length CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 483 of 2438

(2) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Cracked, leaking or faulty cables should

be replaced. Use the following procedure when removing the

high tension cable from the spark plug. First, remove

the cable from the retaining bracket. Then grasp the

terminal as close as possible to the spark plug. Ro-

tate the cover (boot) slightly and pull straight back.

Do not use pliers and do not pull the cable at an

angle. Doing so will damage the insulation, cable

terminal or the spark plug insulator. Wipe spark

plug insulator clean before reinstalling cable

and cover. Resistance cables are identified by the words Elec-

tronic Suppression .

Use an ohmmeter to check cables for opens, loose

terminals or high resistance. (a) Remove cable from spark plug.

(b) Remove cable from the coil tower.

(c) Connect the ohmmeter between spark plug

end terminal and the coil end terminal. Resistance

should be within tolerance shown in the cable re-

sistance chart. If resistance is not within tolerance,

replace cable assembly. Test all spark plug cables

in same manner.

SPARK PLUG SERVICE

When replacing the spark plug cables, route the ca-

bles correctly and secure them in the appropriate re-

tainers. Incorrectly routed cables can cause the radio

to reproduce ignition noise. It can also cause cross ig-

nition of the spark plugs or short circuit the cables to

ground.

SPARK PLUG REMOVAL

Always remove cables by grasping at boot, rotating

the boot 1/2 turn, and pulling straight back in a

steady motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert. (3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

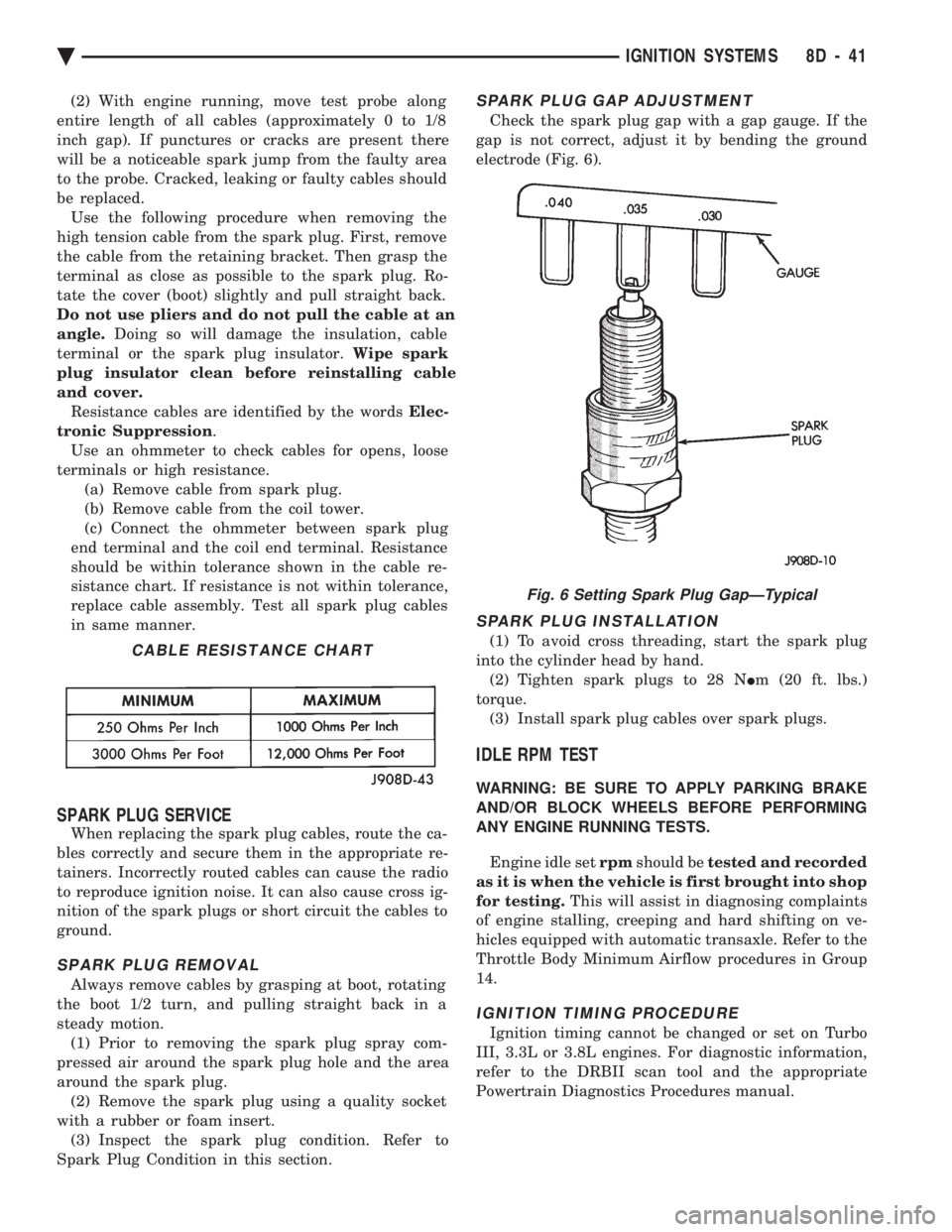

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TEST

WARNING: BE SURE TO APPLY PARKING BRAKE

AND/OR BLOCK WHEELS BEFORE PERFORMING

ANY ENGINE RUNNING TESTS.

Engine idle set rpmshould be tested and recorded

as it is when the vehicle is first brought into shop

for testing. This will assist in diagnosing complaints

of engine stalling, creeping and hard shifting on ve-

hicles equipped with automatic transaxle. Refer to the

Throttle Body Minimum Airflow procedures in Group

14.

IGNITION TIMING PROCEDURE

Ignition timing cannot be changed or set on Turbo

III, 3.3L or 3.8L engines. For diagnostic information,

refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedures manual.

