belt CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 366 of 2438

ACCESSORY DRIVE BELTS INDEX

page page

2.2/2.5L Engine Belts Remove/Install-Adjust .... 24

3.0L Engine Belts Remove/Install and Adjust .... 25

3.3/3.8L and Turbo III Engine Accessory Drive Belt Remove and Install

..................... 26

General Information ....................... 24

GENERAL INFORMATION

PROPER BELT TENSION

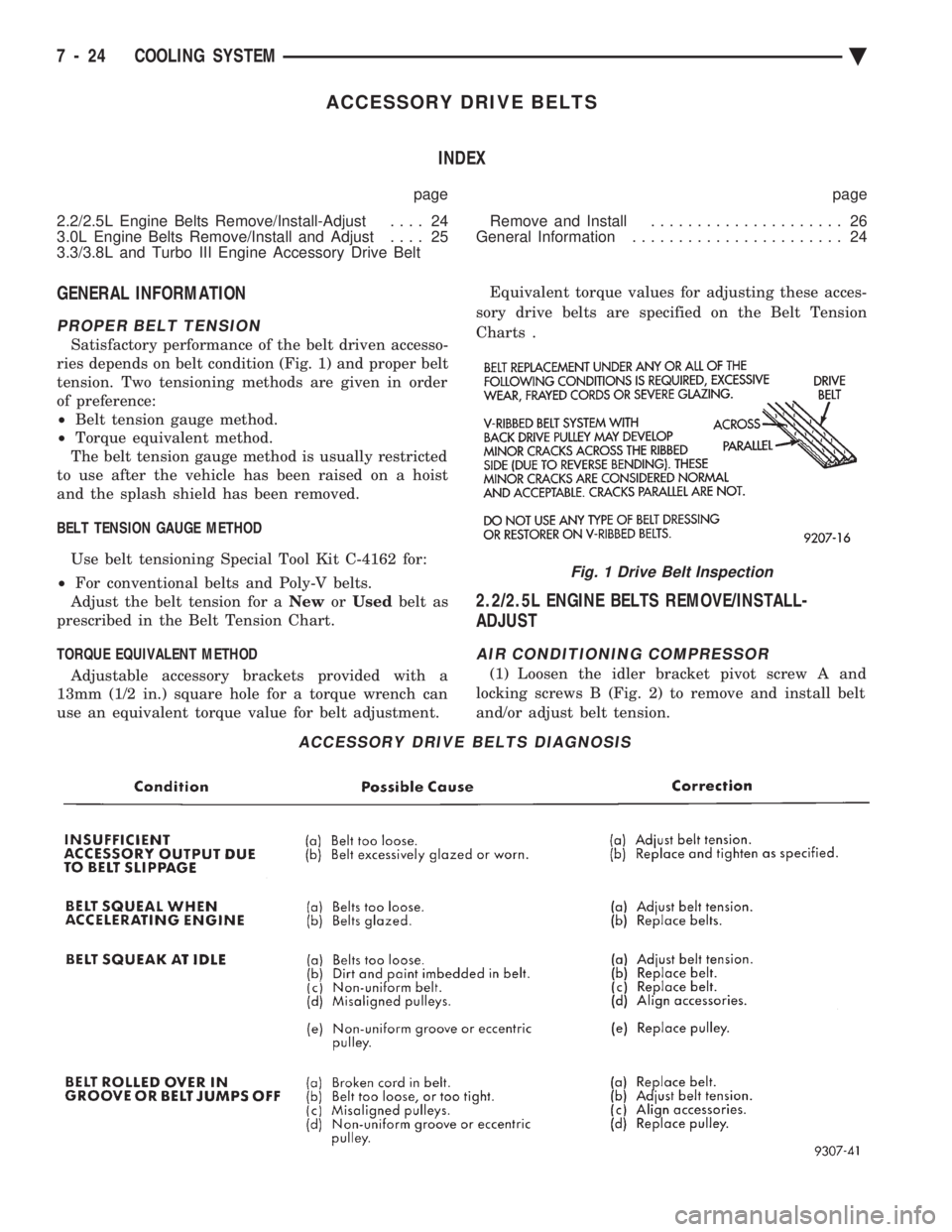

Satisfactory performance of the belt driven accesso-

ries depends on belt condition (Fig. 1) and proper belt

tension. Two tensioning methods are given in order

of preference:

² Belt tension gauge method.

² Torque equivalent method.

The belt tension gauge method is usually restricted

to use after the vehicle has been raised on a hoist

and the splash shield has been removed.

BELT TENSION GAUGE METHOD Use belt tensioning Special Tool Kit C-4162 for:

² For conventional belts and Poly-V belts.

Adjust the belt tension for a NeworUsed belt as

prescribed in the Belt Tension Chart.

TORQUE EQUIVALENT METHOD Adjustable accessory brackets provided with a

13mm (1/2 in.) square hole for a torque wrench can

use an equivalent torque value for belt adjustment. Equivalent torque values for adjusting these acces-

sory drive belts are specified on the Belt Tension

Charts .

