timing belt CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1600 of 2438

CAMSHAFT AND CRANKSHAFT TIMING

PROCEDURE

INSTALLATION

(1) Remove air cleaner fresh air duct.

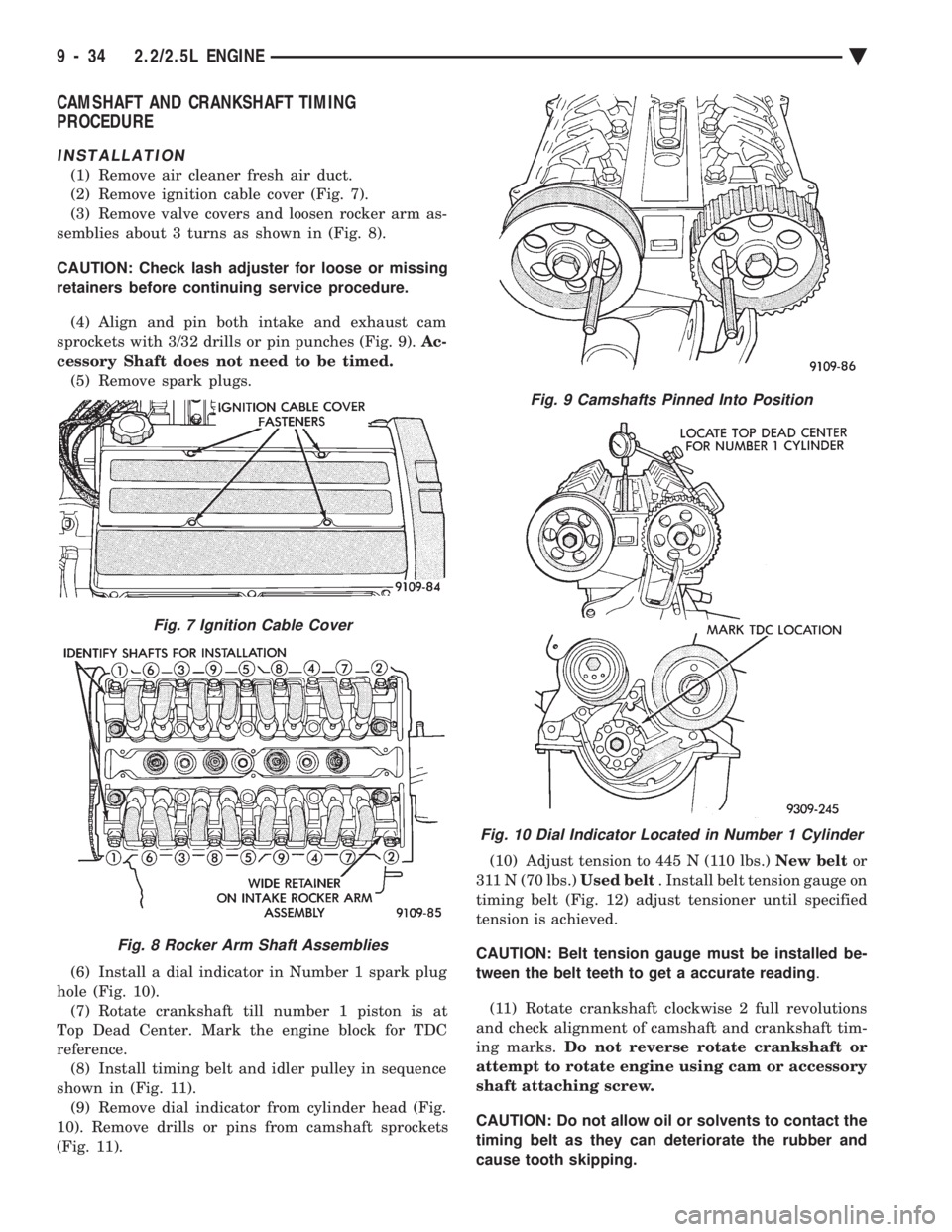

(2) Remove ignition cable cover (Fig. 7).

(3) Remove valve covers and loosen rocker arm as-

semblies about 3 turns as shown in (Fig. 8).

CAUTION: Check lash adjuster for loose or missing

retainers before continuing service procedure.

(4) Align and pin both intake and exhaust cam

sprockets with 3/32 drills or pin punches (Fig. 9). Ac-

cessory Shaft does not need to be timed. (5) Remove spark plugs.

