ECO mode CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 703 of 2438

VEHICLE THEFT SECURITY SYSTEM

CONTENTS

page page

GENERAL INFORMATION .................. 1

SECURITY SYSTEM DOOR SWITCH REPLACEMENT ........................ 2

SECURITY SYSTEM HOOD SWITCH REPLACEMENT ........................ 2 SYSTEM SELF-TESTS

.................... 1

VEHICLE THEFT SECURITY SYSTEM MODULE REPLACEMENT ........................ 2

WHAT WILL TRIGGER THE SYSTEM ........ 1

GENERAL INFORMATION

JUMP-STARTING, VEHICLE EQUIPPED

WITH THEFT SECURITY SYSTEM . After the

booster battery has been connected, the Theft System

must be turned OFF. Using the key, lock then un-

lock either front door. This turns the Theft System

OFF and the remainder of the Jump-Starting proce-

dure can be followed. If this procedure is not followed, the Theft System

electronics will prevent the engine from starting. If a new Powertrain Control Module is installed,

the engine has to be cranked 20 times before the

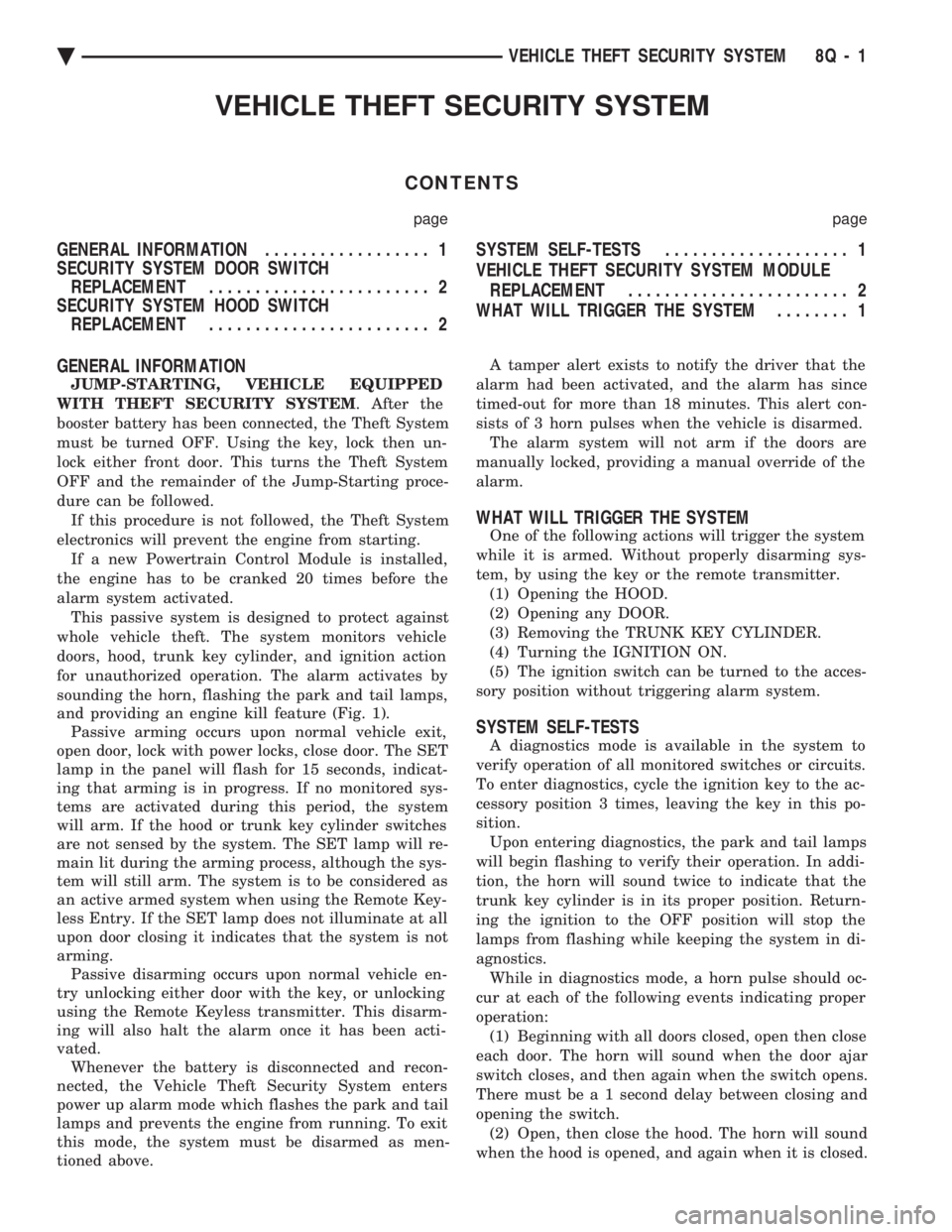

alarm system activated. This passive system is designed to protect against

whole vehicle theft. The system monitors vehicle

doors, hood, trunk key cylinder, and ignition action

for unauthorized operation. The alarm activates by

sounding the horn, flashing the park and tail lamps,

and providing an engine kill feature (Fig. 1). Passive arming occurs upon normal vehicle exit,

open door, lock with power locks, close door. The SET

lamp in the panel will flash for 15 seconds, indicat-

ing that arming is in progress. If no monitored sys-

tems are activated during this period, the system

will arm. If the hood or trunk key cylinder switches

are not sensed by the system. The SET lamp will re-

main lit during the arming process, although the sys-

tem will still arm. The system is to be considered as

an active armed system when using the Remote Key-

less Entry. If the SET lamp does not illuminate at all

upon door closing it indicates that the system is not

arming. Passive disarming occurs upon normal vehicle en-

try unlocking either door with the key, or unlocking

using the Remote Keyless transmitter. This disarm-

ing will also halt the alarm once it has been acti-

vated. Whenever the battery is disconnected and recon-

nected, the Vehicle Theft Security System enters

power up alarm mode which flashes the park and tail

lamps and prevents the engine from running. To exit

this mode, the system must be disarmed as men-

tioned above. A tamper alert exists to notify the driver that the

alarm had been activated, and the alarm has since

timed-out for more than 18 minutes. This alert con-

sists of 3 horn pulses when the vehicle is disarmed. The alarm system will not arm if the doors are

manually locked, providing a manual override of the

alarm.

WHAT WILL TRIGGER THE SYSTEM

One of the following actions will trigger the system

while it is armed. Without properly disarming sys-

tem, by using the key or the remote transmitter. (1) Opening the HOOD.

(2) Opening any DOOR.

(3) Removing the TRUNK KEY CYLINDER.

(4) Turning the IGNITION ON.

(5) The ignition switch can be turned to the acces-

sory position without triggering alarm system.

SYSTEM SELF-TESTS

A diagnostics mode is available in the system to

verify operation of all monitored switches or circuits.

To enter diagnostics, cycle the ignition key to the ac-

cessory position 3 times, leaving the key in this po-

sition. Upon entering diagnostics, the park and tail lamps

will begin flashing to verify their operation. In addi-

tion, the horn will sound twice to indicate that the

trunk key cylinder is in its proper position. Return-

ing the ignition to the OFF position will stop the

lamps from flashing while keeping the system in di-

agnostics. While in diagnostics mode, a horn pulse should oc-

cur at each of the following events indicating proper

operation: (1) Beginning with all doors closed, open then close

each door. The horn will sound when the door ajar

switch closes, and then again when the switch opens.

There must b e a 1 second delay between closing and

opening the switch. (2) Open, then close the hood. The horn will sound

when the hood is opened, and again when it is closed.