CABLE RESISTANCE CHART

Fig. 6 Setting Spark Plug GapÐTypical

Ä IGNITION SYSTEMS 8D - 41

Page 547 of 2438

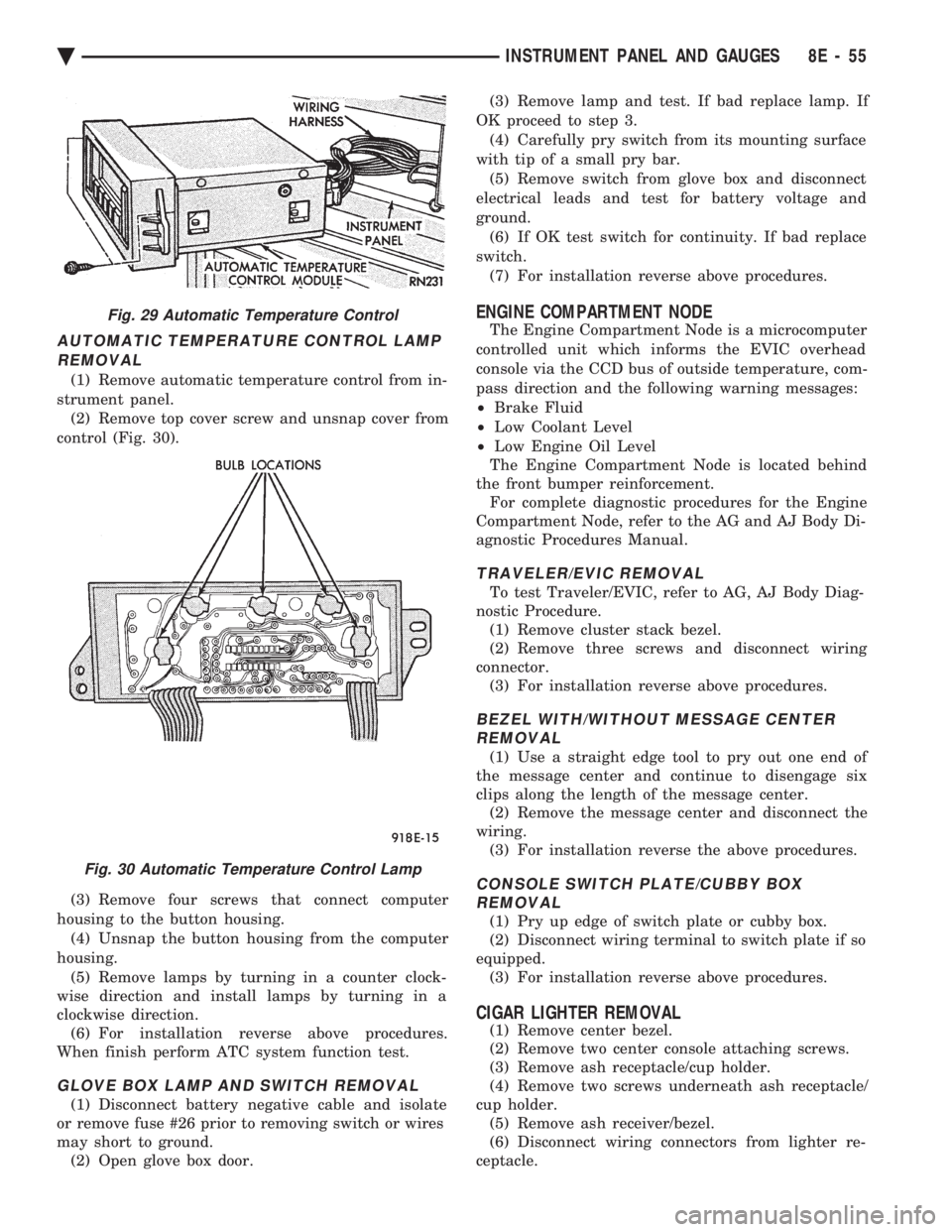

AUTOMATIC TEMPERATURE CONTROL LAMP REMOVAL

(1) Remove automatic temperature control from in-

strument panel. (2) Remove top cover screw and unsnap cover from

control (Fig. 30).

(3) Remove four screws that connect computer

housing to the button housing. (4) Unsnap the button housing from the computer

housing. (5) Remove lamps by turning in a counter clock-

wise direction and install lamps by turning in a

clockwise direction. (6) For installation reverse above procedures.

When finish perform ATC system function test.

GLOVE BOX LAMP AND SWITCH REMOVAL

(1) Disconnect battery negative cable and isolate

or remove fuse #26 prior to removing switch or wires

may short to ground. (2) Open glove box door. (3) Remove lamp and test. If bad replace lamp. If

OK proceed to step 3. (4) Carefully pry switch from its mounting surface

with tip of a small pry bar. (5) Remove switch from glove box and disconnect

electrical leads and test for battery voltage and

ground. (6) If OK test switch for continuity. If bad replace

switch. (7) For installation reverse above procedures.

ENGINE COMPARTMENT NODE

The Engine Compartment Node is a microcomputer

controlled unit which informs the EVIC overhead

console via the CCD bus of outside temperature, com-

pass direction and the following warning messages:

² Brake Fluid

² Low Coolant Level

² Low Engine Oil Level

The Engine Compartment Node is located behind

the front bumper reinforcement. For complete diagnostic procedures for the Engine

Compartment Node, refer to the AG and AJ Body Di-

agnostic Procedures Manual.

TRAVELER/EVIC REMOVAL

To test Traveler/EVIC, refer to AG, AJ Body Diag-

nostic Procedure. (1) Remove cluster stack bezel.

(2) Remove three screws and disconnect wiring

connector. (3) For installation reverse above procedures.

BEZEL WITH/WITHOUT MESSAGE CENTERREMOVAL

(1) Use a straight edge tool to pry out one end of

the message center and continue to disengage six

clips along the length of the message center. (2) Remove the message center and disconnect the

wiring. (3) For installation reverse the above procedures.

CONSOLE SWITCH PLATE/CUBBY BOXREMOVAL

(1) Pry up edge of switch plate or cubby box.

(2) Disconnect wiring terminal to switch plate if so

equipped. (3) For installation reverse above procedures.

CIGAR LIGHTER REMOVAL

(1) Remove center bezel.

(2) Remove two center console attaching screws.

(3) Remove ash receptacle/cup holder.

(4) Remove two screws underneath ash receptacle/

cup holder. (5) Remove ash receiver/bezel.

(6) Disconnect wiring connectors from lighter re-

ceptacle.

