wheel CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2155 of 2438

It is recommended that a two plane dynamic bal-

ancing machine be used when a wheel and tire as-

sembly require balancing. Static balancing should be

used only when a two plane dynamic balancing is not

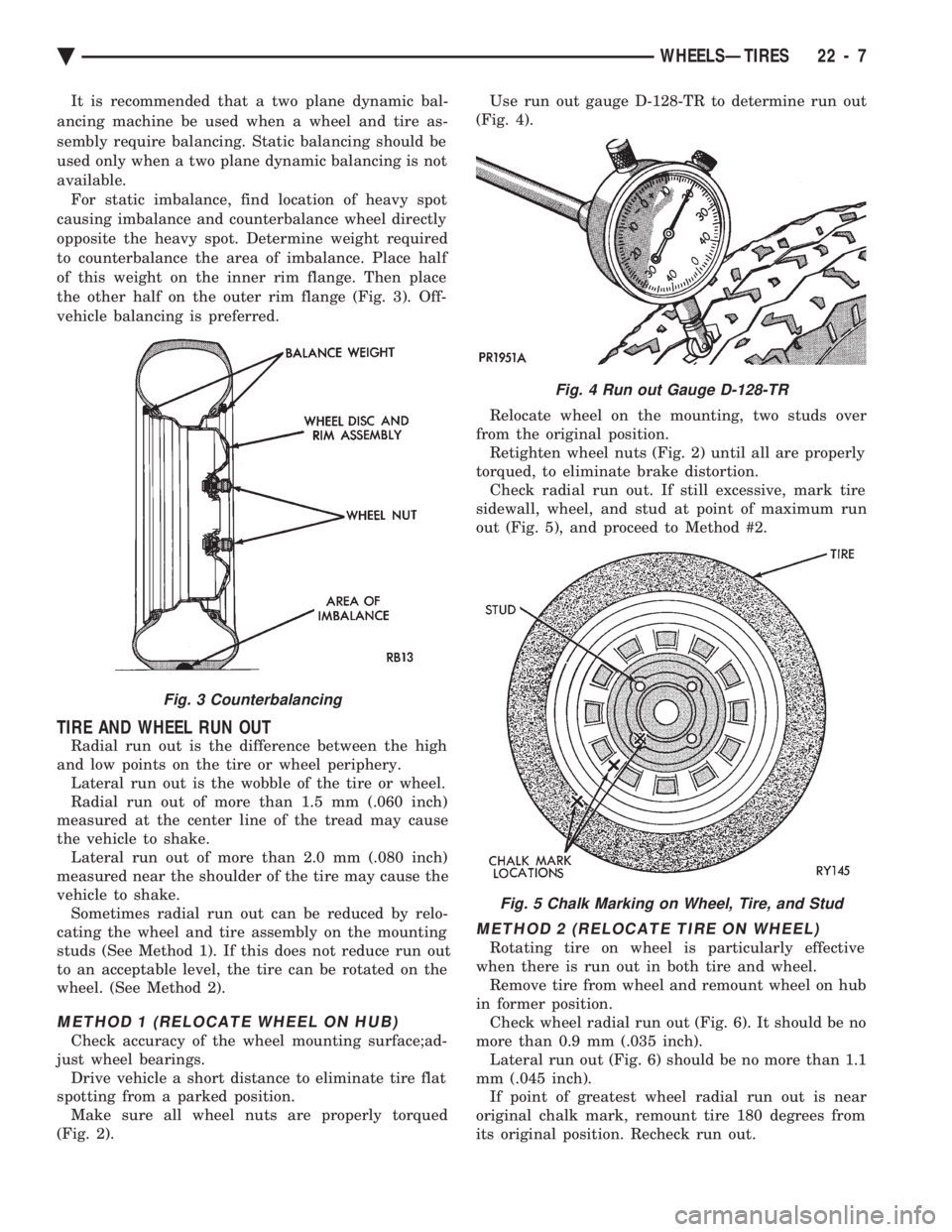

available. For static imbalance, find location of heavy spot

causing imbalance and counterbalance wheel directly

opposite the heavy spot. Determine weight required

to counterbalance the area of imbalance. Place half

of this weight on the inner rim flange. Then place

the other half on the outer rim flange (Fig. 3). Off-

vehicle balancing is preferred.

TIRE AND WHEEL RUN OUT

Radial run out is the difference between the high

and low points on the tire or wheel periphery. Lateral run out is the wobble of the tire or wheel.

Radial run out of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake. Lateral run out of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake. Sometimes radial run out can be reduced by relo-

