ECO mode CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 434 of 2438

(12) Recalibrate compass.

COMPASS DIAGNOSTICS

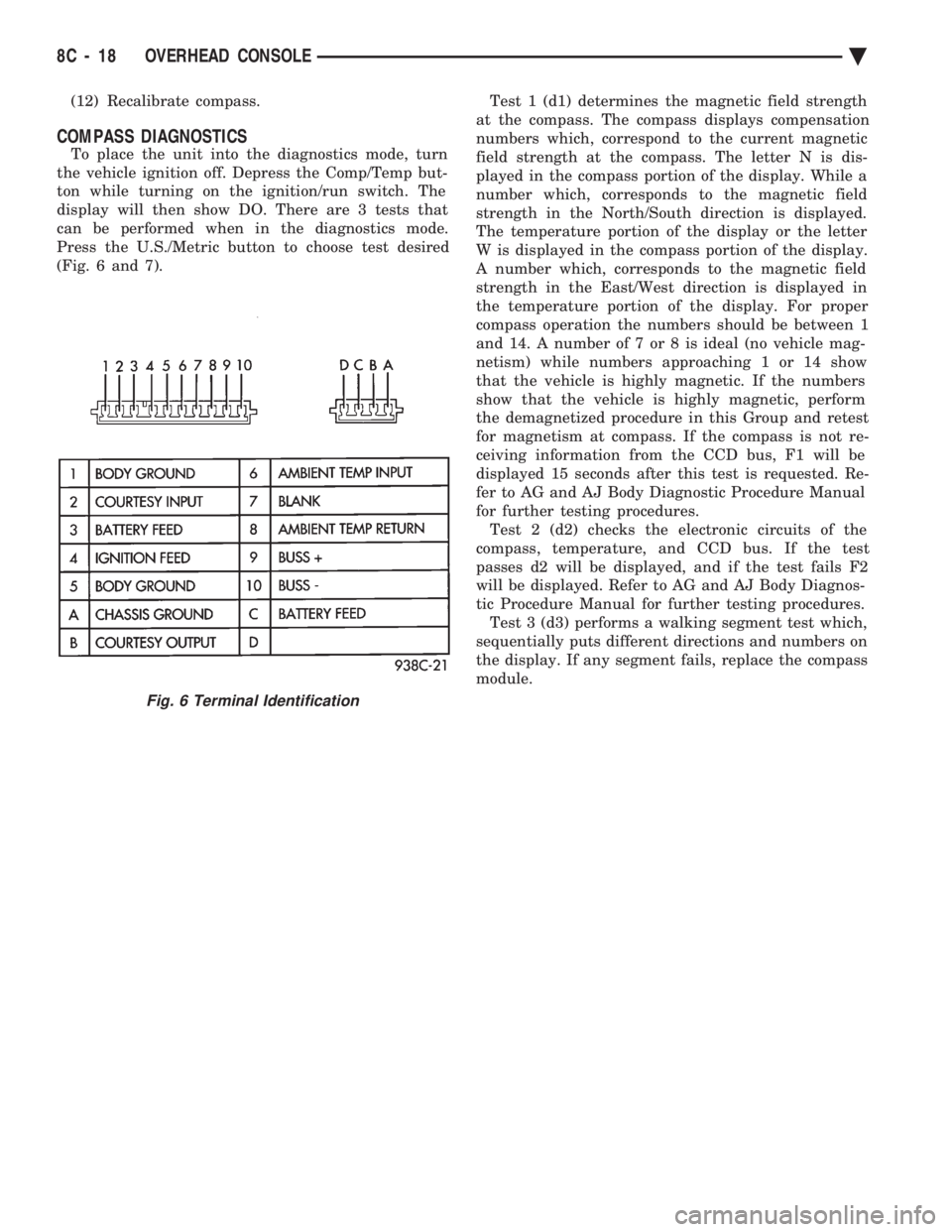

To place the unit into the diagnostics mode, turn

the vehicle ignition off. Depress the Comp/Temp but-

ton while turning on the ignition/run switch. The

display will then show DO. There are 3 tests that

can be performed when in the diagnostics mode.

Press the U.S./Metric button to choose test desired

(Fig. 6 and 7). Test 1 (d1) determines the magnetic field strength

at the compass. The compass displays compensation

numbers which, correspond to the current magnetic

field strength at the compass. The letter N is dis-

played in the compass portion of the display. While a

number which, corresponds to the magnetic field

strength in the North/South direction is displayed.

The temperature portion of the display or the letter

W is displayed in the compass portion of the display.

A number which, corresponds to the magnetic field

strength in the East/West direction is displayed in

the temperature portion of the display. For proper

compass operation the numbers should be between 1

and 14. A number of 7 or 8 is ideal (no vehicle mag-

netism) while numbers approaching 1 or 14 show

that the vehicle is highly magnetic. If the numbers

show that the vehicle is highly magnetic, perform

the demagnetized procedure in this Group and retest

for magnetism at compass. If the compass is not re-

ceiving information from the CCD bus, F1 will be

displayed 15 seconds after this test is requested. Re-

fer to AG and AJ Body Diagnostic Procedure Manual

for further testing procedures. Test 2 (d2) checks the electronic circuits of the

compass, temperature, and CCD bus. If the test

passes d2 will be displayed, and if the test fails F2

will be displayed. Refer to AG and AJ Body Diagnos-

tic Procedure Manual for further testing procedures. Test 3 (d3) performs a walking segment test which,

sequentially puts different directions and numbers on

the display. If any segment fails, replace the compass

module.

