power steering CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 535 of 2438

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position. When the ignition switch is in the ON or OFF po-

sition, or when the radio frequency is being dis-

played, time keeping is accurately maintained. The procedure for setting the clock varies slightly

with each radio. The correct procedure is described

under the individual radio operating instructions re-

ferred to in the Owner's manual supplied with the

vehicle.

WARNING LAMPS

The AG & AJ Body instrument clusters have warn-

ing lamps or indicators with the electronic cluster for

six different systems. These include low oil pressure,

check gauges, brake system, air bag, seat belt, mal-

function indicator (check engine) lamp.

CLUSTER AND GAUGE SERVICE AND TESTING

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel. When power is required for test purposes,

reconnect battery cable for test only. Disconnect negative battery cable after test and be-

fore continuing service procedures. It is not necessary to remove instrument cluster

from vehicle for gauge replacement. Gauges must be pulled straight out, when remov-

ing or pins may be damaged.

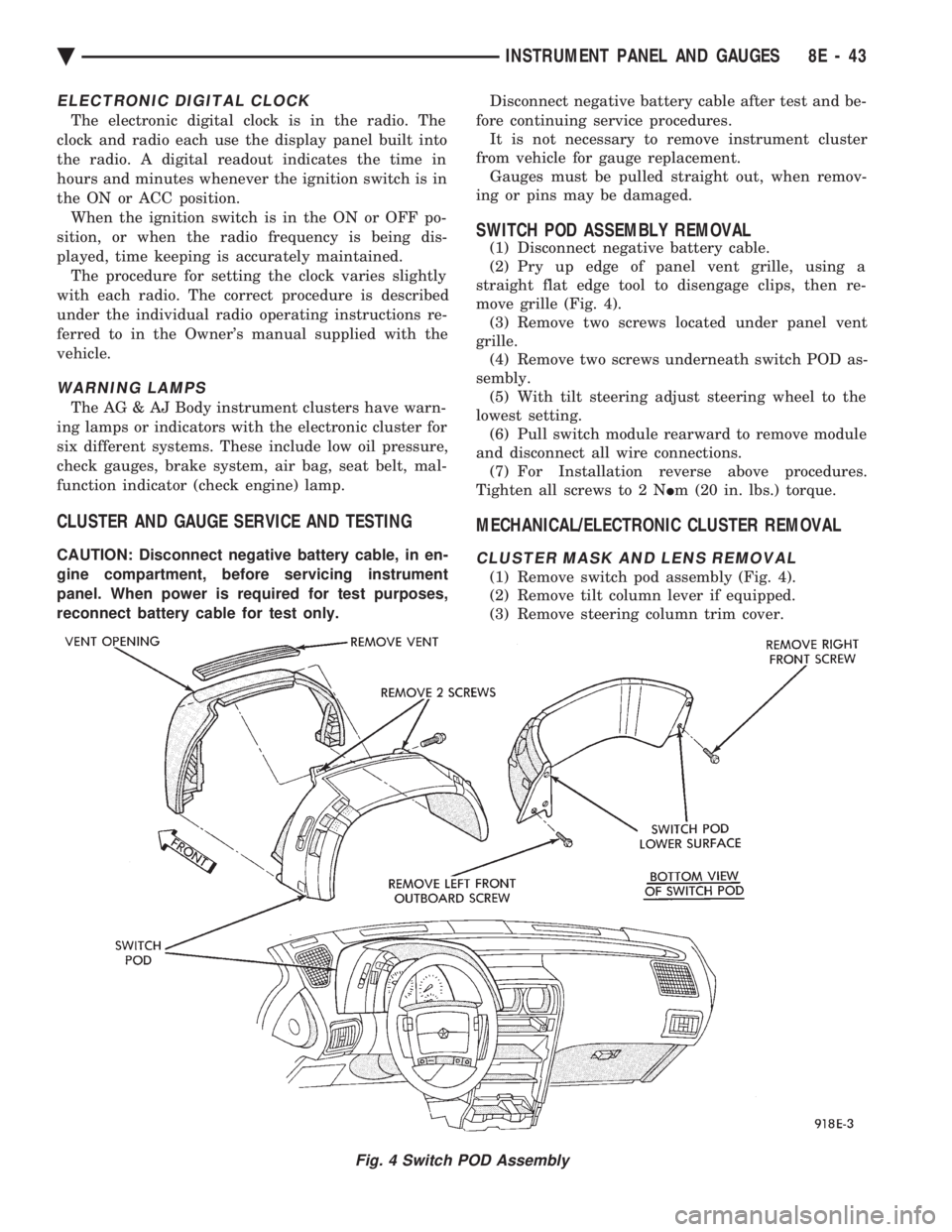

SWITCH POD ASSEMBLY REMOVAL

(1) Disconnect negative battery cable.

(2) Pry up edge of panel vent grille, using a

straight flat edge tool to disengage clips, then re-

move grille (Fig. 4). (3) Remove two screws located under panel vent

grille. (4) Remove two screws underneath switch POD as-

sembly. (5) With tilt steering adjust steering wheel to the

lowest setting. (6) Pull switch module rearward to remove module

and disconnect all wire connections. (7) For Installation reverse above procedures.

Tighten all screws to 2 N Im (20 in. lbs.) torque.

MECHANICAL/ELECTRONIC CLUSTER REMOVAL

CLUSTER MASK AND LENS REMOVAL

(1) Remove switch pod assembly (Fig. 4).

(2) Remove tilt column lever if equipped.

(3) Remove steering column trim cover.

Fig. 4 Switch POD Assembly

Ä INSTRUMENT PANEL AND GAUGES 8E - 43

Page 538 of 2438

(f) If there is a difference in readings, check

printed circuit board for contact to cluster connec-

tors. (g) If OK and contacts are not distorted, replace

printed circuit board. (h) If everything checks out OK, refer to Sending

Unit Test.