Fig. 29 Automatic Temperature Control

Fig. 30 Automatic Temperature Control Lamp

Ä INSTRUMENT PANEL AND GAUGES 8E - 55

Page 587 of 2438

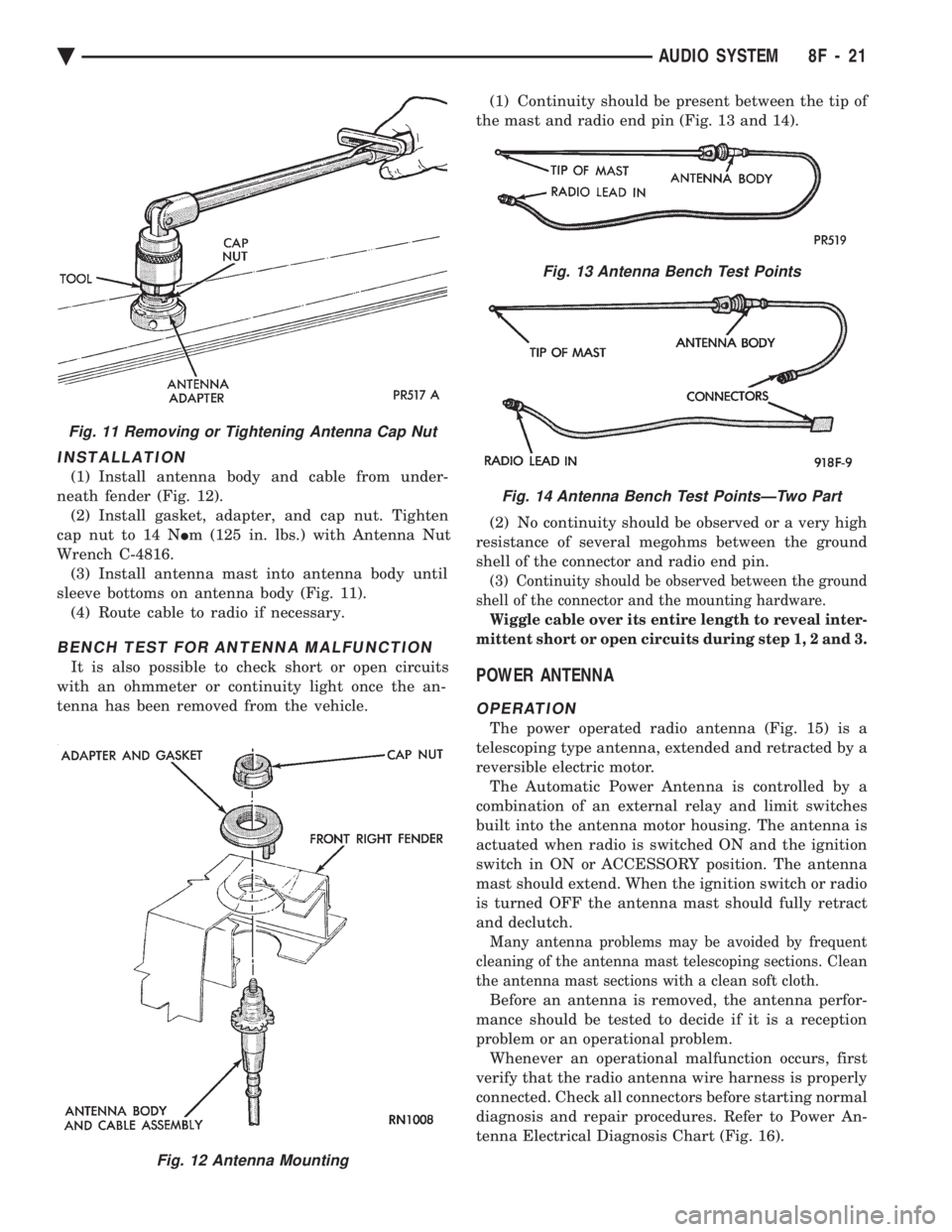

INSTALLATION

(1) Install antenna body and cable from under-

neath fender (Fig. 12). (2) Install gasket, adapter, and cap nut. Tighten

cap nut to 14 N Im (125 in. lbs.) with Antenna Nut

Wrench C-4816. (3) Install antenna mast into antenna body until

sleeve bottoms on antenna body (Fig. 11). (4) Route cable to radio if necessary.

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the an-

tenna has been removed from the vehicle. (1) Continuity should be present between the tip of

the mast and radio end pin (Fig. 13 and 14).

(2) No continuity should be observed or a very high

resistance of several megohms between the ground

shell of the connector and radio end pin.

(3) Continuity should be observed between the ground

shell of the connector and the mounting hardware.

Wiggle cable over its entire length to reveal inter-

mittent short or open circuits during step 1, 2 and 3.

POWER ANTENNA

OPERATION

The power operated radio antenna (Fig. 15) is a

telescoping type antenna, extended and retracted by a

reversible electric motor. The Automatic Power Antenna is controlled by a

combination of an external relay and limit switches

built into the antenna motor housing. The antenna is

actuated when radio is switched ON and the ignition

switch in ON or ACCESSORY position. The antenna

mast should extend. When the ignition switch or radio

is turned OFF the antenna mast should fully retract

and declutch.

Many antenna problems may be avoided by frequent

cleaning of the antenna mast telescoping sections. Clean

the antenna mast sections with a clean soft cloth.

Before an antenna is removed, the antenna perfor-

mance should be tested to decide if it is a reception

problem or an operational problem. Whenever an operational malfunction occurs, first

verify that the radio antenna wire harness is properly

connected. Check all connectors before starting normal

diagnosis and repair procedures. Refer to Power An-

tenna Electrical Diagnosis Chart (Fig. 16).

Fig. 12 Antenna Mounting

Fig. 11 Removing or Tightening Antenna Cap Nut

Fig. 13 Antenna Bench Test Points

Fig. 14 Antenna Bench Test PointsÐTwo Part

Ä AUDIO SYSTEM 8F - 21

Page 755 of 2438

When a fusible link blows it is important to find

out what the problem is. They are placed in the sys-

tem for protection against shorts. Which can be

caused by a component failure or wiring failures. Do

not just replace the fusible link to correct the

problem. When diagnosing a faulty fusible link it is impor-

tant to check the wire carefully. In some instances

the link may be blown and it will not show through

the insulation, the wire should be checked over its

entire length for internal breaks. (1) Disconnect battery negative cable.

(2) Cut out the blown portion of the fusible link.

(3) Strip 1 inch of insulation from each end of the

existing fusible link. (4) Place a piece of heat shrink tubing over one

side of the fusible link. Make sure the tubing will be

long enough to cover and seal the entire repair area. (5) Cut a replacement piece of fusible link approx-

imately two inches longer than the piece removed. (6) Remove one inch of insulation from each end of

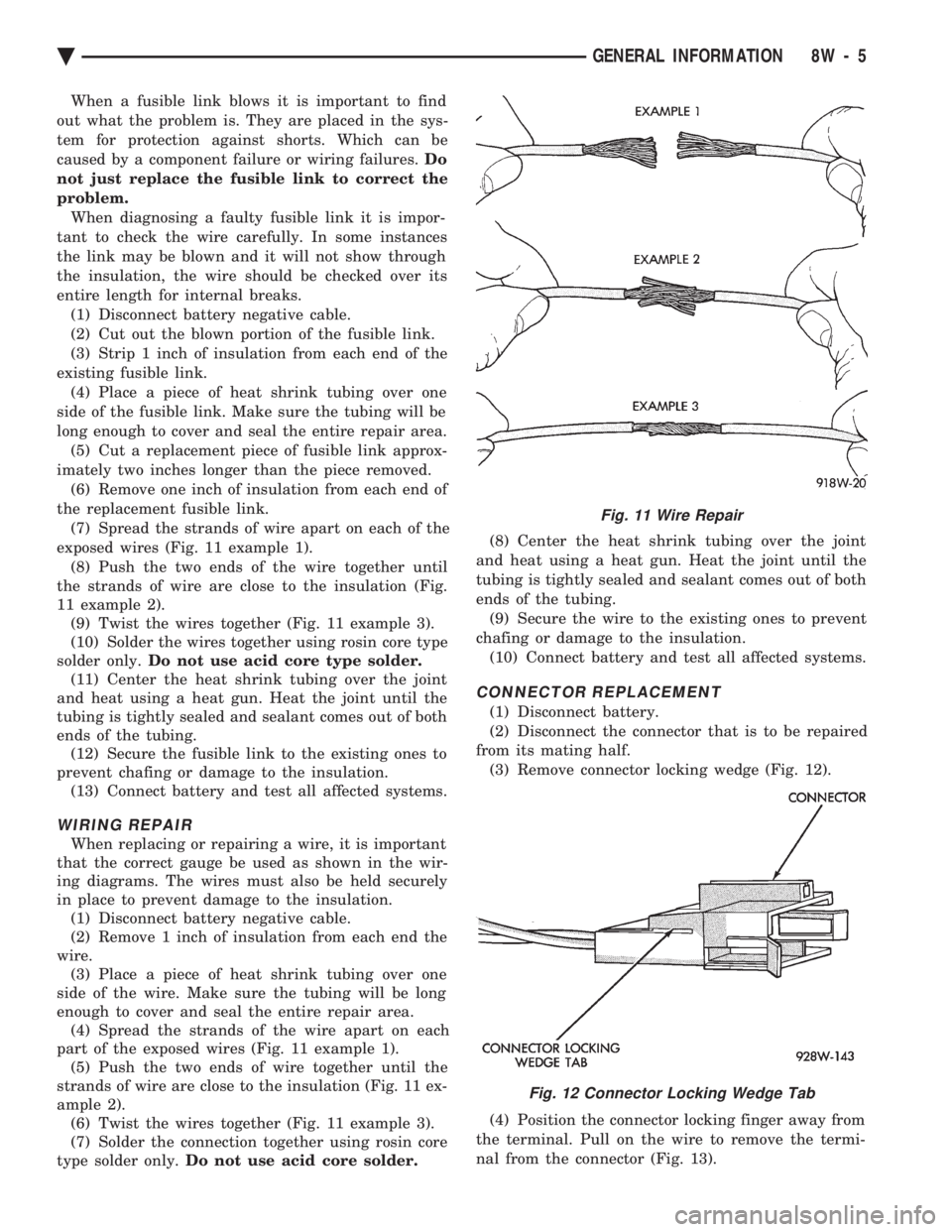

the replacement fusible link. (7) Spread the strands of wire apart on each of the

exposed wires (Fig. 11 example 1). (8) Push the two ends of the wire together until

the strands of wire are close to the insulation (Fig.

