timing belt CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1650 of 2438

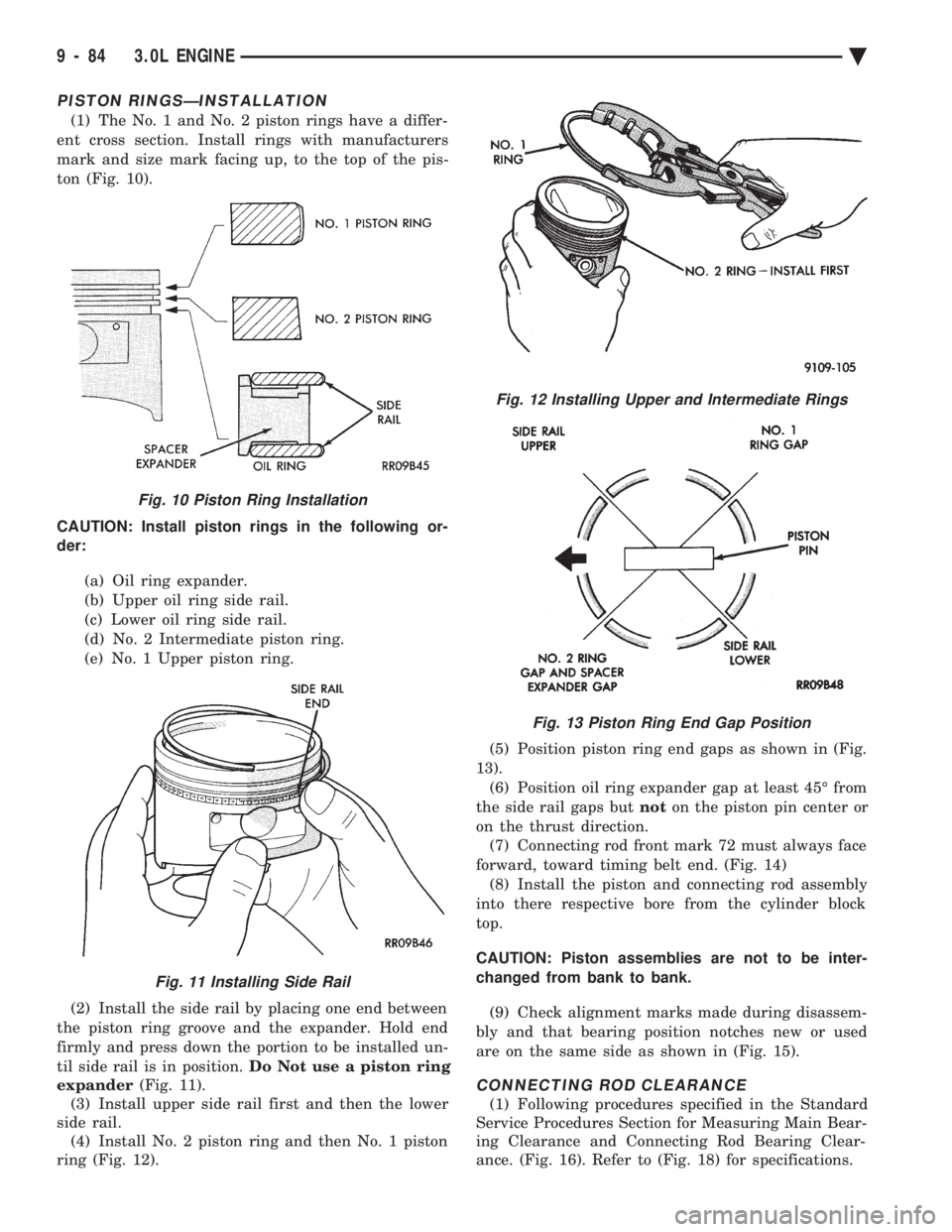

PISTON RINGSÐINSTALLATION

(1) The No. 1 and No. 2 piston rings have a differ-

ent cross section. Install rings with manufacturers

mark and size mark facing up, to the top of the pis-

ton (Fig. 10).

CAUTION: Install piston rings in the following or-

der:

(a) Oil ring expander.

(b) Upper oil ring side rail.

(c) Lower oil ring side rail.

(d) No. 2 Intermediate piston ring.

(e) No. 1 Upper piston ring.

