belt CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 551 of 2438

FUEL TANK SENDING UNIT TEST

Refer to Group 14, Fuel for test procedures.

LOW OIL PRESSURE WARNING LAMP TEST

The low oil pressure warning lamp will illuminate

when the ignition key is turned to the ON position

without engine running. The lamp also illuminates

should the engine oil pressure drop below a safe oil

pressure level. To test the system turn ignition key to the ON po-

sition. If the lamp fails to light, inspect for a broken

or disconnected wire at the oil pressure combination

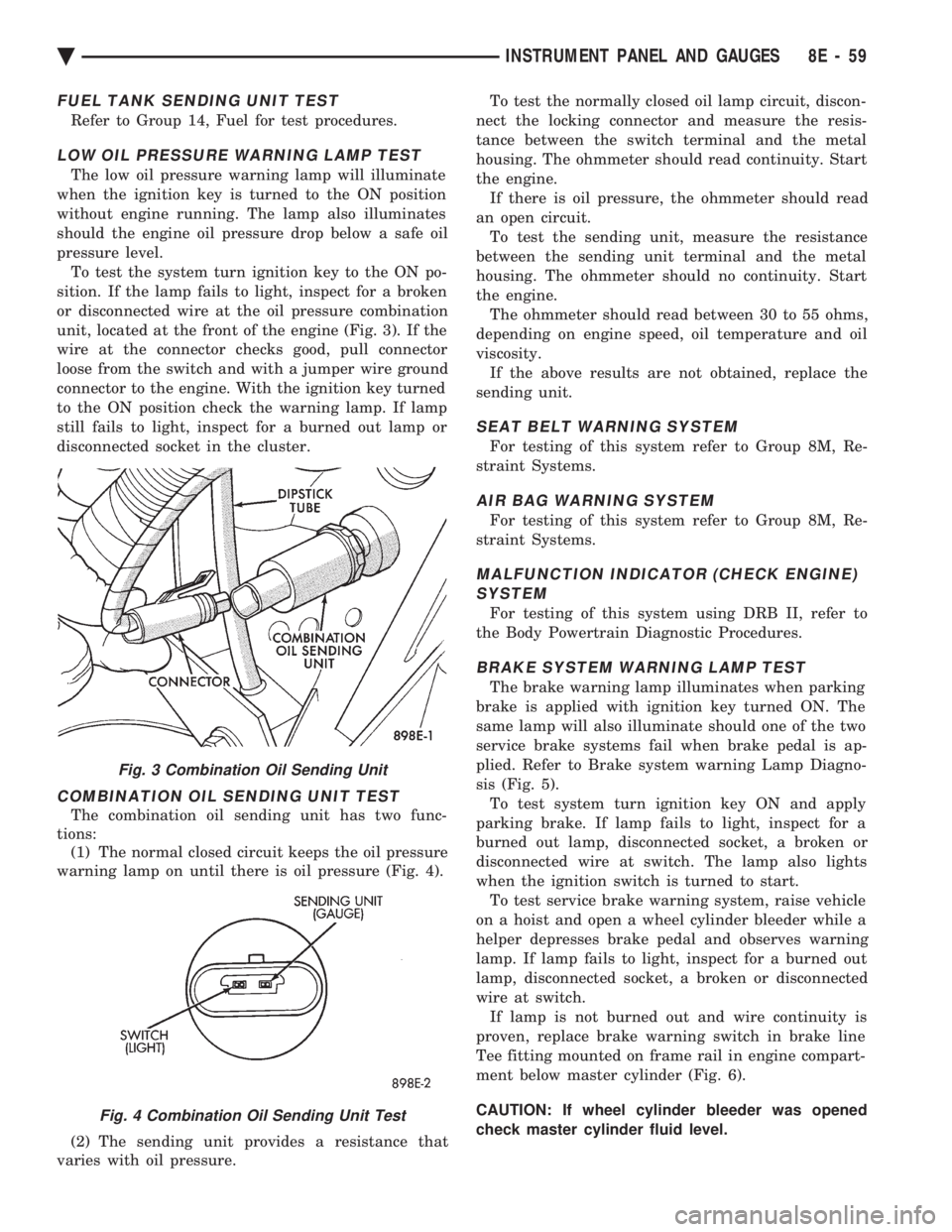

unit, located at the front of the engine (Fig. 3). If the

wire at the connector checks good, pull connector

loose from the switch and with a jumper wire ground

connector to the engine. With the ignition key turned

to the ON position check the warning lamp. If lamp

still fails to light, inspect for a burned out lamp or

disconnected socket in the cluster.

COMBINATION OIL SENDING UNIT TEST

The combination oil sending unit has two func-

tions: (1) The normal closed circuit keeps the oil pressure

warning lamp on until there is oil pressure (Fig. 4).

(2) The sending unit provides a resistance that

varies with oil pressure. To test the normally closed oil lamp circuit, discon-

nect the locking connector and measure the resis-

tance between the switch terminal and the metal

housing. The ohmmeter should read continuity. Start

the engine. If there is oil pressure, the ohmmeter should read

an open circuit. To test the sending unit, measure the resistance

between the sending unit terminal and the metal

housing. The ohmmeter should no continuity. Start

the engine. The ohmmeter should read between 30 to 55 ohms,

depending on engine speed, oil temperature and oil

viscosity. If the above results are not obtained, replace the

sending unit.

SEAT BELT WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

AIR BAG WARNING SYSTEM

For testing of this system refer to Group 8M, Re-

straint Systems.

MALFUNCTION INDICATOR (CHECK ENGINE) SYSTEM

For testing of this system using DRB II, refer to

the Body Powertrain Diagnostic Procedures.

BRAKE SYSTEM WARNING LAMP TEST

The brake warning lamp illuminates when parking

brake is applied with ignition key turned ON. The

same lamp will also illuminate should one of the two

service brake systems fail when brake pedal is ap-

plied. Refer to Brake system warning Lamp Diagno-

sis (Fig. 5). To test system turn ignition key ON and apply

parking brake. If lamp fails to light, inspect for a

burned out lamp, disconnected socket, a broken or

disconnected wire at switch. The lamp also lights

when the ignition switch is turned to start. To test service brake warning system, raise vehicle

on a hoist and open a wheel cylinder bleeder while a

helper depresses brake pedal and observes warning

lamp. If lamp fails to light, inspect for a burned out

lamp, disconnected socket, a broken or disconnected

wire at switch. If lamp is not burned out and wire continuity is

proven, replace brake warning switch in brake line

Tee fitting mounted on frame rail in engine compart-

ment below master cylinder (Fig. 6).

CAUTION: If wheel cylinder bleeder was opened

check master cylinder fluid level.

