length CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 201 of 2438

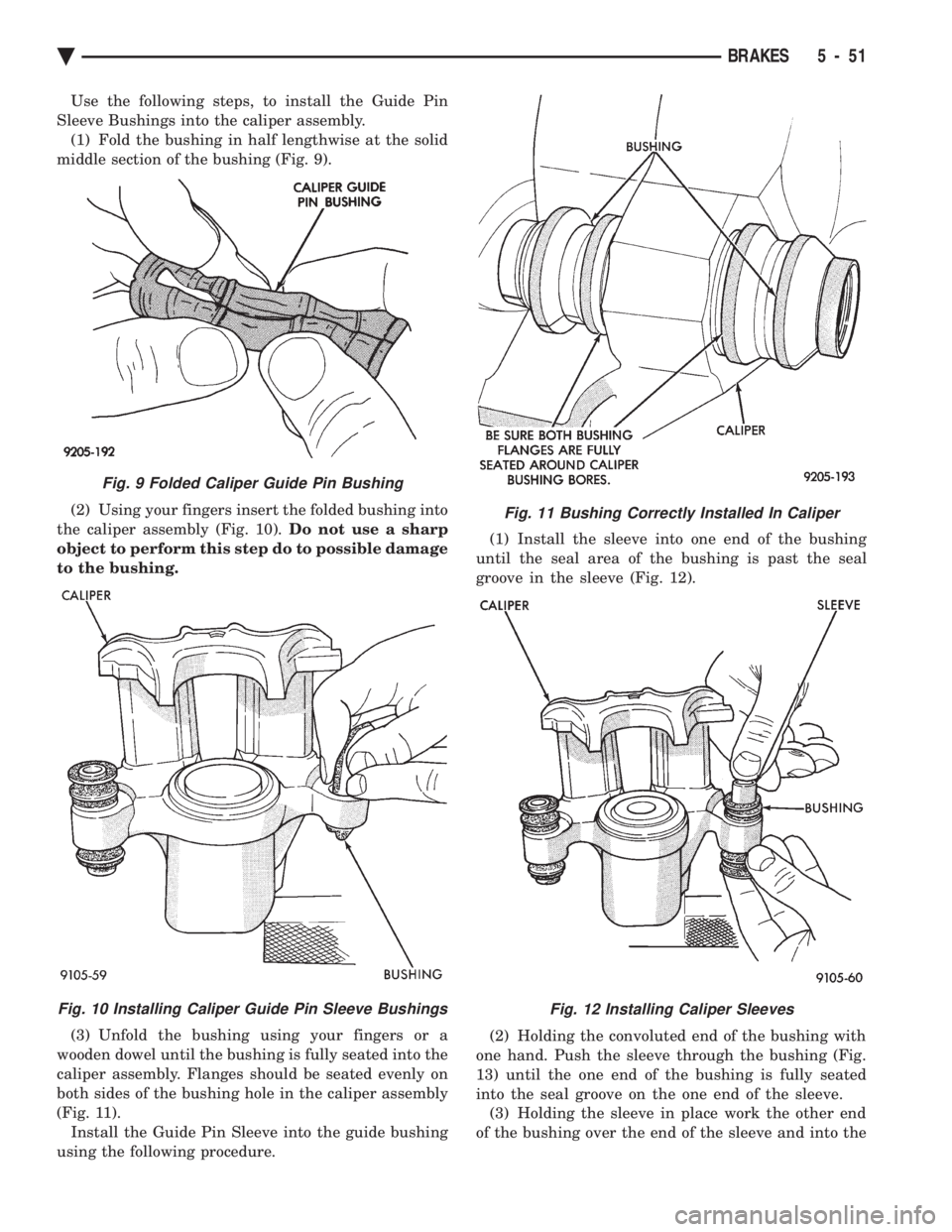

Use the following steps, to install the Guide Pin

Sleeve Bushings into the caliper assembly. (1) Fold the bushing in half lengthwise at the solid

middle section of the bushing (Fig. 9).

(2) Using your fingers insert the folded bushing into

the caliper assembly (Fig. 10). Do not use a sharp

object to perform this step do to possible damage

to the bushing.

(3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated into the

caliper assembly. Flanges should be seated evenly on

both sides of the bushing hole in the caliper assembly

(Fig. 11). Install the Guide Pin Sleeve into the guide bushing

using the following procedure. (1) Install the sleeve into one end of the bushing

until the seal area of the bushing is past the seal

groove in the sleeve (Fig. 12).

(2) Holding the convoluted end of the bushing with

one hand. Push the sleeve through the bushing (Fig.

13) until the one end of the bushing is fully seated

into the seal groove on the one end of the sleeve. (3) Holding the sleeve in place work the other end

of the bushing over the end of the sleeve and into the

Fig. 11 Bushing Correctly Installed In Caliper

Fig. 12 Installing Caliper Sleeves

Fig. 9 Folded Caliper Guide Pin Bushing

Fig. 10 Installing Caliper Guide Pin Sleeve Bushings

Ä BRAKES 5 - 51

Page 213 of 2438

PARKING BRAKE HAND LEVER ASSEMBLY

REMOVAL AND INSTALLATION

REMOVAL (AG AND AJ BODY)

Remove ash receiver or courtesy light from rear of

console. Remove carpet from sides of console. Remove

parking brake trim cover from passenger side of con-

sole (pulls off). Load and lockout parking brake self adjuster (Fig.

6). Disconnect rear cables from equalizer bracket. Remove the 3 hold down nuts and remove hand le-

ver assembly through opening created by removing

console trim cover. Passenger seat might have to be

removed. Also, if metal tab at bottom of console pre-

vents removal of hand brake assembly, bend tab out

of the way. (Bend the tab back to original position af-

terR&Rof hand brake).

INSTALLATION (AG AND AJ BODY)

Install hand lever assembly through side opening

in console and bolt into place. Connect rear parking brake cables to equalizer.

Adjust parking brakes.

Install console trim cover, carpet, passenger seat

and rear ash receiver or courtesy light.