Ä VEHICLE THEFT SECURITY SYSTEM 8Q - 1

Page 704 of 2438

(3) Activate the power door locks in both the

LOCK and UNLOCK directions. The horn will sound

after each activation. (4) Rotate the key in each of the door lock cylin-

ders to the unlock position. The horn will sound as

the switch closes, and again when it opens. There

must b e a 1 second delay between changing switch

states, or the horn will not sound.

² Press the LOCK button,horn will sound.

² Press the UNLOCK button, horn will sound.

(5) Cycle the key to the ignition RUN position. A

single horn pulse will indicate proper operation of

the ignition input. This will also take the module out

of the diagnostics mode. For any of these tests, if the

switch does not remain open or closed for at least 1

second, the horn will only sound once. The lack of a horn pulse, during any operation, in-

dicates a switch failure. Check for continuity at the

switch, if this is good, check for an open or shorted

wire between the switch and alarm module. Also,

check if a new powertrain control module has been

installed recently. Vehicle Theft Security System will

not function until 20 engine cranks. Whenever a Vehicle Theft Security System mal-

function occurs, first verify that the wire harness is

properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to Ve-

hicle Theft Security System Diagnosis Chart (Fig. 3).VEHICLE THEFT SECURITY SYSTEM MODULE

REPLACEMENT

If the Vehicle Theft Security System module is be-

ing removed and no replacement module is being in-

stalled, the module wiring must be disconnected

while the engine is running. Failure to do so will

cause a no-start condition (Fig. 3 and 4). (1) Remove lower right instrument panel silencer.

(2) Remove glove box assembly.

(3) Remove three attaching screws mounting the

bracket to instrument panel. (4) Lower bracket and module assembly, to discon-

nect wire connectors. (5) Remove the Remote keyless module so to have

access to the Security Module two screws attaching

module to bracket. (6) For installation reverse above procedures.

SECURITY SYSTEM HOOD SWITCH REPLACEMENT

(1) Remove screw from left inner fender (Fig. 5).

(2) Disconnect wiring.

(3) Remove switch.

(4) For installation reverse above procedures.

SECURITY SYSTEM DOOR SWITCH REPLACEMENT

(1) Remove door trim panel and water shield. Re-

fer to Group 23, Body.

Fig. 1 Vehicle Theft Security System Components

8Q - 2 VEHICLE THEFT SECURITY SYSTEM Ä

Page 712 of 2438

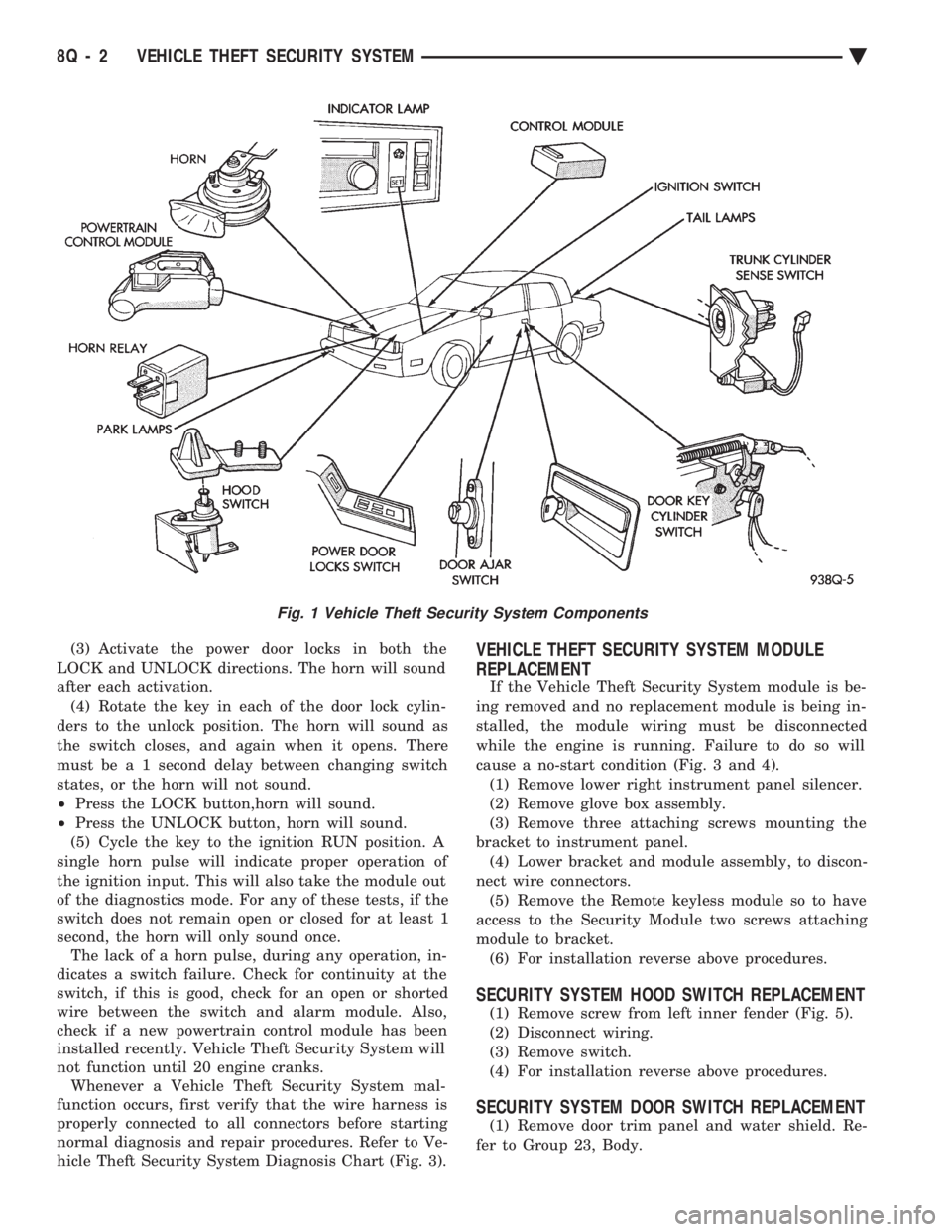

SYSTEM SOFT LIMITS

This portion of the system becomes activated when

the control module must shut off a specific seat, re-

cliner or mirror motor because it has reached the end

of its travel. When a mechanical stall condition is de-

tected, the control module will set a soft limit in its

memory and will not allow the motor to be driven

past that point. To override the soft limits, activate the seat or re-

cliner switch twice in the desired direction holding

the switch activated until the end of travel has been

reached. Reactivate and hold the switch once more

for three seconds. This will cause new soft limits to

be set in the control module.

SETTING SYSTEM SOFT LIMITS

If the control module or motor assemblies have

been replaced, the control module must learn its new

soft limits. To do this, perform the memory seat di-

agnostic self-test. After the tests are completed, the

control module will have learned and memorized its

new soft limits.

TEST PROCEDURES

Before any testing is attempted, the battery should

be carefully charged and all connections and termi-

nals cleaned and tightened to insure proper continu-

ity and grounds.

MEMORY SEAT AND MIRROR DIAGNOSTIC

SELF-TESTS

The system has a built-in set of three self-tests

which check all components in the system while giv-

ing a visual feedback. To enter the first self-test mode, switch test, press

memory position 1 and 2 buttons, hold for at least

five seconds and no longer than ten seconds. Follow

this immediately by pressing the Set button and hold

for at least five seconds but less than ten seconds.

Three seconds after the button is released, the seat,

recliner and mirrors will move to a mid-travel posi-

tion. Within ten seconds, press and release a seat

button to activate a seat or recliner motor. All

switches except the mirror switches may now be

tested one at a time. The memory switches, Position

1 and 2 and Set buttons, may also be tested. A good

switch contact actuation will NOD the seat. The seat

nod consists of seat front up and seat track forward

followed by seat front down and seat track rearward.