cating the wheel and tire assembly on the mounting

studs (See Method 1). If this does not reduce run out

to an acceptable level, the tire can be rotated on the

wheel. (See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

Check accuracy of the wheel mounting surface;ad-

just wheel bearings. Drive vehicle a short distance to eliminate tire flat

spotting from a parked position. Make sure all wheel nuts are properly torqued

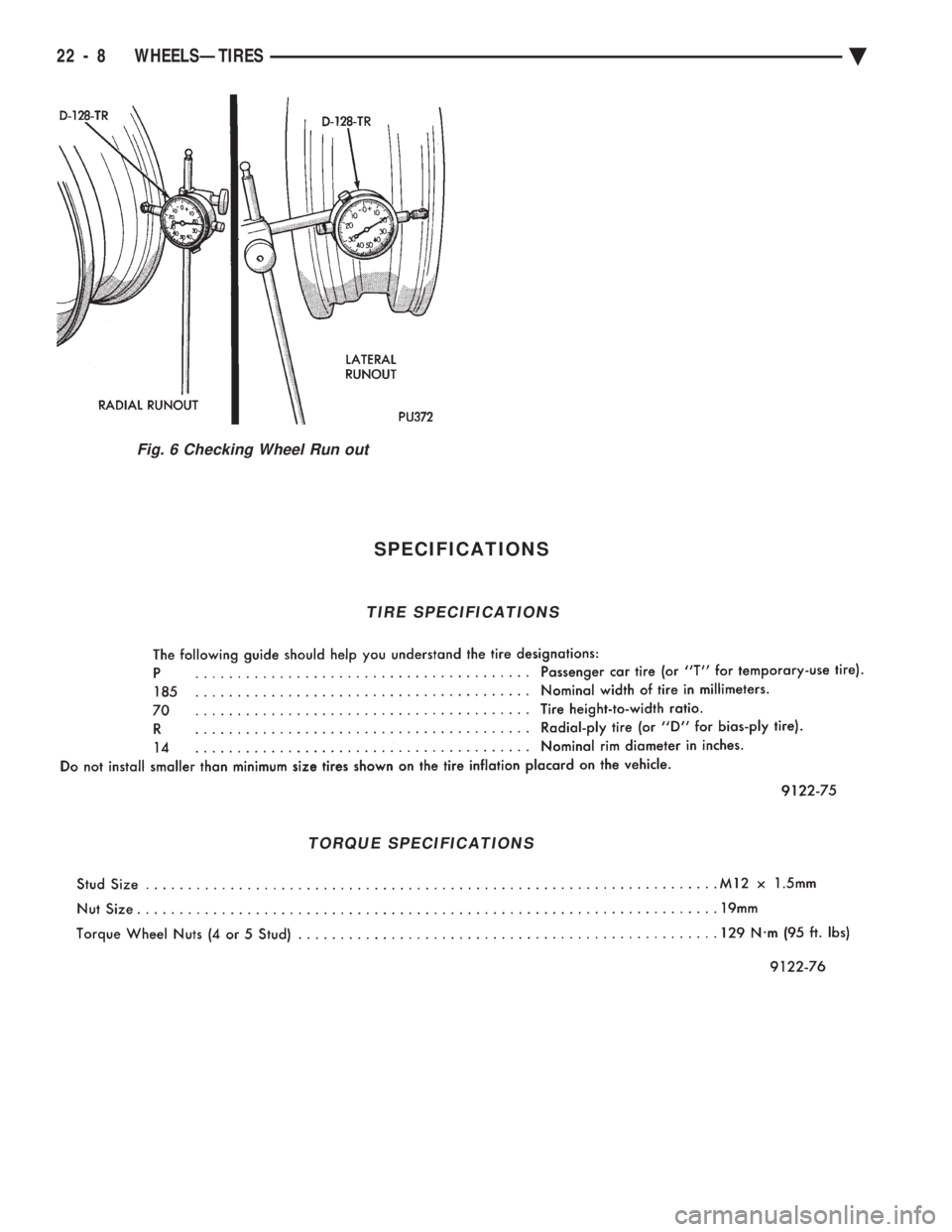

(Fig. 2). Use run out gauge D-128-TR to determine run out

(Fig. 4).

Relocate wheel on the mounting, two studs over

from the original position. Retighten wheel nuts (Fig. 2) until all are properly

torqued, to eliminate brake distortion. Check radial run out. If still excessive, mark tire

sidewall, wheel, and stud at point of maximum run

out (Fig. 5), and proceed to Method #2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

Rotating tire on wheel is particularly effective

when there is run out in both tire and wheel. Remove tire from wheel and remount wheel on hub

in former position. Check wheel radial run out (Fig. 6). It should be no

more than 0.9 mm (.035 inch). Lateral run out (Fig. 6) should be no more than 1.1

mm (.045 inch). If point of greatest wheel radial run out is near

original chalk mark, remount tire 180 degrees from

its original position. Recheck run out.

Fig. 3 Counterbalancing

Fig. 4 Run out Gauge D-128-TR

Fig. 5 Chalk Marking on Wheel, Tire, and Stud

Ä WHEELSÐTIRES 22 - 7

Page 2156 of 2438

SPECIFICATIONS

Fig. 6 Checking Wheel Run out

TIRE SPECIFICATIONS

TORQUE SPECIFICATIONS

22 - 8 WHEELSÐTIRES Ä

Page 2169 of 2438

(2) Remove push-in fasteners holding hood latch

cover to radiator closure panel and separate cover

from vehicle. (3) Disconnect hood release cable casing and cable

end from hood latch assembly. Refer to Hood Latch

Removal procedure in this section. (4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash

panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

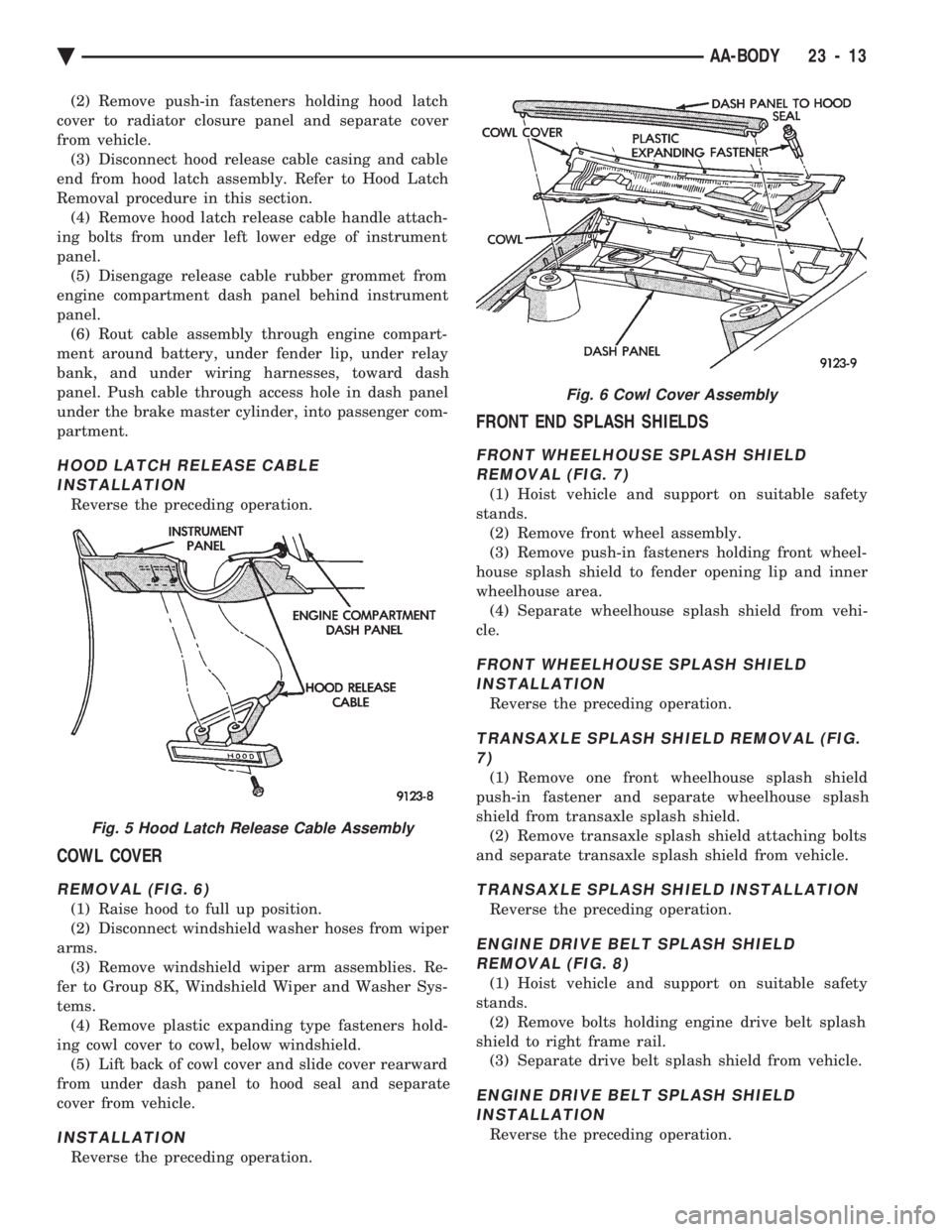

COWL COVER

REMOVAL (FIG. 6)

(1) Raise hood to full up position.

(2) Disconnect windshield washer hoses from wiper

arms. (3) Remove windshield wiper arm assemblies. Re-

fer to Group 8K, Windshield Wiper and Washer Sys-

tems. (4) Remove plastic expanding type fasteners hold-

ing cowl cover to cowl, below windshield. (5) Lift back of cowl cover and slide cover rearward

from under dash panel to hood seal and separate

cover from vehicle.