REMOVAL AND INSTALLATION PARKING BRAKE

SHOES

ALL WITH REAR DISK BRAKES

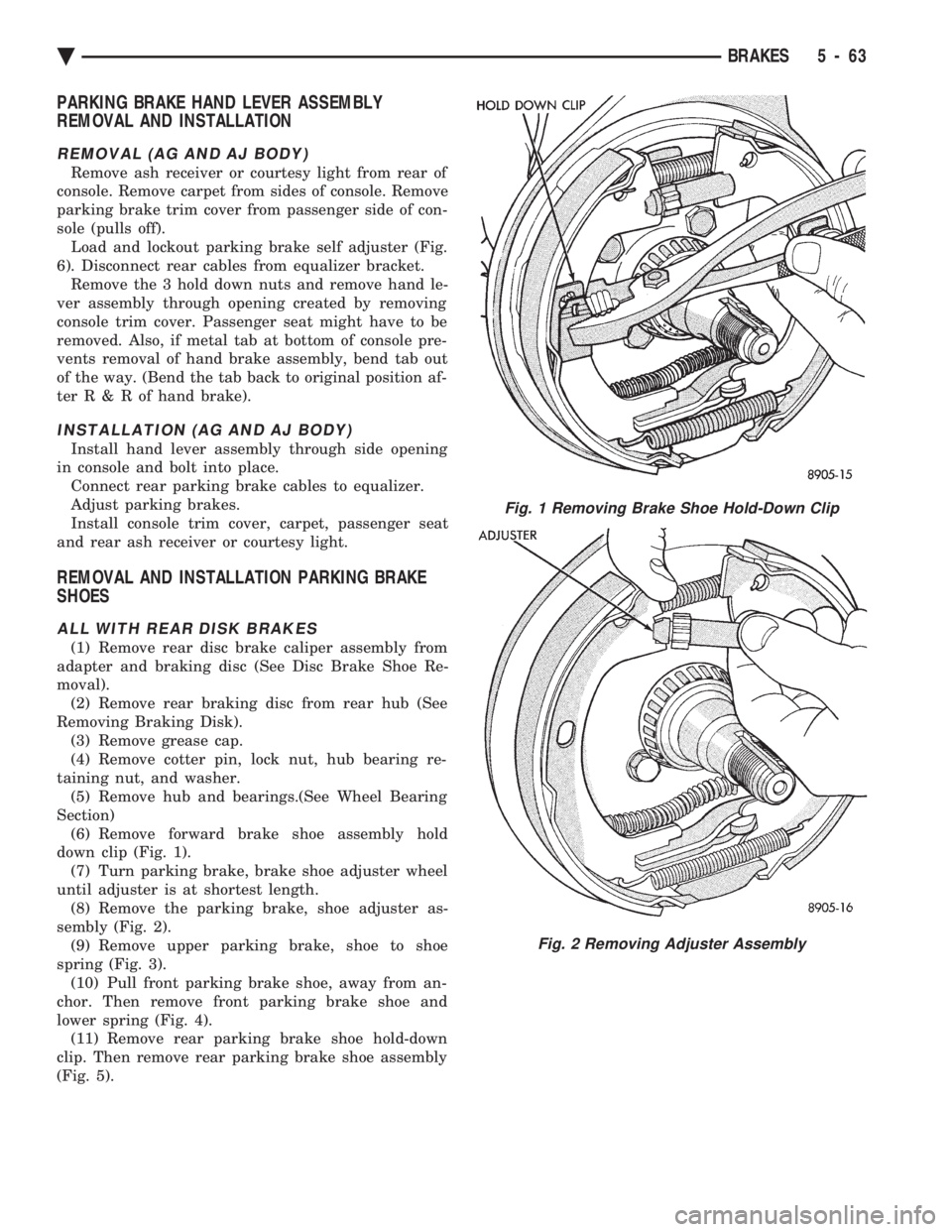

(1) Remove rear disc brake caliper assembly from

adapter and braking disc (See Disc Brake Shoe Re-

moval). (2) Remove rear braking disc from rear hub (See

Removing Braking Disk). (3) Remove grease cap.

(4) Remove cotter pin, lock nut, hub bearing re-

taining nut, and washer. (5) Remove hub and bearings.(See Wheel Bearing

Section) (6) Remove forward brake shoe assembly hold

down clip (Fig. 1). (7) Turn parking brake, brake shoe adjuster wheel

until adjuster is at shortest length. (8) Remove the parking brake, shoe adjuster as-

sembly (Fig. 2). (9) Remove upper parking brake, shoe to shoe

spring (Fig. 3). (10) Pull front parking brake shoe, away from an-

chor. Then remove front parking brake shoe and

lower spring (Fig. 4). (11) Remove rear parking brake shoe hold-down

clip. Then remove rear parking brake shoe assembly

(Fig. 5).

Fig. 1 Removing Brake Shoe Hold-Down Clip

Fig. 2 Removing Adjuster Assembly

Ä BRAKES 5 - 63

Page 344 of 2438

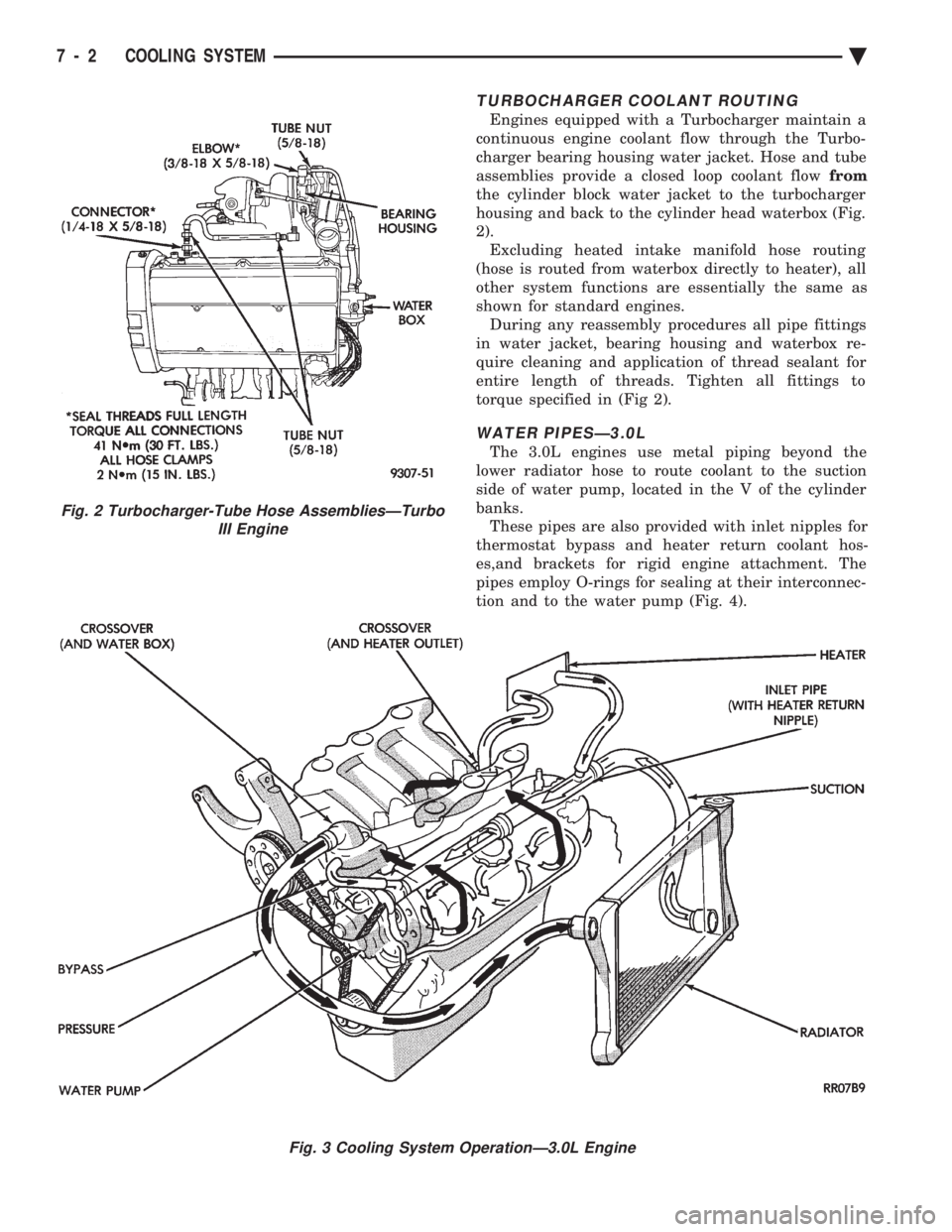

TURBOCHARGER COOLANT ROUTING

Engines equipped with a Turbocharger maintain a

continuous engine coolant flow through the Turbo-

charger bearing housing water jacket. Hose and tube

assemblies provide a closed loop coolant flow from

the cylinder block water jacket to the turbocharger

housing and back to the cylinder head waterbox (Fig.