Fig. 6 Terminal Identification

8C - 18 OVERHEAD CONSOLE Ä

Page 439 of 2438

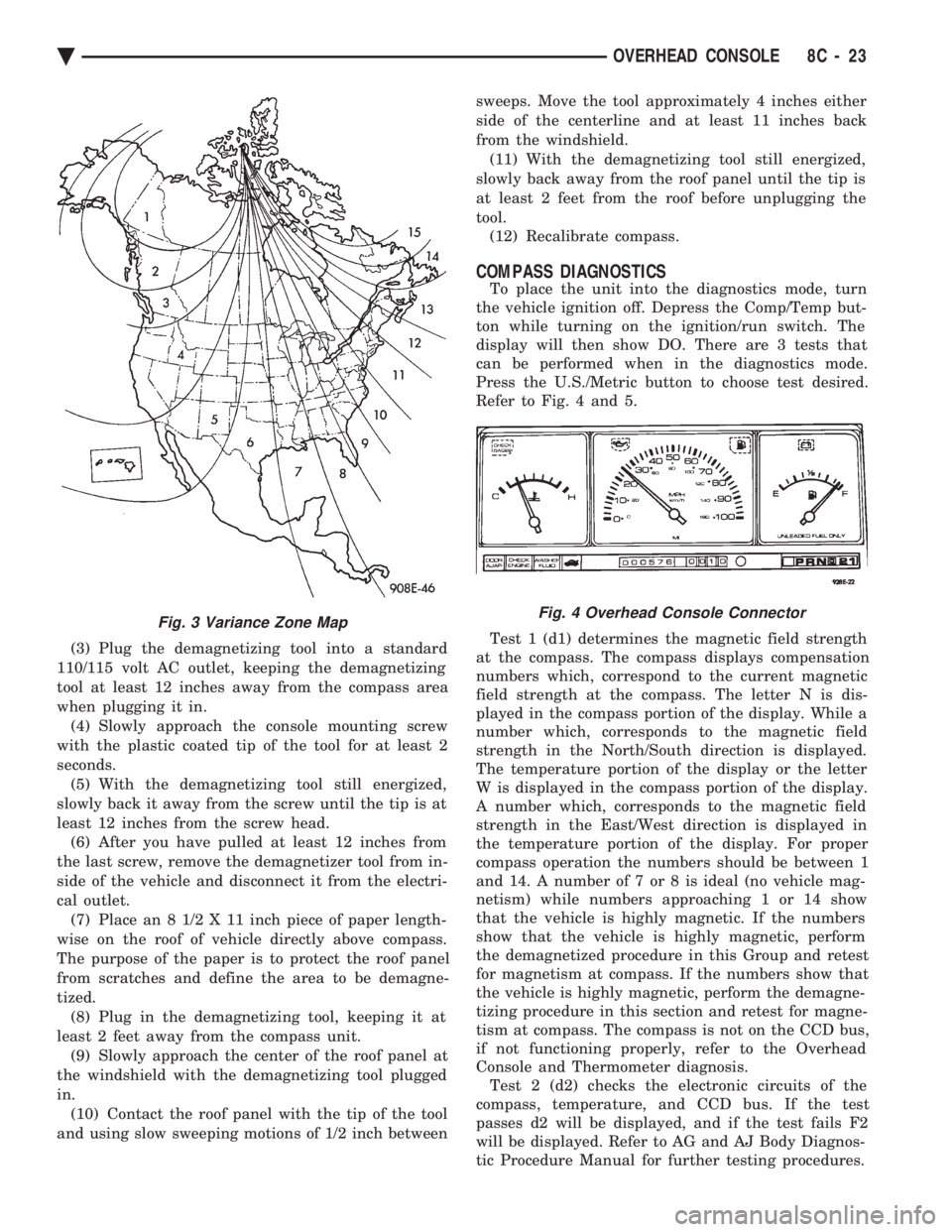

(3) Plug the demagnetizing tool into a standard

110/115 volt AC outlet, keeping the demagnetizing

tool at least 12 inches away from the compass area

when plugging it in. (4) Slowly approach the console mounting screw

with the plastic coated tip of the tool for at least 2

seconds. (5) With the demagnetizing tool still energized,

slowly back it away from the screw until the tip is at

least 12 inches from the screw head. (6) After you have pulled at least 12 inches from

the last screw, remove the demagnetizer tool from in-

side of the vehicle and disconnect it from the electri-

cal outlet. (7) Place an 8 1/2 X 11 inch piece of paper length-

wise on the roof of vehicle directly above compass.

The purpose of the paper is to protect the roof panel

from scratches and define the area to be demagne-

tized. (8) Plug in the demagnetizing tool, keeping it at

least 2 feet away from the compass unit. (9) Slowly approach the center of the roof panel at

the windshield with the demagnetizing tool plugged

in. (10) Contact the roof panel with the tip of the tool

and using slow sweeping motions of 1/2 inch between sweeps. Move the tool approximately 4 inches either

side of the centerline and at least 11 inches back

from the windshield. (11) With the demagnetizing tool still energized,

slowly back away from the roof panel until the tip is

at least 2 feet from the roof before unplugging the

tool. (12) Recalibrate compass.

COMPASS DIAGNOSTICS

To place the unit into the diagnostics mode, turn

the vehicle ignition off. Depress the Comp/Temp but-

ton while turning on the ignition/run switch. The

display will then show DO. There are 3 tests that

can be performed when in the diagnostics mode.

Press the U.S./Metric button to choose test desired.

Refer to Fig. 4 and 5.

Test 1 (d1) determines the magnetic field strength

at the compass. The compass displays compensation

numbers which, correspond to the current magnetic

field strength at the compass. The letter N is dis-

played in the compass portion of the display. While a

number which, corresponds to the magnetic field

strength in the North/South direction is displayed.

The temperature portion of the display or the letter

W is displayed in the compass portion of the display.

A number which, corresponds to the magnetic field

strength in the East/West direction is displayed in

the temperature portion of the display. For proper

compass operation the numbers should be between 1

and 14. A number of 7 or 8 is ideal (no vehicle mag-

netism) while numbers approaching 1 or 14 show

that the vehicle is highly magnetic. If the numbers

show that the vehicle is highly magnetic, perform

the demagnetized procedure in this Group and retest

for magnetism at compass. If the numbers show that

the vehicle is highly magnetic, perform the demagne-

tizing procedure in this section and retest for magne-

tism at compass. The compass is not on the CCD bus,

if not functioning properly, refer to the Overhead

Console and Thermometer diagnosis. Test 2 (d2) checks the electronic circuits of the

compass, temperature, and CCD bus. If the test

passes d2 will be displayed, and if the test fails F2

will be displayed. Refer to AG and AJ Body Diagnos-

tic Procedure Manual for further testing procedures.

Fig. 3 Variance Zone MapFig. 4 Overhead Console Connector

Ä OVERHEAD CONSOLE 8C - 23

Page 546 of 2438

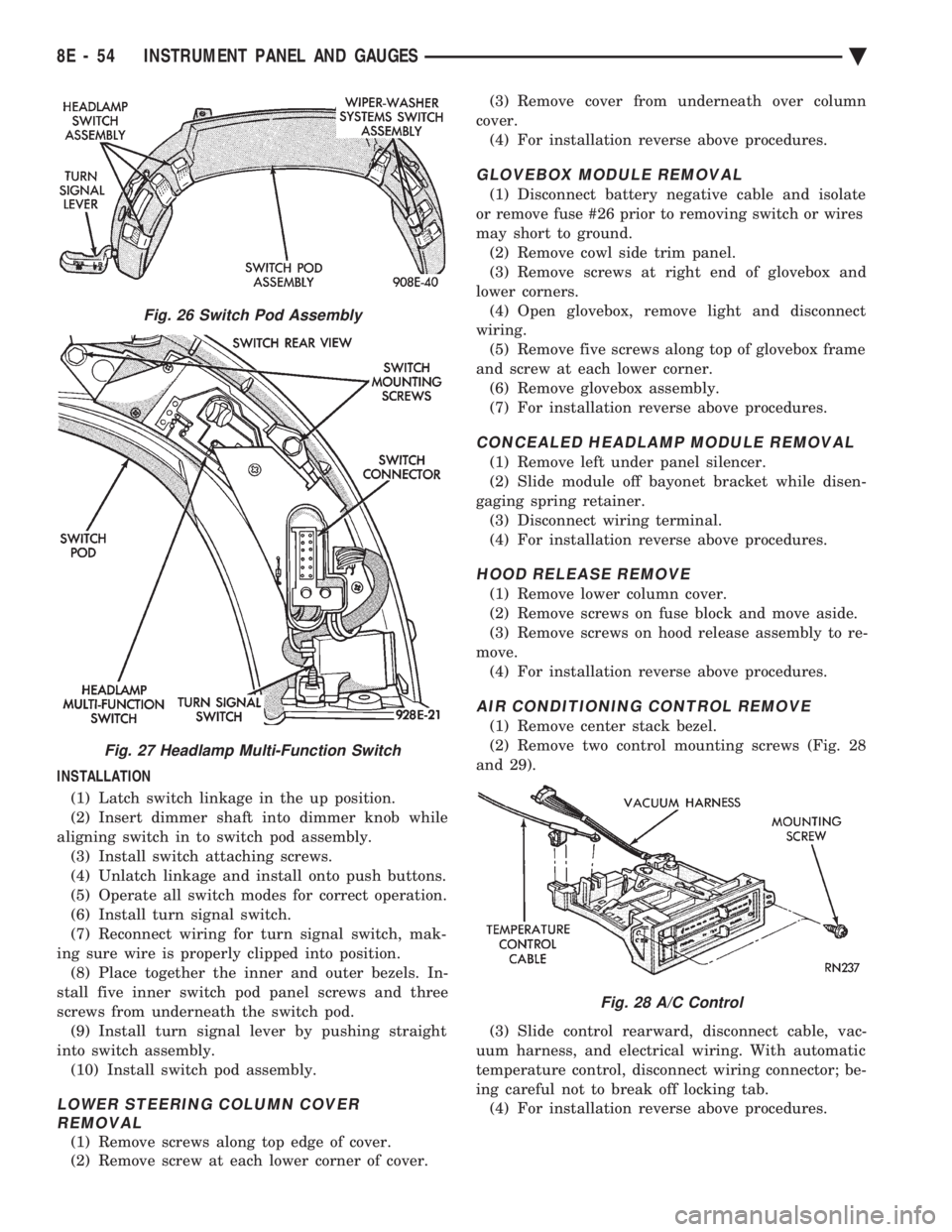

INSTALLATION (1) Latch switch linkage in the up position.

(2) Insert dimmer shaft into dimmer knob while

aligning switch in to switch pod assembly. (3) Install switch attaching screws.

(4) Unlatch linkage and install onto push buttons.

(5) Operate all switch modes for correct operation.

(6) Install turn signal switch.