2.2/2.5L ENGINE BELTS REMOVE/INSTALL-

ADJUST

AIR CONDITIONING COMPRESSOR

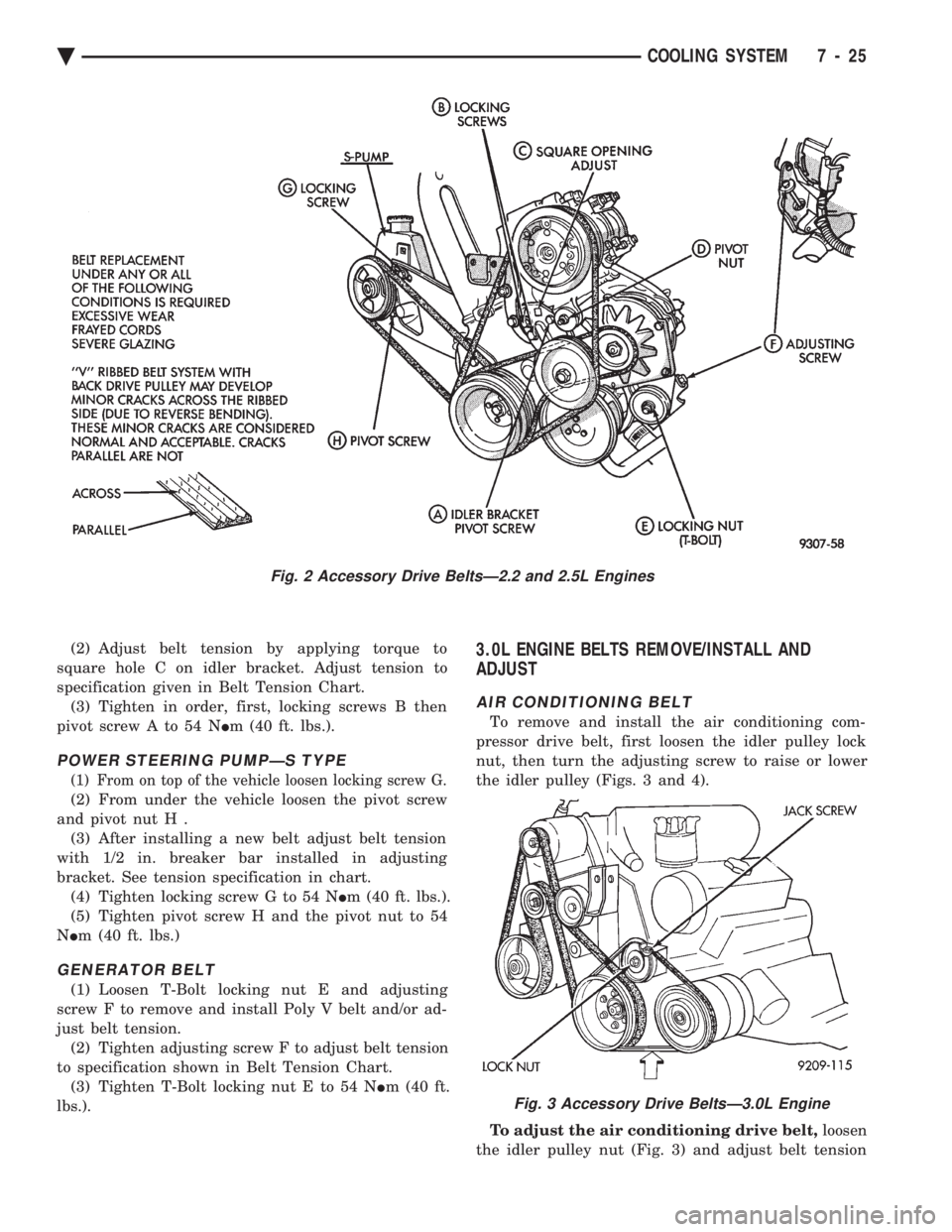

(1) Loosen the idler bracket pivot screw A and

locking screws B (Fig. 2) to remove and install belt

and/or adjust belt tension.

ACCESSORY DRIVE BELTS DIAGNOSIS

Fig. 1 Drive Belt Inspection

7 - 24 COOLING SYSTEM Ä

Page 367 of 2438

(2) Adjust belt tension by applying torque to

square hole C on idler bracket. Adjust tension to

specification given in Belt Tension Chart. (3) Tighten in order, first, locking screws B then

pivot screw A to 54 N Im (40 ft. lbs.).

POWER STEERING PUMPÐS TYPE

(1) From on top of the vehicle loosen locking screw G.

(2) From under the vehicle loosen the pivot screw

and pivot nut H . (3) After installing a new belt adjust belt tension

with 1/2 in. breaker bar installed in adjusting

bracket. See tension specification in chart. (4) Tighten locking screw G to 54 N Im (40 ft. lbs.).

(5) Tighten pivot screw H and the pivot nut to 54

N Im (40 ft. lbs.)

GENERATOR BELT

(1) Loosen T-Bolt locking nut E and adjusting

screw F to remove and install Poly V belt and/or ad-

just belt tension. (2) Tighten adjusting screw F to adjust belt tension

to specification shown in Belt Tension Chart. (3) Tighten T-Bolt locking nut E to 54 N Im (40 ft.

lbs.).

3.0L ENGINE BELTS REMOVE/INSTALL AND

ADJUST

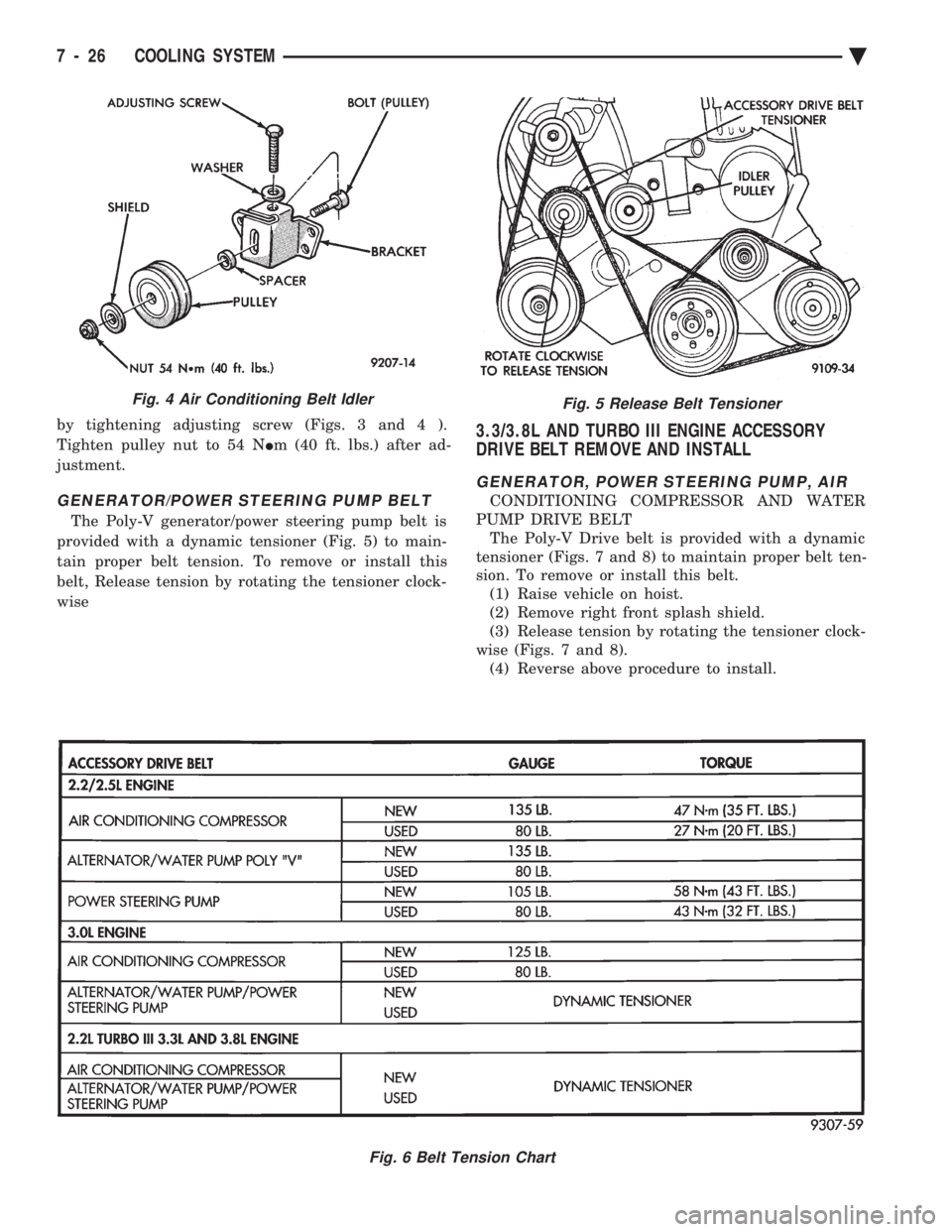

AIR CONDITIONING BELT

To remove and install the air conditioning com-

pressor drive belt, first loosen the idler pulley lock

nut, then turn the adjusting screw to raise or lower

the idler pulley (Figs. 3 and 4).

