wheel CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2203 of 2438

(2) Remove rear shoulder harness turning loop

cover. Remove bolt holding turning loop to quarter

panel. (3) Remove rear seat cushion and back.

(4) Remove push-in fastener holding quarter trim

to roof rail. (5) Remove screws holding quarter trim panel to

wheelhouse kickup. (6) Pull trim panel away from C-pillar and sepa-

rate from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR SHELF TRIM PANEL

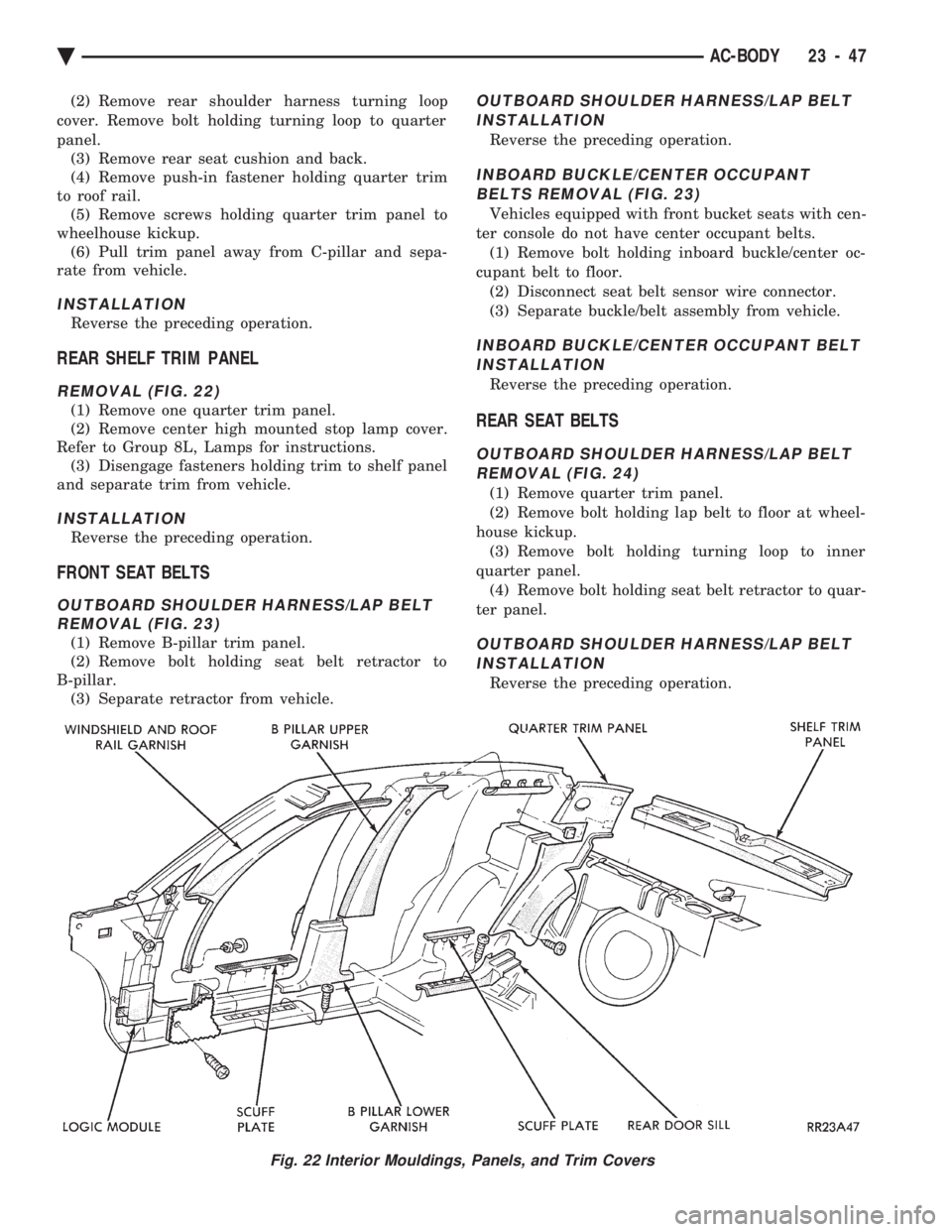

REMOVAL (FIG. 22)

(1) Remove one quarter trim panel.

(2) Remove center high mounted stop lamp cover.

Refer to Group 8L, Lamps for instructions. (3) Disengage fasteners holding trim to shelf panel

and separate trim from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT SEAT BELTS

OUTBOARD SHOULDER HARNESS/LAP BELT REMOVAL (FIG. 23)

(1) Remove B-pillar trim panel.

(2) Remove bolt holding seat belt retractor to

B-pillar. (3) Separate retractor from vehicle.

OUTBOARD SHOULDER HARNESS/LAP BELT

INSTALLATION

Reverse the preceding operation.

INBOARD BUCKLE/CENTER OCCUPANTBELTS REMOVAL (FIG. 23)

Vehicles equipped with front bucket seats with cen-

ter console do not have center occupant belts. (1) Remove bolt holding inboard buckle/center oc-

cupant belt to floor. (2) Disconnect seat belt sensor wire connector.

(3) Separate buckle/belt assembly from vehicle.

INBOARD BUCKLE/CENTER OCCUPANT BELT INSTALLATION

Reverse the preceding operation.

REAR SEAT BELTS

OUTBOARD SHOULDER HARNESS/LAP BELTREMOVAL (FIG. 24)

(1) Remove quarter trim panel.

(2) Remove bolt holding lap belt to floor at wheel-

house kickup. (3) Remove bolt holding turning loop to inner

quarter panel. (4) Remove bolt holding seat belt retractor to quar-

ter panel.

OUTBOARD SHOULDER HARNESS/LAP BELT INSTALLATION

Reverse the preceding operation.

Fig. 22 Interior Mouldings, Panels, and Trim Covers

Ä AC-BODY 23 - 47

Page 2205 of 2438

REAR SEATS

REAR SEAT CUSHION REMOVAL

(1) Remove bolts holding cushion to floor.

(2) Disconnect center occupant seat belts from

cushion. (3) Remove cushion from vehicle.

REAR SEAT CUSHION INSTALLATION

Reverse the preceding operation.

REAR SEAT BACK REMOVAL

(1) Remove rear seat cushion assembly.