(6) Install a dial indicator in Number 1 spark plug

hole (Fig. 10). (7) Rotate crankshaft till number 1 piston is at

Top Dead Center. Mark the engine block for TDC

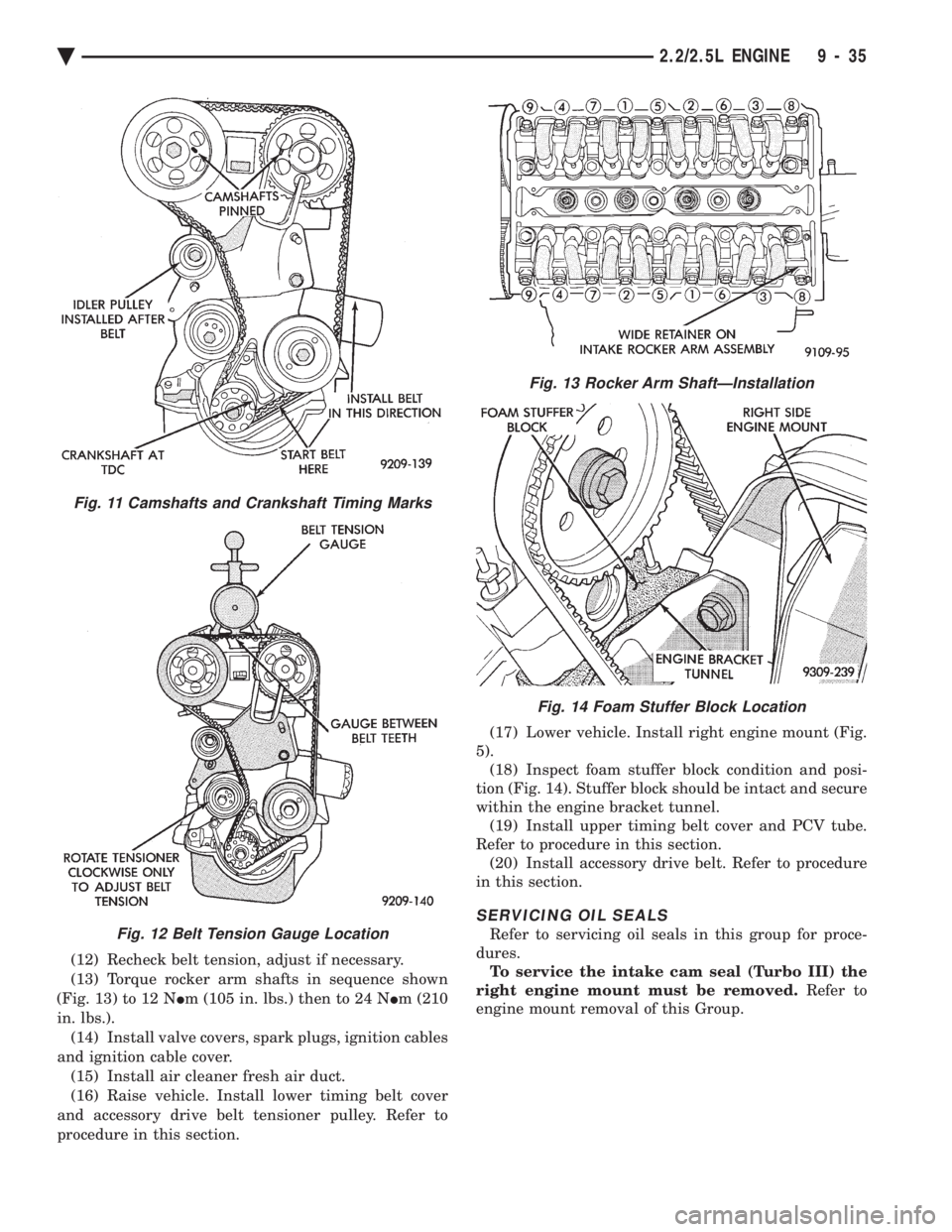

reference. (8) Install timing belt and idler pulley in sequence

shown in (Fig. 11). (9) Remove dial indicator from cylinder head (Fig.

10). Remove drills or pins from camshaft sprockets

(Fig. 11). (10) Adjust tension to 445 N (110 lbs.)

New beltor

311 N (70 lbs.) Used belt. Install belt tension gauge on

timing belt (Fig. 12) adjust tensioner until specified

tension is achieved.

CAUTION: Belt tension gauge must be installed be-

tween the belt teeth to get a accurate reading .

(11) Rotate crankshaft clockwise 2 full revolutions

and check alignment of camshaft and crankshaft tim-

ing marks. Do not reverse rotate crankshaft or

attempt to rotate engine using cam or accessory

shaft attaching screw.

CAUTION: Do not allow oil or solvents to contact the

timing belt as they can deteriorate the rubber and

cause tooth skipping.

Fig. 7 Ignition Cable Cover

Fig. 8 Rocker Arm Shaft Assemblies

Fig. 9 Camshafts Pinned Into Position

Fig. 10 Dial Indicator Located in Number 1 Cylinder

9 - 34 2.2/2.5L ENGINE Ä

Page 1601 of 2438

(12) Recheck belt tension, adjust if necessary.

(13) Torque rocker arm shafts in sequence shown

(Fig. 13) to 12 N Im (105 in. lbs.) then to 24 N Im (210

in. lbs.). (14) Install valve covers, spark plugs, ignition cables

and ignition cable cover. (15) Install air cleaner fresh air duct.

(16) Raise vehicle. Install lower timing belt cover

and accessory drive belt tensioner pulley. Refer to

procedure in this section. (17) Lower vehicle. Install right engine mount (Fig.

5). (18) Inspect foam stuffer block condition and posi-

tion (Fig. 14). Stuffer block should be intact and secure

within the engine bracket tunnel. (19) Install upper timing belt cover and PCV tube.

Refer to procedure in this section. (20) Install accessory drive belt. Refer to procedure

in this section.

SERVICING OIL SEALS

Refer to servicing oil seals in this group for proce-

dures. To service the intake cam seal (Turbo III) the

right engine mount must be removed. Refer to

engine mount removal of this Group.