To adjust the air conditioning drive belt, loosen

the idler pulley nut (Fig. 3) and adjust belt tension

Fig. 2 Accessory Drive BeltsÐ2.2 and 2.5L Engines

Fig. 3 Accessory Drive BeltsÐ3.0L Engine

Ä COOLING SYSTEM 7 - 25

Page 368 of 2438

by tightening adjusting screw (Figs. 3 and 4 ).

Tighten pulley nut to 54 N Im (40 ft. lbs.) after ad-

justment.

GENERATOR/POWER STEERING PUMP BELT

The Poly-V generator/power steering pump belt is

provided with a dynamic tensioner (Fig. 5) to main-

tain proper belt tension. To remove or install this

belt, Release tension by rotating the tensioner clock-

wise

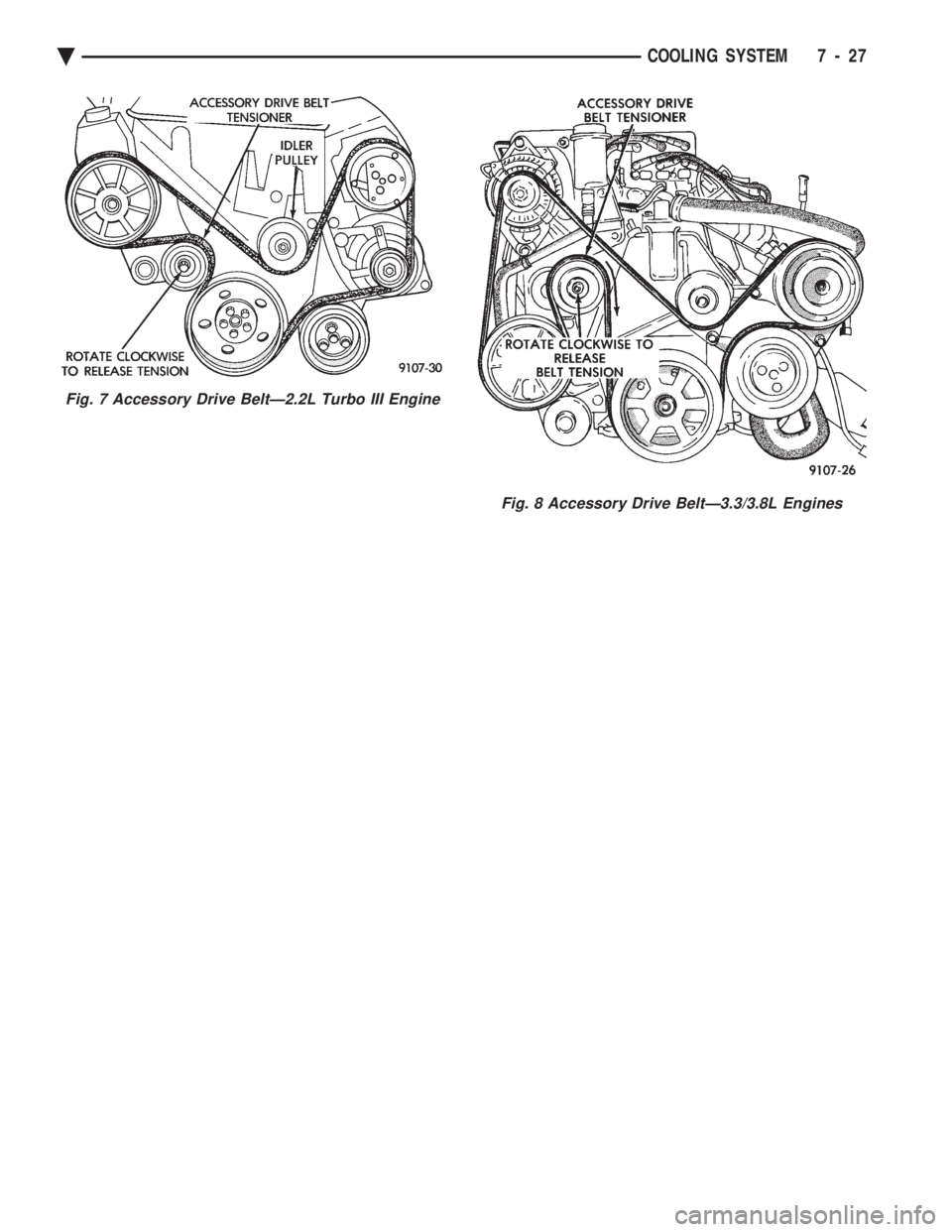

3.3/3.8L AND TURBO III ENGINE ACCESSORY

DRIVE BELT REMOVE AND INSTALL

GENERATOR, POWER STEERING PUMP, AIR

CONDITIONING COMPRESSOR AND WATER

PUMP DRIVE BELT The Poly-V Drive belt is provided with a dynamic

tensioner (Figs. 7 and 8) to maintain proper belt ten-

sion. To remove or install this belt. (1) Raise vehicle on hoist.

(2) Remove right front splash shield.

(3) Release tension by rotating the tensioner clock-

wise (Figs. 7 and 8). (4) Reverse above procedure to install.

Fig. 5 Release Belt Tensioner

Fig. 6 Belt Tension Chart

Fig. 4 Air Conditioning Belt Idler

7 - 26 COOLING SYSTEM Ä

Page 369 of 2438

Fig. 7 Accessory Drive BeltÐ2.2L Turbo III Engine

Fig. 8 Accessory Drive BeltÐ3.3/3.8L Engines

Ä COOLING SYSTEM 7 - 27

Page 376 of 2438

It is important when using the Test Indicator that

the battery be level and have a clean top to see the

correct indications. A light may be required to view

the Indicator.

WARNING: DO NOT USE OPEN FLAME NEAR BAT-

TERY BECAUSE OF EXPLOSIVE GASES AT FORM

ABOVE BATTERY.