(2) Install the side rail by placing one end between

the piston ring groove and the expander. Hold end

firmly and press down the portion to be installed un-

til side rail is in position. Do Not use a piston ring

expander (Fig. 11).

(3) Install upper side rail first and then the lower

side rail. (4) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 12). (5) Position piston ring end gaps as shown in (Fig.

13). (6) Position oil ring expander gap at least 45É from

the side rail gaps but noton the piston pin center or

on the thrust direction. (7) Connecting rod front mark 72 must always face

forward, toward timing belt end. (Fig. 14) (8) Install the piston and connecting rod assembly

into there respective bore from the cylinder block

top.

CAUTION: Piston assemblies are not to be inter-

changed from bank to bank.

(9) Check alignment marks made during disassem-

bly and that bearing position notches new or used

are on the same side as shown in (Fig. 15).

CONNECTING ROD CLEARANCE

(1) Following procedures specified in the Standard

Service Procedures Section for Measuring Main Bear-

ing Clearance and Connecting Rod Bearing Clear-

ance. (Fig. 16). Refer to (Fig. 18) for specifications.

Fig. 10 Piston Ring Installation

Fig. 11 Installing Side Rail

Fig. 12 Installing Upper and Intermediate Rings

Fig. 13 Piston Ring End Gap Position

9 - 84 3.0L ENGINE Ä

Page 1654 of 2438

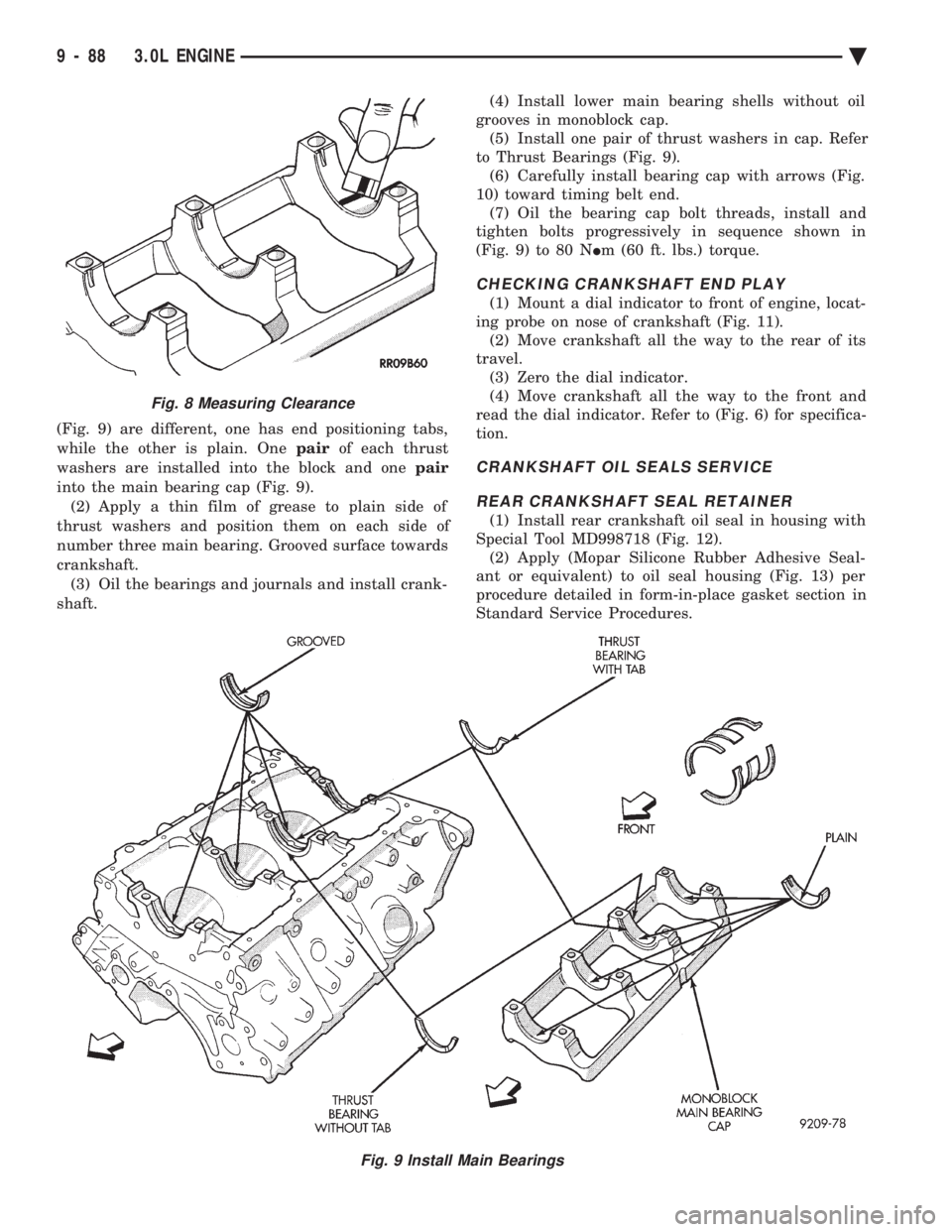

(Fig. 9) are different, one has end positioning tabs,

while the other is plain. One pairof each thrust

washers are installed into the block and one pair

into the main bearing cap (Fig. 9). (2) Apply a thin film of grease to plain side of

thrust washers and position them on each side of

number three main bearing. Grooved surface towards

crankshaft. (3) Oil the bearings and journals and install crank-

shaft. (4) Install lower main bearing shells without oil

grooves in monoblock cap. (5) Install one pair of thrust washers in cap. Refer

to Thrust Bearings (Fig. 9). (6) Carefully install bearing cap with arrows (Fig.

