boot CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1943 of 2438

POWER STEERING GEAR INDEX

page page

General Information ....................... 25

Outer Tie Rod ........................... 27 Steering Gear Service

..................... 25

GENERAL INFORMATION

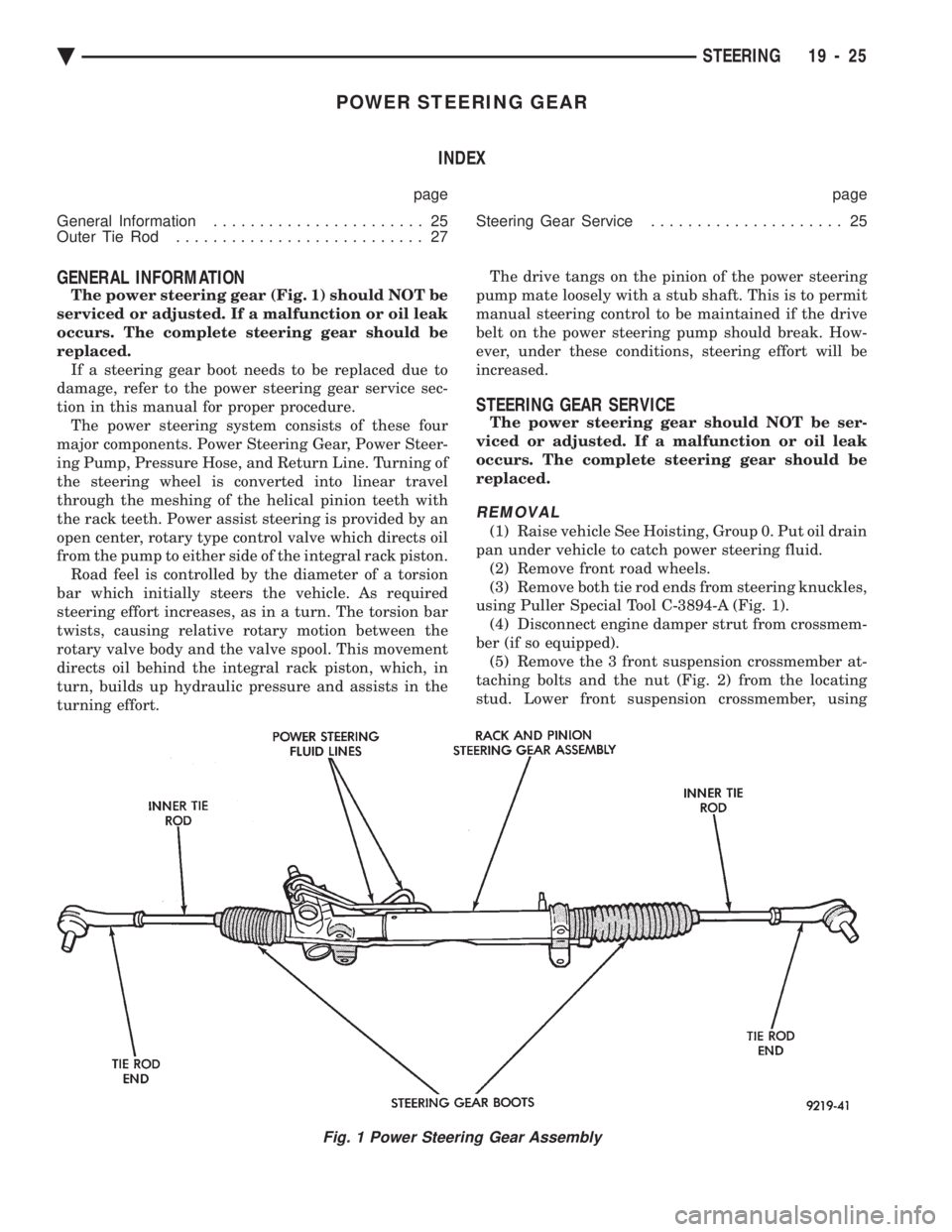

The power steering gear (Fig. 1) should NOT be

serviced or adjusted. If a malfunction or oil leak

occurs. The complete steering gear should be

replaced. If a steering gear boot needs to be replaced due to

damage, refer to the power steering gear service sec-

tion in this manual for proper procedure. The power steering system consists of these four