(2) Remove bolts holding seat back to rear floor

kick-up. (3) Lift seat back upward to disengage upper hooks

from shelf support panel. (4) Separate seat back from vehicle.

REAR SEAT BACK INSTALLATION

Reverse the preceding operation.

BODY MOULDINGS

STICK-ON BODY SIDE MOULDING REMOVALAND INSTALLATION

(1) Warm the effected stick-on moulding and body

metal to approximately 38ÉC (100ÉF) using a suitable

heat lamp or heat gun. (2) Pull stick-on moulding from painted surface.

(3) Remove adhesive tape residue from painted

surface of vehicle. (4) If moulding is to be reused, Remove tape resi-

due from moulding. Clean back of moulding with Mo-

par t, Super Kleen solvent or equivalent. Wipe

moulding dry with lint free cloth. Apply new body

side moulding (two sided adhesive) tape to back of

moulding. (5) Clean body surface with Super Kleen solvent or

equivalent. Wipe surface dry with lint free cloth. (6) Apply a length of masking tape on the body,

parallel to the top edge of the moulding to use as a

guide, if necessary. (7) Remove protective cover from tape on back of

moulding. Apply moulding to body below the mask-

ing tape guide. (8) Remove masking tape guide and heat body and

moulding, see step one. Firmly press moulding to

body surface to assure adhesion.

FRONT WHEEL OPENING MOULDING REMOVAL

(1) Remove screws holding wheel opening mould-

ing to front fender. (2) Separate moulding from fender.

FRONT WHEEL OPENING MOULDINGINSTALLATION

(1) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (2) Install screws around wheel opening.

REAR WHEEL OPENING MOULDING REMOVAL

(1) Remove screws holding wheel opening mould-

ing to quarter panel. (2) Separate wheel opening moulding from quarter

panel.

REAR WHEEL OPENING MOULDING INSTALLATION

(1) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (2) Install screws around wheel opening.

VINYL ROOF BONNET

REMOVAL (FIG. 27)

(1) Remove quarter panel trim covers.

(2) Remove head lining.

(3) Remove nuts holding transverse roof moulding

to roof panel and separate moulding from vehicle. (4) Remove nuts holding vinyl top bonnet to roof.

(5) Remove rear deck filler panel.

(6) Remove screws holding rear window opening

lower valance to body. (7) Disengage hook and loop fasteners holding vi-

nyl top bonnet to quarter panel. (8) Pull vinyl top bonnet away from top panel to

separate bonnet from anti-flutter sealer holding bon-

net to roof.

INSTALLATION

(1) Clean anti-flutter sealer from roof surface and

inside of vinyl roof bonnet. (2) Apply a 20 mm (0.75 in.) bead of anti-flutter

sealer across the roof panel at the mid point between

the front of the bonnet and rear of roof. (3) Apply a 20 mm (0.75 in.) by 150 mm (6 in.)

bead of anti-flutter sealer down each roof side panel

at mid point between the door opening and rear of

roof. (4) Place the bonnet into position on the roof panel

and align to proper fit. (5) Reverse the removal operation.

REAR DECK FILLER PANEL

REMOVAL (FIG. 28)

(1) Raise truck lid to full up position.

(2) Remove screws holding rear deck filler panel to

body in the front trunk opening gutter. (3) Close trunk lid, do not latch.

(4) Lift filler panel upward and separate from ve-

hicle.

Ä AC-BODY 23 - 49

Page 2210 of 2438

(4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under power

distribution center, and under wiring harnesses, to-

ward dash panel. Push cable through access hole in

dash panel under the brake master cylinder, into

passenger compartment.