STATE OF CHARGE TESTS

USING TEST INDICATOR

The built in test hydrometer (Figs. 3, 4 and 5) mea-

sures the specific gravity of the electrolyte. Specific

Gravity (SG) of the electrolyte will show state of

charge voltage. The test indicator WILL NOT show

cranking capacity of the battery. Refer to Battery

Load. Look into the sight glass (Figs. 4 and 5) and

note the color of the indicator (Fig. 5). Refer to the

following description of colors:

² GREEN = 75 to 100 degree state of charge

The battery is adequately charged for further test-

ing and may be returned to use. If the vehicle will

not crank for a maximum 15 seconds, refer to Bat-

tery Load Test in this Group for more information.

² BLACK OR DAR K=0to75degree state of

charge The battery is INADEQUATELY charged and

must be charged until green dot is visible, (12.4 volts

or greater) before the battery is tested or returned to

use. Refer to Causes of Battery Discharging.

² YELLOW OR BRIGHT COLOR = Battery must

be replace

WARNING: DO NOT CHARGE, ASSIST BOOST,

LOAD TEST, OR ADD WATER TO THE BATTERY

WHEN YELLOW OR BRIGHT COLOR DOT IS VISI-

BLE. PERSONAL INJURY MAY OCCUR.

A yellow or bright color dot shows electrolyte level

in battery is below the test indicator (Fig. 5). Water

cannot be added to a maintenance free battery. The

battery must be replaced. A low electrolyte level may

be caused by an over charging condition. Refer to

Generator Test Procedures on Vehicle.

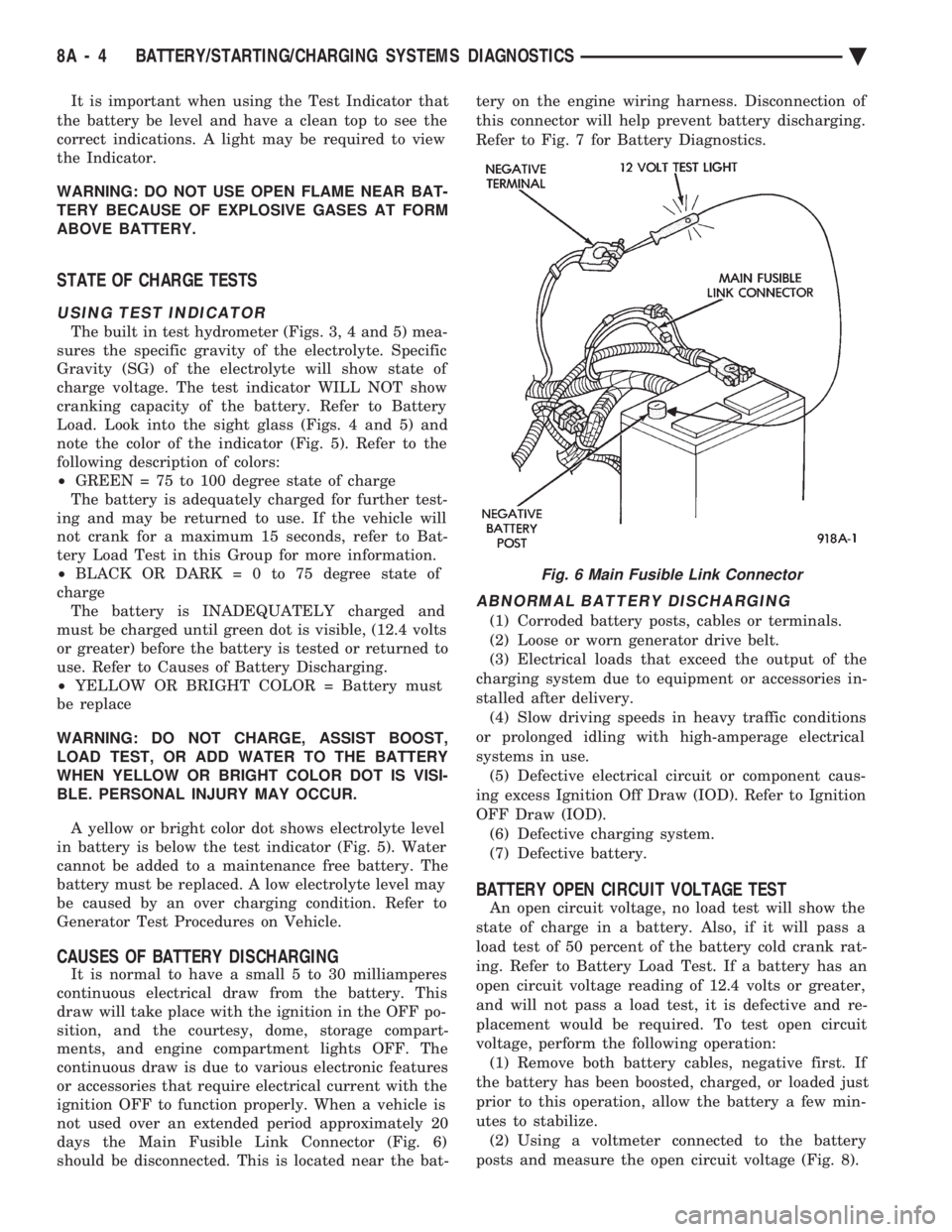

CAUSES OF BATTERY DISCHARGING

It is normal to have a small 5 to 30 milliamperes

continuous electrical draw from the battery. This

draw will take place with the ignition in the OFF po-

sition, and the courtesy, dome, storage compart-

ments, and engine compartment lights OFF. The

continuous draw is due to various electronic features

or accessories that require electrical current with the

ignition OFF to function properly. When a vehicle is

not used over an extended period approximately 20

days the Main Fusible Link Connector (Fig. 6)

should be disconnected. This is located near the bat- tery on the engine wiring harness. Disconnection of

this connector will help prevent battery discharging.

Refer to Fig. 7 for Battery Diagnostics.

ABNORMAL BATTERY DISCHARGING

(1) Corroded battery posts, cables or terminals.

(2) Loose or worn generator drive belt.

(3) Electrical loads that exceed the output of the

charging system due to equipment or accessories in-

stalled after delivery. (4) Slow driving speeds in heavy traffic conditions

or prolonged idling with high-amperage electrical

systems in use. (5) Defective electrical circuit or component caus-

ing excess Ignition Off Draw (IOD). Refer to Ignition

OFF Draw (IOD). (6) Defective charging system.

(7) Defective battery.

BATTERY OPEN CIRCUIT VOLTAGE TEST

An open circuit voltage, no load test will show the

state of charge in a battery. Also, if it will pass a

load test of 50 percent of the battery cold crank rat-

ing. Refer to Battery Load Test. If a battery has an

open circuit voltage reading of 12.4 volts or greater,

and will not pass a load test, it is defective and re-

placement would be required. To test open circuit

voltage, perform the following operation: (1) Remove both battery cables, negative first. If

the battery has been boosted, charged, or loaded just

prior to this operation, allow the battery a few min-

utes to stabilize. (2) Using a voltmeter connected to the battery

posts and measure the open circuit voltage (Fig. 8).

