timing belt CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1583 of 2438

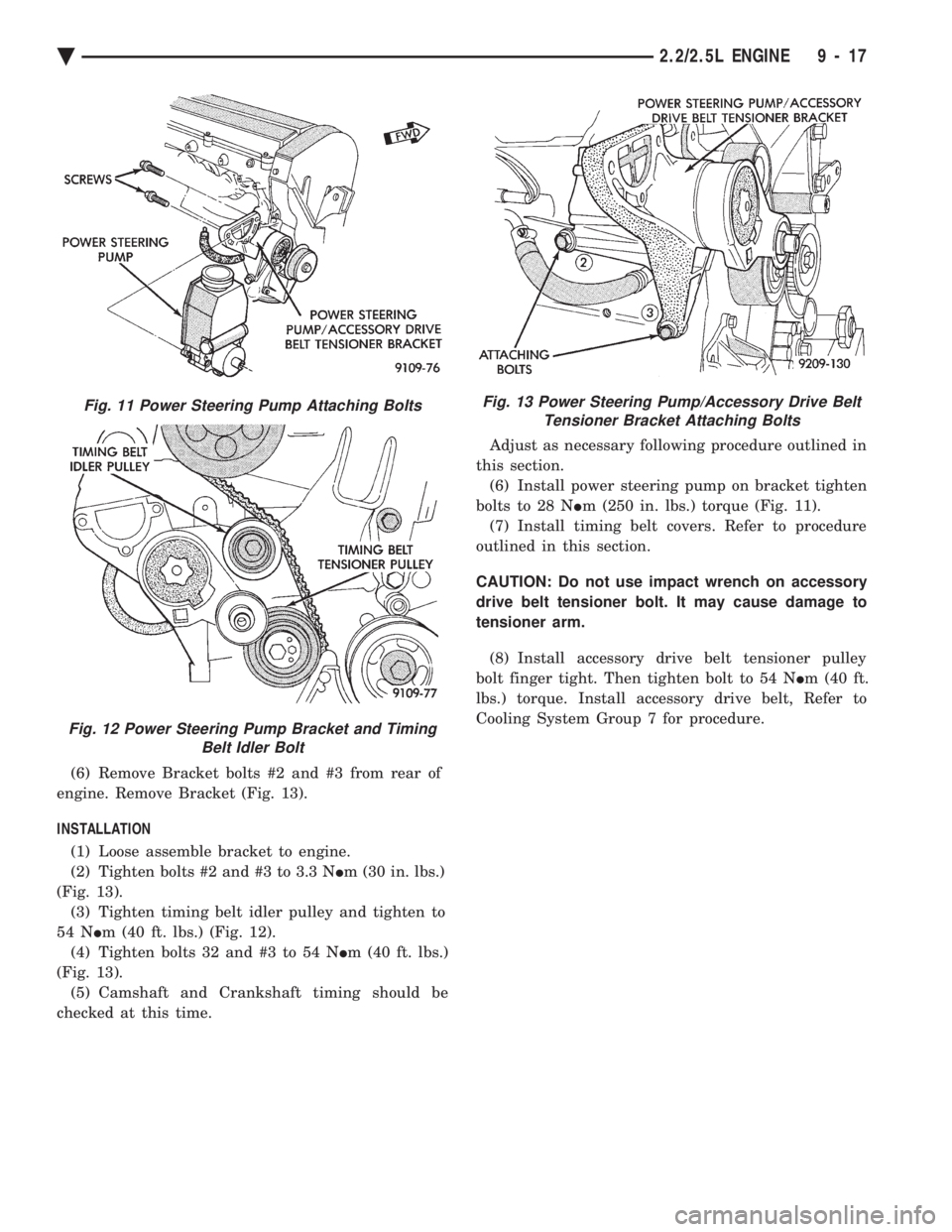

(6) Remove Bracket bolts #2 and #3 from rear of

engine. Remove Bracket (Fig. 13).

INSTALLATION (1) Loose assemble bracket to engine.

(2) Tighten bolts #2 and #3 to 3.3 N Im (30 in. lbs.)

(Fig. 13). (3) Tighten timing belt idler pulley and tighten to

54 N Im (40 ft. lbs.) (Fig. 12).

(4) Tighten bolts 32 and #3 to 54 N Im (40 ft. lbs.)

(Fig. 13). (5) Camshaft and Crankshaft timing should be

checked at this time. Adjust as necessary following procedure outlined in

this section. (6) Install power steering pump on bracket tighten

bolts to 28 N Im (250 in. lbs.) torque (Fig. 11).

(7) Install timing belt covers. Refer to procedure

outlined in this section.

CAUTION: Do not use impact wrench on accessory

drive belt tensioner bolt. It may cause damage to

tensioner arm.

(8) Install accessory drive belt tensioner pulley

bolt finger tight. Then tighten bolt to 54 N Im (40 ft.

lbs.) torque. Install accessory drive belt, Refer to

Cooling System Group 7 for procedure.

Fig. 11 Power Steering Pump Attaching Bolts

Fig. 12 Power Steering Pump Bracket and Timing Belt Idler Bolt

Fig. 13 Power Steering Pump/Accessory Drive BeltTensioner Bracket Attaching Bolts