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

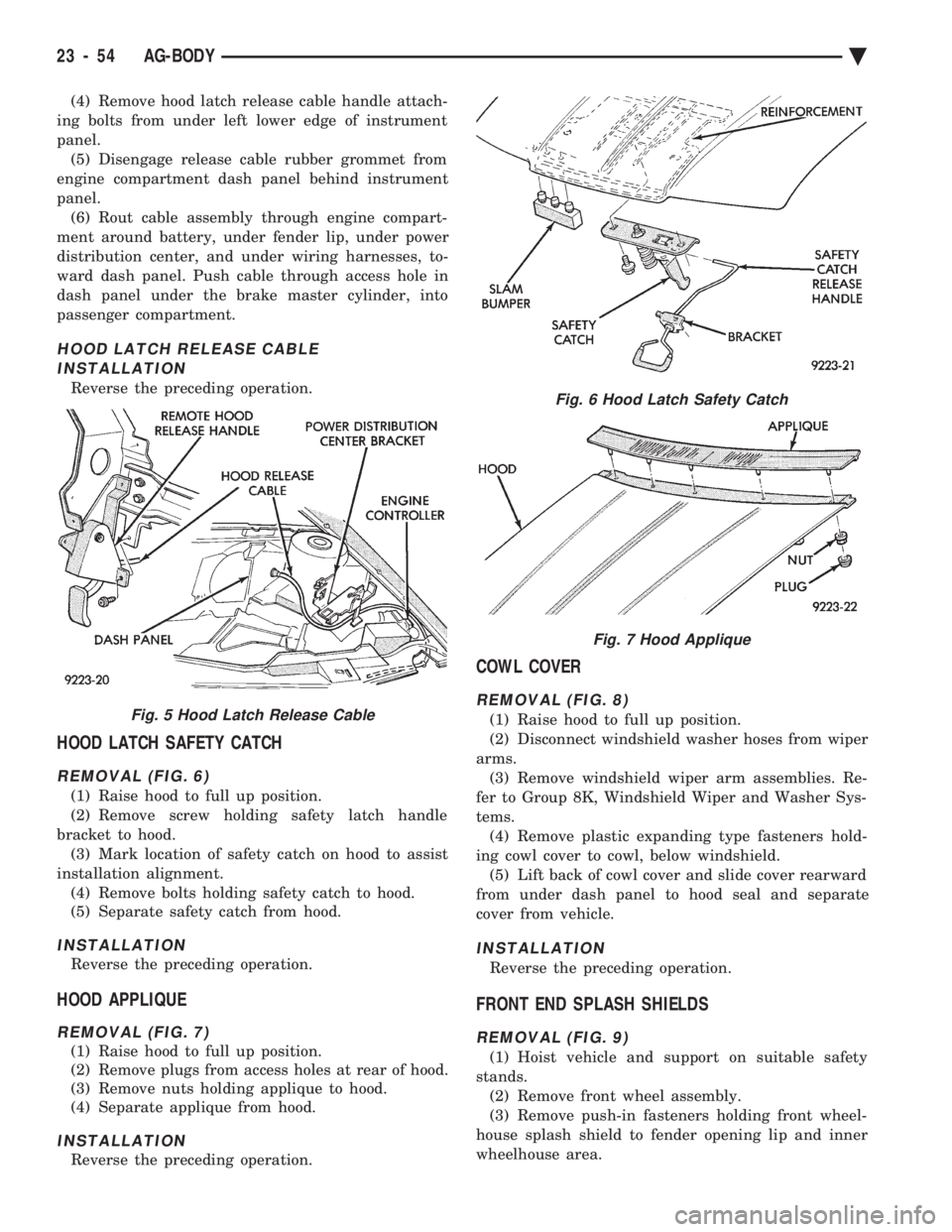

HOOD LATCH SAFETY CATCH

REMOVAL (FIG. 6)

(1) Raise hood to full up position.

(2) Remove screw holding safety latch handle

bracket to hood. (3) Mark location of safety catch on hood to assist

installation alignment. (4) Remove bolts holding safety catch to hood.

(5) Separate safety catch from hood.

INSTALLATION

Reverse the preceding operation.

HOOD APPLIQUE

REMOVAL (FIG. 7)

(1) Raise hood to full up position.

(2) Remove plugs from access holes at rear of hood.

(3) Remove nuts holding applique to hood.

(4) Separate applique from hood.

INSTALLATION

Reverse the preceding operation.

COWL COVER

REMOVAL (FIG. 8)

(1) Raise hood to full up position.

(2) Disconnect windshield washer hoses from wiper

arms. (3) Remove windshield wiper arm assemblies. Re-

fer to Group 8K, Windshield Wiper and Washer Sys-

tems. (4) Remove plastic expanding type fasteners hold-

ing cowl cover to cowl, below windshield. (5) Lift back of cowl cover and slide cover rearward

from under dash panel to hood seal and separate

cover from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT END SPLASH SHIELDS

REMOVAL (FIG. 9)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area.

Fig. 5 Hood Latch Release Cable

Fig. 6 Hood Latch Safety Catch

Fig. 7 Hood Applique

23 - 54 AG-BODY Ä

Page 2211 of 2438

(4) Separate wheelhouse splash shield from vehi-

cle.

INSTALLATION

Reverse the preceding operation.

TRANSAXLE SPLASH SHIELD REMOVAL (FIG. 9)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 10)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELD

INSTALLATION

Reverse the preceding operation.

FRONT FENDER

REMOVAL (FIG. 11)

(1) Remove front side marker lamp assembly. Re-

fer to Group 8L, Lamps for instructions. (2) Remove front bumper as necessary to gain

clearance to remove front fender. Refer to Front

Bumper Removal paragraph in this section. (3) Remove front wheelhouse splash shield. Refer

to Front Wheelhouse Splash Shield Removal para-

graph of this section. (4) Remove side applique as necessary to clear

front fender. Refer to Body Side Applique Removal

paragraph in this section. (5) Remove bolts holding bottom of front fender at

rear of wheel opening. (6) Remove bolt holding front fender to hinge pil-

lar at rear of wheelhouse. (7) Remove bolt holding front fender to cowl at top

of front door opening. (8) Remove bolts holding front fender to underside

of radiator closure panel. (9) Remove bolts holding front fender to front of

radiator closure panel. (10) Raise hood and support hood on a suitable

holding device. Mark hinge for installation indexing.

Remove lower hood hinge attaching bolts and sepa-

rate hinge from front fender. Refer to Hood Hinge

Removal paragraph in this section. (11) Remove bolts holding front fender to inner

wheelhouse along hood opening. (12) Separate front fender from vehicle.