INSTALLATION

Reverse the preceding operation.

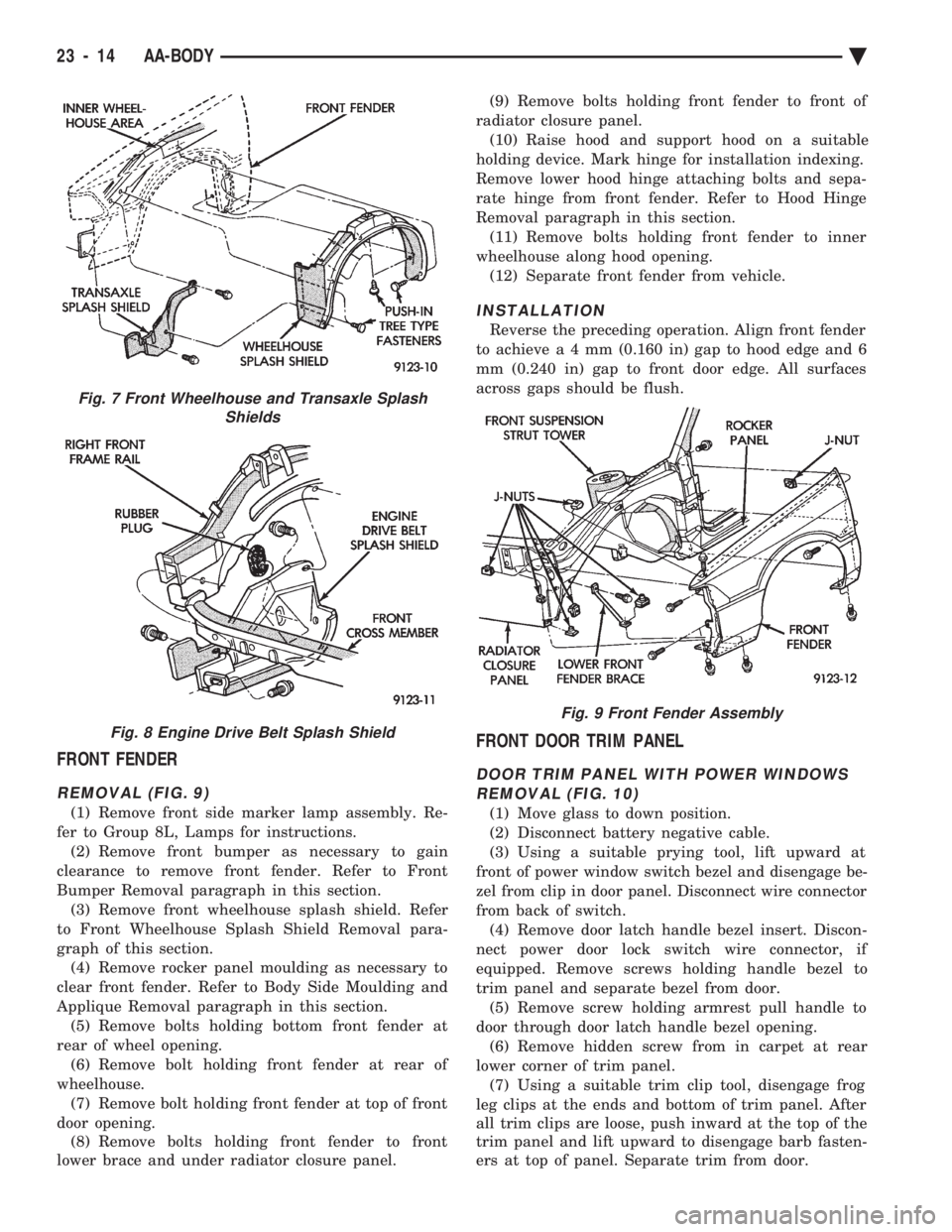

FRONT END SPLASH SHIELDS

FRONT WHEELHOUSE SPLASH SHIELD REMOVAL (FIG. 7)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

TRANSAXLE SPLASH SHIELD REMOVAL (FIG.7)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 8)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

Fig. 5 Hood Latch Release Cable Assembly

Fig. 6 Cowl Cover Assembly

Ä AA-BODY 23 - 13

Page 2170 of 2438

FRONT FENDER

REMOVAL (FIG. 9)

(1) Remove front side marker lamp assembly. Re-

fer to Group 8L, Lamps for instructions. (2) Remove front bumper as necessary to gain

clearance to remove front fender. Refer to Front

Bumper Removal paragraph in this section. (3) Remove front wheelhouse splash shield. Refer

to Front Wheelhouse Splash Shield Removal para-

graph of this section. (4) Remove rocker panel moulding as necessary to

clear front fender. Refer to Body Side Moulding and

Applique Removal paragraph in this section. (5) Remove bolts holding bottom front fender at

rear of wheel opening. (6) Remove bolt holding front fender at rear of

wheelhouse. (7) Remove bolt holding front fender at top of front

door opening. (8) Remove bolts holding front fender to front

lower brace and under radiator closure panel. (9) Remove bolts holding front fender to front of

radiator closure panel. (10) Raise hood and support hood on a suitable

holding device. Mark hinge for installation indexing.

Remove lower hood hinge attaching bolts and sepa-

rate hinge from front fender. Refer to Hood Hinge

Removal paragraph in this section. (11) Remove bolts holding front fender to inner

wheelhouse along hood opening. (12) Separate front fender from vehicle.

INSTALLATION

Reverse the preceding operation. Align front fender

to achiev ea4mm (0.160 in) gap to hood edge and 6

mm (0.240 in) gap to front door edge. All surfaces

across gaps should be flush.

FRONT DOOR TRIM PANEL

DOOR TRIM PANEL WITH POWER WINDOWS REMOVAL (FIG. 10)

(1) Move glass to down position.

(2) Disconnect battery negative cable.

(3) Using a suitable prying tool, lift upward at

front of power window switch bezel and disengage be-

zel from clip in door panel. Disconnect wire connector

from back of switch. (4) Remove door latch handle bezel insert. Discon-

nect power door lock switch wire connector, if

equipped. Remove screws holding handle bezel to

trim panel and separate bezel from door. (5) Remove screw holding armrest pull handle to

door through door latch handle bezel opening. (6) Remove hidden screw from in carpet at rear

lower corner of trim panel. (7) Using a suitable trim clip tool, disengage frog

leg clips at the ends and bottom of trim panel. After

all trim clips are loose, push inward at the top of the

trim panel and lift upward to disengage barb fasten-

ers at top of panel. Separate trim from door.

Fig. 7 Front Wheelhouse and Transaxle Splash Shields

Fig. 8 Engine Drive Belt Splash Shield

Fig. 9 Front Fender Assembly

23 - 14 AA-BODY Ä

Page 2172 of 2438

(6) Separate door from vehicle.

FRONT DOOR INSTALLATION

Reverse the preceding operation. The door should

not require re-alignment. If door does need align-

ment, refer to Front Door Hinge Installation para-

graph in this section.