(7) Reconnect wiring for turn signal switch, mak-

ing sure wire is properly clipped into position. (8) Place together the inner and outer bezels. In-

stall five inner switch pod panel screws and three

screws from underneath the switch pod. (9) Install turn signal lever by pushing straight

into switch assembly. (10) Install switch pod assembly.

LOWER STEERING COLUMN COVER REMOVAL

(1) Remove screws along top edge of cover.

(2) Remove screw at each lower corner of cover. (3) Remove cover from underneath over column

cover. (4) For installation reverse above procedures.

GLOVEBOX MODULE REMOVAL

(1) Disconnect battery negative cable and isolate

or remove fuse #26 prior to removing switch or wires

may short to ground. (2) Remove cowl side trim panel.

(3) Remove screws at right end of glovebox and

lower corners. (4) Open glovebox, remove light and disconnect

wiring. (5) Remove five screws along top of glovebox frame

and screw at each lower corner. (6) Remove glovebox assembly.

(7) For installation reverse above procedures.

CONCEALED HEADLAMP MODULE REMOVAL

(1) Remove left under panel silencer.

(2) Slide module off bayonet bracket while disen-

gaging spring retainer. (3) Disconnect wiring terminal.

(4) For installation reverse above procedures.

HOOD RELEASE REMOVE

(1) Remove lower column cover.

(2) Remove screws on fuse block and move aside.

(3) Remove screws on hood release assembly to re-

move. (4) For installation reverse above procedures.

AIR CONDITIONING CONTROL REMOVE

(1) Remove center stack bezel.

(2) Remove two control mounting screws (Fig. 28

and 29).

(3) Slide control rearward, disconnect cable, vac-

uum harness, and electrical wiring. With automatic

temperature control, disconnect wiring connector; be-

ing careful not to break off locking tab. (4) For installation reverse above procedures.

Fig. 26 Switch Pod Assembly

Fig. 27 Headlamp Multi-Function Switch

Fig. 28 A/C Control

8E - 54 INSTRUMENT PANEL AND GAUGES Ä

Page 614 of 2438

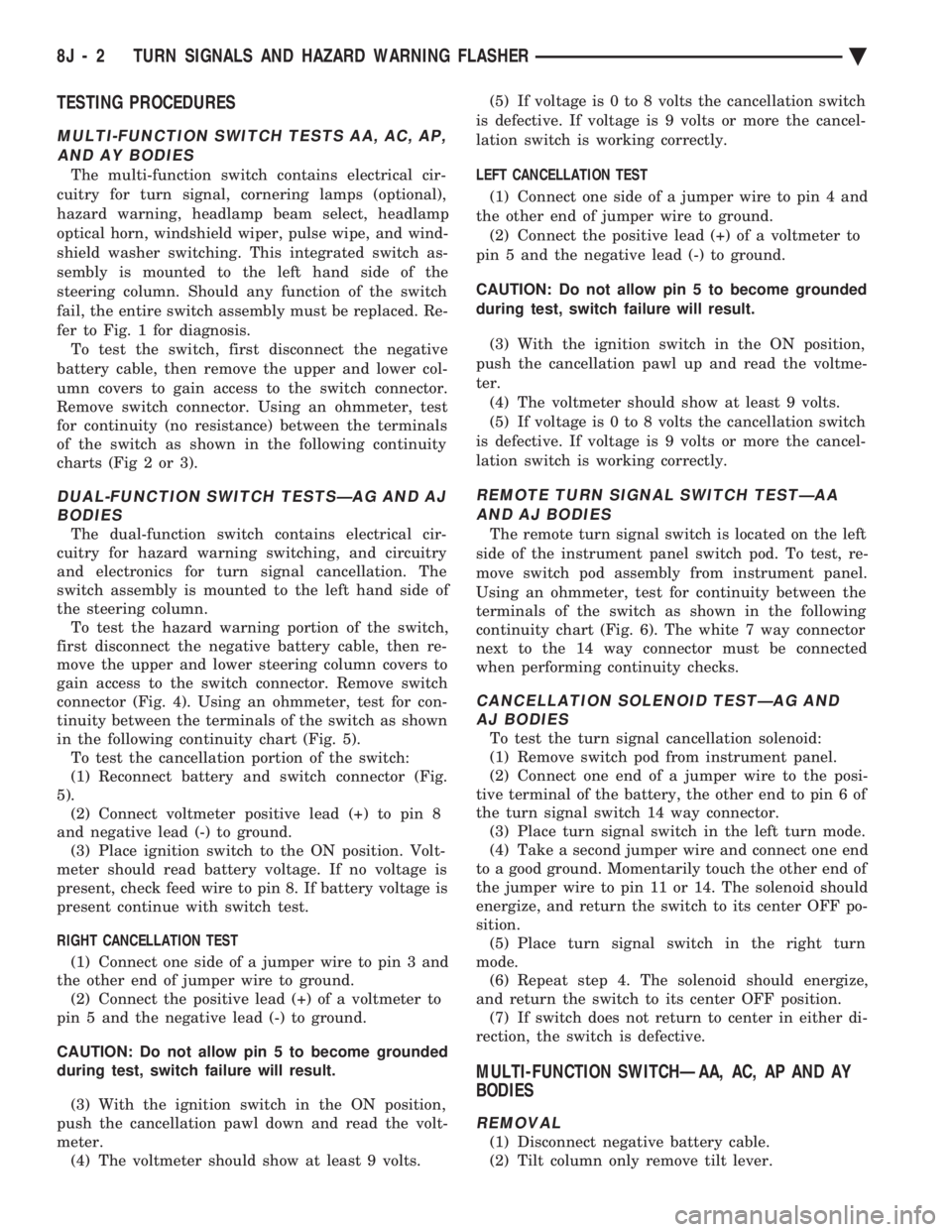

TESTING PROCEDURES

MULTI-FUNCTION SWITCH TESTS AA, AC, AP, AND AY BODIES

The multi-function switch contains electrical cir-

cuitry for turn signal, cornering lamps (optional),

hazard warning, headlamp beam select, headlamp

optical horn, windshield wiper, pulse wipe, and wind-

shield washer switching. This integrated switch as-

sembly is mounted to the left hand side of the

steering column. Should any function of the switch

fail, the entire switch assembly must be replaced. Re-

fer to Fig. 1 for diagnosis. To test the switch, first disconnect the negative

battery cable, then remove the upper and lower col-

umn covers to gain access to the switch connector.

Remove switch connector. Using an ohmmeter, test

for continuity (no resistance) between the terminals

of the switch as shown in the following continuity

charts (Fig 2 or 3).

DUAL-FUNCTION SWITCH TESTSÐAG AND AJ BODIES

The dual-function switch contains electrical cir-

cuitry for hazard warning switching, and circuitry

and electronics for turn signal cancellation. The

switch assembly is mounted to the left hand side of

the steering column. To test the hazard warning portion of the switch,

first disconnect the negative battery cable, then re-

move the upper and lower steering column covers to

gain access to the switch connector. Remove switch

connector (Fig. 4). Using an ohmmeter, test for con-

tinuity between the terminals of the switch as shown

in the following continuity chart (Fig. 5). To test the cancellation portion of the switch:

(1) Reconnect battery and switch connector (Fig.

5). (2) Connect voltmeter positive lead (+) to pin 8

and negative lead (-) to ground. (3) Place ignition switch to the ON position. Volt-

meter should read battery voltage. If no voltage is

present, check feed wire to pin 8. If battery voltage is

present continue with switch test.

RIGHT CANCELLATION TEST (1) Connect one side of a jumper wire to pin 3 and

the other end of jumper wire to ground. (2) Connect the positive lead (+) of a voltmeter to

pin 5 and the negative lead (-) to ground.

CAUTION: Do not allow pin 5 to become grounded

during test, switch failure will result.

(3) With the ignition switch in the ON position,

push the cancellation pawl down and read the volt-

meter. (4) The voltmeter should show at least 9 volts. (5) If voltage is 0 to 8 volts the cancellation switch

is defective. If voltage is 9 volts or more the cancel-

lation switch is working correctly.

LEFT CANCELLATION TEST

(1) Connect one side of a jumper wire to pin 4 and

the other end of jumper wire to ground. (2) Connect the positive lead (+) of a voltmeter to

pin 5 and the negative lead (-) to ground.

CAUTION: Do not allow pin 5 to become grounded

during test, switch failure will result.