major components. Power Steering Gear, Power Steer-

ing Pump, Pressure Hose, and Return Line. Turning of

the steering wheel is converted into linear travel

through the meshing of the helical pinion teeth with

the rack teeth. Power assist steering is provided by an

open center, rotary type control valve which directs oil

from the pump to either side of the integral rack piston. Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As required

steering effort increases, as in a turn. The torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This movement

directs oil behind the integral rack piston, which, in

turn, builds up hydraulic pressure and assists in the

turning effort. The drive tangs on the pinion of the power steering

pump mate loosely with a stub shaft. This is to permit

manual steering control to be maintained if the drive

belt on the power steering pump should break. How-

ever, under these conditions, steering effort will be

increased.

STEERING GEAR SERVICE

The power steering gear should NOT be ser-

viced or adjusted. If a malfunction or oil leak

occurs. The complete steering gear should be

replaced.

REMOVAL

(1) Raise vehicle See Hoisting, Group 0. Put oil drain

pan under vehicle to catch power steering fluid. (2) Remove front road wheels.

(3) Remove both tie rod ends from steering knuckles,

using Puller Special Tool C-3894-A (Fig. 1). (4) Disconnect engine damper strut from crossmem-

ber (if so equipped). (5) Remove the 3 front suspension crossmember at-

taching bolts and the nut (Fig. 2) from the locating

stud. Lower front suspension crossmember, using

Fig. 1 Power Steering Gear Assembly

Ä STEERING 19 - 25

Page 1945 of 2438

bolts and nut on locating stud (Fig. 2). The right rear

crossmember stud is a pilot that correctly locates

the crossmember. Tighten down this bolt first,

then torque all 4 crossmember fasteners to 122

N Im (90 ft. lbs.).

CAUTION: Proper torque on the crossmember to

frame rail mounting bolts is very important.

(3) Torque the 4 bolts (Fig. 3) attaching the steering

gear assembly to front crossmember, to 68 N Im (50 ft.

lbs.). To ensure proper alignment of the steering

gear tighten left front bolt first. (4) Attach the engine damper strut from the engine

to the crossmember (if so equipped). (5) Attach the fluid tubes (Fig. 3) from the power

steering pump to the fittings on the steering gear.

Torque the fluid pressure line to steering gear tube nut

to 31 N Im (275 in. lbs.).

(6) Mount the outer tie rod ends to the steering

knuckles. Install the tie rod end to steering knuckle

attaching nuts. Torque the tie rod end to steering

knuckle nuts to 52 N Im (38 ft. lbs.). Install cotter pin

in tie rod end. (7) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 129

N Im (95 ft. lbs.).

(8) Lower vehicle.

CAUTION: Do not use automatic transmission fluid. (9) Fill power steering pump fluid reservoir to the

(Full-Cold) proper level. (10) Start the engine and let run for a few seconds.

Then turn the engine off.

(11) Add fluid if necessary.

(12) Raise front wheels of vehicle off the ground.

(13) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in

system. Stop engine, check fluid level, and inspect

system for leaks. Fill pump reservoir to correct

level with Mopar t, Power Steering Fluid, or

equivalent. See Checking Fluid Level.

(14) Lower front wheels of vehicle back on the

ground. (15) Adjust toe (Refer to Group 2 Suspension).