2). Excluding heated intake manifold hose routing

(hose is routed from waterbox directly to heater), all

other system functions are essentially the same as

shown for standard engines. During any reassembly procedures all pipe fittings

in water jacket, bearing housing and waterbox re-

quire cleaning and application of thread sealant for

entire length of threads. Tighten all fittings to

torque specified in (Fig 2).

WATER PIPESÐ3.0L

The 3.0L engines use metal piping beyond the

lower radiator hose to route coolant to the suction

side of water pump, located in the V of the cylinder

banks. These pipes are also provided with inlet nipples for

thermostat bypass and heater return coolant hos-

es,and brackets for rigid engine attachment. The

pipes employ O-rings for sealing at their interconnec-

tion and to the water pump (Fig. 4).

Fig. 2 Turbocharger-Tube Hose AssembliesÐTurbo III Engine

Fig. 3 Cooling System OperationÐ3.0L Engine

7 - 2 COOLING SYSTEM Ä

Page 420 of 2438

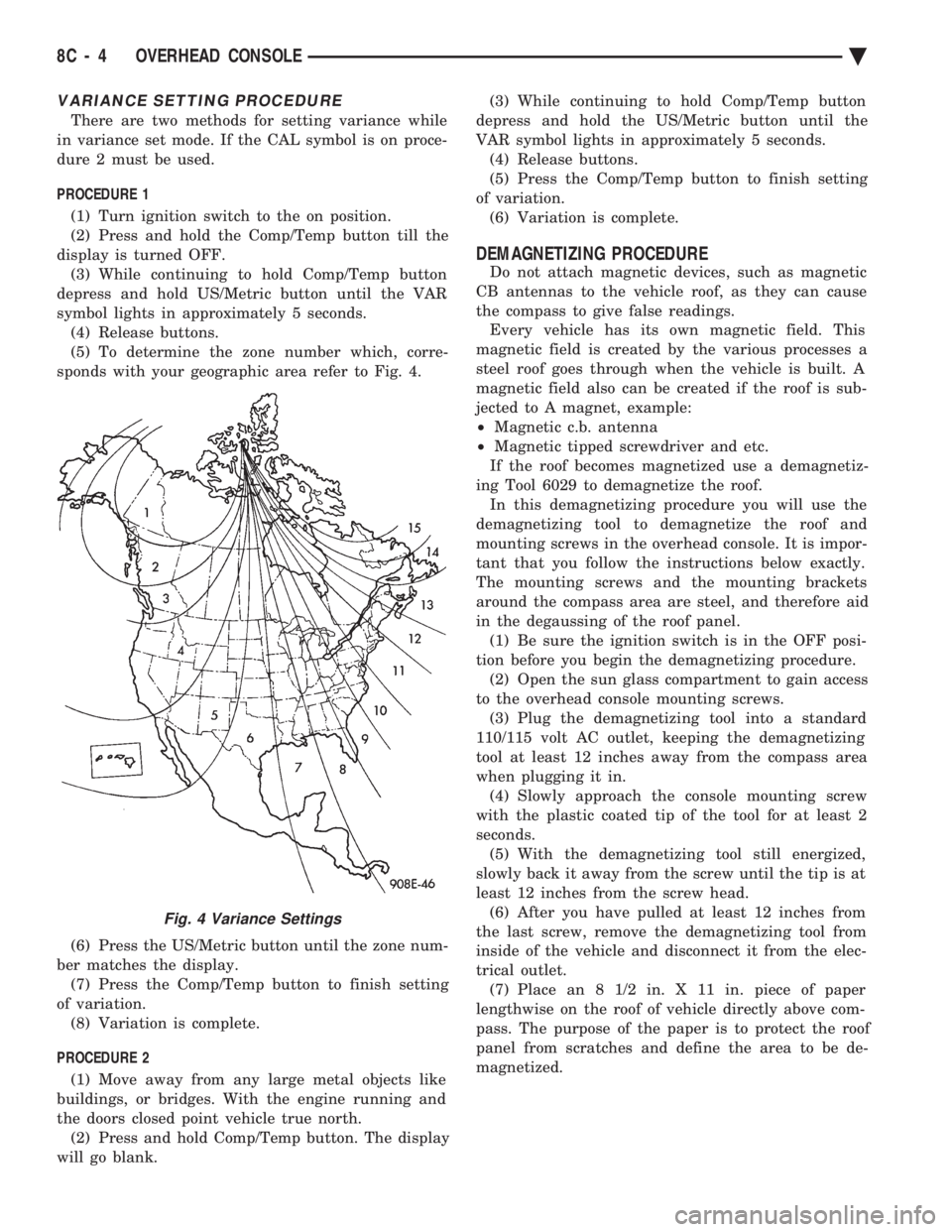

VARIANCE SETTING PROCEDURE

There are two methods for setting variance while

in variance set mode. If the CAL symbol is on proce-

dure 2 must be used.

PROCEDURE 1

(1) Turn ignition switch to the on position.

(2) Press and hold the Comp/Temp button till the

display is turned OFF. (3) While continuing to hold Comp/Temp button

depress and hold US/Metric button until the VAR

symbol lights in approximately 5 seconds. (4) Release buttons.

(5) To determine the zone number which, corre-

sponds with your geographic area refer to Fig. 4.

(6) Press the US/Metric button until the zone num-

ber matches the display. (7) Press the Comp/Temp button to finish setting

of variation. (8) Variation is complete.

PROCEDURE 2 (1) Move away from any large metal objects like

buildings, or bridges. With the engine running and

the doors closed point vehicle true north. (2) Press and hold Comp/Temp button. The display

will go blank. (3) While continuing to hold Comp/Temp button

depress and hold the US/Metric button until the

VAR symbol lights in approximately 5 seconds. (4) Release buttons.

(5) Press the Comp/Temp button to finish setting

of variation. (6) Variation is complete.

DEMAGNETIZING PROCEDURE

Do not attach magnetic devices, such as magnetic

CB antennas to the vehicle roof, as they can cause

the compass to give false readings. Every vehicle has its own magnetic field. This

magnetic field is created by the various processes a

steel roof goes through when the vehicle is built. A

magnetic field also can be created if the roof is sub-

jected to A magnet, example:

² Magnetic c.b. antenna

² Magnetic tipped screwdriver and etc.

If the roof becomes magnetized use a demagnetiz-

ing Tool 6029 to demagnetize the roof. In this demagnetizing procedure you will use the

demagnetizing tool to demagnetize the roof and

mounting screws in the overhead console. It is impor-

tant that you follow the instructions below exactly.

The mounting screws and the mounting brackets

around the compass area are steel, and therefore aid

in the degaussing of the roof panel. (1) Be sure the ignition switch is in the OFF posi-

tion before you begin the demagnetizing procedure. (2) Open the sun glass compartment to gain access

to the overhead console mounting screws. (3) Plug the demagnetizing tool into a standard

110/115 volt AC outlet, keeping the demagnetizing

tool at least 12 inches away from the compass area

when plugging it in. (4) Slowly approach the console mounting screw

with the plastic coated tip of the tool for at least 2

seconds. (5) With the demagnetizing tool still energized,

slowly back it away from the screw until the tip is at

least 12 inches from the screw head. (6) After you have pulled at least 12 inches from

the last screw, remove the demagnetizing tool from

inside of the vehicle and disconnect it from the elec-

trical outlet. (7) Place an 8 1/2 in. X 11 in. piece of paper

lengthwise on the roof of vehicle directly above com-

pass. The purpose of the paper is to protect the roof

panel from scratches and define the area to be de-

magnetized.

Fig. 4 Variance Settings

8C - 4 OVERHEAD CONSOLE Ä

Page 433 of 2438

(4) Drive the vehicle 1 to 3 complete circles. The

CAL light will then go off, showing the compass is

calibrated. If the compass portion of the display:

² It does not display.