Fig. 13 Rocker Arm ShaftÐInstallation

Fig. 14 Foam Stuffer Block Location

Fig. 11 Camshafts and Crankshaft Timing Marks

Fig. 12 Belt Tension Gauge Location

Ä 2.2/2.5L ENGINE 9 - 35

Page 1608 of 2438

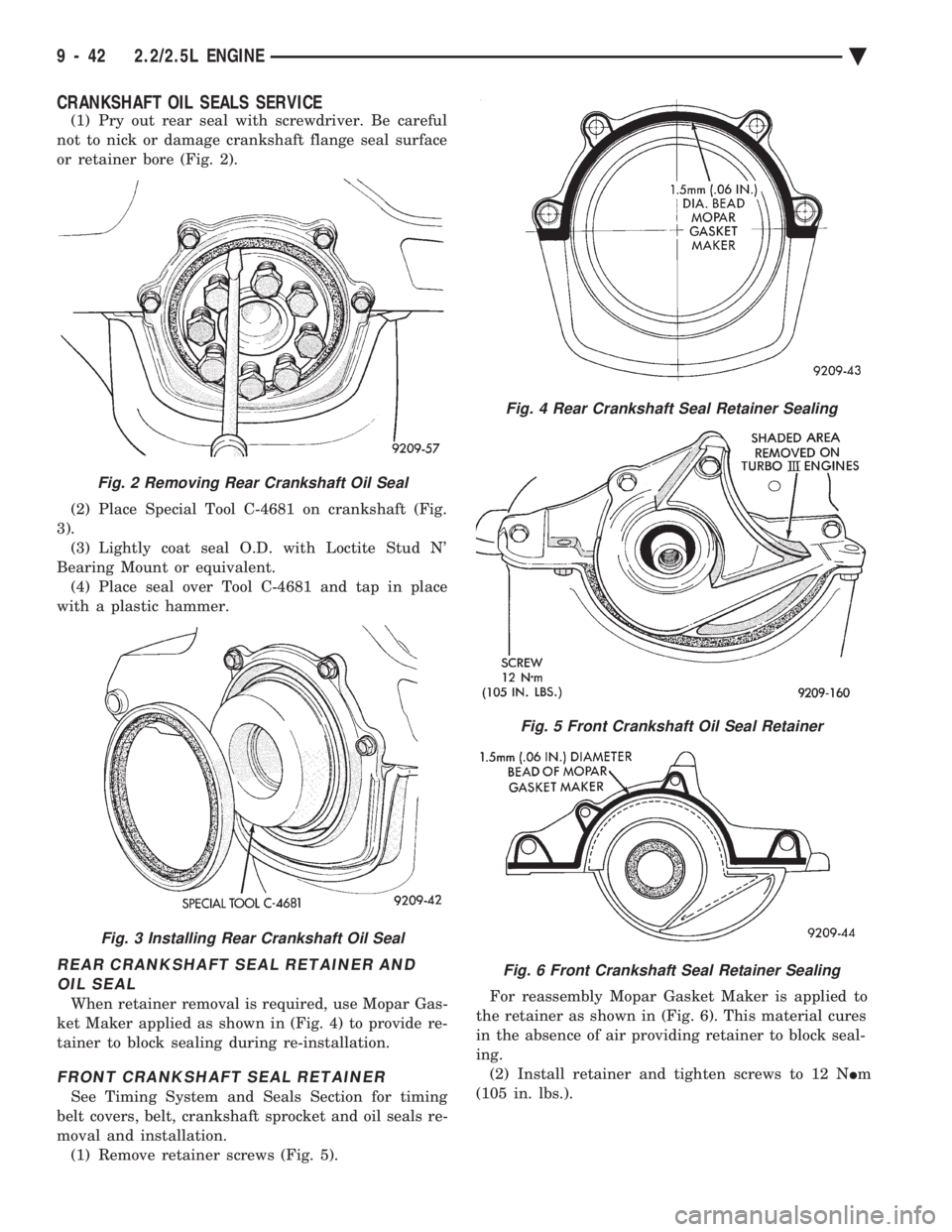

CRANKSHAFT OIL SEALS SERVICE

(1) Pry out rear seal with screwdriver. Be careful

not to nick or damage crankshaft flange seal surface

or retainer bore (Fig. 2).

(2) Place Special Tool C-4681 on crankshaft (Fig.

3). (3) Lightly coat seal O.D. with Loctite Stud N'

Bearing Mount or equivalent. (4) Place seal over Tool C-4681 and tap in place

with a plastic hammer.

REAR CRANKSHAFT SEAL RETAINER AND OIL SEAL

When retainer removal is required, use Mopar Gas-

ket Maker applied as shown in (Fig. 4) to provide re-

tainer to block sealing during re-installation.

FRONT CRANKSHAFT SEAL RETAINER

See Timing System and Seals Section for timing

belt covers, belt, crankshaft sprocket and oil seals re-

moval and installation. (1) Remove retainer screws (Fig. 5). For reassembly Mopar Gasket Maker is applied to

the retainer as shown in (Fig. 6). This material cures

in the absence of air providing retainer to block seal-

ing. (2) Install retainer and tighten screws to 12 N Im

(105 in. lbs.).