Ä 2.2/2.5L ENGINE 9 - 17

Page 1584 of 2438

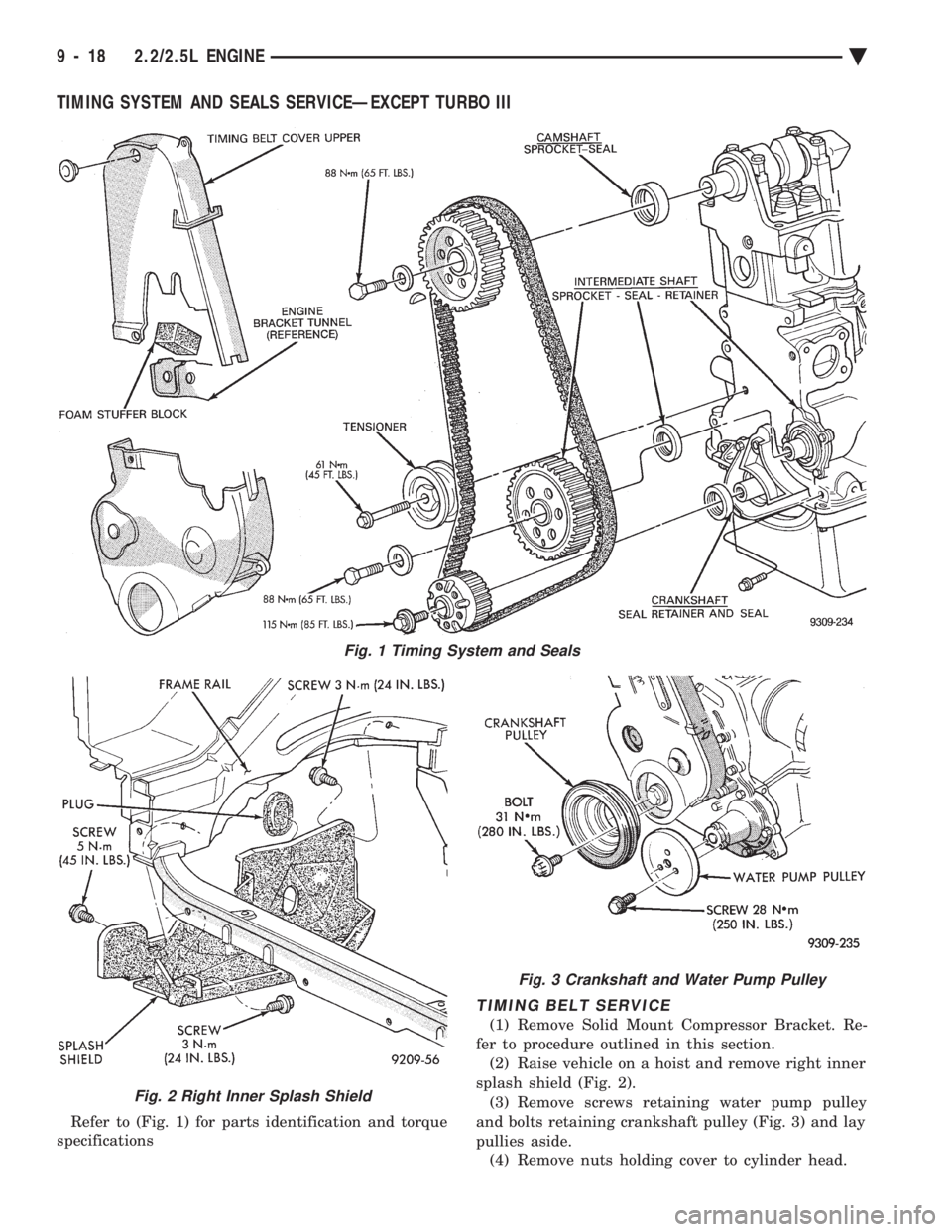

TIMING SYSTEM AND SEALS SERVICEÐEXCEPT TURBO III

Refer to (Fig. 1) for parts identification and torque

specifications

TIMING BELT SERVICE

(1) Remove Solid Mount Compressor Bracket. Re-

fer to procedure outlined in this section. (2) Raise vehicle on a hoist and remove right inner

splash shield (Fig. 2). (3) Remove screws retaining water pump pulley

and bolts retaining crankshaft pulley (Fig. 3) and lay

pullies aside. (4) Remove nuts holding cover to cylinder head.

Fig. 2 Right Inner Splash Shield

Fig. 3 Crankshaft and Water Pump Pulley

Fig. 1 Timing System and Seals

9 - 18 2.2/2.5L ENGINE Ä

Page 1585 of 2438

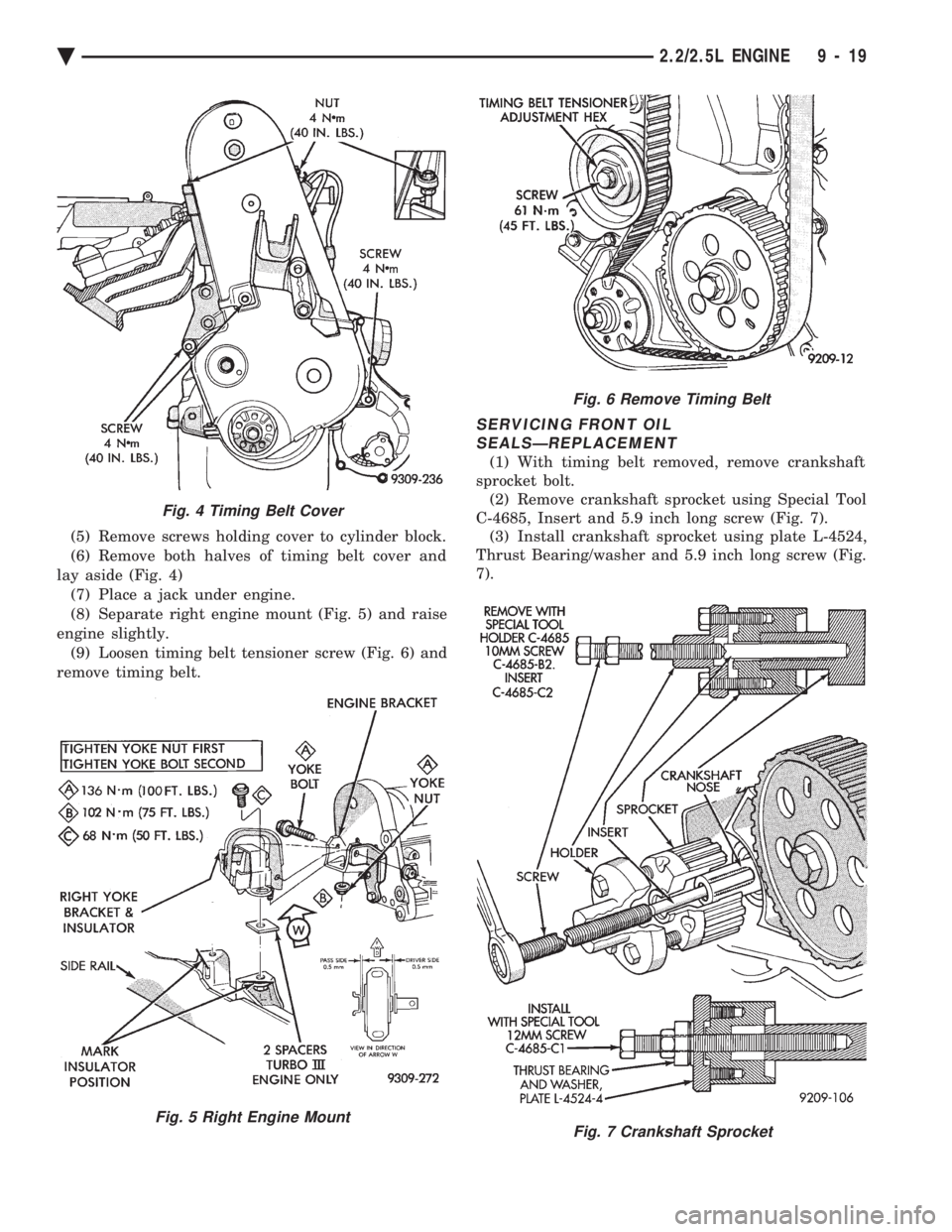

(5) Remove screws holding cover to cylinder block.

