wiring diagram CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 520 of 2438

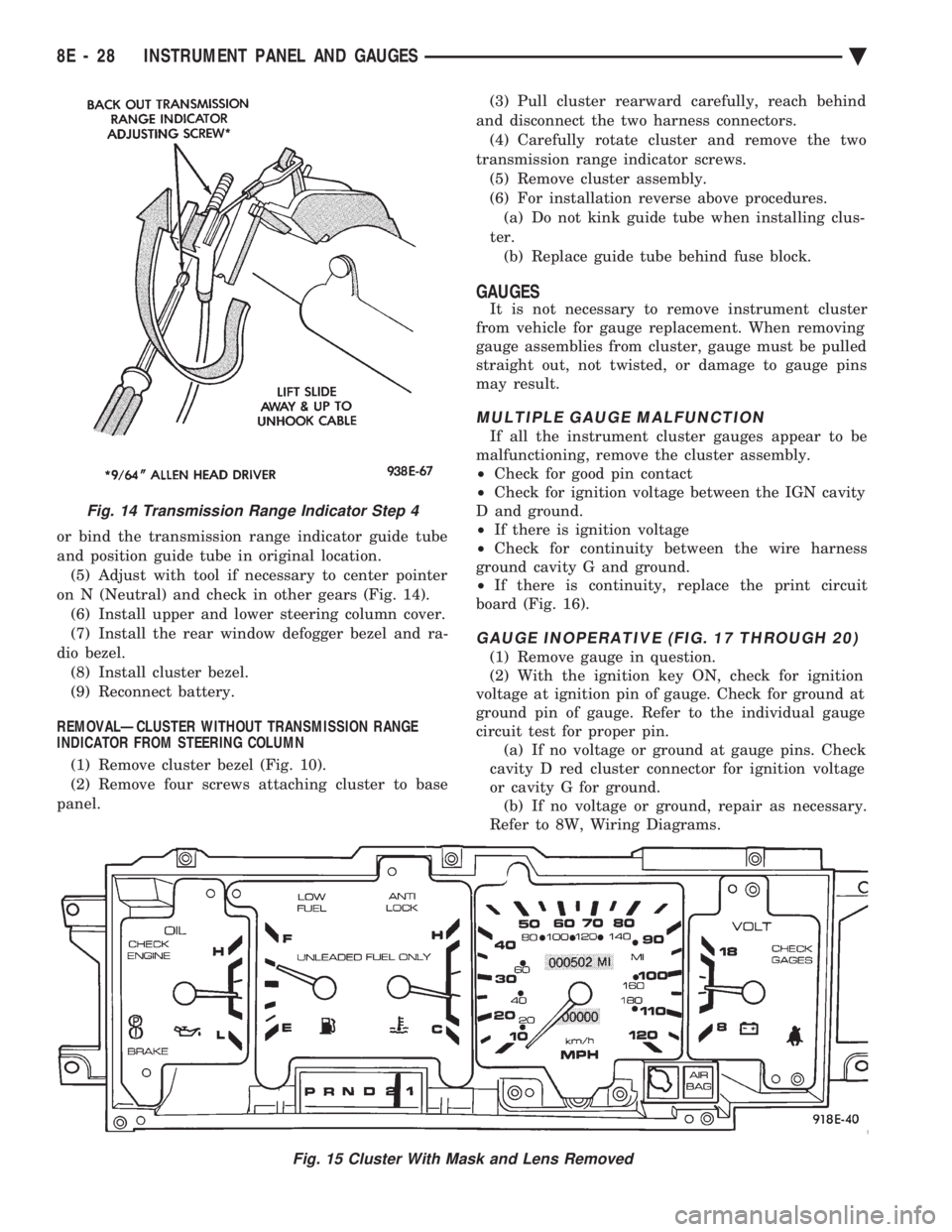

or bind the transmission range indicator guide tube

and position guide tube in original location.(5) Adjust with tool if necessary to center pointer

on N (Neutral) and check in other gears (Fig. 14). (6) Install upper and lower steering column cover.

(7) Install the rear window defogger bezel and ra-

dio bezel. (8) Install cluster bezel.

(9) Reconnect battery.

REMOVALÐCLUSTER WITHOUT TRANSMISSION RANGE

INDICATOR FROM STEERING COLUMN

(1) Remove cluster bezel (Fig. 10).

(2) Remove four screws attaching cluster to base

panel. (3) Pull cluster rearward carefully, reach behind

and disconnect the two harness connectors. (4) Carefully rotate cluster and remove the two

transmission range indicator screws. (5) Remove cluster assembly.

(6) For installation reverse above procedures. (a) Do not kink guide tube when installing clus-

ter. (b) Replace guide tube behind fuse block.

GAUGES

It is not necessary to remove instrument cluster

from vehicle for gauge replacement. When removing

gauge assemblies from cluster, gauge must be pulled

straight out, not twisted, or damage to gauge pins

may result.

MULTIPLE GAUGE MALFUNCTION

If all the instrument cluster gauges appear to be

malfunctioning, remove the cluster assembly.

² Check for good pin contact

² Check for ignition voltage between the IGN cavity

D and ground.

² If there is ignition voltage

² Check for continuity between the wire harness

ground cavity G and ground.

² If there is continuity, replace the print circuit

board (Fig. 16).

GAUGE INOPERATIVE (FIG. 17 THROUGH 20)

(1) Remove gauge in question.

(2) With the ignition key ON, check for ignition

voltage at ignition pin of gauge. Check for ground at

ground pin of gauge. Refer to the individual gauge

circuit test for proper pin. (a) If no voltage or ground at gauge pins. Check

cavity D red cluster connector for ignition voltage

or cavity G for ground. (b) If no voltage or ground, repair as necessary.

Refer to 8W, Wiring Diagrams.