11 example 2). (9) Twist the wires together (Fig. 11 example 3).

(10) Solder the wires together using rosin core type

solder only. Do not use acid core type solder.

(11) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing. (12) Secure the fusible link to the existing ones to

prevent chafing or damage to the insulation. (13) Connect battery and test all affected systems.

WIRING REPAIR

When replacing or repairing a wire, it is important

that the correct gauge be used as shown in the wir-

ing diagrams. The wires must also be held securely

in place to prevent damage to the insulation. (1) Disconnect battery negative cable.

(2) Remove 1 inch of insulation from each end the

wire. (3) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area. (4) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 11 example 1). (5) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 11 ex-

ample 2). (6) Twist the wires together (Fig. 11 example 3).

(7) Solder the connection together using rosin core

type solder only. Do not use acid core solder. (8) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing. (9) Secure the wire to the existing ones to prevent

chafing or damage to the insulation. (10) Connect battery and test all affected systems.

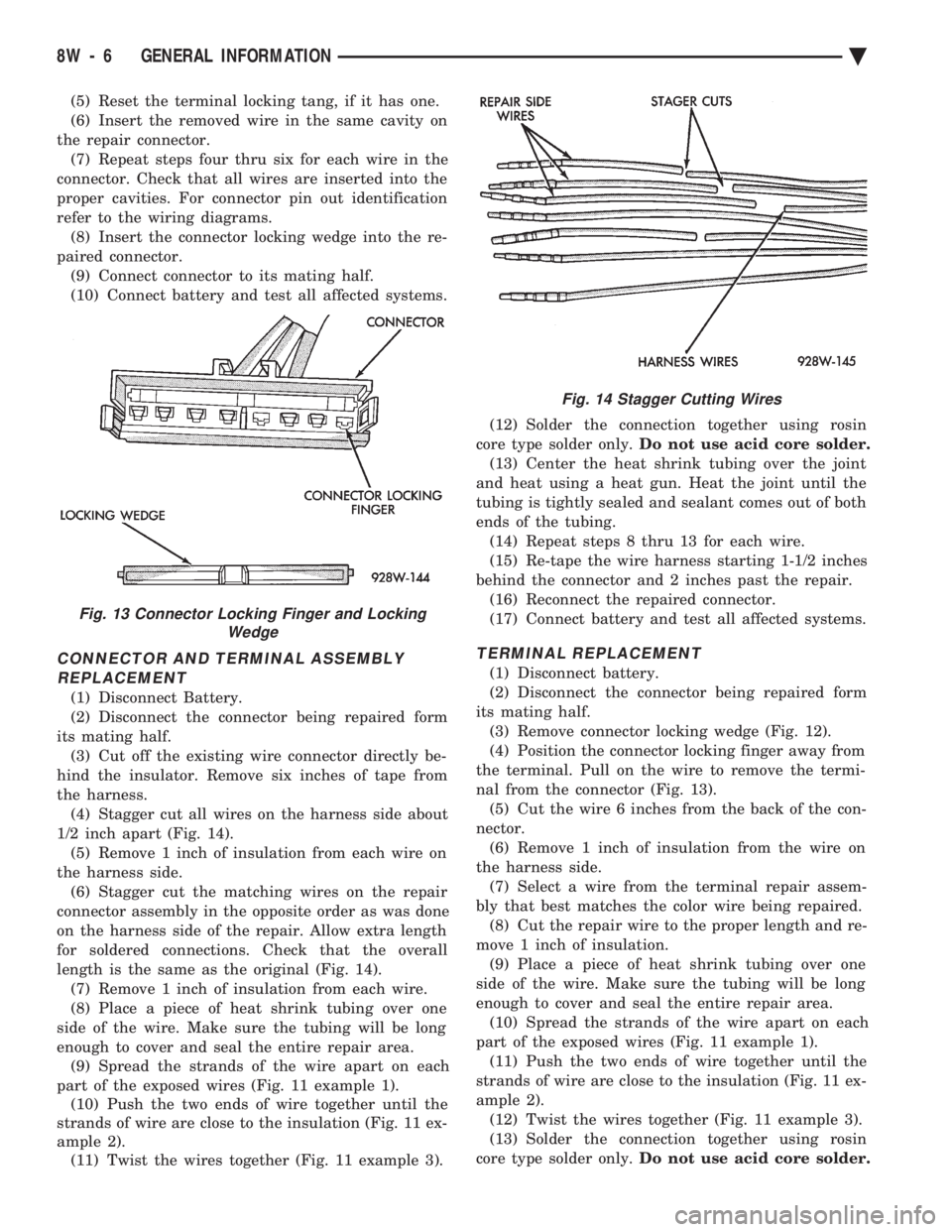

CONNECTOR REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector that is to be repaired

from its mating half. (3) Remove connector locking wedge (Fig. 12).

(4) Position the connector locking finger away from

the terminal. Pull on the wire to remove the termi-

nal from the connector (Fig. 13).

Fig. 11 Wire Repair

Fig. 12 Connector Locking Wedge Tab

Ä GENERAL INFORMATION 8W - 5

Page 756 of 2438

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector. (7) Repeat steps four thru six for each wire in the

connector. Check that all wires are inserted into the

proper cavities. For connector pin out identification

refer to the wiring diagrams. (8) Insert the connector locking wedge into the re-

paired connector. (9) Connect connector to its mating half.

(10) Connect battery and test all affected systems.