(6) Remove both halves of timing belt cover and

lay aside (Fig. 4) (7) Place a jack under engine.

(8) Separate right engine mount (Fig. 5) and raise

engine slightly. (9) Loosen timing belt tensioner screw (Fig. 6) and

remove timing belt.

SERVICING FRONT OIL SEALSÐREPLACEMENT

(1) With timing belt removed, remove crankshaft

sprocket bolt. (2) Remove crankshaft sprocket using Special Tool

C-4685, Insert and 5.9 inch long screw (Fig. 7). (3) Install crankshaft sprocket using plate L-4524,

Thrust Bearing/washer and 5.9 inch long screw (Fig.

7).

Fig. 4 Timing Belt Cover

Fig. 7 Crankshaft SprocketFig. 5 Right Engine Mount

Fig. 6 Remove Timing Belt

Ä 2.2/2.5L ENGINE 9 - 19

Page 1587 of 2438

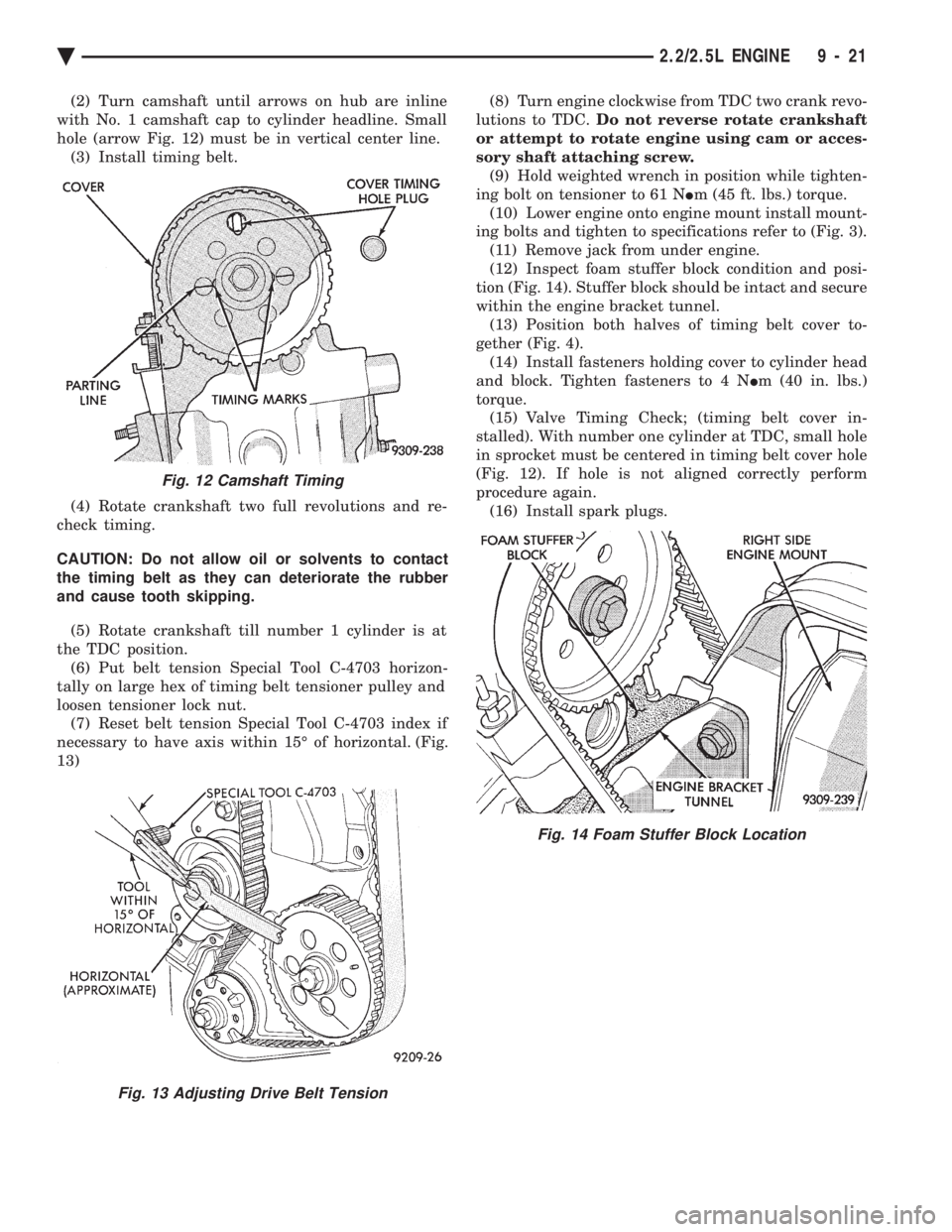

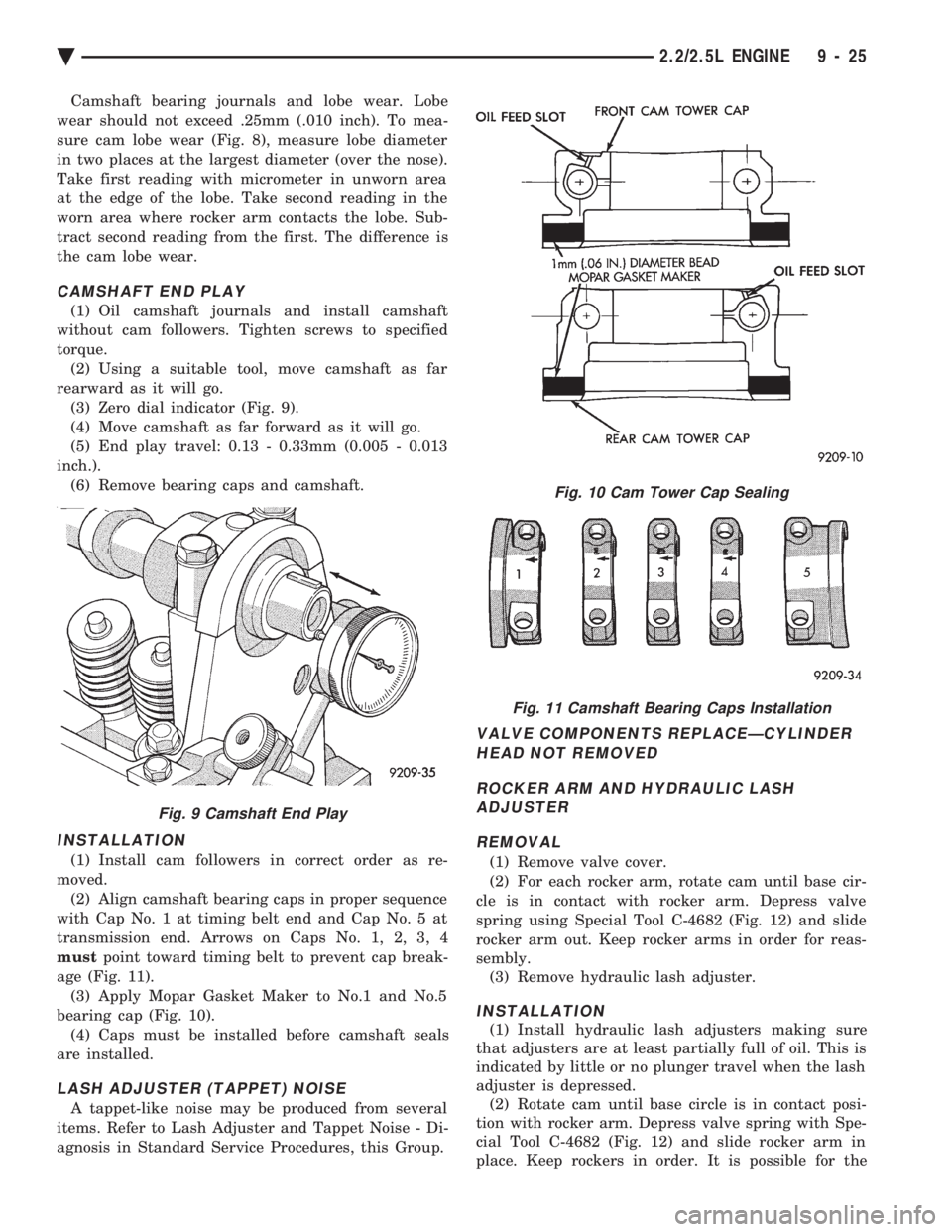

(2) Turn camshaft until arrows on hub are inline

with No. 1 camshaft cap to cylinder headline. Small

hole (arrow Fig. 12) must be in vertical center line. (3) Install timing belt.

(4) Rotate crankshaft two full revolutions and re-

check timing.

CAUTION: Do not allow oil or solvents to contact

the timing belt as they can deteriorate the rubber

and cause tooth skipping.

(5) Rotate crankshaft till number 1 cylinder is at

the TDC position. (6) Put belt tension Special Tool C-4703 horizon-

tally on large hex of timing belt tensioner pulley and

loosen tensioner lock nut. (7) Reset belt tension Special Tool C-4703 index if