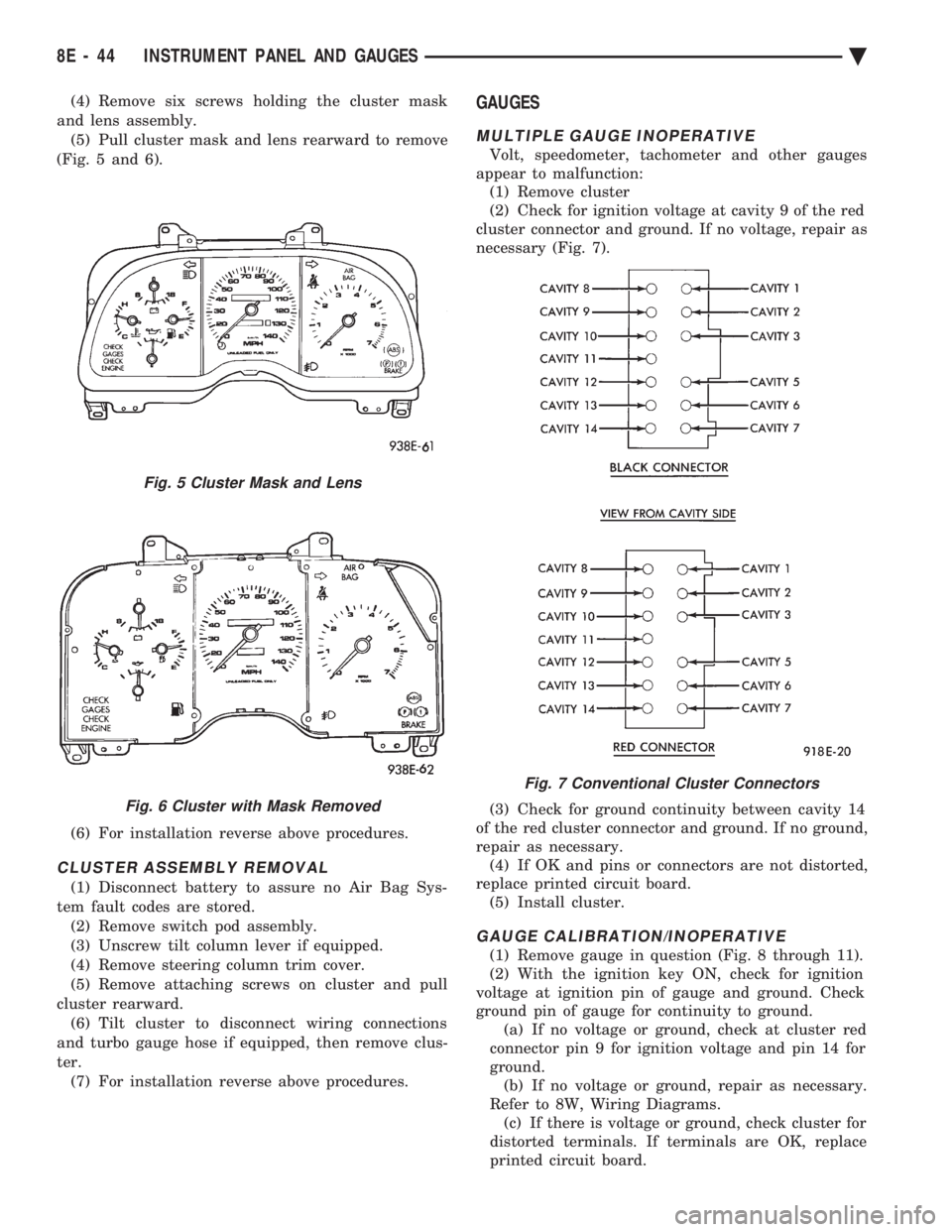

Fig. 15 Cluster With Mask and Lens Removed

Fig. 14 Transmission Range Indicator Step 4

8E - 28 INSTRUMENT PANEL AND GAUGES Ä

Page 536 of 2438

(4) Remove six screws holding the cluster mask

and lens assembly. (5) Pull cluster mask and lens rearward to remove

(Fig. 5 and 6).

(6) For installation reverse above procedures.

CLUSTER ASSEMBLY REMOVAL

(1) Disconnect battery to assure no Air Bag Sys-

tem fault codes are stored. (2) Remove switch pod assembly.

(3) Unscrew tilt column lever if equipped.

(4) Remove steering column trim cover.

(5) Remove attaching screws on cluster and pull

cluster rearward. (6) Tilt cluster to disconnect wiring connections

and turbo gauge hose if equipped, then remove clus-

ter. (7) For installation reverse above procedures.

GAUGES

MULTIPLE GAUGE INOPERATIVE

Volt, speedometer, tachometer and other gauges

appear to malfunction: (1) Remove cluster

(2) Check for ignition voltage at cavity 9 of the red

cluster connector and ground. If no voltage, repair as

necessary (Fig. 7).

(3) Check for ground continuity between cavity 14

of the red cluster connector and ground. If no ground,

repair as necessary. (4) If OK and pins or connectors are not distorted,

replace printed circuit board. (5) Install cluster.

GAUGE CALIBRATION/INOPERATIVE

(1) Remove gauge in question (Fig. 8 through 11).

(2) With the ignition key ON, check for ignition

voltage at ignition pin of gauge and ground. Check

ground pin of gauge for continuity to ground. (a) If no voltage or ground, check at cluster red

connector pin 9 for ignition voltage and pin 14 for

ground. (b) If no voltage or ground, repair as necessary.

Refer to 8W, Wiring Diagrams. (c) If there is voltage or ground, check cluster for

distorted terminals. If terminals are OK, replace

printed circuit board.

