boot CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 191 of 2438

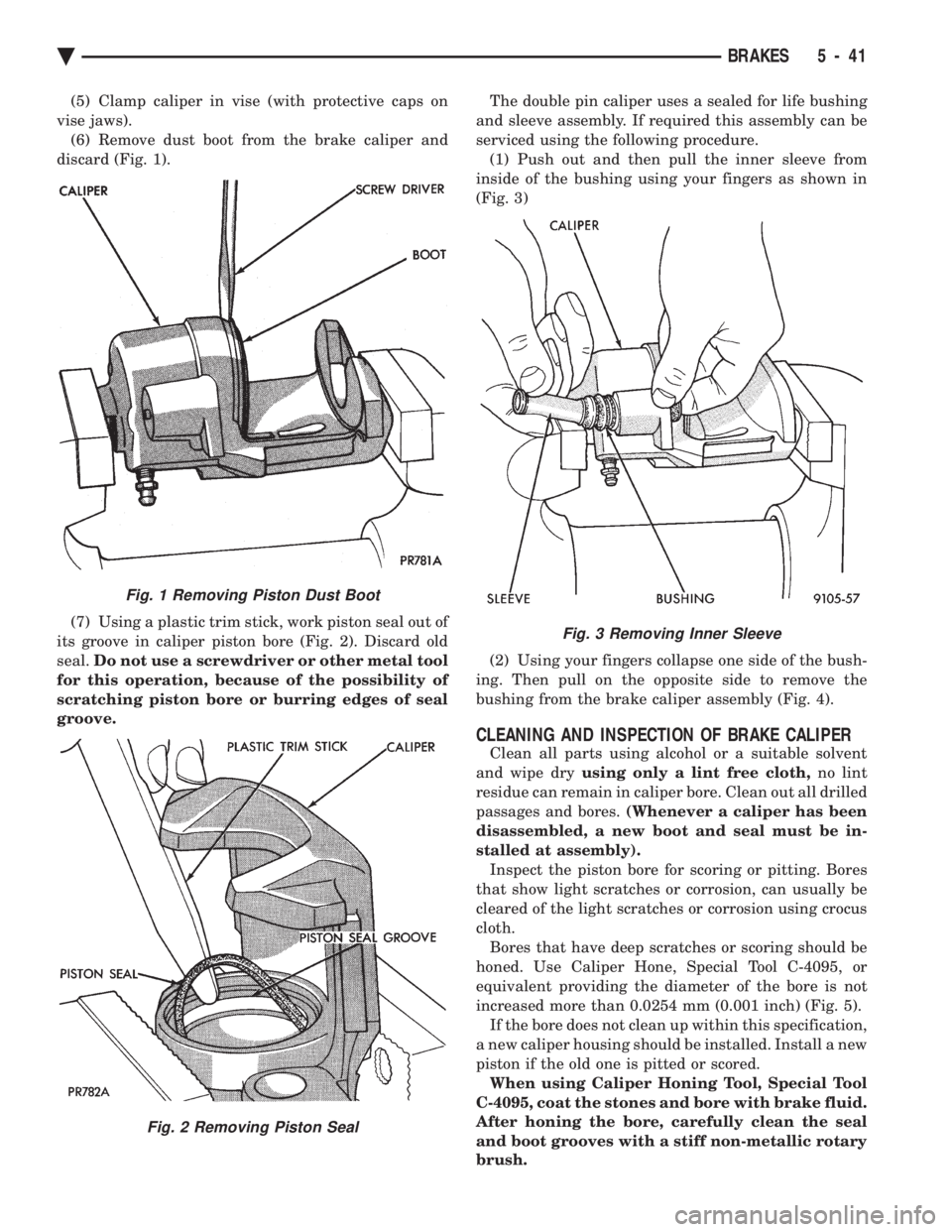

(5) Clamp caliper in vise (with protective caps on

vise jaws). (6) Remove dust boot from the brake caliper and

discard (Fig. 1).