Fig. 2 Removing Rear Crankshaft Oil Seal

Fig. 3 Installing Rear Crankshaft Oil Seal

Fig. 4 Rear Crankshaft Seal Retainer Sealing

Fig. 5 Front Crankshaft Oil Seal Retainer

Fig. 6 Front Crankshaft Seal Retainer Sealing

9 - 42 2.2/2.5L ENGINE Ä

Page 1610 of 2438

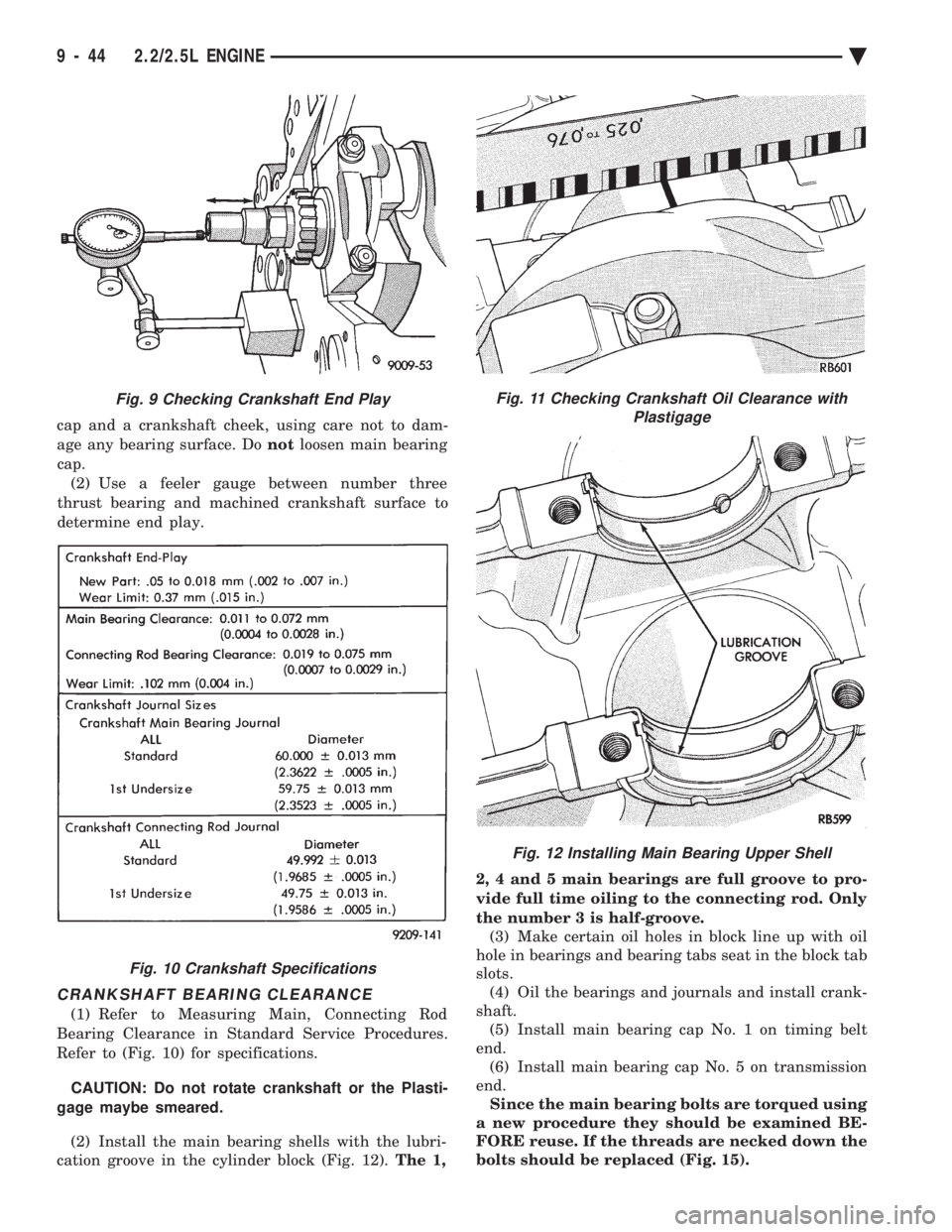

cap and a crankshaft cheek, using care not to dam-

age any bearing surface. Do notloosen main bearing

cap. (2) Use a feeler gauge between number three

thrust bearing and machined crankshaft surface to

determine end play.

CRANKSHAFT BEARING CLEARANCE

(1) Refer to Measuring Main, Connecting Rod

Bearing Clearance in Standard Service Procedures.

Refer to (Fig. 10) for specifications.

CAUTION: Do not rotate crankshaft or the Plasti-

gage maybe smeared.

(2) Install the main bearing shells with the lubri-

cation groove in the cylinder block (Fig. 12). The 1, 2, 4 and 5 main bearings are full groove to pro-

vide full time oiling to the connecting rod. Only

the number 3 is half-groove.

(3) Make certain oil holes in block line up with oil

hole in bearings and bearing tabs seat in the block tab

slots. (4) Oil the bearings and journals and install crank-

shaft. (5) Install main bearing cap No. 1 on timing belt

end. (6) Install main bearing cap No. 5 on transmission

end. Since the main bearing bolts are torqued using

a new procedure they should be examined BE-

FORE reuse. If the threads are necked down the

bolts should be replaced (Fig. 15).

Fig. 9 Checking Crankshaft End Play

Fig. 10 Crankshaft Specifications

Fig. 11 Checking Crankshaft Oil Clearance with Plastigage

Fig. 12 Installing Main Bearing Upper Shell

9 - 44 2.2/2.5L ENGINE Ä

Page 1615 of 2438

CYLINDER BLOCK, PISTON AND CONNECTING ROD ASSEMBLY SERVICE

PISTON AND CONNECTING RODÐREMOVAL

(1) Remove top ridge of cylinder bores with a reliable

ridge reamer before removing pistons from cylinder

block. Be sure to keep tops of pistons covered

during this operation . Mark piston with matching

cylinder number (Fig. 2).

(2) Remove oil pan. Ensure connecting rods and

connecting rod caps for cylinder identification. Identify

them if necessary (Fig. 3). (3) Valve relief toward manifold side of engine. Tur-

bocharged engine pistons will have arrow towards

front of engine. (4) Squirt hole on connecting rod must face timing

belt end of engine. (5) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore. (6) Remove connecting rod cap. Install connecting

rod bolt protectors on connecting rod bolts (Fig. 4).

Push each piston and rod assembly out of cylinder

bore. Be careful not to nick crankshaft journals.

(7) After removal, install bearing cap on the mat-

ing rod.

