roof CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1071 of 2438

Wiring Diagram

Name Sheet Number

Splice Z1-3 ............... .47, 68, 74, 77, 80, 82, 84

Splice Z1-4 .......... .38, 47, 70, 72, 74, 77, 80, 82, 84

Splice Z1-5 ............................. .155

Splice Z1-6 .....36, 124, 125, 127, 131, 135, 160, 162, 164

Splice Z1-7 .................... .39, 160, 162, 164

Splice Z1-8 ........................... .86, 115

Splice Z1-9 .................. .61, 86, 118, 140, 141

Splice Z1-10 ..............................46

Splice Z1-11 .................. .161, 162, 163, 164

Splice Z1-12 .....52, 54, 56, 63, 69, 71, 73, 75, 78, 81, 83

Splice Z1-13 ............. .90, 124, 125, 147, 162, 164

Splice Z1-14 . . . .91, 127, 131, 135, 143, 149, 152, 158, 165

Splice Z1-15 ........... .67, 88, 91, 112, 127, 131, 135,

149, 152, 155, 158, 165

Splice Z1-16 .....88, 91, 112, 127, 131, 135, 150, 155, 165

Splice Z1-17 ....................... .54, 56, 113

Splice Z1-18 ......................... .162, 164

Splice Z1-19 .............. .70, 72, 73, 74, 75, 77, 78,

80, 81, 82, 83, 84

Splice Z2 .......................... .86, 98, 99

Splice Z2-1 ...............................98

Splice Z2-2 ......................... .36, 39, 43

Splice Z12 ....................... .16, 22, 24, 35

Splice Z13 ............................7,9,35

Splice Z14 ...............................35

Stop Lamps .................... .161, 162, 163, 164

Stop Lamp Switch ......................... .38, 59

Switches A/C Ambient Temp ...................... .56, 114

A/C Cycling Switch ..........................54

A/C Fan Cutout ........................ .56, 114

A/C Defrost ........................... .53, 55

A/C Heater Blower ....................... .53, 55

A/C High Pressure Cutout ................54, 56, 114

A/C Low Pressure .................... .53, 55, 114

ATC Temp Control ......................... .116

Automatic Transmission Park/Neutral Position .........12

Backup Lamp ..............................12

Brake Warning Lamp .........................11

Deck Lid Release ......................... .111

Defrost .............................. .53, 55

Dimmer-Headlamp ..........................66

Door Ajar .......................... .92, 93, 94

Door Jamb ............................ .87, 88

Door Window-Left Front ..................... .157

Door Window-Left Rear ..................... .157

Door Window-Right Front .................... .158

Door Window-Right Rear .................... .158

Engine Oil Pressure .................... .30, 31, 32

Fuel Tank Level Gauge Sending Unit Switch ..........36

Glove Box Lamp .......................... .111

Hazard Flasher .............................60

Headlamp ..............................1,65

Headlamp Dimmer .........................1,66

Heated Rear Window ......................4,148

Heater Bi-Level Control Switch ...................51

Horn ...................................63Wiring Diagram

Name Sheet Number

Ignition ................................4,11

Illuminated Entry ...........................91

Illuminated Visor Vanity Mirror Switch ..............89

Intermittent Wiper ...........................61

Key-in .......................... .104, 107, 109

Left Rear Door Jamb Switch ....................87

Optical Horn .............................1,66

Park Brake ...............................11

Power Door Lock-Left Front ................... .139

Power Door Lock-Right Front ...................140

Power Mirrors ........................ .143, 145

Power Recliner Seat .................... .152, 155

Power Seat ................... .149, 150, 152, 155

Power Steering Switch .................... .19, 25

Seat Belt .................................67

Security Alarm-Hood ................. .128, 132, 136

Seat Memory Selector Switch ...................151

Sliding Roof Position ....................... .147

Stop Lamp w/Speed Control ..................38, 59

Stop Lamp w/o Speed Control ................38, 59

Sunroof ............................... .147

Transmission Range Switch .....................35

Turn Signal ...............................60

Vanity Lamp ..............................89

Vehicle Speed Control ........................37

Throttle Body Fuel Injection (TBI) Ignition System (2.5L) ....................... .14, 15, 16, 17, 18

Automatic Shut Down Relay ....................15

Data Link Connector .........................14

Distributor ...............................17

Engine Coolant Temperature Sensor ..........17, 19, 30

EVAP/Purge Solenoid .........................15

Exhaust Gas Recirculation Solenoid ................14

Heated Oxygen Sensor ........................14

Idle Air Control Motor ........................14

Ignition Coil ...............................15

Injector .................................15

MAP Sensor ..............................18

Powertrain Control Module ...........14, 15, 16, 17, 18

Throttle Position (Sensor) ......................18

Vehicle Speed Sensor ........................17

Throttle Position (Sensors) ..................18, 21, 26

Transmission Controller Connector .................177

Transmission Control Module ................33, 34, 35

Transmission Control System ................33, 34, 35

Back-Up Lamp Relay .........................33

Park/Neutral Position Switch ....................33

Safety Shut Down Relay .......................35

Transmission Control Module ...............33, 34, 35

Transmission Output Speed Sensor ................34

Transmission Range Switch .....................35

Transmission Solenoids and Pressure Switches ........35

Turbine Speed Sensor ........................34

Transmission Output Speed Sensor .................34

Transmission Range Lamp with Electronic Cluster ........85

Transmission Solenoid Connector ..................179

Transmission Solenoids and Pressure Switches ..........35

Ä WIRING DIAGRAMS AC-AY BODY 8W - 321

Page 2157 of 2438

BODY

CONTENTS

page page

AA-VEHICLE BODY COMPONENT SERVICE . . . 11

AC-VEHICLE BODY COMPONENT SERVICE . . . 37

AG-VEHICLE BODY COMPONENT SERVICE . . . 52

AJ-VEHICLE BODY COMPONENT SERVICE . . . 71

AJ/27-VEHICLE CONVERTIBLE BODYCOMPONENT SERVICE ................. 86

AP-VEHICLE BODY COMPONENT SERVICE . . . 97

AP/17-VEHICLE CONVERTIBLE BODY COMPONENT SERVICE ................. 117 AY-VEHICLE BODY COMPONENT SERVICE . . 133

BODY DIAGNOSTIC PROCEDURES .......... 2

GENERAL SERVICE INFORMATION .......... 1

PAINT ................................. 4

POWER SUNROOF ....................... 6

WINDSHIELD ........................... 9

GENERAL SERVICE INFORMATION

VEHICLE IDENTIFICATION

Throughout this group, references to the Chrysler

Corporation vehicle family identification code is used

when describing a procedure that is unique to that

vehicle. Refer to Introduction Group of this manual for

detailed information on vehicle identification. If a

procedure is common to all vehicles covered in this

manual, no reference will be made to a vehicle family

code.