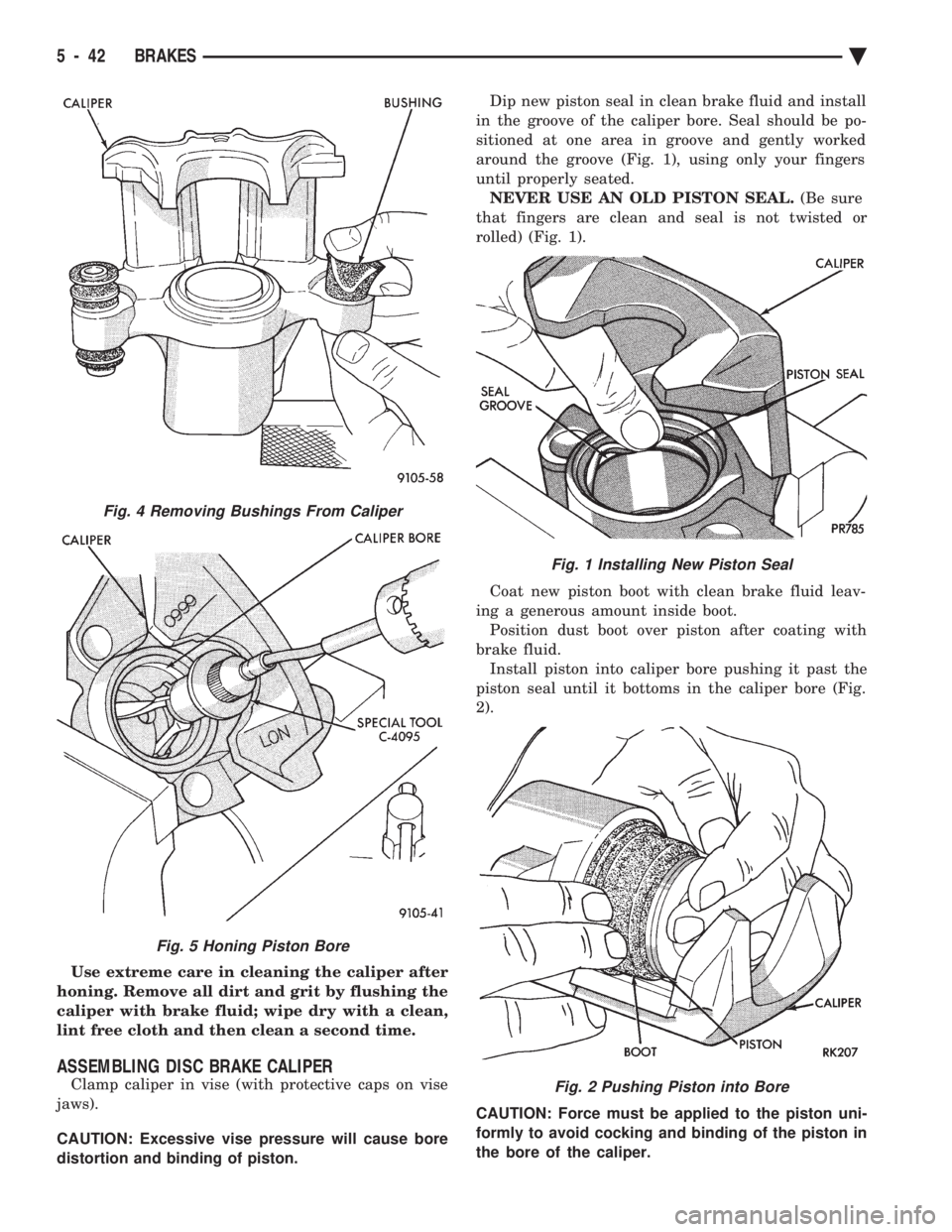

(7) Using a plastic trim stick, work piston seal out of

its groove in caliper piston bore (Fig. 2). Discard old

seal. Do not use a screwdriver or other metal tool

for this operation, because of the possibility of

scratching piston bore or burring edges of seal

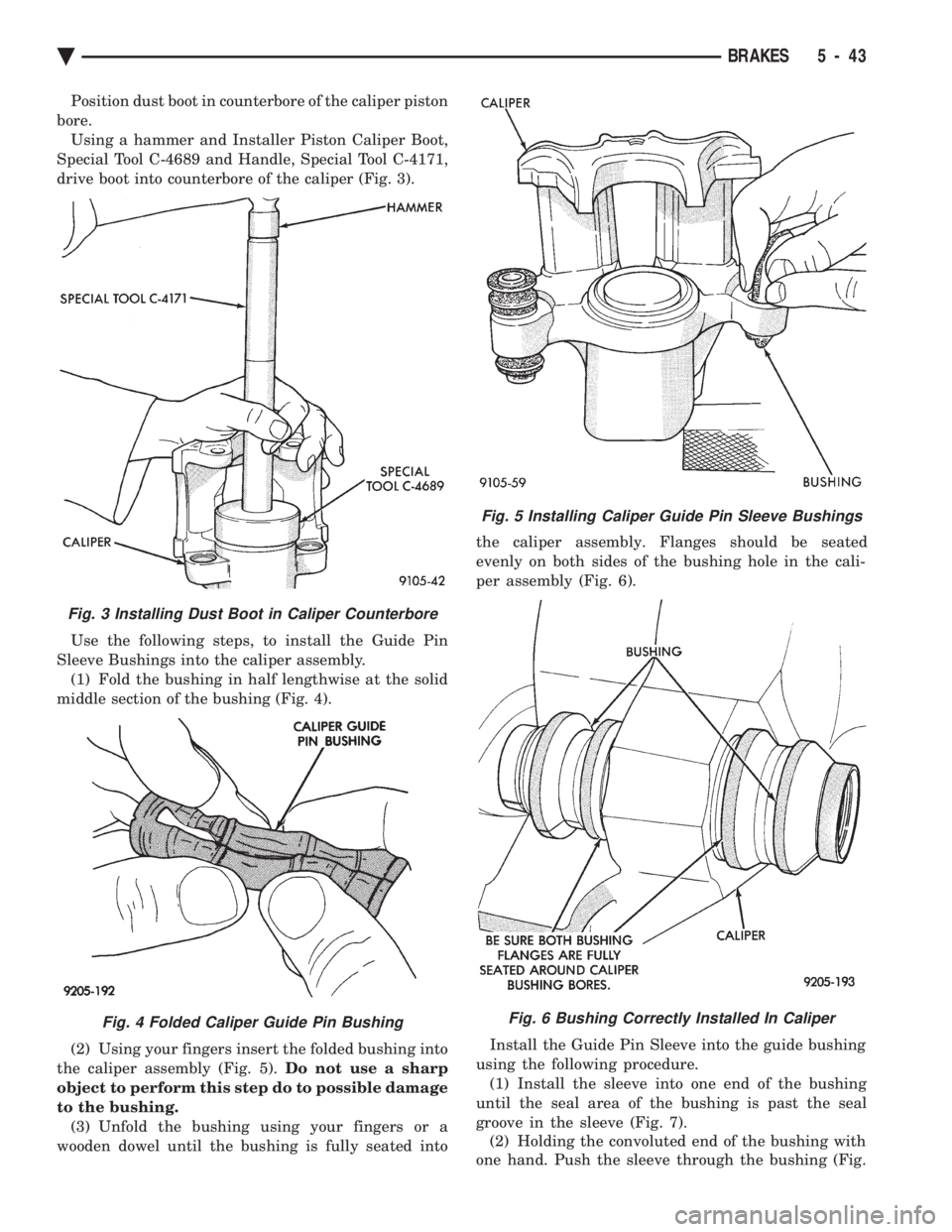

groove. The double pin caliper uses a sealed for life bushing

and sleeve assembly. If required this assembly can be

serviced using the following procedure. (1) Push out and then pull the inner sleeve from

inside of the bushing using your fingers as shown in

(Fig. 3)

(2) Using your fingers collapse one side of the bush-

ing. Then pull on the opposite side to remove the

bushing from the brake caliper assembly (Fig. 4).

CLEANING AND INSPECTION OF BRAKE CALIPER

Clean all parts using alcohol or a suitable solvent

and wipe dry using only a lint free cloth, no lint

residue can remain in caliper bore. Clean out all drilled

passages and bores. (Whenever a caliper has been

disassembled, a new boot and seal must be in-

stalled at assembly). Inspect the piston bore for scoring or pitting. Bores

that show light scratches or corrosion, can usually be

cleared of the light scratches or corrosion using crocus

cloth. Bores that have deep scratches or scoring should be

honed. Use Caliper Hone, Special Tool C-4095, or

equivalent providing the diameter of the bore is not

increased more than 0.0254 mm (0.001 inch) (Fig. 5). If the bore does not clean up within this specification,

a new caliper housing should be installed. Install a new

piston if the old one is pitted or scored. When using Caliper Honing Tool, Special Tool

C-4095, coat the stones and bore with brake fluid.

After honing the bore, carefully clean the seal

and boot grooves with a stiff non-metallic rotary

brush.

Fig. 1 Removing Piston Dust Boot

Fig. 2 Removing Piston Seal

Fig. 3 Removing Inner Sleeve

Ä BRAKES 5 - 41

Page 192 of 2438

Use extreme care in cleaning the caliper after

honing. Remove all dirt and grit by flushing the

caliper with brake fluid; wipe dry with a clean,

lint free cloth and then clean a second time.

ASSEMBLING DISC BRAKE CALIPER

Clamp caliper in vise (with protective caps on vise

jaws).

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston. Dip new piston seal in clean brake fluid and install

in the groove of the caliper bore. Seal should be po-

sitioned at one area in groove and gently worked

around the groove (Fig. 1), using only your fingers

until properly seated. NEVER USE AN OLD PISTON SEAL. (Be sure

that fingers are clean and seal is not twisted or

rolled) (Fig. 1).

Coat new piston boot with clean brake fluid leav-

ing a generous amount inside boot. Position dust boot over piston after coating with

brake fluid. Install piston into caliper bore pushing it past the

piston seal until it bottoms in the caliper bore (Fig.

2).

CAUTION: Force must be applied to the piston uni-

formly to avoid cocking and binding of the piston in

the bore of the caliper.

Fig. 1 Installing New Piston Seal

Fig. 2 Pushing Piston into Bore

Fig. 4 Removing Bushings From Caliper

Fig. 5 Honing Piston Bore

5 - 42 BRAKES Ä

Page 193 of 2438

Position dust boot in counterbore of the caliper piston

bore. Using a hammer and Installer Piston Caliper Boot,

Special Tool C-4689 and Handle, Special Tool C-4171,

drive boot into counterbore of the caliper (Fig. 3).