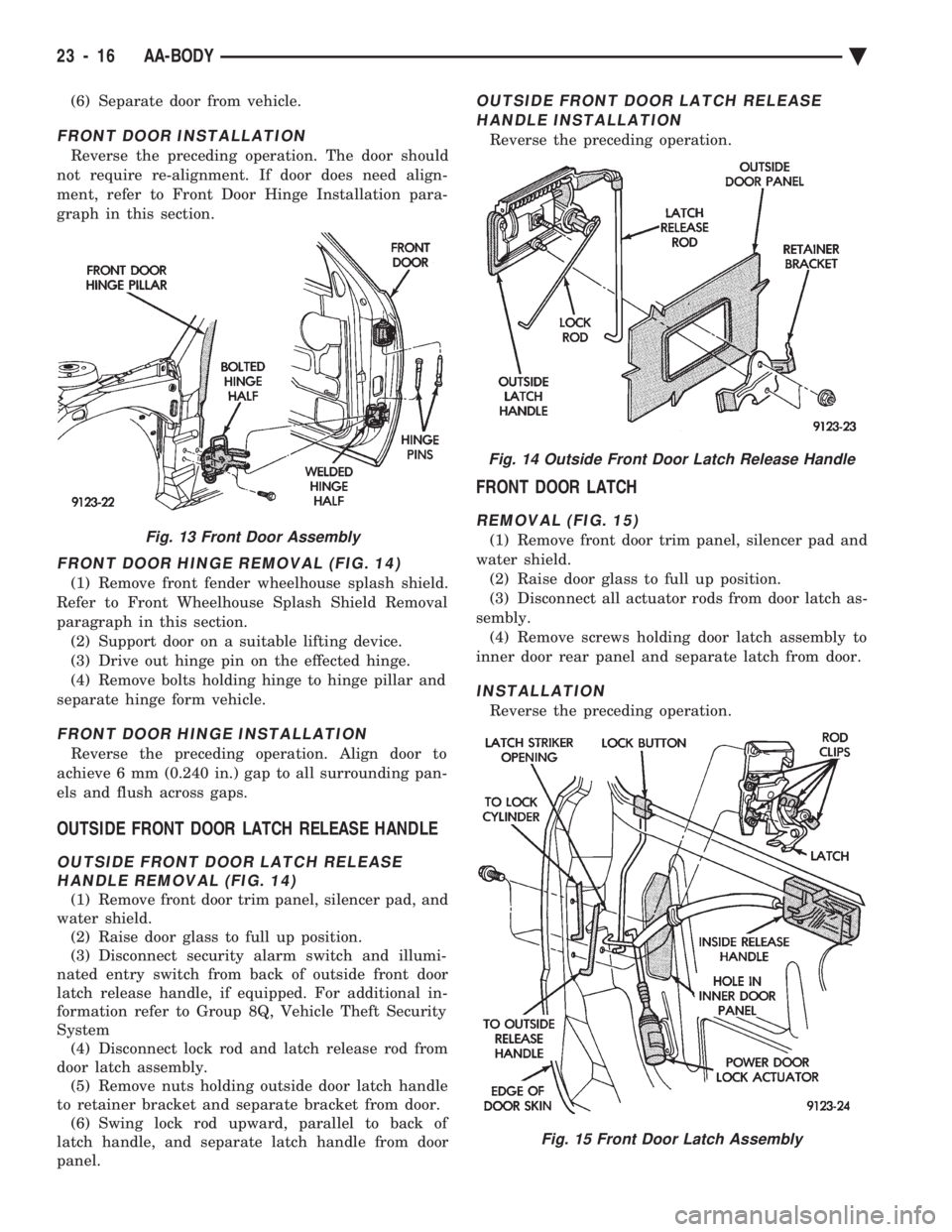

FRONT DOOR HINGE REMOVAL (FIG. 14)

(1) Remove front fender wheelhouse splash shield.

Refer to Front Wheelhouse Splash Shield Removal

paragraph in this section. (2) Support door on a suitable lifting device.

(3) Drive out hinge pin on the effected hinge.

(4) Remove bolts holding hinge to hinge pillar and

separate hinge form vehicle.

FRONT DOOR HINGE INSTALLATION

Reverse the preceding operation. Align door to

achieve 6 mm (0.240 in.) gap to all surrounding pan-

els and flush across gaps.

OUTSIDE FRONT DOOR LATCH RELEASE HANDLE

OUTSIDE FRONT DOOR LATCH RELEASE HANDLE REMOVAL (FIG. 14)

(1) Remove front door trim panel, silencer pad, and

water shield. (2) Raise door glass to full up position.

(3) Disconnect security alarm switch and illumi-

nated entry switch from back of outside front door

latch release handle, if equipped. For additional in-

formation refer to Group 8Q, Vehicle Theft Security

System (4) Disconnect lock rod and latch release rod from

door latch assembly. (5) Remove nuts holding outside door latch handle

to retainer bracket and separate bracket from door. (6) Swing lock rod upward, parallel to back of

latch handle, and separate latch handle from door

panel.

OUTSIDE FRONT DOOR LATCH RELEASE

HANDLE INSTALLATION

Reverse the preceding operation.

FRONT DOOR LATCH

REMOVAL (FIG. 15)

(1) Remove front door trim panel, silencer pad and

water shield. (2) Raise door glass to full up position.

(3) Disconnect all actuator rods from door latch as-

sembly. (4) Remove screws holding door latch assembly to

inner door rear panel and separate latch from door.

INSTALLATION

Reverse the preceding operation.