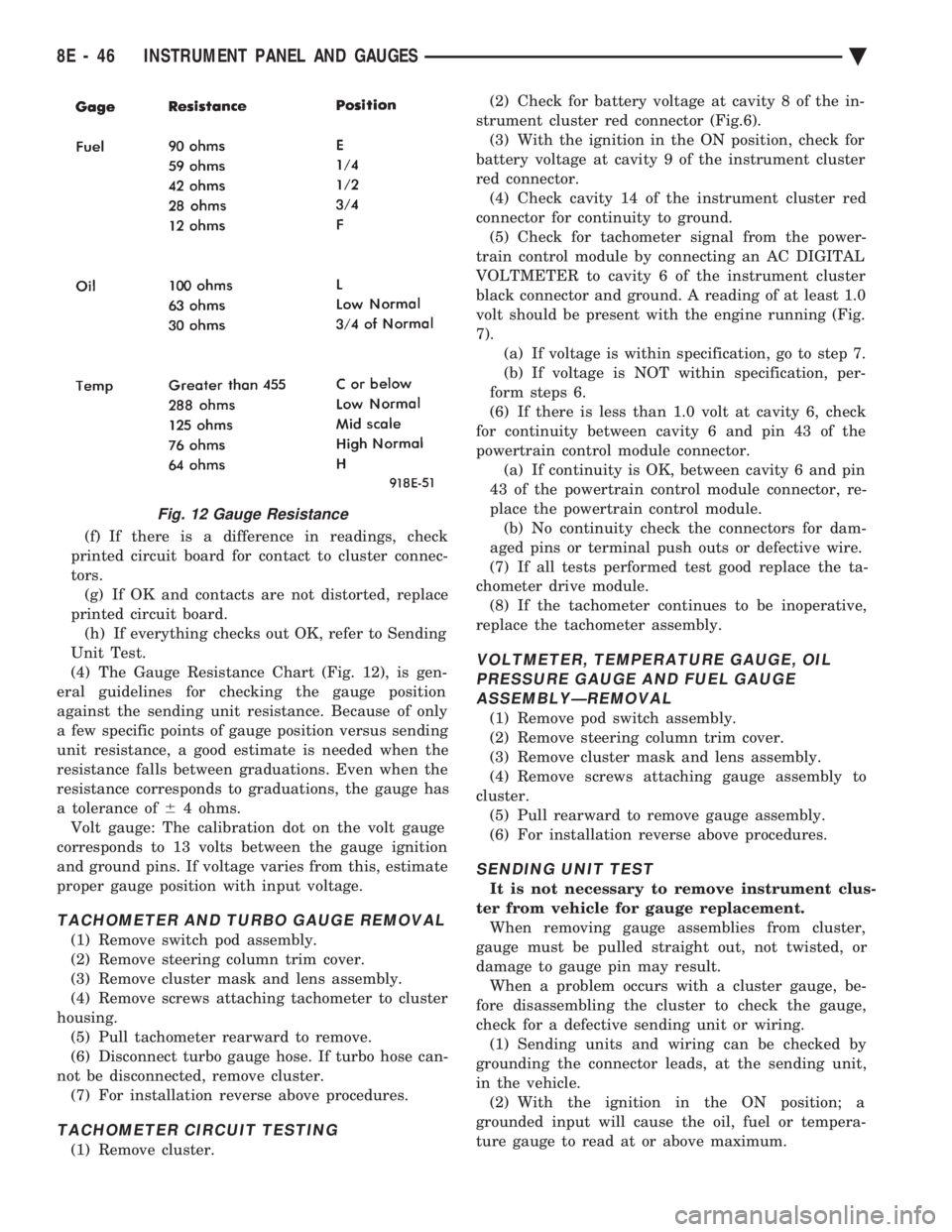

(4) The Gauge Resistance Chart (Fig. 12), is gen-

eral guidelines for checking the gauge position

against the sending unit resistance. Because of only

a few specific points of gauge position versus sending

unit resistance, a good estimate is needed when the

resistance falls between graduations. Even when the

resistance corresponds to graduations, the gauge has

a tolerance of 64 ohms.

Volt gauge: The calibration dot on the volt gauge

corresponds to 13 volts between the gauge ignition

and ground pins. If voltage varies from this, estimate

proper gauge position with input voltage.

TACHOMETER AND TURBO GAUGE REMOVAL

(1) Remove switch pod assembly.

(2) Remove steering column trim cover.

(3) Remove cluster mask and lens assembly.

(4) Remove screws attaching tachometer to cluster

housing. (5) Pull tachometer rearward to remove.

(6) Disconnect turbo gauge hose. If turbo hose can-

not be disconnected, remove cluster. (7) For installation reverse above procedures.

TACHOMETER CIRCUIT TESTING

(1) Remove cluster. (2) Check for battery voltage at cavity 8 of the in-

strument cluster red connector (Fig.6). (3) With the ignition in the ON position, check for

battery voltage at cavity 9 of the instrument cluster

red connector. (4) Check cavity 14 of the instrument cluster red

connector for continuity to ground. (5) Check for tachometer signal from the power-

train control module by connecting an AC DIGITAL

VOLTMETER to cavity 6 of the instrument cluster

black connector and ground. A reading of at least 1.0

volt should be present with the engine running (Fig.

7). (a) If voltage is within specification, go to step 7.

(b) If voltage is NOT within specification, per-

form steps 6.

(6) If there is less than 1.0 volt at cavity 6, check

for continuity between cavity 6 and pin 43 of the

powertrain control module connector. (a) If continuity is OK, between cavity 6 and pin

43 of the powertrain control module connector, re-

place the powertrain control module. (b) No continuity check the connectors for dam-

aged pins or terminal push outs or defective wire.

(7) If all tests performed test good replace the ta-

chometer drive module. (8) If the tachometer continues to be inoperative,

replace the tachometer assembly.

VOLTMETER, TEMPERATURE GAUGE, OIL PRESSURE GAUGE AND FUEL GAUGEASSEMBLYÐREMOVAL

(1) Remove pod switch assembly.

(2) Remove steering column trim cover.

(3) Remove cluster mask and lens assembly.

(4) Remove screws attaching gauge assembly to

cluster. (5) Pull rearward to remove gauge assembly.

(6) For installation reverse above procedures.

SENDING UNIT TEST

It is not necessary to remove instrument clus-

ter from vehicle for gauge replacement. When removing gauge assemblies from cluster,

gauge must be pulled straight out, not twisted, or

damage to gauge pin may result. When a problem occurs with a cluster gauge, be-

fore disassembling the cluster to check the gauge,

check for a defective sending unit or wiring. (1) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (2) With the ignition in the ON position; a

grounded input will cause the oil, fuel or tempera-

ture gauge to read at or above maximum.

Fig. 12 Gauge Resistance

8E - 46 INSTRUMENT PANEL AND GAUGES Ä

Page 559 of 2438

VEHICLE SPEED SENSOR TEST

For testing of the vehicle speed sensor and related

components using DRB II, refer to the appropriate

Powertrain Diagnostics Test Procedure Manual.

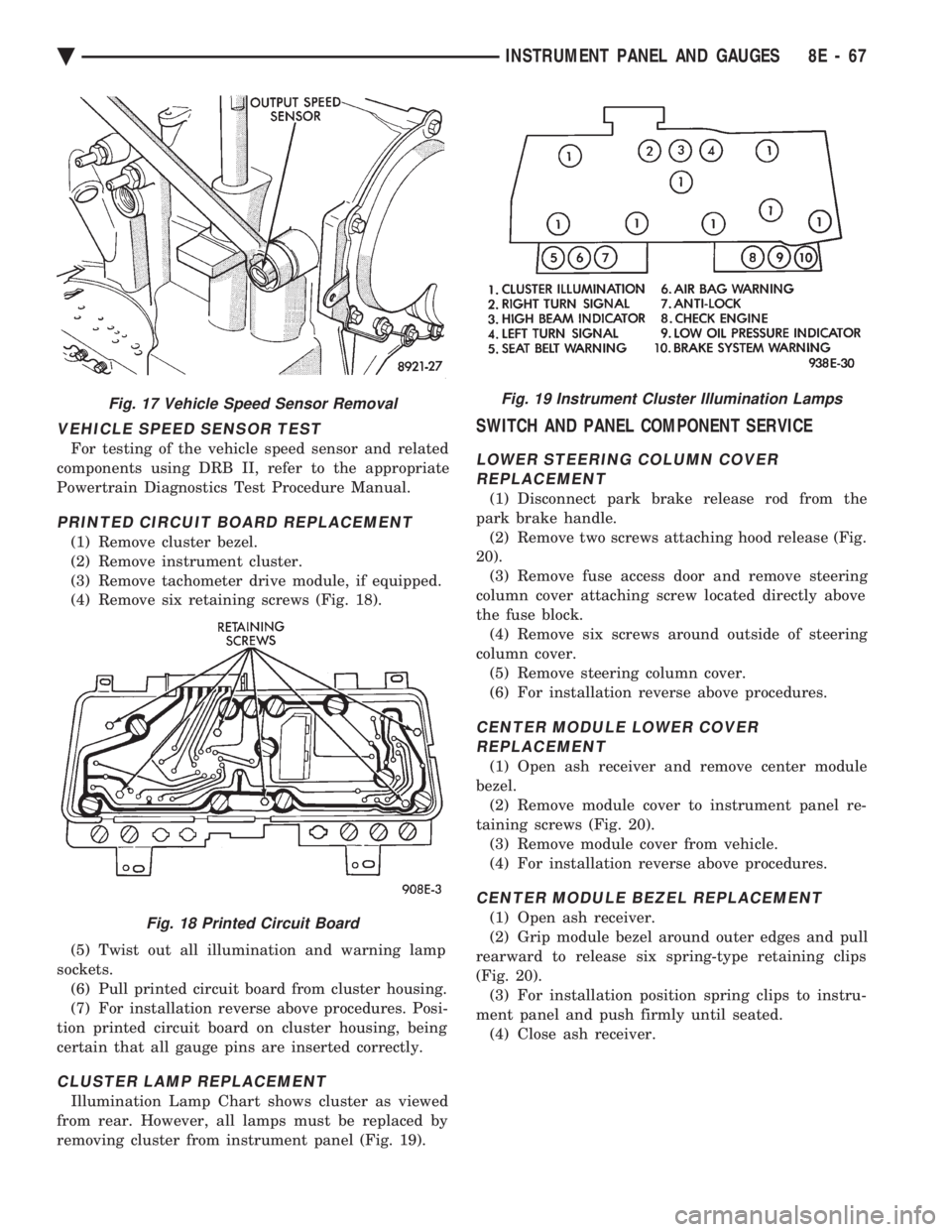

PRINTED CIRCUIT BOARD REPLACEMENT

(1) Remove cluster bezel.

(2) Remove instrument cluster.

(3) Remove tachometer drive module, if equipped.

(4) Remove six retaining screws (Fig. 18).

(5) Twist out all illumination and warning lamp

sockets. (6) Pull printed circuit board from cluster housing.