necessary to have axis within 15É of horizontal. (Fig.

13) (8) Turn engine clockwise from TDC two crank revo-

lutions to TDC. Do not reverse rotate crankshaft

or attempt to rotate engine using cam or acces-

sory shaft attaching screw. (9) Hold weighted wrench in position while tighten-

ing bolt on tensioner to 61 N Im (45 ft. lbs.) torque.

(10) Lower engine onto engine mount install mount-

ing bolts and tighten to specifications refer to (Fig. 3). (11) Remove jack from under engine.

(12) Inspect foam stuffer block condition and posi-

tion (Fig. 14). Stuffer block should be intact and secure

within the engine bracket tunnel. (13) Position both halves of timing belt cover to-

gether (Fig. 4). (14) Install fasteners holding cover to cylinder head

and block. Tighten fasteners to 4 N Im (40 in. lbs.)

torque. (15) Valve Timing Check; (timing belt cover in-

stalled). With number one cylinder at TDC, small hole

in sprocket must be centered in timing belt cover hole

(Fig. 12). If hole is not aligned correctly perform

procedure again. (16) Install spark plugs.

Fig. 12 Camshaft Timing

Fig. 13 Adjusting Drive Belt Tension

Fig. 14 Foam Stuffer Block Location

Ä 2.2/2.5L ENGINE 9 - 21

Page 1589 of 2438

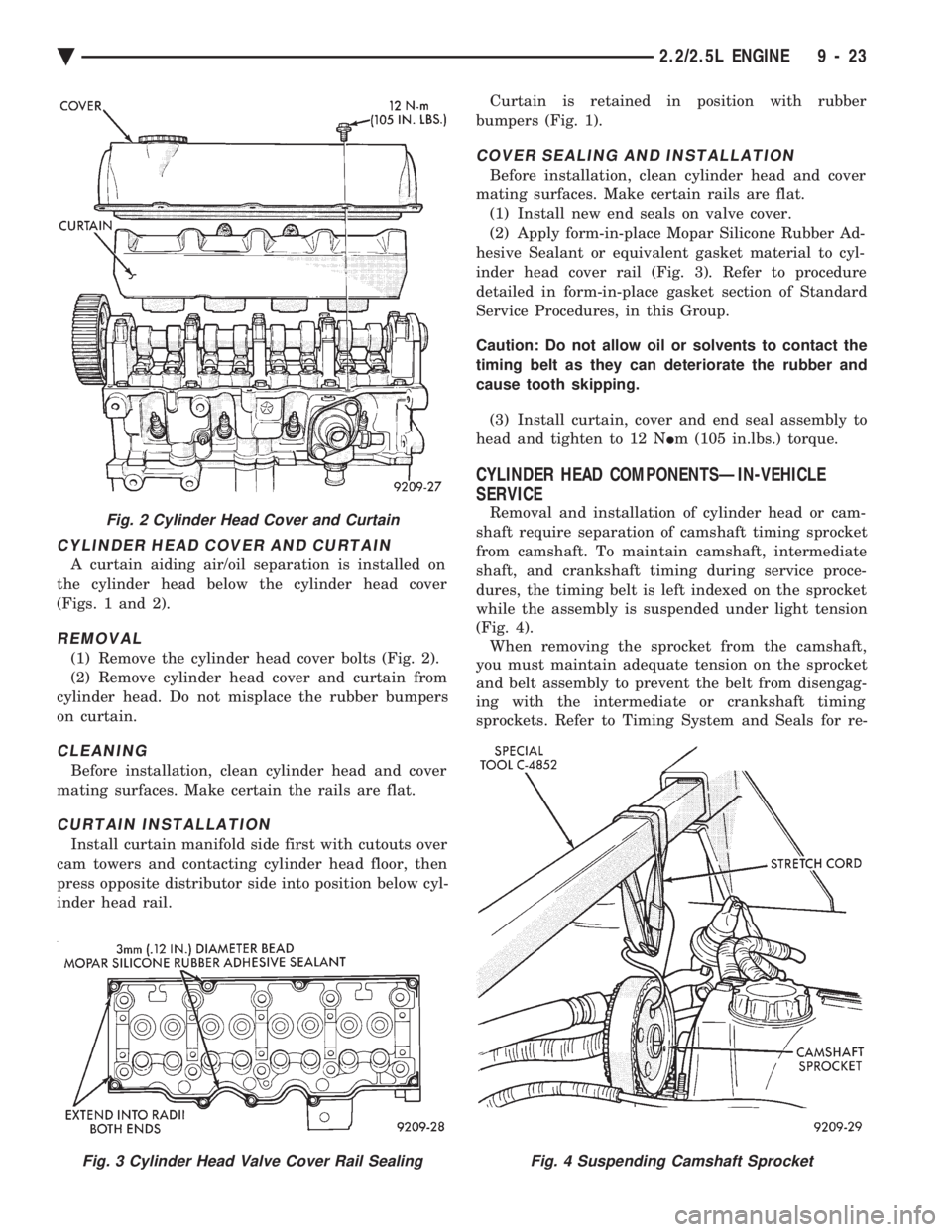

CYLINDER HEAD COVER AND CURTAIN

A curtain aiding air/oil separation is installed on

the cylinder head below the cylinder head cover

(Figs. 1 and 2).