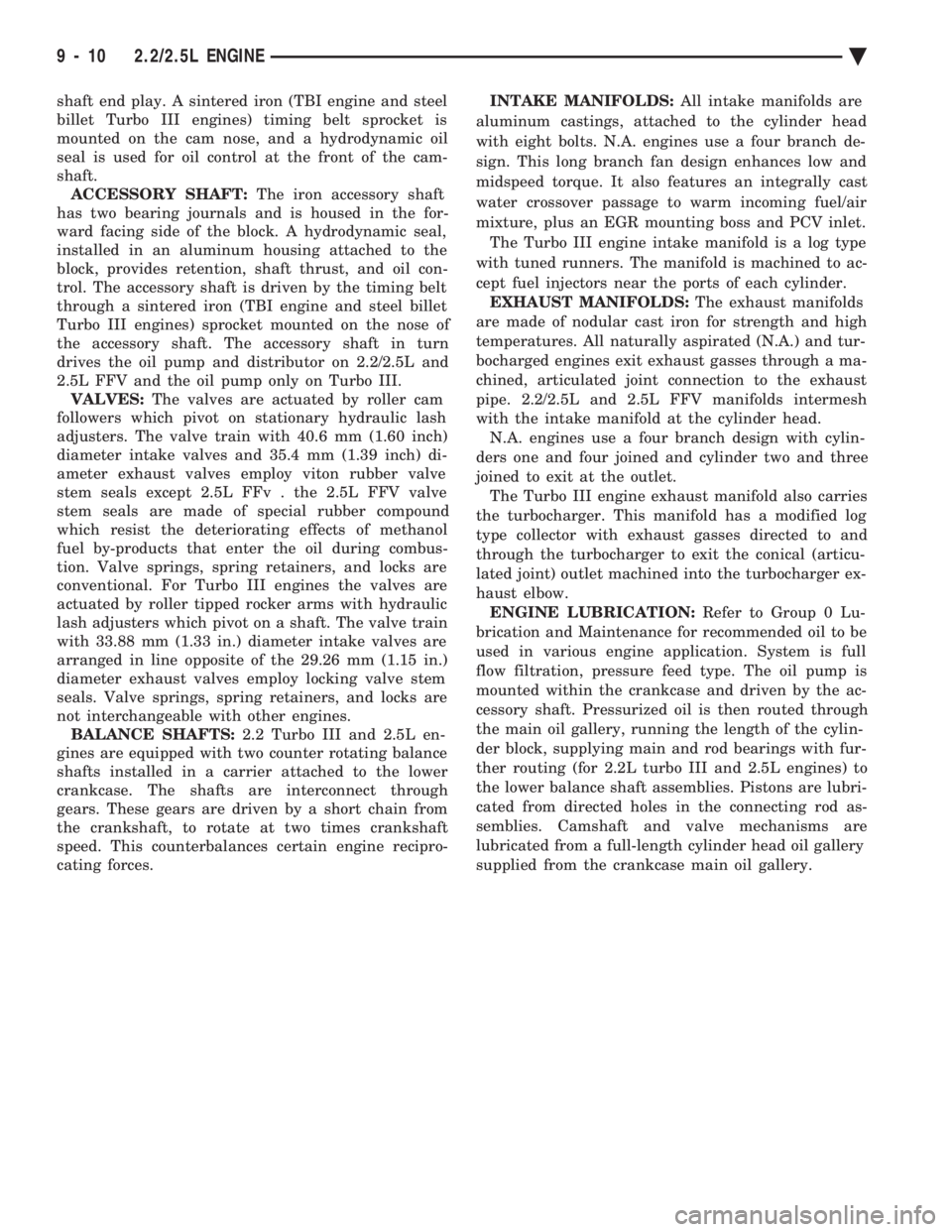

CONNECTOR AND TERMINAL ASSEMBLY REPLACEMENT

(1) Disconnect Battery.

(2) Disconnect the connector being repaired form

its mating half. (3) Cut off the existing wire connector directly be-

hind the insulator. Remove six inches of tape from

the harness. (4) Stagger cut all wires on the harness side about

1/2 inch apart (Fig. 14). (5) Remove 1 inch of insulation from each wire on

the harness side. (6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall

length is the same as the original (Fig. 14). (7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area. (9) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 11 example 1). (10) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 11 ex-

ample 2). (11) Twist the wires together (Fig. 11 example 3). (12) Solder the connection together using rosin

core type solder only. Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing. (14) Repeat steps 8 thru 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair. (16) Reconnect the repaired connector.

(17) Connect battery and test all affected systems.

TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector being repaired form

its mating half. (3) Remove connector locking wedge (Fig. 12).

(4) Position the connector locking finger away from

the terminal. Pull on the wire to remove the termi-

nal from the connector (Fig. 13). (5) Cut the wire 6 inches from the back of the con-

nector. (6) Remove 1 inch of insulation from the wire on

the harness side. (7) Select a wire from the terminal repair assem-

bly that best matches the color wire being repaired. (8) Cut the repair wire to the proper length and re-

move 1 inch of insulation. (9) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area. (10) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 11 example 1). (11) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 11 ex-

ample 2). (12) Twist the wires together (Fig. 11 example 3).

(13) Solder the connection together using rosin

core type solder only. Do not use acid core solder.

Fig. 13 Connector Locking Finger and Locking

Wedge

Fig. 14 Stagger Cutting Wires

8W - 6 GENERAL INFORMATION Ä

Page 1575 of 2438

Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline. Engine components which are required for safe op-

eration using fuel containing methanol alcohol are

identified by a standard green color and/or display

the statement methanol compatible imprinted on the

component. To ensure continued safe operation, these

components must be serviced only with genuine MO-

PAR replacement parts. Methanol compatible parts for the 2.5L FFV (Flex-

ible Fuel Vehicle) engine include, but are not limited

to; the valve stem oil seals, all piston rings, the oil

fill cap, the fuel injectors, fuel rail, fuel pressure reg-

ulator, hoses and the vacuum control harness hose. BLOCK: All four cylinder cast iron blocks have

cast-in recesses in the bottom of each cylinder bore to

provide connecting rod clearance; especially needed

for 2.5L engines. The bores are also siamese to min-

imize engine length. A coolant passage is drilled

cross-ways through the siamese section to enhance

between the bore cooling on some engine types. A

partial open deck is used for cooling and weight re-

duction with oil filter, water pump, and distributor

mounting bosses molded into the front (radiator side)

of the block. Nominal wall thickness is 4.5 mm. Five

main bearing bulkheads and a block skirt extending

3 mm below the crankshaft center line add to the

blocks high rigidity with light weight. CRANKSHAFT: A nodular cast iron crankshaft is

used in TBI engines. A forged steel crankshaft is

used in the Turbo III engine. All engines have 5 main bearings, with number 3 flanged to control

thrust. The 60 mm diameter main and 50 mm diam-

eter crank pin journals (all) have undercut radiuses

fillets that are deep rolled for added strength. To op-

timize bearing loading 4 counterweights are used.

Hydrodynamic seals (installed in diecast aluminum

retainers) provide end sealing, where the crankshaft

exits the block. Anaerobic gasket material is used for

retainer-to-block sealing. No vibration damper is

used. A sintered iron (TBI engine and steel billet

Turbo III engines) timing belt sprocket is mounted

on the crankshaft nose. This sprocket provides mo-

tive power; via timing belt to the camshaft and inter-

mediate shaft sprockets (also sintered iron (TBI

engine and steel billet Turbo III engines) providing

timed valve, distributor, and oil pump actuation. PISTONS: Some Chrysler pistons have cast-in

steel struts at the pin bosses for autothermic control.

All 2.2L and 2.5L piston tops have cuts to provide

valve clearance. Some pistons are dished to provide

various compression ratios. Standard 2.2L and 2.5L

engines are designed for 9.5:1 and 8.9:1 compression

ratios respectively. The 2.5L piston is dished and is a

lightweight design to enhance engine smoothness.

The 2.2L turbo III uses dished pistons providing a

8.3:1 compression ratio. All standard 2.2/2.5L and

2.5L FFV engines use pressed-in piston pins to at-

tach forged steel connecting rods, 2.2L turbo III en-

gine uses a full floating piston pin and connecting

rod assembly. PISTONS RINGS: The 2.2/2.5L engines share

common piston rings throughout, including molybde-

num filled top ring for reliable compression sealing

and a tapered faced intermediate ring for additional

cylinder pressure control. The 2.5L FFV engine fea-

ture all chrome rings for enhanced long term dura-

bility under multi-fueled conditions. CYLINDER HEAD: The cylinder head is cast alu-