(7) For installation reverse above procedures. Posi-

tion printed circuit board on cluster housing, being

certain that all gauge pins are inserted correctly.

CLUSTER LAMP REPLACEMENT

Illumination Lamp Chart shows cluster as viewed

from rear. However, all lamps must be replaced by

removing cluster from instrument panel (Fig. 19).

SWITCH AND PANEL COMPONENT SERVICE

LOWER STEERING COLUMN COVER REPLACEMENT

(1) Disconnect park brake release rod from the

park brake handle. (2) Remove two screws attaching hood release (Fig.

20). (3) Remove fuse access door and remove steering

column cover attaching screw located directly above

the fuse block. (4) Remove six screws around outside of steering

column cover. (5) Remove steering column cover.

(6) For installation reverse above procedures.

CENTER MODULE LOWER COVER REPLACEMENT

(1) Open ash receiver and remove center module

bezel. (2) Remove module cover to instrument panel re-

taining screws (Fig. 20). (3) Remove module cover from vehicle.

(4) For installation reverse above procedures.

CENTER MODULE BEZEL REPLACEMENT

(1) Open ash receiver.

(2) Grip module bezel around outer edges and pull

rearward to release six spring-type retaining clips

(Fig. 20). (3) For installation position spring clips to instru-

ment panel and push firmly until seated. (4) Close ash receiver.

Fig. 17 Vehicle Speed Sensor Removal

Fig. 18 Printed Circuit Board

Fig. 19 Instrument Cluster Illumination Lamps

Ä INSTRUMENT PANEL AND GAUGES 8E - 67

Page 603 of 2438

VEHICLE SPEED CONTROL

CONTENTS

page page

CHECKING FOR FAULT CODE .............. 3

DIAGNOSIS PROCEDURES ................ 2

GENERAL INFORMATION .................. 1

INOPERATIVE SYSTEM ................... 3

POWERTRAIN CONTROL MODULE ELECTRICAL TEST ................................ 5

ROAD TEST ............................ 2

SERVO ELECTRICAL TESTS ............... 4

SERVO UNIT ............................ 9 SERVO VACUUM TEST

................... 9

STOP LAMP VEHICLE SPEED CONTROL SWITCH TEST ......................... 8

VACUUM SUPPLY TEST .................. 9

VEHICLE SPEED CONTROL SWITCH REMOVAL ........................... 10

VEHICLE SPEED CONTROL SWITCH TEST . . . 8

VEHICLE SPEED CONTROL ELECTRICAL TESTS ............................... 3

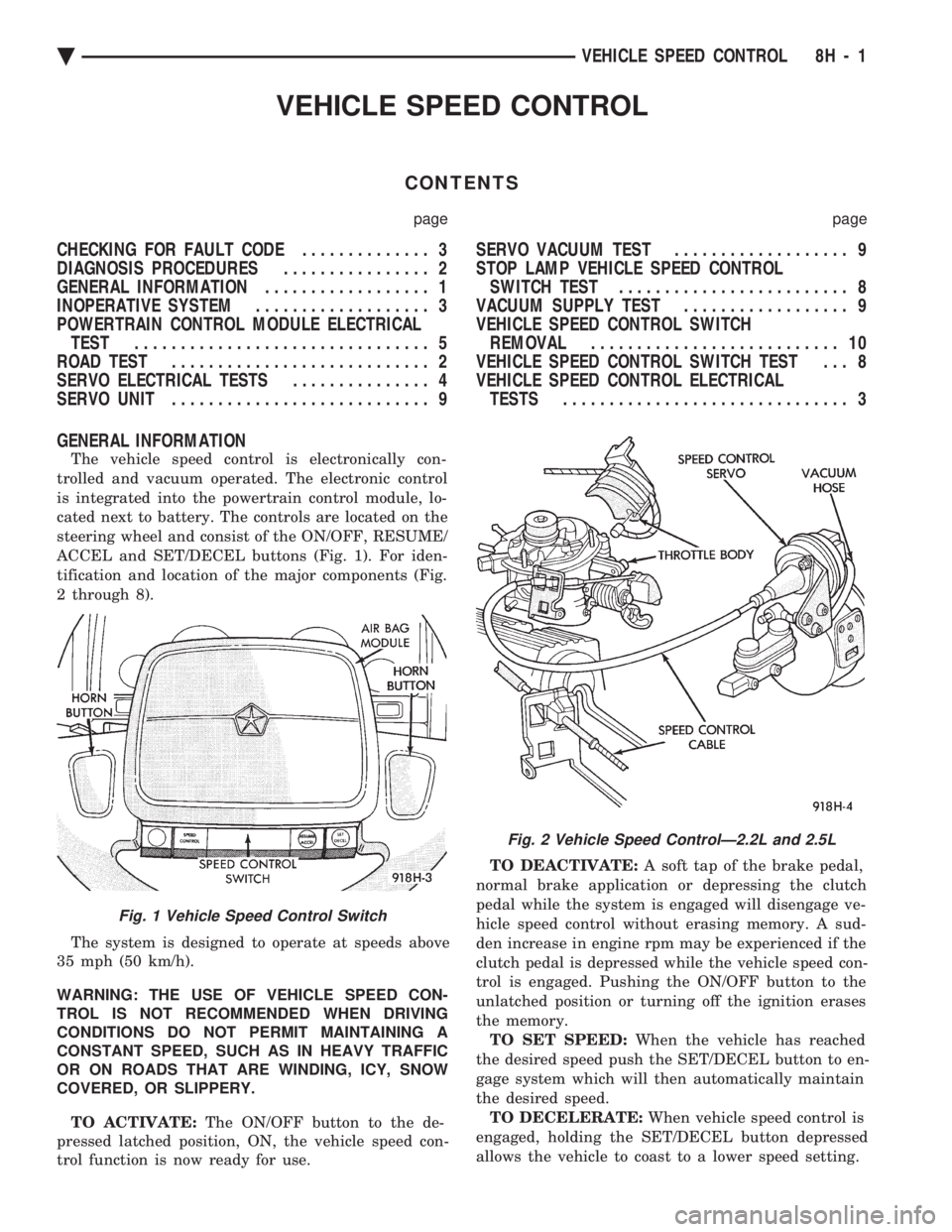

GENERAL INFORMATION

The vehicle speed control is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the powertrain control module, lo-

cated next to battery. The controls are located on the

steering wheel and consist of the ON/OFF, RESUME/

ACCEL and SET/DECEL buttons (Fig. 1). For iden-

tification and location of the major components (Fig.

2 through 8).

The system is designed to operate at speeds above

35 mph (50 km/h).

WARNING: THE USE OF VEHICLE SPEED CON-

TROL IS NOT RECOMMENDED WHEN DRIVING

CONDITIONS DO NOT PERMIT MAINTAINING A

CONSTANT SPEED, SUCH AS IN HEAVY TRAFFIC

OR ON ROADS THAT ARE WINDING, ICY, SNOW

COVERED, OR SLIPPERY.

TO ACTIVATE: The ON/OFF button to the de-

pressed latched position, ON, the vehicle speed con-

trol function is now ready for use. TO DEACTIVATE:

A soft tap of the brake pedal,

normal brake application or depressing the clutch

pedal while the system is engaged will disengage ve-

hicle speed control without erasing memory. A sud-

den increase in engine rpm may be experienced if the

clutch pedal is depressed while the vehicle speed con-

trol is engaged. Pushing the ON/OFF button to the

unlatched position or turning off the ignition erases

the memory. TO SET SPEED: When the vehicle has reached

the desired speed push the SET/DECEL button to en-

gage system which will then automatically maintain

the desired speed. TO DECELERATE: When vehicle speed control is

engaged, holding the SET/DECEL button depressed

allows the vehicle to coast to a lower speed setting.