INSTALLATION

Reverse the preceding operation. Align front fender

to achiev ea4mm (0.160 in) gap to hood edge and 6

Fig. 8 Cowl Cover Assembly

Fig. 9 Front Wheelhouse and Transaxle Splash

ShieldsÐTypical

Fig. 10 Engine Drive Belt Splash ShieldÐTypical

Ä AG-BODY 23 - 55

Page 2213 of 2438

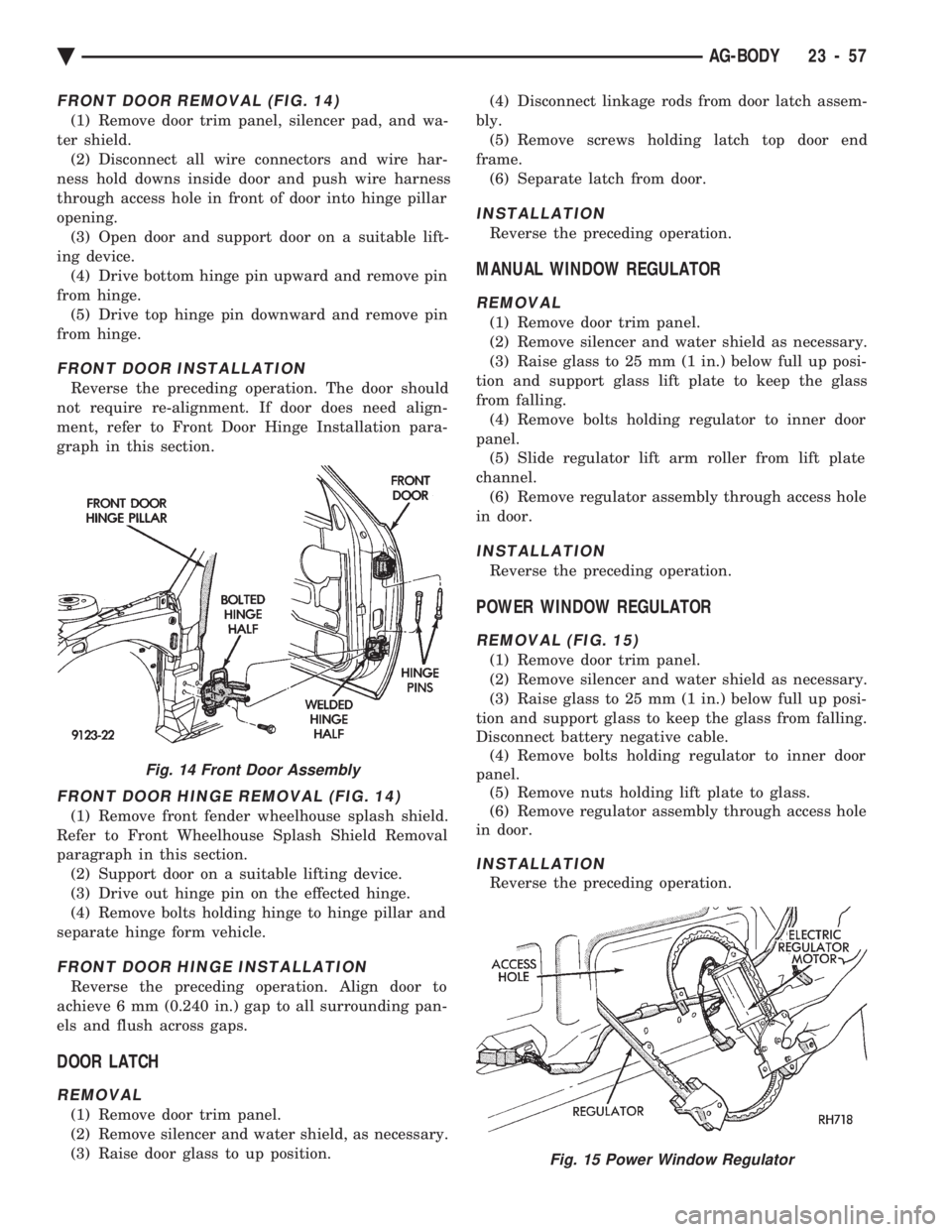

FRONT DOOR REMOVAL (FIG. 14)

(1) Remove door trim panel, silencer pad, and wa-

ter shield. (2) Disconnect all wire connectors and wire har-

ness hold downs inside door and push wire harness

through access hole in front of door into hinge pillar

opening. (3) Open door and support door on a suitable lift-

ing device. (4) Drive bottom hinge pin upward and remove pin

from hinge. (5) Drive top hinge pin downward and remove pin

from hinge.

FRONT DOOR INSTALLATION

Reverse the preceding operation. The door should

not require re-alignment. If door does need align-

ment, refer to Front Door Hinge Installation para-

graph in this section.

FRONT DOOR HINGE REMOVAL (FIG. 14)

(1) Remove front fender wheelhouse splash shield.

Refer to Front Wheelhouse Splash Shield Removal

paragraph in this section. (2) Support door on a suitable lifting device.

(3) Drive out hinge pin on the effected hinge.

(4) Remove bolts holding hinge to hinge pillar and

separate hinge form vehicle.

FRONT DOOR HINGE INSTALLATION

Reverse the preceding operation. Align door to

achieve 6 mm (0.240 in.) gap to all surrounding pan-

els and flush across gaps.

DOOR LATCH

REMOVAL

(1) Remove door trim panel.

(2) Remove silencer and water shield, as necessary.

(3) Raise door glass to up position. (4) Disconnect linkage rods from door latch assem-

bly. (5) Remove screws holding latch top door end

frame. (6) Separate latch from door.

INSTALLATION

Reverse the preceding operation.

MANUAL WINDOW REGULATOR

REMOVAL

(1) Remove door trim panel.

(2) Remove silencer and water shield as necessary.

(3) Raise glass to 25 mm (1 in.) below full up posi-

tion and support glass lift plate to keep the glass

from falling. (4) Remove bolts holding regulator to inner door

panel. (5) Slide regulator lift arm roller from lift plate

channel. (6) Remove regulator assembly through access hole

in door.

INSTALLATION

Reverse the preceding operation.

POWER WINDOW REGULATOR

REMOVAL (FIG. 15)

(1) Remove door trim panel.

(2) Remove silencer and water shield as necessary.

(3) Raise glass to 25 mm (1 in.) below full up posi-

tion and support glass to keep the glass from falling.

Disconnect battery negative cable. (4) Remove bolts holding regulator to inner door

panel. (5) Remove nuts holding lift plate to glass.

(6) Remove regulator assembly through access hole

in door.

INSTALLATION

Reverse the preceding operation.

Fig. 14 Front Door Assembly

Fig. 15 Power Window Regulator

Ä AG-BODY 23 - 57

Page 2216 of 2438

DOOR OPENING WEATHERSTRIPS

REMOVAL

(1) Remove interior trim as necessary to gain ac-

cess to door opening weatherstrip. (2) Pull weatherstrip from pinch flange around

door opening.

INSTALLATION

(1) Locate the middle to the weatherstrip at the

center of the upper pinch flange. Push weatherstrip

onto pinch flange at the top corner near the B-pillar. (2) When the weatherstrip has been installed down

the door opening to the sill pinch flange, mate the

ends of the weatherstrip together and finish install-

ing.

BODY SIDE MOULDINGS

STICK-ON BODY SIDE MOULDING REMOVAL AND INSTALLATION

(1) Warm the effected stick-on moulding and body

metal to approximately 38ÉC (100ÉF) using a suitable

heat lamp or heat gun. (2) Pull stick-on moulding from painted surface.

(3) Remove adhesive tape residue from painted

surface of vehicle. (4) If moulding is to be reused, Remove tape resi-

due from moulding. Clean back of moulding with Mo-

par, Super Kleen solvent or equivalent. Wipe moulding dry with lint free cloth. Apply new body

side moulding (two sided adhesive) tape to back of

moulding. (5) Clean body surface with Mopar, Super Kleen

solvent or equivalent. Wipe surface dry with lint free

cloth. (6) Apply a length of masking tape on the body,

parallel to the top edge of the moulding to use as a

guide, if necessary. (7) Remove protective cover from tape on back of

moulding. Apply moulding to body below the mask-

ing tape guide. (8) Remove masking tape guide and heat body and

moulding, refer to step one. Firmly press moulding to

body surface to assure adhesion.