Use the following steps, to install the Guide Pin

Sleeve Bushings into the caliper assembly. (1) Fold the bushing in half lengthwise at the solid

middle section of the bushing (Fig. 4).

(2) Using your fingers insert the folded bushing into

the caliper assembly (Fig. 5). Do not use a sharp

object to perform this step do to possible damage

to the bushing. (3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated into the caliper assembly. Flanges should be seated

evenly on both sides of the bushing hole in the cali-

per assembly (Fig. 6).

Install the Guide Pin Sleeve into the guide bushing

using the following procedure. (1) Install the sleeve into one end of the bushing

until the seal area of the bushing is past the seal

groove in the sleeve (Fig. 7). (2) Holding the convoluted end of the bushing with

one hand. Push the sleeve through the bushing (Fig.

Fig. 5 Installing Caliper Guide Pin Sleeve Bushings

Fig. 6 Bushing Correctly Installed In Caliper

Fig. 3 Installing Dust Boot in Caliper Counterbore

Fig. 4 Folded Caliper Guide Pin Bushing

Ä BRAKES 5 - 43

Page 196 of 2438

removal will be necessary. Remove the shoe and lin-

ing assemblies (see Brake Shoe Removal).Combined shoe and lining thickness should be

measured at the thinnest part of the assembly. When a shoe and lining assembly is worn to a

thickness of approximately 7.0 mm (9/32 inch) it

should be replaced. Replace both shoe assemblies (inboard and out-

board) on both wheels whenever shoe assemblies on

either side are replaced. If a shoe assembly does not require replacement.

Reinstall it, making sure each shoe assembly is re-

turned to its original position on the wheel of the ve-

hicle from which it was removed. (See Brake Shoe

Installation).

SERVICE PRECAUTIONS

WARNING: DUST AND DIRT ON BRAKE PARTS

GENERATED DURING THE NORMAL USE AND

WEAR OF MOTOR VEHICLE BRAKE SYSTEMS CAN

CONTAIN ASBESTOS FIBERS. BREATHING EXCES-

SIVE CONCENTRATIONS OF ASBESTOS FIBERS

CAN CAUSE SERIOUS BODILY HARM, SUCH AS

ASBESTOSIS AND CANCER. EXTREME CARE

SHOULD BE EXERCISED WHILE SERVICING

BRAKE ASSEMBLIES OR COMPONENTS. DO NOT CLEAN BRAKE ASSEMBLIES OR COM-

PONENTS WITH COMPRESSED AIR OR BY DRY

BRUSHING; USE A VACUUM CLEANER SPECIFI-

CALLY RECOMMENDED FOR USE WITH ASBES-

TOS FIBERS. IF A SUITABLE VACUUM CLEANER IS

NOT AVAILABLE, CLEANING SHOULD BE DONE

WET USING A WATER DAMPENED CLOTH. DO NOT CREATE DUST BY SANDING, GRINDIN-

G,AND/OR SHAVING BRAKE LININGS OR PADS

UNLESS SUCH OPERATION IS DONE WHILE USING

PROPERLY EXHAUST VENTILATED EQUIPMENT. DISPOSE OF ALL DUST AND DIRT SUSPECTED

TO CONTAIN ANY ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS TO MINIMIZE DUST EXPO-

SURE TO YOURSELF AND OTHERS. FOLLOW ALL RECOMMENDED PRACTICES PRE-

SCRIBED BY THE OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION AND THE ENVIRON-

MENTAL PROTECTION AGENCY. FOR THE HAN-

DLING, PROCESSING, AND DISPOSITION OF DUST

OR DIRT WHICH MAY CONTAIN ASBESTOS FI-

BERS. IT IS RECOMMENDED NOT TO BREATH ANY

TYPE OF BRAKE LINING MATERIAL DUST EVEN

ASBESTOS FREE, DUE TO THE FIBROUS NATURE

OF THE MATERIALS BEING USED.

Grease or any other foreign material must be kept

off the caliper assembly, surfaces of the braking disc

and external surfaces of the hub, during service pro-

cedures. Handling the braking disc and caliper should be done

in such a way as to avoid deformation of the disc and

scratching or nicking the brake linings (pads). During removal and installation of a wheel and tire

assembly, use care not to strike the caliper. Before vehicle is moved after any brake service

work, be sure to obtain a firm brake pedal.

BRAKE SHOE REMOVAL

(1) Raise vehicle on jackstands or centered on a

hoist. (2) Remove rear wheel and tire assemblies.

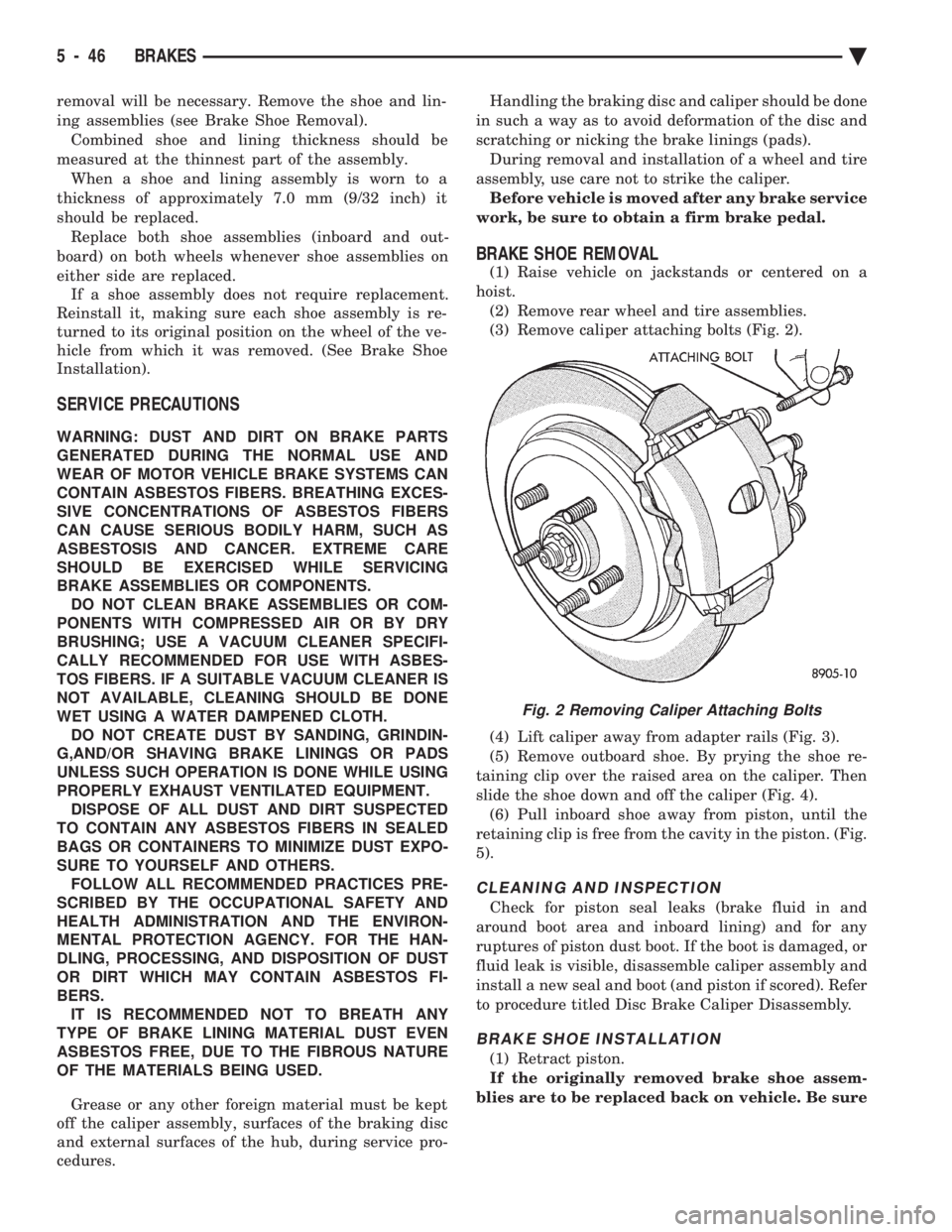

(3) Remove caliper attaching bolts (Fig. 2).