(3) With the ignition switch in the ON position,

push the cancellation pawl up and read the voltme-

ter. (4) The voltmeter should show at least 9 volts.

(5) If voltage is 0 to 8 volts the cancellation switch

is defective. If voltage is 9 volts or more the cancel-

lation switch is working correctly.

REMOTE TURN SIGNAL SWITCH TESTÐAA AND AJ BODIES

The remote turn signal switch is located on the left

side of the instrument panel switch pod. To test, re-

move switch pod assembly from instrument panel.

Using an ohmmeter, test for continuity between the

terminals of the switch as shown in the following

continuity chart (Fig. 6). The white 7 way connector

next to the 14 way connector must be connected

when performing continuity checks.

CANCELLATION SOLENOID TESTÐAG AND AJ BODIES

To test the turn signal cancellation solenoid:

(1) Remove switch pod from instrument panel.

(2) Connect one end of a jumper wire to the posi-

tive terminal of the battery, the other end to pin 6 of

the turn signal switch 14 way connector. (3) Place turn signal switch in the left turn mode.

(4) Take a second jumper wire and connect one end

to a good ground. Momentarily touch the other end of

the jumper wire to pin 11 or 14. The solenoid should

energize, and return the switch to its center OFF po-

sition. (5) Place turn signal switch in the right turn

mode. (6) Repeat step 4. The solenoid should energize,

and return the switch to its center OFF position. (7) If switch does not return to center in either di-

rection, the switch is defective.

MULTI-FUNCTION SWITCHÐAA, AC, AP AND AY

BODIES

REMOVAL

(1) Disconnect negative battery cable.

(2) Tilt column only remove tilt lever.

8J - 2 TURN SIGNALS AND HAZARD WARNING FLASHER Ä

Page 621 of 2438

WINDSHIELD WIPER AND WASHER SYSTEMS

CONTENTS

page page

GENERAL WIPER INFORMATION ........... 1

INTERMITTENT WINDSHIELD WIPER MOTOR AND SWITCH SERVICE PROCEDURES .... 12

WINDSHIELD WASHERS ................. 17 WINDSHIELD WIPER BLADE AND ARM SERVICE

PROCEDURES ......................... 1

WINDSHIELD WIPER MOTOR AND LINKAGE ASSEMBLY SERVICE PROCEDURES ....... 3

GENERAL WIPER INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The windshield wipers can be operated with the

windshield wiper switch only when the ignition

switch is in the ACCESSORY or IGNITION position.

A fuse, located in the fuse block, protects the cir-

cuitry of the wiper system and the vehicle. The wiper motor has permanent magnet fields. The speeds are determined by current flow to the appro-

priate set of brushes. The intermittent wipe system, in addition to low

and high speed, has a delay mode. The delay mode

has a range of 2 to 15 seconds. This is accomplished

by a variable resistor in the wiper switch and is con-

trolled electrically by a relay. The wiper system completes the wipe cycle when

the switch is turned OFF. The blades park in the

lowest portion of the wipe pattern.

WINDSHIELD WIPER BLADE AND ARM SERVICE PROCEDURES

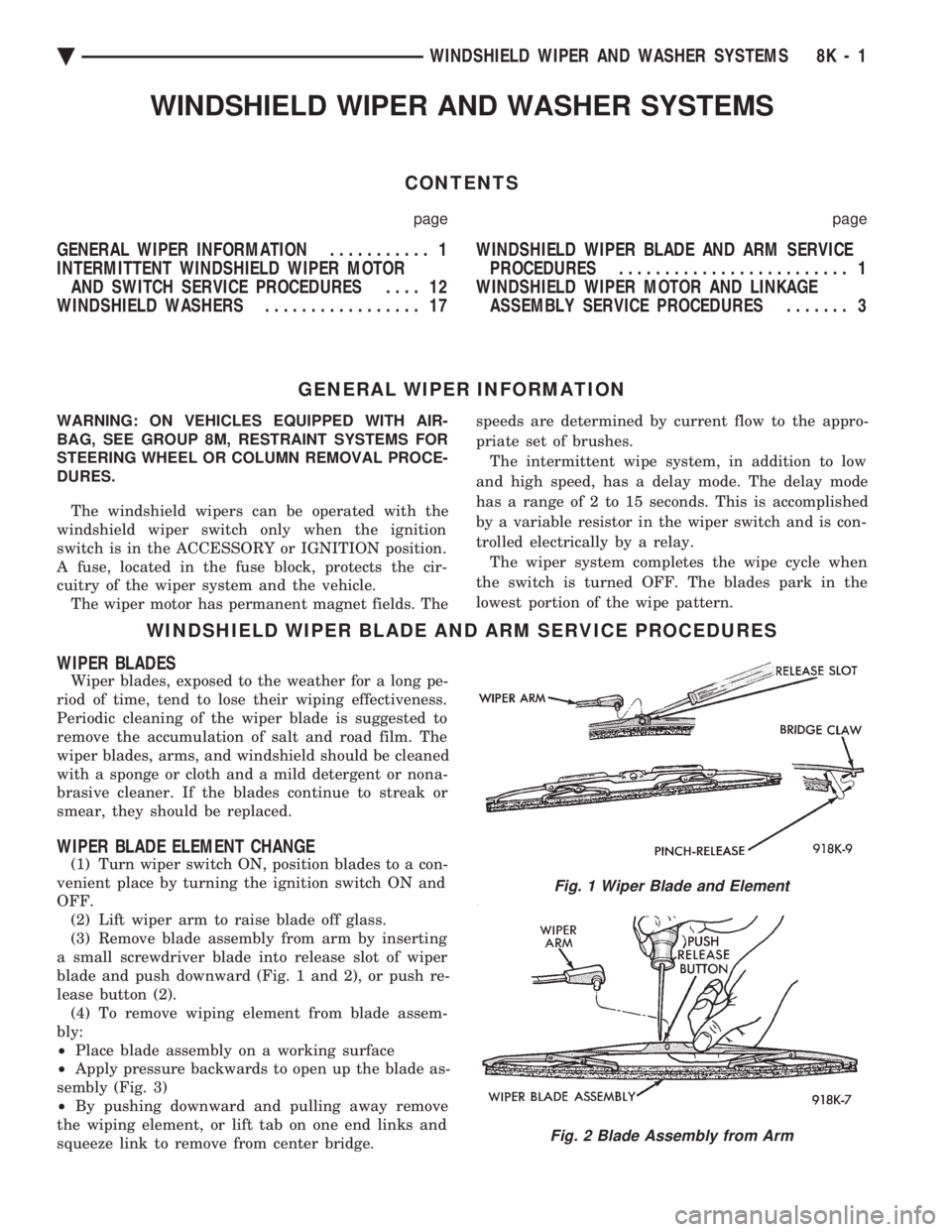

WIPER BLADES

Wiper blades, exposed to the weather for a long pe-

riod of time, tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is suggested to

remove the accumulation of salt and road film. The

wiper blades, arms, and windshield should be cleaned

with a sponge or cloth and a mild detergent or nona-

brasive cleaner. If the blades continue to streak or

smear, they should be replaced.

WIPER BLADE ELEMENT CHANGE

(1) Turn wiper switch ON, position blades to a con-

venient place by turning the ignition switch ON and

OFF. (2) Lift wiper arm to raise blade off glass.

(3) Remove blade assembly from arm by inserting

a small screwdriver blade into release slot of wiper

blade and push downward (Fig. 1 and 2), or push re-

lease button (2). (4) To remove wiping element from blade assem-

bly:

² Place blade assembly on a working surface

² Apply pressure backwards to open up the blade as-

sembly (Fig. 3)

² By pushing downward and pulling away remove

the wiping element, or lift tab on one end links and

squeeze link to remove from center bridge.

Fig. 1 Wiper Blade and Element

Fig. 2 Blade Assembly from Arm

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 1

Page 632 of 2438

INTERMITTENT WINDSHIELD WIPER MOTOR AND SWITCH SERVICE PROCEDURES

INDEX

page page

Intermittent Windshield Wiper Switch Tests ..... 12

Intermittent Wipe Switch Test ............... 14

Intermittent Wiper Function Tests ............ 14

Intermittent Wiper Motor System Test ......... 12 Pulse Intermittent Windshield Wiper Controller

(PIWWC) .............................. 15

Standard Wiper Switch Test ................ 14

Wiper Switch Service Procedure ............. 15

INTERMITTENT WIPER MOTOR SYSTEM TEST

Intermittent Wiper Motor Service Procedures for

diagnosis of problems which do not involve the delay

function, refer to the Two-Speed Motor Function

Tests. The two-speed functions of all wiper motors

are identical. If a problem occurs, only in the DELAY mode, the

following tests are to be performed.