SAFETY PRECAUTIONS AND WARNINGS

WARNING: WHEN SERVICING A VEHICLE EQUIPPED

WITH AIRBAG RESTRAINT SYSTEM, REVIEW ALL

PRECAUTIONS IN GROUP 8M, RESTRAINT SYS-

TEMS. PERSONAL INJURY CAN RESULT. EYE PROTECTION SHOULD BE USED WHEN SER-

VICING GLASS COMPONENTS. PERSONAL INJURY

CAN RESULT. USE A BREATHING FILTER WHEN SPRAYING

PAINT OR SOLVENTS IN A CONFINED AREA. PER-

SONAL INJURY CAN RESULT. AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL BASED CLEANING SOLVENTS.

PERSONAL INJURY CAN RESULT. DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched in

a inner body panel, verify depth of space to the outer

body panel, electrical wiring, or other components.

Damage to vehicle can result. Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result. Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to finish

or color can result. Do not hammer or pound on plastic trim panel

attaching fasteners when servicing interior trim. Plas-

tic panel can break.

Chrysler Corporation uses many different types of

push-in fasteners to secure the interior and exterior

trim to the body . Most of these fasteners can be reused

to assemble the trim during various repair procedures.

At times a push-in fastener cannot be removed without

damaging the fastener or the component it is holding.

If it is not possible to remove a fastener without

damaging a component or body, cut or brake the

fastener and use a new one when installing the com-

ponent. Never pry or pound on a plastic or press-board

trim component. Using a suitable fork-type prying

device, pry the fastener from the retaining hole behind

the component being removed. When installing, verify

that fastener is aligned with the retaining hole, by

hand, push directly on or over the fastener until it

seats. Apply a low force pull to the panel to verify that

it is secure. When it is necessary to remove components to service

another, it should not be necessary to apply excessive

force or bend a component to remove it. Before damag-

ing a component to be reused, verify there is no hidden

fasteners or captured edges holding the component in.

Often a fastener is hidden by carpeting nap or trim

plugs.

Ä BODY 23 - 1

Page 2162 of 2438

POWER SUNROOF INDEX

page page

Adjustment Bracket ........................ 7

Drain Channel ............................ 7

Drive Cable Locators ....................... 7

Drive Cables ............................. 8

General Information ........................ 6

Glass Panel ............................. 7 Glass Vertical Height Adjustment

.............. 6

Guide Assembly .......................... 8

Motor and Drive Gears ..................... 7

Sunshade ............................... 8

Wind Deflector ........................... 6

GENERAL INFORMATION

All sunroofs are equipped with drain tubes that are

located in the A, B or C-pillars. The drain tubes

must be kept open to prevent water from entering

the passenger compartment.

LUBRICATION

(1) Lubricate cables with Lubriplate or equivalent

when cables are replaced. (2) Periodically clean dirt from guide rail covers.

DRAIN TUBES

² Inspect the drain holes, located in the trough

around the sunroof opening to verify they are clear.

Inspection should be performed at least once a year

or when problems are suspected. If drain hose or

tubes are plugged, use compressed air or blunt flexi-

ble wire to clear them. If tubes cannot be cleared,

they must be repaired.

² The lower ends of the rear drain tubes are located

in the rear quarter panel drop wells. To clear rear

drain tubes, use compressed air or blunt flexible wire

from the lower ends of the tubes.

GLASS VERTICAL HEIGHT ADJUSTMENT

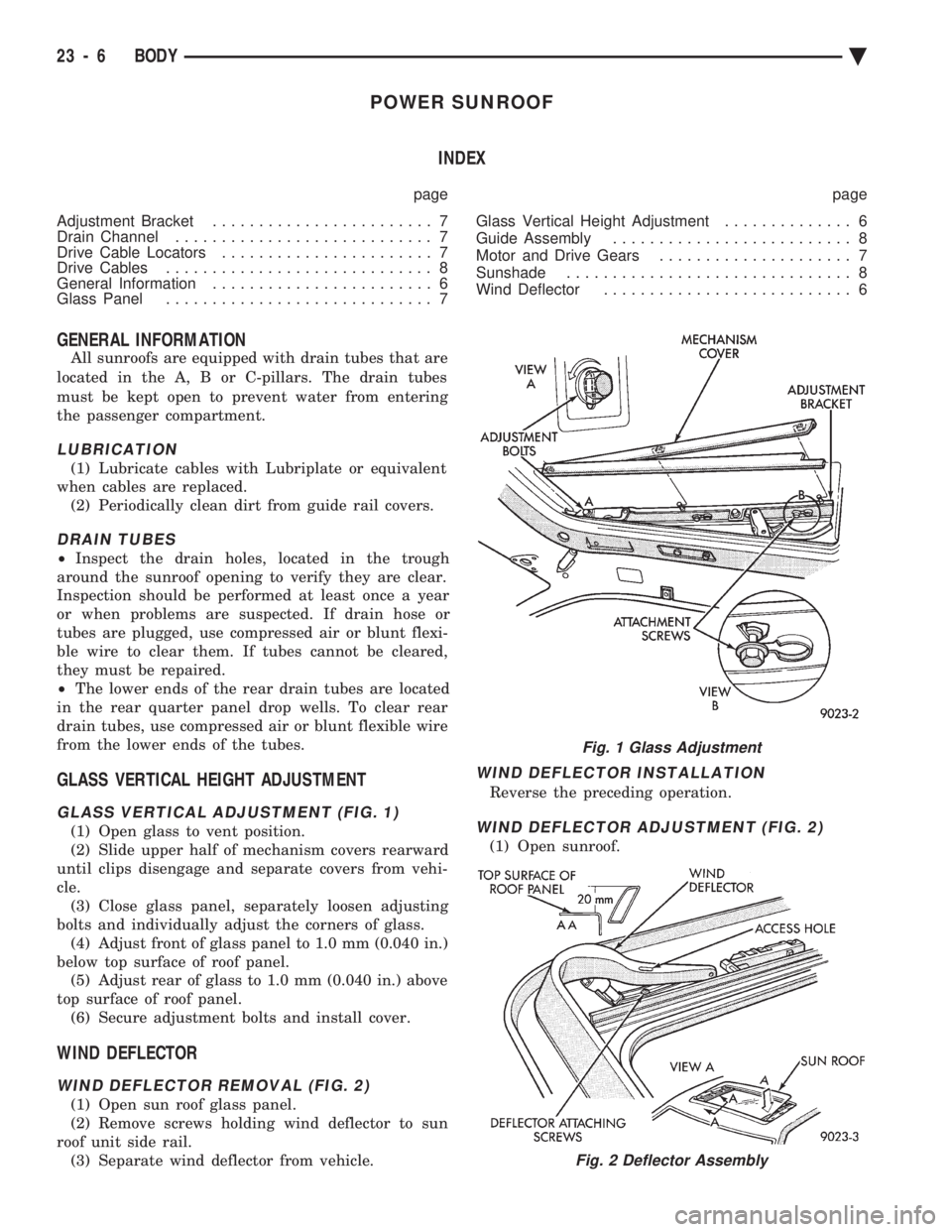

GLASS VERTICAL ADJUSTMENT (FIG. 1)

(1) Open glass to vent position.