Fig. 13 Front Door Assembly

Fig. 14 Outside Front Door Latch Release Handle

Fig. 15 Front Door Latch Assembly

23 - 16 AA-BODY Ä

Page 2181 of 2438

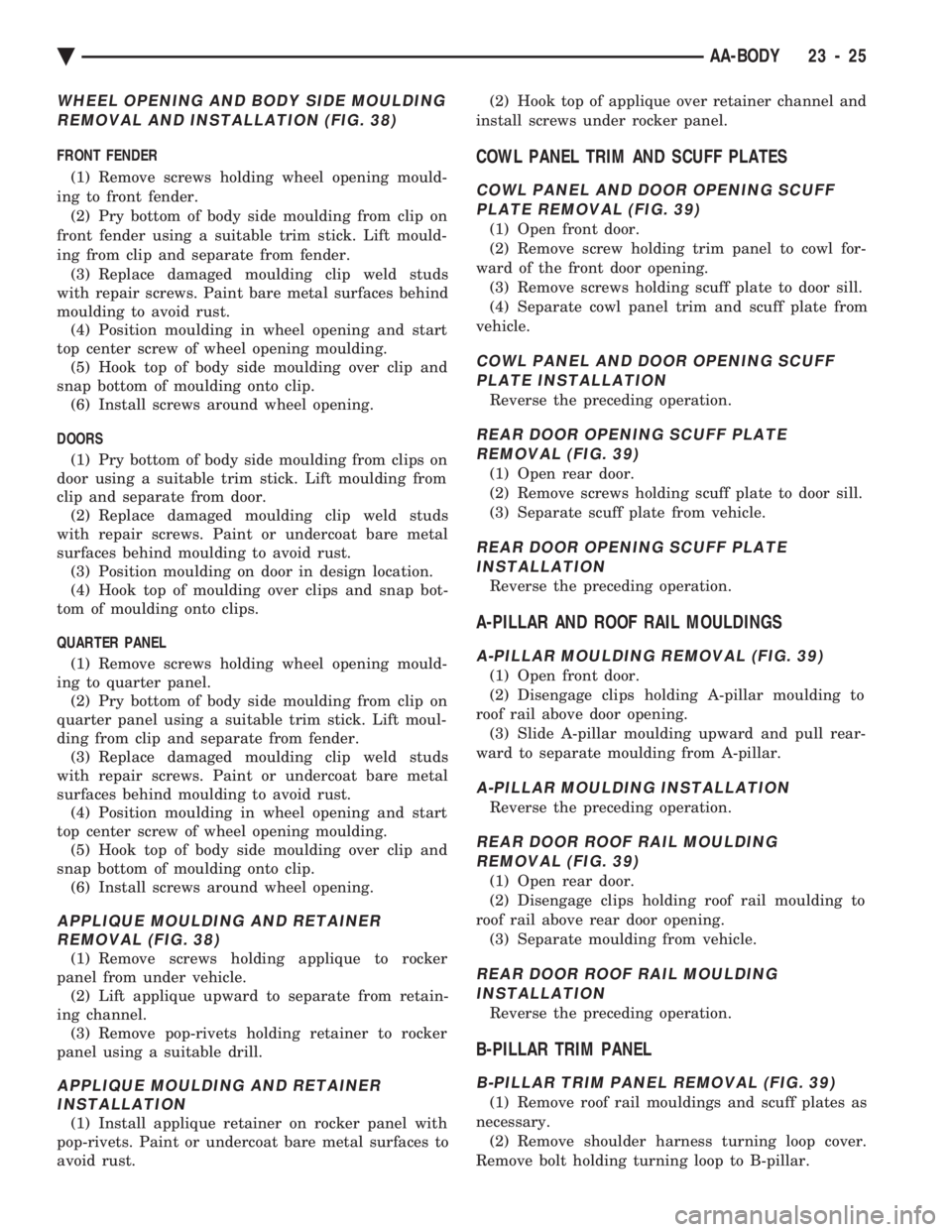

WHEEL OPENING AND BODY SIDE MOULDING REMOVAL AND INSTALLATION (FIG. 38)

FRONT FENDER

(1) Remove screws holding wheel opening mould-

ing to front fender. (2) Pry bottom of body side moulding from clip on

front fender using a suitable trim stick. Lift mould-

ing from clip and separate from fender. (3) Replace damaged moulding clip weld studs

with repair screws. Paint bare metal surfaces behind

moulding to avoid rust. (4) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (5) Hook top of body side moulding over clip and

snap bottom of moulding onto clip. (6) Install screws around wheel opening.

DOORS (1) Pry bottom of body side moulding from clips on

door using a suitable trim stick. Lift moulding from

clip and separate from door. (2) Replace damaged moulding clip weld studs

with repair screws. Paint or undercoat bare metal

surfaces behind moulding to avoid rust. (3) Position moulding on door in design location.

(4) Hook top of moulding over clips and snap bot-

tom of moulding onto clips.

QUARTER PANEL (1) Remove screws holding wheel opening mould-

ing to quarter panel. (2) Pry bottom of body side moulding from clip on

quarter panel using a suitable trim stick. Lift moul-

ding from clip and separate from fender. (3) Replace damaged moulding clip weld studs

with repair screws. Paint or undercoat bare metal

surfaces behind moulding to avoid rust. (4) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (5) Hook top of body side moulding over clip and

snap bottom of moulding onto clip. (6) Install screws around wheel opening.

APPLIQUE MOULDING AND RETAINERREMOVAL (FIG. 38)

(1) Remove screws holding applique to rocker

panel from under vehicle. (2) Lift applique upward to separate from retain-

ing channel. (3) Remove pop-rivets holding retainer to rocker

panel using a suitable drill.

APPLIQUE MOULDING AND RETAINER INSTALLATION

(1) Install applique retainer on rocker panel with

pop-rivets. Paint or undercoat bare metal surfaces to

avoid rust. (2) Hook top of applique over retainer channel and

install screws under rocker panel.

COWL PANEL TRIM AND SCUFF PLATES

COWL PANEL AND DOOR OPENING SCUFF PLATE REMOVAL (FIG. 39)

(1) Open front door.

(2) Remove screw holding trim panel to cowl for-

ward of the front door opening. (3) Remove screws holding scuff plate to door sill.

(4) Separate cowl panel trim and scuff plate from

vehicle.

COWL PANEL AND DOOR OPENING SCUFF PLATE INSTALLATION

Reverse the preceding operation.

REAR DOOR OPENING SCUFF PLATEREMOVAL (FIG. 39)

(1) Open rear door.

(2) Remove screws holding scuff plate to door sill.

(3) Separate scuff plate from vehicle.

REAR DOOR OPENING SCUFF PLATEINSTALLATION

Reverse the preceding operation.

A-PILLAR AND ROOF RAIL MOULDINGS

A-PILLAR MOULDING REMOVAL (FIG. 39)

(1) Open front door.

(2) Disengage clips holding A-pillar moulding to

roof rail above door opening. (3) Slide A-pillar moulding upward and pull rear-

ward to separate moulding from A-pillar.

A-PILLAR MOULDING INSTALLATION

Reverse the preceding operation.

REAR DOOR ROOF RAIL MOULDING REMOVAL (FIG. 39)

(1) Open rear door.

(2) Disengage clips holding roof rail moulding to

roof rail above rear door opening. (3) Separate moulding from vehicle.

REAR DOOR ROOF RAIL MOULDINGINSTALLATION

Reverse the preceding operation.