INTERMITTENT WINDSHIELD WIPER SWITCH

TESTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

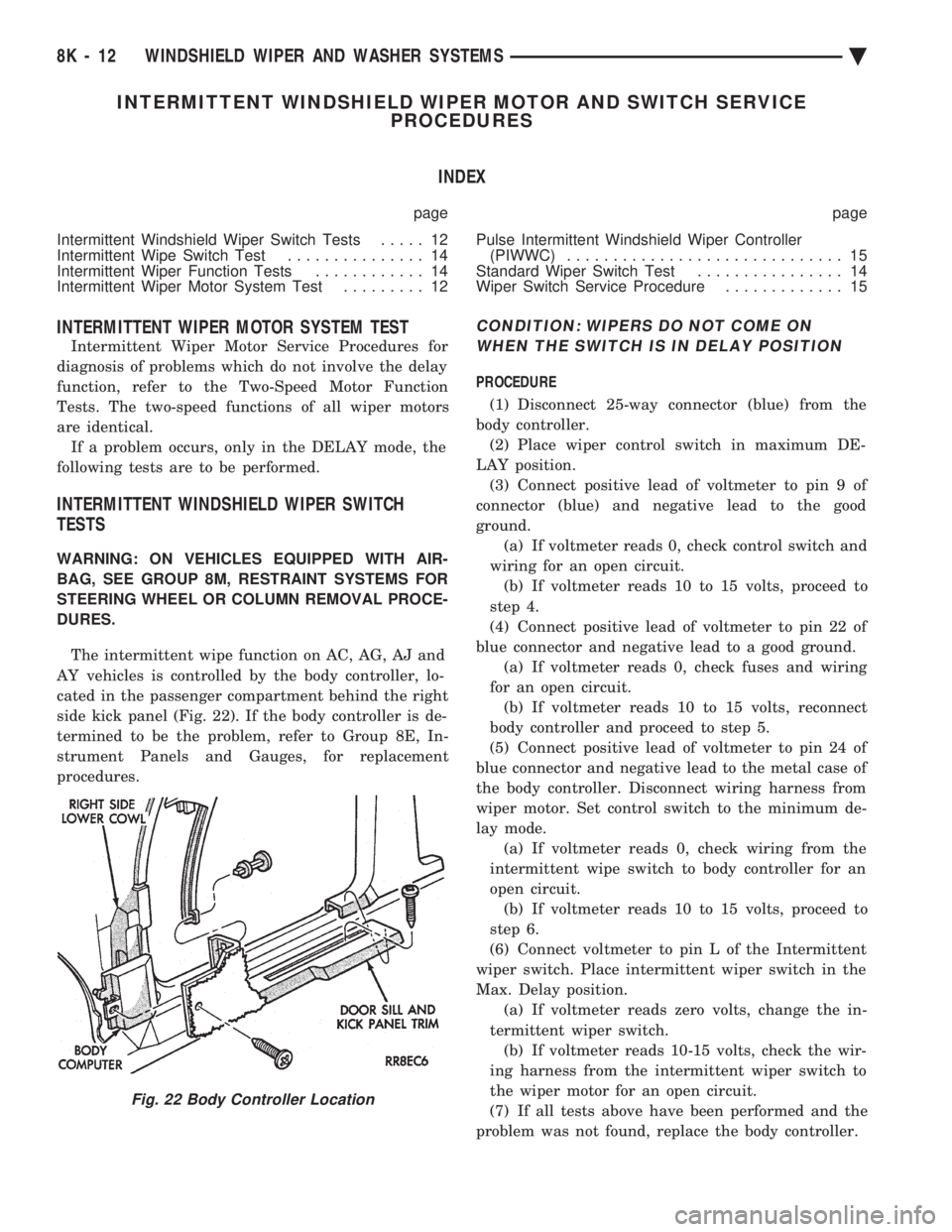

The intermittent wipe function on AC, AG, AJ and

AY vehicles is controlled by the body controller, lo-

cated in the passenger compartment behind the right

side kick panel (Fig. 22). If the body controller is de-

termined to be the problem, refer to Group 8E, In-

strument Panels and Gauges, for replacement

procedures.

CONDITION: WIPERS DO NOT COME ON WHEN THE SWITCH IS IN DELAY POSITION

PROCEDURE

(1) Disconnect 25-way connector (blue) from the

body controller. (2) Place wiper control switch in maximum DE-

LAY position. (3) Connect positive lead of voltmeter to pin 9 of

connector (blue) and negative lead to the good

ground. (a) If voltmeter reads 0, check control switch and

wiring for an open circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 4.

(4) Connect positive lead of voltmeter to pin 22 of

blue connector and negative lead to a good ground. (a) If voltmeter reads 0, check fuses and wiring

for an open circuit. (b) If voltmeter reads 10 to 15 volts, reconnect

body controller and proceed to step 5.

(5) Connect positive lead of voltmeter to pin 24 of

blue connector and negative lead to the metal case of

the body controller. Disconnect wiring harness from

wiper motor. Set control switch to the minimum de-

lay mode. (a) If voltmeter reads 0, check wiring from the

intermittent wipe switch to body controller for an

open circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 6.

(6) Connect voltmeter to pin L of the Intermittent

wiper switch. Place intermittent wiper switch in the

Max. Delay position. (a) If voltmeter reads zero volts, change the in-

termittent wiper switch. (b) If voltmeter reads 10-15 volts, check the wir-

ing harness from the intermittent wiper switch to

the wiper motor for an open circuit.

(7) If all tests above have been performed and the

problem was not found, replace the body controller.

Fig. 22 Body Controller Location

8K - 12 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 633 of 2438

CONDITION: WIPERS START TO WIPE, BUT STOP BEFORE ONE COMPLETE CYCLE ANDDO NOT RETURN TO PARK POSITION

PROCEDURE

(1) Verify that motor will park when the column

switch is put in the OFF position. (2) Set wiper control switch to maximum DELAY

and allow motor to run until it stops during the wipe

cycle. When motor stops, disconnect 25-way blue con-

nector from the body controller. (3) Connect positive lead of voltmeter to pin 20 of

blue connector and negative lead to the metal case of

the body controller. (a) If voltmeter reads 0, check wiring for an open

circuit. (b) If voltmeter reads 10 to 15 volts, proceed to

step 4.

(4) Using an ohmmeter or continuity tester; (a) Check for continuity between pins 20 and 24

of blue connector of the body controller. (b) Reverse ohmmeter leads on pins 20 and 24,

again checking for continuity. (c) If continuity between pins 20 and 24 is not

observed in both steps a and b, replace the body

controller.

CONDITION: EXCESSIVE DELAY OF MORE THAN 30 SECONDS OR INADEQUATEVARIATION IN DELAY

PROCEDURE

(1) Variations in delay should be as follows: (a) Minimum delay control to extreme counter-

clockwise position before first detent of 1/2 to 2 sec-

onds. (b) Maximum delay control to extreme clockwise

position before OFF detent of 15 to 25 seconds.

(2) If there is excessive delay or no variations in

delay, remove the wiper motor wiring harness while

the motor is parked in the OFF position. (3) Remove 25-way blue connector from the body

controller. (4) Set wiper control switch to maximum DELAY

position. (5) With ignition switch in ON position, measure

voltage between pin 9 of black connector and a good

ground. (a) If voltmeter reads 0, proceed to step 6.

(b) If voltmeter reads 10 to 15 volts, proceed to

step 7.

(6) Set wiper control switch to minimum DELAY

position and measure voltage between pin 9 of blue

connector and a good ground. If voltmeter reads 0,

check for an open circuit in the intermittent wipe

wiring harness. (7) Remove wiper motor circuit fuse. (8) Using an ohmmeter, measure the resistance be-

tween pins 9 and 22 of the body controller 25-way

black connector. Set the wiper control switch first to

minimum DELAY and then maximum DELAY. (a) If resistance reading at minimum DELAY

setting is between 0 and 15 ohms, and at maxi-

mum DELAY setting the resistance is between

240,000 and 400,000 ohms, replace the body con-

troller. (b) If the resistance values above are not ob-

tained, replace the wiper control switch.