(4) Lift caliper away from adapter rails (Fig. 3).

(5) Remove outboard shoe. By prying the shoe re-

taining clip over the raised area on the caliper. Then

slide the shoe down and off the caliper (Fig. 4). (6) Pull inboard shoe away from piston, until the

retaining clip is free from the cavity in the piston. (Fig.

5).

CLEANING AND INSPECTION

Check for piston seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of piston dust boot. If the boot is damaged, or

fluid leak is visible, disassemble caliper assembly and

install a new seal and boot (and piston if scored). Refer

to procedure titled Disc Brake Caliper Disassembly.

BRAKE SHOE INSTALLATION

(1) Retract piston.

If the originally removed brake shoe assem-

blies are to be replaced back on vehicle. Be sure

Fig. 2 Removing Caliper Attaching Bolts

5 - 46 BRAKES Ä

Page 198 of 2438

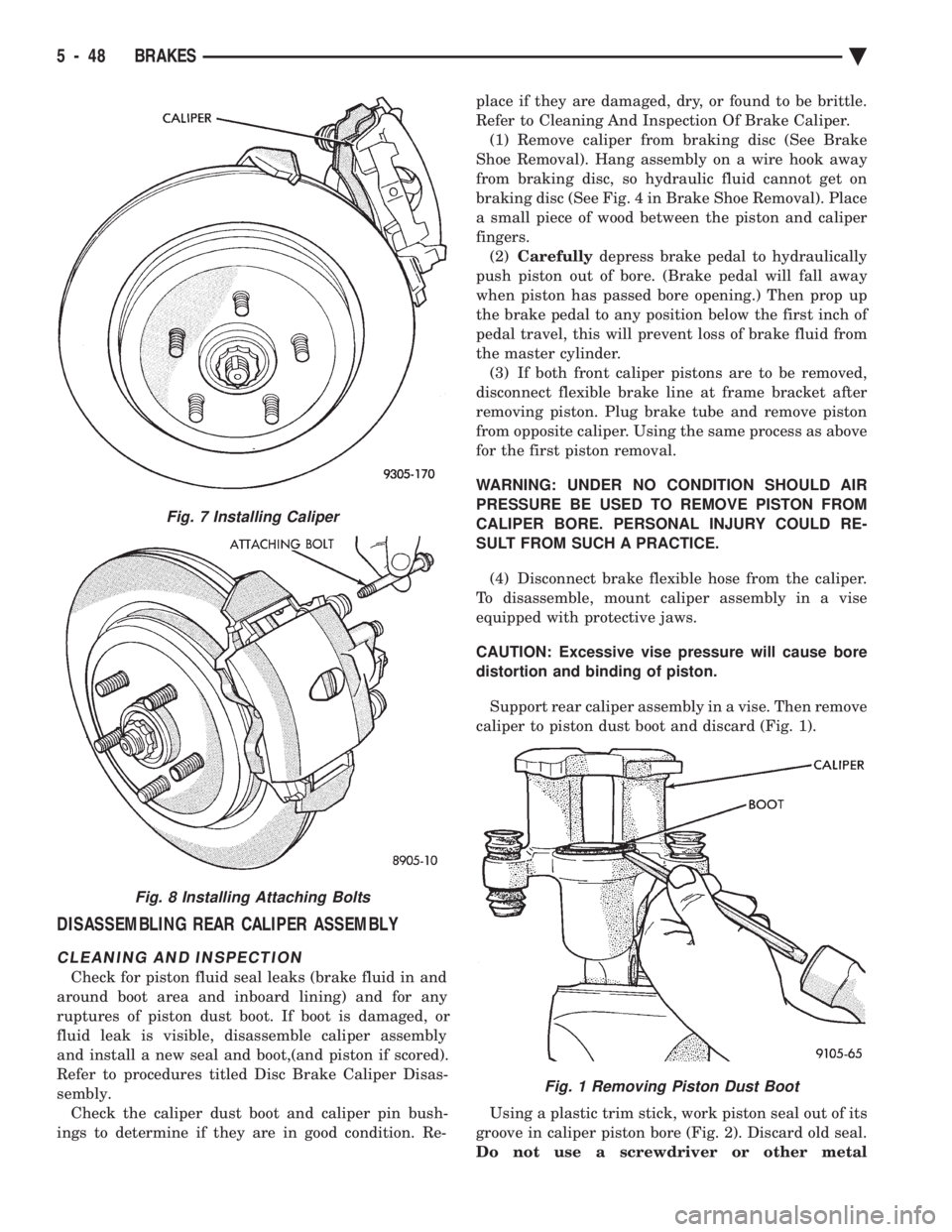

DISASSEMBLING REAR CALIPER ASSEMBLY

CLEANING AND INSPECTION

Check for piston fluid seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of piston dust boot. If boot is damaged, or

fluid leak is visible, disassemble caliper assembly

and install a new seal and boot,(and piston if scored).

Refer to procedures titled Disc Brake Caliper Disas-

sembly. Check the caliper dust boot and caliper pin bush-

ings to determine if they are in good condition. Re- place if they are damaged, dry, or found to be brittle.

Refer to Cleaning And Inspection Of Brake Caliper. (1) Remove caliper from braking disc (See Brake

Shoe Removal). Hang assembly on a wire hook away

from braking disc, so hydraulic fluid cannot get on

braking disc (See Fig. 4 in Brake Shoe Removal). Place

a small piece of wood between the piston and caliper

fingers. (2) Carefully depress brake pedal to hydraulically

push piston out of bore. (Brake pedal will fall away

when piston has passed bore opening.) Then prop up

the brake pedal to any position below the first inch of

pedal travel, this will prevent loss of brake fluid from

the master cylinder. (3) If both front caliper pistons are to be removed,

disconnect flexible brake line at frame bracket after

removing piston. Plug brake tube and remove piston

from opposite caliper. Using the same process as above

for the first piston removal.

WARNING: UNDER NO CONDITION SHOULD AIR

PRESSURE BE USED TO REMOVE PISTON FROM

CALIPER BORE. PERSONAL INJURY COULD RE-

SULT FROM SUCH A PRACTICE.

(4) Disconnect brake flexible hose from the caliper.

To disassemble, mount caliper assembly in a vise

equipped with protective jaws.

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston.