Fig. 1 Cylinder Block, Piston and Connecting Rod Assembly

Fig. 3 Identify Connecting Rod to Cylinder

Fig. 2 Piston Marking

Ä 2.2/2.5L ENGINE 9 - 49

Page 1632 of 2438

3.0L ENGINE INDEX

page page

Accessory Drive Belt Service ................ 70

Auto Lash Adjuster ....................... 75

Camshaft Service ........................ 76

Checking Engine Oil Pressure ............... 93

Crankshaft and Cylinder Block, Assembly Service . 86

Cylinder Block ........................... 89

Cylinder Head ........................... 78

Cylinder Head and Camshaft Service ......... 75

Engine Assembly ......................... 69

Engine Lubrication System ................. 91

Engine Mounts .......................... 68 Engine Specifications

..................... 95

General Information ....................... 66

Oil Filter and Bracket ..................... 94

Oil Pan ................................ 92

Oil Pump Service ........................ 92

Piston and Connecting Rod Assembly Service . . . 82

Timing Belt InspectionÐIn Vehicle ............ 72

Timing Belt Service ....................... 72

Valve Service ........................... 80

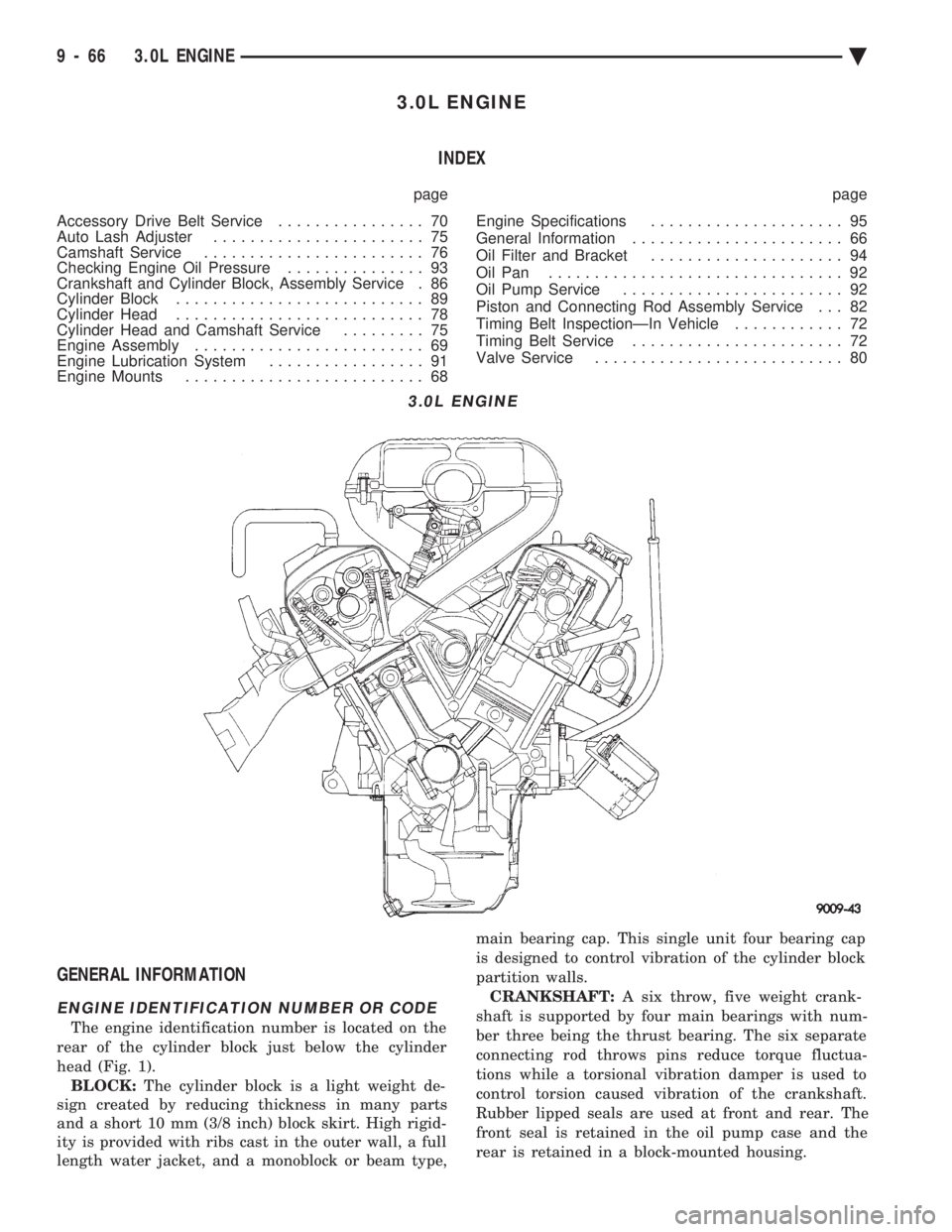

GENERAL INFORMATION

ENGINE IDENTIFICATION NUMBER OR CODE

The engine identification number is located on the

rear of the cylinder block just below the cylinder

head (Fig. 1). BLOCK: The cylinder block is a light weight de-

sign created by reducing thickness in many parts

and a short 10 mm (3/8 inch) block skirt. High rigid-

ity is provided with ribs cast in the outer wall, a full

length water jacket, and a monoblock or beam type, main bearing cap. This single unit four bearing cap

is designed to control vibration of the cylinder block

partition walls.

CRANKSHAFT: A six throw, five weight crank-

shaft is supported by four main bearings with num-

ber three being the thrust bearing. The six separate

connecting rod throws pins reduce torque fluctua-

tions while a torsional vibration damper is used to

control torsion caused vibration of the crankshaft.

Rubber lipped seals are used at front and rear. The

front seal is retained in the oil pump case and the

rear is retained in a block-mounted housing.

3.0L ENGINE

9 - 66 3.0L ENGINE Ä

Page 1633 of 2438

PISTONS: Are aluminum alloy with a steel strut,

short height, and thin wall so as to be autothermic

and light weight. The piston head with valve re-

cesses, in combination with the cylinder head, forms

a compact spherical head with clearance for total

valve lift with pistons at top dead center. The piston

skirt, top and second ring lands are finished to a ta-

pered roughness for oil retention and high resistance

to scuffing. Piston pins, press-fitted into place, join

the pistons to the connecting rods. CYLINDER HEAD: The alloy cylinder heads fea- ture cross-flow type intake and exhaust ports. Valve