Fig. 5 Cluster Mask and Lens

Fig. 6 Cluster with Mask Removed

Fig. 7 Conventional Cluster Connectors

8E - 44 INSTRUMENT PANEL AND GAUGES Ä

Page 553 of 2438

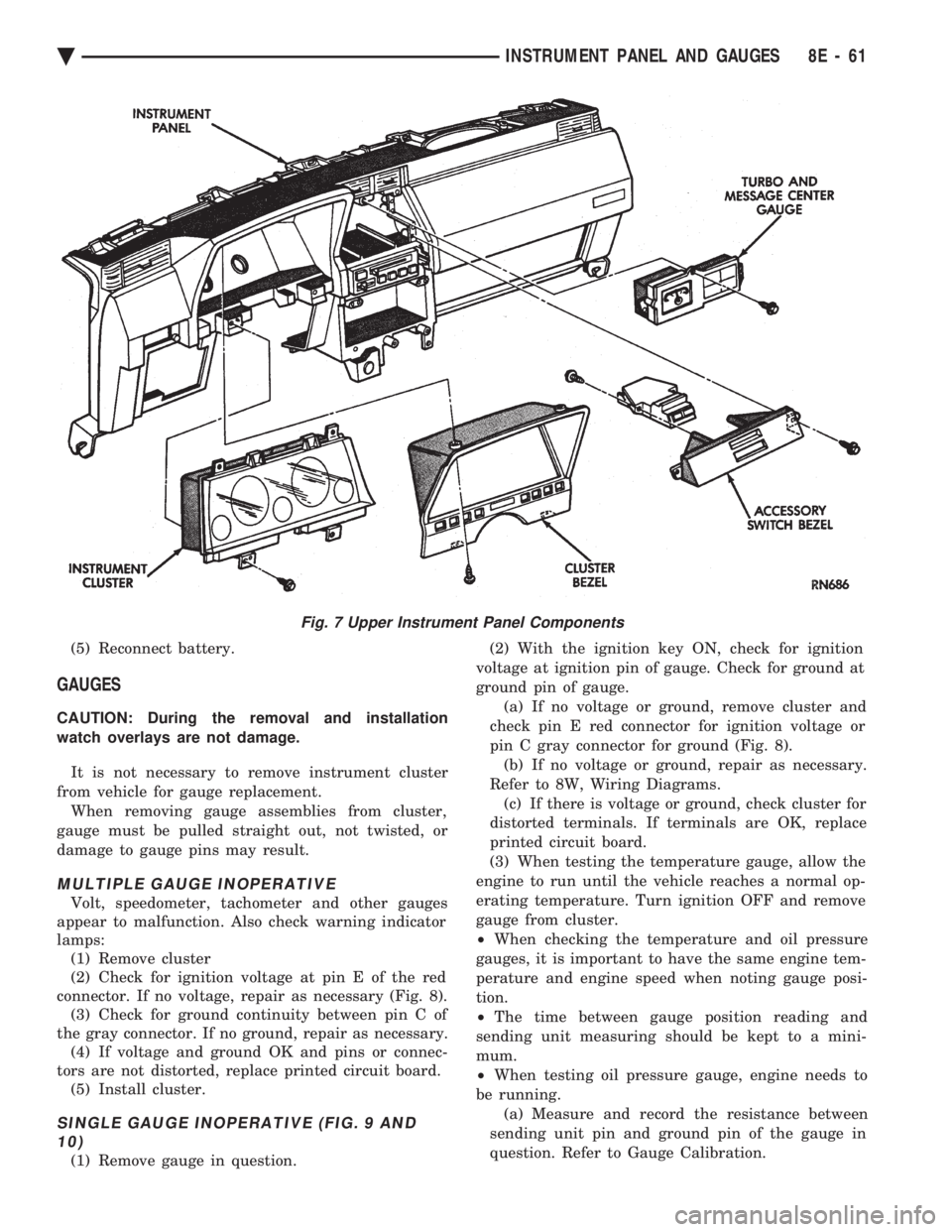

(5) Reconnect battery.

GAUGES

CAUTION: During the removal and installation

watch overlays are not damage.

It is not necessary to remove instrument cluster

from vehicle for gauge replacement. When removing gauge assemblies from cluster,

gauge must be pulled straight out, not twisted, or

damage to gauge pins may result.

MULTIPLE GAUGE INOPERATIVE

Volt, speedometer, tachometer and other gauges

appear to malfunction. Also check warning indicator

lamps: (1) Remove cluster

(2) Check for ignition voltage at pin E of the red

connector. If no voltage, repair as necessary (Fig. 8). (3) Check for ground continuity between pin C of

the gray connector. If no ground, repair as necessary. (4) If voltage and ground OK and pins or connec-

tors are not distorted, replace printed circuit board. (5) Install cluster.

SINGLE GAUGE INOPERATIVE (FIG. 9 AND10)

(1) Remove gauge in question. (2) With the ignition key ON, check for ignition

voltage at ignition pin of gauge. Check for ground at

ground pin of gauge. (a) If no voltage or ground, remove cluster and

check pin E red connector for ignition voltage or

pin C gray connector for ground (Fig. 8). (b) If no voltage or ground, repair as necessary.

Refer to 8W, Wiring Diagrams. (c) If there is voltage or ground, check cluster for

distorted terminals. If terminals are OK, replace

printed circuit board.

(3) When testing the temperature gauge, allow the

engine to run until the vehicle reaches a normal op-

erating temperature. Turn ignition OFF and remove

gauge from cluster.

² When checking the temperature and oil pressure

gauges, it is important to have the same engine tem-

perature and engine speed when noting gauge posi-

tion.

² The time between gauge position reading and

sending unit measuring should be kept to a mini-

mum.

² When testing oil pressure gauge, engine needs to

be running. (a) Measure and record the resistance between

sending unit pin and ground pin of the gauge in

question. Refer to Gauge Calibration.

Fig. 7 Upper Instrument Panel Components

Ä INSTRUMENT PANEL AND GAUGES 8E - 61

Page 606 of 2438

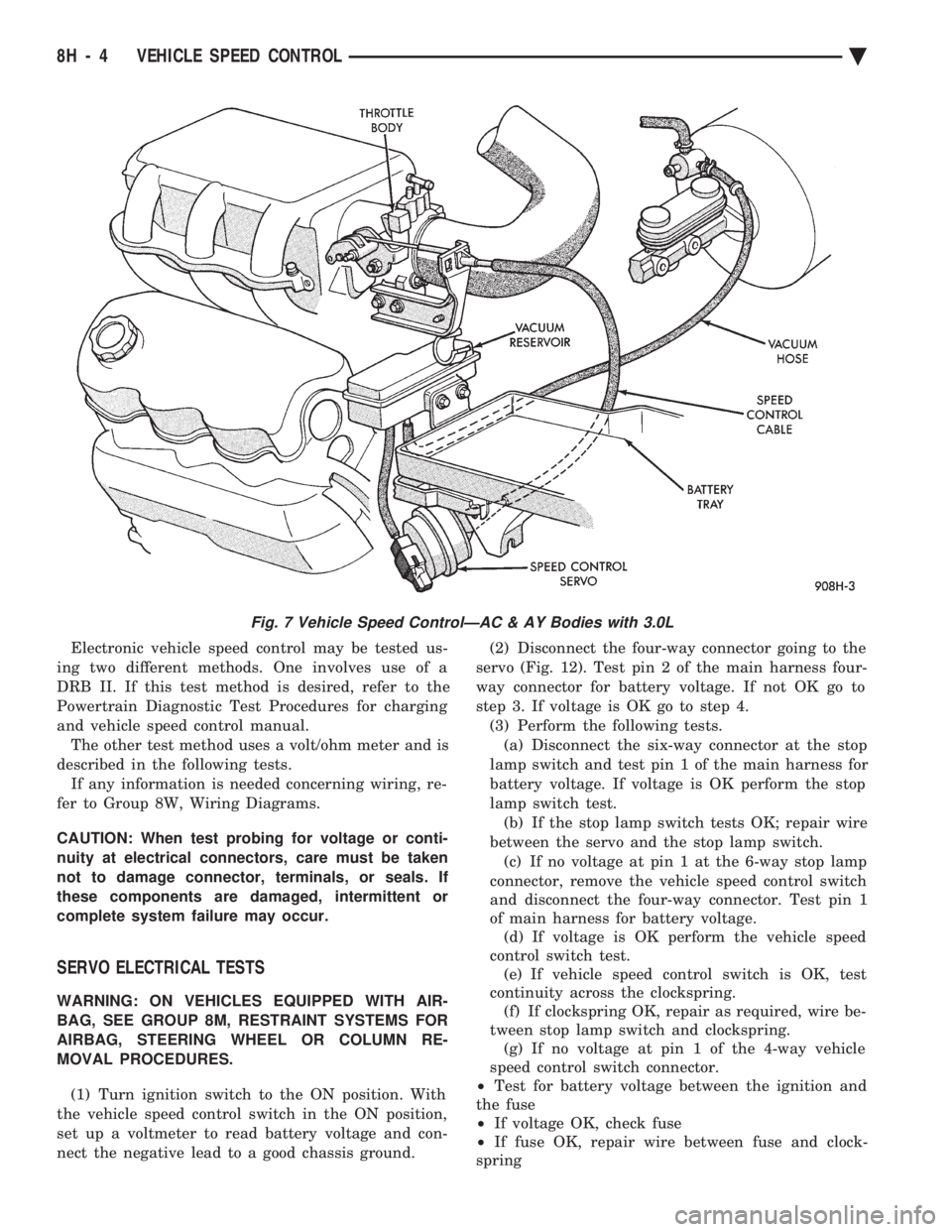

Electronic vehicle speed control may be tested us-

ing two different methods. One involves use of a

DRB II. If this test method is desired, refer to the

Powertrain Diagnostic Test Procedures for charging

and vehicle speed control manual. The other test method uses a volt/ohm meter and is