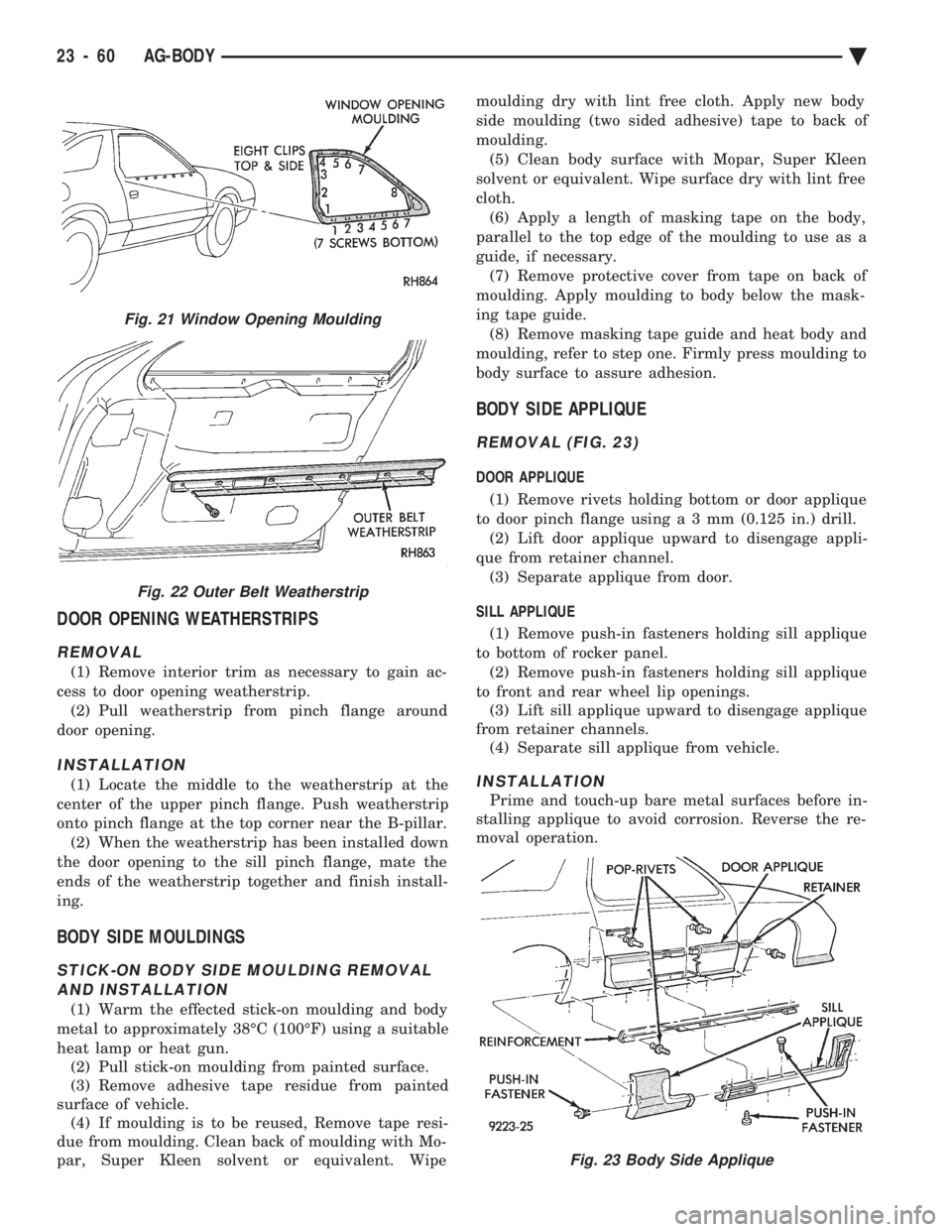

BODY SIDE APPLIQUE

REMOVAL (FIG. 23)

DOOR APPLIQUE

(1) Remove rivets holding bottom or door applique

to door pinch flange usin ga3mm(0.125 in.) drill.

(2) Lift door applique upward to disengage appli-

que from retainer channel. (3) Separate applique from door.

SILL APPLIQUE (1) Remove push-in fasteners holding sill applique

to bottom of rocker panel. (2) Remove push-in fasteners holding sill applique

to front and rear wheel lip openings. (3) Lift sill applique upward to disengage applique

from retainer channels. (4) Separate sill applique from vehicle.

INSTALLATION

Prime and touch-up bare metal surfaces before in-

stalling applique to avoid corrosion. Reverse the re-

moval operation.

Fig. 21 Window Opening Moulding

Fig. 22 Outer Belt Weatherstrip

Fig. 23 Body Side Applique

23 - 60 AG-BODY Ä

Page 2218 of 2438

(5) Remove bolt holding belt retractor to quarter

panel. (6) Separate belt from vehicle.

OUTBOARD SHOULDER HARNESS/LAP BELTINSTALLATION

Reverse the preceding operation.

INBOARD BUCKLE REMOVAL (FIG. 26)

(1) Remove bolt holding inboard buckle to floor. (2) Disconnect seat belt sensor wire connector, if

equipped. (3) Separate buckle assembly from vehicle.

INBOARD BUCKLE INSTALLATION

Reverse the preceding operation.

REAR SEAT BELTS

REAR OUTBOARD SHOULDER HARNESS/LAPBELT REMOVAL (FIG. 27)

(1) Remove lower and upper quarter trim panel.

(2) Remove bolt holding lap belt anchor to floor at

wheelhouse kickup. (3) Remove bolt holding seat belt retractor to quar-

ter panel.

REAR OUTBOARD SHOULDER HARNESS/LAP BELT INSTALLATION

Reverse the preceding operation.

REAR INBOARD BUCKLE REMOVAL (FIG. 27)

(1) Lift seat belt buckle anchor cover to expose

bolt. (2) Remove bolt holding inboard buckle/center oc-

cupant belt to seat frame. (3) Separate buckle from vehicle.