Support rear caliper assembly in a vise. Then remove

caliper to piston dust boot and discard (Fig. 1).

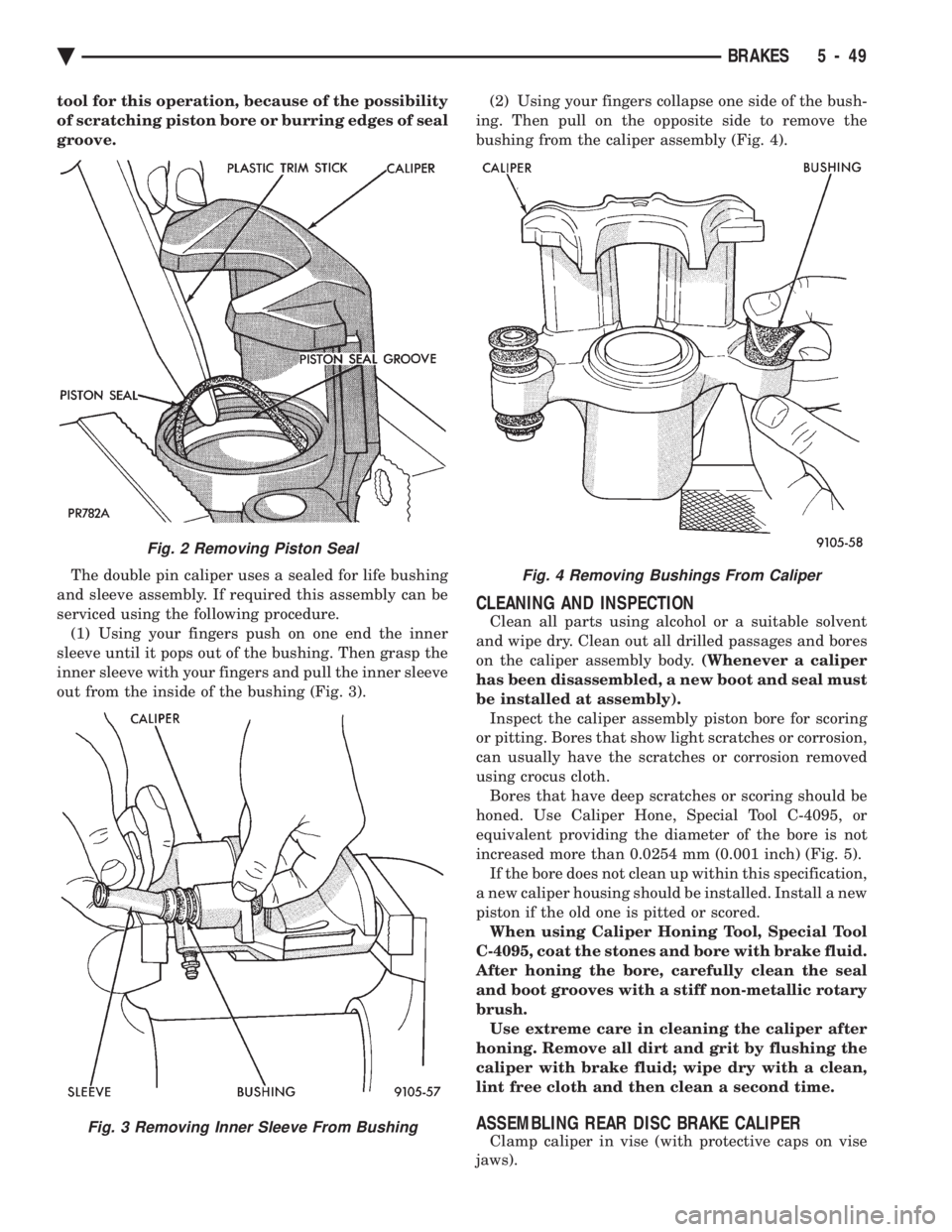

Using a plastic trim stick, work piston seal out of its

groove in caliper piston bore (Fig. 2). Discard old seal.

Do not use a screwdriver or other metal

Fig. 7 Installing Caliper

Fig. 8 Installing Attaching Bolts

Fig. 1 Removing Piston Dust Boot

5 - 48 BRAKES Ä

Page 199 of 2438

tool for this operation, because of the possibility

of scratching piston bore or burring edges of seal

groove. The double pin caliper uses a sealed for life bushing

and sleeve assembly. If required this assembly can be

serviced using the following procedure. (1) Using your fingers push on one end the inner

sleeve until it pops out of the bushing. Then grasp the

inner sleeve with your fingers and pull the inner sleeve

out from the inside of the bushing (Fig. 3). (2) Using your fingers collapse one side of the bush-

ing. Then pull on the opposite side to remove the

bushing from the caliper assembly (Fig. 4).

CLEANING AND INSPECTION

Clean all parts using alcohol or a suitable solvent

and wipe dry. Clean out all drilled passages and bores

on the caliper assembly body. (Whenever a caliper

has been disassembled, a new boot and seal must

be installed at assembly). Inspect the caliper assembly piston bore for scoring

or pitting. Bores that show light scratches or corrosion,

can usually have the scratches or corrosion removed

using crocus cloth. Bores that have deep scratches or scoring should be

honed. Use Caliper Hone, Special Tool C-4095, or

equivalent providing the diameter of the bore is not

increased more than 0.0254 mm (0.001 inch) (Fig. 5). If the bore does not clean up within this specification,

a new caliper housing should be installed. Install a new

piston if the old one is pitted or scored. When using Caliper Honing Tool, Special Tool

C-4095, coat the stones and bore with brake fluid.

After honing the bore, carefully clean the seal

and boot grooves with a stiff non-metallic rotary

brush. Use extreme care in cleaning the caliper after

honing. Remove all dirt and grit by flushing the

caliper with brake fluid; wipe dry with a clean,

lint free cloth and then clean a second time.