described in the following tests. If any information is needed concerning wiring, re-

fer to Group 8W, Wiring Diagrams.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SERVO ELECTRICAL TESTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

AIRBAG, STEERING WHEEL OR COLUMN RE-

MOVAL PROCEDURES.

(1) Turn ignition switch to the ON position. With

the vehicle speed control switch in the ON position,

set up a voltmeter to read battery voltage and con-

nect the negative lead to a good chassis ground. (2) Disconnect the four-way connector going to the

servo (Fig. 12). Test pin 2 of the main harness four-

way connector for battery voltage. If not OK go to

step 3. If voltage is OK go to step 4. (3) Perform the following tests.(a) Disconnect the six-way connector at the stop

lamp switch and test pin 1 of the main harness for

battery voltage. If voltage is OK perform the stop

lamp switch test. (b) If the stop lamp switch tests OK; repair wire

between the servo and the stop lamp switch. (c) If no voltage at pin 1 at the 6-way stop lamp

connector, remove the vehicle speed control switch

and disconnect the four-way connector. Test pin 1

of main harness for battery voltage. (d) If voltage is OK perform the vehicle speed

control switch test. (e) If vehicle speed control switch is OK, test

continuity across the clockspring. (f) If clockspring OK, repair as required, wire be-

tween stop lamp switch and clockspring. (g) If no voltage at pin 1 of the 4-way vehicle

speed control switch connector.

² Test for battery voltage between the ignition and

the fuse

² If voltage OK, check fuse

² If fuse OK, repair wire between fuse and clock-

spring

Fig. 7 Vehicle Speed ControlÐAC & AY Bodies with 3.0L

8H - 4 VEHICLE SPEED CONTROL Ä

Page 626 of 2438

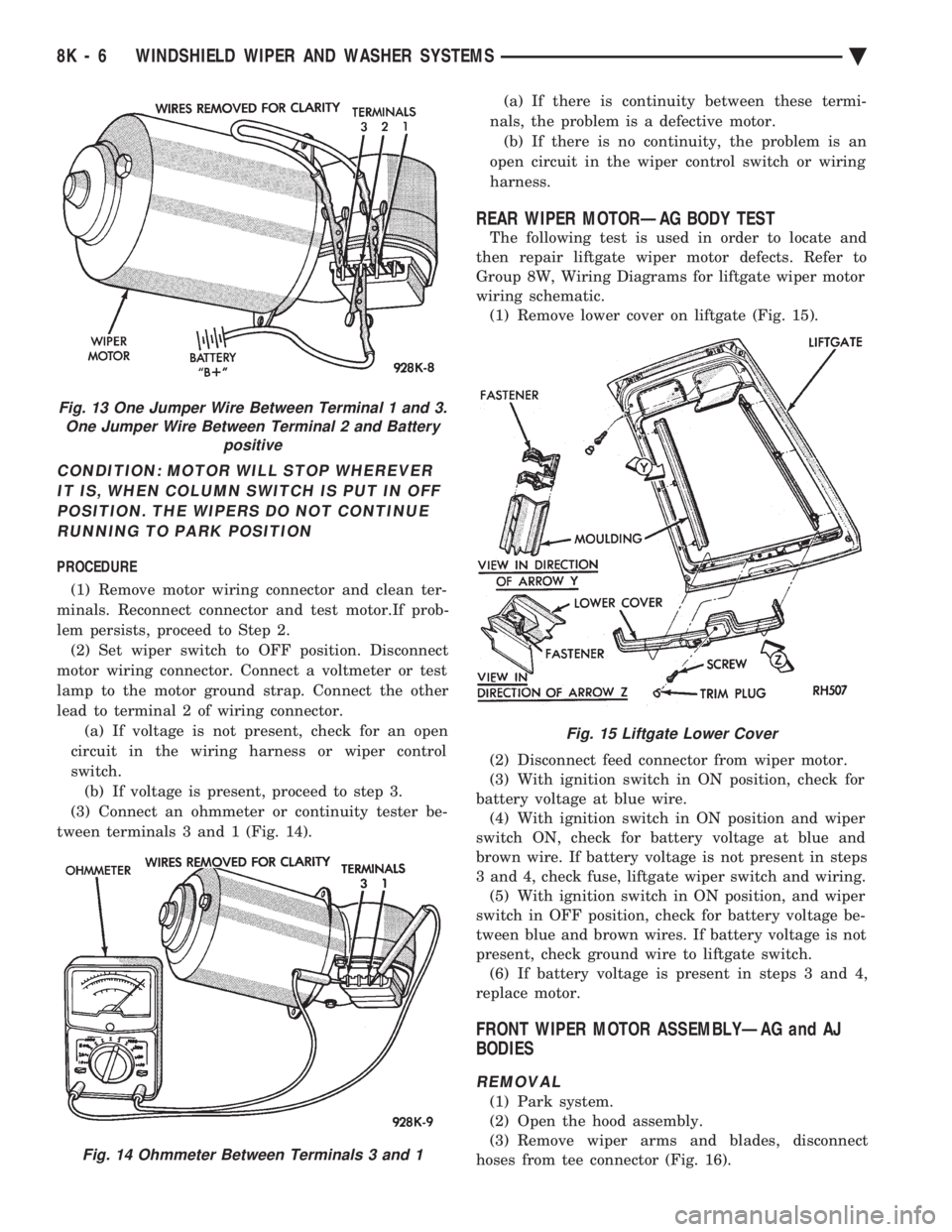

CONDITION: MOTOR WILL STOP WHEREVER IT IS, WHEN COLUMN SWITCH IS PUT IN OFFPOSITION. THE WIPERS DO NOT CONTINUERUNNING TO PARK POSITION

PROCEDURE

(1) Remove motor wiring connector and clean ter-

minals. Reconnect connector and test motor.If prob-

lem persists, proceed to Step 2. (2) Set wiper switch to OFF position. Disconnect

motor wiring connector. Connect a voltmeter or test

lamp to the motor ground strap. Connect the other

lead to terminal 2 of wiring connector. (a) If voltage is not present, check for an open

circuit in the wiring harness or wiper control

switch. (b) If voltage is present, proceed to step 3.