Fig. 3 Combination Oil Sending Unit

Fig. 4 Combination Oil Sending Unit Test

Ä INSTRUMENT PANEL AND GAUGES 8E - 59

Page 564 of 2438

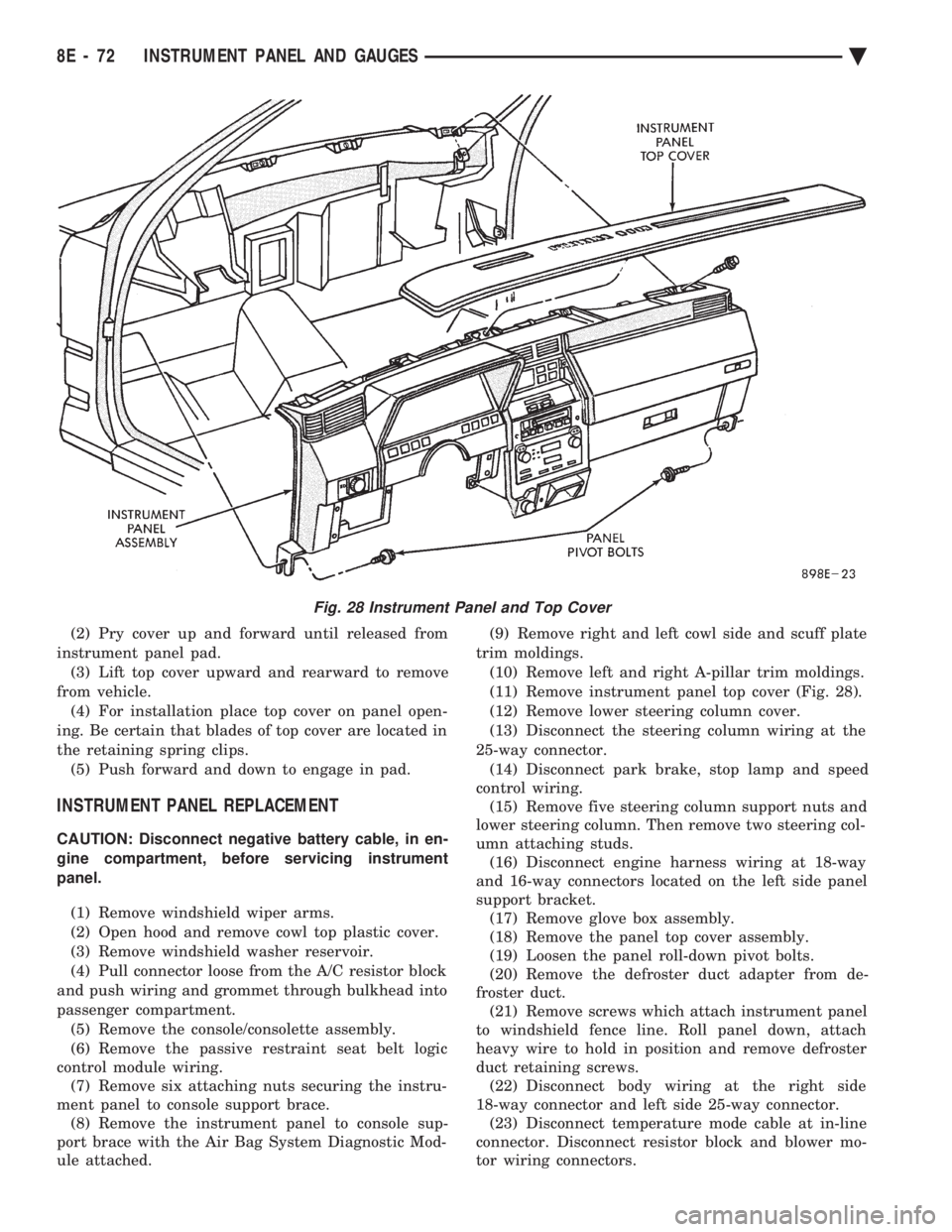

(2) Pry cover up and forward until released from

instrument panel pad. (3) Lift top cover upward and rearward to remove

from vehicle. (4) For installation place top cover on panel open-

ing. Be certain that blades of top cover are located in

the retaining spring clips. (5) Push forward and down to engage in pad.

INSTRUMENT PANEL REPLACEMENT

CAUTION: Disconnect negative battery cable, in en-

gine compartment, before servicing instrument

panel.

(1) Remove windshield wiper arms.

(2) Open hood and remove cowl top plastic cover.

(3) Remove windshield washer reservoir.

(4) Pull connector loose from the A/C resistor block

and push wiring and grommet through bulkhead into

passenger compartment. (5) Remove the console/consolette assembly.

(6) Remove the passive restraint seat belt logic

control module wiring. (7) Remove six attaching nuts securing the instru-

ment panel to console support brace. (8) Remove the instrument panel to console sup-

port brace with the Air Bag System Diagnostic Mod-

ule attached. (9) Remove right and left cowl side and scuff plate

trim moldings. (10) Remove left and right A-pillar trim moldings.

(11) Remove instrument panel top cover (Fig. 28).

(12) Remove lower steering column cover.

(13) Disconnect the steering column wiring at the

25-way connector. (14) Disconnect park brake, stop lamp and speed

control wiring. (15) Remove five steering column support nuts and

lower steering column. Then remove two steering col-

umn attaching studs. (16) Disconnect engine harness wiring at 18-way

and 16-way connectors located on the left side panel

support bracket. (17) Remove glove box assembly.

(18) Remove the panel top cover assembly.

(19) Loosen the panel roll-down pivot bolts.

(20) Remove the defroster duct adapter from de-

froster duct. (21) Remove screws which attach instrument panel

to windshield fence line. Roll panel down, attach

heavy wire to hold in position and remove defroster

duct retaining screws. (22) Disconnect body wiring at the right side

18-way connector and left side 25-way connector. (23) Disconnect temperature mode cable at in-line

connector. Disconnect resistor block and blower mo-

tor wiring connectors.