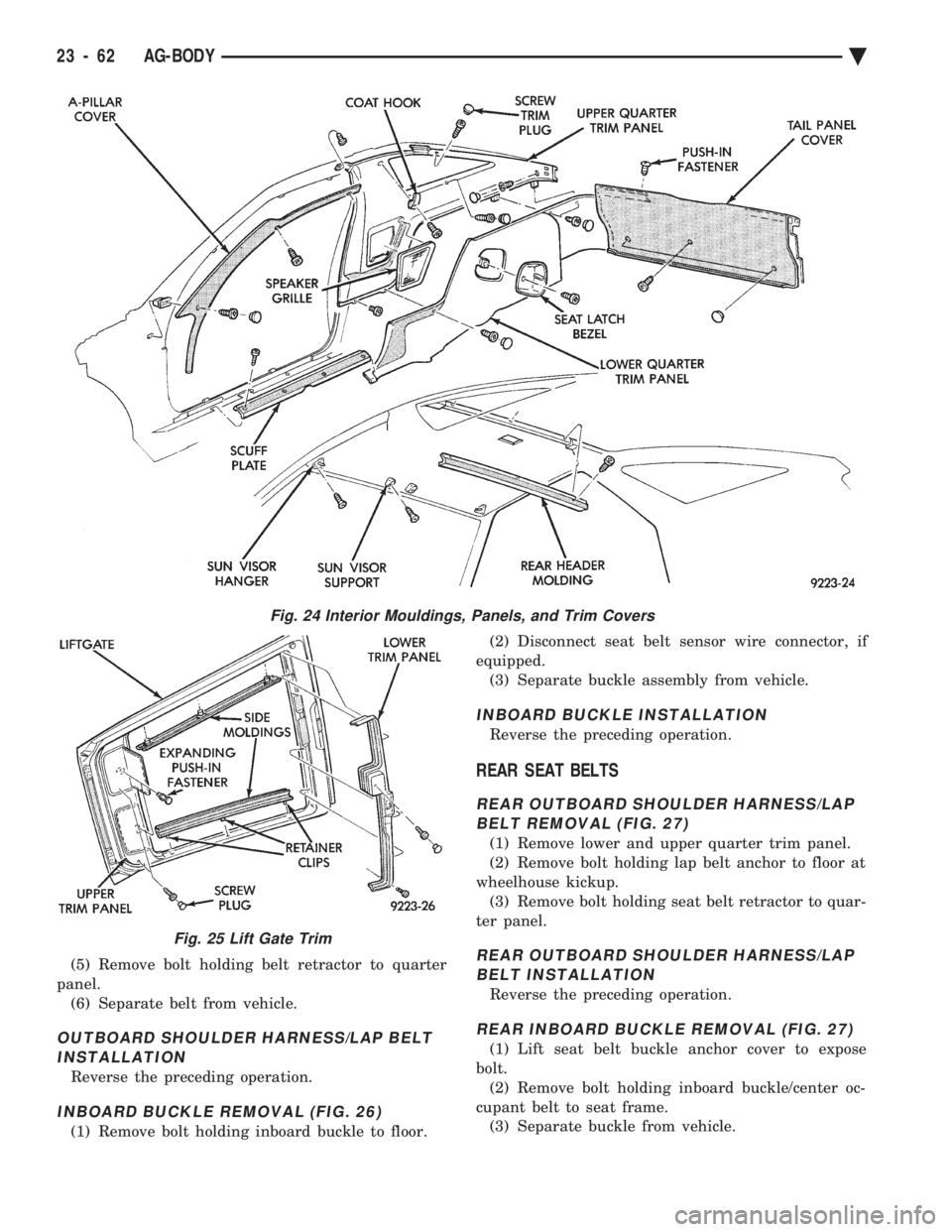

Fig. 24 Interior Mouldings, Panels, and Trim Covers

Fig. 25 Lift Gate Trim

23 - 62 AG-BODY Ä

Page 2223 of 2438

(4) Separate molding from roof panel.

INSTALLATION

Reverse the preceding operation.