REMOVAL

(1) Remove the cylinder head cover bolts (Fig. 2).

(2) Remove cylinder head cover and curtain from

cylinder head. Do not misplace the rubber bumpers

on curtain.

CLEANING

Before installation, clean cylinder head and cover

mating surfaces. Make certain the rails are flat.

CURTAIN INSTALLATION

Install curtain manifold side first with cutouts over

cam towers and contacting cylinder head floor, then

press opposite distributor side into position below cyl-

inder head rail. Curtain is retained in position with rubber

bumpers (Fig. 1).

COVER SEALING AND INSTALLATION

Before installation, clean cylinder head and cover

mating surfaces. Make certain rails are flat. (1) Install new end seals on valve cover.

(2) Apply form-in-place Mopar Silicone Rubber Ad-

hesive Sealant or equivalent gasket material to cyl-

inder head cover rail (Fig. 3). Refer to procedure

detailed in form-in-place gasket section of Standard

Service Procedures, in this Group.

Caution: Do not allow oil or solvents to contact the

timing belt as they can deteriorate the rubber and

cause tooth skipping.

(3) Install curtain, cover and end seal assembly to

head and tighten to 12 N Im (105 in.lbs.) torque.

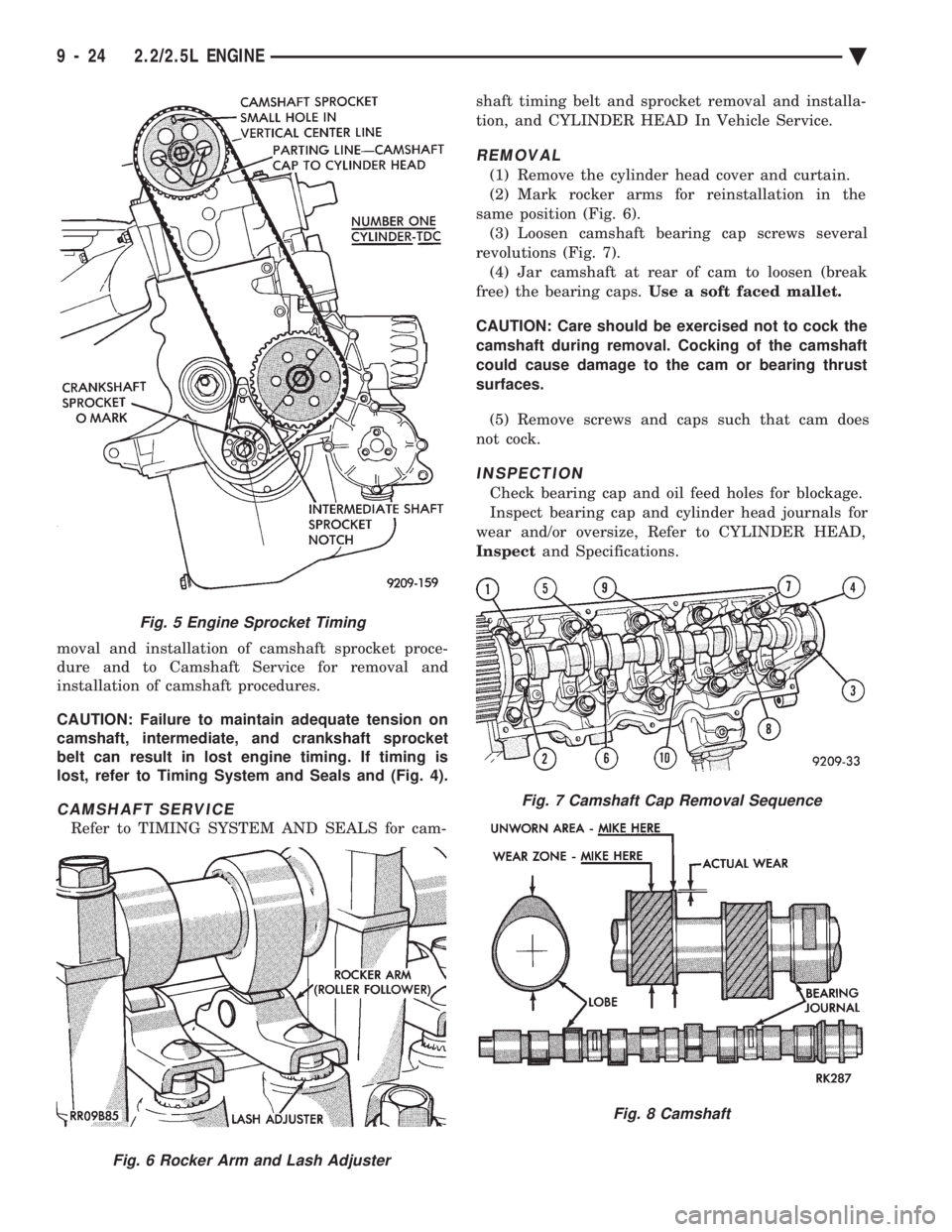

CYLINDER HEAD COMPONENTSÐIN-VEHICLE

SERVICE

Removal and installation of cylinder head or cam-

shaft require separation of camshaft timing sprocket

from camshaft. To maintain camshaft, intermediate

shaft, and crankshaft timing during service proce-

dures, the timing belt is left indexed on the sprocket

while the assembly is suspended under light tension

(Fig. 4). When removing the sprocket from the camshaft,

you must maintain adequate tension on the sprocket

and belt assembly to prevent the belt from disengag-

ing with the intermediate or crankshaft timing

sprockets. Refer to Timing System and Seals for re-Fig. 2 Cylinder Head Cover and Curtain

Fig. 3 Cylinder Head Valve Cover Rail SealingFig. 4 Suspending Camshaft Sprocket

Ä 2.2/2.5L ENGINE 9 - 23

Page 1590 of 2438

moval and installation of camshaft sprocket proce-

dure and to Camshaft Service for removal and

installation of camshaft procedures.