minum with in-line valves. The 2.2/2.5L and 2.5L

FFV valves are arranged with alternating exhaust

and intake. The intake and exhaust ports are located

in the rearward, facing side of the head. The Turbo

III valves are arranged in two inline banks, with the

ports of the bank of two intake valves per cylinder

facing toward the radiator side of engine and ports of

the bank of two exhaust valve per cylinder facing to-

ward the dash panel. The intake ports feed fast-burn

design combustion chambers (2.2/2.5L and 2.5L FFV

only) with the spark plug located close to the center

line of the combustion chamber for optimum effi-

ciency. An integral oil gallery within the cylinder

head supplies oil to the hydraulic lash adjusters,

camshaft, and valve mechanisms. CAMSHAFT: The nodular iron camshaft has five

bearing journals (2.2/2.5L and 2.5L FFV). The Turbo

III employs dual camshafts that have nine bearing

journals. Flanges at the rear journal control cam-

Fig. 1 Engine Identification

Ä 2.2/2.5L ENGINE 9 - 9

Page 1576 of 2438

shaft end play. A sintered iron (TBI engine and steel

billet Turbo III engines) timing belt sprocket is

mounted on the cam nose, and a hydrodynamic oil

seal is used for oil control at the front of the cam-

shaft. ACCESSORY SHAFT: The iron accessory shaft

has two bearing journals and is housed in the for-

ward facing side of the block. A hydrodynamic seal,

installed in an aluminum housing attached to the

block, provides retention, shaft thrust, and oil con-

trol. The accessory shaft is driven by the timing belt

through a sintered iron (TBI engine and steel billet

Turbo III engines) sprocket mounted on the nose of

the accessory shaft. The accessory shaft in turn

drives the oil pump and distributor on 2.2/2.5L and

2.5L FFV and the oil pump only on Turbo III. VALVES: The valves are actuated by roller cam

followers which pivot on stationary hydraulic lash

adjusters. The valve train with 40.6 mm (1.60 inch)

diameter intake valves and 35.4 mm (1.39 inch) di-

ameter exhaust valves employ viton rubber valve

stem seals except 2.5L FFv . the 2.5L FFV valve

stem seals are made of special rubber compound

which resist the deteriorating effects of methanol

fuel by-products that enter the oil during combus-

tion. Valve springs, spring retainers, and locks are

conventional. For Turbo III engines the valves are

actuated by roller tipped rocker arms with hydraulic

lash adjusters which pivot on a shaft. The valve train

with 33.88 mm (1.33 in.) diameter intake valves are

arranged in line opposite of the 29.26 mm (1.15 in.)

diameter exhaust valves employ locking valve stem

seals. Valve springs, spring retainers, and locks are

not interchangeable with other engines. BALANCE SHAFTS: 2.2 Turbo III and 2.5L en-

gines are equipped with two counter rotating balance

shafts installed in a carrier attached to the lower

crankcase. The shafts are interconnect through

gears. These gears are driven by a short chain from

the crankshaft, to rotate at two times crankshaft

speed. This counterbalances certain engine recipro-

cating forces. INTAKE MANIFOLDS:

All intake manifolds are

aluminum castings, attached to the cylinder head

with eight bolts. N.A. engines use a four branch de-

sign. This long branch fan design enhances low and

midspeed torque. It also features an integrally cast

water crossover passage to warm incoming fuel/air

mixture, plus an EGR mounting boss and PCV inlet. The Turbo III engine intake manifold is a log type

with tuned runners. The manifold is machined to ac-

cept fuel injectors near the ports of each cylinder. EXHAUST MANIFOLDS: The exhaust manifolds

are made of nodular cast iron for strength and high

temperatures. All naturally aspirated (N.A.) and tur-

bocharged engines exit exhaust gasses through a ma-

chined, articulated joint connection to the exhaust

pipe. 2.2/2.5L and 2.5L FFV manifolds intermesh

with the intake manifold at the cylinder head. N.A. engines use a four branch design with cylin-

ders one and four joined and cylinder two and three

joined to exit at the outlet. The Turbo III engine exhaust manifold also carries

the turbocharger. This manifold has a modified log

type collector with exhaust gasses directed to and

through the turbocharger to exit the conical (articu-

lated joint) outlet machined into the turbocharger ex-

haust elbow. ENGINE LUBRICATION: Refer to Group 0 Lu-

brication and Maintenance for recommended oil to be

used in various engine application. System is full

flow filtration, pressure feed type. The oil pump is

mounted within the crankcase and driven by the ac-

cessory shaft. Pressurized oil is then routed through

the main oil gallery, running the length of the cylin-

der block, supplying main and rod bearings with fur-

ther routing (for 2.2L turbo III and 2.5L engines) to

the lower balance shaft assemblies. Pistons are lubri-

cated from directed holes in the connecting rod as-

semblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

9 - 10 2.2/2.5L ENGINE Ä

Page 1578 of 2438

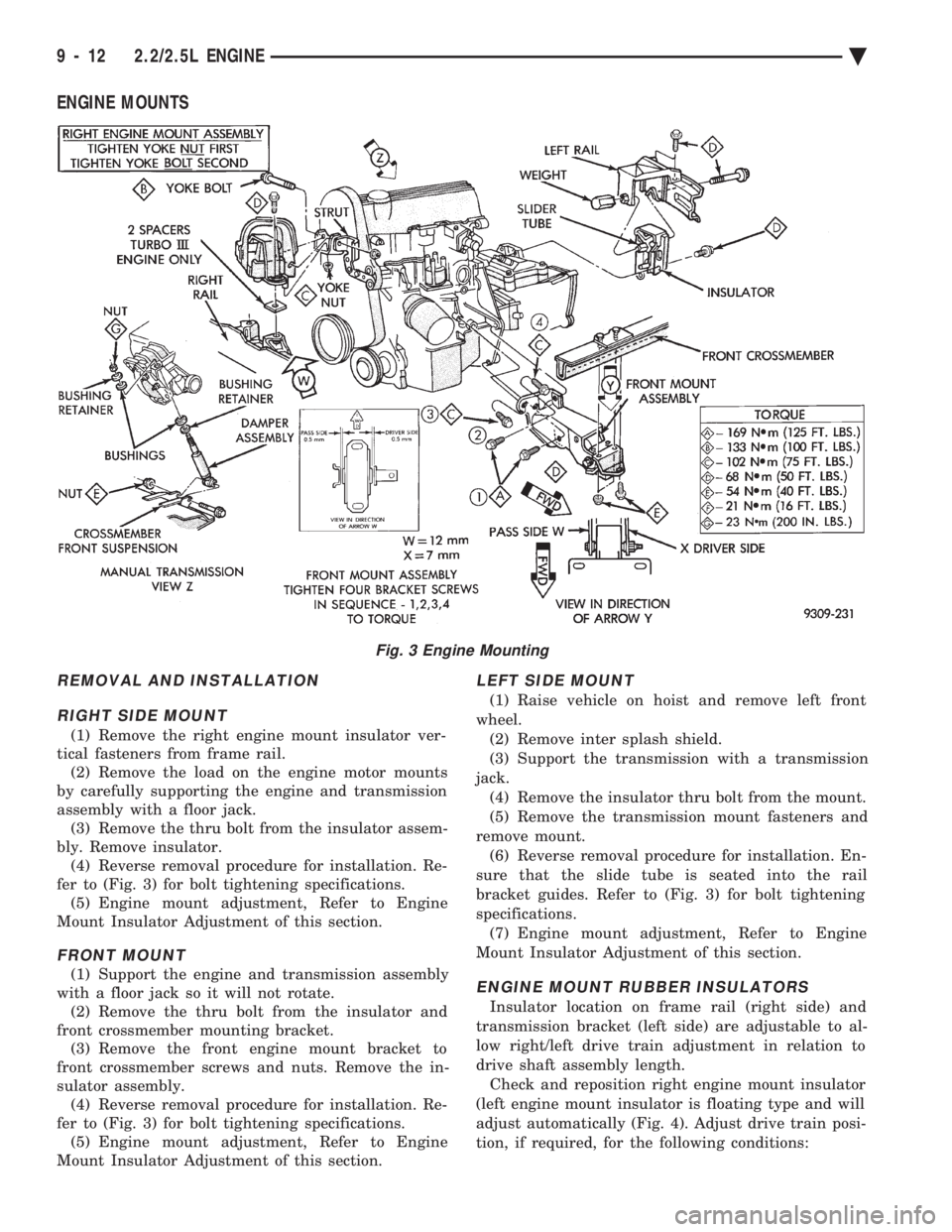

ENGINE MOUNTS

REMOVAL AND INSTALLATION RIGHT SIDE MOUNT

(1) Remove the right engine mount insulator ver-

tical fasteners from frame rail. (2) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack. (3) Remove the thru bolt from the insulator assem-

bly. Remove insulator. (4) Reverse removal procedure for installation. Re-

fer to (Fig. 3) for bolt tightening specifications. (5) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