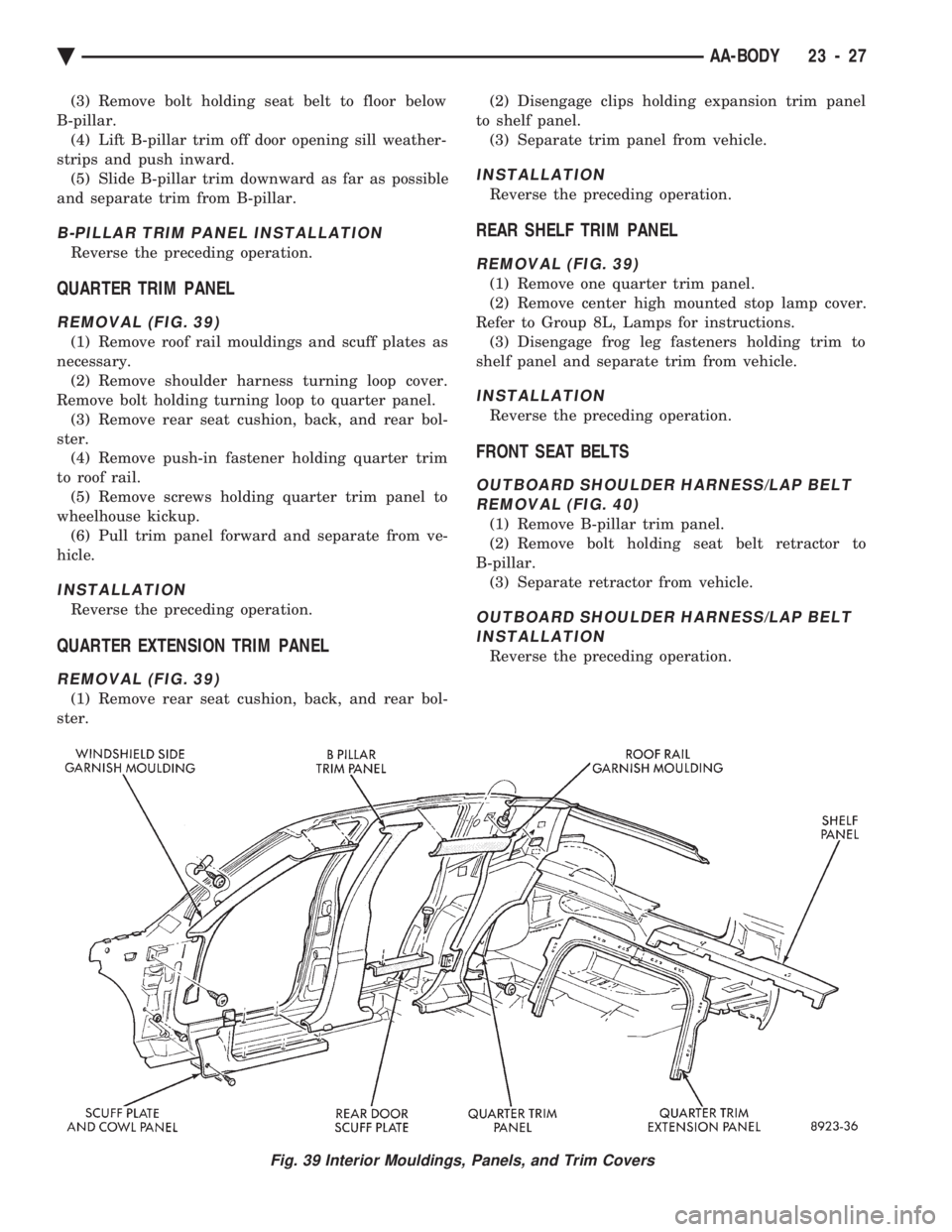

B-PILLAR TRIM PANEL

B-PILLAR TRIM PANEL REMOVAL (FIG. 39)

(1) Remove roof rail mouldings and scuff plates as

necessary. (2) Remove shoulder harness turning loop cover.

Remove bolt holding turning loop to B-pillar.

Ä AA-BODY 23 - 25

Page 2183 of 2438

(3) Remove bolt holding seat belt to floor below

B-pillar. (4) Lift B-pillar trim off door opening sill weather-

strips and push inward. (5) Slide B-pillar trim downward as far as possible

and separate trim from B-pillar.

B-PILLAR TRIM PANEL INSTALLATION

Reverse the preceding operation.

QUARTER TRIM PANEL

REMOVAL (FIG. 39)

(1) Remove roof rail mouldings and scuff plates as

necessary. (2) Remove shoulder harness turning loop cover.

Remove bolt holding turning loop to quarter panel. (3) Remove rear seat cushion, back, and rear bol-

ster. (4) Remove push-in fastener holding quarter trim

to roof rail. (5) Remove screws holding quarter trim panel to

wheelhouse kickup. (6) Pull trim panel forward and separate from ve-

hicle.

INSTALLATION

Reverse the preceding operation.

QUARTER EXTENSION TRIM PANEL

REMOVAL (FIG. 39)

(1) Remove rear seat cushion, back, and rear bol-

ster. (2) Disengage clips holding expansion trim panel

to shelf panel. (3) Separate trim panel from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR SHELF TRIM PANEL

REMOVAL (FIG. 39)

(1) Remove one quarter trim panel.

(2) Remove center high mounted stop lamp cover.

Refer to Group 8L, Lamps for instructions. (3) Disengage frog leg fasteners holding trim to

shelf panel and separate trim from vehicle.

INSTALLATION

Reverse the preceding operation.

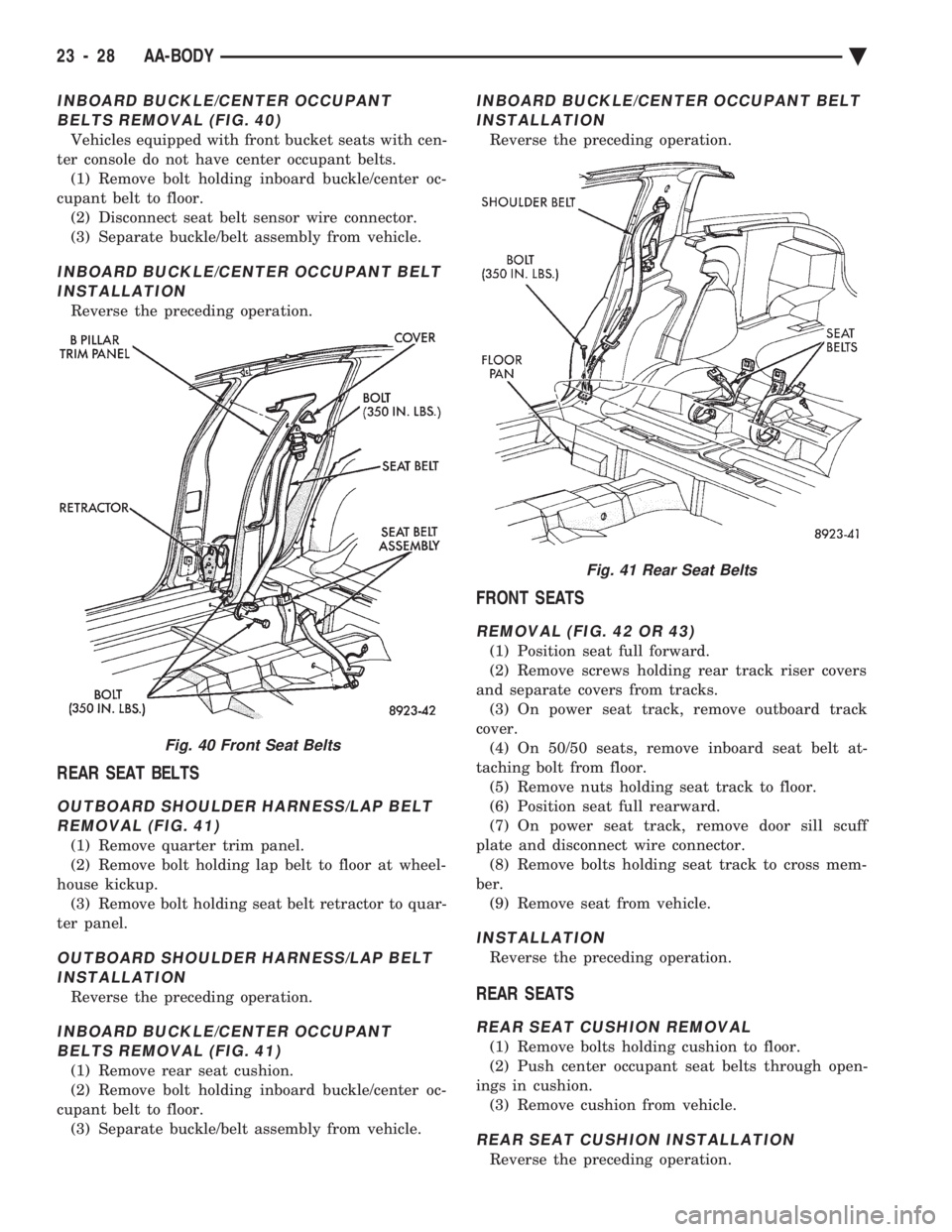

FRONT SEAT BELTS

OUTBOARD SHOULDER HARNESS/LAP BELT REMOVAL (FIG. 40)

(1) Remove B-pillar trim panel.