The nod also includes both outside power rear view

mirrors operating in the vertical plane. The system

will continue NODDING for good switches until 10

seconds pass without any switch actuation. Within 10 seconds of the last seat nod, press mem-

ory position 1 and 2 buttons for at least 5 seconds

Fig. 9 Seat AdjusterÐAA Body

8R - 6 POWER SEATS Ä

Page 714 of 2438

but less than 10 seconds, and then release. The seat

will move, after 3 seconds, to a full down and rear-

ward position. This is the seat check mode. The control module

will now move the motors to a stall in forward, rear-

ward, front up, front down, rear up, rear down, re-

cliner forward, and recliner rear ward positions. If a

problem exists, the control module will not move that

part of the seat. After all motors have been run to

stall, the system will pause for 3 seconds, then re-

turn to the mid-travel position. The control module will now move the seat through

its positions for two seconds run time. If a problem has been found, the control module

will go into a loop and just move the problem part of

the system. To exit the loop, press the Set or Position

1 or 2 buttons or repair the fault; i.e.: repair a ter-

minal push out, etc. When the seat movements are complete, the sys-

tem will return to its normal operating mode unless

memory Position 1 and 2 buttons are held for at least

five seconds, but less than ten seconds and then re-

leased. The seat will return to its mid-travel position

and the mirrors will move full downward and to the

left. This is the mirror check mode. The control mod-

ule will then move the right mirror fully horizontal

outboard, and horizontal inboard. This is followed by

the left mirror fully horizontal inboard, horizontal

out board, vertical up, and vertical down. Each motor

will be driven until the associated mirror plane face

has been stalled for up to 1-1/2 seconds at each end

of travel. If the control module encounters a problem

with any position sensing rheostat that is connected

to each motor, that particular motor will not be ac-

tuated. After an other three second pause, the control

module will again try running the mirror motors in

the directions given above plus the right mirror ver-

tical up and vertical down. Any motor that has no

problem will run for two seconds in each of the given

directions. If a problem is found, the control module will go

into a loop and move only the problem part of the

system. To exit the loop, repair the fault, or press the

Set, Position 1 or 2 buttons. The control module will

then finish the motor actuation that are shown

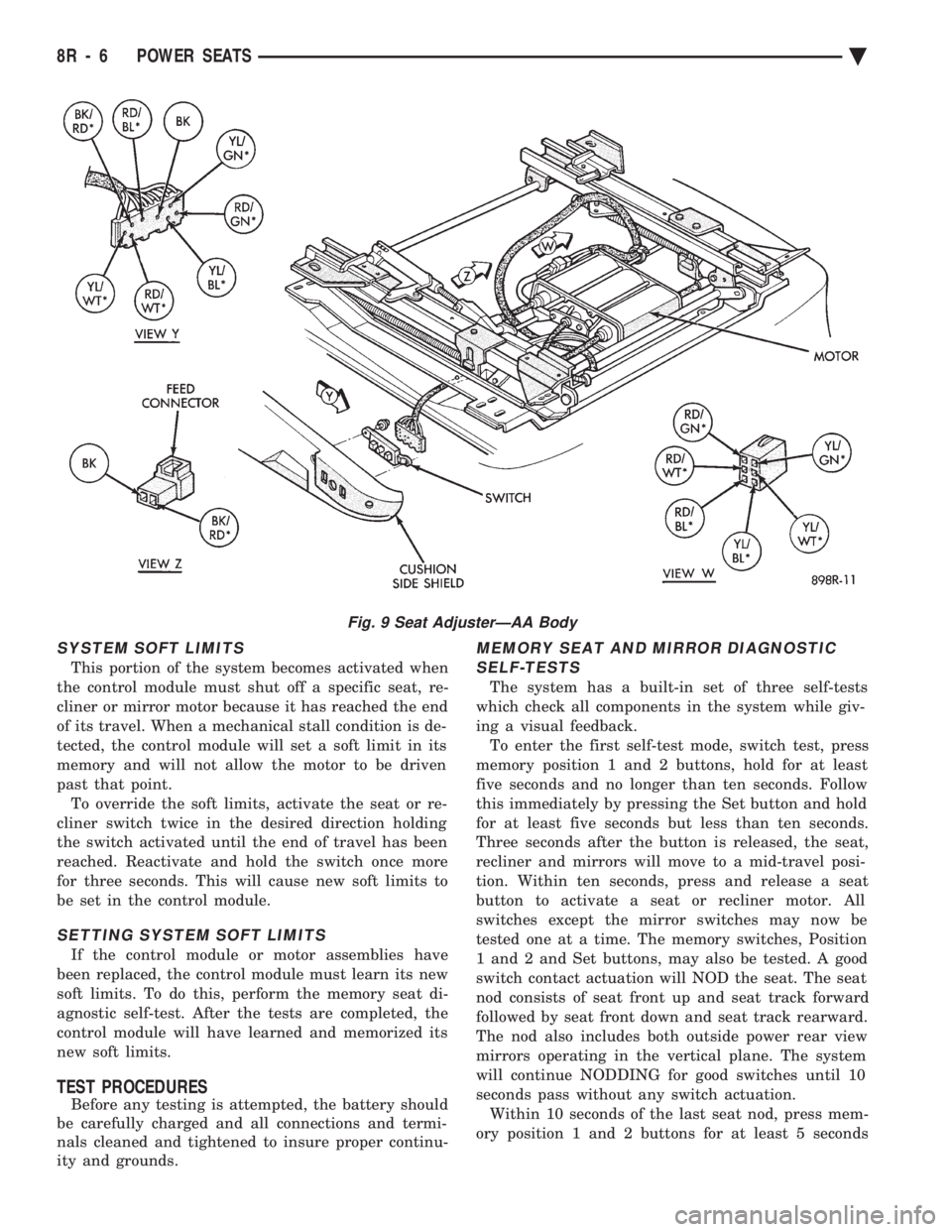

Fig. 13 Seat Wing Switch Continuity

Fig. 14 Lumbar Switch Continuity

Fig. 15 Memory Seat Switch

8R - 8 POWER SEATS Ä

Page 715 of 2438

above. When the control module has finished, it will

return to the normal operating mode after ten sec-

onds if no further switches are activated.The control module will also return to normal op-

erating mode if any manual seat or recliner move-

ment switch is actuated during the ten second

timeout. If the system has found a problem, refer to the ap-

propriate diagnosis condition.

POWER MEMORY SEAT, RECLINER AND

MIRRORS DIAGNOSIS

Before any diagnosis is done on the system, move

the seat switches and listen for relays clicking in the

control module under the seat. If relays can be heard,

the main battery and ground circuits to the control

module as well as the battery circuit to the switches

in the driver's door are good. When checking for voltage or continuity, always

use a volt/ohm meter to get accurate readings. The

seat and recliner switches must be activated to check

for voltage at the seat and recliner motors or at the

input to the control module from the switches. The control module creates a special voltage supply

for the position sensing functions. It also shuts down

after five seconds, in order to check this or any other

voltage being fed back to the control module. A

switch may have to be activated more than once to

verify a voltage reading. The voltage from the con-

trol module that feeds the seat and recliner position

sensing potentiometer, will be between 4.5 to 5 volts.

For simplicity in the diagnosis section, the feed volt-

age will be called 5 volts. On the position sensing

wires, these voltages will always be less than 5 volts

but more than 0 volts. Typically the high level is at

a maximum of about 4.25 volts and the low level can

be as little as 0.1 volts. If any seat or recliner potentiometer or mirror

rheostat position sense wires are crossed, the control

module will not move that part of the system. The

seat or mirror will be in a fault diagnostic mode.

CONDITION: SYSTEM WILL NOT OPERATE.