Fig. 6 Main Fusible Link Connector

8A - 4 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS Ä

Page 383 of 2438

STARTER TEST PROCEDURES ON VEHICLE INDEX

page page

Diagnostic Preparation ..................... 11

General Information ....................... 11 Starter Control Circuit Tests

................ 15

Starter Feed Circuit Tests .................. 11

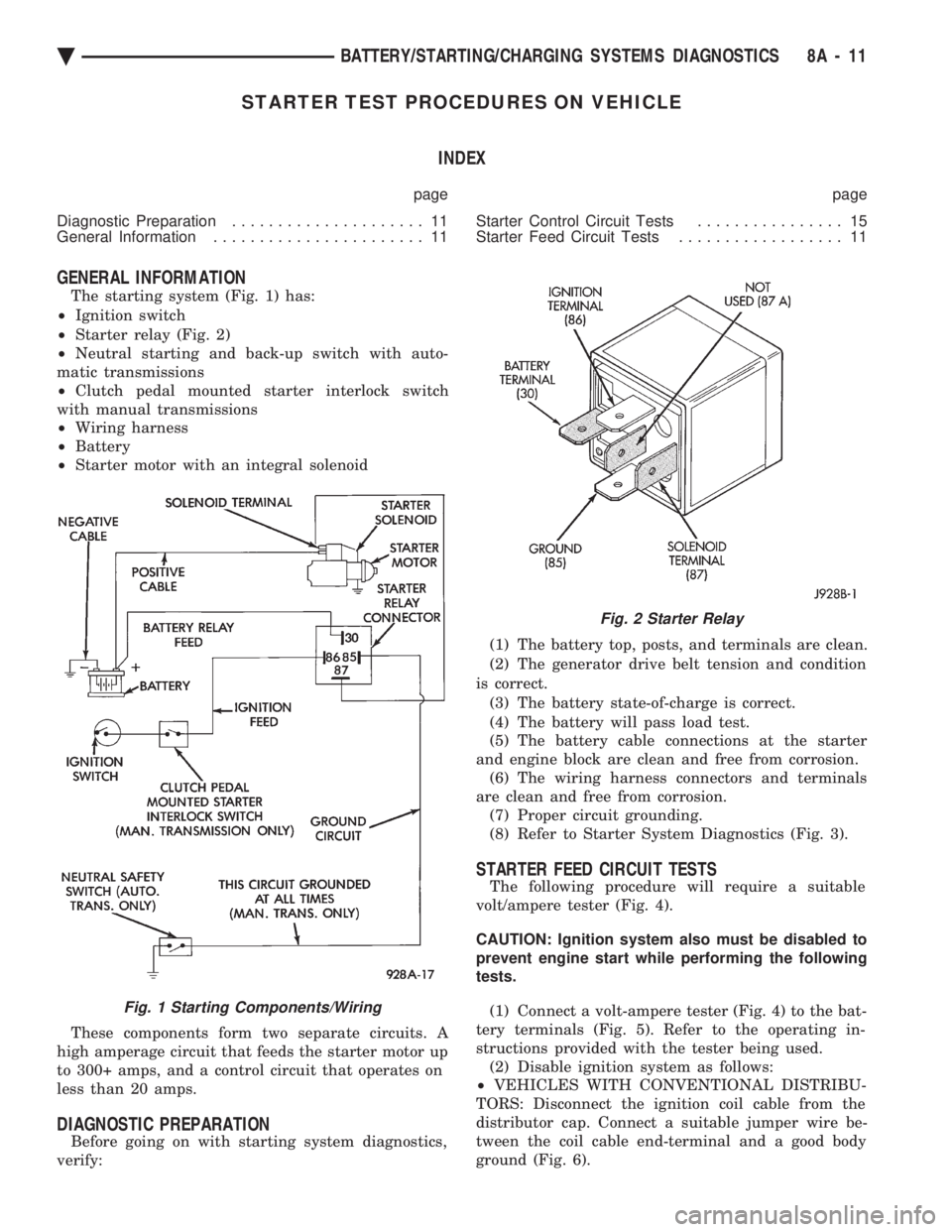

GENERAL INFORMATION

The starting system (Fig. 1) has:

² Ignition switch

² Starter relay (Fig. 2)

² Neutral starting and back-up switch with auto-

matic transmissions

² Clutch pedal mounted starter interlock switch

with manual transmissions

² Wiring harness

² Battery

² Starter motor with an integral solenoid

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

DIAGNOSTIC PREPARATION

Before going on with starting system diagnostics,

verify: (1) The battery top, posts, and terminals are clean.

(2) The generator drive belt tension and condition

is correct. (3) The battery state-of-charge is correct.

(4) The battery will pass load test.

(5) The battery cable connections at the starter

and engine block are clean and free from corrosion. (6) The wiring harness connectors and terminals

are clean and free from corrosion. (7) Proper circuit grounding.

(8) Refer to Starter System Diagnostics (Fig. 3).

STARTER FEED CIRCUIT TESTS

The following procedure will require a suitable

volt/ampere tester (Fig. 4).

CAUTION: Ignition system also must be disabled to

prevent engine start while performing the following

tests.

(1) Connect a volt-ampere tester (Fig. 4) to the bat-

tery terminals (Fig. 5). Refer to the operating in-

structions provided with the tester being used. (2) Disable ignition system as follows:

² VEHICLES WITH CONVENTIONAL DISTRIBU-

TORS: Disconnect the ignition coil cable from the

distributor cap. Connect a suitable jumper wire be-

tween the coil cable end-terminal and a good body

ground (Fig. 6).

Fig. 1 Starting Components/Wiring

Fig. 2 Starter Relay

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 11

Page 411 of 2438

GENERATOR INDEX

page page

General Information ........................ 9

Generator ReplacementÐ2.2L Turbo Engine (With 16 Valve Cylinder Head) ............. 10 Generator ReplacementÐ2.2L/2.5L Engine

...... 9

Generator ReplacementÐ3.0L Engine ......... 10

Generator ReplacementÐ3.3L/3.8L Engine ..... 11

GENERAL INFORMATION

This section will cover generator removal and instal-

lation only. Information covering generator on-vehicle

testing and diagnosis can be found in Group 8A,

Battery/Starting/Charging Systems Diagnostics. To

identify the generator, refer to the Generator Specifi-

cation chart at the rear of this section. These generators are not intended to be disas-

sembled for service. It must be replaced as an

assembly.