(2) Remove bolt holding seat belt retractor to

B-pillar. (3) Separate retractor from vehicle.

OUTBOARD SHOULDER HARNESS/LAP BELTINSTALLATION

Reverse the preceding operation.

Fig. 39 Interior Mouldings, Panels, and Trim Covers

Ä AA-BODY 23 - 27

Page 2184 of 2438

INBOARD BUCKLE/CENTER OCCUPANT BELTS REMOVAL (FIG. 40)

Vehicles equipped with front bucket seats with cen-

ter console do not have center occupant belts. (1) Remove bolt holding inboard buckle/center oc-

cupant belt to floor. (2) Disconnect seat belt sensor wire connector.

(3) Separate buckle/belt assembly from vehicle.

INBOARD BUCKLE/CENTER OCCUPANT BELT INSTALLATION

Reverse the preceding operation.

REAR SEAT BELTS

OUTBOARD SHOULDER HARNESS/LAP BELTREMOVAL (FIG. 41)

(1) Remove quarter trim panel.

(2) Remove bolt holding lap belt to floor at wheel-

house kickup. (3) Remove bolt holding seat belt retractor to quar-

ter panel.

OUTBOARD SHOULDER HARNESS/LAP BELT INSTALLATION

Reverse the preceding operation.

INBOARD BUCKLE/CENTER OCCUPANTBELTS REMOVAL (FIG. 41)

(1) Remove rear seat cushion.

(2) Remove bolt holding inboard buckle/center oc-

cupant belt to floor. (3) Separate buckle/belt assembly from vehicle.

INBOARD BUCKLE/CENTER OCCUPANT BELTINSTALLATION

Reverse the preceding operation.

FRONT SEATS

REMOVAL (FIG. 42 OR 43)

(1) Position seat full forward.

(2) Remove screws holding rear track riser covers

and separate covers from tracks. (3) On power seat track, remove outboard track

cover. (4) On 50/50 seats, remove inboard seat belt at-

taching bolt from floor. (5) Remove nuts holding seat track to floor.

(6) Position seat full rearward.

(7) On power seat track, remove door sill scuff

plate and disconnect wire connector. (8) Remove bolts holding seat track to cross mem-

ber. (9) Remove seat from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR SEATS

REAR SEAT CUSHION REMOVAL

(1) Remove bolts holding cushion to floor.

(2) Push center occupant seat belts through open-

ings in cushion. (3) Remove cushion from vehicle.

REAR SEAT CUSHION INSTALLATION

Reverse the preceding operation.

Fig. 40 Front Seat Belts

Fig. 41 Rear Seat Belts

23 - 28 AA-BODY Ä

Page 2196 of 2438

panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

INSTALLATION

Reverse the preceding operation.

FRONT END SPLASH SHIELDS

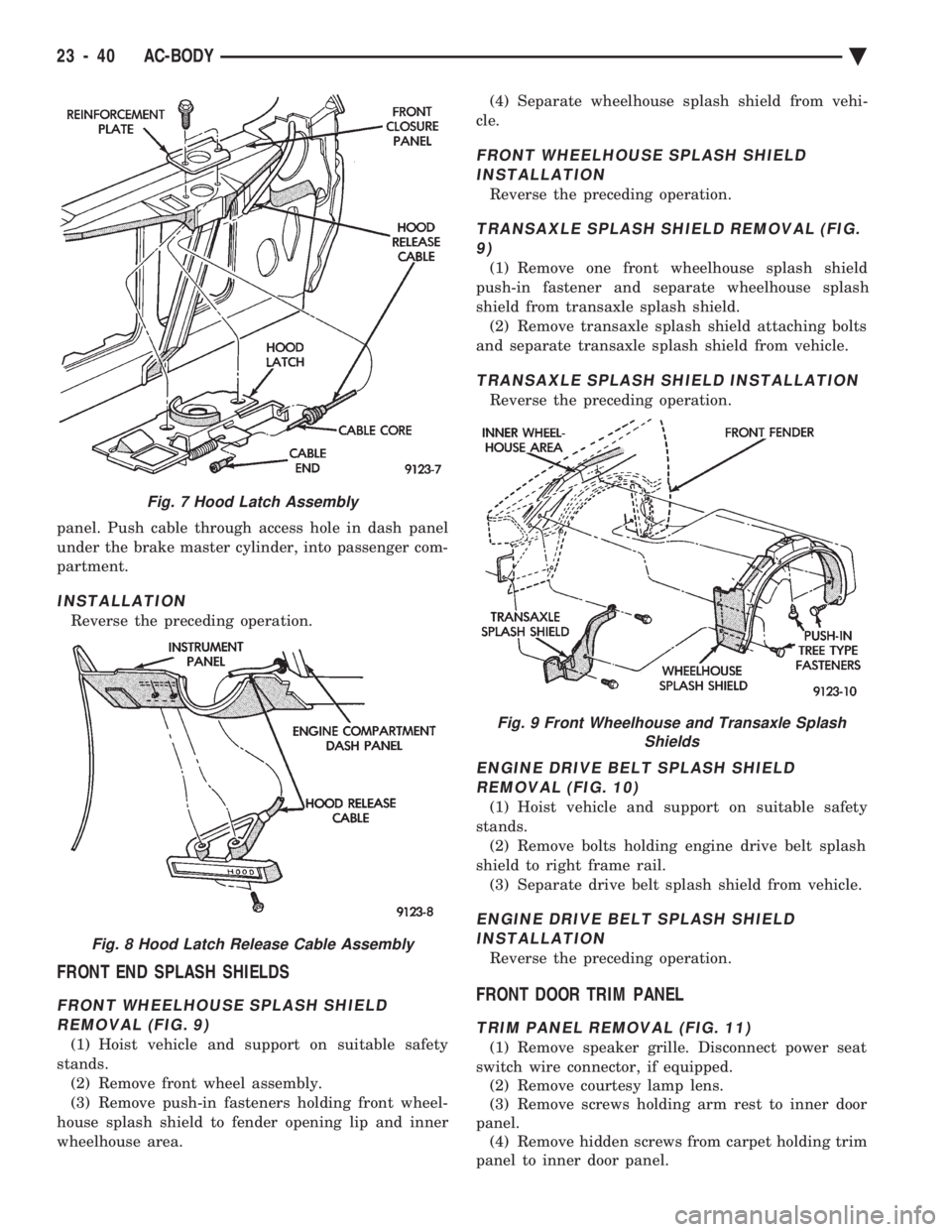

FRONT WHEELHOUSE SPLASH SHIELD REMOVAL (FIG. 9)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

TRANSAXLE SPLASH SHIELD REMOVAL (FIG.9)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