PROCEDURE

(1) Check for forward/rearward operation of re-

cliner. If not operable, check for an open or loose cir-

cuit breaker mounted in board on the relay bank in

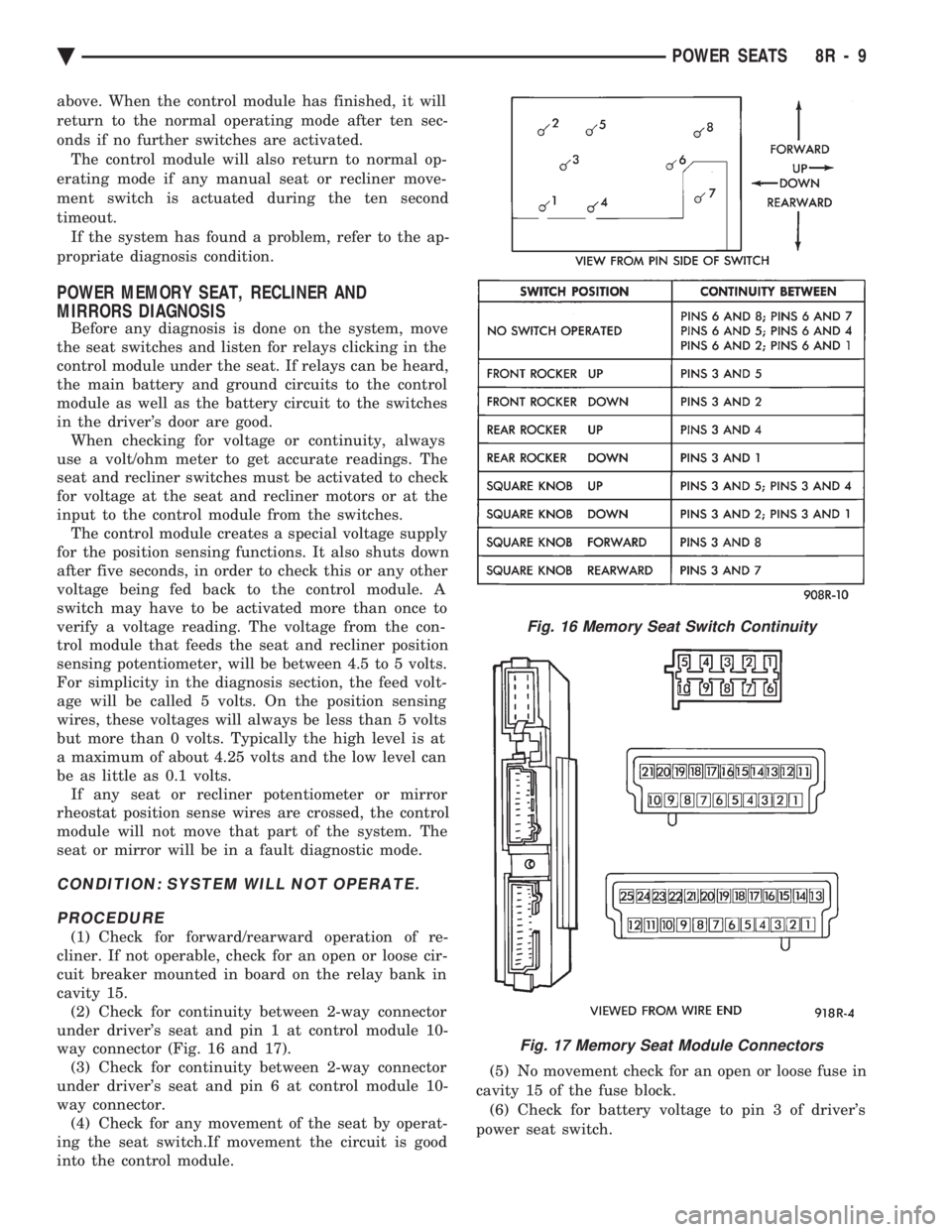

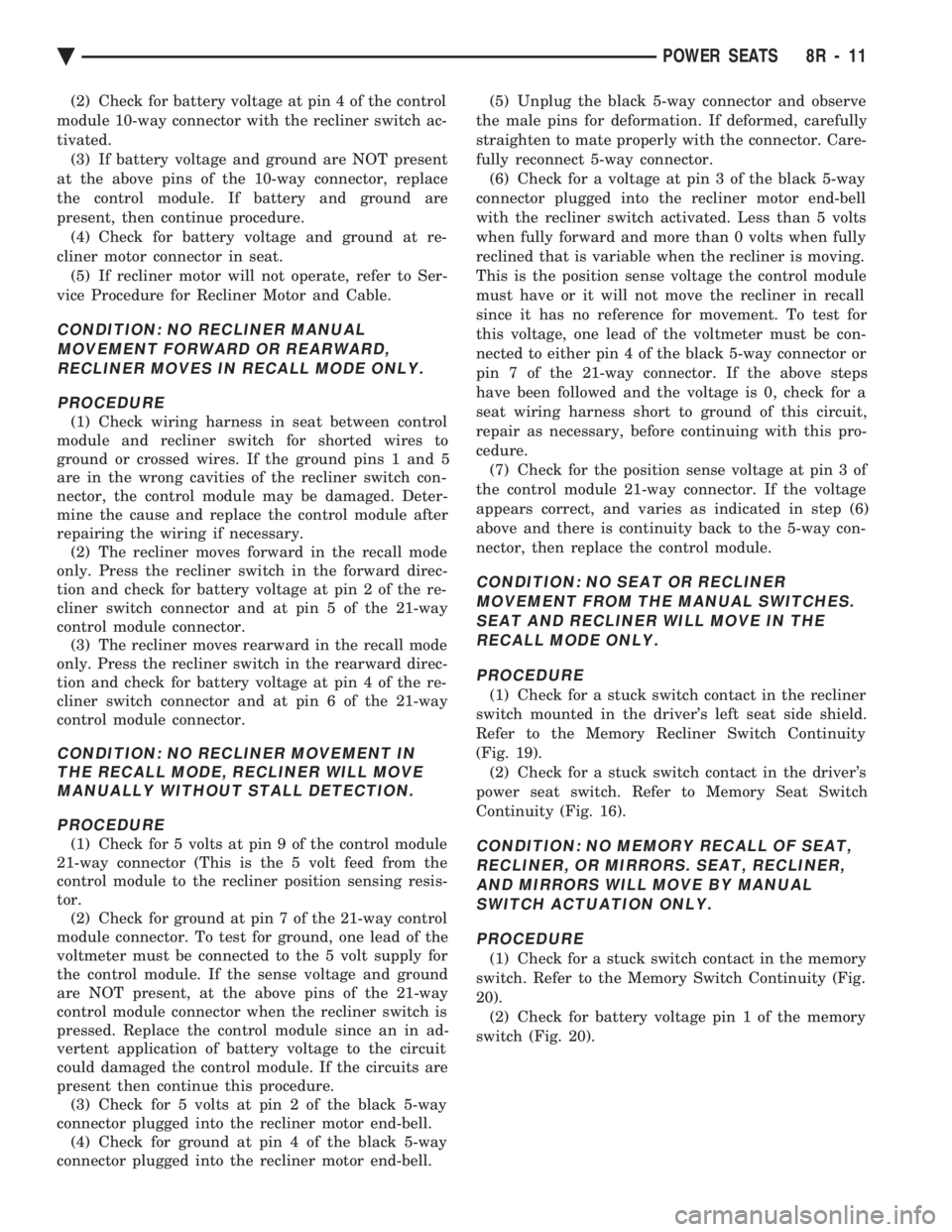

cavity 15. (2) Check for continuity between 2-way connector

under driver's seat and pin 1 at control module 10-

way connector (Fig. 16 and 17). (3) Check for continuity between 2-way connector

under driver's seat and pin 6 at control module 10-

way connector. (4) Check for any movement of the seat by operat-

ing the seat switch.If movement the circuit is good

into the control module. (5) No movement check for an open or loose fuse in

cavity 15 of the fuse block. (6) Check for battery voltage to pin 3 of driver's

power seat switch.