10) toward timing belt end. (7) Oil the bearing cap bolt threads, install and

tighten bolts progressively in sequence shown in

(Fig. 9) to 80 N Im (60 ft. lbs.) torque.

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 11). (2) Move crankshaft all the way to the rear of its

travel. (3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to (Fig. 6) for specifica-

tion.

CRANKSHAFT OIL SEALS SERVICE

REAR CRANKSHAFT SEAL RETAINER

(1) Install rear crankshaft oil seal in housing with

Special Tool MD998718 (Fig. 12). (2) Apply (Mopar Silicone Rubber Adhesive Seal-

ant or equivalent) to oil seal housing (Fig. 13) per

procedure detailed in form-in-place gasket section in

Standard Service Procedures.

Fig. 9 Install Main Bearings

Fig. 8 Measuring Clearance

9 - 88 3.0L ENGINE Ä

Page 1658 of 2438

OIL PAN

The oil pan is made of sheet metal and is provided

with a baffle-plate to prevent fluctuations in the oil

level while the vehicle is running (Fig. 2).

OIL PAN SEALING AND INSTALLATION

Oil pan to crankcase sealing is provided with Mo-

par Silicone Rubber Adhesive Sealant or equivalent

gasket material. See Form-In-Place Gaskets in Stan-

dard Service Procedures. (1) Apply sealant as shown in (Fig. 3).

(2) Install pan and tighten screws to 6 N Im (50 in.

lbs.) in sequence shown in (Fig. 4).

OIL PUMP SERVICE

The oil pump assembly is mounted on the timing

belt end of the cylinder block with the inner pump

rotor indexed and installed on the crankshaft nose.

(Fig. 5). The oil pump case also retains the crankshaft front

oil seal and provides oil pan front end closure.

REMOVAL

Remove accessory drive system. Refer to Accessory

Drive Service in this group. Remove 5 bolts that attach oil pump to block (Fig.

6).

INSPECTION OIL PUMP

(1) Check oil pump case for damage and remove

rear cover. (2) Remove pump rotors and inspect case for exces-

sive wear. (3) Measure clearance between case and inner ro-

tor (Fig. 8). (4) Insert the rotor into the oil pump case (Figs. 9

and 10) and measure clearance with a feeler gauge

as indicated.