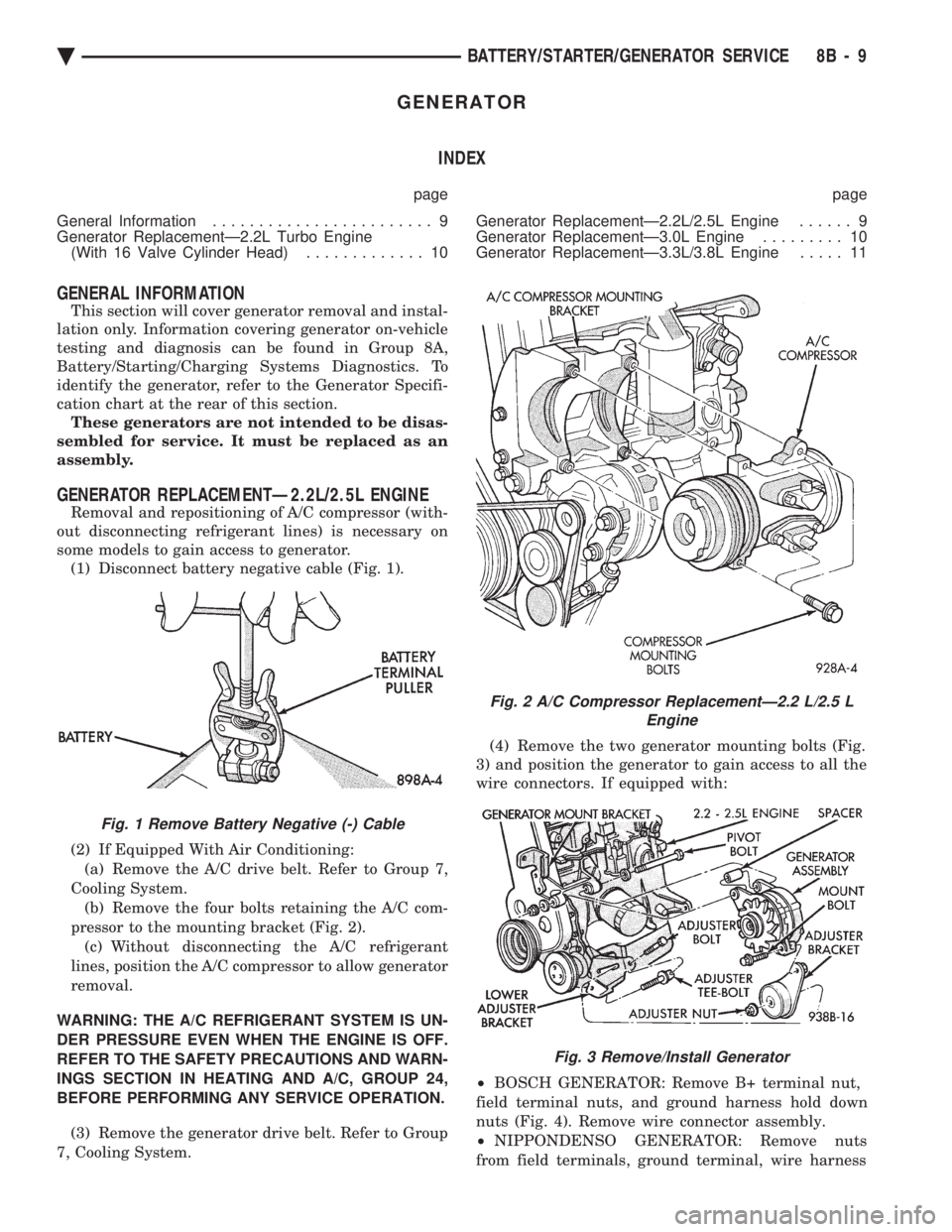

GENERATOR REPLACEMENTÐ2.2L/2.5L ENGINE

Removal and repositioning of A/C compressor (with-

out disconnecting refrigerant lines) is necessary on

some models to gain access to generator. (1) Disconnect battery negative cable (Fig. 1).

(2) If Equipped With Air Conditioning:

(a) Remove the A/C drive belt. Refer to Group 7,

Cooling System. (b) Remove the four bolts retaining the A/C com-

pressor to the mounting bracket (Fig. 2). (c) Without disconnecting the A/C refrigerant

lines, position the A/C compressor to allow generator

removal.

WARNING: THE A/C REFRIGERANT SYSTEM IS UN-

DER PRESSURE EVEN WHEN THE ENGINE IS OFF.

REFER TO THE SAFETY PRECAUTIONS AND WARN-

INGS SECTION IN HEATING AND A/C, GROUP 24,

BEFORE PERFORMING ANY SERVICE OPERATION. (3) Remove the generator drive belt. Refer to Group

7, Cooling System. (4) Remove the two generator mounting bolts (Fig.

3) and position the generator to gain access to all the

wire connectors. If equipped with:

² BOSCH GENERATOR: Remove B+ terminal nut,

field terminal nuts, and ground harness hold down

nuts (Fig. 4). Remove wire connector assembly.