guides and inserts are hardened cast iron. Valves of

heat resistance steel are arranged i

n a V with each

camshaft on center. To improve combustion speed the

chambers are a compact spherical design with a

squish area of approximately 30 percent of the piston

top area. The cylinder heads are common to either

cylinder bank by reversing the direction of installa-

tion. CAMSHAFTS: Two overhead camshafts provide

valve actuation, one front (radiator side of cylinder

bank) and one rear. The front camshaft is provided

with a distributor drive and is longer. Both cam-

shafts are supported by four bearing journals, thrust

for the front camshaft is taken at journal two and

the rear at journal three. Front and rear camshaft

driving sprockets are interchangeable. The sprockets

and the engine water pump are driven by a single

notched timing belt. ROCKER ARM SHAFTS: The shafts are retained

by the camshaft bearing journal caps. Four shafts are

used, one for each intake and exhaust rocker arm as-

sembly on each cylinder head. The hollow shafts pro-

vide a duct for lubricating oil flow from the cylinder

head to the valve mechanisms. ROCKER ARMS: Are of light weight die-cast

with roller type follower operating against the cam

shaft. The valve actuating end of the rocker arms are

machined to retain hydraulic lash adjusters, elimi-

nating valve lash adjustment. VALVES: Are made of heat resistant steel and are

further treated to resist heat. VALVE SPRINGS: Are especially designed to be