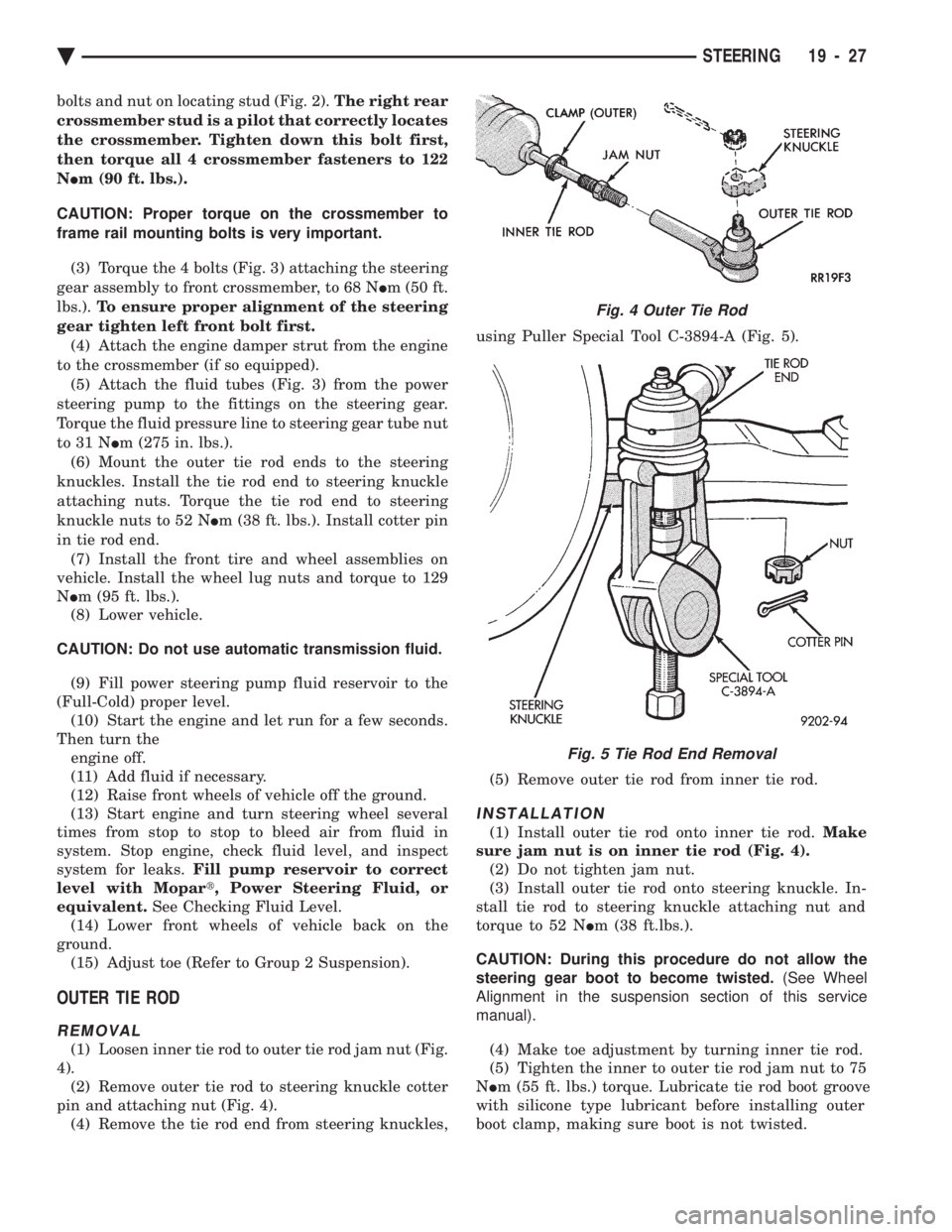

OUTER TIE ROD

REMOVAL

(1) Loosen inner tie rod to outer tie rod jam nut (Fig.

4). (2) Remove outer tie rod to steering knuckle cotter

pin and attaching nut (Fig. 4). (4) Remove the tie rod end from steering knuckles, using Puller Special Tool C-3894-A (Fig. 5).

(5) Remove outer tie rod from inner tie rod.

INSTALLATION

(1) Install outer tie rod onto inner tie rod. Make

sure jam nut is on inner tie rod (Fig. 4). (2) Do not tighten jam nut.

(3) Install outer tie rod onto steering knuckle. In-

stall tie rod to steering knuckle attaching nut and

torque to 52 N Im (38 ft.lbs.).

CAUTION: During this procedure do not allow the

steering gear boot to become twisted. (See Wheel

Alignment in the suspension section of this service

manual).

(4) Make toe adjustment by turning inner tie rod.

(5) Tighten the inner to outer tie rod jam nut to 75

N Im (55 ft. lbs.) torque. Lubricate tie rod boot groove

with silicone type lubricant before installing outer

boot clamp, making sure boot is not twisted.