Fig. 1 Vehicle Speed Control Switch

Fig. 2 Vehicle Speed ControlÐ2.2L and 2.5L

Ä VEHICLE SPEED CONTROL 8H - 1

Page 606 of 2438

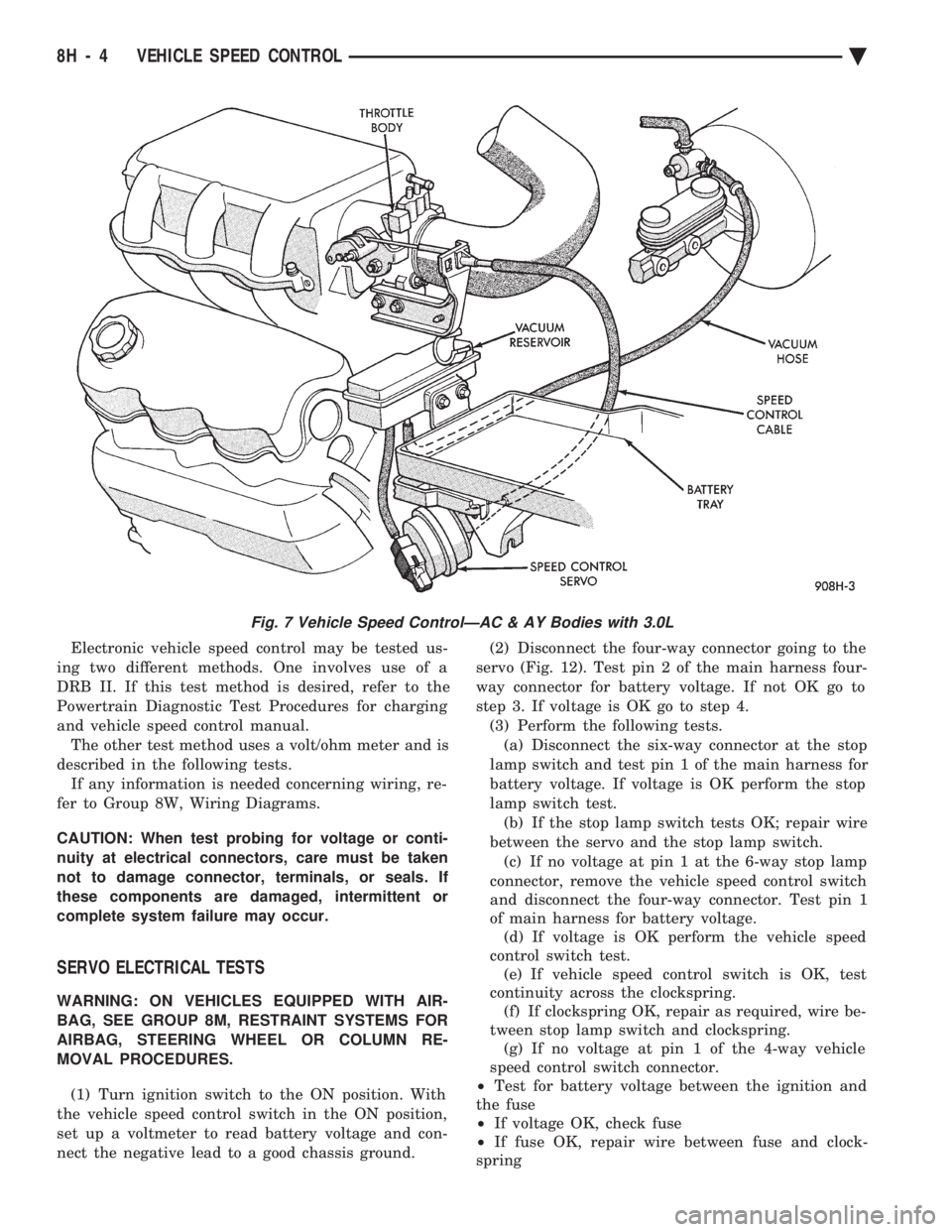

Electronic vehicle speed control may be tested us-

ing two different methods. One involves use of a

DRB II. If this test method is desired, refer to the

Powertrain Diagnostic Test Procedures for charging

and vehicle speed control manual. The other test method uses a volt/ohm meter and is

described in the following tests. If any information is needed concerning wiring, re-

fer to Group 8W, Wiring Diagrams.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SERVO ELECTRICAL TESTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

AIRBAG, STEERING WHEEL OR COLUMN RE-

MOVAL PROCEDURES.

(1) Turn ignition switch to the ON position. With

the vehicle speed control switch in the ON position,

set up a voltmeter to read battery voltage and con-

nect the negative lead to a good chassis ground. (2) Disconnect the four-way connector going to the

servo (Fig. 12). Test pin 2 of the main harness four-

way connector for battery voltage. If not OK go to

step 3. If voltage is OK go to step 4. (3) Perform the following tests.(a) Disconnect the six-way connector at the stop

lamp switch and test pin 1 of the main harness for

battery voltage. If voltage is OK perform the stop

lamp switch test. (b) If the stop lamp switch tests OK; repair wire

between the servo and the stop lamp switch. (c) If no voltage at pin 1 at the 6-way stop lamp

connector, remove the vehicle speed control switch

and disconnect the four-way connector. Test pin 1

of main harness for battery voltage. (d) If voltage is OK perform the vehicle speed

control switch test. (e) If vehicle speed control switch is OK, test

continuity across the clockspring. (f) If clockspring OK, repair as required, wire be-

tween stop lamp switch and clockspring. (g) If no voltage at pin 1 of the 4-way vehicle

speed control switch connector.

² Test for battery voltage between the ignition and

the fuse

² If voltage OK, check fuse

² If fuse OK, repair wire between fuse and clock-

spring

Fig. 7 Vehicle Speed ControlÐAC & AY Bodies with 3.0L

8H - 4 VEHICLE SPEED CONTROL Ä

Page 607 of 2438

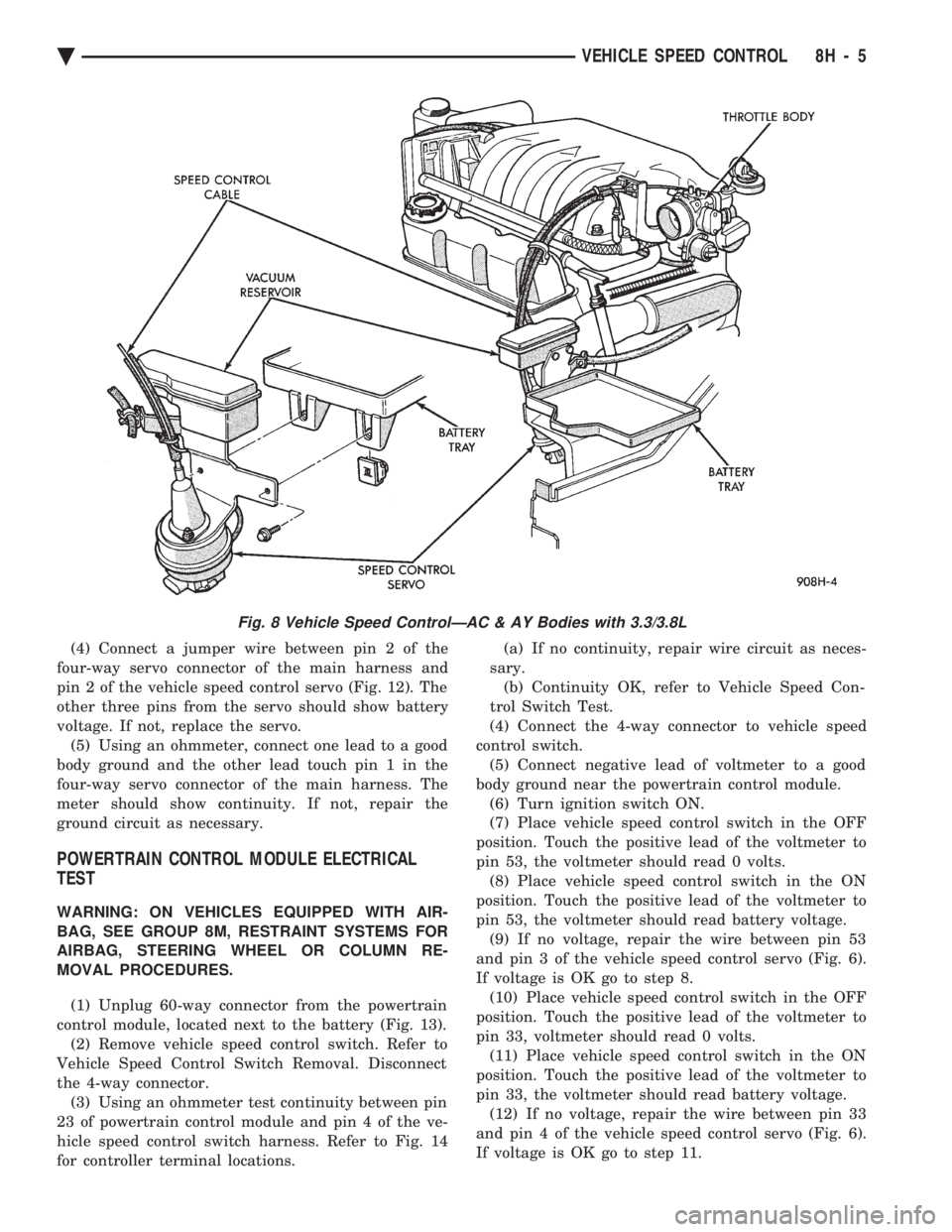

(4) Connect a jumper wire between pin 2 of the

four-way servo connector of the main harness and

pin 2 of the vehicle speed control servo (Fig. 12). The

other three pins from the servo should show battery

voltage. If not, replace the servo. (5) Using an ohmmeter, connect one lead to a good

body ground and the other lead touch pin 1 in the

four-way servo connector of the main harness. The

meter should show continuity. If not, repair the

ground circuit as necessary.