(3) Connect an ohmmeter or continuity tester be-

tween terminals 3 and 1 (Fig. 14). (a) If there is continuity between these termi-

nals, the problem is a defective motor. (b) If there is no continuity, the problem is an

open circuit in the wiper control switch or wiring

harness.

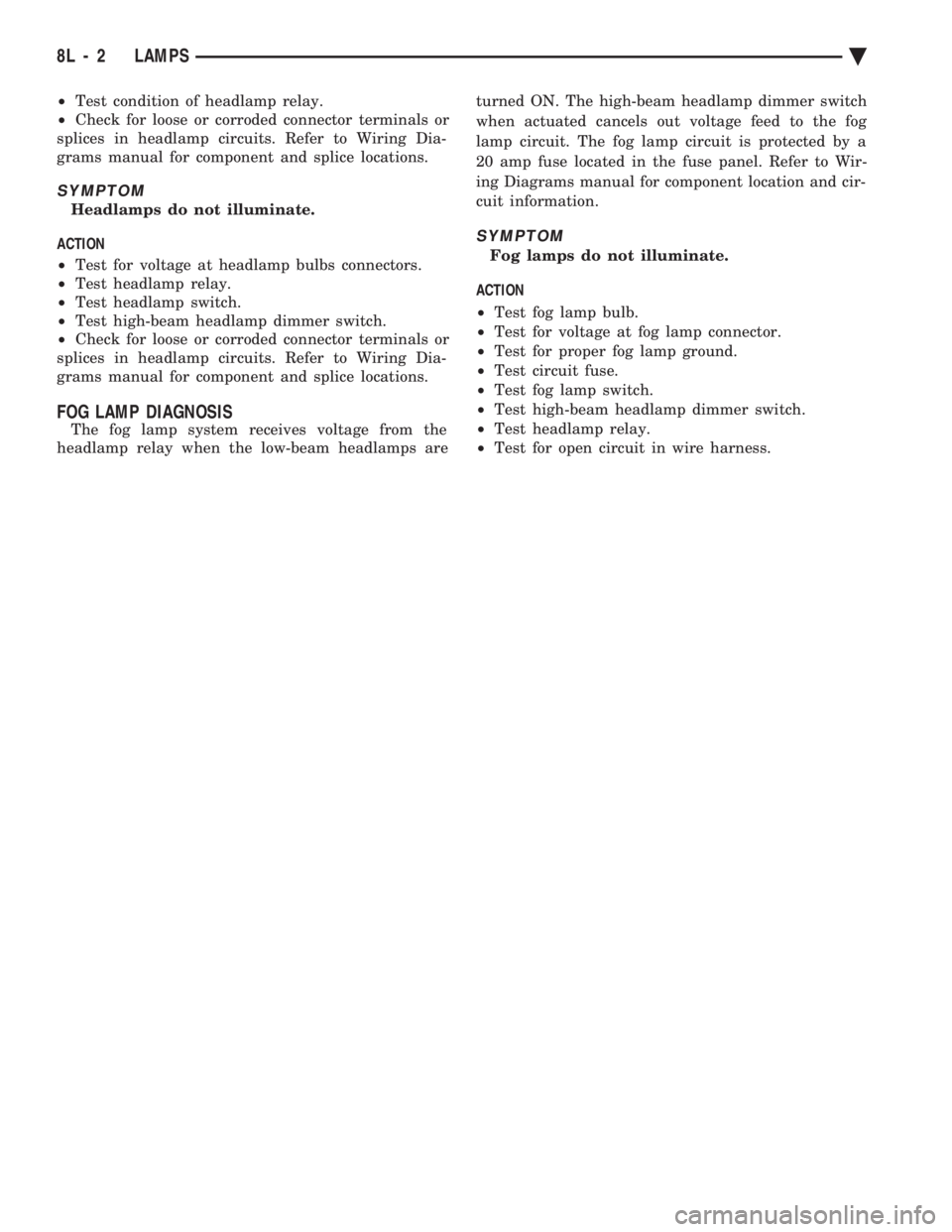

REAR WIPER MOTORÐAG BODY TEST

The following test is used in order to locate and

then repair liftgate wiper motor defects. Refer to

Group 8W, Wiring Diagrams for liftgate wiper motor

wiring schematic. (1) Remove lower cover on liftgate (Fig. 15).

(2) Disconnect feed connector from wiper motor.

(3) With ignition switch in ON position, check for

battery voltage at blue wire. (4) With ignition switch in ON position and wiper

switch ON, check for battery voltage at blue and

brown wire. If battery voltage is not present in steps

3 and 4, check fuse, liftgate wiper switch and wiring. (5) With ignition switch in ON position, and wiper

switch in OFF position, check for battery voltage be-

tween blue and brown wires. If battery voltage is not

present, check ground wire to liftgate switch. (6) If battery voltage is present in steps 3 and 4,

replace motor.

FRONT WIPER MOTOR ASSEMBLYÐAG and AJ

BODIES

REMOVAL

(1) Park system.

(2) Open the hood assembly.

(3) Remove wiper arms and blades, disconnect

hoses from tee connector (Fig. 16).

Fig. 13 One Jumper Wire Between Terminal 1 and 3. One Jumper Wire Between Terminal 2 and Battery positive

Fig. 14 Ohmmeter Between Terminals 3 and 1

Fig. 15 Liftgate Lower Cover

8K - 6 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 643 of 2438

LAMPS

CONTENTS

page page

BULB APPLICATION TABLE ............... 38

CONCEALED HEADLAMPS ................ 27

EXTERIOR LAMP SWITCHES AND HEADLAMP ALIGNMENT ........................... 3

EXTERIOR LAMP SYSTEMS .............. 25

EXTERIOR LAMPSÐAA BODY ............. 7

EXTERIOR LAMPSÐAC BODY ............ 10 EXTERIOR LAMPSÐAG BODY

............ 14

EXTERIOR LAMPSÐAJ BODY ............ 16

EXTERIOR LAMPSÐAP BODY ............ 19

EXTERIOR LAMPSÐAY-BODY ............ 22

GENERAL INFORMATION .................. 1

ILLUMINATED ENTRY SYSTEM ........... 33

GENERAL INFORMATION

Each vehicle is equipped with lamps used for illumi-

nating and indicating purposes. A circuit must have a

good ground to be complete. Circuit ground occurs

when the lamp socket makes contact with the metal

body. On vehicles with plastic lamps, a wire between

the socket and the body makes the grounds. When changing lamp bulbs, check the socket for

corrosion. If corrosion is present, clean contacts with a

wire brush and coat the inside of the socket with

Mopar tMulti-purpose Grease or equivalent.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or any possibly oily surface, reduced

bulb life will result.