² NIPPONDENSO GENERATOR: Remove nuts

from field terminals, ground terminal, wire harness

Fig. 1 Remove Battery Negative (-) Cable

Fig. 2 A/C Compressor ReplacementÐ2.2 L/2.5 L Engine

Fig. 3 Remove/Install Generator

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 9

Page 412 of 2438

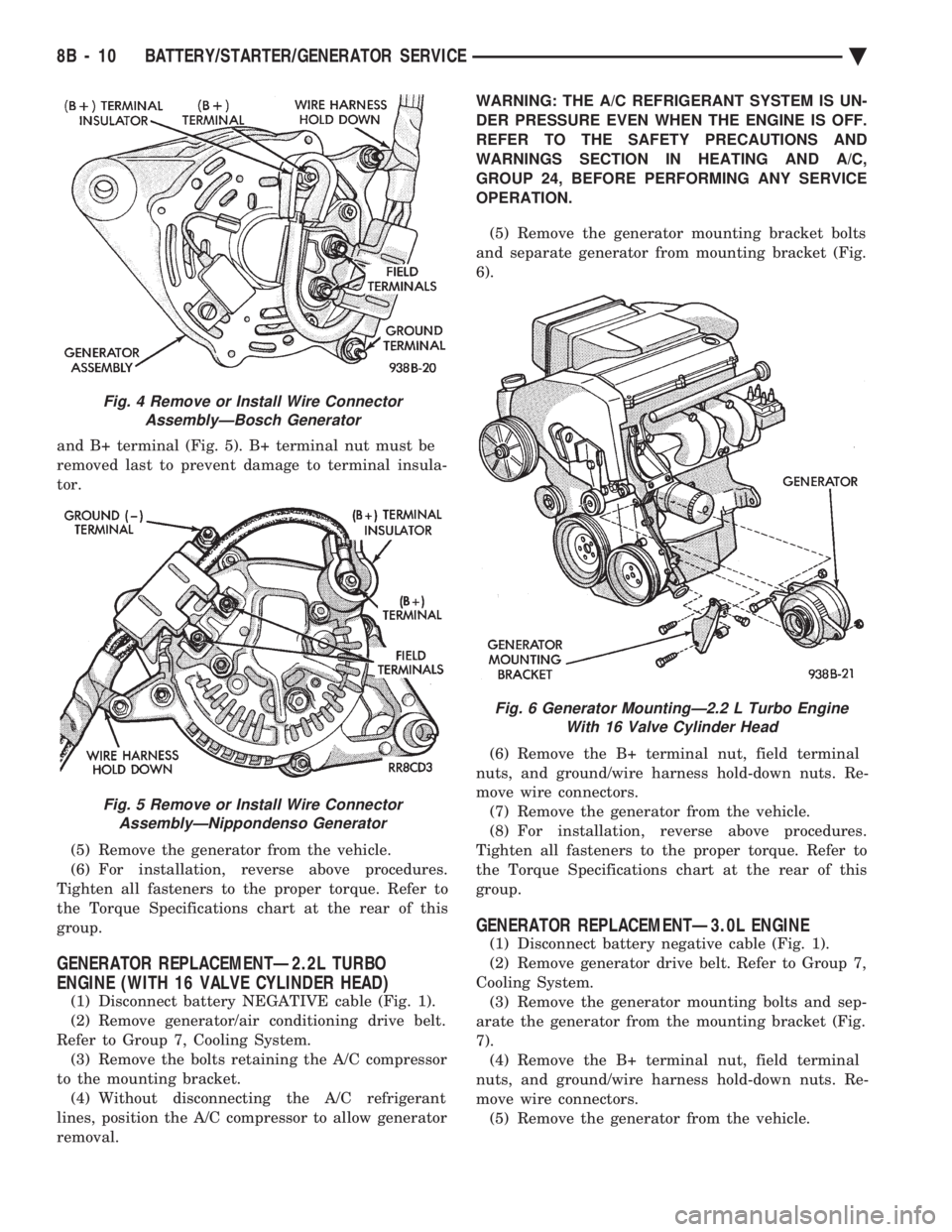

and B+ terminal (Fig. 5). B+ terminal nut must be

removed last to prevent damage to terminal insula-

tor. (5) Remove the generator from the vehicle.

(6) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

GENERATOR REPLACEMENTÐ2.2L TURBO

ENGINE (WITH 16 VALVE CYLINDER HEAD)

(1) Disconnect battery NEGATIVE cable (Fig. 1).

(2) Remove generator/air conditioning drive belt.

Refer to Group 7, Cooling System. (3) Remove the bolts retaining the A/C compressor

to the mounting bracket. (4) Without disconnecting the A/C refrigerant

lines, position the A/C compressor to allow generator

removal. WARNING: THE A/C REFRIGERANT SYSTEM IS UN-

DER PRESSURE EVEN WHEN THE ENGINE IS OFF.

REFER TO THE SAFETY PRECAUTIONS AND

WARNINGS SECTION IN HEATING AND A/C,

GROUP 24, BEFORE PERFORMING ANY SERVICE

OPERATION.

(5) Remove the generator mounting bracket bolts

and separate generator from mounting bracket (Fig.

6).

(6) Remove the B+ terminal nut, field terminal

nuts, and ground/wire harness hold-down nuts. Re-

move wire connectors. (7) Remove the generator from the vehicle.

(8) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

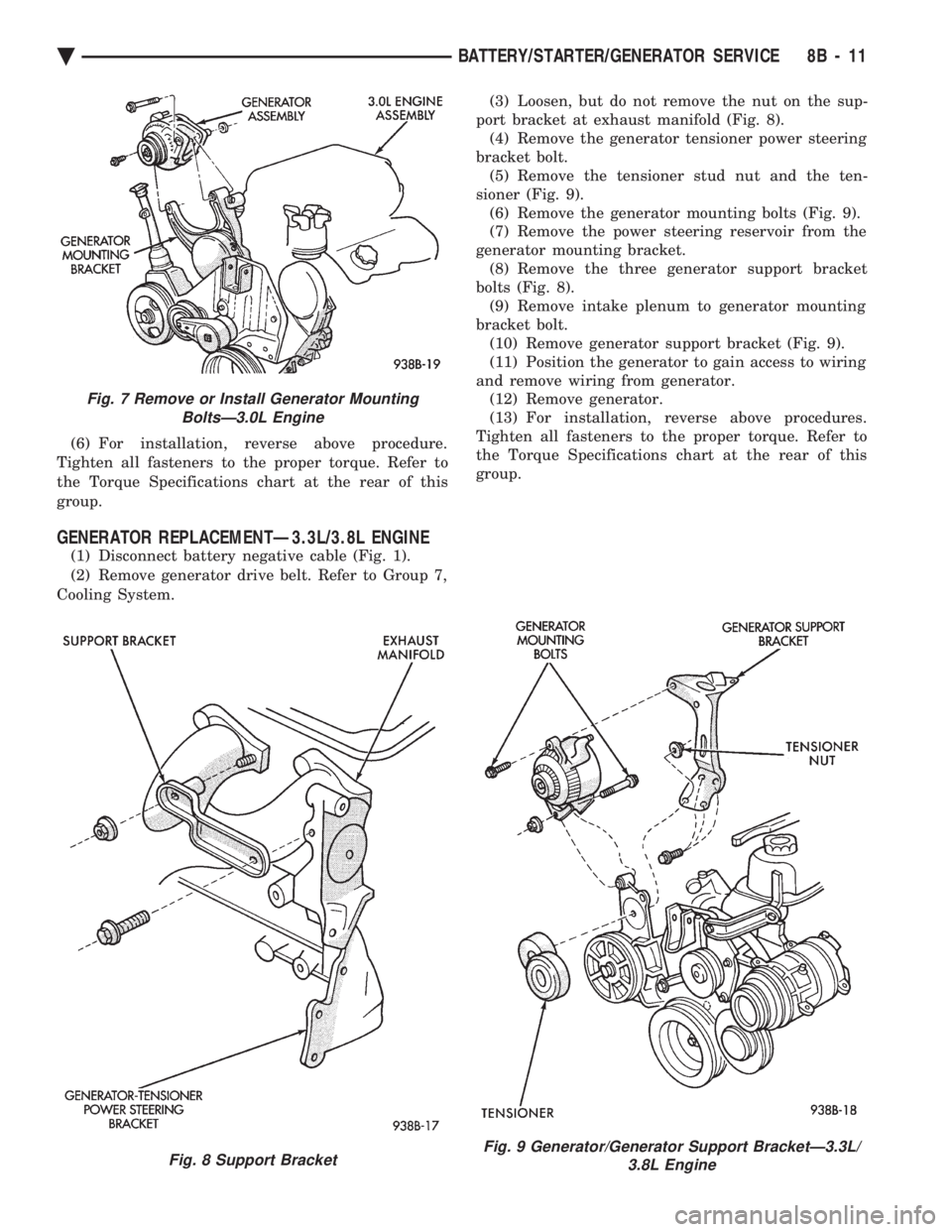

GENERATOR REPLACEMENTÐ3.0L ENGINE

(1) Disconnect battery negative cable (Fig. 1).