CONDITION: WIPERS DO NOT RUN CONTINUALLY WHEN WASH CONTROL ISOPERATED DURING DELAY MODE

PROCEDURE

(1) Disconnect 25-way blue connector from the

body controller (2) Using a voltmeter, connect the positive lead to

pin 10 of the (Black) connector. Connect negative

lead to the body computer metal case. (3) Set wiper control switch to DELAY position.

(4) Depress wash switch.

(5) If voltage reads 0, check switch relay and wir-

ing. (6) If voltage is between 10 and 15 volts, the prob-

lem is in the body controller.

CONDITION: IN DELAY MODE, WIPERS RUN CONTINUALLY WHEN WASH IS OPERATEDBUT DO NOT PROVIDE FOUR EXTRA WIPESWHEN WASH CONTROL IS RELEASED

PROCEDURE

Replace body controller.

CONDITION: WIPERS START ERRATICALLY DURING DELAY MODE

PROCEDURE

(1) Verify that the ground connection at the in-

strument panel is making a good connection, free

from paint and is tight. (2) Verify that the motor ground strap is making

good contact and that the motor mounting bolts are

tight. (3) Verify that the wiring connections to the body

controller, wiper motor, and wiper motor switch are

tight and free of corrosion. (4) If condition is not corrected, problem is with

the body controller

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 13

Page 634 of 2438

INTERMITTENT WIPER FUNCTION TESTS

CONDITION: EXCESSIVE DELAY OF MORE THAN 30 SECONDS OR INADEQUATEVARIATION IN DELAY

PROCEDURE

Variations in delay should be as follows:

(1) Minimum delay control to extreme counter-

clockwise position before first detent of one half to

two seconds. (2) Maximum delay control to extreme clockwise

position before off detent of ten to thirty seconds. (3) If there is excessive delay or no variations in

delay proceed to intermittent wipe switch test.

CONDITION: IN DELAY MODE WIPERS RUN CONTINUALLY WHEN WASH IS OPERATEDBUT DO NOT PROVIDE AN EXTRA WIPEWHEN THE WASH CONTROL IS RELEASED

PROCEDURE

Replace the control unit.

CONDITION: WIPERS START ERRATICALLY DURING DELAY MODE

PROCEDURE

(1) Verify that the ground connection at the in-

strument panel is making good connection, free from

paint and is tight. (2) Verify that the motor ground strap is making

good contact and that the motor mounting bolts are

tight. (3) Verify that the wiring ground connections for

the intermittent wipe control unit and the wiper

switch are tight. (4) If condition is not corrected, replace control

unit.

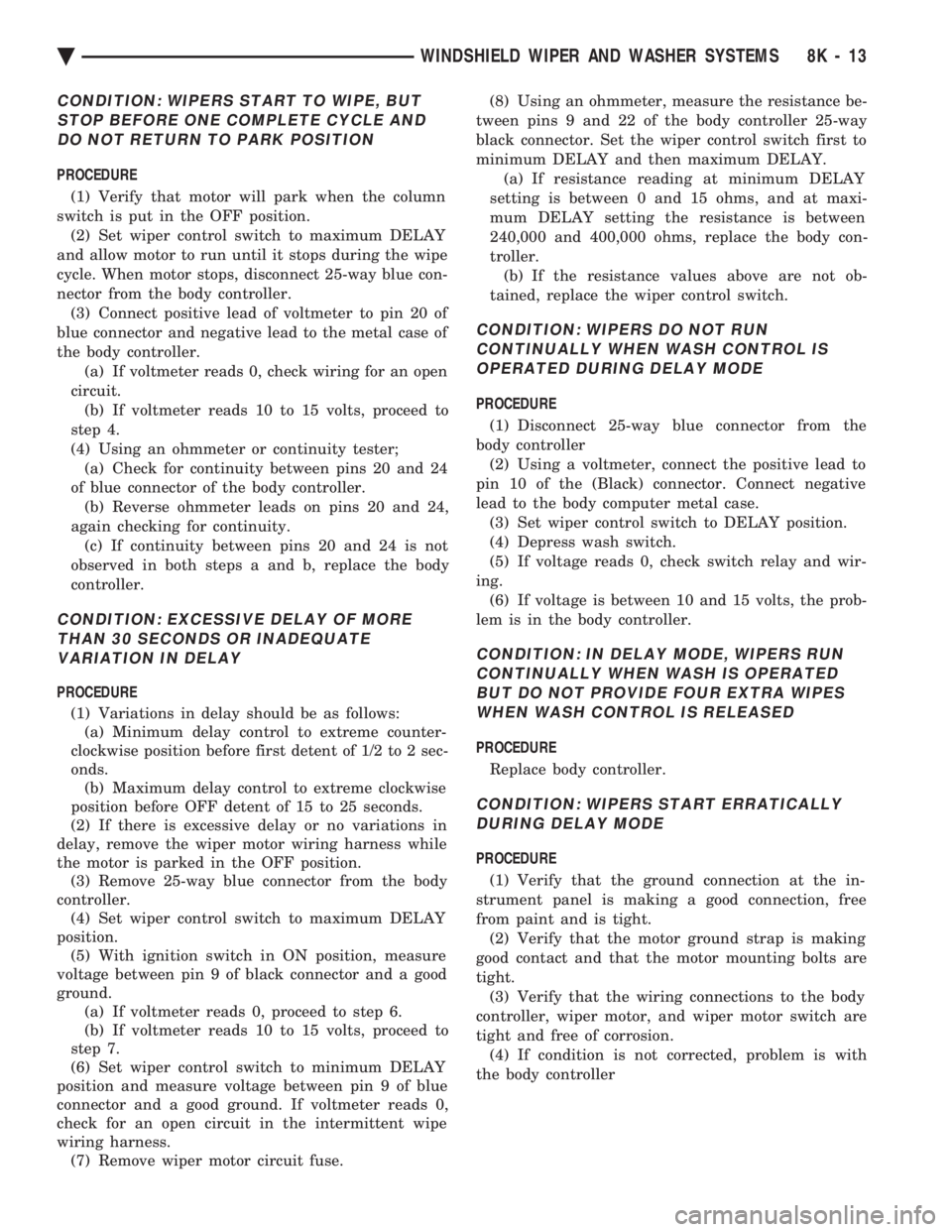

STANDARD WIPER SWITCH TEST

AP BODY

To test the switch, first disconnect the switch wires

from the body wiring in the steering column. Using

an ohmmeter, test for continuity between the termi-

nals of the switch, as indicated in the following con-

tinuity chart. The identity of each terminal is shown

in Fig. 23.