Fig. 2 Oil Pan

Fig. 3 Oil Pan Sealing

Fig. 4 Oil Pan Screw Tightening Sequence

Fig. 5 Oil Pump-Installed

Fig. 6 Oil Pump Assembly

9 - 92 3.0L ENGINE Ä

Page 1675 of 2438

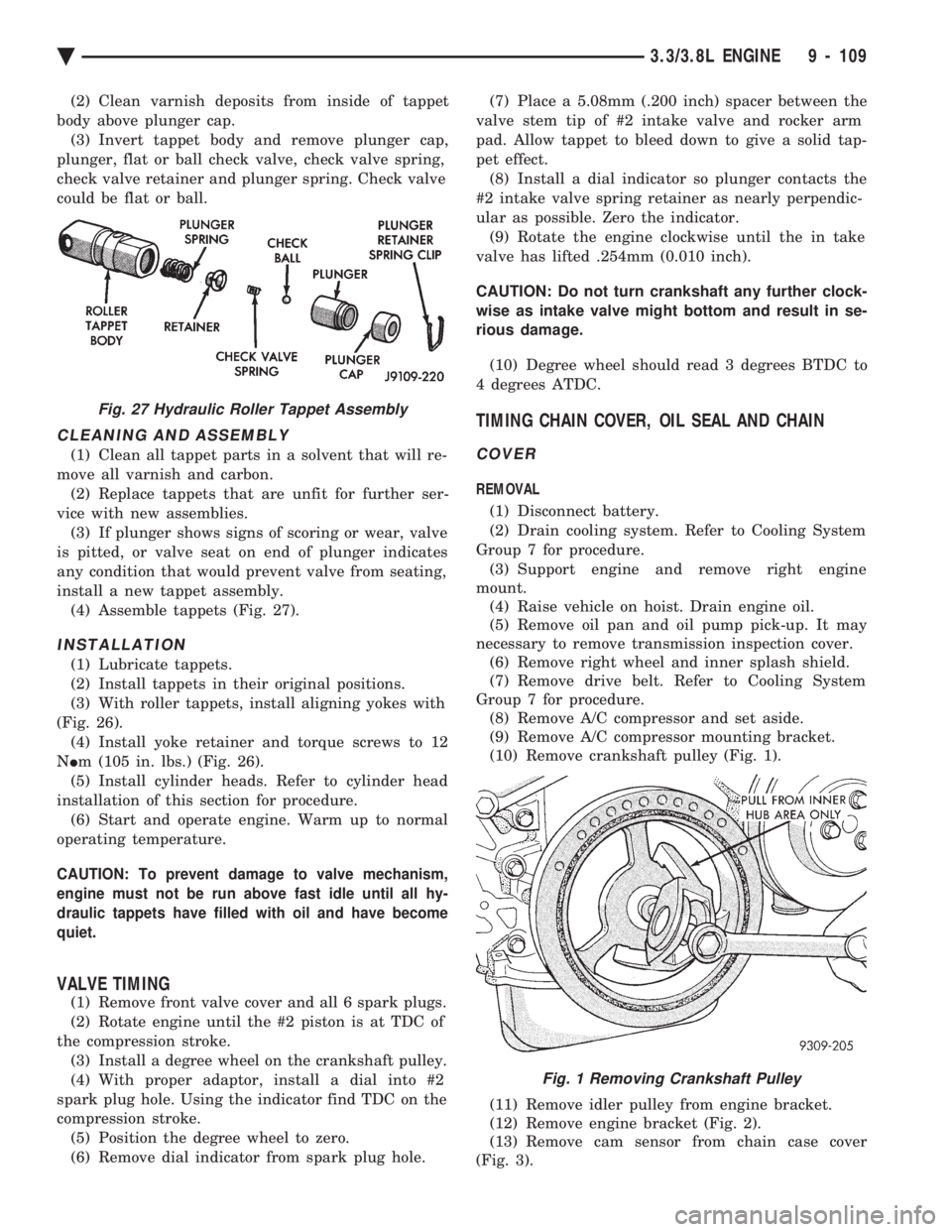

(2) Clean varnish deposits from inside of tappet

body above plunger cap. (3) Invert tappet body and remove plunger cap,

plunger, flat or ball check valve, check valve spring,

check valve retainer and plunger spring. Check valve

could be flat or ball.

CLEANING AND ASSEMBLY

(1) Clean all tappet parts in a solvent that will re-

move all varnish and carbon. (2) Replace tappets that are unfit for further ser-

vice with new assemblies. (3) If plunger shows signs of scoring or wear, valve

is pitted, or valve seat on end of plunger indicates

any condition that would prevent valve from seating,

install a new tappet assembly. (4) Assemble tappets (Fig. 27).

INSTALLATION

(1) Lubricate tappets.

(2) Install tappets in their original positions.

(3) With roller tappets, install aligning yokes with

(Fig. 26). (4) Install yoke retainer and torque screws to 12

N Im (105 in. lbs.) (Fig. 26).

(5) Install cylinder heads. Refer to cylinder head

installation of this section for procedure. (6) Start and operate engine. Warm up to normal

operating temperature.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all hy-

draulic tappets have filled with oil and have become

quiet.