² Readings are not accurate after calibration.

² The vehicle may have too much magnetism for the

compass to be accurate.

² The compass circuitry is not working properly.

² Refer to Variance Procedure, Demagnetizing Pro-

cedure and/or Compass Diagnostics.

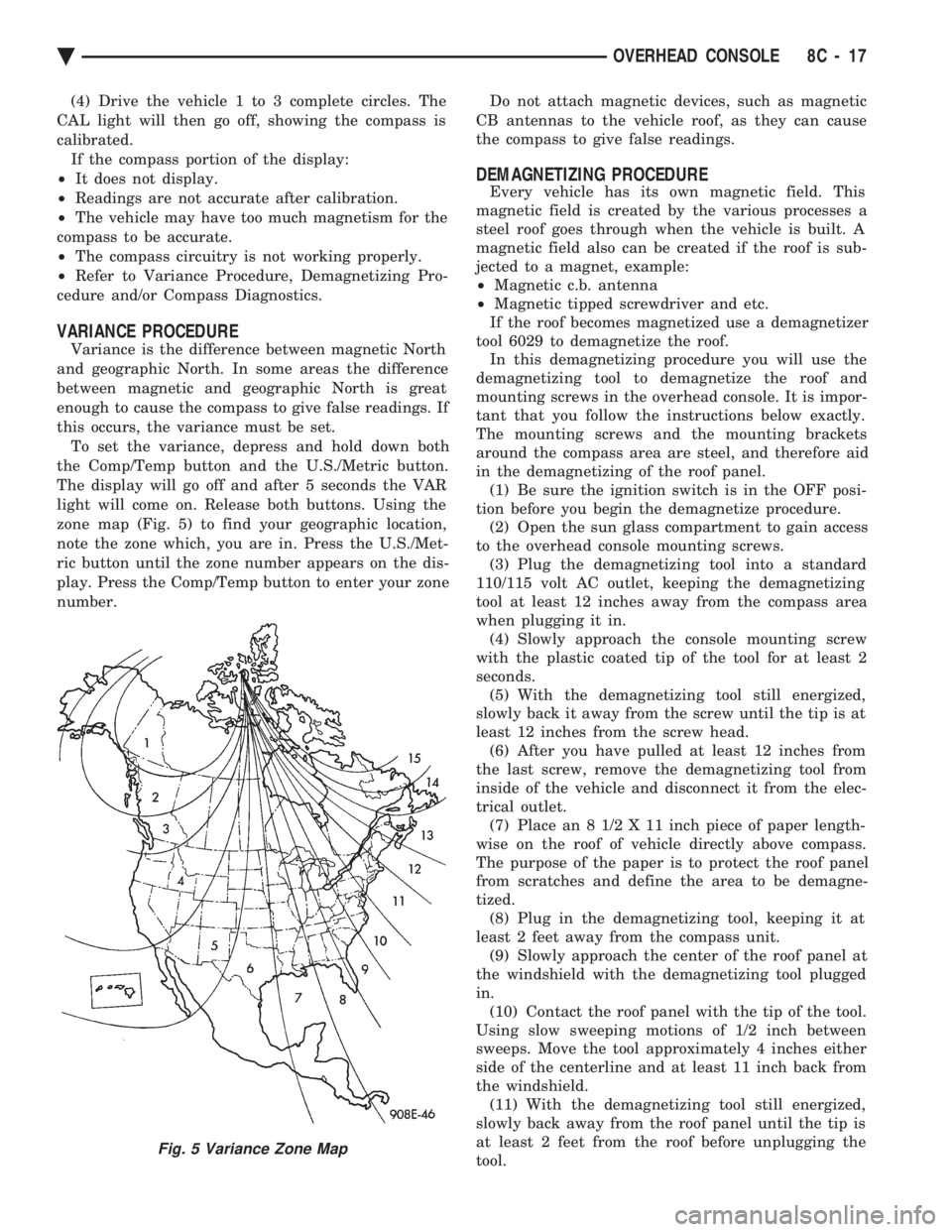

VARIANCE PROCEDURE

Variance is the difference between magnetic North

and geographic North. In some areas the difference

between magnetic and geographic North is great

enough to cause the compass to give false readings. If

this occurs, the variance must be set. To set the variance, depress and hold down both

the Comp/Temp button and the U.S./Metric button.

The display will go off and after 5 seconds the VAR

light will come on. Release both buttons. Using the

zone map (Fig. 5) to find your geographic location,

note the zone which, you are in. Press the U.S./Met-

ric button until the zone number appears on the dis-

play. Press the Comp/Temp button to enter your zone

number. Do not attach magnetic devices, such as magnetic

CB antennas to the vehicle roof, as they can cause

the compass to give false readings.

DEMAGNETIZING PROCEDURE

Every vehicle has its own magnetic field. This

magnetic field is created by the various processes a

steel roof goes through when the vehicle is built. A

magnetic field also can be created if the roof is sub-

jected to a magnet, example:

² Magnetic c.b. antenna

² Magnetic tipped screwdriver and etc.

If the roof becomes magnetized use a demagnetizer

tool 6029 to demagnetize the roof. In this demagnetizing procedure you will use the

demagnetizing tool to demagnetize the roof and

mounting screws in the overhead console. It is impor-

tant that you follow the instructions below exactly.

The mounting screws and the mounting brackets

around the compass area are steel, and therefore aid

in the demagnetizing of the roof panel. (1) Be sure the ignition switch is in the OFF posi-

tion before you begin the demagnetize procedure. (2) Open the sun glass compartment to gain access

to the overhead console mounting screws. (3) Plug the demagnetizing tool into a standard

110/115 volt AC outlet, keeping the demagnetizing

tool at least 12 inches away from the compass area

when plugging it in. (4) Slowly approach the console mounting screw

with the plastic coated tip of the tool for at least 2

seconds. (5) With the demagnetizing tool still energized,

slowly back it away from the screw until the tip is at

least 12 inches from the screw head. (6) After you have pulled at least 12 inches from

the last screw, remove the demagnetizing tool from

inside of the vehicle and disconnect it from the elec-

trical outlet. (7) Place an 8 1/2 X 11 inch piece of paper length-

wise on the roof of vehicle directly above compass.

The purpose of the paper is to protect the roof panel

from scratches and define the area to be demagne-

tized. (8) Plug in the demagnetizing tool, keeping it at

least 2 feet away from the compass unit. (9) Slowly approach the center of the roof panel at

the windshield with the demagnetizing tool plugged

in. (10) Contact the roof panel with the tip of the tool.

Using slow sweeping motions of 1/2 inch between

sweeps. Move the tool approximately 4 inches either

side of the centerline and at least 11 inch back from

the windshield. (11) With the demagnetizing tool still energized,

slowly back away from the roof panel until the tip is

at least 2 feet from the roof before unplugging the

tool.