Fig. 28 Instrument Panel and Top Cover

8E - 72 INSTRUMENT PANEL AND GAUGES Ä

Page 592 of 2438

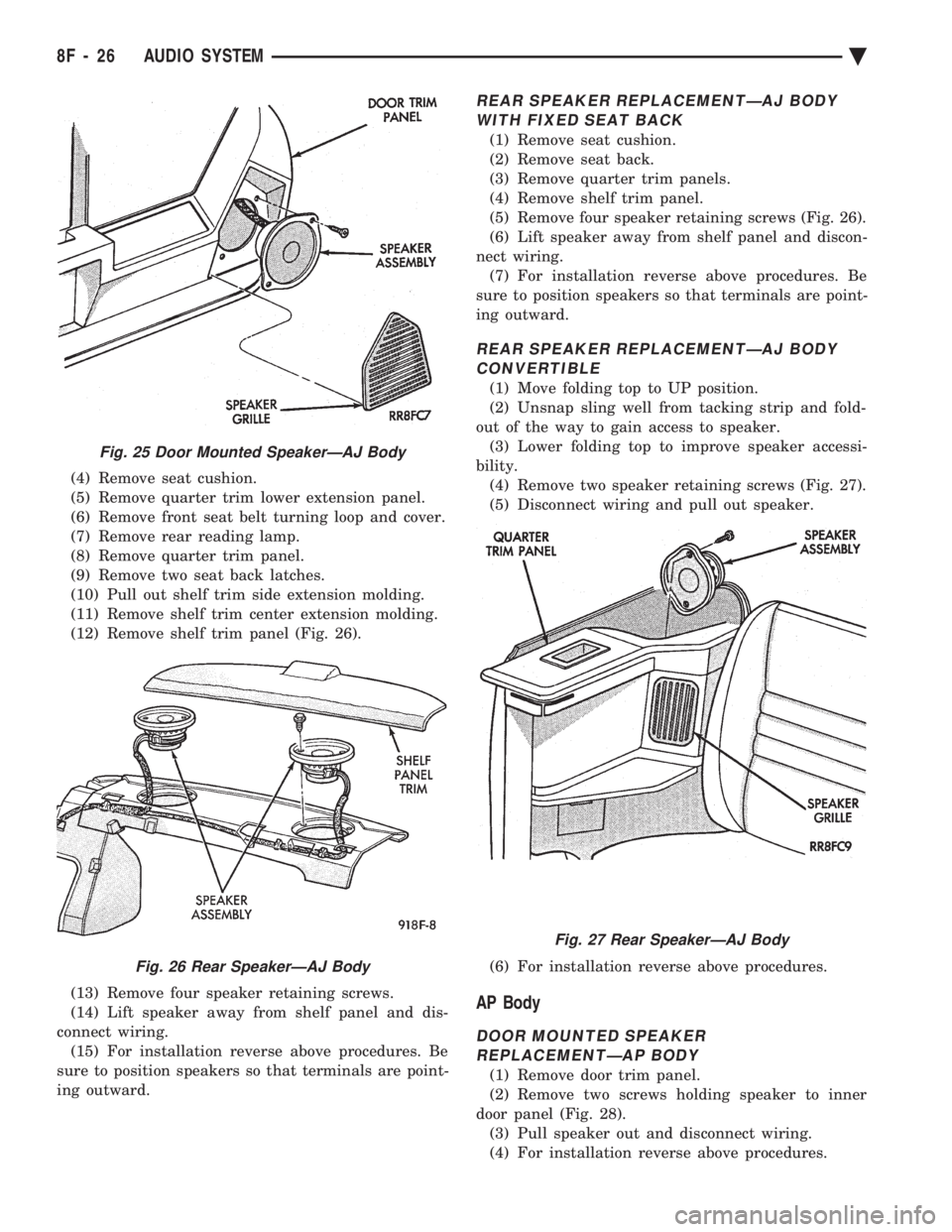

(4) Remove seat cushion.

(5) Remove quarter trim lower extension panel.

(6) Remove front seat belt turning loop and cover.

(7) Remove rear reading lamp.

(8) Remove quarter trim panel.

(9) Remove two seat back latches.

(10) Pull out shelf trim side extension molding.

(11) Remove shelf trim center extension molding.

(12) Remove shelf trim panel (Fig. 26).

(13) Remove four speaker retaining screws.

(14) Lift speaker away from shelf panel and dis-

connect wiring. (15) For installation reverse above procedures. Be

sure to position speakers so that terminals are point-

ing outward.

REAR SPEAKER REPLACEMENTÐAJ BODY WITH FIXED SEAT BACK

(1) Remove seat cushion.

(2) Remove seat back.

(3) Remove quarter trim panels.

(4) Remove shelf trim panel.

(5) Remove four speaker retaining screws (Fig. 26).

(6) Lift speaker away from shelf panel and discon-

nect wiring. (7) For installation reverse above procedures. Be

sure to position speakers so that terminals are point-

ing outward.

REAR SPEAKER REPLACEMENTÐAJ BODY CONVERTIBLE

(1) Move folding top to UP position.

(2) Unsnap sling well from tacking strip and fold-

out of the way to gain access to speaker. (3) Lower folding top to improve speaker accessi-

bility. (4) Remove two speaker retaining screws (Fig. 27).

(5) Disconnect wiring and pull out speaker.

(6) For installation reverse above procedures.

AP Body

DOOR MOUNTED SPEAKER REPLACEMENTÐAP BODY

(1) Remove door trim panel.

(2) Remove two screws holding speaker to inner

door panel (Fig. 28). (3) Pull speaker out and disconnect wiring.

(4) For installation reverse above procedures.

Fig. 25 Door Mounted SpeakerÐAJ Body

Fig. 26 Rear SpeakerÐAJ Body

Fig. 27 Rear SpeakerÐAJ Body

8F - 26 AUDIO SYSTEM Ä

Page 681 of 2438

AA .............................................................................74

Low Fuel

AA ...........................................................................103

AP ............................................................................161

AC, AY...............................................................PC194

AG, AJ ............................................................5269245

Low Washer Fluid

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Oil Pressure

All .......................................................................PC194

Trunk Open

AA, AC, AY .............................................................74

AP ............................................................................161

AG, AJ ............................................................4437661

Theft Alarm Set

AC, AY....................................................................168

AG, AJ ............................................................4437661

Turn Signal (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Turn Signal (EIC)

AA, AY ..............................................................PC194

Seat Belt (MIC)

AA ...........................................................................103

AC, AG, AJ, AP, AY .......................................PC194

Seat Belt (EIC)

AA, AY ..............................................................PC194

AJ ............................................................................103

DIMMER CONTROLLED LAMPS

Service procedures for most of the lamps in the in-

strument panel, Instrument cluster and switches are

located in Group 8E, Instrument Panel and Gauges. A/C Heater Control

All ..............................................................................37

Automatic Temperature Control

All ....................................................................4437661

Column Gearshift Indicator

AA, AC, AY ...........................................................161

Console Gearshift Indicator

AP ............................................................................194

AA, AG, AJ ............................................................161

Fog Lamp Switch Symbol

AG ......................................................................PC194

Headlamp Dimmer Switch

AG, AJ ......................................................................37

Headlamp Switch Symbol

AC, AY....................................................................161

AG, AJ ......................................................................37

Heater Control

All ............................................................................158

EVIC

AJ...........................................................................ASC

Instrument Cluster (MIC)

All .......................................................................PC194

Instrument Cluster (EIC) AA, AY .....................................................................74

Message Center

AA, AC, AY .............................................................74

AP ............................................................................161

Navigator/Travel Companion

AA, AJ ......................................................................74

Radio

All ..........................................................................ASC

Rear Defogger Switch

Not Serviceable, Replace Switch

Rear Wiper Switch

AG .............................................................................37

Theft Alarm

AC, AY....................................................................161

Top Lift Switch

AJ ....................................................................5268053

Travel Computer

All ..........................................................................ASC

Turbo Gauge

AP ............................................................................161

Windshield Wiper Switch

AG, AJ ......................................................................37

NON-DIMMING LAMPS

Service procedures for most of the lamps in the fol-

lowing list can be found in Group 23, Body. Some

components have lamps that can only be serviced by

a Authorized Service Center (ASC) after the compo-

nent is removed from the vehicle. Contact local

dealer for location of nearest ASC. Ash Receiver

AA .............................................................................74

AC, AP, AY ............................................................161

AG, AJ ......................................................................37

Center Console Rear

AJ ............................................................................906

Cigar Lighter

AA, AP ....................................................................161

Courtesy

AA, AC, AY-S .....................................................214-2

AJ ............................................................................906

AY-P.....................................................................212-2

Dome

ALL ......................................................................211-2

Engine Compartment

All ............................................................................105

Glove Compartment

All ..........................................................................1891

Ignition Lock

All ..............................................................................37

Inside Rear View Mirror

AJ ............................................................................168

Overhead Console

AA ...........................................................................912

AC, AY....................................................................906

AG, AJ, AP .........................................................212-2

Reading Lamp Front

All ............................................................................906

Ä LAMPS 8L - 39

Page 711 of 2438

wing. Refer to Owner Manual supplied with vehicle

for complete instructions for seat operation.