VALVE TIMING

(1) Remove front valve cover and all 6 spark plugs.

(2) Rotate engine until the #2 piston is at TDC of

the compression stroke. (3) Install a degree wheel on the crankshaft pulley.

(4) With proper adaptor, install a dial into #2

spark plug hole. Using the indicator find TDC on the

compression stroke. (5) Position the degree wheel to zero.

(6) Remove dial indicator from spark plug hole. (7) Place a 5.08mm (.200 inch) spacer between the

valve stem tip of #2 intake valve and rocker arm

pad. Allow tappet to bleed down to give a solid tap-

pet effect. (8) Install a dial indicator so plunger contacts the

#2 intake valve spring retainer as nearly perpendic-

ular as possible. Zero the indicator. (9) Rotate the engine clockwise until the in take

valve has lifted .254mm (0.010 inch).

CAUTION: Do not turn crankshaft any further clock-

wise as intake valve might bottom and result in se-

rious damage.

(10) Degree wheel should read 3 degrees BTDC to

4 degrees ATDC.

TIMING CHAIN COVER, OIL SEAL AND CHAIN

COVER

REMOVAL

(1) Disconnect battery.

(2) Drain cooling system. Refer to Cooling System

Group 7 for procedure. (3) Support engine and remove right engine

mount. (4) Raise vehicle on hoist. Drain engine oil.

(5) Remove oil pan and oil pump pick-up. It may

necessary to remove transmission inspection cover. (6) Remove right wheel and inner splash shield.

(7) Remove drive belt. Refer to Cooling System

Group 7 for procedure. (8) Remove A/C compressor and set aside.

(9) Remove A/C compressor mounting bracket.

(10) Remove crankshaft pulley (Fig. 1).

(11) Remove idler pulley from engine bracket.

(12) Remove engine bracket (Fig. 2).

(13) Remove cam sensor from chain case cover

(Fig. 3).