Fig. 5 Variance Zone Map

Ä OVERHEAD CONSOLE 8C - 17

Page 436 of 2438

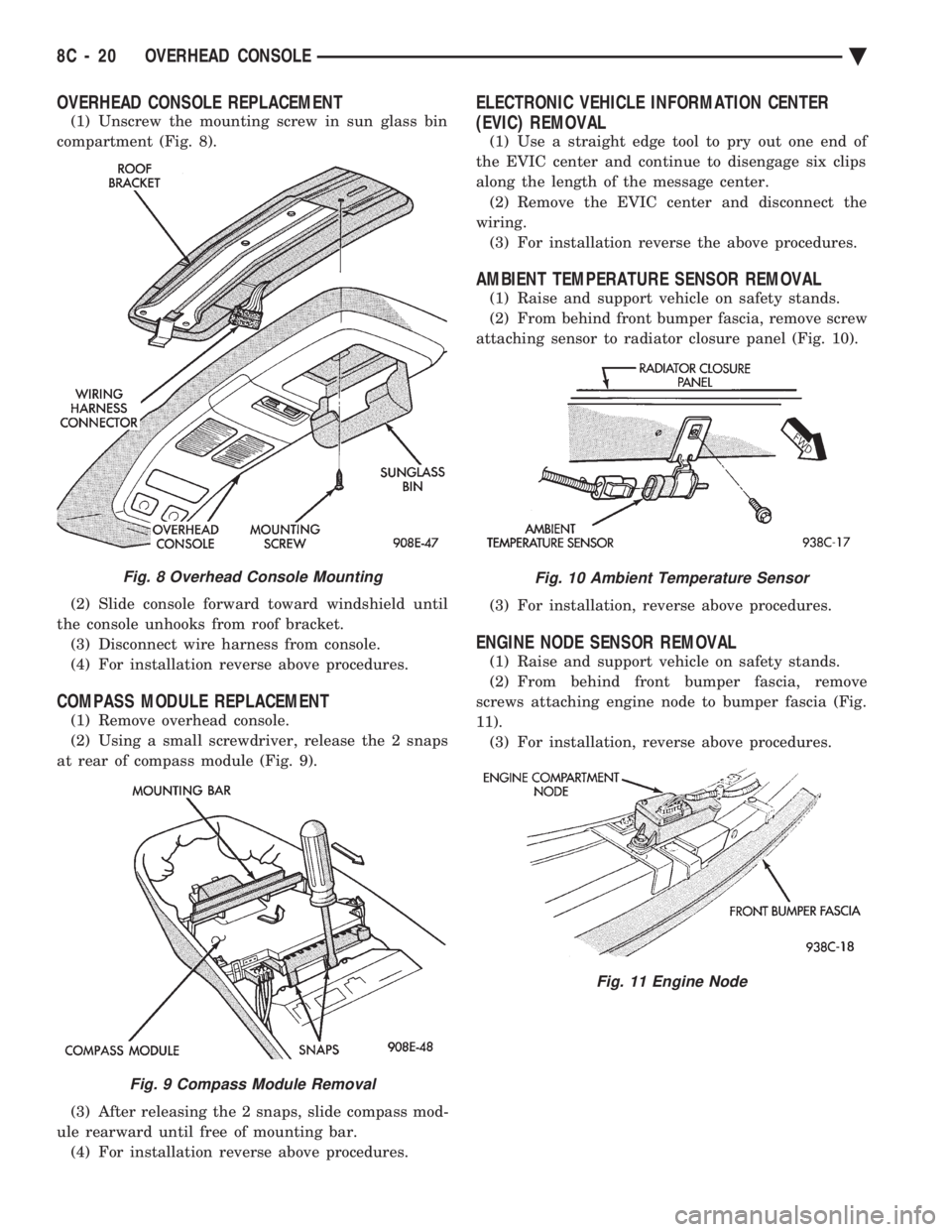

OVERHEAD CONSOLE REPLACEMENT

(1) Unscrew the mounting screw in sun glass bin

compartment (Fig. 8).

(2) Slide console forward toward windshield until

the console unhooks from roof bracket. (3) Disconnect wire harness from console.

(4) For installation reverse above procedures.

COMPASS MODULE REPLACEMENT

(1) Remove overhead console.

(2) Using a small screwdriver, release the 2 snaps

at rear of compass module (Fig. 9).

(3) After releasing the 2 snaps, slide compass mod-

ule rearward until free of mounting bar. (4) For installation reverse above procedures.

ELECTRONIC VEHICLE INFORMATION CENTER

(EVIC) REMOVAL

(1) Use a straight edge tool to pry out one end of

the EVIC center and continue to disengage six clips

along the length of the message center. (2) Remove the EVIC center and disconnect the

wiring. (3) For installation reverse the above procedures.

AMBIENT TEMPERATURE SENSOR REMOVAL

(1) Raise and support vehicle on safety stands.

(2) From behind front bumper fascia, remove screw

attaching sensor to radiator closure panel (Fig. 10).

(3) For installation, reverse above procedures.

ENGINE NODE SENSOR REMOVAL

(1) Raise and support vehicle on safety stands.

(2) From behind front bumper fascia, remove

screws attaching engine node to bumper fascia (Fig.

11). (3) For installation, reverse above procedures.

Fig. 8 Overhead Console Mounting

Fig. 9 Compass Module Removal

Fig. 10 Ambient Temperature Sensor

Fig. 11 Engine Node

8C - 20 OVERHEAD CONSOLE Ä

Page 439 of 2438

(3) Plug the demagnetizing tool into a standard

110/115 volt AC outlet, keeping the demagnetizing

tool at least 12 inches away from the compass area

when plugging it in. (4) Slowly approach the console mounting screw

with the plastic coated tip of the tool for at least 2

seconds. (5) With the demagnetizing tool still energized,

slowly back it away from the screw until the tip is at

least 12 inches from the screw head. (6) After you have pulled at least 12 inches from

the last screw, remove the demagnetizer tool from in-

side of the vehicle and disconnect it from the electri-

cal outlet. (7) Place an 8 1/2 X 11 inch piece of paper length-

wise on the roof of vehicle directly above compass.

The purpose of the paper is to protect the roof panel

from scratches and define the area to be demagne-

tized. (8) Plug in the demagnetizing tool, keeping it at

least 2 feet away from the compass unit. (9) Slowly approach the center of the roof panel at

the windshield with the demagnetizing tool plugged

in. (10) Contact the roof panel with the tip of the tool

and using slow sweeping motions of 1/2 inch between sweeps. Move the tool approximately 4 inches either

side of the centerline and at least 11 inches back

from the windshield. (11) With the demagnetizing tool still energized,

slowly back away from the roof panel until the tip is

at least 2 feet from the roof before unplugging the

tool. (12) Recalibrate compass.