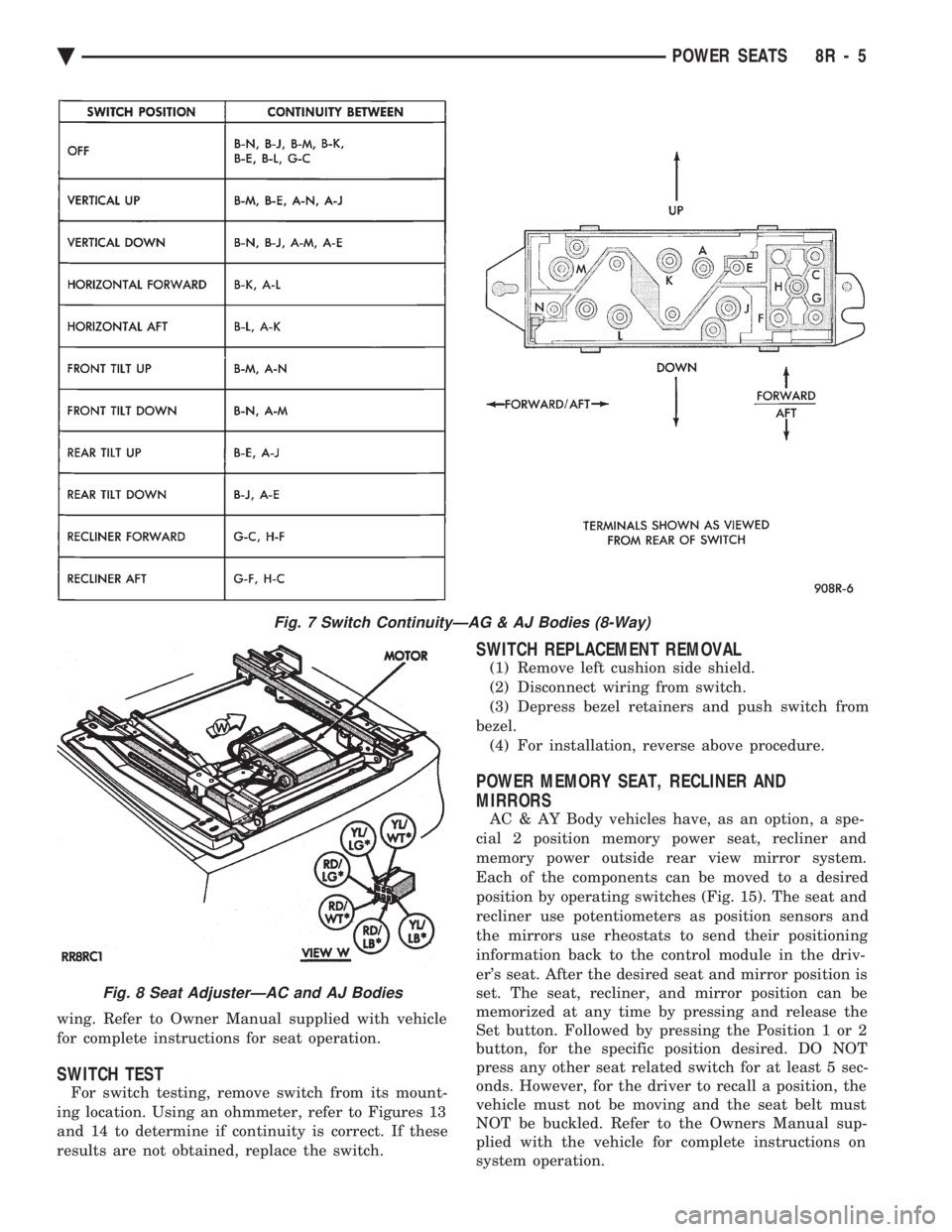

SWITCH TEST

For switch testing, remove switch from its mount-

ing location. Using an ohmmeter, refer to Figures 13

and 14 to determine if continuity is correct. If these

results are not obtained, replace the switch.

SWITCH REPLACEMENT REMOVAL

(1) Remove left cushion side shield.

(2) Disconnect wiring from switch.

(3) Depress bezel retainers and push switch from

bezel. (4) For installation, reverse above procedure.