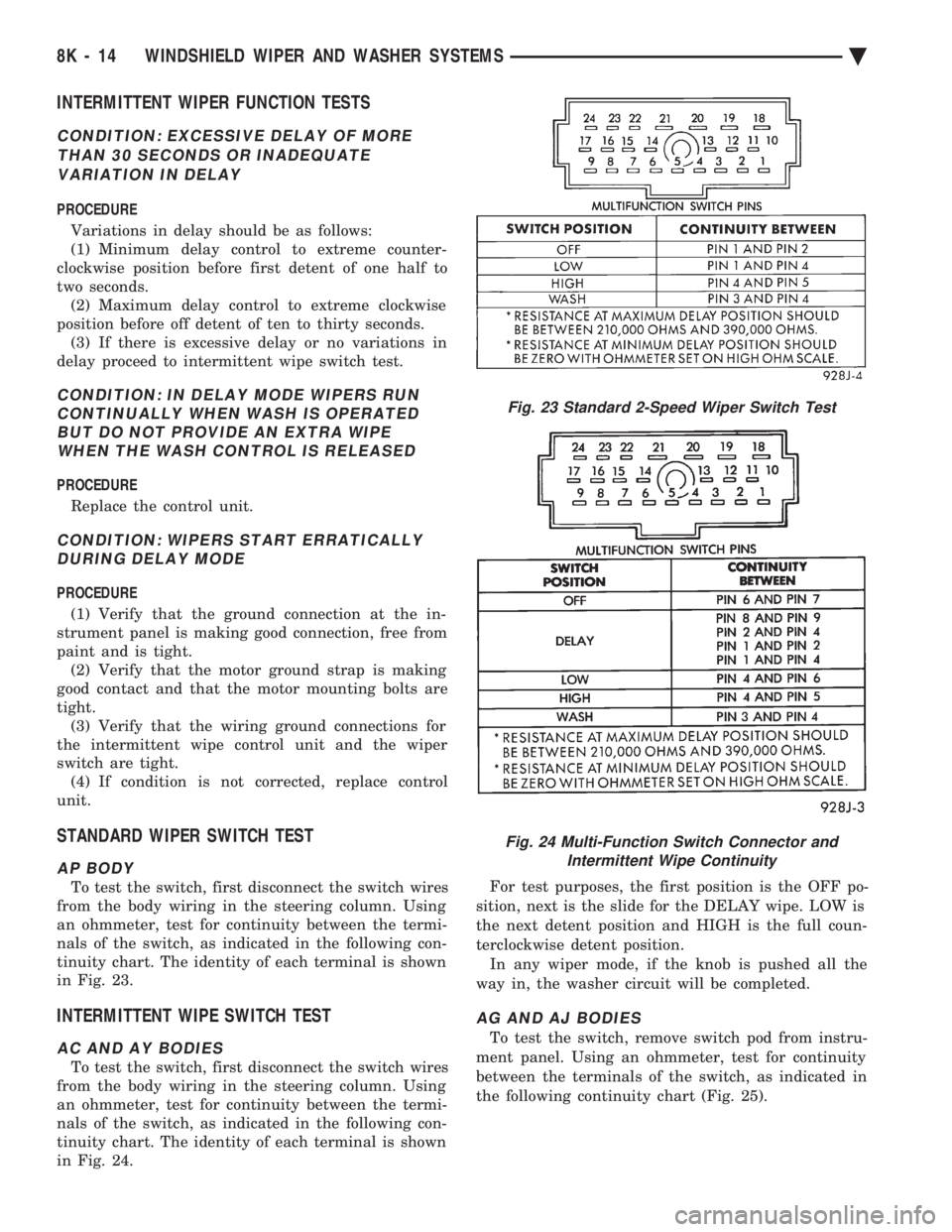

INTERMITTENT WIPE SWITCH TEST

AC AND AY BODIES

To test the switch, first disconnect the switch wires

from the body wiring in the steering column. Using

an ohmmeter, test for continuity between the termi-

nals of the switch, as indicated in the following con-

tinuity chart. The identity of each terminal is shown

in Fig. 24. For test purposes, the first position is the OFF po-

sition, next is the slide for the DELAY wipe. LOW is

the next detent position and HIGH is the full coun-

terclockwise detent position. In any wiper mode, if the knob is pushed all the

way in, the washer circuit will be completed.

AG AND AJ BODIES

To test the switch, remove switch pod from instru-

ment panel. Using an ohmmeter, test for continuity

between the terminals of the switch, as indicated in

the following continuity chart (Fig. 25).

Fig. 23 Standard 2-Speed Wiper Switch Test

Fig. 24 Multi-Function Switch Connector and Intermittent Wipe Continuity

8K - 14 WINDSHIELD WIPER AND WASHER SYSTEMS Ä

Page 691 of 2438

REAR WINDOW DEFOGGER

CONTENTS

page page

CONTROL SWITCH/TIMER RELAY MODULE . . 1

GENERAL INFORMATION .................. 1REPAIR GRID LINES, TERMINALS AND PIGTAILS.3

SERVICE PROCEDURES ................... 1

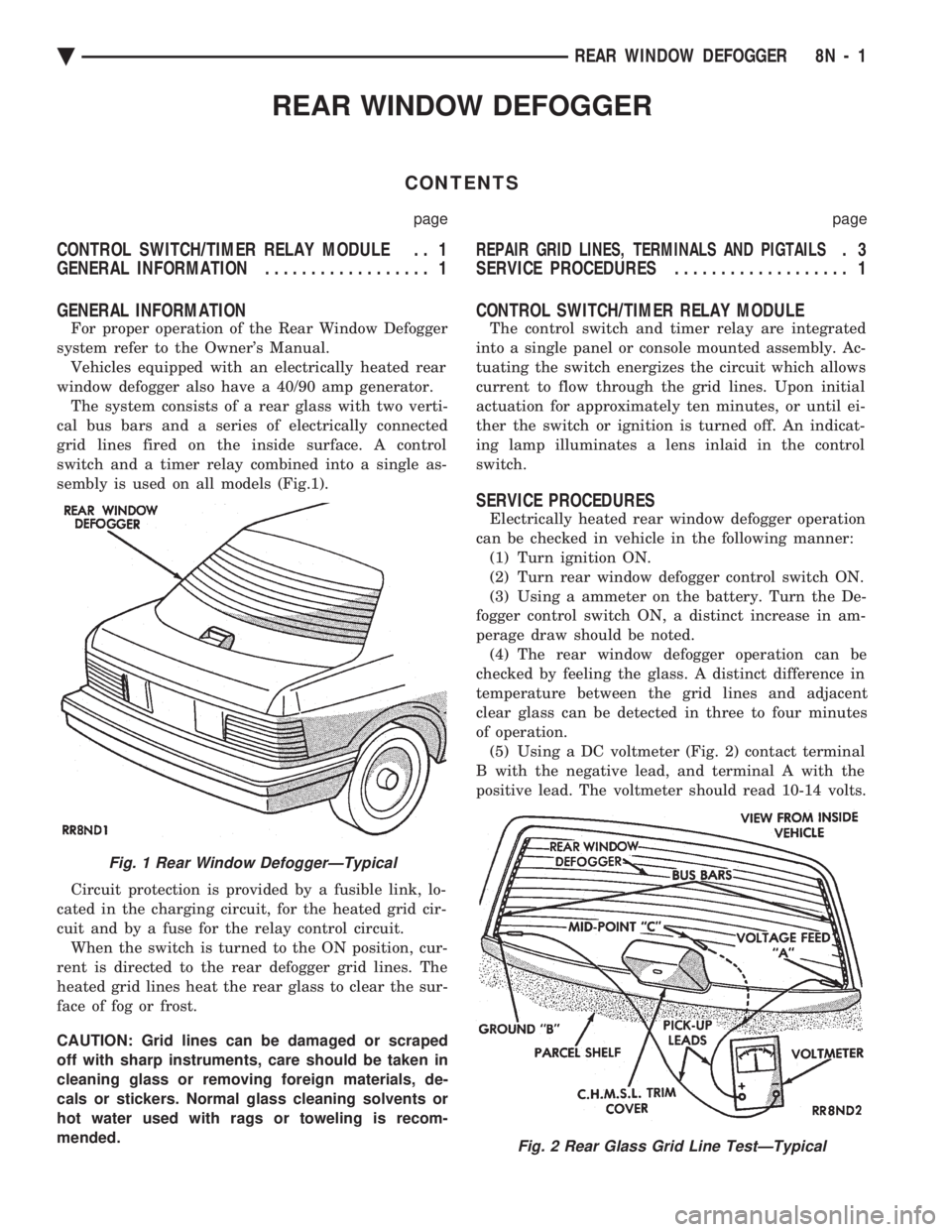

GENERAL INFORMATION

For proper operation of the Rear Window Defogger

system refer to the Owner's Manual. Vehicles equipped with an electrically heated rear

window defogger also have a 40/90 amp generator. The system consists of a rear glass with two verti-

cal bus bars and a series of electrically connected

grid lines fired on the inside surface. A control

switch and a timer relay combined into a single as-

sembly is used on all models (Fig.1).

Circuit protection is provided by a fusible link, lo-

cated in the charging circuit, for the heated grid cir-

cuit and by a fuse for the relay control circuit. When the switch is turned to the ON position, cur-

rent is directed to the rear defogger grid lines. The

heated grid lines heat the rear glass to clear the sur-

face of fog or frost.

CAUTION: Grid lines can be damaged or scraped

off with sharp instruments, care should be taken in

cleaning glass or removing foreign materials, de-

cals or stickers. Normal glass cleaning solvents or

hot water used with rags or toweling is recom-

mended.