(2) Slide upper half of mechanism covers rearward

until clips disengage and separate covers from vehi-

cle. (3) Close glass panel, separately loosen adjusting

bolts and individually adjust the corners of glass. (4) Adjust front of glass panel to 1.0 mm (0.040 in.)

below top surface of roof panel. (5) Adjust rear of glass to 1.0 mm (0.040 in.) above

top surface of roof panel. (6) Secure adjustment bolts and install cover.

WIND DEFLECTOR

WIND DEFLECTOR REMOVAL (FIG. 2)

(1) Open sun roof glass panel.

(2) Remove screws holding wind deflector to sun

roof unit side rail. (3) Separate wind deflector from vehicle.

WIND DEFLECTOR INSTALLATION

Reverse the preceding operation.

WIND DEFLECTOR ADJUSTMENT (FIG. 2)

(1) Open sunroof.

Fig. 1 Glass Adjustment

Fig. 2 Deflector Assembly

23 - 6 BODY Ä

Page 2163 of 2438

(2) position wind deflector so 19 mm (0.75 in.)

above top surface of roof panel and 1 mm (0.040 in.)

rearward of roof panel forward edge. (3) Secure wind deflector to sunroof unit.

GLASS PANEL

GLASS PANEL REMOVAL

(1) Remove wind deflector mechanism covers (Fig.

1). (2) Position glass to vent position.

(3) Position sunshade full rearward.

(4) Loosen nuts holding glass panel to side adjust-

ment brackets. (5) Slide glass panel rearward 12 mm (0.5 in.) and

separate glass from sunroof unit.

GLASS PANEL INSTALLATION

(1) Position glass panel in opening with logo rear-

ward and slide panel forward 12 mm (0.5 in.). (2) Verify that attaching nuts are below top sur-

face of glass adjustment brackets. (3) Close sunroof to center glass panel in roof open-

ing. (4) Tighten center screws to hold adjustment.

(5) Open glass to vent position and tighten nuts to

8N Im (70.8 in-lbs.).

(6) Close glass and check alignment.

(7) Install the mechanism covers.

(8) Adjust wind deflector, if necessary.

ADJUSTMENT BRACKET

ADJUSTMENT BRACKET REMOVAL (FIG. 3)

(1) Remove wind deflector, mechanism covers and

glass panel. (2) Move glass carriage to vent position and re-

move rearward adjustment bolt from adjustment

bracket. (3) Lift rear of adjustment bracket to highest ver-

tical position and disengage front of bracket from

unit.

ADJUSTMENT BRACKET INSTALLATION

Reverse the preceding operation. Adjust glass, and

wind deflector as necessary.

DRAIN CHANNEL

DRAIN CHANNEL REMOVAL

(1) Remove wind deflector mechanism covers and

glass panel. (2) Locate glass carriage to vent position and drain

channel in full forward position. (3) Remove screws holding drain channel to sup-

port frame.

DRAIN CHANNEL INSTALLATION

Reverse the preceding operation.

DRIVE CABLE LOCATORS

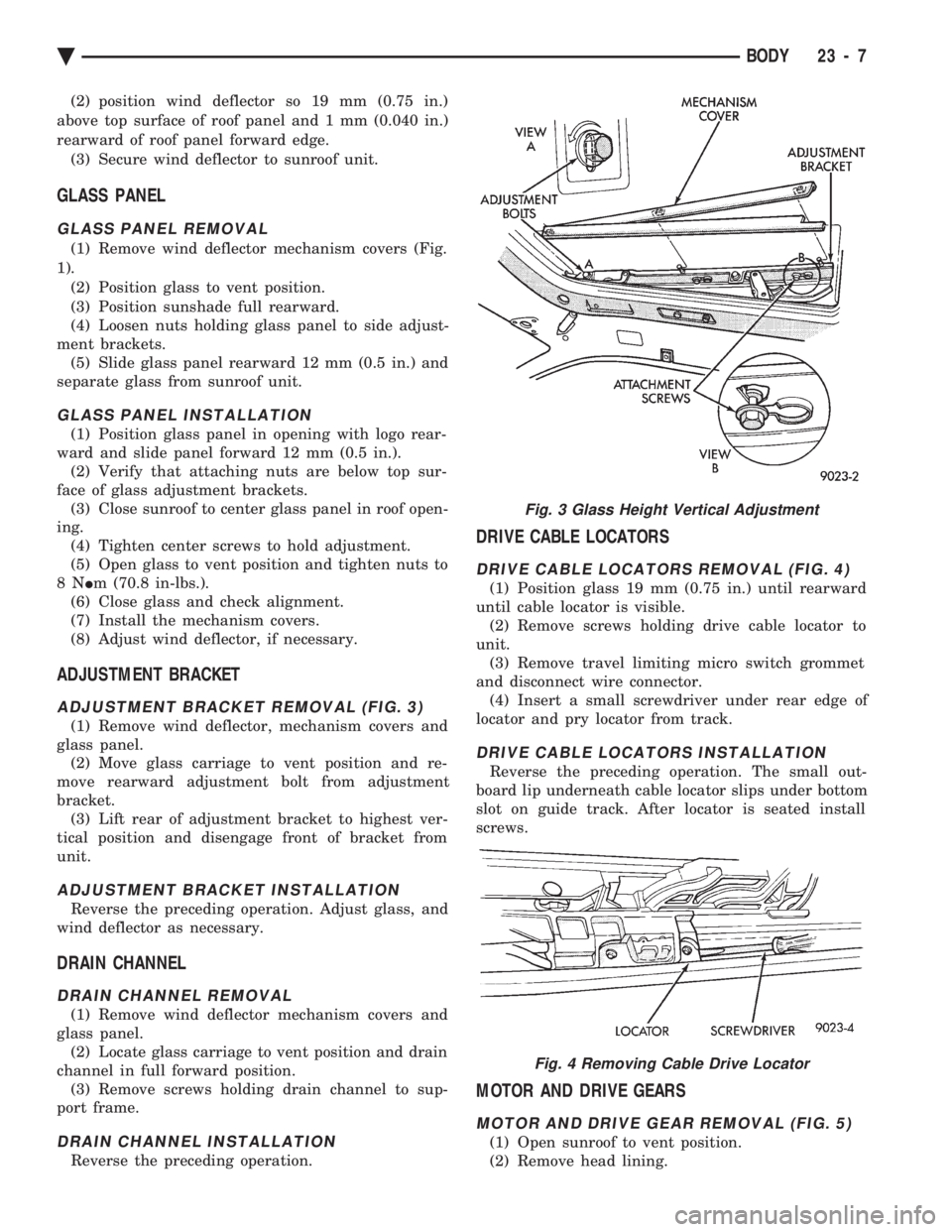

DRIVE CABLE LOCATORS REMOVAL (FIG. 4)

(1) Position glass 19 mm (0.75 in.) until rearward

until cable locator is visible. (2) Remove screws holding drive cable locator to

unit. (3) Remove travel limiting micro switch grommet

and disconnect wire connector. (4) Insert a small screwdriver under rear edge of

locator and pry locator from track.

DRIVE CABLE LOCATORS INSTALLATION

Reverse the preceding operation. The small out-

board lip underneath cable locator slips under bottom

slot on guide track. After locator is seated install

screws.