POWER MEMORY SEAT, RECLINER AND

MIRRORS

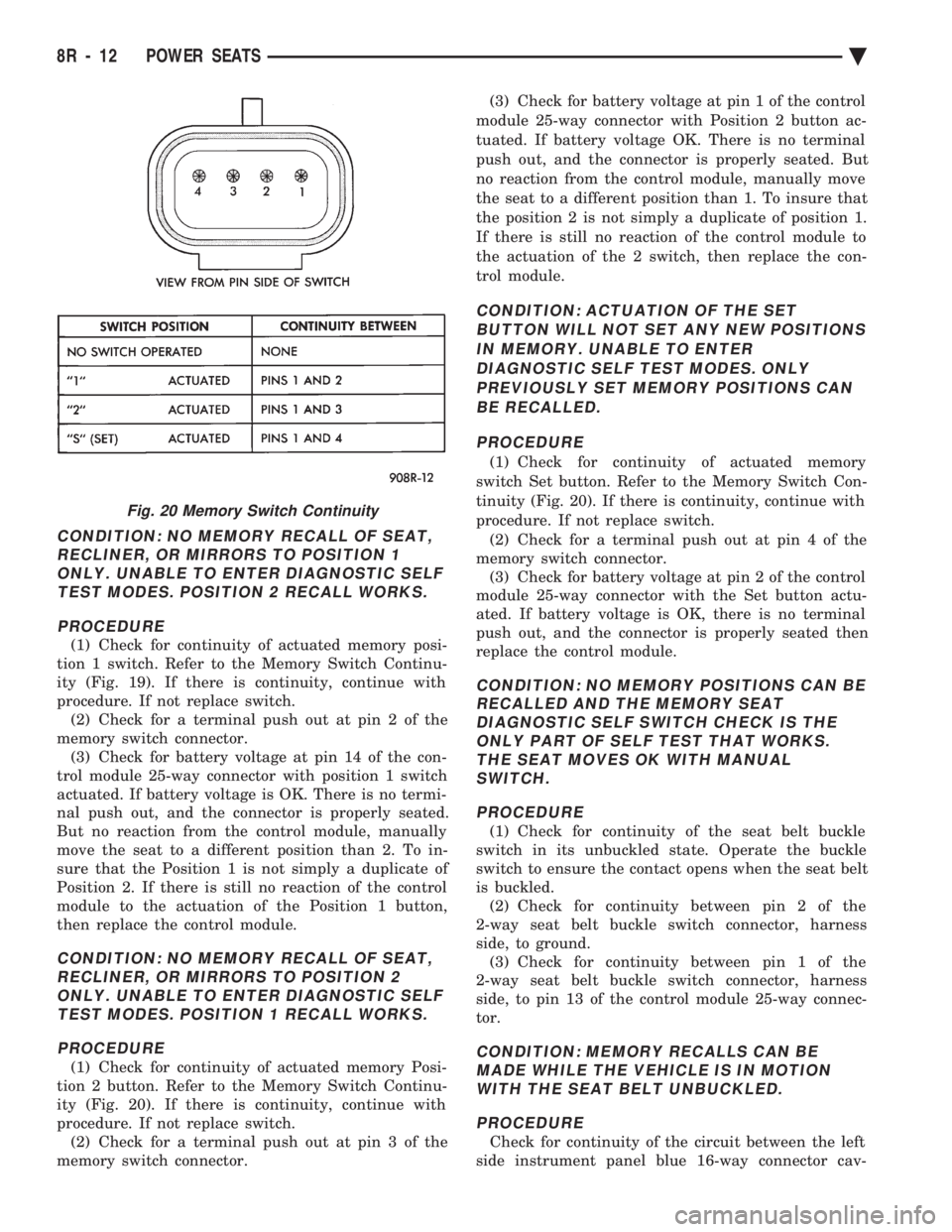

AC & AY Body vehicles have, as an option, a spe-

cial 2 position memory power seat, recliner and

memory power outside rear view mirror system.

Each of the components can be moved to a desired

position by operating switches (Fig. 15). The seat and

recliner use potentiometers as position sensors and

the mirrors use rheostats to send their positioning

information back to the control module in the driv-

er's seat. After the desired seat and mirror position is

set. The seat, recliner, and mirror position can be

memorized at any time by pressing and release the

Set button. Followed by pressing the Position 1 or 2

button, for the specific position desired. DO NOT

press any other seat related switch for at least 5 sec-

onds. However, for the driver to recall a position, the

vehicle must not be moving and the seat belt must

NOT be buckled. Refer to the Owners Manual sup-

plied with the vehicle for complete instructions on

system operation.

Fig. 7 Switch ContinuityÐAG & AJ Bodies (8-Way)

Fig. 8 Seat AdjusterÐAC and AJ Bodies

Ä POWER SEATS 8R - 5

Page 718 of 2438

CONDITION: NO MEMORY RECALL OF SEAT, RECLINER, OR MIRRORS TO POSITION 1ONLY. UNABLE TO ENTER DIAGNOSTIC SELFTEST MODES. POSITION 2 RECALL WORKS.

PROCEDURE

(1) Check for continuity of actuated memory posi-

tion 1 switch. Refer to the Memory Switch Continu-

ity (Fig. 19). If there is continuity, continue with

procedure. If not replace switch. (2) Check for a terminal push out at pin 2 of the

memory switch connector. (3) Check for battery voltage at pin 14 of the con-

trol module 25-way connector with position 1 switch

actuated. If battery voltage is OK. There is no termi-

nal push out, and the connector is properly seated.

But no reaction from the control module, manually

move the seat to a different position than 2. To in-

sure that the Position 1 is not simply a duplicate of

Position 2. If there is still no reaction of the control

module to the actuation of the Position 1 button,

then replace the control module.

CONDITION: NO MEMORY RECALL OF SEAT, RECLINER, OR MIRRORS TO POSITION 2ONLY. UNABLE TO ENTER DIAGNOSTIC SELFTEST MODES. POSITION 1 RECALL WORKS.

PROCEDURE

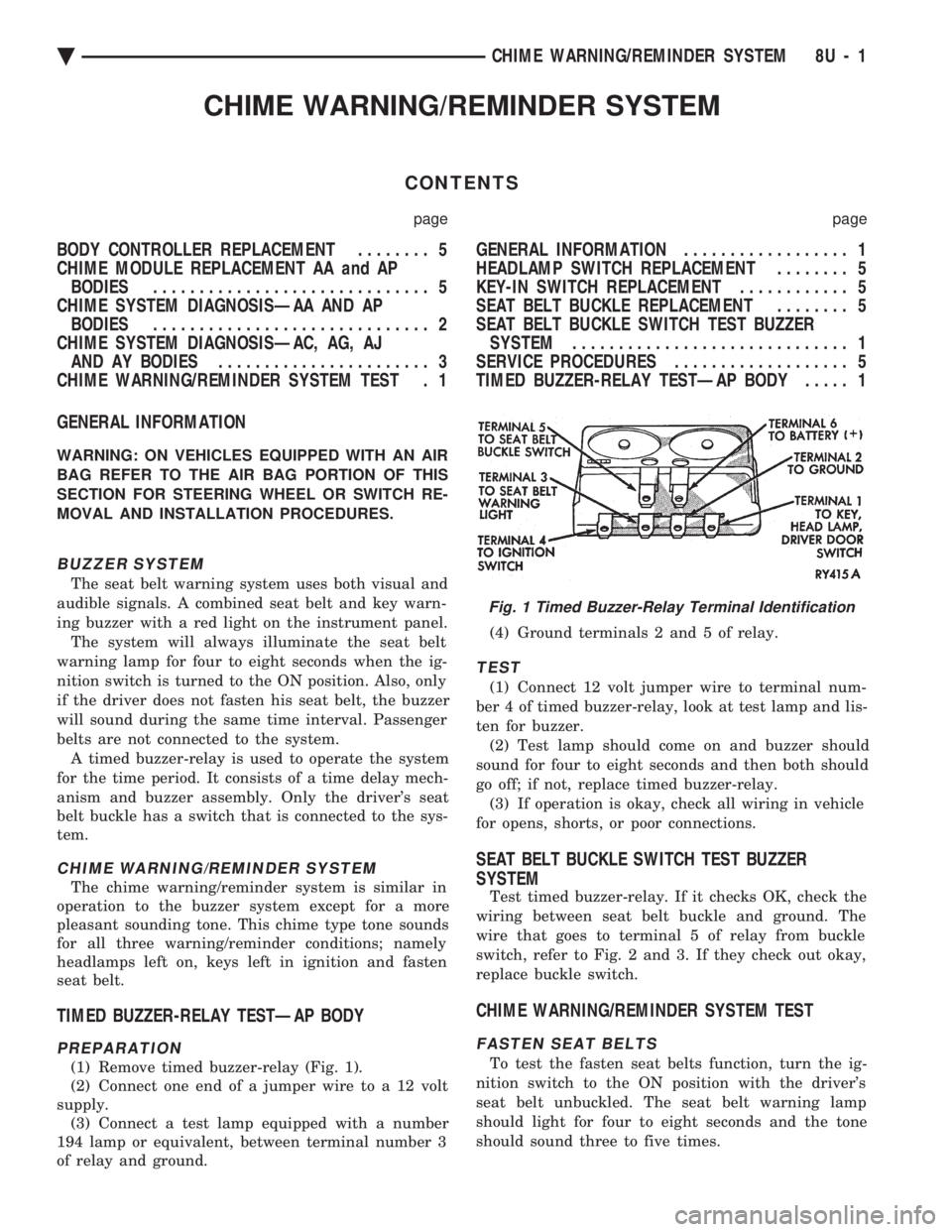

(1) Check for continuity of actuated memory Posi-

tion 2 button. Refer to the Memory Switch Continu-

ity (Fig. 20). If there is continuity, continue with

procedure. If not replace switch. (2) Check for a terminal push out at pin 3 of the

memory switch connector. (3) Check for battery voltage at pin 1 of the control

module 25-way connector with Position 2 button ac-

tuated. If battery voltage OK. There is no terminal

push out, and the connector is properly seated. But

no reaction from the control module, manually move

the seat to a different position than 1. To insure that

the position 2 is not simply a duplicate of position 1.