CAUTION: Failure to maintain adequate tension on

camshaft, intermediate, and crankshaft sprocket

belt can result in lost engine timing. If timing is

lost, refer to Timing System and Seals and (Fig. 4).

CAMSHAFT SERVICE

Refer to TIMING SYSTEM AND SEALS for cam- shaft timing belt and sprocket removal and installa-

tion, and CYLINDER HEAD In Vehicle Service.

REMOVAL

(1) Remove the cylinder head cover and curtain.

(2) Mark rocker arms for reinstallation in the

same position (Fig. 6). (3) Loosen camshaft bearing cap screws several

revolutions (Fig. 7). (4) Jar camshaft at rear of cam to loosen (break

free) the bearing caps. Use a soft faced mallet.

CAUTION: Care should be exercised not to cock the

camshaft during removal. Cocking of the camshaft

could cause damage to the cam or bearing thrust

surfaces.

(5) Remove screws and caps such that cam does

not cock.

INSPECTION

Check bearing cap and oil feed holes for blockage.

Inspect bearing cap and cylinder head journals for

wear and/or oversize, Refer to CYLINDER HEAD,

Inspect and Specifications.

Fig. 5 Engine Sprocket Timing

Fig. 6 Rocker Arm and Lash Adjuster

Fig. 7 Camshaft Cap Removal Sequence

Fig. 8 Camshaft

9 - 24 2.2/2.5L ENGINE Ä

Page 1591 of 2438

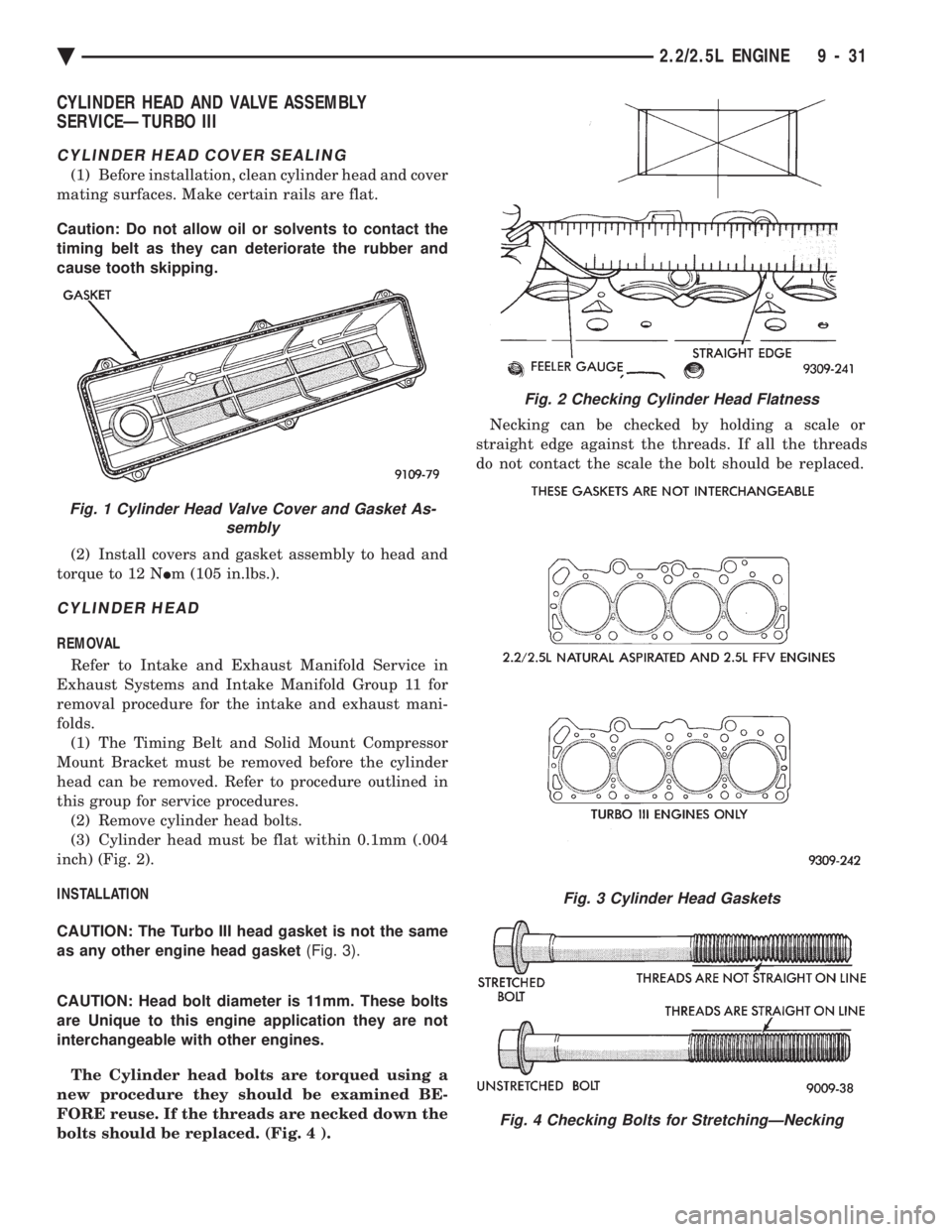

Camshaft bearing journals and lobe wear. Lobe

wear should not exceed .25mm (.010 inch). To mea-

sure cam lobe wear (Fig. 8), measure lobe diameter

in two places at the largest diameter (over the nose).

Take first reading with micrometer in unworn area

at the edge of the lobe. Take second reading in the

worn area where rocker arm contacts the lobe. Sub-

tract second reading from the first. The difference is

the cam lobe wear.

CAMSHAFT END PLAY

(1) Oil camshaft journals and install camshaft

without cam followers. Tighten screws to specified

torque. (2) Using a suitable tool, move camshaft as far

rearward as it will go. (3) Zero dial indicator (Fig. 9).

(4) Move camshaft as far forward as it will go.

(5) End play travel: 0.13 - 0.33mm (0.005 - 0.013

inch.). (6) Remove bearing caps and camshaft.

INSTALLATION

(1) Install cam followers in correct order as re-

moved. (2) Align camshaft bearing caps in proper sequence

with Cap No. 1 at timing belt end and Cap No. 5 at

transmission end. Arrows on Caps No. 1, 2, 3, 4

must point toward timing belt to prevent cap break-

age (Fig. 11). (3) Apply Mopar Gasket Maker to No.1 and No.5

bearing cap (Fig. 10). (4) Caps must be installed before camshaft seals

are installed.

LASH ADJUSTER (TAPPET) NOISE

A tappet-like noise may be produced from several

items. Refer to Lash Adjuster and Tappet Noise - Di-

agnosis in Standard Service Procedures, this Group.

VALVE COMPONENTS REPLACEÐCYLINDER HEAD NOT REMOVED

ROCKER ARM AND HYDRAULIC LASH ADJUSTER

REMOVAL

(1) Remove valve cover.