(2) Remove generator drive belt. Refer to Group 7,

Cooling System. (3) Remove the generator mounting bolts and sep-

arate the generator from the mounting bracket (Fig.

7). (4) Remove the B+ terminal nut, field terminal

nuts, and ground/wire harness hold-down nuts. Re-

move wire connectors. (5) Remove the generator from the vehicle.

Fig. 4 Remove or Install Wire Connector AssemblyÐBosch Generator

Fig. 5 Remove or Install Wire ConnectorAssemblyÐNippondenso Generator

Fig. 6 Generator MountingÐ2.2 L Turbo Engine With 16 Valve Cylinder Head

8B - 10 BATTERY/STARTER/GENERATOR SERVICE Ä

Page 413 of 2438

(6) For installation, reverse above procedure.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

GENERATOR REPLACEMENTÐ3.3L/3.8L ENGINE

(1) Disconnect battery negative cable (Fig. 1).

(2) Remove generator drive belt. Refer to Group 7,

Cooling System. (3) Loosen, but do not remove the nut on the sup-

port bracket at exhaust manifold (Fig. 8). (4) Remove the generator tensioner power steering

bracket bolt. (5) Remove the tensioner stud nut and the ten-

sioner (Fig. 9). (6) Remove the generator mounting bolts (Fig. 9).

(7) Remove the power steering reservoir from the

generator mounting bracket. (8) Remove the three generator support bracket

bolts (Fig. 8). (9) Remove intake plenum to generator mounting

bracket bolt. (10) Remove generator support bracket (Fig. 9).

(11) Position the generator to gain access to wiring

and remove wiring from generator. (12) Remove generator.

(13) For installation, reverse above procedures.

Tighten all fasteners to the proper torque. Refer to

the Torque Specifications chart at the rear of this

group.

Fig. 7 Remove or Install Generator Mounting BoltsÐ3.0L Engine

Fig. 8 Support BracketFig. 9 Generator/Generator Support BracketÐ3.3L/ 3.8L Engine

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 11

Page 424 of 2438

VISUAL MESSAGES

Following are the visual messages and the condi-

tions under which, the messages will be given:

² Keys in ignition

² Exterior lamps on

These messages will appear if the conditions are

present and the driver's door is open while the igni-

tion switch is in the OFF, LOCK, or ACC positions.

A tone will sound until the condition is corrected or

the door is closed.

² Passenger door ajar

² Driver door ajar

² Trunk ajar

² Park brake engaged

² Right rear door ajar

² Left rear door ajar

These messages will appear if a condition is de-

tected after the vehicle is in motion. When the con-

dition is corrected, a short tone will sound to

acknowledge the action. LOW OIL PRESSURE

If this message is displayed while the vehicle is at

cruising speeds, immediate attention is required. If

this message appears at idle speed, increase the idle

speed and the message should go off. If the message

remains on, immediate attention is required. ENGINE TEMP CRITICAL

This message appears when a sensor has determined

that the engine coolant is overheating. If this message

comes on and stays on, immediate action is required.

COOLANT LEVEL LOW

LOW FUEL LEVEL

LOW BRAKE FLUID

WASHER FLUID LOW

These messages will appear if a continuous warn-

ing condition is detected while the engine is running.

Inspection is required. To clear this message from

the display, after the condition is corrected, the igni-

tion switch must be turned OFF. CHECK TRANS

This message will appear if a continuous warning

condition is detected while the engine is running. Im-

mediate attention is recommended. To clear this mes-

sage from the display, after the condition has been

corrected, the ignition switch must be turned OFF. VOLTAGE IMPROPER

This message will appear if a continuous warning

condition is detected. Immediate attention is re-

quired. To clear this message from the display, after

the condition has been corrected, the ignition switch

must be turned OFF. TURN SIGNAL ON

This message will appear if the turn signal is left

on while vehicle speed is over 15 mph and the vehi-

cle has traveled over one-half mile. FASTEN SEAT BELTS An intermittent chime tone will sound for several

seconds if the seat belt is not fastened. CHK ENGINE OIL LEVEL

If this message is delivered, a check of the engine

oil dipstick is suggested. To clear this message, after

the condition is corrected, the ignition switch must

be turned OFF. HEADLAMP OUT

BRAKE LAMP OUT

TAIL LAMP OUT

These conditions are monitored only when the lamps

are on. The message will remain, even after the lamp is

replaced, until the lamp is turned on and operates.

SERVICE REMINDER

The maintenance reminder statement is programmed

to provide general information only. Refer to Group 0,

Lubrication & Maintenance for specific vehicle require-

ments.

The service reminder message is displayed at 7,500

miles or 12 months intervals, which ever comes first. MONITORED SYSTEMS OK

If there is no warning condition to report, the mes-

sage Monitored Systems OK is displayed (Fig. 2).

AUTOMATIC CALIBRATION SET PROCEDURE

The engine compartment node will continuously

and automatically recalibrate the compass under nor-

mal driving conditions. As long as the vehicle is

turning, the engine compartment node will record

new compass data. This new data will be used to

recalibrate the compass at a rate of at least once per

full (360 degree) turn of the vehicle. Automatic cali-

bration does not require operator interface.

MANUAL CALIBRATION SET PROCEDURE

Manual compass calibration has been replaced by

automatic calibration set procedure. The manual cal-

ibration set procedure is available, but no longer

serves any useful purpose.

EVIC SELF CHECK DIAGNOSTICS

Ignition switch ON, the EVIC not displaying any

message, may imply a system failure and not an

EVIC failure. Turn the ignition OFF, close all vehi-

cle doors and wait at least 60 seconds before begin-

ning test. Turn ignition switch to the ON position.

Pressing the TEMP, FUEL and INFO buttons at the

same time shall provide the visual message MOD-

ULE SELF CHECK for two seconds. Following at

two second interval there will be messages:

² E2-0 SELF CHECK

² E3-0 SELF CHECK

² END OF SELF CHECK

Showing the microcomputer is working properly.

When the self check mode and message shows:

² E2-1

² E3-2

This would show a fault exists in the EVIC's micro-

computer and the EVIC should be replaced (Fig. 3).

8C - 8 OVERHEAD CONSOLE Ä