MOTOR AND DRIVE GEARS

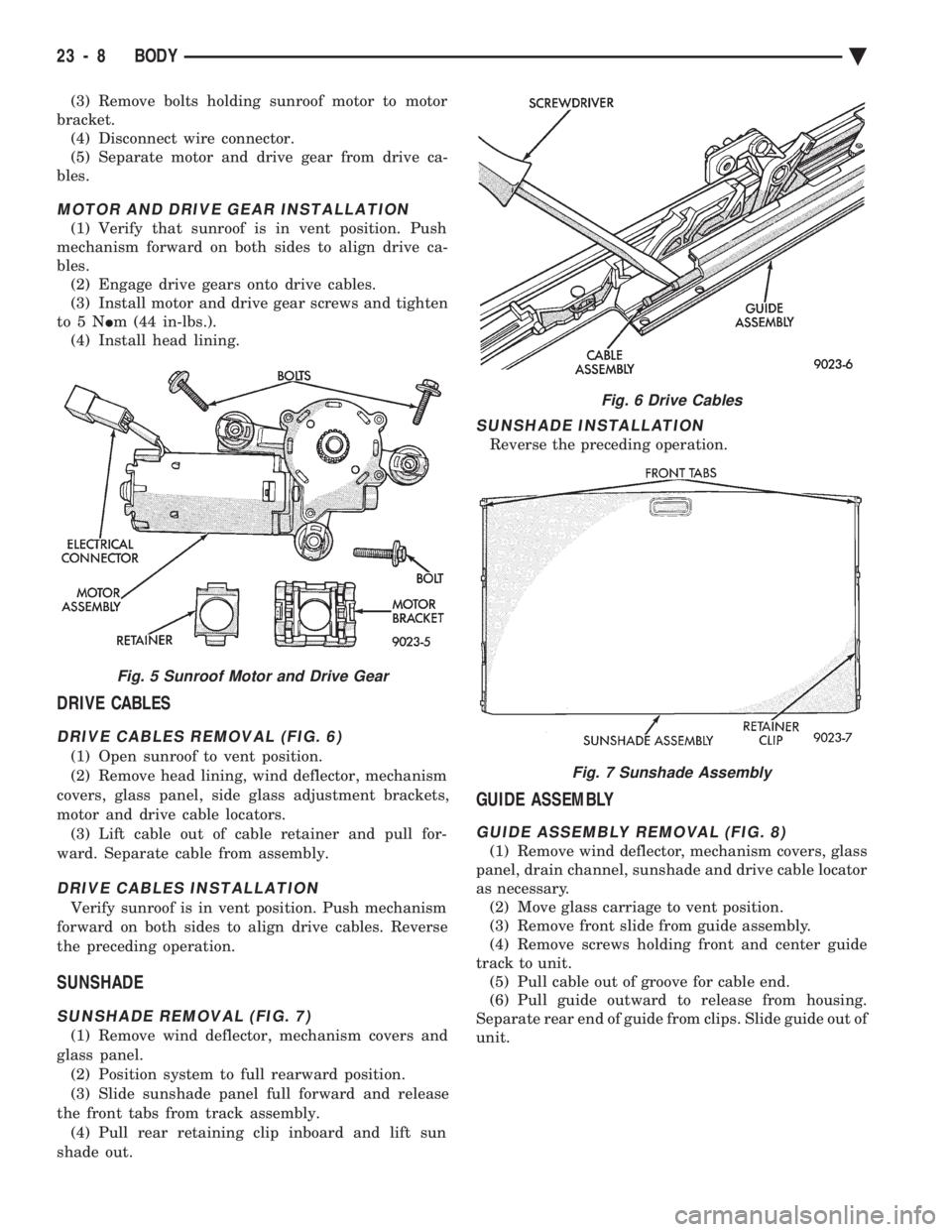

MOTOR AND DRIVE GEAR REMOVAL (FIG. 5)

(1) Open sunroof to vent position.

(2) Remove head lining.

Fig. 3 Glass Height Vertical Adjustment

Fig. 4 Removing Cable Drive Locator

Ä BODY 23 - 7

Page 2164 of 2438

(3) Remove bolts holding sunroof motor to motor

bracket. (4) Disconnect wire connector.

(5) Separate motor and drive gear from drive ca-

bles.

MOTOR AND DRIVE GEAR INSTALLATION

(1) Verify that sunroof is in vent position. Push

mechanism forward on both sides to align drive ca-

bles. (2) Engage drive gears onto drive cables.

(3) Install motor and drive gear screws and tighten

to5N Im (44 in-lbs.).

(4) Install head lining.