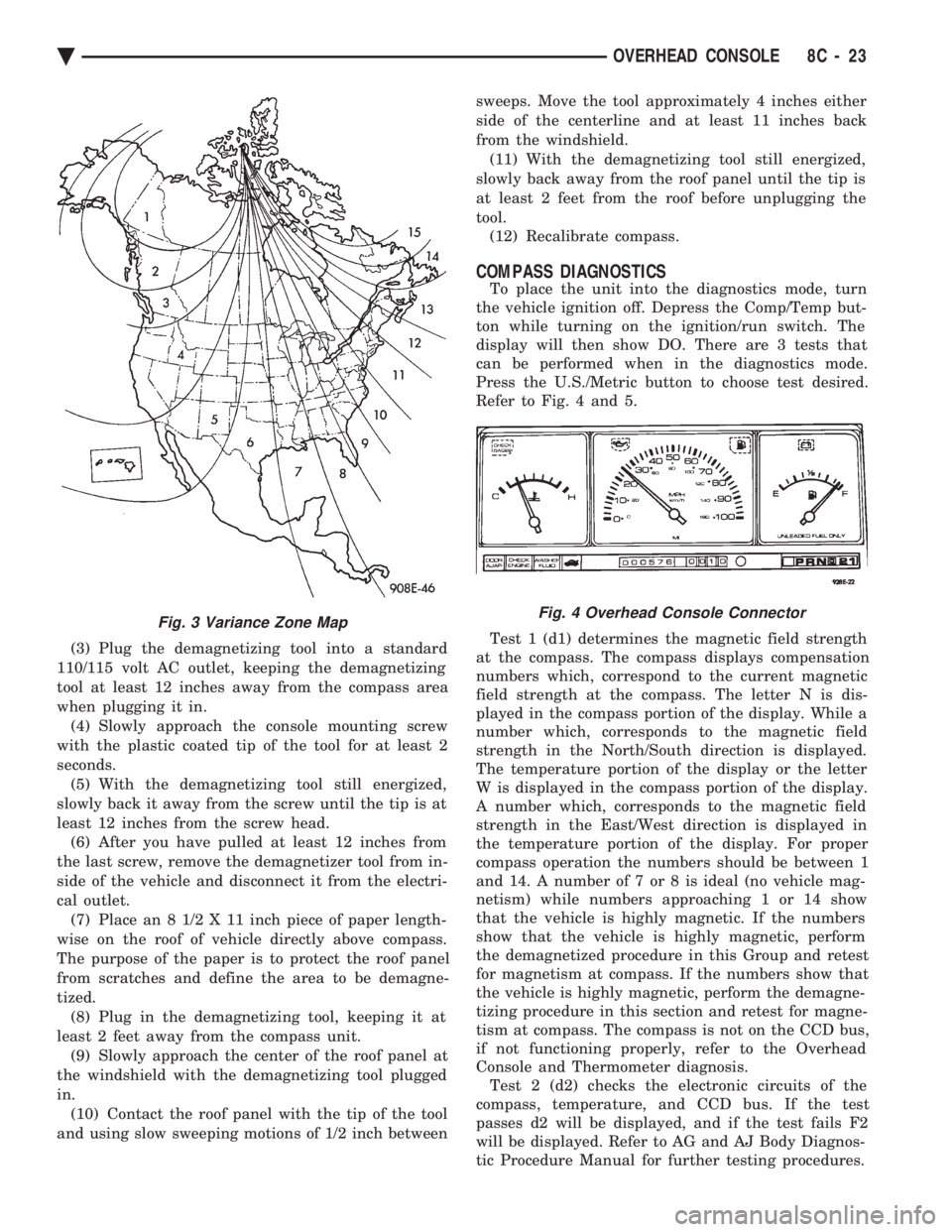

COMPASS DIAGNOSTICS

To place the unit into the diagnostics mode, turn

the vehicle ignition off. Depress the Comp/Temp but-

ton while turning on the ignition/run switch. The

display will then show DO. There are 3 tests that

can be performed when in the diagnostics mode.

Press the U.S./Metric button to choose test desired.

Refer to Fig. 4 and 5.

Test 1 (d1) determines the magnetic field strength

at the compass. The compass displays compensation

numbers which, correspond to the current magnetic

field strength at the compass. The letter N is dis-

played in the compass portion of the display. While a

number which, corresponds to the magnetic field

strength in the North/South direction is displayed.

The temperature portion of the display or the letter

W is displayed in the compass portion of the display.

A number which, corresponds to the magnetic field

strength in the East/West direction is displayed in

the temperature portion of the display. For proper

compass operation the numbers should be between 1

and 14. A number of 7 or 8 is ideal (no vehicle mag-

netism) while numbers approaching 1 or 14 show

that the vehicle is highly magnetic. If the numbers

show that the vehicle is highly magnetic, perform

the demagnetized procedure in this Group and retest

for magnetism at compass. If the numbers show that

the vehicle is highly magnetic, perform the demagne-

tizing procedure in this section and retest for magne-

tism at compass. The compass is not on the CCD bus,

if not functioning properly, refer to the Overhead

Console and Thermometer diagnosis. Test 2 (d2) checks the electronic circuits of the

compass, temperature, and CCD bus. If the test

passes d2 will be displayed, and if the test fails F2

will be displayed. Refer to AG and AJ Body Diagnos-

tic Procedure Manual for further testing procedures.

Fig. 3 Variance Zone MapFig. 4 Overhead Console Connector

Ä OVERHEAD CONSOLE 8C - 23

Page 445 of 2438

When testing secondary cables for punctures and

cracks with an oscilloscope follow the equipment

manufacturers instructions. If an oscilloscope is not available, secondary cables

can be tested as follows:

CAUTION: Do not leave any one spark plug cable

disconnected any longer than necessary during test-

ing. Excessive heat could damage the catalytic con-

verter. Total test time must not exceed ten minutes.

(a) With the engine not running, connect one end

of a test probe to a good ground. Use a probe made of

insulated wire with insulated alligator clips on each

end. (b) With engine running, move test probe along

entire length of all cables (approximately 0 to 1/8

inch gap). If punctures or cracks are present there

will be a noticeable spark jump from the faulty area

to the probe. Check the coil cable the same way.

Replace cracked, leaking or faulty cables.

When replacing cables, install the new high

tension cable and nipple assembly over cap or

coil tower. When entering the terminal into the

tower, push lightly, then pinch the large diam-

eter of nipple to release air trapped between the

nipple and tower. Continue pushing on the cable

and nipple until cables are properly seated in the

cap towers. A snap should be heard as terminal

goes into place. Use the same procedure to install cable in coil tower.

Wipe the spark plug insulator clean before reinstalling

cable and cover. Use the following procedure when removing the high

tension cable from the spark plug. First, remove the

cable from the retaining bracket. Then grasp the ter-

minal as close as possible to the spark plug. Rotate the

cover and pull the cable straight back. Pulling on the

cable itself will damage the conductor and termi-

nal connection. Do not use pliers and do not pull

the cable at an angle. Doing so will damage the

insulation, cable terminal or the spark plug in-

sulator. Wipe spark plug insulator clean before

reinstalling cable and cover. Resistance type cable is identified by the words

Electronic Suppression printed on the cable jacket.