BODY IDENTIFICATION

Throughout this Group, references are made to the

vehicle family or body code. To decode the vehicle

identification plates, refer to the Introduction Section

at the front of this manual.

DIAGNOSTIC PROCEDURES

Begin electrical system failure diagnosis by testing

all related fuses and circuit breakers in the fuse block

and engine compartment. When a vehicle experiences problems with the head-

lamp system, verify the condition of the battery con-

nections, charging system, headlamp bulbs, wire con-

nectors, relay, high beam dimmer switch and headlamp

switch. Refer to Wiring Diagrams manual for compo-

nent locations and circuit information.

SYMPTOM

Headlamps are dim when engine is idling of

with ignition turned OFF. Canada cars must

have lamps ON. ACTION

² Clean battery terminal clamps and posts. Refer to

Group 8B, Battery/Starter/Generator Service for

proper procedures.

² Test charging system output. Refer to Group 8A,

Battery/Starting/Charging Systems Diagnostics for

proper testing procedures.

² Test for high resistance in headlamp circuits.

² Defective headlamp bulb.

SYMPTOM

Bulbs burn out frequently.

ACTION

² Test charging system output. Refer to Group 8A,

Battery/Starting/Charging Systems Diagnostics for

proper testing procedures.

² Check for loose or corroded connector terminals or

splices in headlamp circuits. Refer to Wiring Diagrams

manual for component and splice locations.

SYMPTOM

Headlamps are dim with engine running above

idle. Canada cars must have lamps ON.

ACTION

² Test charging system output. Refer to Group 8A,

Battery/Starting/Charging Systems Diagnostics for

proper testing procedures.

² Test for high resistance in headlamp circuits.

² Defective headlamp bulb.

SYMPTOM

Headlamps flash randomly.

ACTION

² Test for poor circuit ground.

² Test for high resistance in headlamp circuits.

Ä LAMPS 8L - 1

Page 644 of 2438

² Test condition of headlamp relay.

² Check for loose or corroded connector terminals or

splices in headlamp circuits. Refer to Wiring Dia-

grams manual for component and splice locations.

SYMPTOM

Headlamps do not illuminate.

ACTION

² Test for voltage at headlamp bulbs connectors.

² Test headlamp relay.

² Test headlamp switch.

² Test high-beam headlamp dimmer switch.

² Check for loose or corroded connector terminals or

splices in headlamp circuits. Refer to Wiring Dia-

grams manual for component and splice locations.

FOG LAMP DIAGNOSIS

The fog lamp system receives voltage from the

headlamp relay when the low-beam headlamps are turned ON. The high-beam headlamp dimmer switch

when actuated cancels out voltage feed to the fog

lamp circuit. The fog lamp circuit is protected by a

20 amp fuse located in the fuse panel. Refer to Wir-

ing Diagrams manual for component location and cir-

cuit information.

SYMPTOM

Fog lamps do not illuminate.

ACTION

² Test fog lamp bulb.

² Test for voltage at fog lamp connector.

² Test for proper fog lamp ground.

² Test circuit fuse.

² Test fog lamp switch.

² Test high-beam headlamp dimmer switch.

² Test headlamp relay.

² Test for open circuit in wire harness.

8L - 2 LAMPS Ä

Page 645 of 2438

EXTERIOR LAMP SWITCHES AND HEADLAMP ALIGNMENT INDEX

page page

Headlamp Adjustment Using Alignment Screen .... 3

Headlamp Alignment ....................... 3

Headlamp Alignment Preparation .............. 3 Headlamp Dimmer Switch

................... 3

Headlamp Switch .......................... 3

HEADLAMP SWITCH

Service procedures for the headlamp switch can be

found in Group 8E, Instrument Panel and Gauges. More

information can be found in Wiring Diagrams manual.

HEADLAMP DIMMER SWITCH

The headlamp dimmer switch is incorporated into

the turn signal switch. Proper procedures can be found

in Group 8J, Turn Signal and Flashers. More informa-

tion can be found in Group 8W, Wiring Diagrams.

HEADLAMP ALIGNMENT

Headlamps can be aligned using the screen method

provided in this section. Alignment Tool C4466-A or

equivalent can also be used. Refer to instructions

provided with the tool for proper procedures. The

preferred headlamp alignment setting is 0 for the

left/right adjustment and 0 for the up/down ad-

justment.

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation. (2) Inspect and correct damaged or defective compo-

nents that could interfere with proper headlamp align-

ment. (3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is not heavily loaded.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5 lbs.)

of weight over the fuel tank for each estimated gallon of

missing fuel.

HEADLAMP ADJUSTMENT USING ALIGNMENT

SCREEN

ALIGNMENT SCREEN PREPARATION (FIG. 1 AND 2)

(1) Position vehicle on a level surface perpendicular

to a flat wall 7.62 meters (25 ft) away from front of

headlamp lens. (2) If necessary, tape a line on the floor 7.62 meters

(25 ft) away from and parallel to the wall.

(3) From the floor up 1.27 meters (5 ft), tape a line on

the wall at the centerline of the vehicle. Sight along the

centerline of the vehicle (from rear of vehicle forward) to

verify accuracy of the line placement.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize. (5) Jounce front suspension three times by pushing

downward on front bumper and releasing. (6) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to the

alignment screen (with tape). Use this line for up/down

adjustment reference. (7) Measure distance from the centerline of the ve-

hicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

side of vehicle centerline. Use these lines for left/right

adjustment reference.

HEADLAMP ADJUSTMENT (FIG. 3, 4, 5, 6 OR 7)

A properly aimed low beam headlamp will project the

top edge of low beam hot spot on the alignment screen

from 50 mm (2 in.) above to 50 mm (2 in.) below the

headlamp centerline. The side-to-side left edge of low

beam hot spot should be from 50 mm (2 in.) left to

50mm (2 in.) right of headlamp centerline (Fig. 1). The

preferred headlamp alignment is 0 for the

up/down adjustment and 0 for the left/right ad-

justment. The high beams on a vehicle with aero

headlamps cannot be aligned. The high beam pattern

should be correct when the low beams are aligned

properly. To adjust headlamp alignment, rotate alignment

screws to achieve the specified low beam hot spot

pattern.

CAUTION: Do not cover an illuminated headlamp for

more then 15 seconds. Lamp will overheat and burn

or melt cover.

To adjust headlamps, rotate alignment screws to

achieve the specified high intensity pattern (Fig. 1 or

2).

FOG LAMP ALIGNMENT (FIG. 8)

Prepare an alignment screen. Refer to Alignment

Screen Preparation paragraph in this section. A prop-

erly aligned fog lamp will project a pattern on the

alignment screen 100 mm (4 in.) below the fog lamp

centerline and straight ahead.