Fig. 4 Outer Tie Rod

Fig. 5 Tie Rod End Removal

Ä STEERING 19 - 27

Page 1963 of 2438

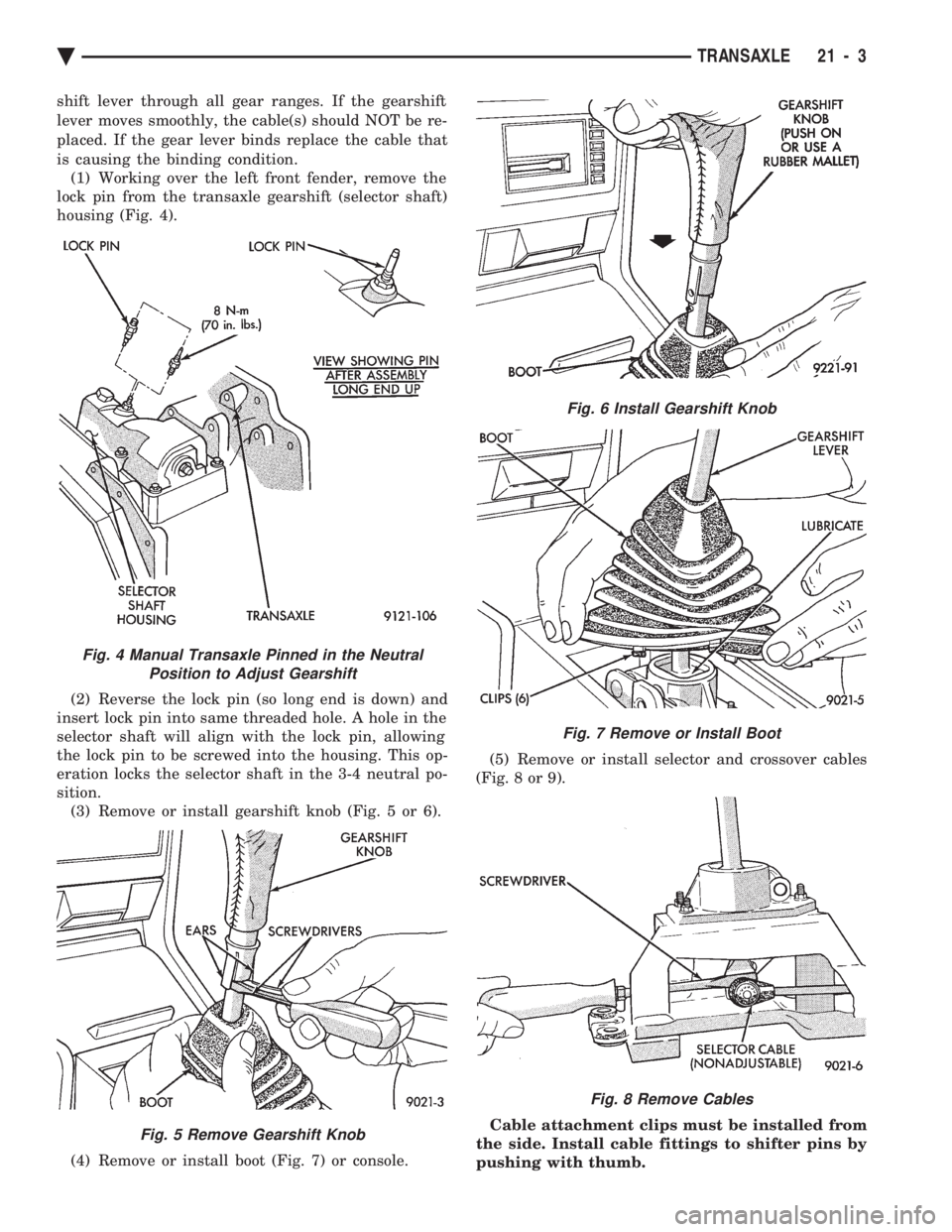

shift lever through all gear ranges. If the gearshift

lever moves smoothly, the cable(s) should NOT be re-

placed. If the gear lever binds replace the cable that

is causing the binding condition. (1) Working over the left front fender, remove the

lock pin from the transaxle gearshift (selector shaft)

housing (Fig. 4).

(2) Reverse the lock pin (so long end is down) and

insert lock pin into same threaded hole. A hole in the

selector shaft will align with the lock pin, allowing

the lock pin to be screwed into the housing. This op-

eration locks the selector shaft in the 3-4 neutral po-

sition. (3) Remove or install gearshift knob (Fig. 5 or 6).

(4) Remove or install boot (Fig. 7) or console. (5) Remove or install selector and crossover cables

(Fig. 8 or 9).

Cable attachment clips must be installed from

the side. Install cable fittings to shifter pins by

pushing with thumb.