DRIVE CABLES

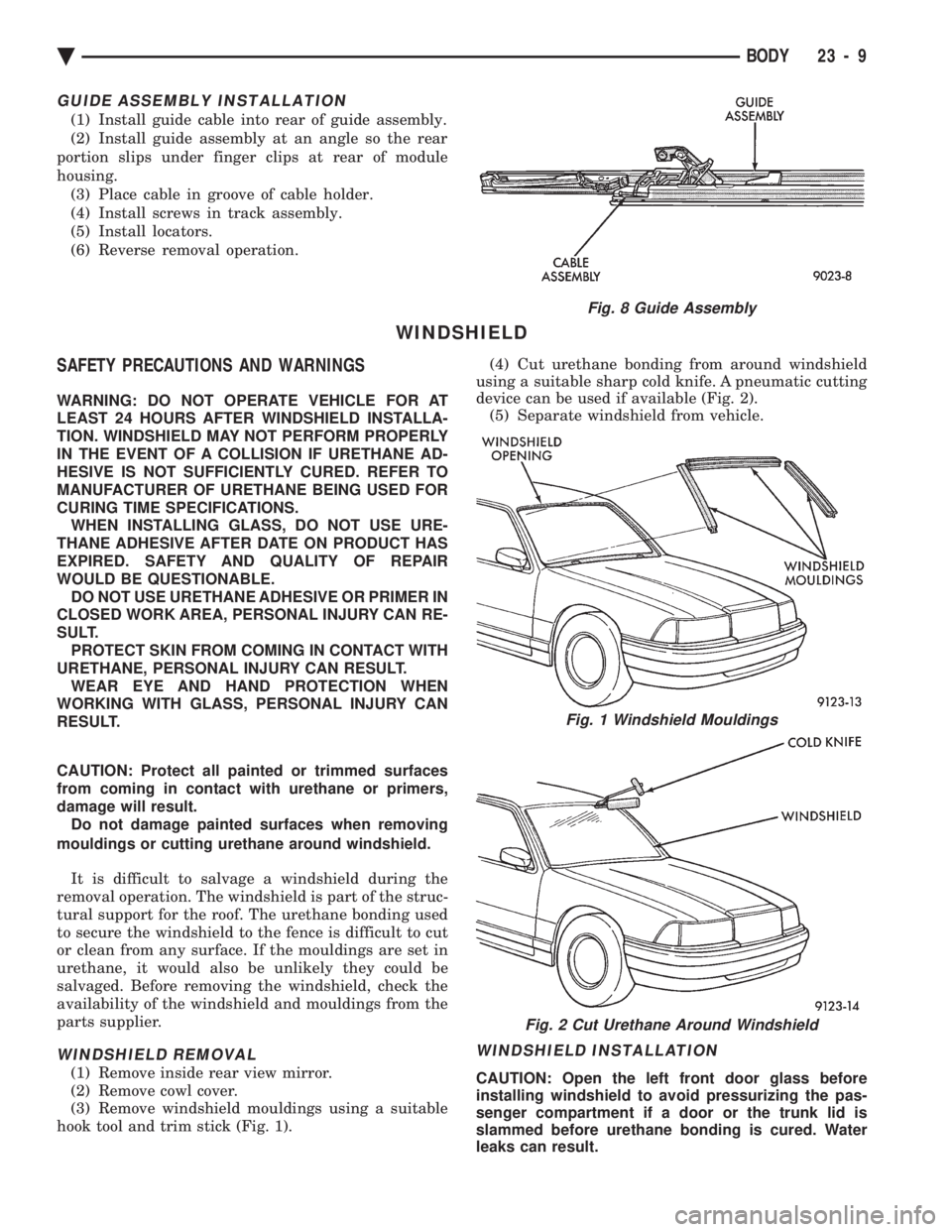

DRIVE CABLES REMOVAL (FIG. 6)

(1) Open sunroof to vent position.

(2) Remove head lining, wind deflector, mechanism

covers, glass panel, side glass adjustment brackets,

motor and drive cable locators. (3) Lift cable out of cable retainer and pull for-

ward. Separate cable from assembly.

DRIVE CABLES INSTALLATION

Verify sunroof is in vent position. Push mechanism

forward on both sides to align drive cables. Reverse

the preceding operation.

SUNSHADE

SUNSHADE REMOVAL (FIG. 7)

(1) Remove wind deflector, mechanism covers and

glass panel. (2) Position system to full rearward position.

(3) Slide sunshade panel full forward and release

the front tabs from track assembly. (4) Pull rear retaining clip inboard and lift sun

shade out.

SUNSHADE INSTALLATION

Reverse the preceding operation.

GUIDE ASSEMBLY

GUIDE ASSEMBLY REMOVAL (FIG. 8)

(1) Remove wind deflector, mechanism covers, glass

panel, drain channel, sunshade and drive cable locator

as necessary. (2) Move glass carriage to vent position.

(3) Remove front slide from guide assembly.

(4) Remove screws holding front and center guide

track to unit. (5) Pull cable out of groove for cable end.

(6) Pull guide outward to release from housing.

Separate rear end of guide from clips. Slide guide out of

unit.

Fig. 5 Sunroof Motor and Drive Gear

Fig. 6 Drive Cables

Fig. 7 Sunshade Assembly

23 - 8 BODY Ä

Page 2165 of 2438

GUIDE ASSEMBLY INSTALLATION

(1) Install guide cable into rear of guide assembly.

(2) Install guide assembly at an angle so the rear

portion slips under finger clips at rear of module

housing. (3) Place cable in groove of cable holder.

(4) Install screws in track assembly.

(5) Install locators.

(6) Reverse removal operation.

WINDSHIELD

SAFETY PRECAUTIONS AND WARNINGS

WARNING: DO NOT OPERATE VEHICLE FOR AT

LEAST 24 HOURS AFTER WINDSHIELD INSTALLA-

TION. WINDSHIELD MAY NOT PERFORM PROPERLY

IN THE EVENT OF A COLLISION IF URETHANE AD-

HESIVE IS NOT SUFFICIENTLY CURED. REFER TO

MANUFACTURER OF URETHANE BEING USED FOR

CURING TIME SPECIFICATIONS. WHEN INSTALLING GLASS, DO NOT USE URE-

THANE ADHESIVE AFTER DATE ON PRODUCT HAS

EXPIRED. SAFETY AND QUALITY OF REPAIR

WOULD BE QUESTIONABLE. DO NOT USE URETHANE ADHESIVE OR PRIMER IN

CLOSED WORK AREA, PERSONAL INJURY CAN RE-

SULT. PROTECT SKIN FROM COMING IN CONTACT WITH

URETHANE, PERSONAL INJURY CAN RESULT. WEAR EYE AND HAND PROTECTION WHEN

WORKING WITH GLASS, PERSONAL INJURY CAN

RESULT.

CAUTION: Protect all painted or trimmed surfaces

from coming in contact with urethane or primers,

damage will result. Do not damage painted surfaces when removing

mouldings or cutting urethane around windshield.

It is difficult to salvage a windshield during the

removal operation. The windshield is part of the struc-

tural support for the roof. The urethane bonding used

to secure the windshield to the fence is difficult to cut

or clean from any surface. If the mouldings are set in

urethane, it would also be unlikely they could be

salvaged. Before removing the windshield, check the

availability of the windshield and mouldings from the

parts supplier.