Fig. 16 Memory Seat Switch Continuity

Fig. 17 Memory Seat Module Connectors

Ä POWER SEATS 8R - 9

Page 717 of 2438

(2) Check for battery voltage at pin 4 of the control

module 10-way connector with the recliner switch ac-

tivated. (3) If battery voltage and ground are NOT present

at the above pins of the 10-way connector, replace

the control module. If battery and ground are

present, then continue procedure. (4) Check for battery voltage and ground at re-

cliner motor connector in seat. (5) If recliner motor will not operate, refer to Ser-

vice Procedure for Recliner Motor and Cable.

CONDITION: NO RECLINER MANUAL MOVEMENT FORWARD OR REARWARD,RECLINER MOVES IN RECALL MODE ONLY.

PROCEDURE

(1) Check wiring harness in seat between control

module and recliner switch for shorted wires to

ground or crossed wires. If the ground pins 1 and 5

are in the wrong cavities of the recliner switch con-

nector, the control module may be damaged. Deter-

mine the cause and replace the control module after

repairing the wiring if necessary. (2) The recliner moves forward in the recall mode

only. Press the recliner switch in the forward direc-

tion and check for battery voltage at pin 2 of the re-

cliner switch connector and at pin 5 of the 21-way

control module connector. (3) The recliner moves rearward in the recall mode

only. Press the recliner switch in the rearward direc-

tion and check for battery voltage at pin 4 of the re-

cliner switch connector and at pin 6 of the 21-way

control module connector.

CONDITION: NO RECLINER MOVEMENT IN THE RECALL MODE, RECLINER WILL MOVEMANUALLY WITHOUT STALL DETECTION.

PROCEDURE

(1) Check for 5 volts at pin 9 of the control module

21-way connector (This is the 5 volt feed from the

control module to the recliner position sensing resis-

tor. (2) Check for ground at pin 7 of the 21-way control

module connector. To test for ground, one lead of the

voltmeter must be connected to the 5 volt supply for

the control module. If the sense voltage and ground

are NOT present, at the above pins of the 21-way

control module connector when the recliner switch is

pressed. Replace the control module since an in ad-

vertent application of battery voltage to the circuit

could damaged the control module. If the circuits are

present then continue this procedure. (3) Check for 5 volts at pin 2 of the black 5-way

connector plugged into the recliner motor end-bell. (4) Check for ground at pin 4 of the black 5-way

connector plugged into the recliner motor end-bell. (5) Unplug the black 5-way connector and observe

the male pins for deformation. If deformed, carefully

straighten to mate properly with the connector. Care-

fully reconnect 5-way connector. (6) Check for a voltage at pin 3 of the black 5-way

connector plugged into the recliner motor end-bell

with the recliner switch activated. Less than 5 volts

when fully forward and more than 0 volts when fully

reclined that is variable when the recliner is moving.

This is the position sense voltage the control module

must have or it will not move the recliner in recall

since it has no reference for movement. To test for

this voltage, one lead of the voltmeter must be con-

nected to either pin 4 of the black 5-way connector or

pin 7 of the 21-way connector. If the above steps

have been followed and the voltage is 0, check for a

seat wiring harness short to ground of this circuit,

repair as necessary, before continuing with this pro-

cedure. (7) Check for the position sense voltage at pin 3 of

the control module 21-way connector. If the voltage

appears correct, and varies as indicated in step (6)

above and there is continuity back to the 5-way con-

nector, then replace the control module.

CONDITION: NO SEAT OR RECLINER MOVEMENT FROM THE MANUAL SWITCHES.SEAT AND RECLINER WILL MOVE IN THERECALL MODE ONLY.

PROCEDURE

(1) Check for a stuck switch contact in the recliner

switch mounted in the driver's left seat side shield.

Refer to the Memory Recliner Switch Continuity

(Fig. 19). (2) Check for a stuck switch contact in the driver's

power seat switch. Refer to Memory Seat Switch

Continuity (Fig. 16).

CONDITION: NO MEMORY RECALL OF SEAT, RECLINER, OR MIRRORS. SEAT, RECLINER,AND MIRRORS WILL MOVE BY MANUALSWITCH ACTUATION ONLY.

PROCEDURE

(1) Check for a stuck switch contact in the memory

switch. Refer to the Memory Switch Continuity (Fig.

20). (2) Check for battery voltage pin 1 of the memory

switch (Fig. 20).

Ä POWER SEATS 8R - 11

Page 719 of 2438

ity 9 and pin 7 of the control module 25-way connec-

tor. The vehicle speed sensor signal can be tested

with a volt/ohmmeter at pin 7 of the control module

25-way connector. Turn on the vehicle ignition and

check fo r a 5 volt signal as the vehicle is moved

about 3 to 5 feet. If not repair open wiring, terminal

push out, bad crimp, drive in vehicle speed sensor,

etc., as necessary to correct condition. Ensure that

the 25-way connector is plugged into the control

module securely. Road test vehicle after repairs have

been made to ensure that no recalls can occur while

moving.

CONDITION: INSTRUMENT CLUSTER SPEEDOMETER STAYS AT 0 MPH/ (0 KM/H)WHILE VEHICLE IS MOVING, BODYCOMPUTER DOES NOT LOCK DOORS AT 15MPH (24 KM/H), AND THE SPEED CONTROLWILL NOT ACCEPT A SPEED SET.

PROCEDURE

(1) Remove driver's seat anchor bolts and nuts. Ad-

just the driver's seat to a safe driving position. Dis-

connect the 25-way connector from the memory seat

control module. Replace the driver's seat anchor bolts

and nuts. Road test the vehicle to complete this diag-

nosis. If the doors lock, the cruise control accepts a

set, and the speedometer now works, replace the

Memory Seat control module. (2) After replacing the Memory Seat control mod-

ule, perform the memory seat diagnostic self tests.

This teaches the new module it's soft limits and now

re-road test the vehicle before returning it to the cus-

tomer.

CONDITION: NO SEAT MOVEMENT IN THE RECALL MODE, SEAT WILL MOVE BYMANUAL SWITCH ACTUATION IN ALLDIRECTIONS WITHOUT STALL DETECTION.

PROCEDURE

(1) Check for 5 volts at pin 10 of the control mod-

ule 25-way connector. This is the 5 volt feed from the

control module to the seat track position sensing po-

tentiometer. (2) Check for ground at pin 8 of the control module

25-way connector. To test for ground, one lead of the

voltmeter must be connected to either the 5 volt sup-

ply for the control module or the battery positive. If

the sense voltage and ground are NOT present at the

above pins of the 21-way control module connector.

When the seat switch is pressed, replace the control

module. An inadvertent application of battery volt-

age to the circuit could damaged the control module.

If the voltage and ground circuits are present then

continue this procedure. (3) Check for 5 volts at pin 5 of the natural 5-way

connector plugged into the power seat adjuster mo-

tors end-bell. (4) Check for ground at pin 4 of the natural 5-way

connector plugged into the power seat adjuster mo-

tors end-bell. If the power seat adjuster still has no

movement in the recall mode, then continue this pro-

cedure. (5) Disconnect the natural 5-way connector from

the power seat adjuster motors end-bell. (6) Check with an ohmmeter for a resistance read-

ing that may be from 2600 to 4000 ohms between

pins 4 and 5 of the motors end-bell connector. If

there is an open circuit reading or the reading ob-

tained falls outside this range, then replace the seat

motor package assembly. After replacement of the

seat motor package, reconnect all wiring connectors

and reinstall seat assembly in vehicle. Operate the

switches manually to cause maximum seat move-

ment in all directions. Perform the memory seat di-

agnostic self check so the control module will learn

the new soft limits of the assembly.