short. The valve spring wire cross-section is oval

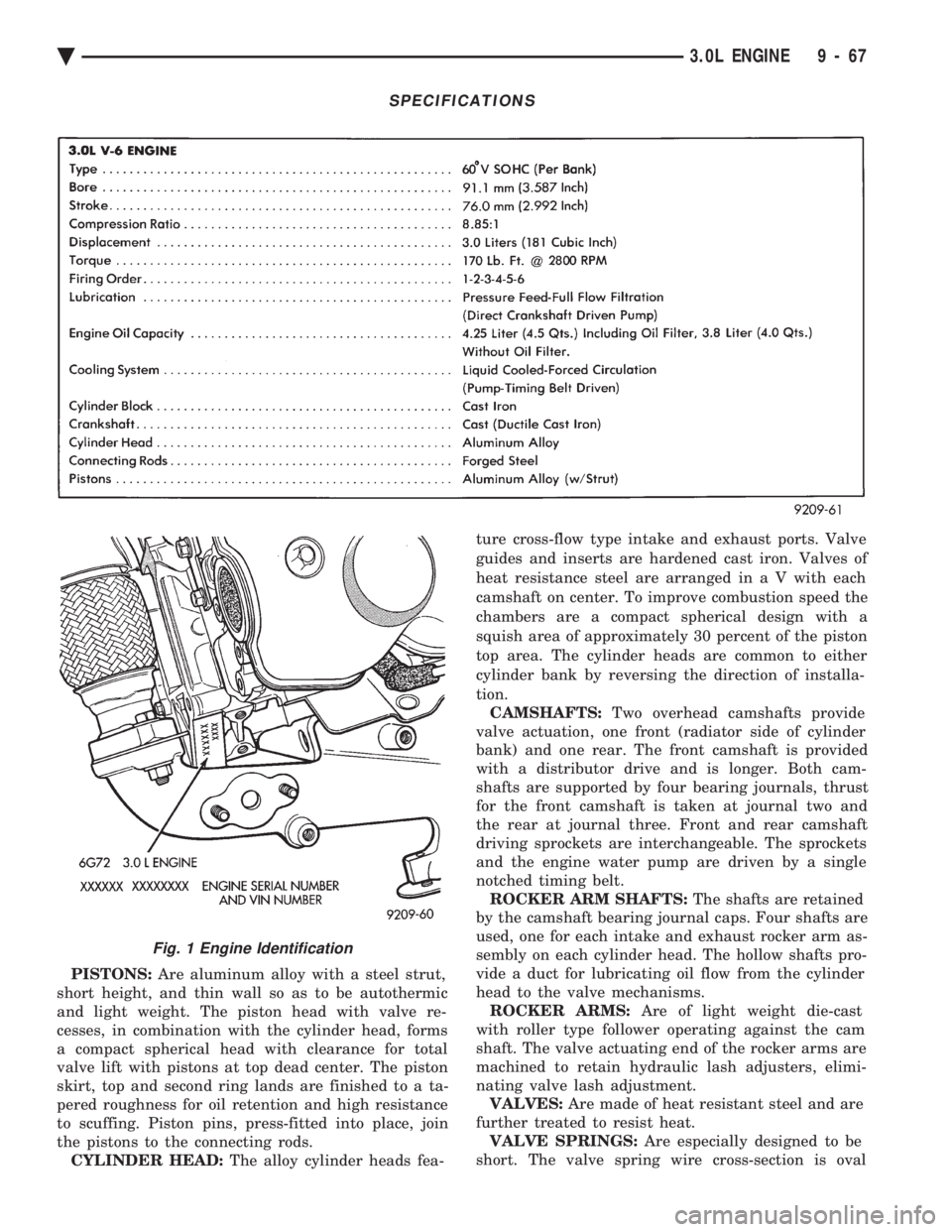

SPECIFICATIONS

Fig. 1 Engine Identification

Ä 3.0L ENGINE 9 - 67

Page 1638 of 2438

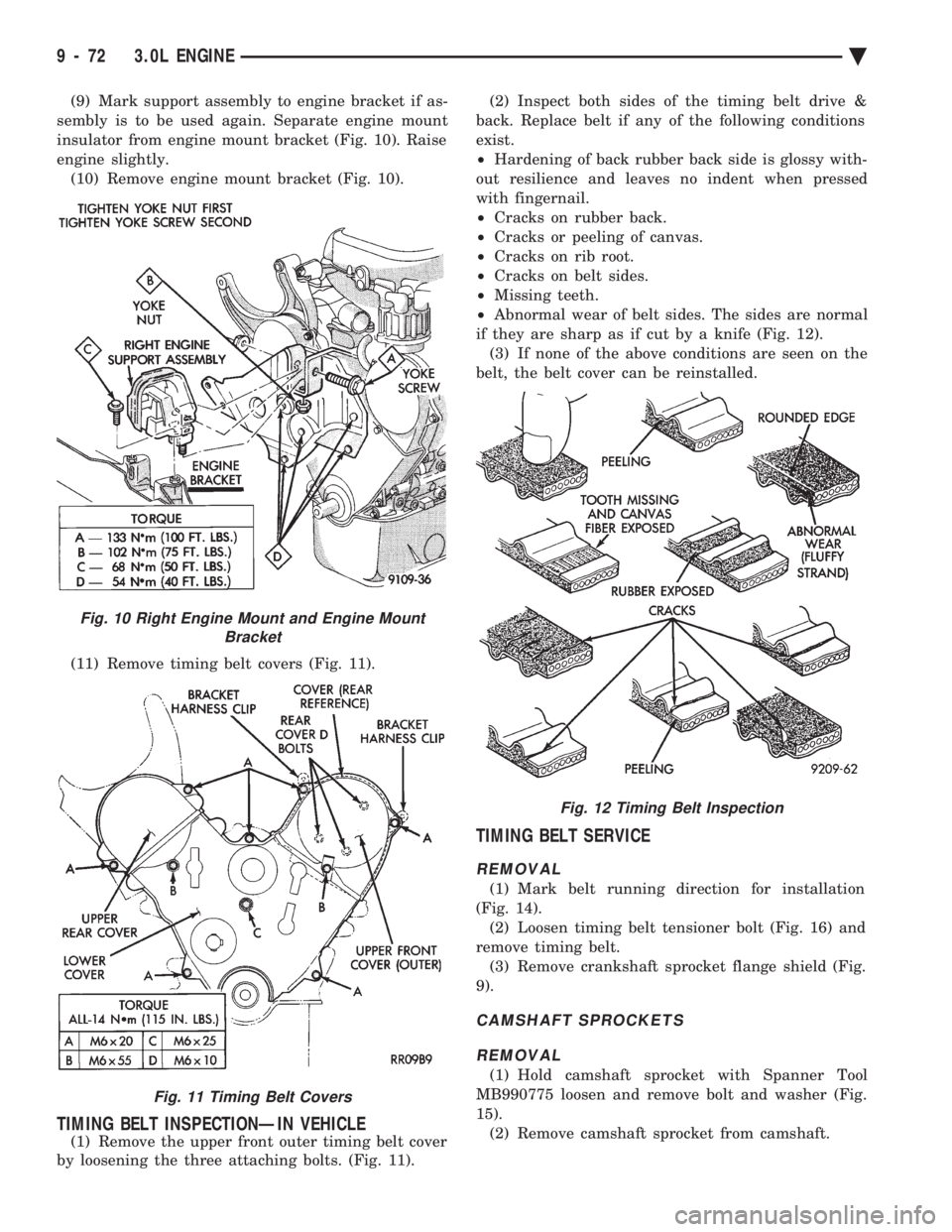

(9) Mark support assembly to engine bracket if as-

sembly is to be used again. Separate engine mount

insulator from engine mount bracket (Fig. 10). Raise

engine slightly. (10) Remove engine mount bracket (Fig. 10).

(11) Remove timing belt covers (Fig. 11).

TIMING BELT INSPECTIONÐIN VEHICLE

(1) Remove the upper front outer timing belt cover

by loosening the three attaching bolts. (Fig. 11). (2) Inspect both sides of the timing belt drive &

back. Replace belt if any of the following conditions

exist.

² Hardening of back rubber back side is glossy with-

out resilience and leaves no indent when pressed

with fingernail.

² Cracks on rubber back.

² Cracks or peeling of canvas.

² Cracks on rib root.

² Cracks on belt sides.

² Missing teeth.

² Abnormal wear of belt sides. The sides are normal

if they are sharp as if cut by a knife (Fig. 12). (3) If none of the above conditions are seen on the

belt, the belt cover can be reinstalled.

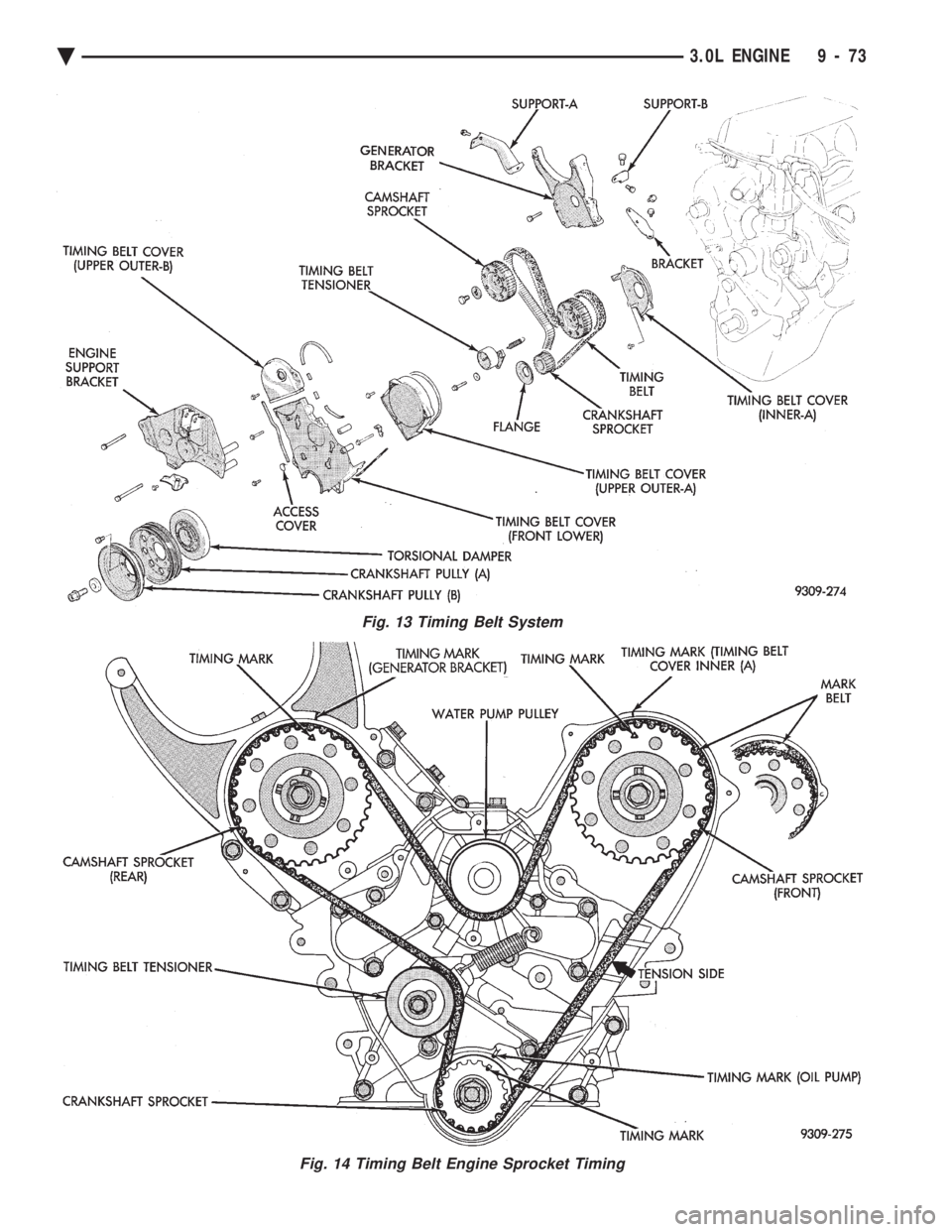

TIMING BELT SERVICE

REMOVAL

(1) Mark belt running direction for installation

(Fig. 14). (2) Loosen timing belt tensioner bolt (Fig. 16) and

remove timing belt. (3) Remove crankshaft sprocket flange shield (Fig.

9).