Fig. 27 Hydraulic Roller Tappet Assembly

Fig. 1 Removing Crankshaft Pulley

Ä 3.3/3.8L ENGINE 9 - 109

Page 1677 of 2438

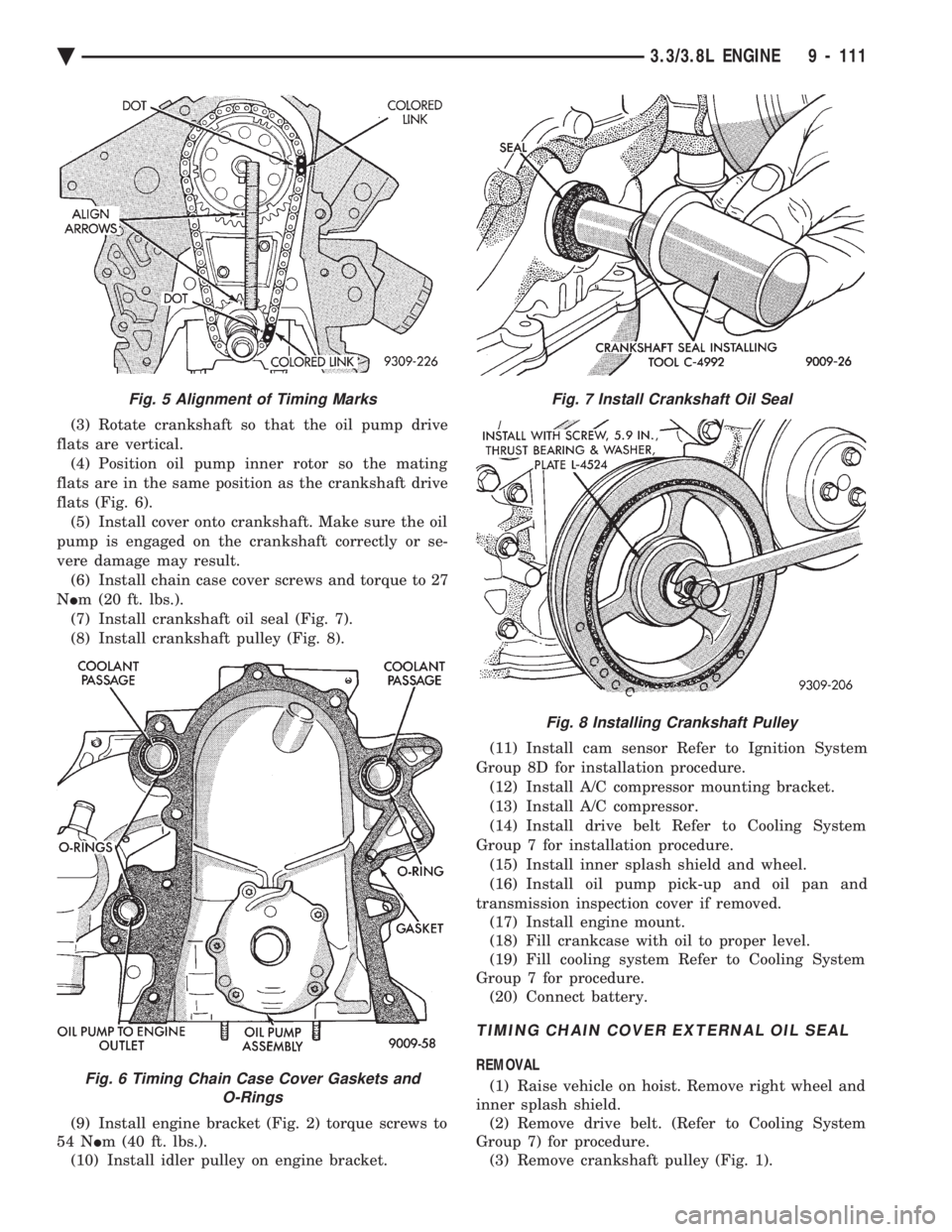

(3) Rotate crankshaft so that the oil pump drive

flats are vertical. (4) Position oil pump inner rotor so the mating

flats are in the same position as the crankshaft drive

flats (Fig. 6). (5) Install cover onto crankshaft. Make sure the oil

pump is engaged on the crankshaft correctly or se-

vere damage may result. (6) Install chain case cover screws and torque to 27

N Im (20 ft. lbs.).

(7) Install crankshaft oil seal (Fig. 7).

(8) Install crankshaft pulley (Fig. 8).

(9) Install engine bracket (Fig. 2) torque screws to

54 N Im (40 ft. lbs.).

(10) Install idler pulley on engine bracket. (11) Install cam sensor Refer to Ignition System

Group 8D for installation procedure. (12) Install A/C compressor mounting bracket.

(13) Install A/C compressor.

(14) Install drive belt Refer to Cooling System

Group 7 for installation procedure. (15) Install inner splash shield and wheel.

(16) Install oil pump pick-up and oil pan and

transmission inspection cover if removed. (17) Install engine mount.

(18) Fill crankcase with oil to proper level.

(19) Fill cooling system Refer to Cooling System

Group 7 for procedure. (20) Connect battery.

TIMING CHAIN COVER EXTERNAL OIL SEAL

REMOVAL

(1) Raise vehicle on hoist. Remove right wheel and

inner splash shield. (2) Remove drive belt. (Refer to Cooling System

Group 7) for procedure. (3) Remove crankshaft pulley (Fig. 1).