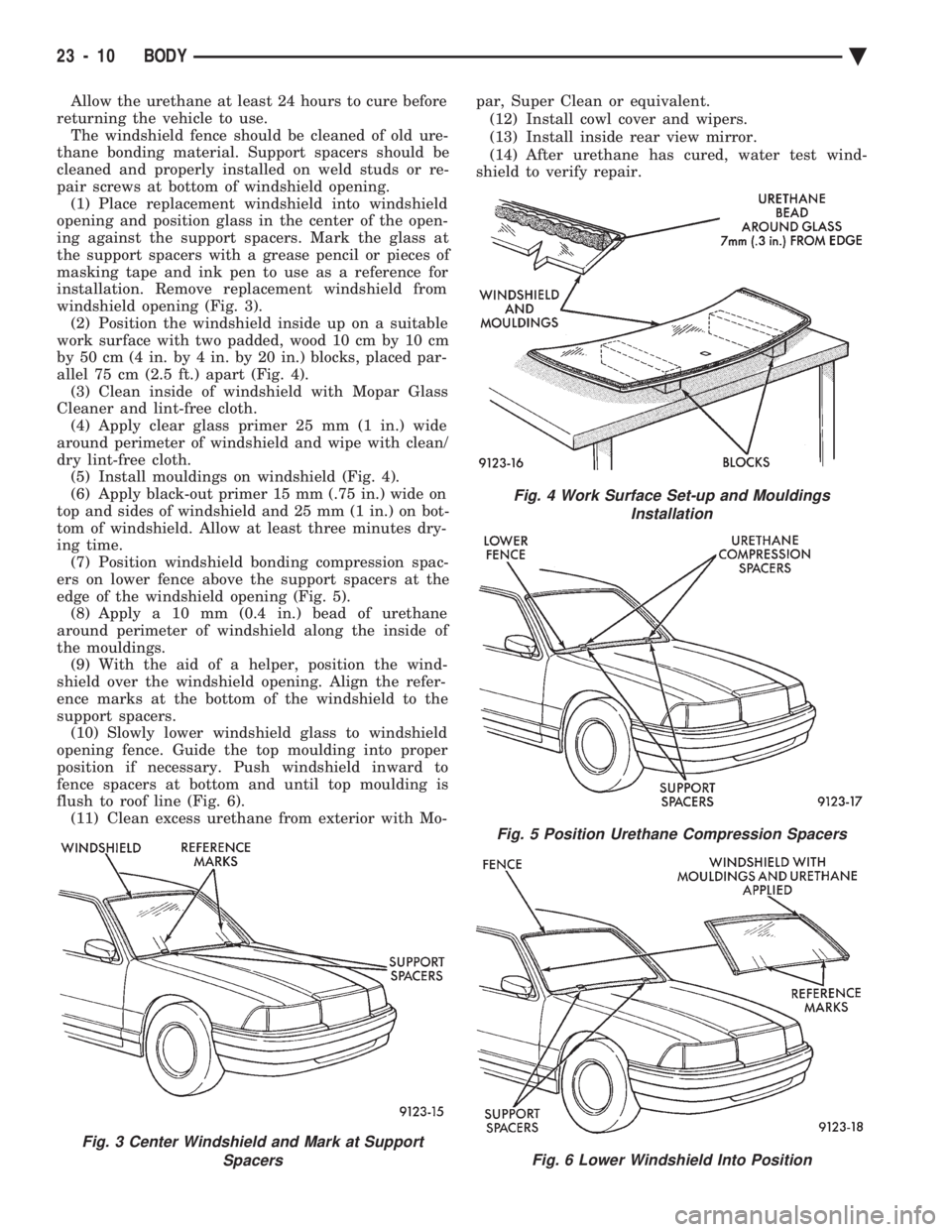

WINDSHIELD REMOVAL

(1) Remove inside rear view mirror.

(2) Remove cowl cover.

(3) Remove windshield mouldings using a suitable

hook tool and trim stick (Fig. 1). (4) Cut urethane bonding from around windshield

using a suitable sharp cold knife. A pneumatic cutting

device can be used if available (Fig. 2). (5) Separate windshield from vehicle.

WINDSHIELD INSTALLATION

CAUTION: Open the left front door glass before

installing windshield to avoid pressurizing the pas-

senger compartment if a door or the trunk lid is

slammed before urethane bonding is cured. Water

leaks can result.

Fig. 8 Guide Assembly

Fig. 1 Windshield Mouldings

Fig. 2 Cut Urethane Around Windshield

Ä BODY 23 - 9

Page 2166 of 2438

Allow the urethane at least 24 hours to cure before

returning the vehicle to use. The windshield fence should be cleaned of old ure-

thane bonding material. Support spacers should be

cleaned and properly installed on weld studs or re-

pair screws at bottom of windshield opening. (1) Place replacement windshield into windshield

opening and position glass in the center of the open-

ing against the support spacers. Mark the glass at

the support spacers with a grease pencil or pieces of

masking tape and ink pen to use as a reference for

installation. Remove replacement windshield from

windshield opening (Fig. 3). (2) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart (Fig. 4). (3) Clean inside of windshield with Mopar Glass

Cleaner and lint-free cloth. (4) Apply clear glass primer 25 mm (1 in.) wide

around perimeter of windshield and wipe with clean/

dry lint-free cloth. (5) Install mouldings on windshield (Fig. 4).

(6) Apply black-out primer 15 mm (.75 in.) wide on

top and sides of windshield and 25 mm (1 in.) on bot-

tom of windshield. Allow at least three minutes dry-

ing time. (7) Position windshield bonding compression spac-

ers on lower fence above the support spacers at the

edge of the windshield opening (Fig. 5). (8) Apply a 10 mm (0.4 in.) bead of urethane

around perimeter of windshield along the inside of

the mouldings. (9) With the aid of a helper, position the wind-

shield over the windshield opening. Align the refer-

ence marks at the bottom of the windshield to the

support spacers. (10) Slowly lower windshield glass to windshield

opening fence. Guide the top moulding into proper

position if necessary. Push windshield inward to

fence spacers at bottom and until top moulding is

flush to roof line (Fig. 6). (11) Clean excess urethane from exterior with Mo- par, Super Clean or equivalent.

(12) Install cowl cover and wipers.

(13) Install inside rear view mirror.

(14) After urethane has cured, water test wind-

shield to verify repair.