POWERTRAIN CONTROL MODULE ELECTRICAL

TEST

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

AIRBAG, STEERING WHEEL OR COLUMN RE-

MOVAL PROCEDURES.

(1) Unplug 60-way connector from the powertrain

control module, located next to the battery (Fig. 13). (2) Remove vehicle speed control switch. Refer to

Vehicle Speed Control Switch Removal. Disconnect

the 4-way connector. (3) Using an ohmmeter test continuity between pin

23 of powertrain control module and pin 4 of the ve-

hicle speed control switch harness. Refer to Fig. 14

for controller terminal locations. (a) If no continuity, repair wire circuit as neces-

sary. (b) Continuity OK, refer to Vehicle Speed Con-

trol Switch Test.

(4) Connect the 4-way connector to vehicle speed

control switch. (5) Connect negative lead of voltmeter to a good

body ground near the powertrain control module. (6) Turn ignition switch ON.

(7) Place vehicle speed control switch in the OFF

position. Touch the positive lead of the voltmeter to

pin 53, the voltmeter should read 0 volts. (8) Place vehicle speed control switch in the ON

position. Touch the positive lead of the voltmeter to

pin 53, the voltmeter should read battery voltage. (9) If no voltage, repair the wire between pin 53

and pin 3 of the vehicle speed control servo (Fig. 6).

If voltage is OK go to step 8. (10) Place vehicle speed control switch in the OFF

position. Touch the positive lead of the voltmeter to

pin 33, voltmeter should read 0 volts. (11) Place vehicle speed control switch in the ON

position. Touch the positive lead of the voltmeter to

pin 33, the voltmeter should read battery voltage. (12) If no voltage, repair the wire between pin 33

and pin 4 of the vehicle speed control servo (Fig. 6).

If voltage is OK go to step 11.

Fig. 8 Vehicle Speed ControlÐAC & AY Bodies with 3.3/3.8L

Ä VEHICLE SPEED CONTROL 8H - 5

Page 686 of 2438

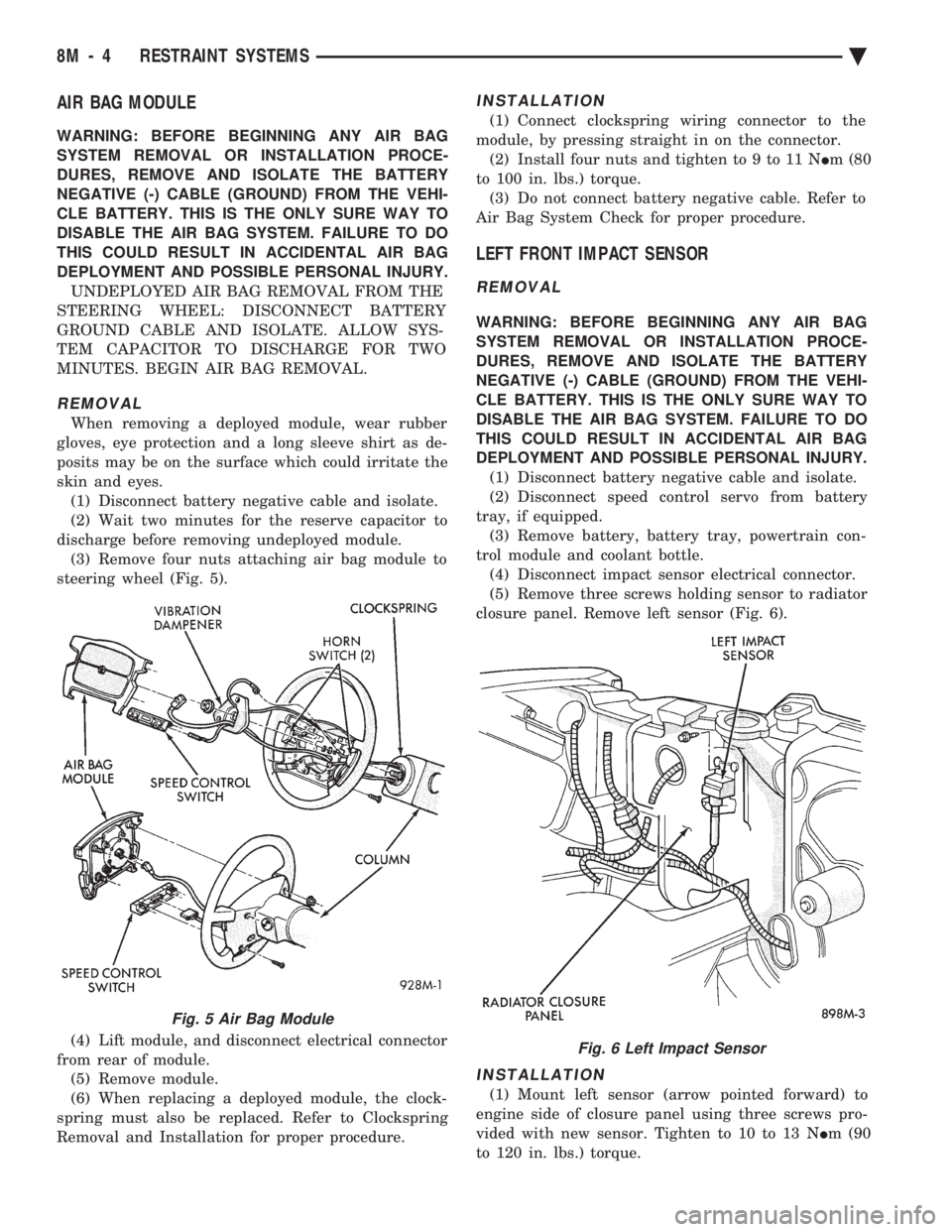

AIR BAG MODULE

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. UNDEPLOYED AIR BAG REMOVAL FROM THE

STEERING WHEEL: DISCONNECT BATTERY

GROUND CABLE AND ISOLATE. ALLOW SYS-

TEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES. BEGIN AIR BAG REMOVAL.

REMOVAL

When removing a deployed module, wear rubber

gloves, eye protection and a long sleeve shirt as de-

posits may be on the surface which could irritate the

skin and eyes. (1) Disconnect battery negative cable and isolate.

(2) Wait two minutes for the reserve capacitor to

discharge before removing undeployed module. (3) Remove four nuts attaching air bag module to

steering wheel (Fig. 5).

(4) Lift module, and disconnect electrical connector

from rear of module. (5) Remove module.

(6) When replacing a deployed module, the clock-

spring must also be replaced. Refer to Clockspring

Removal and Installation for proper procedure.

INSTALLATION

(1) Connect clockspring wiring connector to the

module, by pressing straight in on the connector. (2) Install four nuts and tighten to 9 to 11 N Im (80

to 100 in. lbs.) torque. (3) Do not connect battery negative cable. Refer to

Air Bag System Check for proper procedure.

LEFT FRONT IMPACT SENSOR

REMOVAL

WARNING: BEFORE BEGINNING ANY AIR BAG

SYSTEM REMOVAL OR INSTALLATION PROCE-

DURES, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY. (1) Disconnect battery negative cable and isolate.

(2) Disconnect speed control servo from battery

tray, if equipped. (3) Remove battery, battery tray, powertrain con-

trol module and coolant bottle. (4) Disconnect impact sensor electrical connector.

(5) Remove three screws holding sensor to radiator

closure panel. Remove left sensor (Fig. 6).

INSTALLATION

(1) Mount left sensor (arrow pointed forward) to

engine side of closure panel using three screws pro-

vided with new sensor. Tighten to 10 to 13 N Im (90

to 120 in. lbs.) torque.