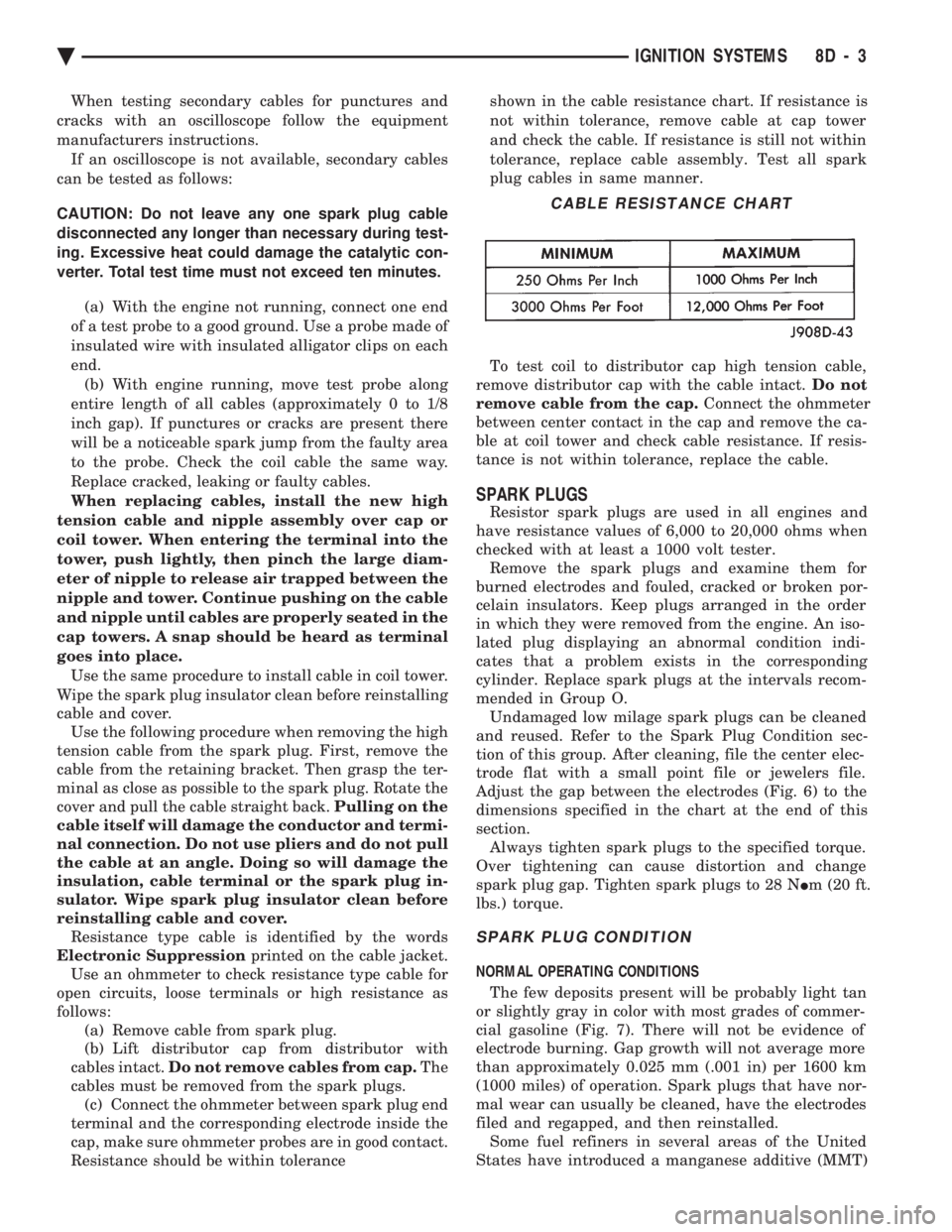

Use an ohmmeter to check resistance type cable for

open circuits, loose terminals or high resistance as

follows: (a) Remove cable from spark plug.

(b) Lift distributor cap from distributor with

cables intact. Do not remove cables from cap. The

cables must be removed from the spark plugs. (c) Connect the ohmmeter between spark plug end

terminal and the corresponding electrode inside the

cap, make sure ohmmeter probes are in good contact.

Resistance should be within tolerance shown in the cable resistance chart. If resistance is

not within tolerance, remove cable at cap tower

and check the cable. If resistance is still not within

tolerance, replace cable assembly. Test all spark

plug cables in same manner.

To test coil to distributor cap high tension cable,

remove distributor cap with the cable intact. Do not

remove cable from the cap. Connect the ohmmeter

between center contact in the cap and remove the ca-

ble at coil tower and check cable resistance. If resis-

tance is not within tolerance, replace the cable.

SPARK PLUGS

Resistor spark plugs are used in all engines and

have resistance values of 6,000 to 20,000 ohms when

checked with at least a 1000 volt tester. Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

mended in Group O. Undamaged low milage spark plugs can be cleaned

and reused. Refer to the Spark Plug Condition sec-

tion of this group. After cleaning, file the center elec-

trode flat with a small point file or jewelers file.

Adjust the gap between the electrodes (Fig. 6) to the

dimensions specified in the chart at the end of this

section. Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and change

spark plug gap. Tighten spark plugs to 28 N Im (20 ft.

lbs.) torque.

SPARK PLUG CONDITION

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 7). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation. Spark plugs that have nor-

mal wear can usually be cleaned, have the electrodes

filed and regapped, and then reinstalled. Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

CABLE RESISTANCE CHART

Ä IGNITION SYSTEMS 8D - 3

Page 447 of 2438

(Fig. 9). This short circuits the electrodes. Spark

plugs with electrode gap bridging can be cleaned us-

ing standard procedures.

SCAVENGER DEPOSITS Fuel scavenger deposits may be either white or yel-

low (Fig. 10). They may appear to be harmful, but

are a normal condition caused by chemical additives

in certain fuels. These additives are designed to

change the chemical nature of deposits and decrease

spark plug misfire tendencies. Accumulation on the

ground electrode and shell area may be heavy but

the deposits are easily removed. Spark plugs with

scavenger deposits can be considered normal in con-

dition and be cleaned using standard procedures.