Ä LAMPS 8L - 3

Page 652 of 2438

EXTERIOR LAMPSÐAC BODY INDEX

page page

Aero Headlamp Bulb ...................... 10

Aero Headlamp Housing ................... 11

Aero HeadlampsÐAC/D-Body ............... 10

Center High Mounted Stop Lamp (CHMSL) ..... 13

Center High-Mounted Stop Lamp (CHMSL) Bulb . 13

Cornering Lamp Assembly .................. 12

Cornering Lamp Bulb ..................... 12

Front Side Marker BulbÐAC/C-Body .......... 12

Front Side Marker LampÐAC/C-Body ......... 12

Headlamp Diagnosis ...................... 10 Headlamp Sealed BeamÐAC/C Body

......... 10

License Plate Lamp/Bulb ................... 13

Park/Turn Signal Lamp or BulbÐAC/C-Body .... 11

Park/Turn Signal Lamp or BulbÐAC/D-Body .... 11

Rear Side Marker Lamp BulbÐAC/C-Body ..... 13

Rear Side Marker LampÐAC/C-Body ......... 13

Tail, Stop, Turn Signal, Back-Up and Side Marker LampÐAC/D-Body ...................... 12

Tail, Stop, Turn Signal, Back-Up LampÐAC/C or AY/S-Body ............................ 12

HEADLAMP DIAGNOSIS

Refer to the Headlamp Diagnosis at the beginning of

this Group. Refer to Wiring Diagrams Manual for

circuit and component locations.

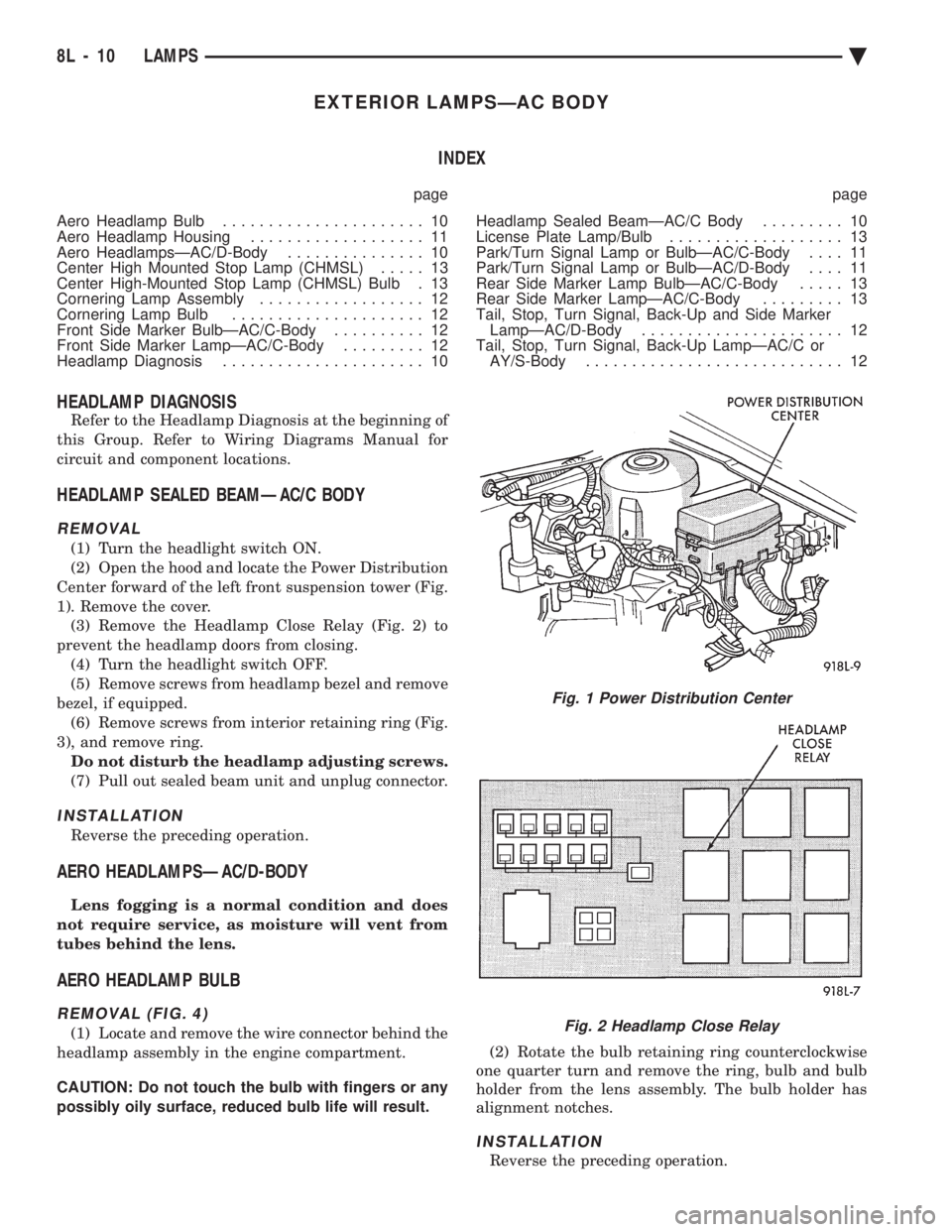

HEADLAMP SEALED BEAMÐAC/C BODY

REMOVAL

(1) Turn the headlight switch ON.

(2) Open the hood and locate the Power Distribution

Center forward of the left front suspension tower (Fig.

1). Remove the cover. (3) Remove the Headlamp Close Relay (Fig. 2) to

prevent the headlamp doors from closing. (4) Turn the headlight switch OFF.

(5) Remove screws from headlamp bezel and remove

bezel, if equipped. (6) Remove screws from interior retaining ring (Fig.

3), and remove ring. Do not disturb the headlamp adjusting screws.

(7) Pull out sealed beam unit and unplug connector.

INSTALLATION

Reverse the preceding operation.

AERO HEADLAMPSÐAC/D-BODY

Lens fogging is a normal condition and does

not require service, as moisture will vent from

tubes behind the lens.

AERO HEADLAMP BULB

REMOVAL (FIG. 4)

(1) Locate and remove the wire connector behind the

headlamp assembly in the engine compartment.

CAUTION: Do not touch the bulb with fingers or any

possibly oily surface, reduced bulb life will result. (2) Rotate the bulb retaining ring counterclockwise

one quarter turn and remove the ring, bulb and bulb

holder from the lens assembly. The bulb holder has

alignment notches.

INSTALLATION

Reverse the preceding operation.