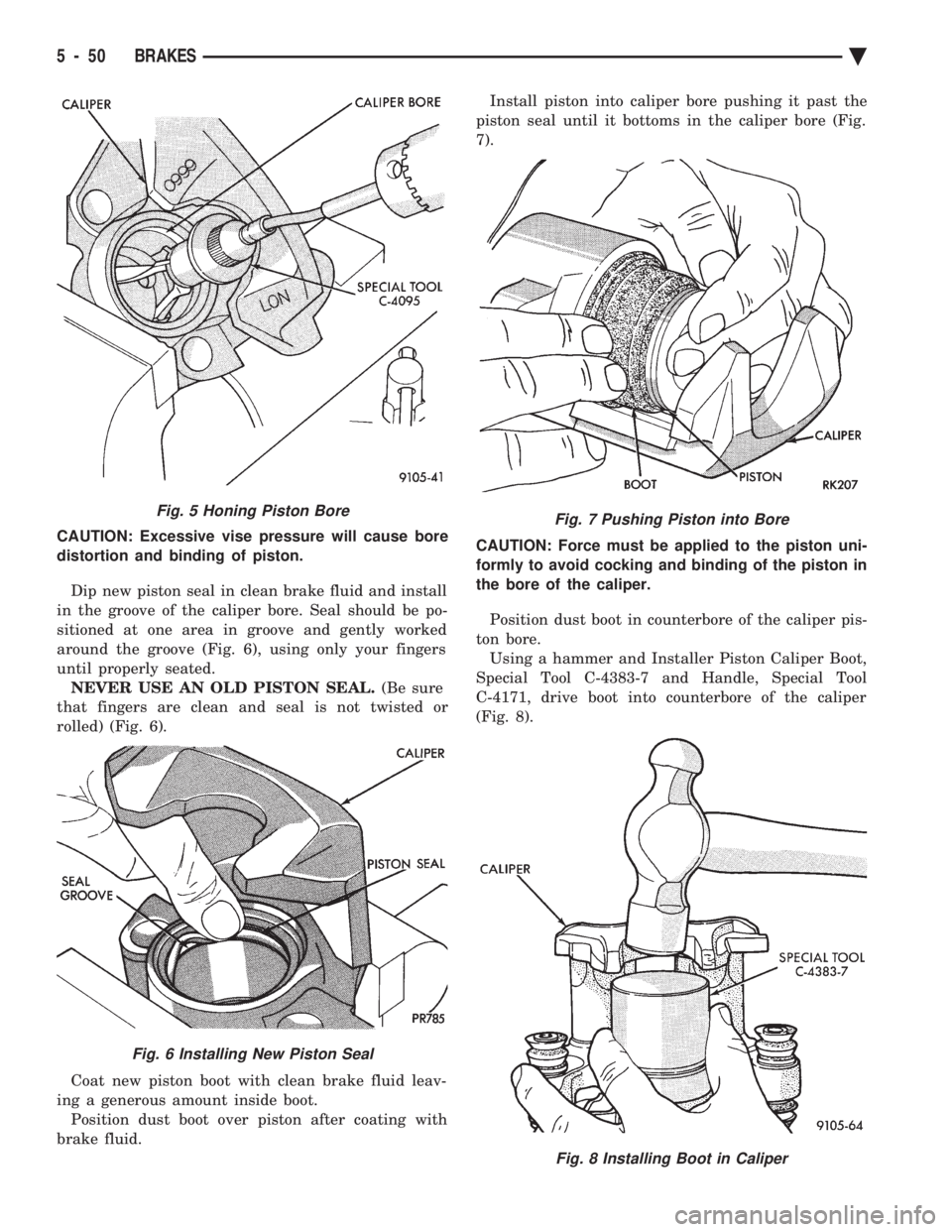

ASSEMBLING REAR DISC BRAKE CALIPER

Clamp caliper in vise (with protective caps on vise

jaws).

Fig. 2 Removing Piston Seal

Fig. 3 Removing Inner Sleeve From Bushing

Fig. 4 Removing Bushings From Caliper

Ä BRAKES 5 - 49

Page 200 of 2438

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston. Dip new piston seal in clean brake fluid and install

in the groove of the caliper bore. Seal should be po-

sitioned at one area in groove and gently worked

around the groove (Fig. 6), using only your fingers

until properly seated. NEVER USE AN OLD PISTON SEAL. (Be sure

that fingers are clean and seal is not twisted or

rolled) (Fig. 6).

Coat new piston boot with clean brake fluid leav-

ing a generous amount inside boot. Position dust boot over piston after coating with

brake fluid. Install piston into caliper bore pushing it past the

piston seal until it bottoms in the caliper bore (Fig.

7).

CAUTION: Force must be applied to the piston uni-

formly to avoid cocking and binding of the piston in

the bore of the caliper.

Position dust boot in counterbore of the caliper pis-

ton bore. Using a hammer and Installer Piston Caliper Boot,

Special Tool C-4383-7 and Handle, Special Tool

C-4171, drive boot into counterbore of the caliper

(Fig. 8).

Fig. 5 Honing Piston Bore

Fig. 6 Installing New Piston Seal

Fig. 7 Pushing Piston into Bore

Fig. 8 Installing Boot in Caliper

5 - 50 BRAKES Ä

Page 448 of 2438

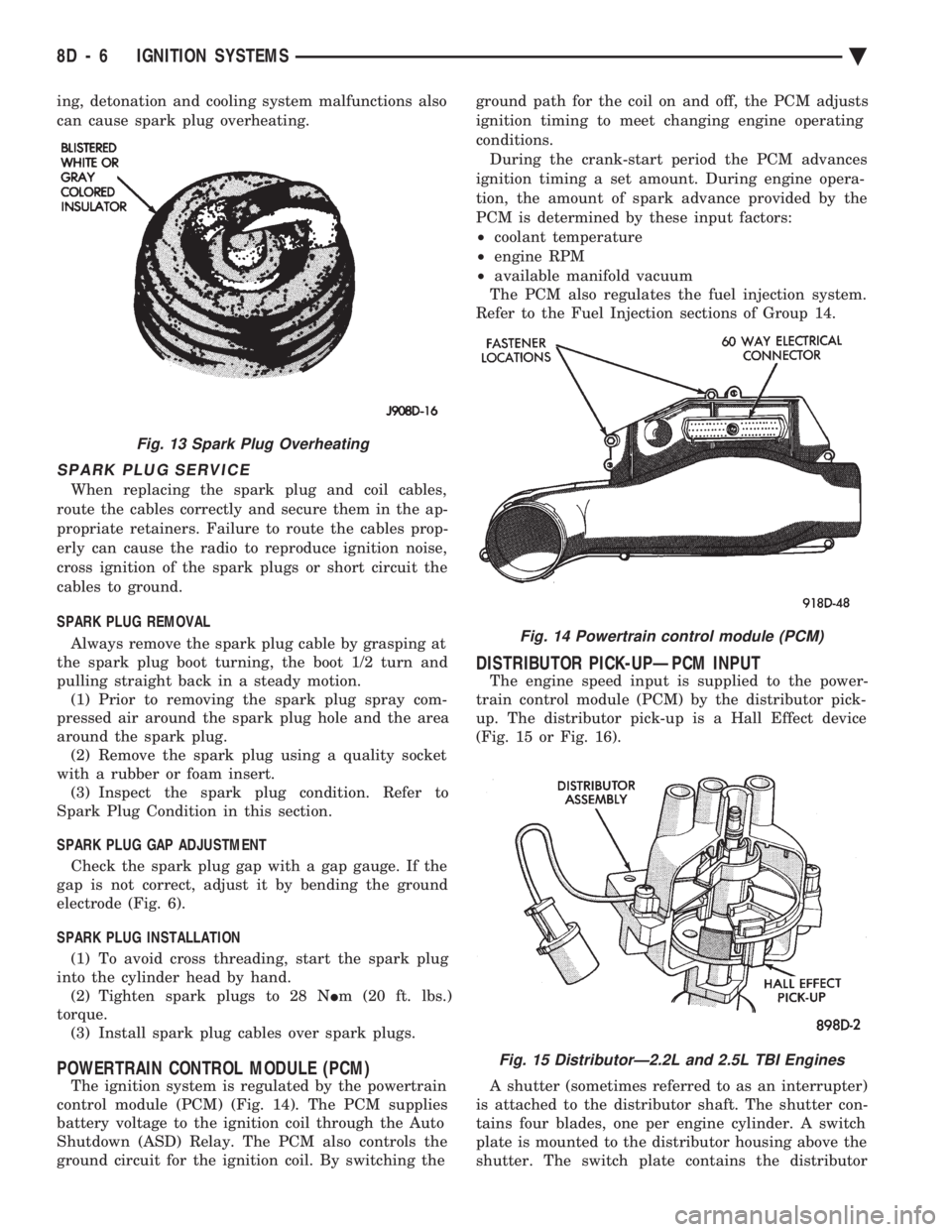

ing, detonation and cooling system malfunctions also

can cause spark plug overheating.