CONDITION: NO SEAT TRACK FORWARD OR REARWARD MOVEMENT IN THE RECALLMODE, SEAT TRACK WILL MOVE FORWARDOR REARWARD BY MANUAL SWITCHACTUATION WITHOUT STALL DETECTION.

PROCEDURE

(1) Check for a voltage at pin 12 of the control

module 21-way connector. Less than 5 volts for the

seat track fully forward and more than 0 volts when

fully rearward. This voltage should vary correspond-

ing to the position. (2) Check for a voltage at pin 1 of the natural

5-way connector, Same as in step (1) above. The

ground lead connected to pin 4 of the 5-way connec-

tor. If the voltage reading is at 0 volts, disconnect

the 5-way natural connector and check for a short to

ground in the harness. If no short is found, reconnect

the connector and continue the procedure. (3) Check for the voltage to vary as noted above, if

it does not vary as the seat track is moved forward

and rearward, the sensing potentiometer is defective.

Replace the seat motor package assembly. After re-

placement of the seat motor package, reconnect all

wiring connectors and reinstall seat assembly in ve-

hicle. Operate the switches manually to cause maxi-

mum seat movement in all directions. Perform the

memory seat diagnostic self check so the control

module will learn the new soft limits of the assem-

bly.

Ä POWER SEATS 8R - 13

Page 720 of 2438

CONDITION: NO SEAT TRACK FRONT UP OR DOWN MOVEMENT IN THE RECALL MODE,SEAT TRACK FRONT WILL MOVE UP ORDOWN BY MANUAL SWITCH ACTUATIONWITHOUT STALL DETECTION.

PROCEDURE

(1) Check for a voltage at pin 2 of the control mod-

ule 21-way connector. Less than 5 volts for the seat

track front full up and more than 0 volts when fully

down. (2) Check for a voltage at pin 2 of the natural

5-way connector. Same as in step (1) above. With the

ground lead of the meter at pin 4 of this connector. If

the voltage reading is at 0 volts, disconnect the

5-way natural connector and check for a short to

ground in the harness. If no short is found, reconnect

the connector and continue the procedure. (3) Check for the voltage to vary as noted above, if

it does not vary as the seat track front is moved up

and down, the sensing potentiometer is defective. Re-

place the seat motor package assembly. After re-

placement of the seat motor package, reconnect all

wiring connectors and reinstall seat assembly in ve-

hicle. Operate the switches manually to cause maxi-

mum seat movement in all directions. Perform the

memory seat diagnostic self check so the control

module will learn the new soft limits of the assem-

bly.

CONDITION: NO SEAT TRACK REAR UP OR DOWN MOVEMENT IN THE RECALL MODE,SEAT TRACK REAR WILL MOVE UP OR DOWNBY MANUAL SWITCH ACTUATION WITHOUTSTALL DETECTION.

PROCEDURE

(1) Check for a voltage at pin 13 of the control

module 21-way connector. Less than 5 volts for the

seat track rear full up and more than 0 volts when

fully down. (2) Check for a voltage at pin 3 of the natural

5-way connector. Same as in step (1) above. The

ground lead connected to pin 4 of the 5-way connec-

tor. If the voltage reading is at 0 volts, disconnect

the 5-way natural connector and check for a short to

ground in the harness. If no short is found, reconnect

the connector and continue the procedure. (3) Check for the voltage to vary as noted above, if

it does not vary as the seat track rear is moved up

and down, the sensing potentiometer is defective. Re-

place the seat motor package assembly. After re-

placement of the seat motor package, reconnect all

wiring connectors and reinstall seat assembly in ve-

hicle. Operate the switches manually to cause maxi-

mum seat movement in all directions. Perform the

diagnostic self seat check so the control module will

learn the new soft limits of the assembly.

CONDITION: NO MOVEMENT OF THE SEAT,

SEAT WILL MOVE IN THE RECALL MODEONLY.