If there is still no reaction of the control module to

the actuation of the 2 switch, then replace the con-

trol module.

CONDITION: ACTUATION OF THE SET BUTTON WILL NOT SET ANY NEW POSITIONSIN MEMORY. UNABLE TO ENTERDIAGNOSTIC SELF TEST MODES. ONLYPREVIOUSLY SET MEMORY POSITIONS CANBE RECALLED.

PROCEDURE

(1) Check for continuity of actuated memory

switch Set button. Refer to the Memory Switch Con-

tinuity (Fig. 20). If there is continuity, continue with

procedure. If not replace switch. (2) Check for a terminal push out at pin 4 of the

memory switch connector. (3) Check for battery voltage at pin 2 of the control

module 25-way connector with the Set button actu-

ated. If battery voltage is OK, there is no terminal

push out, and the connector is properly seated then

replace the control module.

CONDITION: NO MEMORY POSITIONS CAN BE RECALLED AND THE MEMORY SEATDIAGNOSTIC SELF SWITCH CHECK IS THEONLY PART OF SELF TEST THAT WORKS.THE SEAT MOVES OK WITH MANUALSWITCH.

PROCEDURE

(1) Check for continuity of the seat belt buckle

switch in its unbuckled state. Operate the buckle

switch to ensure the contact opens when the seat belt

is buckled. (2) Check for continuity between pin 2 of the

2-way seat belt buckle switch connector, harness

side, to ground. (3) Check for continuity between pin 1 of the

2-way seat belt buckle switch connector, harness

side, to pin 13 of the control module 25-way connec-

tor.

CONDITION: MEMORY RECALLS CAN BE MADE WHILE THE VEHICLE IS IN MOTIONWITH THE SEAT BELT UNBUCKLED.

PROCEDURE

Check for continuity of the circuit between the left

side instrument panel blue 16-way connector cav-

Fig. 20 Memory Switch Continuity

8R - 12 POWER SEATS Ä

Page 745 of 2438

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

BODY CONTROLLER REPLACEMENT ........ 5

CHIME MODULE REPLACEMENT AA and AP BODIES .............................. 5

CHIME SYSTEM DIAGNOSISÐAA AND AP BODIES .............................. 2

CHIME SYSTEM DIAGNOSISÐAC, AG, AJ AND AY BODIES ....................... 3

CHIME WARNING/REMINDER SYSTEM TEST . 1 GENERAL INFORMATION

.................. 1

HEADLAMP SWITCH REPLACEMENT ........ 5

KEY-IN SWITCH REPLACEMENT ............ 5

SEAT BELT BUCKLE REPLACEMENT ........ 5

SEAT BELT BUCKLE SWITCH TEST BUZZER SYSTEM .............................. 1

SERVICE PROCEDURES ................... 5

TIMED BUZZER-RELAY TESTÐAP BODY ..... 1

GENERAL INFORMATION

WARNING: ON VEHICLES EQUIPPED WITH AN AIR

BAG REFER TO THE AIR BAG PORTION OF THIS

SECTION FOR STEERING WHEEL OR SWITCH RE-

MOVAL AND INSTALLATION PROCEDURES.

BUZZER SYSTEM

The seat belt warning system uses both visual and

audible signals. A combined seat belt and key warn-

ing buzzer with a red light on the instrument panel. The system will always illuminate the seat belt

warning lamp for four to eight seconds when the ig-

nition switch is turned to the ON position. Also, only

if the driver does not fasten his seat belt, the buzzer

will sound during the same time interval. Passenger

belts are not connected to the system. A timed buzzer-relay is used to operate the system

for the time period. It consists of a time delay mech-

anism and buzzer assembly. Only the driver's seat

belt buckle has a switch that is connected to the sys-

tem.

CHIME WARNING/REMINDER SYSTEM

The chime warning/reminder system is similar in

operation to the buzzer system except for a more

pleasant sounding tone. This chime type tone sounds

for all three warning/reminder conditions; namely

headlamps left on, keys left in ignition and fasten

seat belt.