SPARK PLUG SERVICE

When replacing the spark plug and coil cables,

route the cables correctly and secure them in the ap-

propriate retainers. Failure to route the cables prop-

erly can cause the radio to reproduce ignition noise,

cross ignition of the spark plugs or short circuit the

cables to ground.

SPARK PLUG REMOVAL

Always remove the spark plug cable by grasping at

the spark plug boot turning, the boot 1/2 turn and

pulling straight back in a steady motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert. (3) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

SPARK PLUG GAP ADJUSTMENT Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION (1) To avoid cross threading, start the spark plug

into the cylinder head by hand. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

POWERTRAIN CONTROL MODULE (PCM)

The ignition system is regulated by the powertrain

control module (PCM) (Fig. 14). The PCM supplies

battery voltage to the ignition coil through the Auto

Shutdown (ASD) Relay. The PCM also controls the

ground circuit for the ignition coil. By switching the ground path for the coil on and off, the PCM adjusts

ignition timing to meet changing engine operating

conditions.

During the crank-start period the PCM advances

ignition timing a set amount. During engine opera-

tion, the amount of spark advance provided by the

PCM is determined by these input factors:

² coolant temperature

² engine RPM

² available manifold vacuum

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

DISTRIBUTOR PICK-UPÐPCM INPUT

The engine speed input is supplied to the power-

train control module (PCM) by the distributor pick-

up. The distributor pick-up is a Hall Effect device

(Fig. 15 or Fig. 16).

A shutter (sometimes referred to as an interrupter)

is attached to the distributor shaft. The shutter con-

tains four blades, one per engine cylinder. A switch

plate is mounted to the distributor housing above the

shutter. The switch plate contains the distributor

Fig. 14 Powertrain control module (PCM)

Fig. 15 DistributorÐ2.2L and 2.5L TBI Engines

Fig. 13 Spark Plug Overheating

8D - 6 IGNITION SYSTEMS Ä

Page 453 of 2438

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐDIAGNOSTIC PROCEDURES

INDEX

page page

Coolant Temperature Sensor Test ............ 13

Failure to Start TestÐ2.5L TBI and 3.0L Engines . 12

General Information ....................... 11

Ignition Coil ............................. 11 Manifold Absolute Pressure (MAP) Sensor Test . 13

Poor Performance Test .................... 13

Spark Plugs ............................ 11

Testing for Spark at Coil ................... 11

GENERAL INFORMATION

For additional information, refer to On Board Di-

agnostics in the Fuel Injection General Diagnosis

sections of Group 14. Also, refer to the DRBII scan

tool and appropriate Powertrain Diagnostic Proce-

dures Manual.

SPARK PLUGS

Faulty or fouled spark plugs may perform well at

idle speed, but frequently fail at higher engine

speeds. Faulty plugs can be identified in a number of

ways: poor fuel economy, power loss, decrease in en-

gine speed, hard starting and, in general, poor en-

gine performance. Spark plugs also malfunction because of carbon

fouling, excessive electrode air gap, or a broken insu-

lator. Refer to the General Information Section of

this group for spark plug diagnosis.

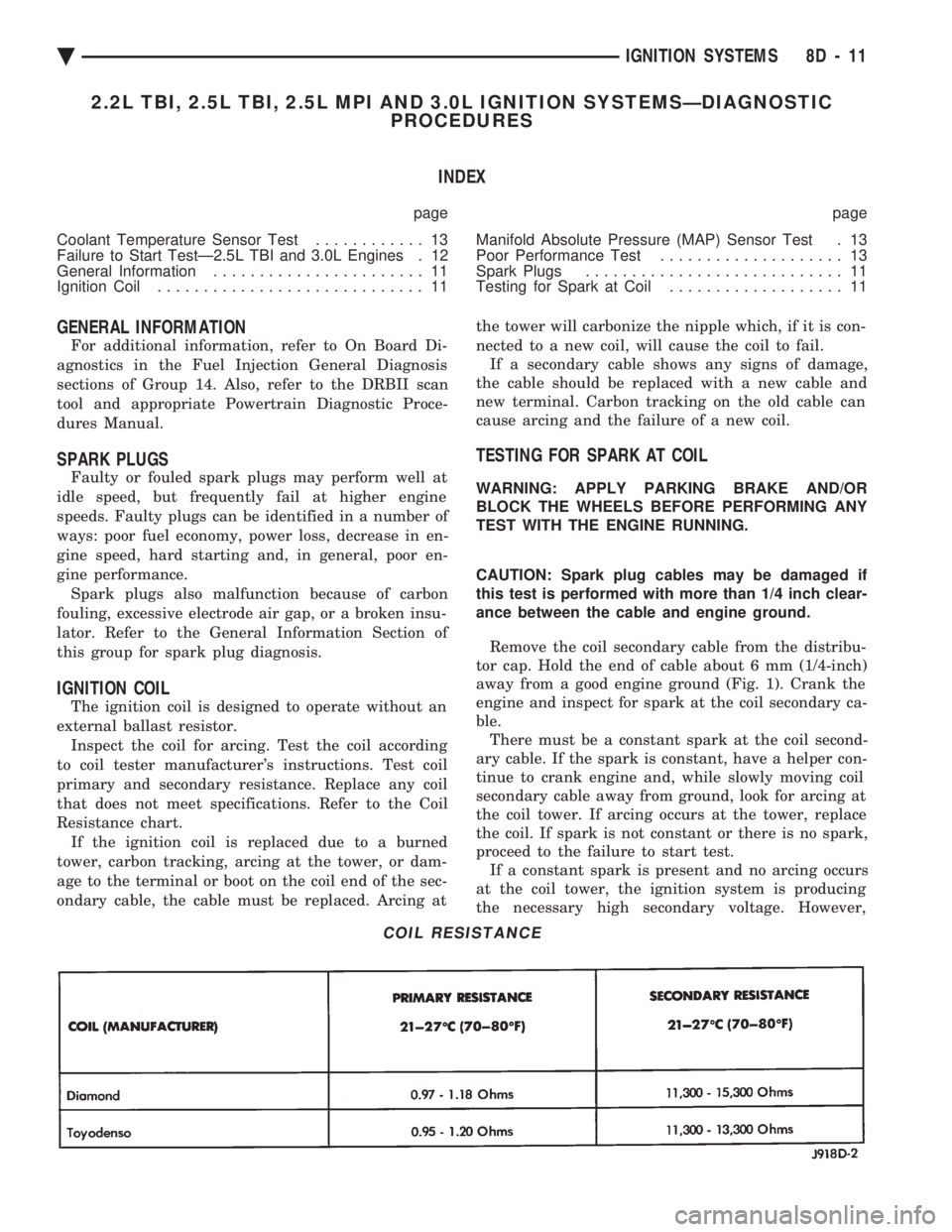

IGNITION COIL

The ignition coil is designed to operate without an

external ballast resistor. Inspect the coil for arcing. Test the coil according

to coil tester manufacturer's instructions. Test coil

primary and secondary resistance. Replace any coil

that does not meet specifications. Refer to the Coil

Resistance chart. If the ignition coil is replaced due to a burned

tower, carbon tracking, arcing at the tower, or dam-

age to the terminal or boot on the coil end of the sec-

ondary cable, the cable must be replaced. Arcing at the tower will carbonize the nipple which, if it is con-

nected to a new coil, will cause the coil to fail. If a secondary cable shows any signs of damage,

the cable should be replaced with a new cable and

new terminal. Carbon tracking on the old cable can

cause arcing and the failure of a new coil.