PROCEDURE

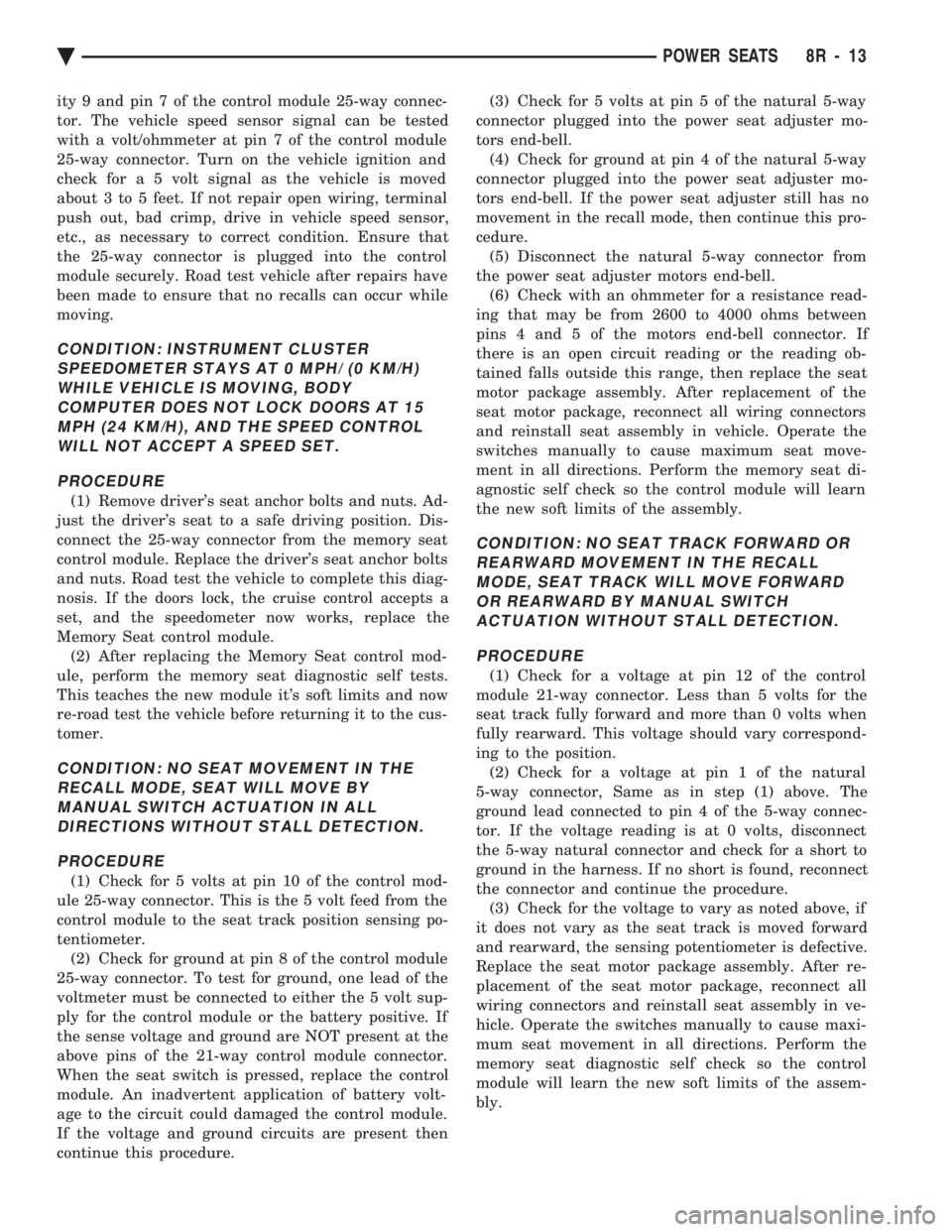

(1) Check for battery voltage to terminal 3 of driv-

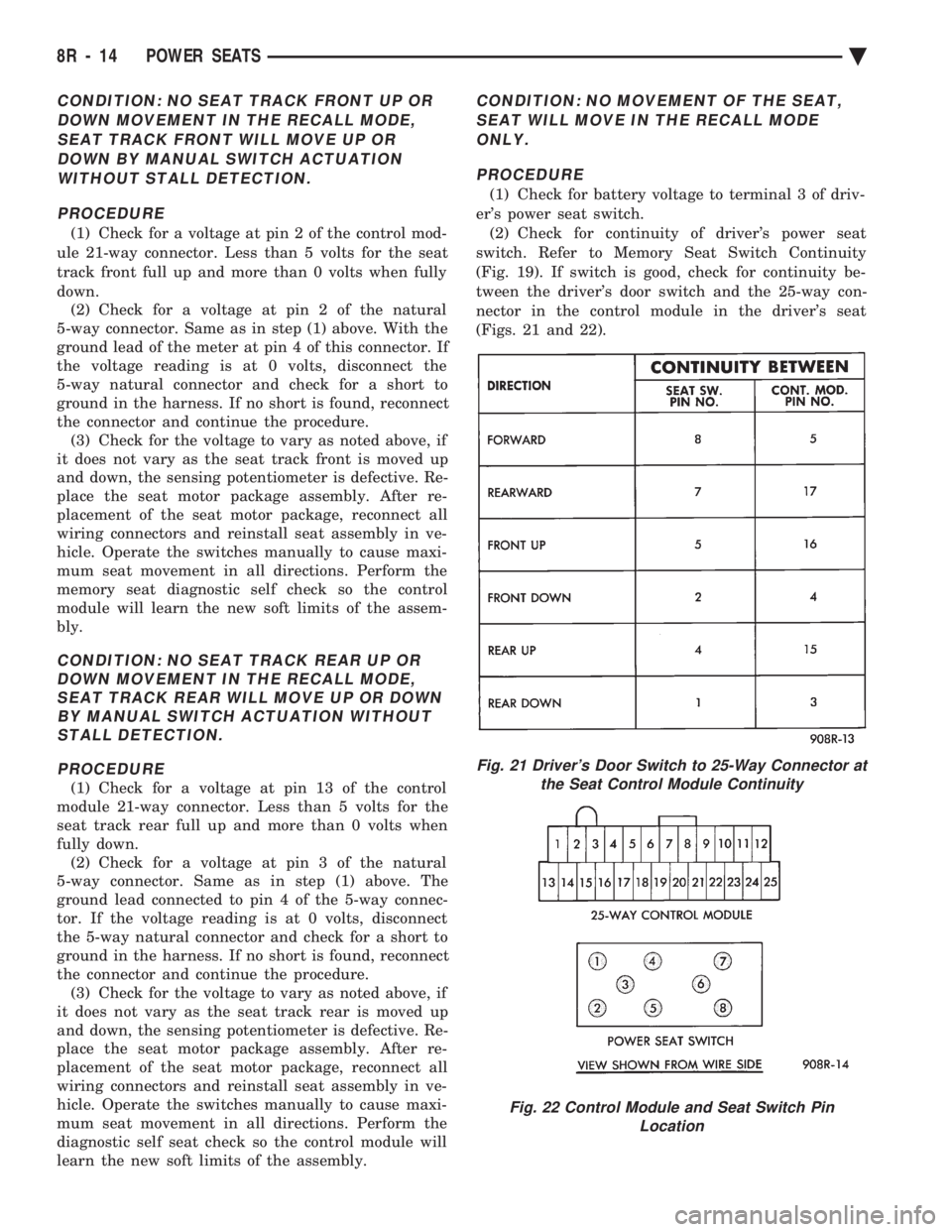

er's power seat switch. (2) Check for continuity of driver's power seat

switch. Refer to Memory Seat Switch Continuity

(Fig. 19). If switch is good, check for continuity be-

tween the driver's door switch and the 25-way con-

nector in the control module in the driver's seat

(Figs. 21 and 22).

Fig. 21 Driver's Door Switch to 25-Way Connector at the Seat Control Module Continuity

Fig. 22 Control Module and Seat Switch Pin Location

8R - 14 POWER SEATS Ä

Page 743 of 2438

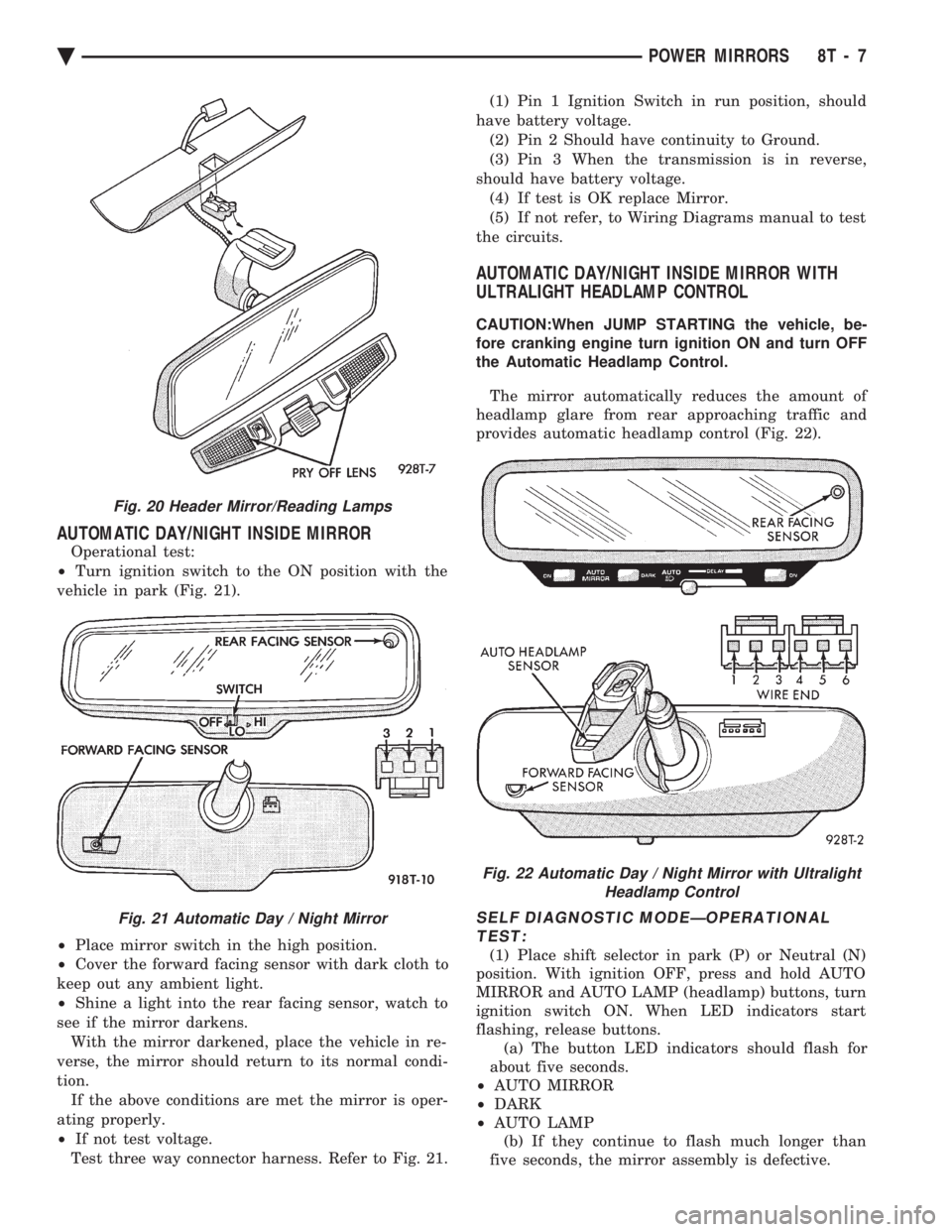

AUTOMATIC DAY/NIGHT INSIDE MIRROR

Operational test:

² Turn ignition switch to the ON position with the

vehicle in park (Fig. 21).