Fig. 5 Alignment of Timing Marks

Fig. 6 Timing Chain Case Cover Gaskets and O-Rings

Fig. 7 Install Crankshaft Oil Seal

Fig. 8 Installing Crankshaft Pulley

Ä 3.3/3.8L ENGINE 9 - 111

Page 1678 of 2438

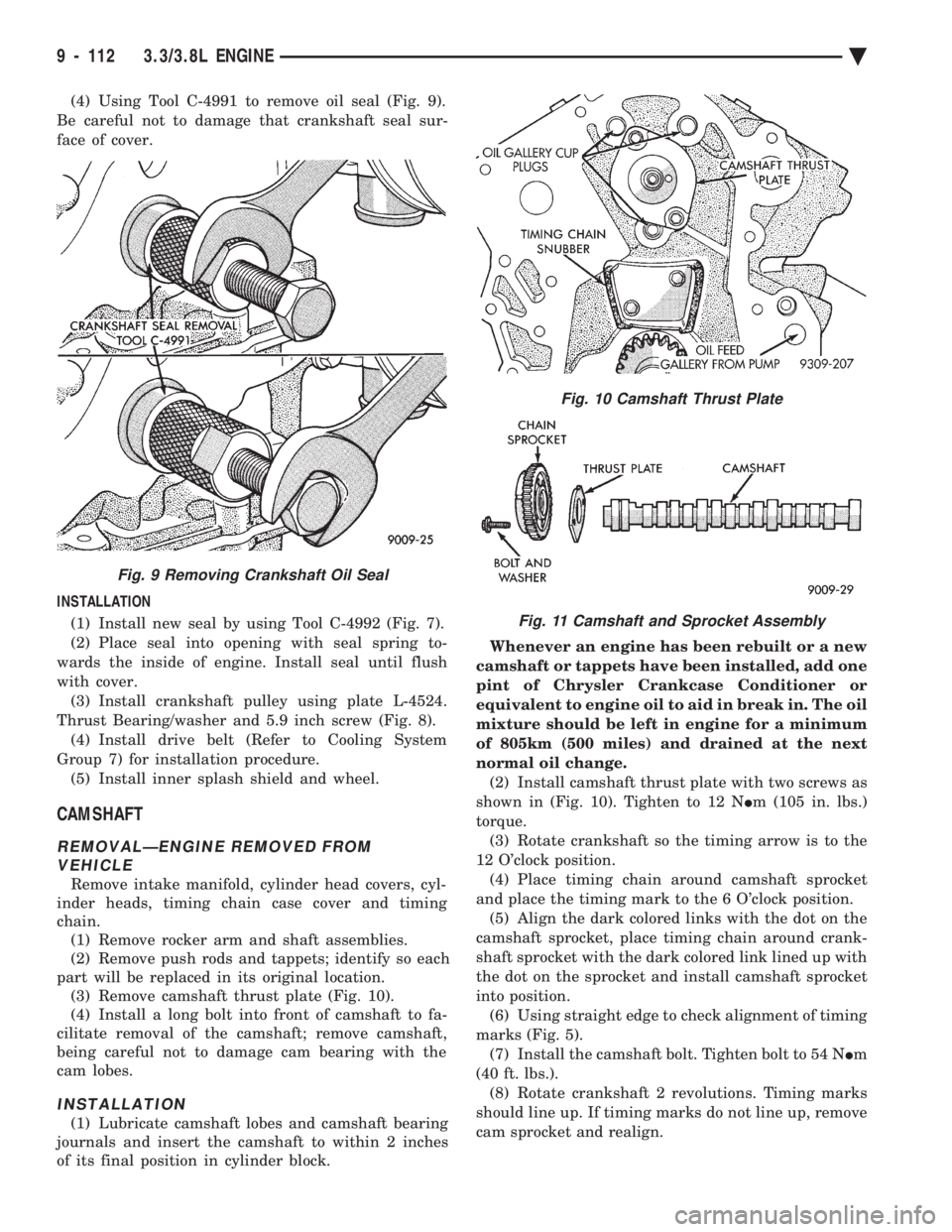

(4) Using Tool C-4991 to remove oil seal (Fig. 9).

Be careful not to damage that crankshaft seal sur-

face of cover.

INSTALLATION (1) Install new seal by using Tool C-4992 (Fig. 7).

(2) Place seal into opening with seal spring to-

wards the inside of engine. Install seal until flush

with cover. (3) Install crankshaft pulley using plate L-4524.

Thrust Bearing/washer and 5.9 inch screw (Fig. 8). (4) Install drive belt (Refer to Cooling System

Group 7) for installation procedure. (5) Install inner splash shield and wheel.

CAMSHAFT

REMOVALÐENGINE REMOVED FROM VEHICLE

Remove intake manifold, cylinder head covers, cyl-

inder heads, timing chain case cover and timing

chain. (1) Remove rocker arm and shaft assemblies.

(2) Remove push rods and tappets; identify so each

part will be replaced in its original location. (3) Remove camshaft thrust plate (Fig. 10).

(4) Install a long bolt into front of camshaft to fa-

cilitate removal of the camshaft; remove camshaft,

being careful not to damage cam bearing with the

cam lobes.

INSTALLATION

(1) Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft to within 2 inches

of its final position in cylinder block. Whenever an engine has been rebuilt or a new

camshaft or tappets have been installed, add one

pint of Chrysler Crankcase Conditioner or

equivalent to engine oil to aid in break in. The oil

mixture should be left in engine for a minimum

of 805km (500 miles) and drained at the next

normal oil change. (2) Install camshaft thrust plate with two screws as

shown in (Fig. 10). Tighten to 12 N Im (105 in. lbs.)

torque. (3) Rotate crankshaft so the timing arrow is to the

12 O'clock position. (4) Place timing chain around camshaft sprocket

and place the timing mark to the 6 O'clock position. (5) Align the dark colored links with the dot on the

camshaft sprocket, place timing chain around crank-

shaft sprocket with the dark colored link lined up with

the dot on the sprocket and install camshaft sprocket

into position. (6) Using straight edge to check alignment of timing

marks (Fig. 5). (7) Install the camshaft bolt. Tighten bolt to 54 N Im

(40 ft. lbs.). (8) Rotate crankshaft 2 revolutions. Timing marks

should line up. If timing marks do not line up, remove

cam sprocket and realign.

