) Remove the carpeted panels from both sides of

the console. (13) Un-clip the radio antenna cable from the

metal support (Fig. 6) located behind and below the

glove box opening. (14) Instrument panel removal is not necessary to

remove the A/C-heater assembly from the vehicle.

24 - 62 HEATING AND AIR CONDITIONING Ä