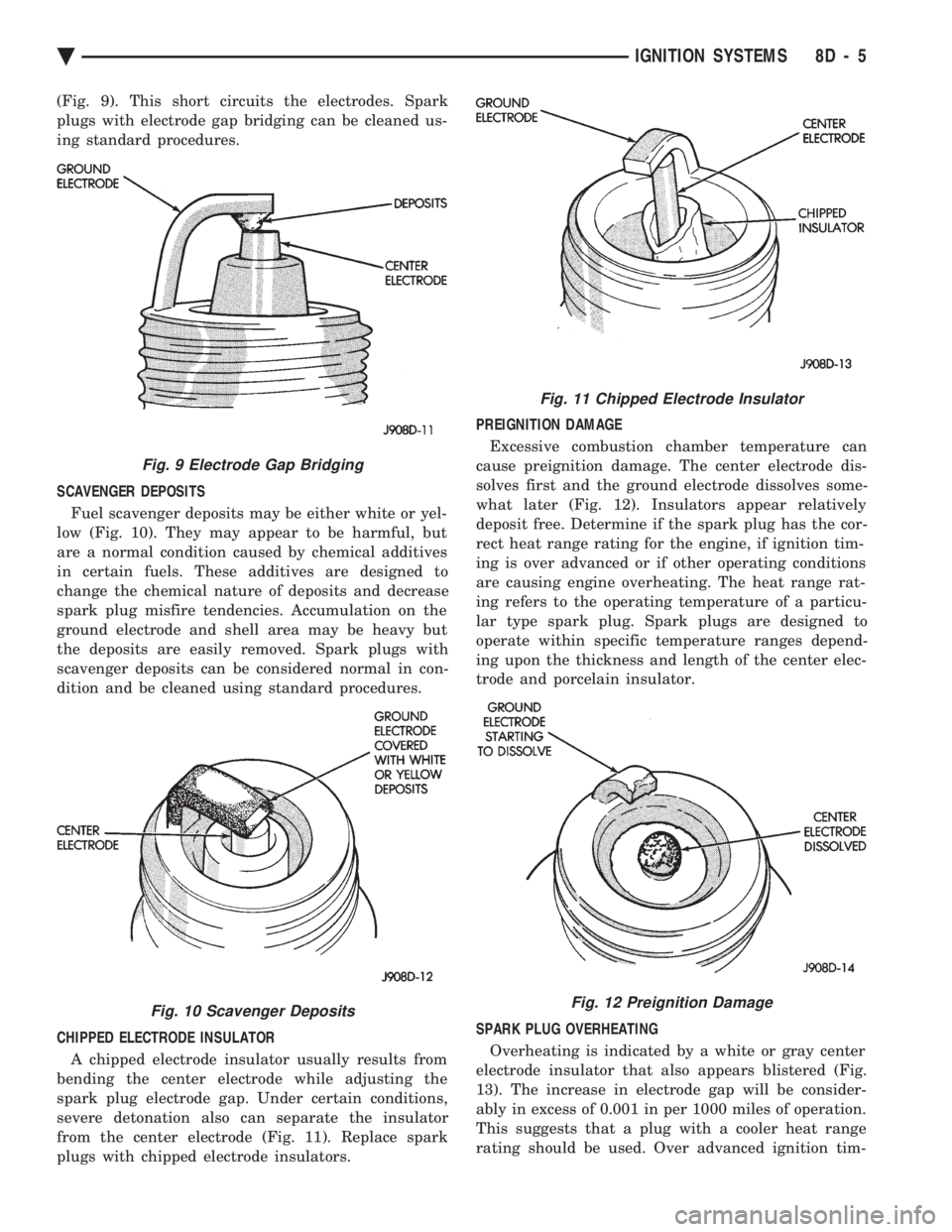

CHIPPED ELECTRODE INSULATOR A chipped electrode insulator usually results from

bending the center electrode while adjusting the

spark plug electrode gap. Under certain conditions,

severe detonation also can separate the insulator

from the center electrode (Fig. 11). Replace spark

plugs with chipped electrode insulators. PREIGNITION DAMAGE

Excessive combustion chamber temperature can

cause preignition damage. The center electrode dis-

solves first and the ground electrode dissolves some-

what later (Fig. 12). Insulators appear relatively

deposit free. Determine if the spark plug has the cor-

rect heat range rating for the engine, if ignition tim-

ing is over advanced or if other operating conditions

are causing engine overheating. The heat range rat-

ing refers to the operating temperature of a particu-

lar type spark plug. Spark plugs are designed to

operate within specific temperature ranges depend-

ing upon the thickness and length of the center elec-

trode and porcelain insulator.

SPARK PLUG OVERHEATING Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

13). The increase in electrode gap will be consider-

ably in excess of 0.001 in per 1000 miles of operation.

This suggests that a plug with a cooler heat range

rating should be used. Over advanced ignition tim-

Fig. 9 Electrode Gap Bridging

Fig. 10 Scavenger Deposits

Fig. 11 Chipped Electrode Insulator

Fig. 12 Preignition Damage

Ä IGNITION SYSTEMS 8D - 5

Page 470 of 2438

SCAVENGER DEPOSITS Fuel scavenger deposits may be either white or yel-

low (Fig. 12). They may appear to be harmful, but

are a normal condition caused by chemical additives

in certain fuels. These additives are designed to

change the chemical nature of deposits and decrease

spark plug misfire tendencies. Accumulation on the

ground electrode and shell area may be heavy but

the deposits are easily removed. Spark plugs with

scavenger deposits can be considered normal in con-

dition and be cleaned using standard procedures.

CHIPPED ELECTRODE INSULATOR A chipped electrode insulator usually results from

bending the center electrode while adjusting the

spark plug electrode gap. Under certain conditions,

severe detonation also can separate the insulator

from the center electrode (Fig. 13). Spark plugs with

chipped electrode insulators must be replaced.

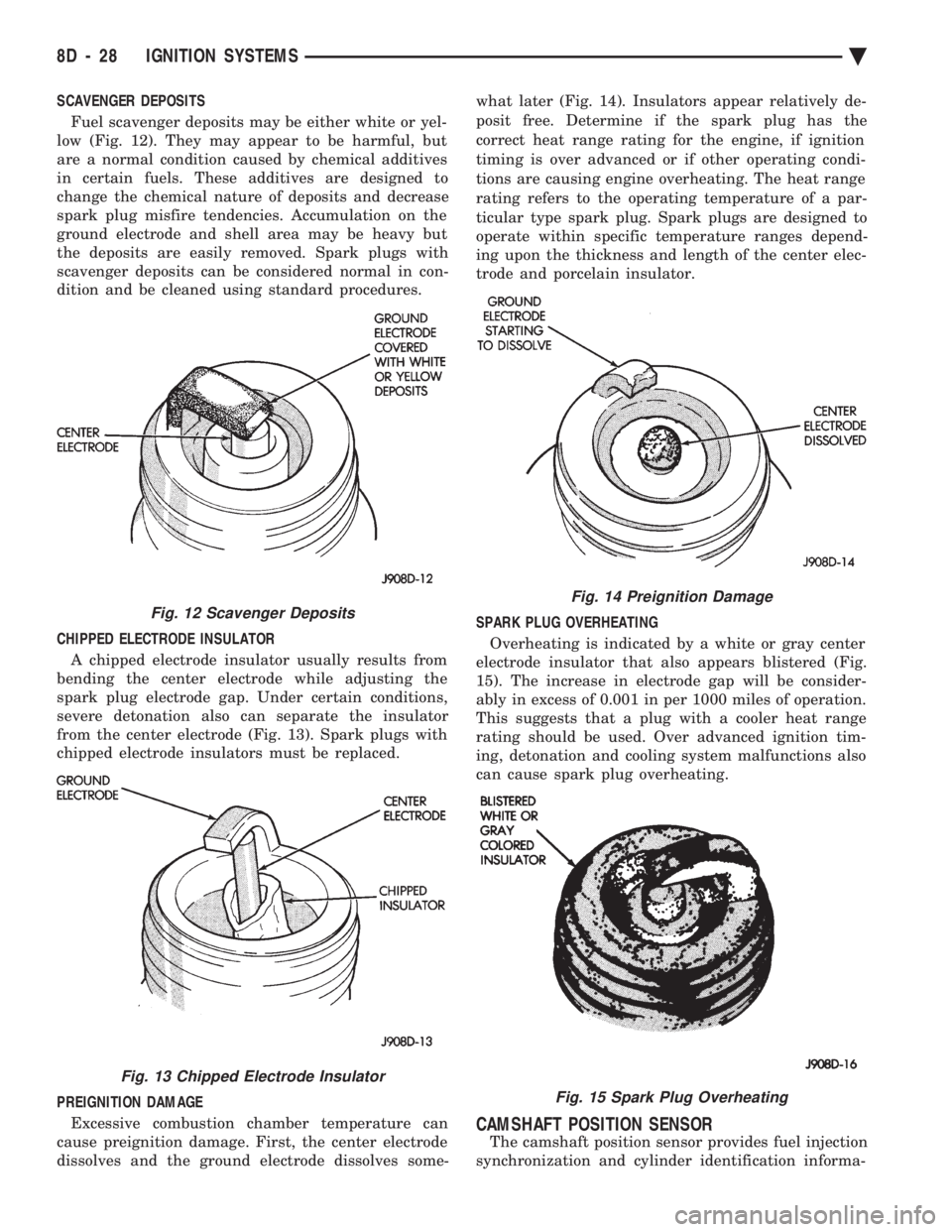

PREIGNITION DAMAGE

Excessive combustion chamber temperature can

cause preignition damage. First, the center electrode

dissolves and the ground electrode dissolves some- what later (Fig. 14). Insulators appear relatively de-

posit free. Determine if the spark plug has the

correct heat range rating for the engine, if ignition

timing is over advanced or if other operating condi-

tions are causing engine overheating. The heat range

rating refers to the operating temperature of a par-

ticular type spark plug. Spark plugs are designed to

operate within specific temperature ranges depend-

ing upon the thickness and length of the center elec-

trode and porcelain insulator.

SPARK PLUG OVERHEATING

Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

15). The increase in electrode gap will be consider-

ably in excess of 0.001 in per 1000 miles of operation.

This suggests that a plug with a cooler heat range

rating should be used. Over advanced ignition tim-

ing, detonation and cooling system malfunctions also

can cause spark plug overheating.

CAMSHAFT POSITION SENSOR

The camshaft position sensor provides fuel injection

synchronization and cylinder identification informa-

Fig. 12 Scavenger Deposits

Fig. 13 Chipped Electrode Insulator

Fig. 14 Preignition Damage

Fig. 15 Spark Plug Overheating

8D - 28 IGNITION SYSTEMS Ä