Fig. 5 Air Bag Module

Fig. 6 Left Impact Sensor

8M - 4 RESTRAINT SYSTEMS Ä

Page 700 of 2438

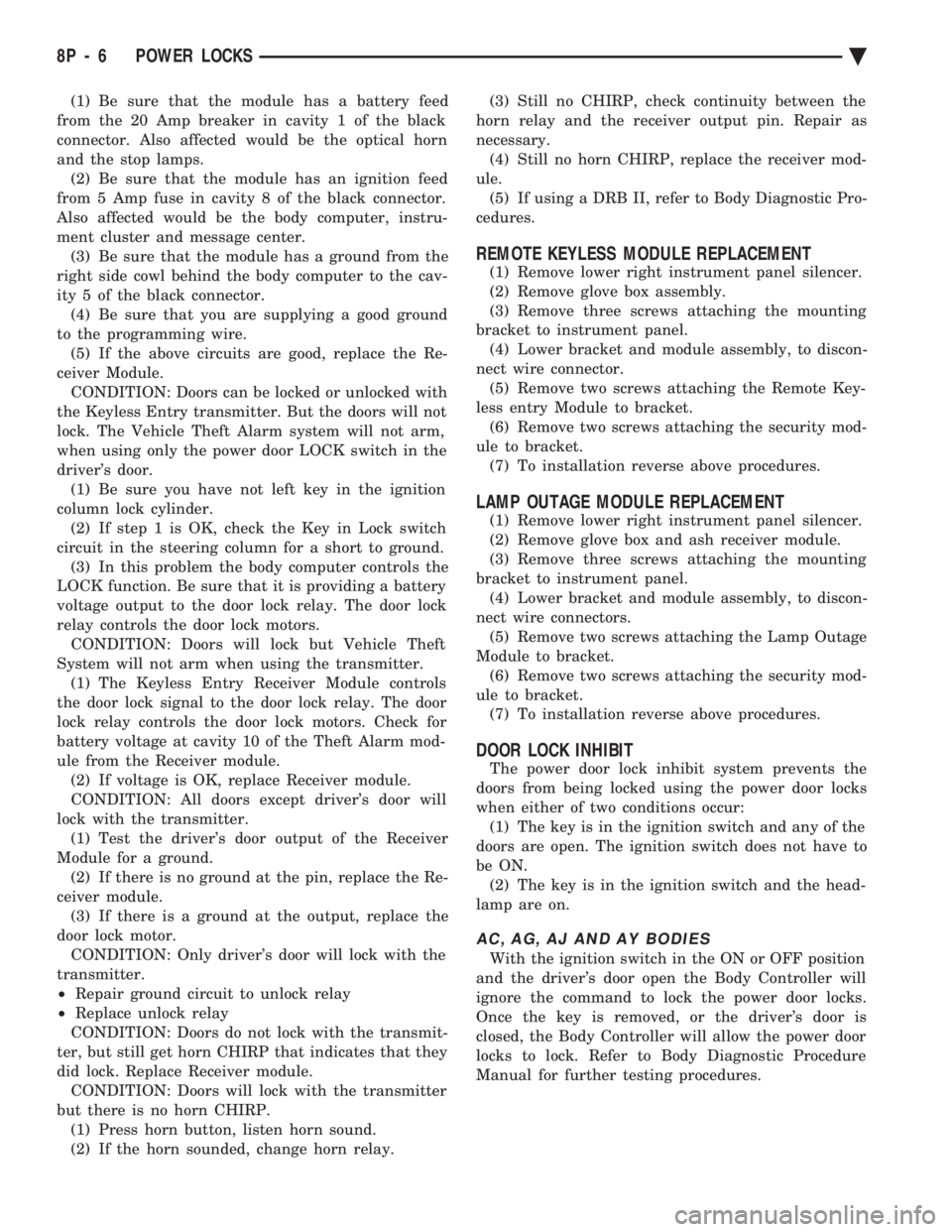

(1) Be sure that the module has a battery feed

from the 20 Amp breaker in cavity 1 of the black

connector. Also affected would be the optical horn

and the stop lamps. (2) Be sure that the module has an ignition feed

from 5 Amp fuse in cavity 8 of the black connector.

Also affected would be the body computer, instru-

ment cluster and message center. (3) Be sure that the module has a ground from the

right side cowl behind the body computer to the cav-

ity 5 of the black connector. (4) Be sure that you are supplying a good ground

to the programming wire. (5) If the above circuits are good, replace the Re-

ceiver Module. CONDITION: Doors can be locked or unlocked with

the Keyless Entry transmitter. But the doors will not

lock. The Vehicle Theft Alarm system will not arm,

when using only the power door LOCK switch in the

driver's door. (1) Be sure you have not left key in the ignition

column lock cylinder. (2) If step 1 is OK, check the Key in Lock switch

circuit in the steering column for a short to ground. (3) In this problem the body computer controls the

LOCK function. Be sure that it is providing a battery

voltage output to the door lock relay. The door lock

relay controls the door lock motors. CONDITION: Doors will lock but Vehicle Theft

System will not arm when using the transmitter. (1) The Keyless Entry Receiver Module controls

the door lock signal to the door lock relay. The door

lock relay controls the door lock motors. Check for

battery voltage at cavity 10 of the Theft Alarm mod-

ule from the Receiver module. (2) If voltage is OK, replace Receiver module.

CONDITION: All doors except driver's door will

lock with the transmitter. (1) Test the driver's door output of the Receiver

Module for a ground. (2) If there is no ground at the pin, replace the Re-

ceiver module. (3) If there is a ground at the output, replace the

door lock motor. CONDITION: Only driver's door will lock with the

transmitter.

² Repair ground circuit to unlock relay

² Replace unlock relay

CONDITION: Doors do not lock with the transmit-

ter, but still get horn CHIRP that indicates that they

did lock. Replace Receiver module. CONDITION: Doors will lock with the transmitter

but there is no horn CHIRP. (1) Press horn button, listen horn sound.

(2) If the horn sounded, change horn relay. (3) Still no CHIRP, check continuity between the

horn relay and the receiver output pin. Repair as

necessary. (4) Still no horn CHIRP, replace the receiver mod-

ule. (5) If using a DRB II, refer to Body Diagnostic Pro-

cedures.

REMOTE KEYLESS MODULE REPLACEMENT

(1) Remove lower right instrument panel silencer.

(2) Remove glove box assembly.

(3) Remove three screws attaching the mounting

bracket to instrument panel. (4) Lower bracket and module assembly, to discon-

nect wire connector. (5) Remove two screws attaching the Remote Key-

less entry Module to bracket. (6) Remove two screws attaching the security mod-

ule to bracket. (7) To installation reverse above procedures.

LAMP OUTAGE MODULE REPLACEMENT

(1) Remove lower right instrument panel silencer.

(2) Remove glove box and ash receiver module.

(3) Remove three screws attaching the mounting

bracket to instrument panel. (4) Lower bracket and module assembly, to discon-

nect wire connectors. (5) Remove two screws attaching the Lamp Outage

Module to bracket. (6) Remove two screws attaching the security mod-

ule to bracket. (7) To installation reverse above procedures.

DOOR LOCK INHIBIT

The power door lock inhibit system prevents the

doors from being locked using the power door locks

when either of two conditions occur: (1) The key is in the ignition switch and any of the

doors are open. The ignition switch does not have to

be ON. (2) The key is in the ignition switch and the head-

lamp are on.

AC, AG, AJ AND AY BODIES

With the ignition switch in the ON or OFF position

and the driver's door open the Body Controller will

ignore the command to lock the power door locks.

Once the key is removed, or the driver's door is

closed, the Body Controller will allow the power door

locks to lock. Refer to Body Diagnostic Procedure

Manual for further testing procedures.