Fig. 3 Center Windshield and Mark at Support

Spacers

Fig. 4 Work Surface Set-up and MouldingsInstallation

Fig. 5 Position Urethane Compression Spacers

Fig. 6 Lower Windshield Into Position

23 - 10 BODY Ä

Page 2167 of 2438

AA-VEHICLE BODY COMPONENT SERVICE INDEX

page page

A-Pillar and Roof Rail Mouldings ............. 25

B-Pillar Trim Panel ....................... 25

Body Side Moulding and Applique ............ 24

Cowl Cover ............................. 13

Cowl Panel Trim and Scuff Plates ............ 25

Door Opening Weatherstrips ................ 24

Floor Carpet ............................ 30

Front Center Console ..................... 29

Front Door and Hinge ..................... 15

Front Door Belt Moulding and Weatherstrip ..... 17

Front Door Glass ........................ 17

Front Door Glass Channel and Run Weatherstrip . 18

Front Door Glass Run Lower Channel ......... 18

Front Door Latch ......................... 16

Front Door Side View Mirror ................ 17

Front Door Silencer and Water Shield ......... 15

Front Door Trim Panel .................... 14

Front Door Window Regulator/Manual ......... 18

Front Door Window Regulator/Power .......... 19

Front End Splash Shields .................. 13

Front Fender ............................ 14

Front Power Door Lock Actuator ............. 19

Front Seat Belts ......................... 27

Front Seats ............................. 28

Fuel Fill Door ........................... 36

Grille .................................. 11

Head Lining ............................. 30

Hood and Hinges ........................ 11

Hood Latch and Release Cable .............. 12

Outside Front Door Latch Release Handle ..... 16

Outside Rear Door Latch Release Handle ...... 21 Overhead Console

........................ 30

Quarter Extension Trim Panel ............... 27

Quarter Trim Panel ....................... 27

Rear Deck Filler Panel .................... 31

Rear Door and Hinge ..................... 20

Rear Door Belt Moulding and Weatherstrip ..... 22

Rear Door Glass ......................... 22

Rear Door Glass Run Weatherstrip ........... 22

Rear Door Glass Stationary Glass Module ..... 23

Rear Door Latch ......................... 21

Rear Door Silencer and Water Shield ......... 20

Rear Door Trim Panel ..................... 20

Rear Door Window Regulator/Manual ......... 23

Rear Door Window Regulator/Power .......... 23

Rear Power Door Lock Actuator ............. 22

Rear Seat Belts .......................... 28

Rear Seats ............................. 28

Rear Shelf Trim Panel ..................... 27

Rear Window Glass ...................... 32

Sun Roof Air Deflector .................... 31

Sun Roof Drain Tubes .................... 31

Sun Roof Weatherstrip .................... 31

Trunk Lid .............................. 33

Trunk Lid Hinge ......................... 34

Trunk Lid Latch .......................... 34

Trunk Lid Lock .......................... 34

Trunk Lid Luggage Rack ................... 35

Trunk Lid Torsion Bar ..................... 34

Trunk Lining ............................ 35

Trunk Opening Weatherstrip ................ 35

Vinyl Roof Bonnet ........................ 31

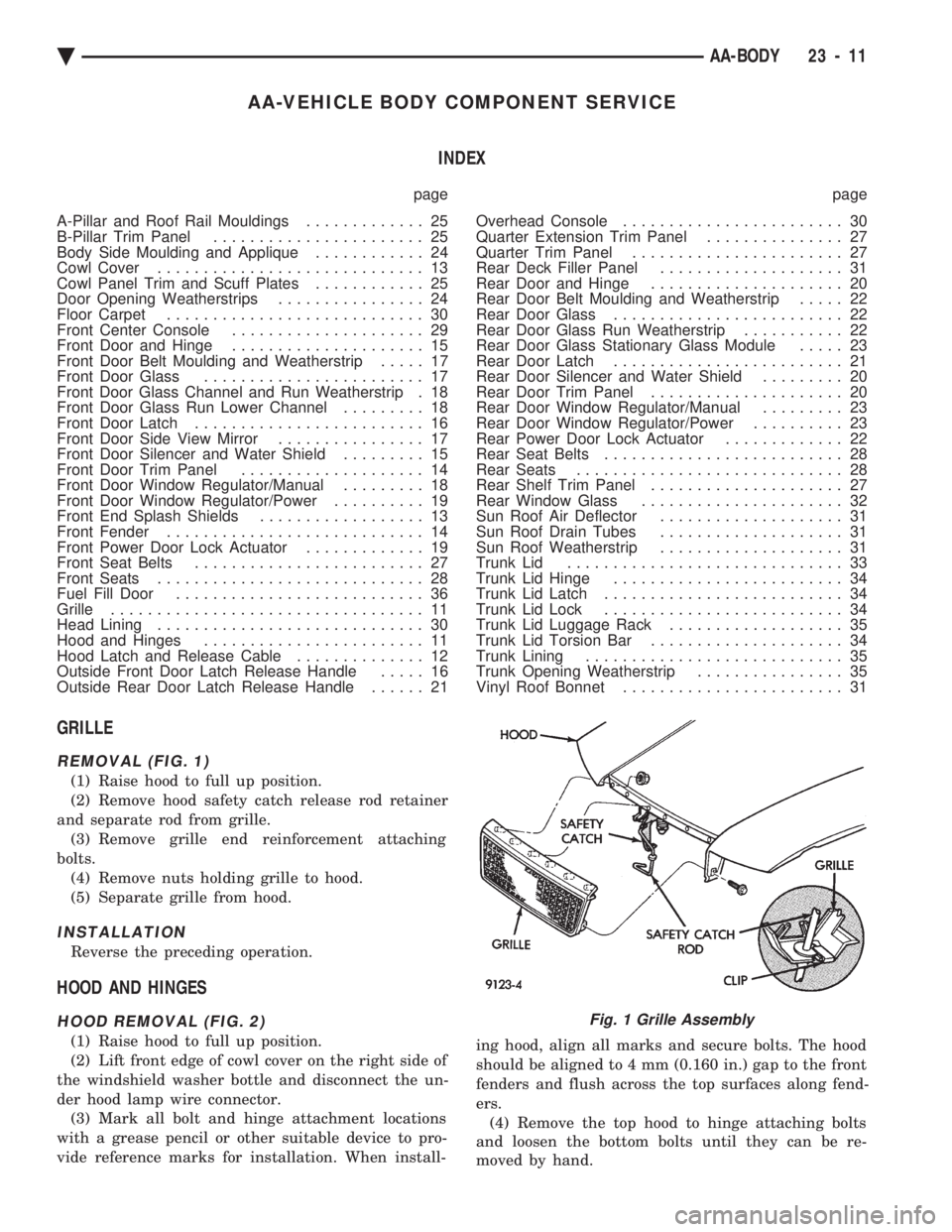

GRILLE

REMOVAL (FIG. 1)

(1) Raise hood to full up position.

(2) Remove hood safety catch release rod retainer

and separate rod from grille. (3) Remove grille end reinforcement attaching

bolts. (4) Remove nuts holding grille to hood.

(5) Separate grille from hood.

INSTALLATION

Reverse the preceding operation.

HOOD AND HINGES

HOOD REMOVAL (FIG. 2)

(1) Raise hood to full up position.

(2) Lift front edge of cowl cover on the right side of

the windshield washer bottle and disconnect the un-

der hood lamp wire connector. (3) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When install- ing hood, align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers. (4) Remove the top hood to hinge attaching bolts

and loosen the bottom bolts until they can be re-

moved by hand.

Fig. 1 Grille Assembly

Ä AA-BODY 23 - 11

Page 2181 of 2438

WHEEL OPENING AND BODY SIDE MOULDING REMOVAL AND INSTALLATION (FIG. 38)

FRONT FENDER

(1) Remove screws holding wheel opening mould-

ing to front fender. (2) Pry bottom of body side moulding from clip on

front fender using a suitable trim stick. Lift mould-

ing from clip and separate from fender. (3) Replace damaged moulding clip weld studs

with repair screws. Paint bare metal surfaces behind

moulding to avoid rust. (4) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (5) Hook top of body side moulding over clip and

snap bottom of moulding onto clip. (6) Install screws around wheel opening.

DOORS (1) Pry bottom of body side moulding from clips on

door using a suitable trim stick. Lift moulding from

clip and separate from door. (2) Replace damaged moulding clip weld studs

with repair screws. Paint or undercoat bare metal

surfaces behind moulding to avoid rust. (3) Position moulding on door in design location.

(4) Hook top of moulding over clips and snap bot-

tom of moulding onto clips.

QUARTER PANEL (1) Remove screws holding wheel opening mould-

ing to quarter panel. (2) Pry bottom of body side moulding from clip on

quarter panel using a suitable trim stick. Lift moul-

ding from clip and separate from fender. (3) Replace damaged moulding clip weld studs

with repair screws. Paint or undercoat bare metal

surfaces behind moulding to avoid rust. (4) Position moulding in wheel opening and start

top center screw of wheel opening moulding. (5) Hook top of body side moulding over clip and

snap bottom of moulding onto clip. (6) Install screws around wheel opening.

APPLIQUE MOULDING AND RETAINERREMOVAL (FIG. 38)

(1) Remove screws holding applique to rocker

panel from under vehicle. (2) Lift applique upward to separate from retain-

ing channel. (3) Remove pop-rivets holding retainer to rocker

panel using a suitable drill.

APPLIQUE MOULDING AND RETAINER INSTALLATION

(1) Install applique retainer on rocker panel with

pop-rivets. Paint or undercoat bare metal surfaces to

avoid rust. (2) Hook top of applique over retainer channel and

install screws under rocker panel.