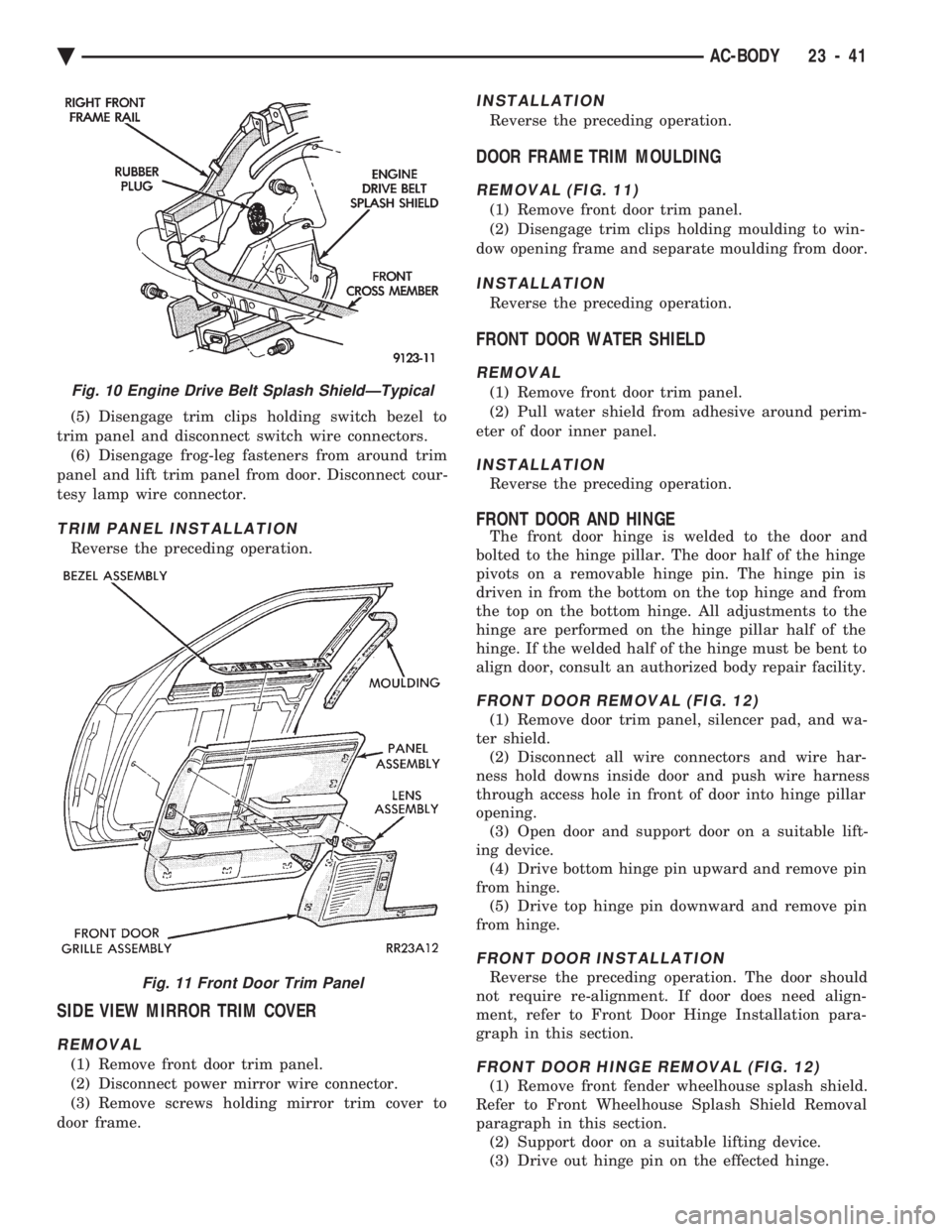

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 10)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

FRONT DOOR TRIM PANEL

TRIM PANEL REMOVAL (FIG. 11)

(1) Remove speaker grille. Disconnect power seat

switch wire connector, if equipped. (2) Remove courtesy lamp lens.

(3) Remove screws holding arm rest to inner door

panel. (4) Remove hidden screws from carpet holding trim

panel to inner door panel.

Fig. 7 Hood Latch Assembly

Fig. 8 Hood Latch Release Cable Assembly

Fig. 9 Front Wheelhouse and Transaxle Splash Shields

23 - 40 AC-BODY Ä

Page 2197 of 2438

(5) Disengage trim clips holding switch bezel to

trim panel and disconnect switch wire connectors. (6) Disengage frog-leg fasteners from around trim

panel and lift trim panel from door. Disconnect cour-

tesy lamp wire connector.

TRIM PANEL INSTALLATION

Reverse the preceding operation.

SIDE VIEW MIRROR TRIM COVER

REMOVAL

(1) Remove front door trim panel.

(2) Disconnect power mirror wire connector.

(3) Remove screws holding mirror trim cover to

door frame.

INSTALLATION

Reverse the preceding operation.

DOOR FRAME TRIM MOULDING

REMOVAL (FIG. 11)

(1) Remove front door trim panel.

(2) Disengage trim clips holding moulding to win-

dow opening frame and separate moulding from door.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR WATER SHIELD

REMOVAL

(1) Remove front door trim panel.

(2) Pull water shield from adhesive around perim-

eter of door inner panel.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR AND HINGE

The front door hinge is welded to the door and

bolted to the hinge pillar. The door half of the hinge

pivots on a removable hinge pin. The hinge pin is

driven in from the bottom on the top hinge and from

the top on the bottom hinge. All adjustments to the

hinge are performed on the hinge pillar half of the

hinge. If the welded half of the hinge must be bent to

align door, consult an authorized body repair facility.

FRONT DOOR REMOVAL (FIG. 12)

(1) Remove door trim panel, silencer pad, and wa-

ter shield. (2) Disconnect all wire connectors and wire har-

ness hold downs inside door and push wire harness

through access hole in front of door into hinge pillar

opening. (3) Open door and support door on a suitable lift-

ing device. (4) Drive bottom hinge pin upward and remove pin

from hinge. (5) Drive top hinge pin downward and remove pin

from hinge.

FRONT DOOR INSTALLATION

Reverse the preceding operation. The door should

not require re-alignment. If door does need align-

ment, refer to Front Door Hinge Installation para-

graph in this section.

FRONT DOOR HINGE REMOVAL (FIG. 12)

(1) Remove front fender wheelhouse splash shield.

Refer to Front Wheelhouse Splash Shield Removal

paragraph in this section. (2) Support door on a suitable lifting device.

(3) Drive out hinge pin on the effected hinge.

Fig. 10 Engine Drive Belt Splash ShieldÐTypical

Fig. 11 Front Door Trim Panel

Ä AC-BODY 23 - 41