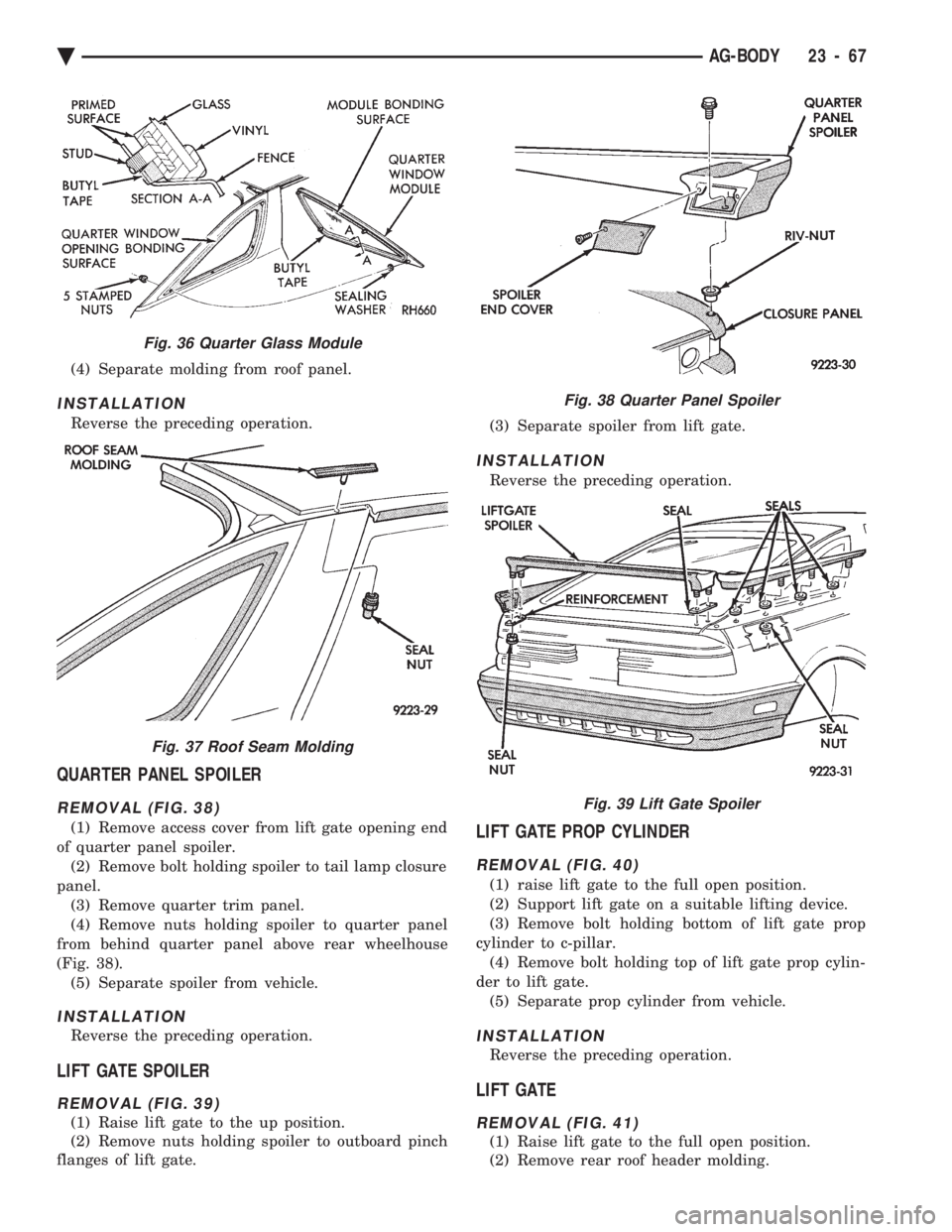

QUARTER PANEL SPOILER

REMOVAL (FIG. 38)

(1) Remove access cover from lift gate opening end

of quarter panel spoiler. (2) Remove bolt holding spoiler to tail lamp closure

panel. (3) Remove quarter trim panel.

(4) Remove nuts holding spoiler to quarter panel

from behind quarter panel above rear wheelhouse

(Fig. 38). (5) Separate spoiler from vehicle.

INSTALLATION

Reverse the preceding operation.

LIFT GATE SPOILER

REMOVAL (FIG. 39)

(1) Raise lift gate to the up position.

(2) Remove nuts holding spoiler to outboard pinch

flanges of lift gate. (3) Separate spoiler from lift gate.

INSTALLATION

Reverse the preceding operation.

LIFT GATE PROP CYLINDER

REMOVAL (FIG. 40)

(1) raise lift gate to the full open position.

(2) Support lift gate on a suitable lifting device.

(3) Remove bolt holding bottom of lift gate prop

cylinder to c-pillar. (4) Remove bolt holding top of lift gate prop cylin-

der to lift gate. (5) Separate prop cylinder from vehicle.

INSTALLATION

Reverse the preceding operation.

LIFT GATE

REMOVAL (FIG. 41)

(1) Raise lift gate to the full open position.

(2) Remove rear roof header molding.

Fig. 36 Quarter Glass Module

Fig. 37 Roof Seam Molding

Fig. 38 Quarter Panel Spoiler

Fig. 39 Lift Gate Spoiler

Ä AG-BODY 23 - 67

Page 2229 of 2438

(4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

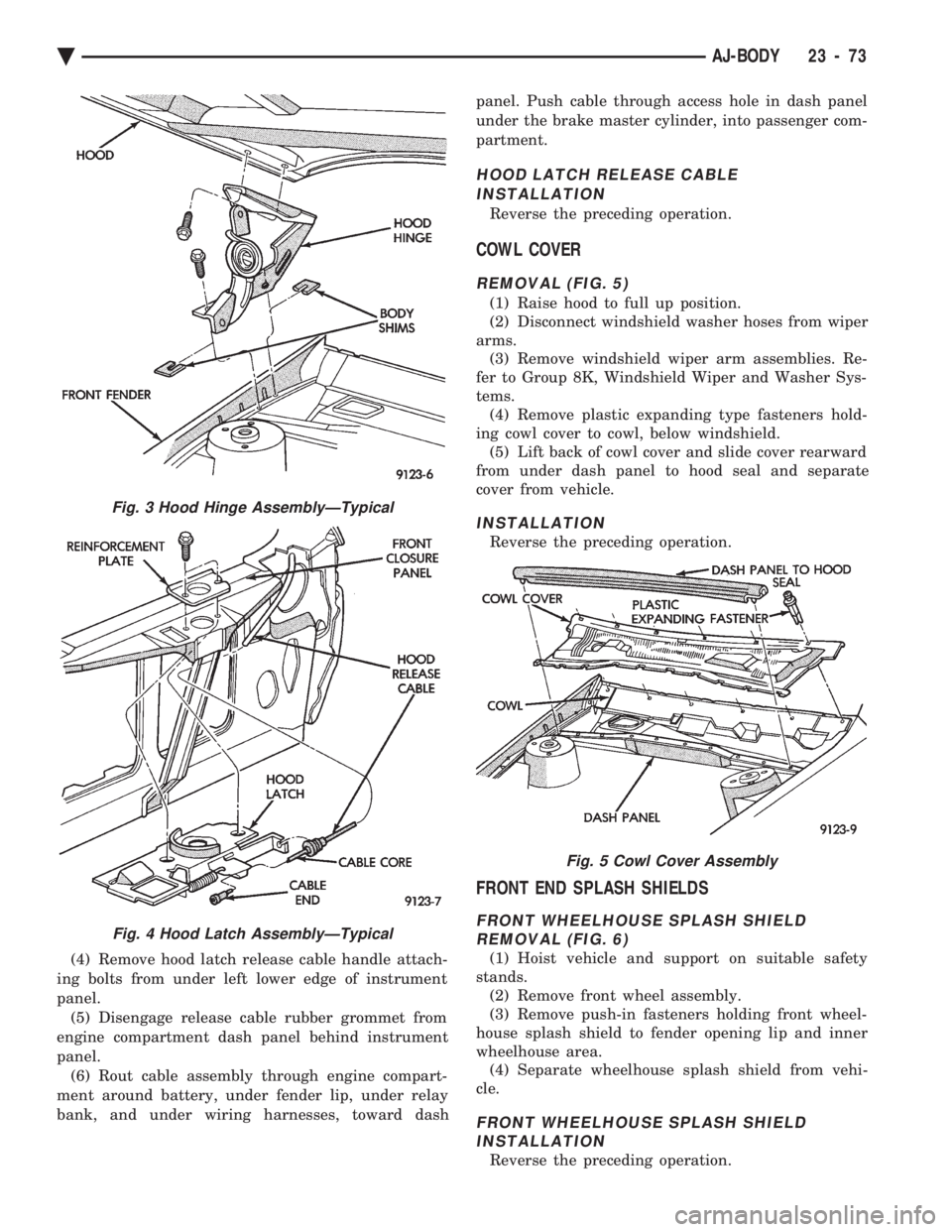

COWL COVER

REMOVAL (FIG. 5)

(1) Raise hood to full up position.