Fig. 1 Power Distribution Center

Fig. 2 Headlamp Close Relay

8L - 10 LAMPS Ä

Page 661 of 2438

EXTERIOR LAMPSÐAP BODY INDEX

page page

Center High Mounted Stop Lamp (CHMSL)Ð AP/24-44-Body ......................... 21

Center High Mounted Stop Lamp BulbÐ AP/24-44-Body ......................... 21

Fog Lamp Bulb .......................... 21

Fog Lamps ............................. 21

Front Side Marker Lamp or Bulb ............. 20

Headlamp Bulb .......................... 19 Headlamp Diagnosis

...................... 19

Headlamp Housing ....................... 19

License Plate Lamp or Bulb ................ 20

Park and Turn Signal Lamp or Bulb .......... 20

Tail, Stop, Turn Signal, Back-Up and Side Marker Lamp ................................ 20

Tail, Stop, Turn Signal, Back-Up and Side Marker Lamp Bulbs ........................... 20

HEADLAMP DIAGNOSIS

For headlamp diagnosis, refer to the headlamp di-

agnosis chart at the beginning of this group. Refer to

Wiring Diagrams manual for circuit and component

locations.

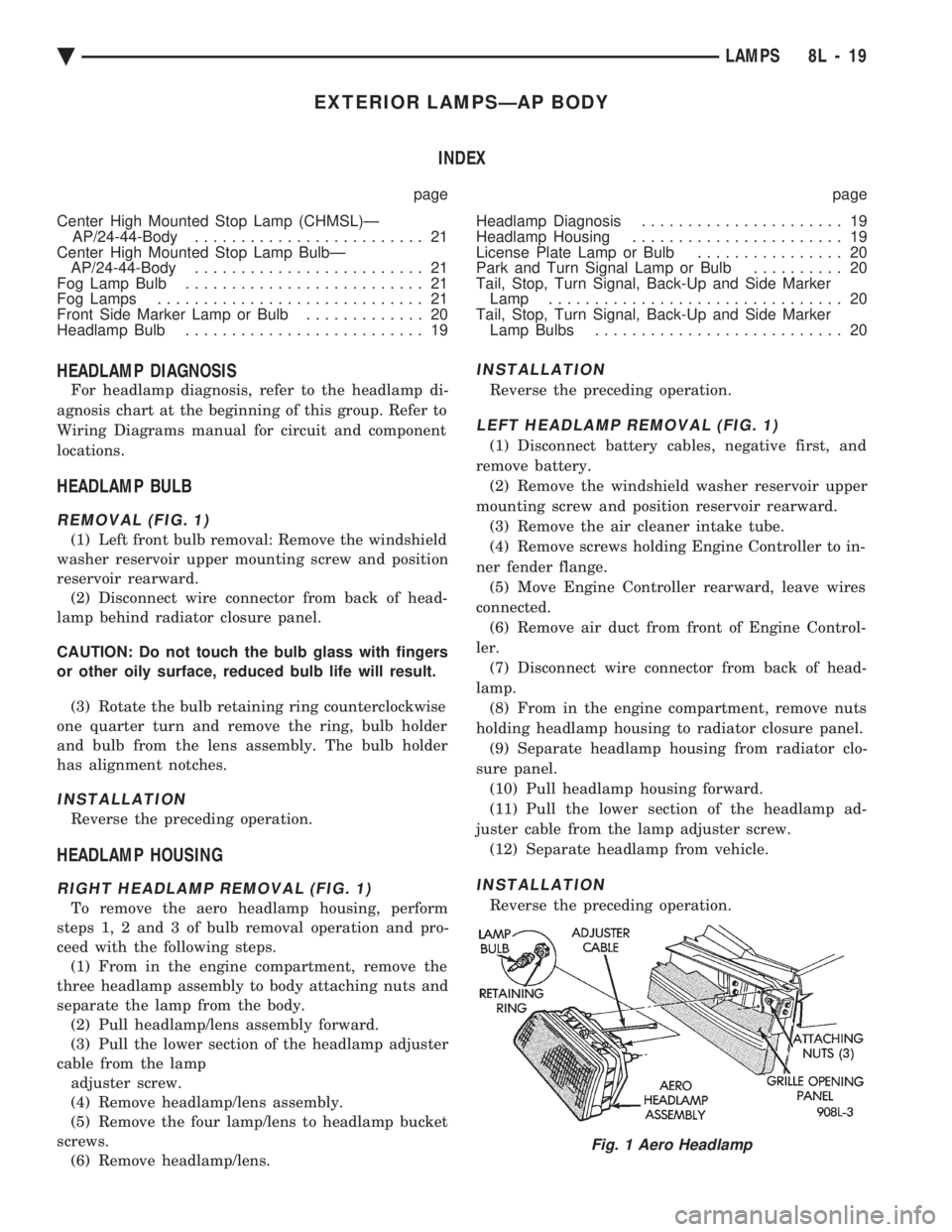

HEADLAMP BULB

REMOVAL (FIG. 1)

(1) Left front bulb removal: Remove the windshield

washer reservoir upper mounting screw and position

reservoir rearward. (2) Disconnect wire connector from back of head-

lamp behind radiator closure panel.

CAUTION: Do not touch the bulb glass with fingers

or other oily surface, reduced bulb life will result.

(3) Rotate the bulb retaining ring counterclockwise

one quarter turn and remove the ring, bulb holder

and bulb from the lens assembly. The bulb holder

has alignment notches.

INSTALLATION

Reverse the preceding operation.

HEADLAMP HOUSING

RIGHT HEADLAMP REMOVAL (FIG. 1)

To remove the aero headlamp housing, perform

steps 1, 2 and 3 of bulb removal operation and pro-

ceed with the following steps. (1) From in the engine compartment, remove the

three headlamp assembly to body attaching nuts and

separate the lamp from the body. (2) Pull headlamp/lens assembly forward.

(3) Pull the lower section of the headlamp adjuster

cable from the lamp adjuster screw.

(4) Remove headlamp/lens assembly.

(5) Remove the four lamp/lens to headlamp bucket

screws. (6) Remove headlamp/lens.

INSTALLATION

Reverse the preceding operation.

LEFT HEADLAMP REMOVAL (FIG. 1)

(1) Disconnect battery cables, negative first, and

remove battery. (2) Remove the windshield washer reservoir upper

mounting screw and position reservoir rearward. (3) Remove the air cleaner intake tube.

(4) Remove screws holding Engine Controller to in-

ner fender flange. (5) Move Engine Controller rearward, leave wires

connected. (6) Remove air duct from front of Engine Control-

ler. (7) Disconnect wire connector from back of head-

lamp. (8) From in the engine compartment, remove nuts

holding headlamp housing to radiator closure panel. (9) Separate headlamp housing from radiator clo-

sure panel. (10) Pull headlamp housing forward.

(11) Pull the lower section of the headlamp ad-

juster cable from the lamp adjuster screw. (12) Separate headlamp from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 1 Aero Headlamp

Ä LAMPS 8L - 19