FRONT MOUNT

(1) Support the engine and transmission assembly

with a floor jack so it will not rotate. (2) Remove the thru bolt from the insulator and

front crossmember mounting bracket. (3) Remove the front engine mount bracket to

front crossmember screws and nuts. Remove the in-

sulator assembly. (4) Reverse removal procedure for installation. Re-

fer to (Fig. 3) for bolt tightening specifications. (5) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

LEFT SIDE MOUNT

(1) Raise vehicle on hoist and remove left front

wheel. (2) Remove inter splash shield.

(3) Support the transmission with a transmission

jack. (4) Remove the insulator thru bolt from the mount.

(5) Remove the transmission mount fasteners and

remove mount. (6) Reverse removal procedure for installation. En-

sure that the slide tube is seated into the rail

bracket guides. Refer to (Fig. 3) for bolt tightening

specifications. (7) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

ENGINE MOUNT RUBBER INSULATORS

Insulator location on frame rail (right side) and

transmission bracket (left side) are adjustable to al-

low right/left drive train adjustment in relation to

drive shaft assembly length. Check and reposition right engine mount insulator

(left engine mount insulator is floating type and will

adjust automatically (Fig. 4). Adjust drive train posi-

tion, if required, for the following conditions:

Fig. 3 Engine Mounting

9 - 12 2.2/2.5L ENGINE Ä

Page 1579 of 2438

² Drive shaft distress: See Driveshafts in Suspension,

Group 2.

² Any front end structural damage (after repair).

² Insulator replacement.

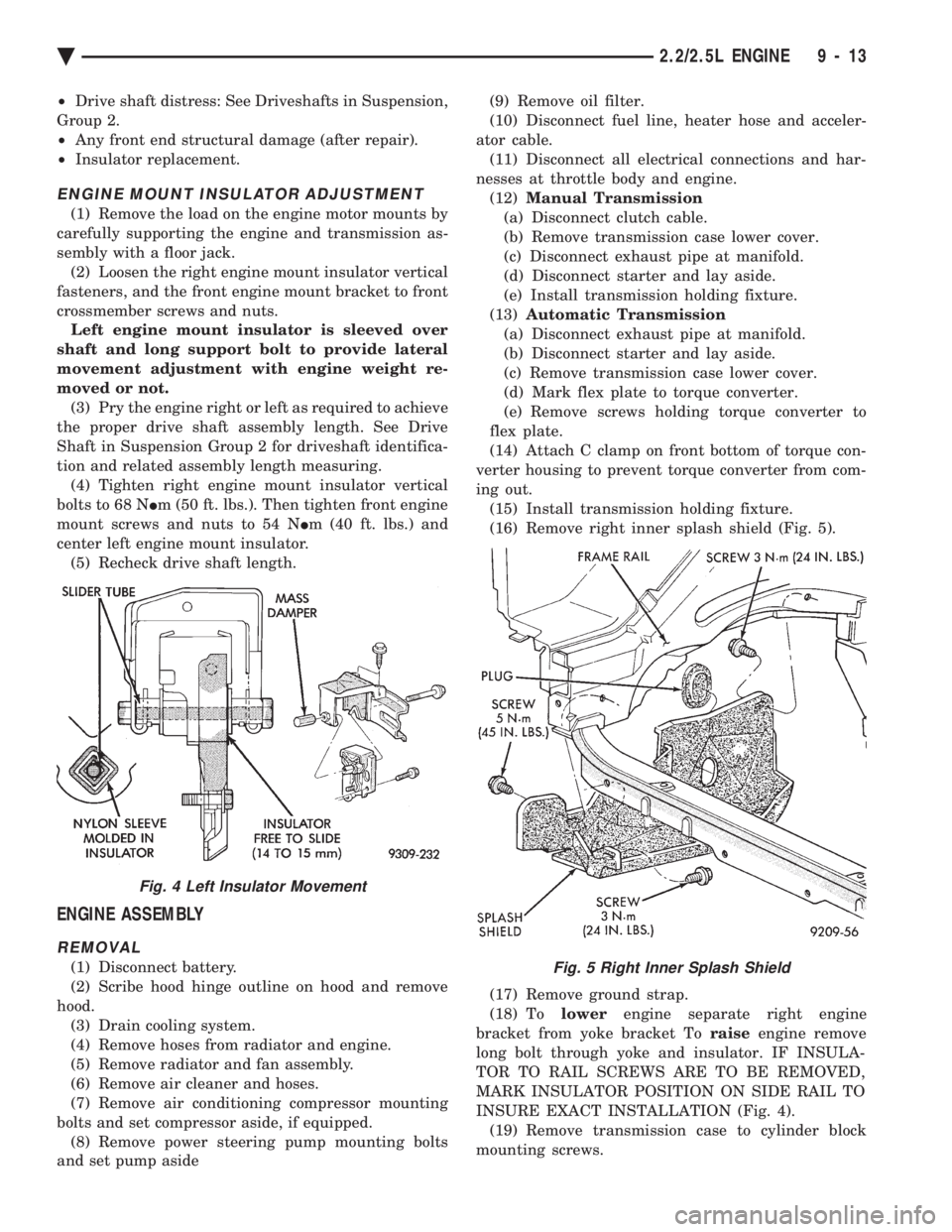

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts by

carefully supporting the engine and transmission as-

sembly with a floor jack. (2) Loosen the right engine mount insulator vertical

fasteners, and the front engine mount bracket to front

crossmember screws and nuts. Left engine mount insulator is sleeved over

shaft and long support bolt to provide lateral

movement adjustment with engine weight re-

moved or not. (3) Pry the engine right or left as required to achieve

the proper drive shaft assembly length. See Drive

Shaft in Suspension Group 2 for driveshaft identifica-

tion and related assembly length measuring. (4) Tighten right engine mount insulator vertical

bolts to 68 N Im (50 ft. lbs.). Then tighten front engine

mount screws and nuts to 54 N Im (40 ft. lbs.) and

center left engine mount insulator. (5) Recheck drive shaft length.

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect battery.

(2) Scribe hood hinge outline on hood and remove

hood. (3) Drain cooling system.

(4) Remove hoses from radiator and engine.

(5) Remove radiator and fan assembly.

(6) Remove air cleaner and hoses.

(7) Remove air conditioning compressor mounting

bolts and set compressor aside, if equipped. (8) Remove power steering pump mounting bolts

and set pump aside (9) Remove oil filter.

(10) Disconnect fuel line, heater hose and acceler-

ator cable. (11) Disconnect all electrical connections and har-

nesses at throttle body and engine. (12) Manual Transmission

(a) Disconnect clutch cable.

(b) Remove transmission case lower cover.

(c) Disconnect exhaust pipe at manifold.

(d) Disconnect starter and lay aside.