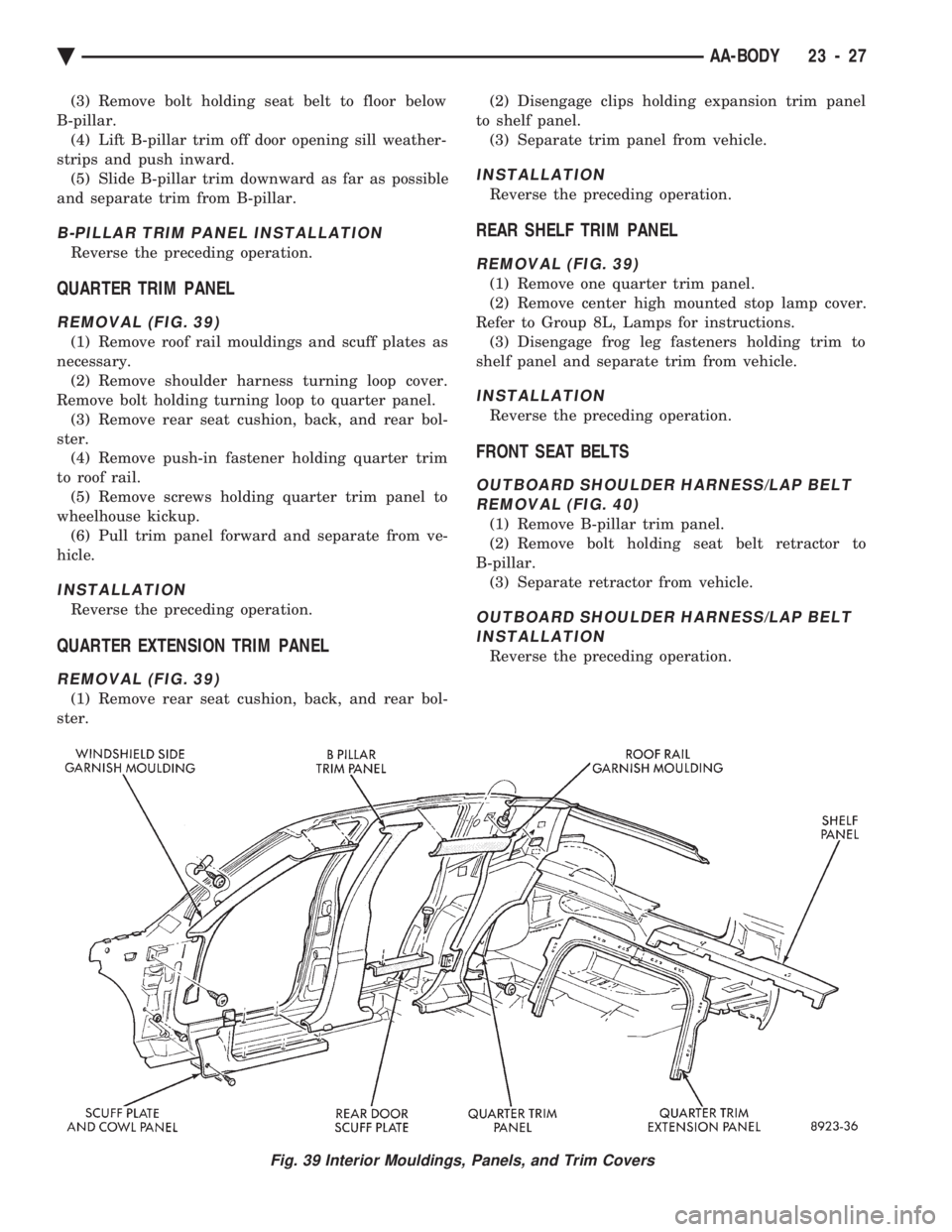

COWL PANEL TRIM AND SCUFF PLATES

COWL PANEL AND DOOR OPENING SCUFF PLATE REMOVAL (FIG. 39)

(1) Open front door.

(2) Remove screw holding trim panel to cowl for-

ward of the front door opening. (3) Remove screws holding scuff plate to door sill.

(4) Separate cowl panel trim and scuff plate from

vehicle.

COWL PANEL AND DOOR OPENING SCUFF PLATE INSTALLATION

Reverse the preceding operation.

REAR DOOR OPENING SCUFF PLATEREMOVAL (FIG. 39)

(1) Open rear door.

(2) Remove screws holding scuff plate to door sill.

(3) Separate scuff plate from vehicle.

REAR DOOR OPENING SCUFF PLATEINSTALLATION

Reverse the preceding operation.

A-PILLAR AND ROOF RAIL MOULDINGS

A-PILLAR MOULDING REMOVAL (FIG. 39)

(1) Open front door.

(2) Disengage clips holding A-pillar moulding to

roof rail above door opening. (3) Slide A-pillar moulding upward and pull rear-

ward to separate moulding from A-pillar.

A-PILLAR MOULDING INSTALLATION

Reverse the preceding operation.

REAR DOOR ROOF RAIL MOULDING REMOVAL (FIG. 39)

(1) Open rear door.

(2) Disengage clips holding roof rail moulding to

roof rail above rear door opening. (3) Separate moulding from vehicle.

REAR DOOR ROOF RAIL MOULDINGINSTALLATION

Reverse the preceding operation.

B-PILLAR TRIM PANEL

B-PILLAR TRIM PANEL REMOVAL (FIG. 39)

(1) Remove roof rail mouldings and scuff plates as

necessary. (2) Remove shoulder harness turning loop cover.

Remove bolt holding turning loop to B-pillar.

Ä AA-BODY 23 - 25

Page 2183 of 2438

(3) Remove bolt holding seat belt to floor below

B-pillar. (4) Lift B-pillar trim off door opening sill weather-

strips and push inward. (5) Slide B-pillar trim downward as far as possible

and separate trim from B-pillar.

B-PILLAR TRIM PANEL INSTALLATION

Reverse the preceding operation.

QUARTER TRIM PANEL

REMOVAL (FIG. 39)

(1) Remove roof rail mouldings and scuff plates as

necessary. (2) Remove shoulder harness turning loop cover.

Remove bolt holding turning loop to quarter panel. (3) Remove rear seat cushion, back, and rear bol-

ster. (4) Remove push-in fastener holding quarter trim

to roof rail. (5) Remove screws holding quarter trim panel to

wheelhouse kickup. (6) Pull trim panel forward and separate from ve-

hicle.

INSTALLATION

Reverse the preceding operation.

QUARTER EXTENSION TRIM PANEL

REMOVAL (FIG. 39)

(1) Remove rear seat cushion, back, and rear bol-

ster. (2) Disengage clips holding expansion trim panel

to shelf panel. (3) Separate trim panel from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR SHELF TRIM PANEL

REMOVAL (FIG. 39)

(1) Remove one quarter trim panel.

(2) Remove center high mounted stop lamp cover.

Refer to Group 8L, Lamps for instructions. (3) Disengage frog leg fasteners holding trim to

shelf panel and separate trim from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT SEAT BELTS

OUTBOARD SHOULDER HARNESS/LAP BELT REMOVAL (FIG. 40)

(1) Remove B-pillar trim panel.

(2) Remove bolt holding seat belt retractor to

B-pillar. (3) Separate retractor from vehicle.

OUTBOARD SHOULDER HARNESS/LAP BELTINSTALLATION

Reverse the preceding operation.

Fig. 39 Interior Mouldings, Panels, and Trim Covers

Ä AA-BODY 23 - 27