Fig. 9 Removing Crankshaft Oil Seal

Fig. 10 Camshaft Thrust Plate

Fig. 11 Camshaft and Sprocket Assembly

9 - 112 3.3/3.8L ENGINE Ä

Page 1811 of 2438

the PCM to store diagnostic trouble codes for other

systems. For example, a fuel pressure problem will not

register a fault directly, but could cause a rich or lean

condition. This could cause the PCM to store an oxygen

sensor diagnostic trouble code. Fuel Pressure - The vacuum assisted fuel pressure

regulator controls fuel system pressure. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, stuck open regulator, or a pinched

fuel supply or return line. However, these could result

in a rich or lean condition causing the PCM to store an

oxygen sensor diagnostic trouble code. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing belt, camshaft sprocket and

crankshaft sprocket. However, these could result in a

rich or lean condition causing the PCM to store an

oxygen sensor diagnostic trouble code. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Mechanical Malfunctions - The

PCM cannot determine if a fuel injector is clogged, the

needle is sticking or if the wrong injector is installed.

However, these could result in a rich or lean condition

causing the PCM to store an oxygen sensor diagnostic

trouble code. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM cannot detect a

disconnected (open vacuum line) restricted, plugged or

loaded evaporative purge canister. Vacuum Assist - The PCM cannot detect leaks or

restrictions in the vacuum circuits of vacuum assisted

engine control system devices. However, these could

cause the PCM to store a MAP sensor diagnostic

trouble code and cause a high idle condition. PCM System Ground - The PCM cannot determine

a poor system ground. However, one or more diagnostic

trouble codes may be generated as a result of this

condition. PCM Connector Engagement - The PCM may not

be able to determine spread or damaged connector

pins. However, it might store diagnostic trouble codes

as a result of spread connector pins.HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for the

device. If the input voltage is not within limits and other

criteria are met, the PCM stores a diagnostic trouble code

in memory. Other diagnostic trouble code criteria might

include engine RPM limits or input voltages from other

sensors or switches that must be present before verifying

a diagnostic trouble code condition.

DIAGNOSTIC TROUBLE CODES

A diagnostic trouble code indicates the powertrain

control module (PCM) has recognized an abnormal

condition in the system. Abnormal conditions are usu-

ally shorted or open circuits.

The technician can display diagnostic trouble codes in

two ways. The first way is to cycle the ignition switch and

count the number of times the malfunction indicator lamp

(check engine lamp on the instrument panel) flashes on

and off. The DRBII scan tool provides the second method

of displaying diagnostic trouble codes. Diagnostic trouble

codes indicate the results of a circuit failure, but do not

directly identify the failed component.

For a list of Diagnostic Trouble Codes, refer to

the charts at the end of this section.

OBTAINING DIAGNOSTIC TROUBLE CODES

USING DRBII SCAN TOOL

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE. (1) Connect DRBII scan tool to the data link (diag-

nostic) connector located in the engine compartment,

next to the PCM (Fig. 1). (2) If possible, start the engine and cycle the A/C

switch if applicable. Shut off the engine. (3)

Turn the ignition switch on, access Read Fault

Screen. Record all the diagnostic trouble codes shown on

the DRBII scan tool. [Observe the malfunction indicator

lamp (check engine lamp) on the instrument panel. The

lamp should light for 2 seconds then go out (bulb check)].

To erase diagnostic trouble codes, use the Erase

Trouble Code data screen on the DRBII scan tool.

USING THE MALFUNCTION INDICATOR LAMP (1) Cycle the ignition key On - Off - On - Off - On

within 5 seconds. (2) Count the number of times the malfunction indi-

cator lamp (check engine lamp on the instrument

panel) flashes on and off. The number of flashes

represents the trouble code. There is a slight pause be-

Ä FUEL SYSTEMS 14 - 71