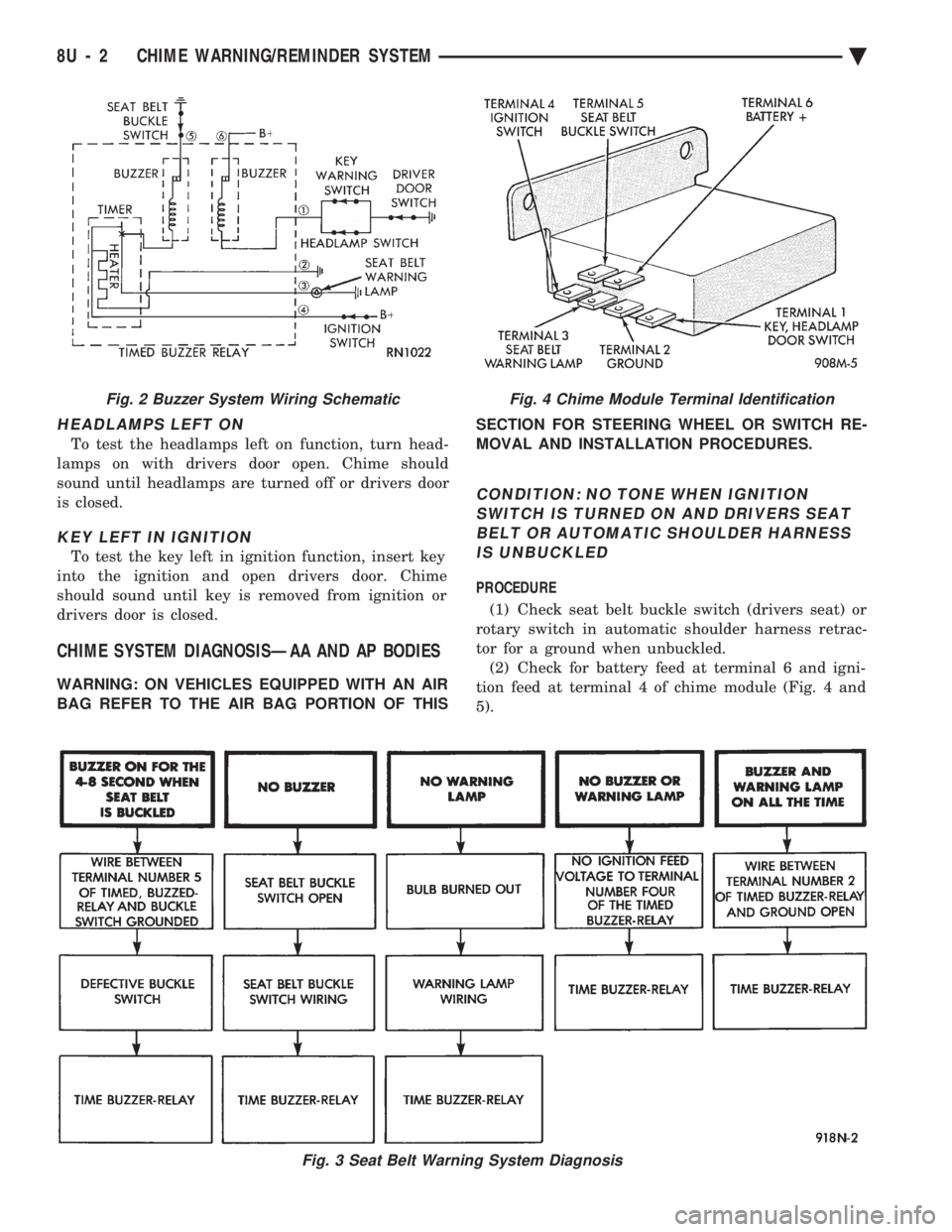

TIMED BUZZER-RELAY TESTÐAP BODY

PREPARATION

(1) Remove timed buzzer-relay (Fig. 1).

(2) Connect one end of a jumper wire to a 12 volt

supply. (3) Connect a test lamp equipped with a number

194 lamp or equivalent, between terminal number 3

of relay and ground. (4) Ground terminals 2 and 5 of relay.

TEST

(1) Connect 12 volt jumper wire to terminal num-

ber 4 of timed buzzer-relay, look at test lamp and lis-

ten for buzzer. (2) Test lamp should come on and buzzer should

sound for four to eight seconds and then both should

go off; if not, replace timed buzzer-relay. (3) If operation is okay, check all wiring in vehicle

for opens, shorts, or poor connections.

SEAT BELT BUCKLE SWITCH TEST BUZZER

SYSTEM

Test timed buzzer-relay. If it checks OK, check the

wiring between seat belt buckle and ground. The

wire that goes to terminal 5 of relay from buckle

switch, refer to Fig. 2 and 3. If they check out okay,

replace buckle switch.

CHIME WARNING/REMINDER SYSTEM TEST

FASTEN SEAT BELTS

To test the fasten seat belts function, turn the ig-

nition switch to the ON position with the driver's

seat belt unbuckled. The seat belt warning lamp

should light for four to eight seconds and the tone

should sound three to five times.

Fig. 1 Timed Buzzer-Relay Terminal Identification

Ä CHIME WARNING/REMINDER SYSTEM 8U - 1

Page 746 of 2438

HEADLAMPS LEFT ON

To test the headlamps left on function, turn head-

lamps on with drivers door open. Chime should

sound until headlamps are turned off or drivers door

is closed.

KEY LEFT IN IGNITION

To test the key left in ignition function, insert key

into the ignition and open drivers door. Chime

should sound until key is removed from ignition or

drivers door is closed.

CHIME SYSTEM DIAGNOSISÐAA AND AP BODIES

WARNING: ON VEHICLES EQUIPPED WITH AN AIR

BAG REFER TO THE AIR BAG PORTION OF THIS SECTION FOR STEERING WHEEL OR SWITCH RE-

MOVAL AND INSTALLATION PROCEDURES.

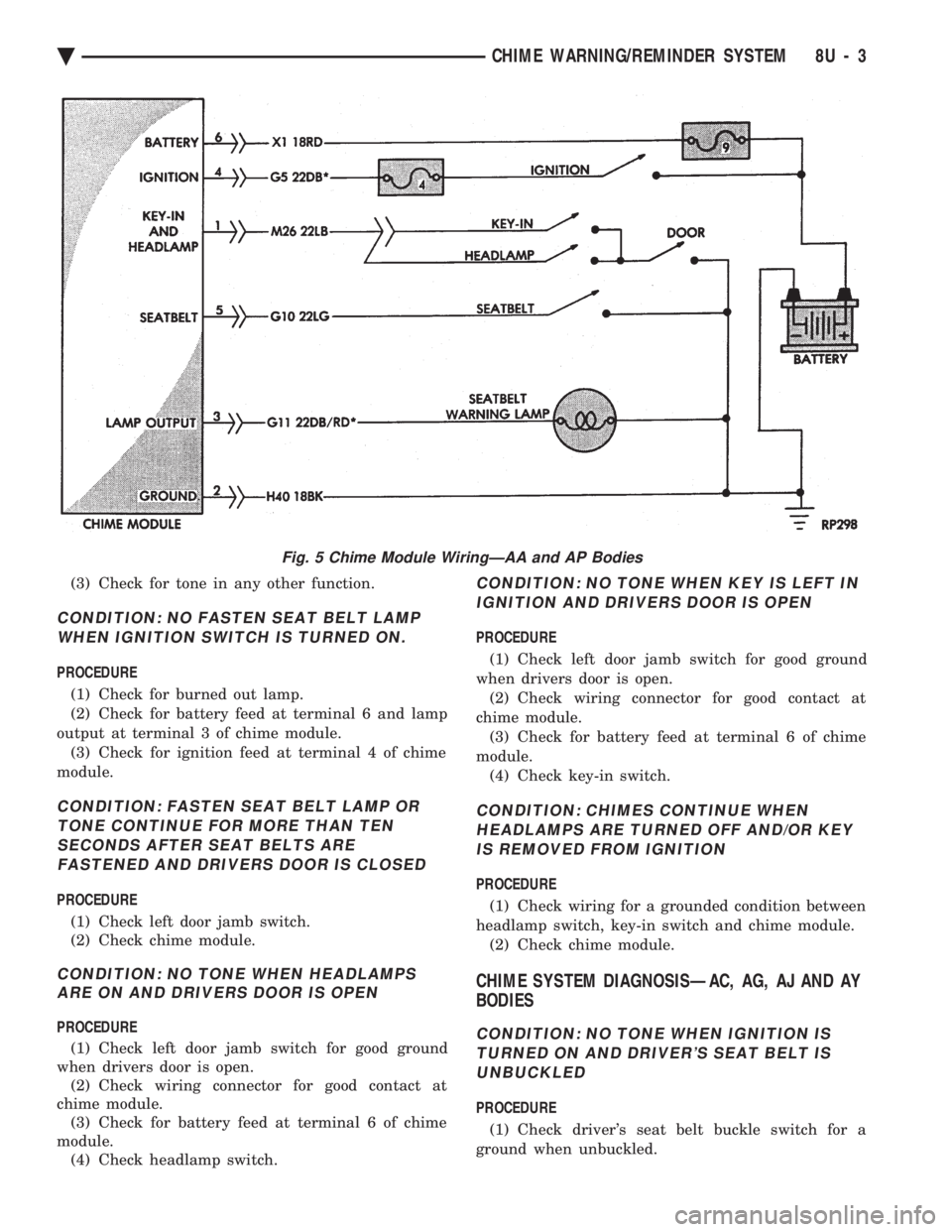

CONDITION: NO TONE WHEN IGNITION

SWITCH IS TURNED ON AND DRIVERS SEATBELT OR AUTOMATIC SHOULDER HARNESSIS UNBUCKLED

PROCEDURE

(1) Check seat belt buckle switch (drivers seat) or

rotary switch in automatic shoulder harness retrac-

tor for a ground when unbuckled. (2) Check for battery feed at terminal 6 and igni-

tion feed at terminal 4 of chime module (Fig. 4 and

5).