(e) Install transmission holding fixture.

(13) Automatic Transmission

(a) Disconnect exhaust pipe at manifold.

(b) Disconnect starter and lay aside.

(c) Remove transmission case lower cover.

(d) Mark flex plate to torque converter.

(e) Remove screws holding torque converter to

flex plate.

(14) Attach C clamp on front bottom of torque con-

verter housing to prevent torque converter from com-

ing out. (15) Install transmission holding fixture.

(16) Remove right inner splash shield (Fig. 5).

(17) Remove ground strap.

(18) To lowerengine separate right engine

bracket from yoke bracket To raiseengine remove

long bolt through yoke and insulator. IF INSULA-

TOR TO RAIL SCREWS ARE TO BE REMOVED,

MARK INSULATOR POSITION ON SIDE RAIL TO

INSURE EXACT INSTALLATION (Fig. 4). (19) Remove transmission case to cylinder block

mounting screws.Fig. 5 Right Inner Splash Shield

Fig. 4 Left Insulator Movement

Ä 2.2/2.5L ENGINE 9 - 13

Page 1594 of 2438

springs using Tool C-3422-B. (2) Remove valve retaining locks, valve spring re-

tainers, valve stem seals and valve springs. (3) Before removing valves, remove any burrs

from valve stem lock grooves to prevent damage

to the valve guides. Identify valves to insure instal-

lation in original location.

VALVE INSPECTION (1) Clean valves thoroughly and discard burned,

warped and cracked valves. (2) Measure valve stems for wear.

(3) If valve stems are worn more than 0.05 mm (.002

inch.) replace valve.

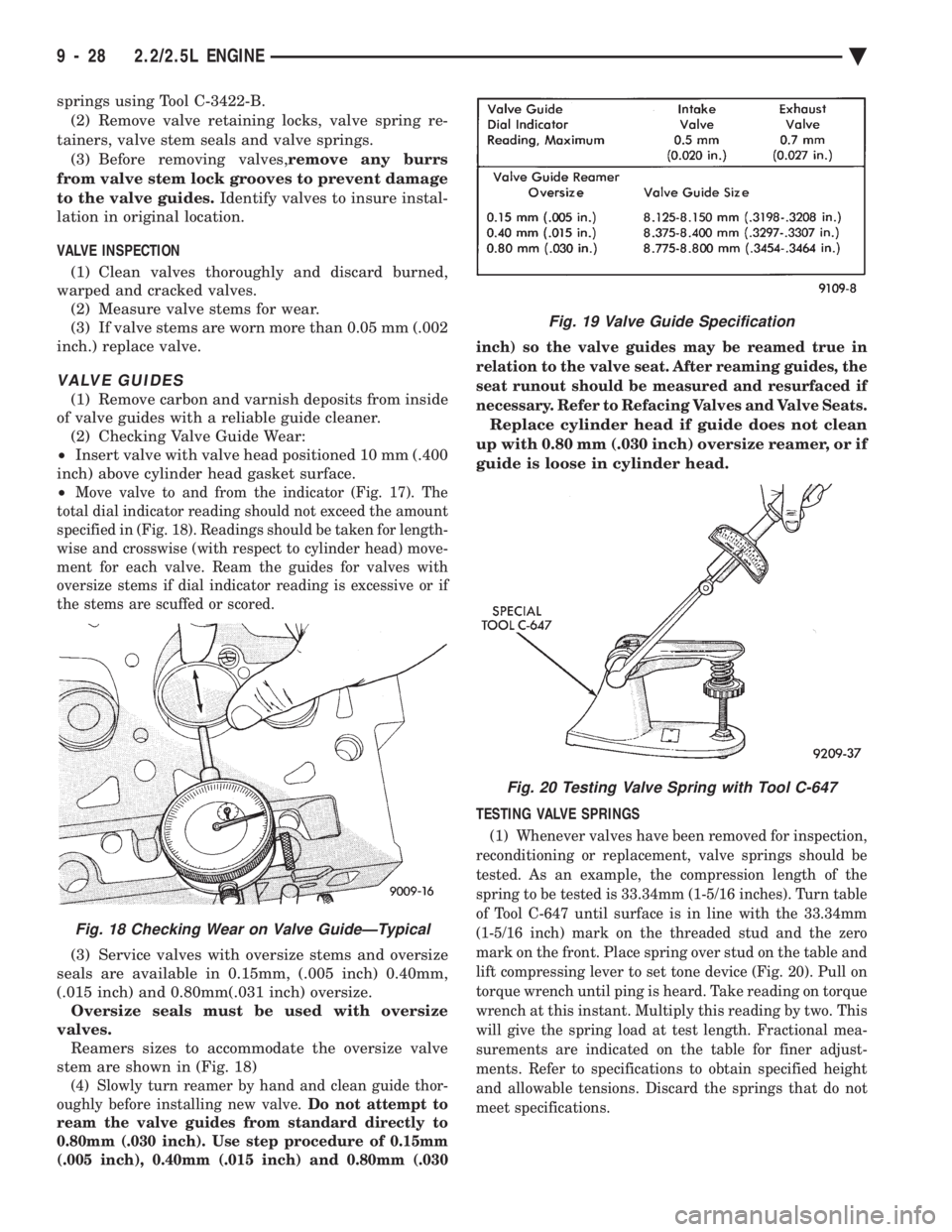

VALVE GUIDES

(1) Remove carbon and varnish deposits from inside

of valve guides with a reliable guide cleaner. (2) Checking Valve Guide Wear:

² Insert valve with valve head positioned 10 mm (.400

inch) above cylinder head gasket surface.

²

Move valve to and from the indicator (Fig. 17). The

total dial indicator reading should not exceed the amount

specified in (Fig. 18). Readings should be taken for length-

wise and crosswise (with respect to cylinder head) move-

ment for each valve. Ream the guides for valves with

oversize stems if dial indicator reading is excessive or if

the stems are scuffed or scored.

(3) Service valves with oversize stems and oversize

seals are available in 0.15mm, (.005 inch) 0.40mm,

(.015 inch) and 0.80mm(.031 inch) oversize. Oversize seals must be used with oversize

valves. Reamers sizes to accommodate the oversize valve

stem are shown in (Fig. 18)

(4) Slowly turn reamer by hand and clean guide thor-

oughly before installing new valve. Do not attempt to

ream the valve guides from standard directly to

0.80mm (.030 inch). Use step procedure of 0.15mm

(.005 inch), 0.40mm (.015 inch) and 0.80mm (.030 inch) so the valve guides may be reamed true in

relation to the valve seat. After reaming guides, the

seat runout should be measured and resurfaced if

necessary. Refer to Refacing Valves and Valve Seats.

Replace cylinder head if guide does not clean

up with 0.80 mm (.030 inch) oversize reamer, or if

guide is loose in cylinder head.

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should be

tested. As an example, the compression length of the

spring to be tested is 33.34mm (1-5/16 inches). Turn table

of Tool C-647 until surface is in line with the 33.34mm

(1-5/16 inch) mark on the threaded stud and the zero

mark on the front. Place spring over stud on the table and

lift compressing lever to set tone device (Fig. 20). Pull on

torque wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional mea-

surements are indicated on the table for finer adjust-

ments. Refer to specifications to obtain specified height

and allowable tensions. Discard the springs that do not

meet specifications.

Fig. 18 Checking Wear on Valve GuideÐTypical

Fig. 19 Valve Guide Specification

Fig. 20 Testing Valve Spring with Tool C-647

9 - 28 2.2/2.5L ENGINE Ä