TESTING FOR SPARK AT COIL

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK THE WHEELS BEFORE PERFORMING ANY

TEST WITH THE ENGINE RUNNING.

CAUTION: Spark plug cables may be damaged if

this test is performed with more than 1/4 inch clear-

ance between the cable and engine ground.

Remove the coil secondary cable from the distribu-

tor cap. Hold the end of cable about 6 mm (1/4-inch)

away from a good engine ground (Fig. 1). Crank the

engine and inspect for spark at the coil secondary ca-

ble. There must be a constant spark at the coil second-

ary cable. If the spark is constant, have a helper con-

tinue to crank engine and, while slowly moving coil

secondary cable away from ground, look for arcing at

the coil tower. If arcing occurs at the tower, replace

the coil. If spark is not constant or there is no spark,

proceed to the failure to start test. If a constant spark is present and no arcing occurs

at the coil tower, the ignition system is producing

the necessary high secondary voltage. However,

COIL RESISTANCE

Ä IGNITION SYSTEMS 8D - 11

Page 457 of 2438

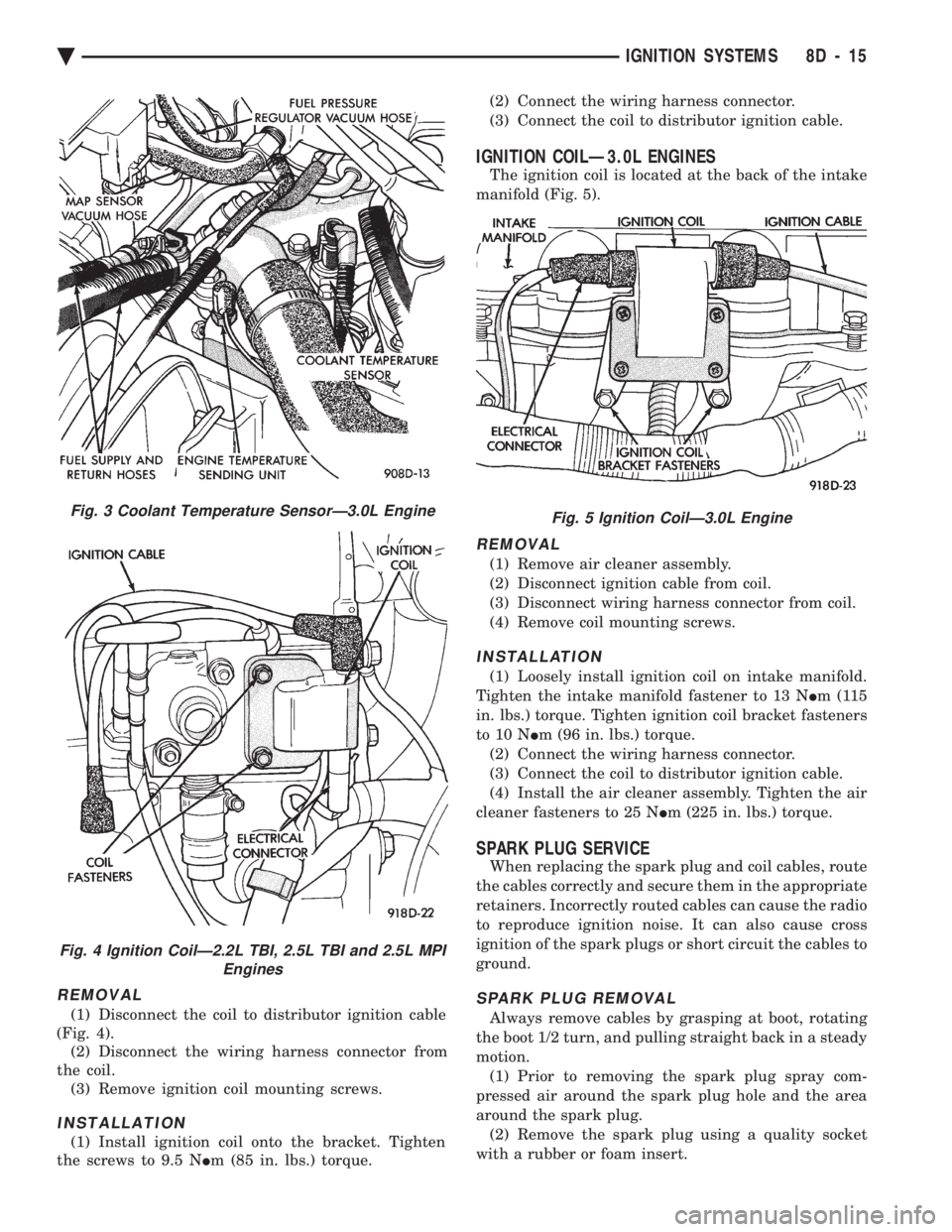

REMOVAL

(1) Disconnect the coil to distributor ignition cable

(Fig. 4). (2) Disconnect the wiring harness connector from

the coil. (3) Remove ignition coil mounting screws.

INSTALLATION

(1) Install ignition coil onto the bracket. Tighten

the screws to 9.5 N Im (85 in. lbs.) torque. (2) Connect the wiring harness connector.

(3) Connect the coil to distributor ignition cable.

IGNITION COILÐ3.0L ENGINES

The ignition coil is located at the back of the intake

manifold (Fig. 5).

REMOVAL

(1) Remove air cleaner assembly.

(2) Disconnect ignition cable from coil.

(3) Disconnect wiring harness connector from coil.

(4) Remove coil mounting screws.

INSTALLATION

(1) Loosely install ignition coil on intake manifold.

Tighten the intake manifold fastener to 13 N Im(115

in. lbs.) torque. Tighten ignition coil bracket fasteners

to 10 N Im (96 in. lbs.) torque.

(2) Connect the wiring harness connector.

(3) Connect the coil to distributor ignition cable.

(4) Install the air cleaner assembly. Tighten the air

cleaner fasteners to 25 N Im (225 in. lbs.) torque.

SPARK PLUG SERVICE

When replacing the spark plug and coil cables, route

the cables correctly and secure them in the appropriate

retainers. Incorrectly routed cables can cause the radio

to reproduce ignition noise. It can also cause cross

ignition of the spark plugs or short circuit the cables to

ground.

SPARK PLUG REMOVAL

Always remove cables by grasping at boot, rotating

the boot 1/2 turn, and pulling straight back in a steady

motion. (1) Prior to removing the spark plug spray com-

pressed air around the spark plug hole and the area

around the spark plug. (2) Remove the spark plug using a quality socket

with a rubber or foam insert.

Fig. 3 Coolant Temperature SensorÐ3.0L Engine

Fig. 4 Ignition CoilÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines

Fig. 5 Ignition CoilÐ3.0L Engine

Ä IGNITION SYSTEMS 8D - 15