(2) Disconnect windshield washer hoses from wiper

arms. (3) Remove windshield wiper arm assemblies. Re-

fer to Group 8K, Windshield Wiper and Washer Sys-

tems. (4) Remove plastic expanding type fasteners hold-

ing cowl cover to cowl, below windshield. (5) Lift back of cowl cover and slide cover rearward

from under dash panel to hood seal and separate

cover from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT END SPLASH SHIELDS

FRONT WHEELHOUSE SPLASH SHIELD REMOVAL (FIG. 6)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

Fig. 3 Hood Hinge AssemblyÐTypical

Fig. 4 Hood Latch AssemblyÐTypical

Fig. 5 Cowl Cover Assembly

Ä AJ-BODY 23 - 73

Page 2230 of 2438

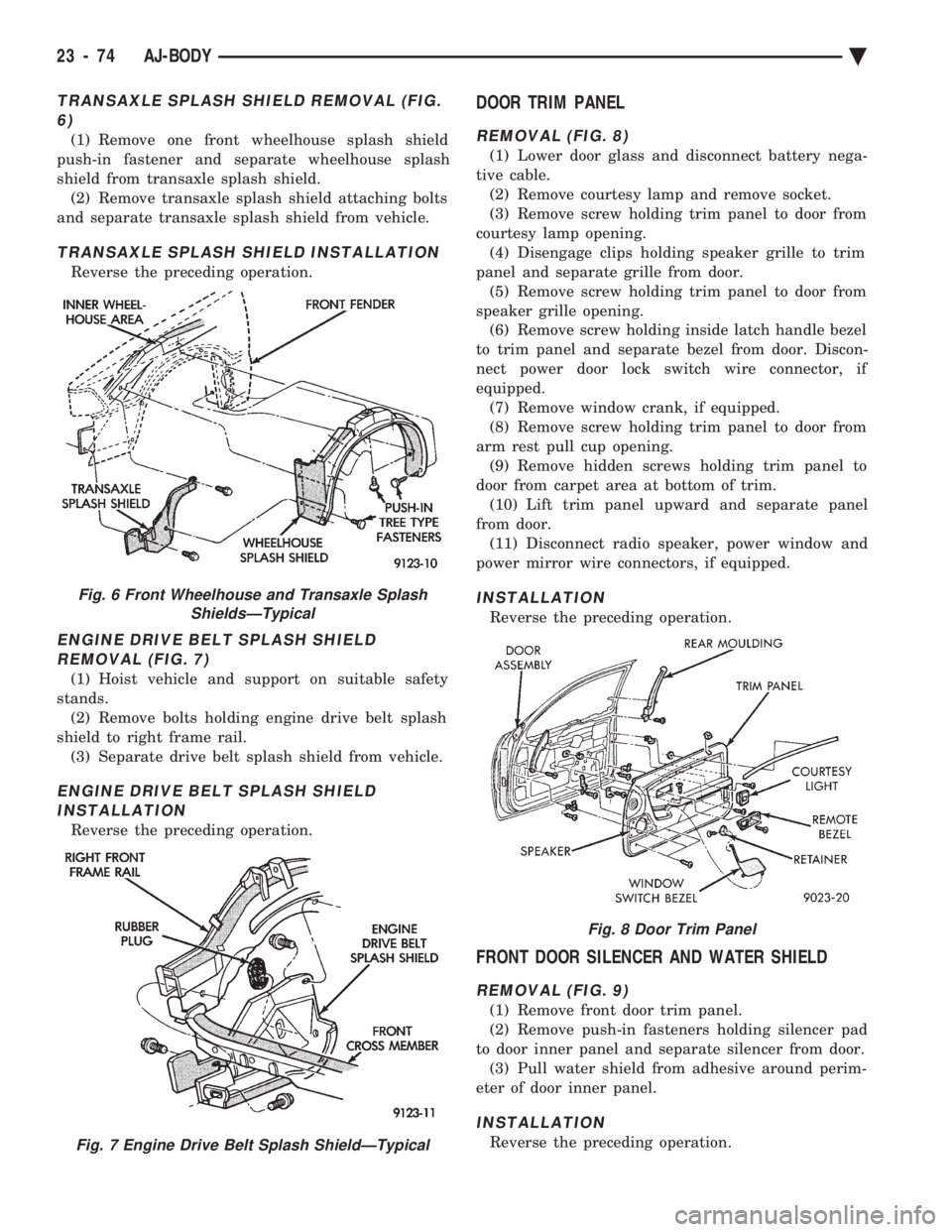

TRANSAXLE SPLASH SHIELD REMOVAL (FIG. 6)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 7)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

DOOR TRIM PANEL

REMOVAL (FIG. 8)

(1) Lower door glass and disconnect battery nega-

tive cable. (2) Remove courtesy lamp and remove socket.

(3) Remove screw holding trim panel to door from

courtesy lamp opening. (4) Disengage clips holding speaker grille to trim

panel and separate grille from door. (5) Remove screw holding trim panel to door from

speaker grille opening. (6) Remove screw holding inside latch handle bezel

to trim panel and separate bezel from door. Discon-

nect power door lock switch wire connector, if

equipped. (7) Remove window crank, if equipped.

(8) Remove screw holding trim panel to door from

arm rest pull cup opening. (9) Remove hidden screws holding trim panel to

door from carpet area at bottom of trim. (10) Lift trim panel upward and separate panel

from door. (11) Disconnect radio speaker, power window and

power mirror wire connectors, if equipped.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR SILENCER AND WATER SHIELD

REMOVAL (FIG. 9)

(1) Remove front door trim panel.

(2) Remove push-in fasteners holding silencer pad

to door inner panel and separate silencer from door. (3) Pull water shield from adhesive around perim-

eter of door inner panel.

INSTALLATION

Reverse the preceding operation.

Fig. 6 Front Wheelhouse and Transaxle Splash ShieldsÐTypical

Fig. 7 Engine Drive Belt Splash ShieldÐTypical

Fig. 8 Door Trim Panel

23 - 74 AJ-BODY Ä