Fig. 3 Seat Belt Warning System Diagnosis

Fig. 4 Chime Module Terminal IdentificationFig. 2 Buzzer System Wiring Schematic

8U - 2 CHIME WARNING/REMINDER SYSTEM Ä

Page 747 of 2438

(3) Check for tone in any other function.

CONDITION: NO FASTEN SEAT BELT LAMP WHEN IGNITION SWITCH IS TURNED ON.

PROCEDURE

(1) Check for burned out lamp.

(2) Check for battery feed at terminal 6 and lamp

output at terminal 3 of chime module. (3) Check for ignition feed at terminal 4 of chime

module.

CONDITION: FASTEN SEAT BELT LAMP OR TONE CONTINUE FOR MORE THAN TENSECONDS AFTER SEAT BELTS AREFASTENED AND DRIVERS DOOR IS CLOSED

PROCEDURE

(1) Check left door jamb switch.

(2) Check chime module.

CONDITION: NO TONE WHEN HEADLAMPS ARE ON AND DRIVERS DOOR IS OPEN

PROCEDURE

(1) Check left door jamb switch for good ground

when drivers door is open. (2) Check wiring connector for good contact at

chime module. (3) Check for battery feed at terminal 6 of chime

module. (4) Check headlamp switch.

CONDITION: NO TONE WHEN KEY IS LEFT IN

IGNITION AND DRIVERS DOOR IS OPEN

PROCEDURE

(1) Check left door jamb switch for good ground

when drivers door is open. (2) Check wiring connector for good contact at

chime module. (3) Check for battery feed at terminal 6 of chime

module. (4) Check key-in switch.

CONDITION: CHIMES CONTINUE WHENHEADLAMPS ARE TURNED OFF AND/OR KEYIS REMOVED FROM IGNITION

PROCEDURE

(1) Check wiring for a grounded condition between

headlamp switch, key-in switch and chime module. (2) Check chime module.

CHIME SYSTEM DIAGNOSISÐAC, AG, AJ AND AY

BODIES

CONDITION: NO TONE WHEN IGNITION IS

TURNED ON AND DRIVER'S SEAT BELT ISUNBUCKLED

PROCEDURE

(1) Check driver's seat belt buckle switch for a

ground when unbuckled.

Fig. 5 Chime Module WiringÐAA and AP Bodies

Ä CHIME WARNING/REMINDER SYSTEM 8U - 3

Page 748 of 2438

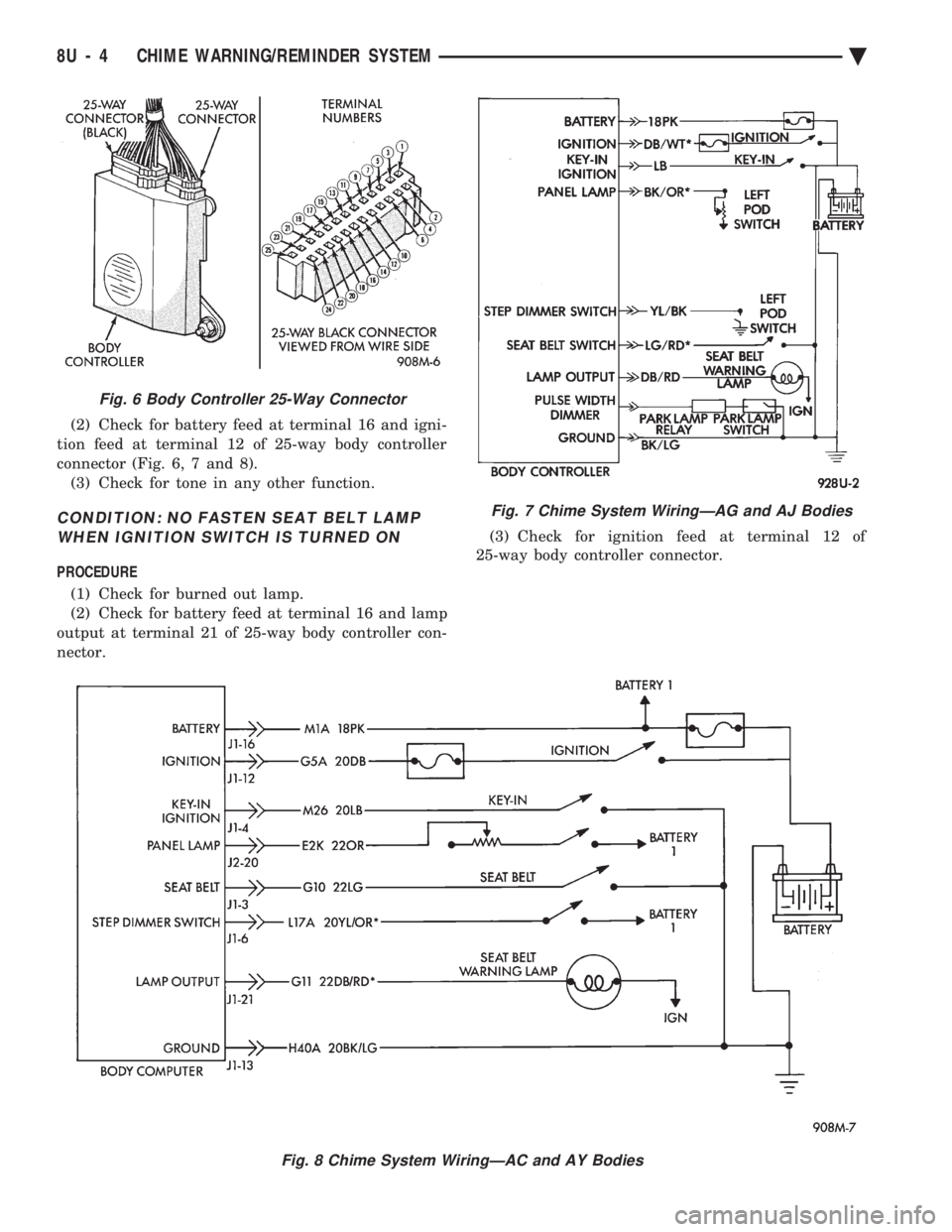

(2) Check for battery feed at terminal 16 and igni-

tion feed at terminal 12 of 25-way body controller

connector (Fig. 6, 7 and 8). (3) Check for tone in any other function.

CONDITION: NO FASTEN SEAT BELT LAMPWHEN IGNITION SWITCH IS TURNED ON

PROCEDURE

(1) Check for burned out lamp.

(2) Check for battery feed at terminal 16 and lamp

output at terminal 21 of 25-way body controller con-

nector. (3) Check for ignition feed at terminal 12 of

25-way body controller connector.

Fig. 6 Body Controller 25-Way Connector

Fig. 7 Chime System WiringÐAG and AJ Bodies

Fig. 8 Chime System WiringÐAC and AY Bodies

8U - 4 CHIME WARNING/REMINDER SYSTEM Ä