CONTROL SWITCH/TIMER RELAY MODULE

The control switch and timer relay are integrated

into a single panel or console mounted assembly. Ac-

tuating the switch energizes the circuit which allows

current to flow through the grid lines. Upon initial

actuation for approximately ten minutes, or until ei-

ther the switch or ignition is turned off. An indicat-

ing lamp illuminates a lens inlaid in the control

switch.

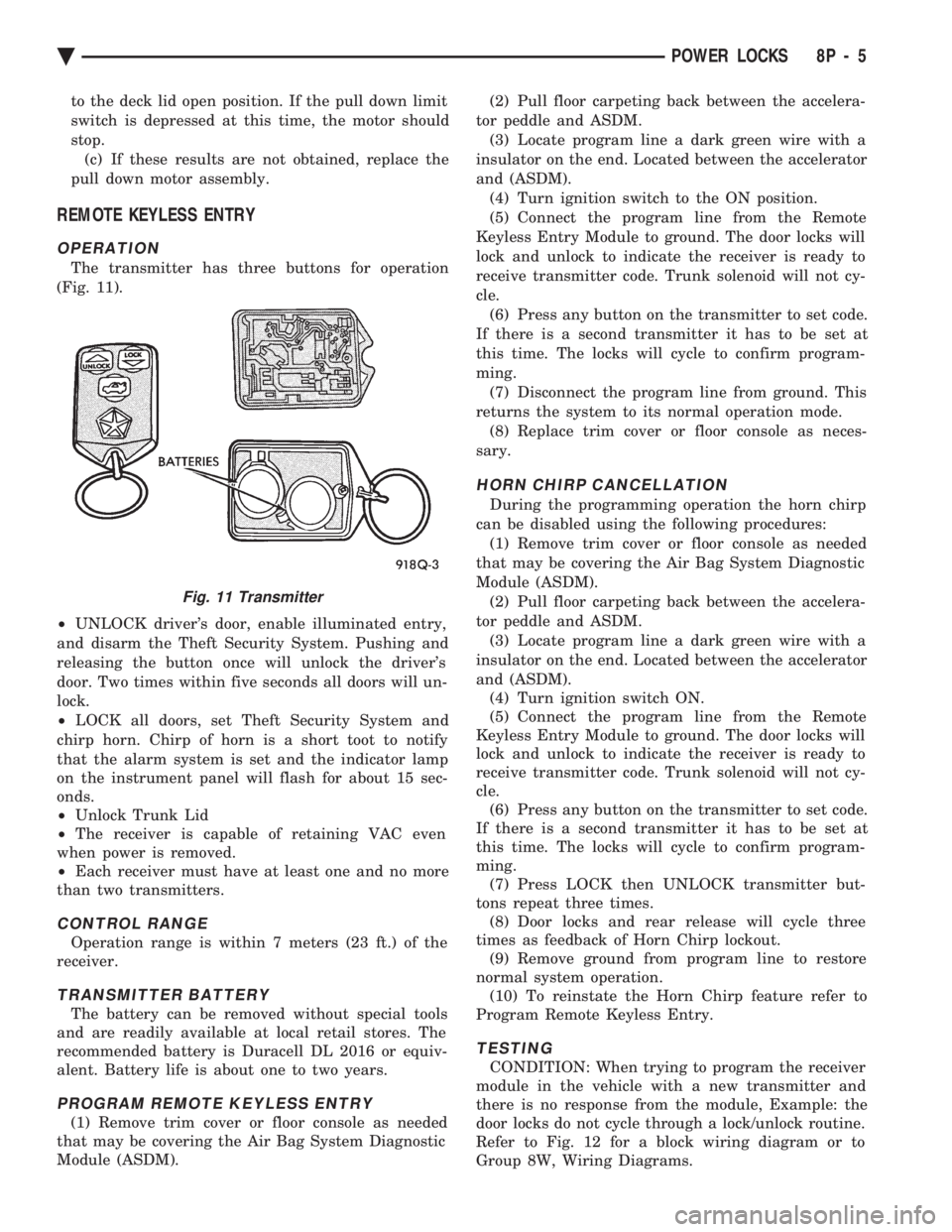

SERVICE PROCEDURES

Electrically heated rear window defogger operation

can be checked in vehicle in the following manner: (1) Turn ignition ON.

(2) Turn rear window defogger control switch ON.

(3) Using a ammeter on the battery. Turn the De-

fogger control switch ON, a distinct increase in am-

perage draw should be noted. (4) The rear window defogger operation can be

checked by feeling the glass. A distinct difference in

temperature between the grid lines and adjacent

clear glass can be detected in three to four minutes

of operation. (5) Using a DC voltmeter (Fig. 2) contact terminal

B with the negative lead, and terminal A with the

positive lead. The voltmeter should read 10-14 volts.

Fig. 1 Rear Window DefoggerÐTypical

Fig. 2 Rear Glass Grid Line TestÐTypical

Ä REAR WINDOW DEFOGGER 8N - 1

Page 699 of 2438

to the deck lid open position. If the pull down limit

switch is depressed at this time, the motor should

stop.(c) If these results are not obtained, replace the

pull down motor assembly.

REMOTE KEYLESS ENTRY

OPERATION

The transmitter has three buttons for operation

(Fig. 11).

² UNLOCK driver's door, enable illuminated entry,

and disarm the Theft Security System. Pushing and

releasing the button once will unlock the driver's

door. Two times within five seconds all doors will un-

lock.

² LOCK all doors, set Theft Security System and

chirp horn. Chirp of horn is a short toot to notify

that the alarm system is set and the indicator lamp

on the instrument panel will flash for about 15 sec-

onds.

² Unlock Trunk Lid

² The receiver is capable of retaining VAC even

when power is removed.

² Each receiver must have at least one and no more

than two transmitters.

CONTROL RANGE

Operation range is within 7 meters (23 ft.) of the

receiver.

TRANSMITTER BATTERY

The battery can be removed without special tools

and are readily available at local retail stores. The

recommended battery is Duracell DL 2016 or equiv-

alent. Battery life is about one to two years.

PROGRAM REMOTE KEYLESS ENTRY

(1) Remove trim cover or floor console as needed

that may be covering the Air Bag System Diagnostic

Module (ASDM). (2) Pull floor carpeting back between the accelera-

tor peddle and ASDM. (3) Locate program line a dark green wire with a

insulator on the end. Located between the accelerator

and (ASDM). (4) Turn ignition switch to the ON position.

(5) Connect the program line from the Remote

Keyless Entry Module to ground. The door locks will

lock and unlock to indicate the receiver is ready to

receive transmitter code. Trunk solenoid will not cy-

cle. (6) Press any button on the transmitter to set code.

If there is a second transmitter it has to be set at

this time. The locks will cycle to confirm program-

ming. (7) Disconnect the program line from ground. This

returns the system to its normal operation mode. (8) Replace trim cover or floor console as neces-

sary.

HORN CHIRP CANCELLATION

During the programming operation the horn chirp

can be disabled using the following procedures: (1) Remove trim cover or floor console as needed

that may be covering the Air Bag System Diagnostic

Module (ASDM). (2) Pull floor carpeting back between the accelera-

tor peddle and ASDM. (3) Locate program line a dark green wire with a

insulator on the end. Located between the accelerator

and (ASDM). (4) Turn ignition switch ON.

(5) Connect the program line from the Remote

Keyless Entry Module to ground. The door locks will

lock and unlock to indicate the receiver is ready to

receive transmitter code. Trunk solenoid will not cy-

cle. (6) Press any button on the transmitter to set code.

If there is a second transmitter it has to be set at

this time. The locks will cycle to confirm program-

ming. (7) Press LOCK then UNLOCK transmitter but-

tons repeat three times. (8) Door locks and rear release will cycle three

times as feedback of Horn Chirp lockout. (9) Remove ground from program line to restore

normal system operation. (10) To reinstate the Horn Chirp feature refer to

Program Remote Keyless Entry.

TESTING

CONDITION: When trying to program the receiver

module in the vehicle with a new transmitter and

there is no response from the module, Example: the

door locks do not cycle through a lock/unlock routine.

Refer to Fig. 12 for a block wiring diagram or to

Group 8W, Wiring Diagrams.

Fig. 11 Transmitter

Ä POWER LOCKS 8P - 5