(2) For each rocker arm, rotate cam until base cir-

cle is in contact with rocker arm. Depress valve

spring using Special Tool C-4682 (Fig. 12) and slide

rocker arm out. Keep rocker arms in order for reas-

sembly. (3) Remove hydraulic lash adjuster.

INSTALLATION

(1) Install hydraulic lash adjusters making sure

that adjusters are at least partially full of oil. This is

indicated by little or no plunger travel when the lash

adjuster is depressed. (2) Rotate cam until base circle is in contact posi-

tion with rocker arm. Depress valve spring with Spe-

cial Tool C-4682 (Fig. 12) and slide rocker arm in

place. Keep rockers in order. It is possible for the

Fig. 9 Camshaft End Play

Fig. 10 Cam Tower Cap Sealing

Fig. 11 Camshaft Bearing Caps Installation

Ä 2.2/2.5L ENGINE 9 - 25

Page 1597 of 2438

CYLINDER HEAD AND VALVE ASSEMBLY

SERVICEÐTURBO III

CYLINDER HEAD COVER SEALING

(1) Before installation, clean cylinder head and cover

mating surfaces. Make certain rails are flat.

Caution: Do not allow oil or solvents to contact the

timing belt as they can deteriorate the rubber and

cause tooth skipping.

(2) Install covers and gasket assembly to head and

torque to 12 N Im (105 in.lbs.).

CYLINDER HEAD

REMOVAL

Refer to Intake and Exhaust Manifold Service in

Exhaust Systems and Intake Manifold Group 11 for

removal procedure for the intake and exhaust mani-

folds. (1) The Timing Belt and Solid Mount Compressor

Mount Bracket must be removed before the cylinder

head can be removed. Refer to procedure outlined in

this group for service procedures. (2) Remove cylinder head bolts.

(3) Cylinder head must be flat within 0.1mm (.004

inch) (Fig. 2).

INSTALLATION

CAUTION: The Turbo III head gasket is not the same

as any other engine head gasket (Fig. 3).

CAUTION: Head bolt diameter is 11mm. These bolts

are Unique to this engine application they are not

interchangeable with other engines.

The Cylinder head bolts are torqued using a

new procedure they should be examined BE-

FORE reuse. If the threads are necked down the

bolts should be replaced. (Fig. 4 ). Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale the bolt should be replaced.

Fig. 2 Checking Cylinder Head Flatness

Fig. 3 Cylinder Head Gaskets

Fig. 4 Checking Bolts for StretchingÐNecking

Fig. 1 Cylinder Head Valve Cover and Gasket As- sembly

Ä 2.2/2.5L ENGINE 9 - 31

Page 1598 of 2438

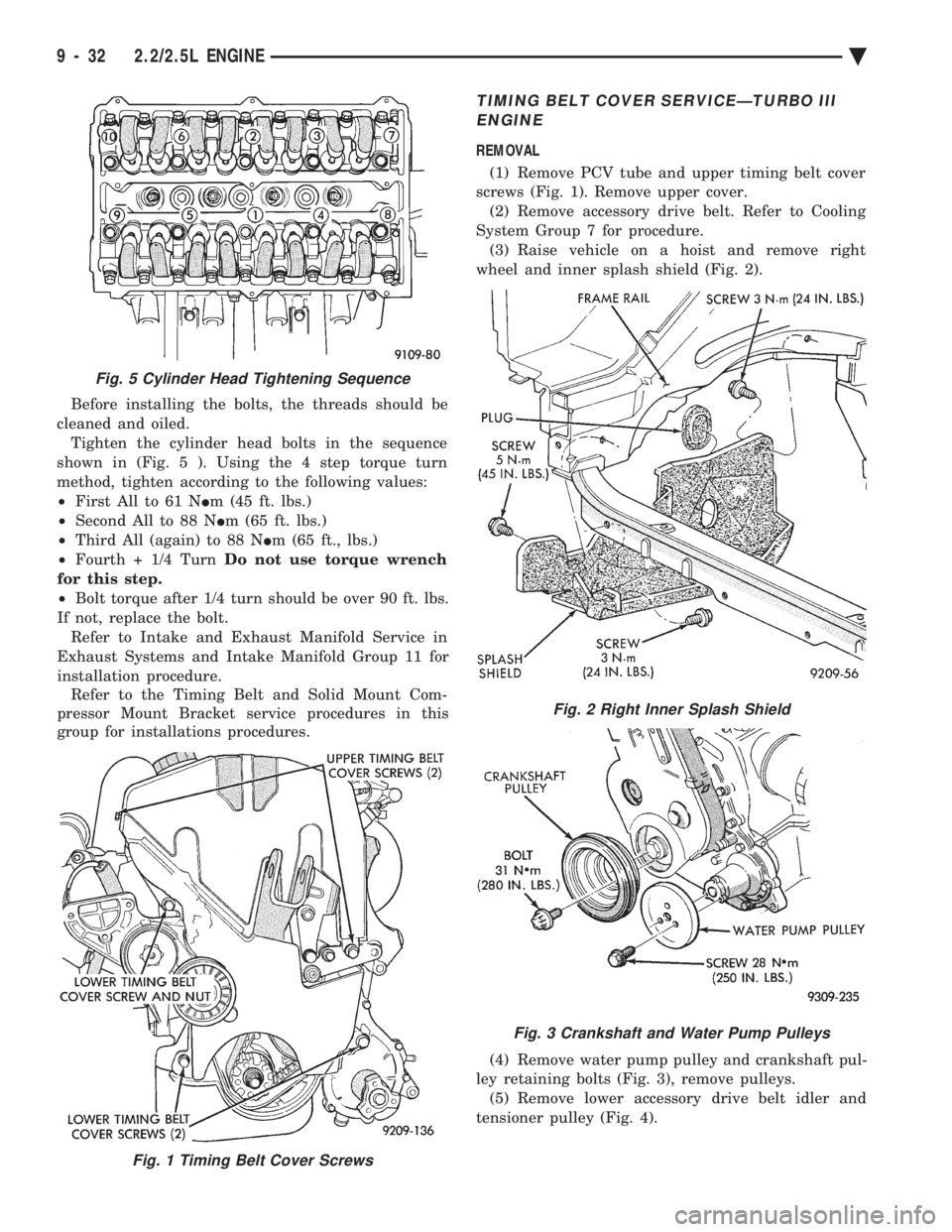

Before installing the bolts, the threads should be

cleaned and oiled. Tighten the cylinder head bolts in the sequence

shown in (Fig. 5 ). Using the 4 step torque turn

method, tighten according to the following values:

² First All to 61 N Im (45 ft. lbs.)

² Second All to 88 N Im (65 ft. lbs.)