8P - 6 POWER LOCKS Ä

Page 932 of 2438

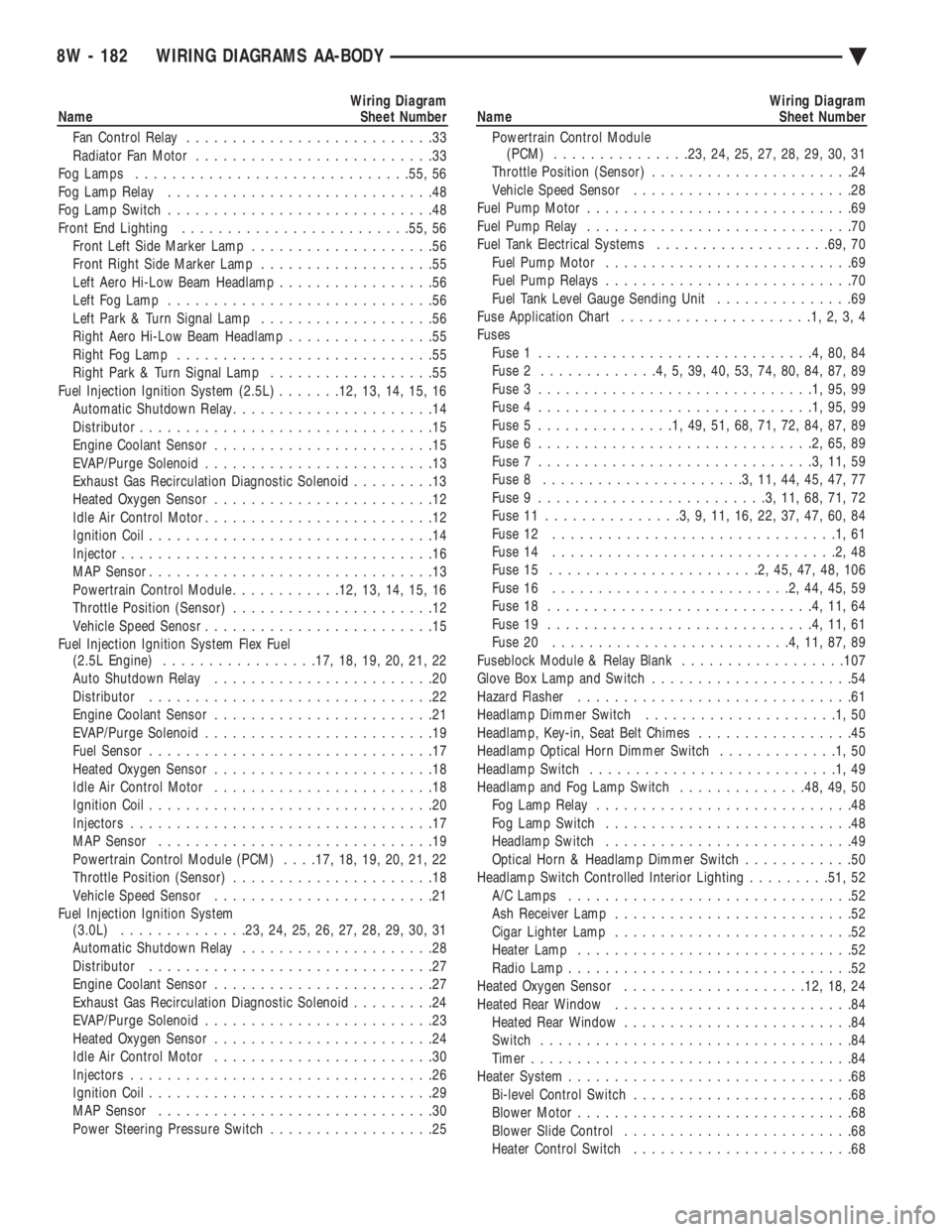

Wiring Diagram

Name Sheet Number

Fan Control Relay ...........................33

Radiator Fan Motor ..........................33

Fog Lamps ............................. .55, 56

Fog Lamp Relay .............................48

Fog Lamp Switch .............................48

Front End Lighting ........................ .55, 56

Front Left Side Marker Lamp ....................56

Front Right Side Marker Lamp ...................55

Left Aero Hi-Low Beam Headlamp .................56

Left Fog Lamp .............................56

Left Park & Turn Signal Lamp ...................56

Right Aero Hi-Low Beam Headlamp ................55

Right Fog Lamp ............................55

Right Park & Turn Signal Lamp ..................55

Fuel Injection Ignition System (2.5L) .......12, 13, 14, 15, 16

Automatic Shutdown Relay ......................14

Distributor ................................15

Engine Coolant Sensor ........................15

EVAP/Purge Solenoid .........................13

Exhaust Gas Recirculation Diagnostic Solenoid .........13

Heated Oxygen Sensor ........................12

Idle Air Control Motor .........................12

Ignition Coil ...............................14

Injector ..................................16

MAP Sensor ...............................13

Powertrain Control Module ............12, 13, 14, 15, 16

Throttle Position (Sensor) ......................12

Vehicle Speed Senosr .........................15

Fuel Injection Ignition System Flex Fuel (2.5L Engine) ................ .17, 18, 19, 20, 21, 22

Auto Shutdown Relay ........................20

Distributor ...............................22

Engine Coolant Sensor ........................21

EVAP/Purge Solenoid .........................19

Fuel Sensor ...............................17

Heated Oxygen Sensor ........................18

Idle Air Control Motor ........................18

Ignition Coil ...............................20

Injectors .................................17

MAP Sensor ..............................19

Powertrain Control Module (PCM) . . . .17, 18, 19, 20, 21, 22

Throttle Position (Sensor) ......................18

Vehicle Speed Sensor ........................21

Fuel Injection Ignition System (3.0L) ............. .23, 24, 25, 26, 27, 28, 29, 30, 31