CAMSHAFT SPROCKETS

REMOVAL

(1) Hold camshaft sprocket with Spanner Tool

MB990775 loosen and remove bolt and washer (Fig.

15). (2) Remove camshaft sprocket from camshaft.

Fig. 10 Right Engine Mount and Engine Mount Bracket

Fig. 11 Timing Belt Covers

Fig. 12 Timing Belt Inspection

9 - 72 3.0L ENGINE Ä

Page 1639 of 2438

Fig. 13 Timing Belt System

Fig. 14 Timing Belt Engine Sprocket Timing

Ä 3.0L ENGINE 9 - 73

Page 1640 of 2438

INSTALLATION

(1) Place camshaft sprocket on camshaft.

(2) Install bolt and washer to camshaft. Using

Spanner Tool MB990775 hold camshaft sprocket and

torque bolt to 95 N Im (70 ft. lbs.) (Fig. 15).

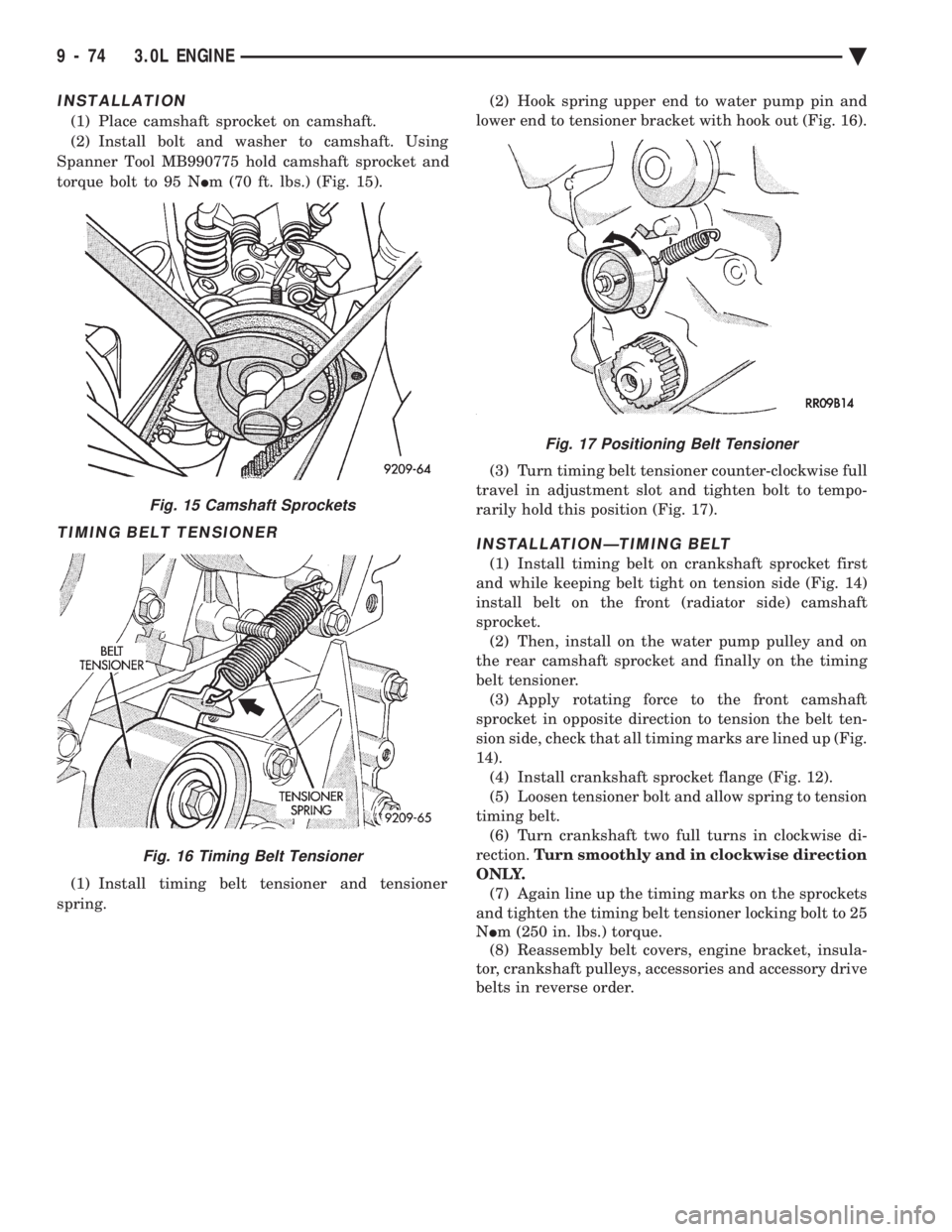

TIMING BELT TENSIONER

(1) Install timing belt tensioner and tensioner

spring. (2) Hook spring upper end to water pump pin and

lower end to tensioner bracket with hook out (Fig. 16).

(3) Turn timing belt tensioner counter-clockwise full

travel in adjustment slot and tighten bolt to tempo-

rarily hold this position (Fig. 17).

INSTALLATIONÐTIMING BELT

(1) Install timing belt on crankshaft sprocket first

and while keeping belt tight on tension side (Fig. 14)

install belt on the front (radiator side) camshaft

sprocket. (2) Then, install on the water pump pulley and on

the rear camshaft sprocket and finally on the timing

belt tensioner. (3) Apply rotating force to the front camshaft

sprocket in opposite direction to tension the belt ten-

sion side, check that all timing marks are lined up (Fig.

14). (4) Install crankshaft sprocket flange (Fig. 12).

(5) Loosen tensioner bolt and allow spring to tension

timing belt. (6) Turn crankshaft two full turns in clockwise di-

rection. Turn smoothly and in clockwise direction

ONLY. (7) Again line up the timing marks on the sprockets

and tighten the timing belt tensioner locking bolt to 25

N Im (250 in. lbs.) torque.

(8) Reassembly belt covers, engine bracket, insula-

tor, crankshaft pulleys, accessories and accessory drive

belts in reverse order.

Fig. 15 Camshaft Sprockets

Fig. 16 Timing Belt Tensioner

Fig. 17 Positioning Belt Tensioner

9 - 74 3.0L ENGINE Ä