² Third All (again) to 88 N Im (65 ft., lbs.)

² Fourth + 1/4 Turn Do not use torque wrench

for this step.

² Bolt torque after 1/4 turn should be over 90 ft. lbs.

If not, replace the bolt. Refer to Intake and Exhaust Manifold Service in

Exhaust Systems and Intake Manifold Group 11 for

installation procedure. Refer to the Timing Belt and Solid Mount Com-

pressor Mount Bracket service procedures in this

group for installations procedures.

TIMING BELT COVER SERVICEÐTURBO III

ENGINE

REMOVAL

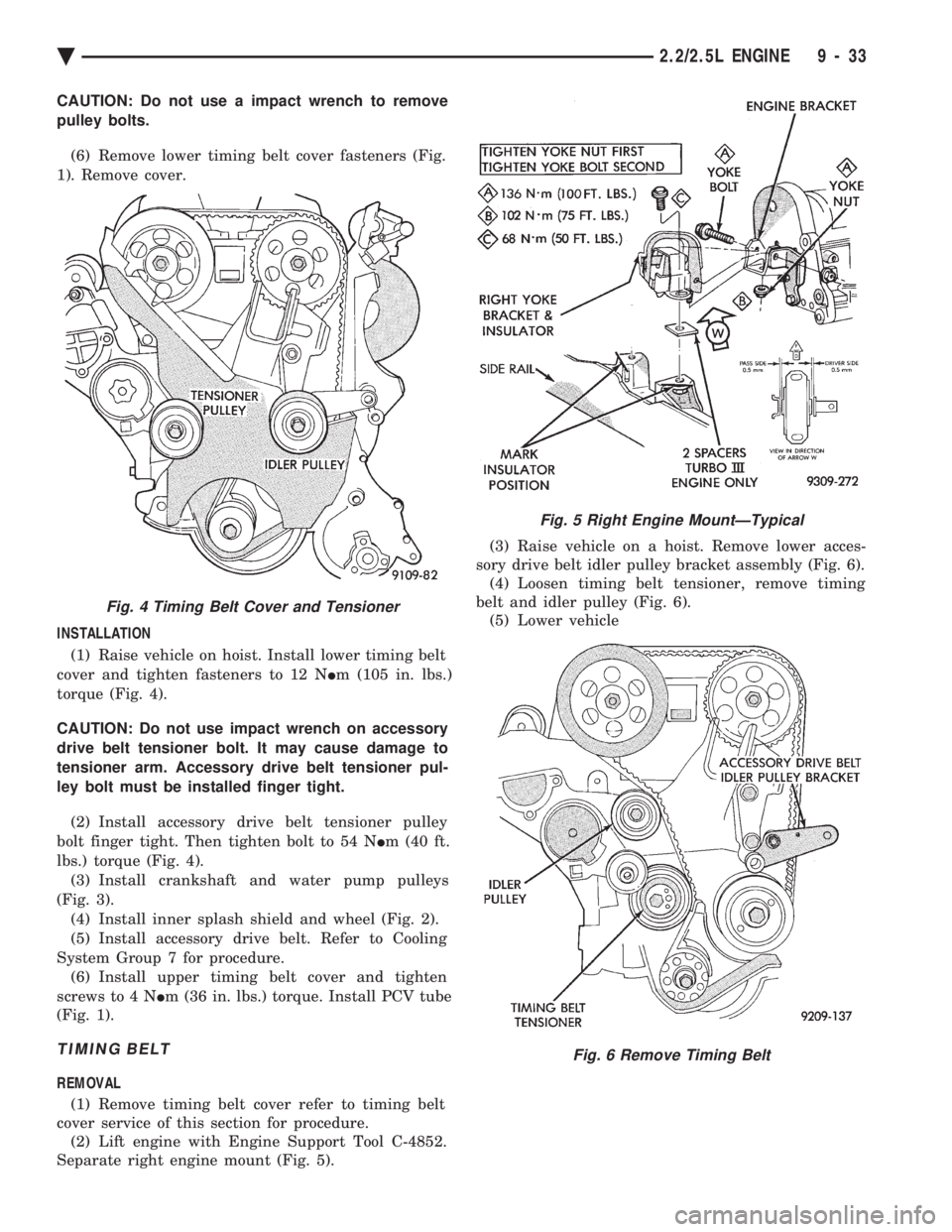

(1) Remove PCV tube and upper timing belt cover

screws (Fig. 1). Remove upper cover. (2) Remove accessory drive belt. Refer to Cooling

System Group 7 for procedure. (3) Raise vehicle on a hoist and remove right

wheel and inner splash shield (Fig. 2).

(4) Remove water pump pulley and crankshaft pul-

ley retaining bolts (Fig. 3), remove pulleys. (5) Remove lower accessory drive belt idler and

tensioner pulley (Fig. 4).

Fig. 1 Timing Belt Cover Screws

Fig. 5 Cylinder Head Tightening Sequence

Fig. 2 Right Inner Splash Shield

Fig. 3 Crankshaft and Water Pump Pulleys

9 - 32 2.2/2.5L ENGINE Ä

Page 1599 of 2438

CAUTION: Do not use a impact wrench to remove

pulley bolts. (6) Remove lower timing belt cover fasteners (Fig.

1). Remove cover.

INSTALLATION (1) Raise vehicle on hoist. Install lower timing belt

cover and tighten fasteners to 12 N Im (105 in. lbs.)

torque (Fig. 4).

CAUTION: Do not use impact wrench on accessory

drive belt tensioner bolt. It may cause damage to

tensioner arm. Accessory drive belt tensioner pul-

ley bolt must be installed finger tight. (2) Install accessory drive belt tensioner pulley

bolt finger tight. Then tighten bolt to 54 N Im (40 ft.

lbs.) torque (Fig. 4). (3) Install crankshaft and water pump pulleys

(Fig. 3). (4) Install inner splash shield and wheel (Fig. 2).

(5) Install accessory drive belt. Refer to Cooling

System Group 7 for procedure. (6) Install upper timing belt cover and tighten

screws to 4 N Im (36 in. lbs.) torque. Install PCV tube

(Fig. 1).

TIMING BELT

REMOVAL

(1) Remove timing belt cover refer to timing belt

cover service of this section for procedure. (2) Lift engine with Engine Support Tool C-4852.

Separate right engine mount (Fig. 5). (3) Raise vehicle on a hoist. Remove lower acces-

sory drive belt idler pulley bracket assembly (Fig. 6). (4) Loosen timing belt tensioner, remove timing

belt and idler pulley (Fig. 6). (5) Lower vehicle

Fig. 4 Timing Belt Cover and Tensioner

Fig. 5 Right Engine MountÐTypical

Fig. 6 Remove Timing Belt

Ä 2.2/2.5L ENGINE 9 - 33