² Place mirror switch in the high position.

² Cover the forward facing sensor with dark cloth to

keep out any ambient light.

² Shine a light into the rear facing sensor, watch to

see if the mirror darkens. With the mirror darkened, place the vehicle in re-

verse, the mirror should return to its normal condi-

tion. If the above conditions are met the mirror is oper-

ating properly.

² If not test voltage.

Test three way connector harness. Refer to Fig. 21. (1) Pin 1 Ignition Switch in run position, should

have battery voltage. (2) Pin 2 Should have continuity to Ground.

(3) Pin 3 When the transmission is in reverse,

should have battery voltage. (4) If test is OK replace Mirror.

(5) If not refer, to Wiring Diagrams manual to test

the circuits.

AUTOMATIC DAY/NIGHT INSIDE MIRROR WITH

ULTRALIGHT HEADLAMP CONTROL

CAUTION:When JUMP STARTING the vehicle, be-

fore cranking engine turn ignition ON and turn OFF

the Automatic Headlamp Control.

The mirror automatically reduces the amount of

headlamp glare from rear approaching traffic and

provides automatic headlamp control (Fig. 22).

SELF DIAGNOSTIC MODEÐOPERATIONAL TEST:

(1) Place shift selector in park (P) or Neutral (N)

position. With ignition OFF, press and hold AUTO

MIRROR and AUTO LAMP (headlamp) buttons, turn

ignition switch ON. When LED indicators start

flashing, release buttons. (a) The button LED indicators should flash for

about five seconds.

² AUTO MIRROR

² DARK

² AUTO LAMP

(b) If they continue to flash much longer than

five seconds, the mirror assembly is defective.

Fig. 20 Header Mirror/Reading Lamps

Fig. 21 Automatic Day / Night Mirror

Fig. 22 Automatic Day / Night Mirror with Ultralight Headlamp Control

Ä POWER MIRRORS 8T - 7

Page 751 of 2438

GENERAL INFORMATION

CONTENTS

page page

CIRCUIT IDENTIFICATION ................. 3

COMPONENT IDENTIFICATION ............. 3

CONNECTORS ........................... 4

FUSIBLE LINKS ......................... 4

HARNESS REPAIR ....................... 4

LOCATING A SYSTEM .................... 3 SECONDARY IGNITION WIRING

............ 1

SPLICE LOCATIONS ...................... 3

SYMBOLS, FUSES AND RELAYS ........... 7

TROUBLESHOOTING WIRING PROBLEMS .... 4

WIRE CODE IDENTIFICATION .............. 2

WIRING DIAGRAM SHEETS AND INDEXES . . . 1

The wiring diagrams contain the latest information

at the time of publication. Throughout this group ref-

erences may be made to a particular vehicle by letter

or number designation. A chart showing the break-

down of these designations is included below.

SECONDARY IGNITION WIRING

Secondary ignition wiring is shown in Figures 1, 2,

3, 4, and 5. For information on distributor operation

or ignition systems refer to Group 8D Ignition Sys-

tems.

WIRING DIAGRAM SHEETS AND INDEXES

The diagrams are organized to show the basic ve-

hicle and all of its options. Add-on or non-factory op-

tions are not covered. The diagram pages are

identified by a sheet number which is located at the

lower right or left hand corner of each sheet. Page

numbers at the top of each page do not apply to

diagram sheets. Diagram sheets show all information relating to

the system. This includes feeds, grounds, switch in-

ternal circuity, connectors, splices, and pin identifica-

tion for controllers and modules.

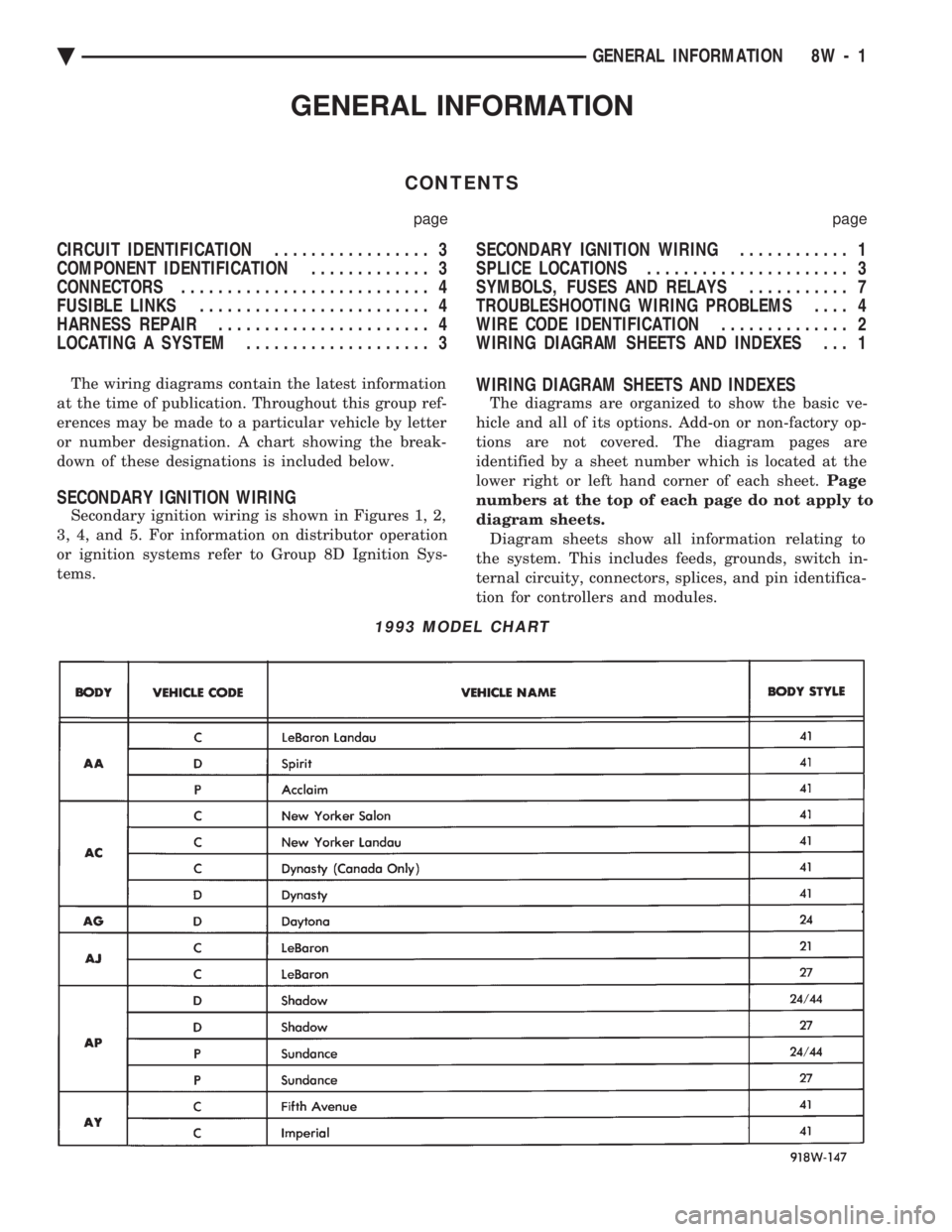

1993 MODEL CHART

Ä GENERAL INFORMATION 8W - 1