Automatic Shutdown Relay .....................28

Distributor ...............................27

Engine Coolant Sensor ........................27

Exhaust Gas Recirculation Diagnostic Solenoid .........24

EVAP/Purge Solenoid .........................23

Heated Oxygen Sensor ........................24

Idle Air Control Motor ........................30

Injectors .................................26

Ignition Coil ...............................29

MAP Sensor ..............................30

Power Steering Pressure Switch ..................25Wiring Diagram

Name Sheet Number

Powertrain Control Module (PCM) .............. .23, 24, 25, 27, 28, 29, 30, 31

Throttle Position (Sensor) ......................24

Vehicle Speed Sensor ........................28

Fuel Pump Motor .............................69

Fuel Pump Relay .............................70

Fuel Tank Electrical Systems ...................69, 70

Fuel Pump Motor ...........................69

Fuel Pump Relays ...........................70

Fuel Tank Level Gauge Sending Unit ...............69

Fuse Application Chart .....................1,2,3,4

Fuses Fuse 1 ..............................4,80,84

Fuse 2 .............4,5,39,40,53,74,80,84,87,89

Fuse 3 ..............................1,95,99

Fuse 4 ..............................1,95,99

Fuse 5 ...............1,49,51,68,71,72,84,87,89

Fuse 6 ..............................2,65,89

Fuse 7 ..............................3,11,59

Fuse 8 ......................3,11,44,45,47,77

Fuse 9 .........................3,11,68,71,72

Fuse 11 ...............3,9,11,16,22,37,47,60,84

Fuse 12 ...............................1,61

Fuse 14 ...............................2,48

Fuse 15 .......................2,45,47,48,106

Fuse 16 ..........................2,44,45,59

Fuse 18 .............................4,11,64

Fuse 19 .............................4,11,61

Fuse 20 ..........................4,11,87,89

Fuseblock Module & Relay Blank ..................107

Glove Box Lamp and Switch ......................54

Hazard Flasher ..............................61

Headlamp Dimmer Switch .....................1,50

Headlamp, Key-in, Seat Belt Chimes .................45

Headlamp Optical Horn Dimmer Switch .............1,50

Headlamp Switch ...........................1,49

Headlamp and Fog Lamp Switch ..............48, 49, 50

Fog Lamp Relay ............................48

Fog Lamp Switch ...........................48

Headlamp Switch ...........................49

Optical Horn & Headlamp Dimmer Switch ............50

Headlamp Switch Controlled Interior Lighting .........51, 52

A/C Lamps ...............................52

Ash Receiver Lamp ..........................52

Cigar Lighter Lamp ..........................52

Heater Lamp ..............................52

Radio Lamp ...............................52

Heated Oxygen Sensor ................... .12, 18, 24

Heated Rear Window ..........................84

Heated Rear Window .........................84

Switch ..................................84

Timer ...................................84

Heater System ...............................68

Bi-level Control Switch ........................68

Blower Motor ..............................68

Blower Slide Control .........................68

Heater Control Switch ........................68

8W - 182 WIRING DIAGRAMS AA-BODY Ä

Page 936 of 2438

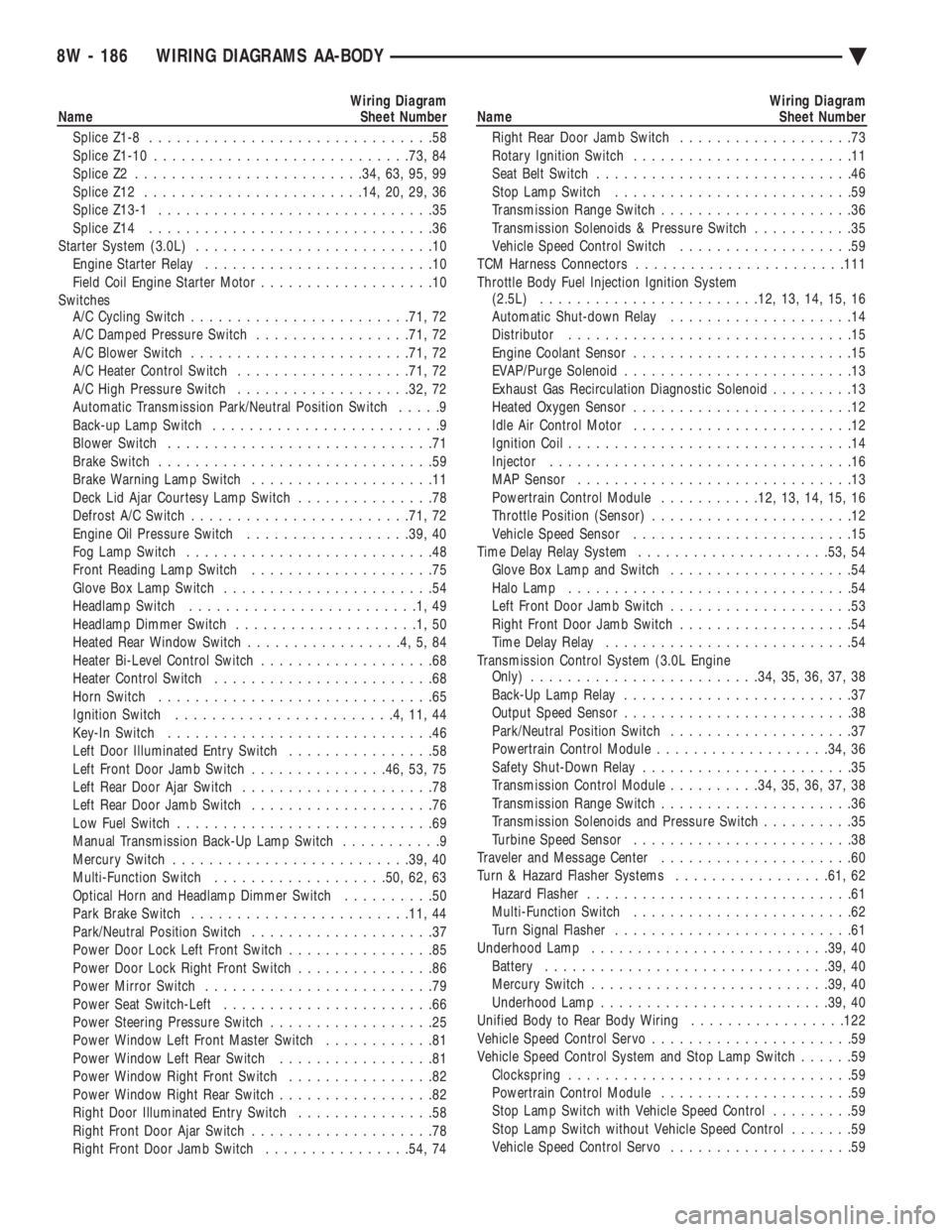

Wiring Diagram

Name Sheet Number

Splice Z1-8 ...............................58

Splice Z1-10 ........................... .73, 84

Splice Z2 ........................ .34, 63, 95, 99

Splice Z12 ....................... .14, 20, 29, 36

Splice Z13-1 ..............................35

Splice Z14 ...............................36

Starter System (3.0L) ..........................10

Engine Starter Relay .........................10

Field Coil Engine Starter Motor ...................10

Switches A/C Cycling Switch ....................... .71, 72

A/C Damped Pressure Switch .................71, 72

A/C Blower Switch ....................... .71, 72

A/C Heater Control Switch .................. .71, 72

A/C High Pressure Switch .................. .32, 72

Automatic Transmission Park/Neutral Position Switch .....9

Back-up Lamp Switch .........................9

Blower Switch .............................71

Brake Switch ..............................59

Brake Warning Lamp Switch ....................11

Deck Lid Ajar Courtesy Lamp Switch ...............78

Defrost A/C Switch ....................... .71, 72

Engine Oil Pressure Switch ..................39, 40

Fog Lamp Switch ...........................48

Front Reading Lamp Switch ....................75

Glove Box Lamp Switch .......................54

Headlamp Switch .........................1,49

Headlamp Dimmer Switch ....................1,50

Heated Rear Window Switch .................4,5,84

Heater Bi-Level Control Switch ...................68

Heater Control Switch ........................68

Horn Switch ..............................65

Ignition Switch ........................4,11,44

Key-In Switch .............................46

Left Door Illuminated Entry Switch ................58

Left Front Door Jamb Switch ...............46, 53, 75

Left Rear Door Ajar Switch .....................78

Left Rear Door Jamb Switch ....................76

Low Fuel Switch ............................69

Manual Transmission Back-Up Lamp Switch ...........9

Mercury Switch ......................... .39, 40

Multi-Function Switch .................. .50, 62, 63

Optical Horn and Headlamp Dimmer Switch ..........50

Park Brake Switch ....................... .11, 44

Park/Neutral Position Switch ....................37

Power Door Lock Left Front Switch ................85

Power Door Lock Right Front Switch ...............86

Power Mirror Switch .........................79

Power Seat Switch-Left .......................66

Power Steering Pressure Switch ..................25

Power Window Left Front Master Switch ............81

Power Window Left Rear Switch .................81

Power Window Right Front Switch ................82

Power Window Right Rear Switch .................82

Right Door Illuminated Entry Switch ...............58

Right Front Door Ajar Switch ....................78

Right Front Door Jamb Switch ................54, 74Wiring Diagram

Name Sheet Number

Right Rear Door Jamb Switch ...................73

Rotary Ignition Switch ........................11

Seat Belt Switch ............................46

Stop Lamp Switch ..........................59

Transmission Range Switch .....................36

Transmission Solenoids & Pressure Switch ...........35

Vehicle Speed Control Switch ...................59

TCM Harness Connectors ...................... .111

Throttle Body Fuel Injection Ignition System (2.5L) ....................... .12, 13, 14, 15, 16

Automatic Shut-down Relay ....................14

Distributor ...............................15

Engine Coolant Sensor ........................15

EVAP/Purge Solenoid .........................13

Exhaust Gas Recirculation Diagnostic Solenoid .........13

Heated Oxygen Sensor ........................12

Idle Air Control Motor ........................12

Ignition Coil ...............................14

Injector .................................16

MAP Sensor ..............................13

Powertrain Control Module ...........12, 13, 14, 15, 16

Throttle Position (Sensor) ......................12

Vehicle Speed Sensor ........................15

Time Delay Relay System .................... .53, 54

Glove Box Lamp and Switch ....................54

Halo Lamp ...............................54

Left Front Door Jamb Switch ....................53

Right Front Door Jamb Switch ...................54

Time Delay Relay ...........................54

Transmission Control System (3.0L Engine Only) ........................ .34, 35, 36, 37, 38

Back-Up Lamp Relay .........................37

Output Speed Sensor .........................38

Park/Neutral Position Switch ....................37

Powertrain Control Module .................. .34, 36

Safety Shut-Down Relay .......................35

Transmission Control Module ..........34, 35, 36, 37, 38

Transmission Range Switch .....................36

Transmission Solenoids and Pressure Switch ..........35

Turbine Speed Sensor ........................38

Traveler and Message Center .....................60

Turn & Hazard Flasher Systems .................61, 62

Hazard Flasher .............................61

Multi-Function Switch ........................62

Turn Signal Flasher ..........................61

Underhood Lamp ......................... .39, 40

Battery .............................. .39, 40

Mercury Switch ......................... .39, 40

Underhood Lamp ........................ .39, 40

Unified Body to Rear Body Wiring .................122

Vehicle Speed Control Servo ......................59

Vehicle Speed Control System and Stop Lamp Switch ......59

Clockspring ...............................59

Powertrain Control Module .....................59

Stop Lamp Switch with Vehicle Speed Control .........59

Stop Lamp Switch without Vehicle Speed Control .......59

Vehicle Speed Control Servo ....................59

8W - 186 WIRING DIAGRAMS AA-BODY Ä