Fig. 4 Manual Transaxle Pinned in the Neutral Position to Adjust Gearshift

Fig. 5 Remove Gearshift Knob

Fig. 6 Install Gearshift Knob

Fig. 7 Remove or Install Boot

Fig. 8 Remove Cables

Ä TRANSAXLE 21 - 3

Page 1981 of 2438

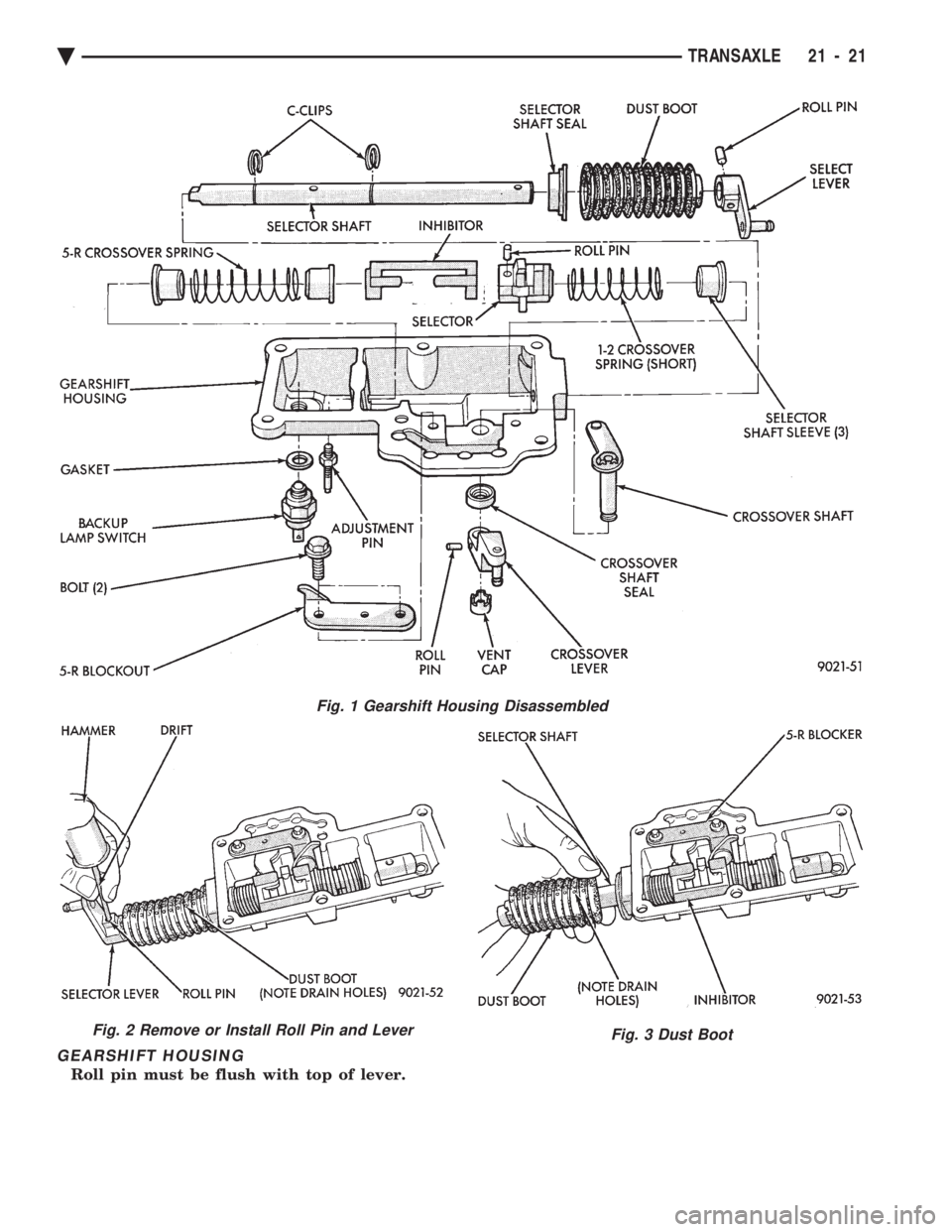

GEARSHIFT HOUSING

Roll pin must be flush with top of lever.

Fig. 1 Gearshift Housing Disassembled

Fig. 2 Remove or Install Roll Pin and LeverFig. 3 Dust Boot

Ä TRANSAXLE 21 - 21

Page 2185 of 2438

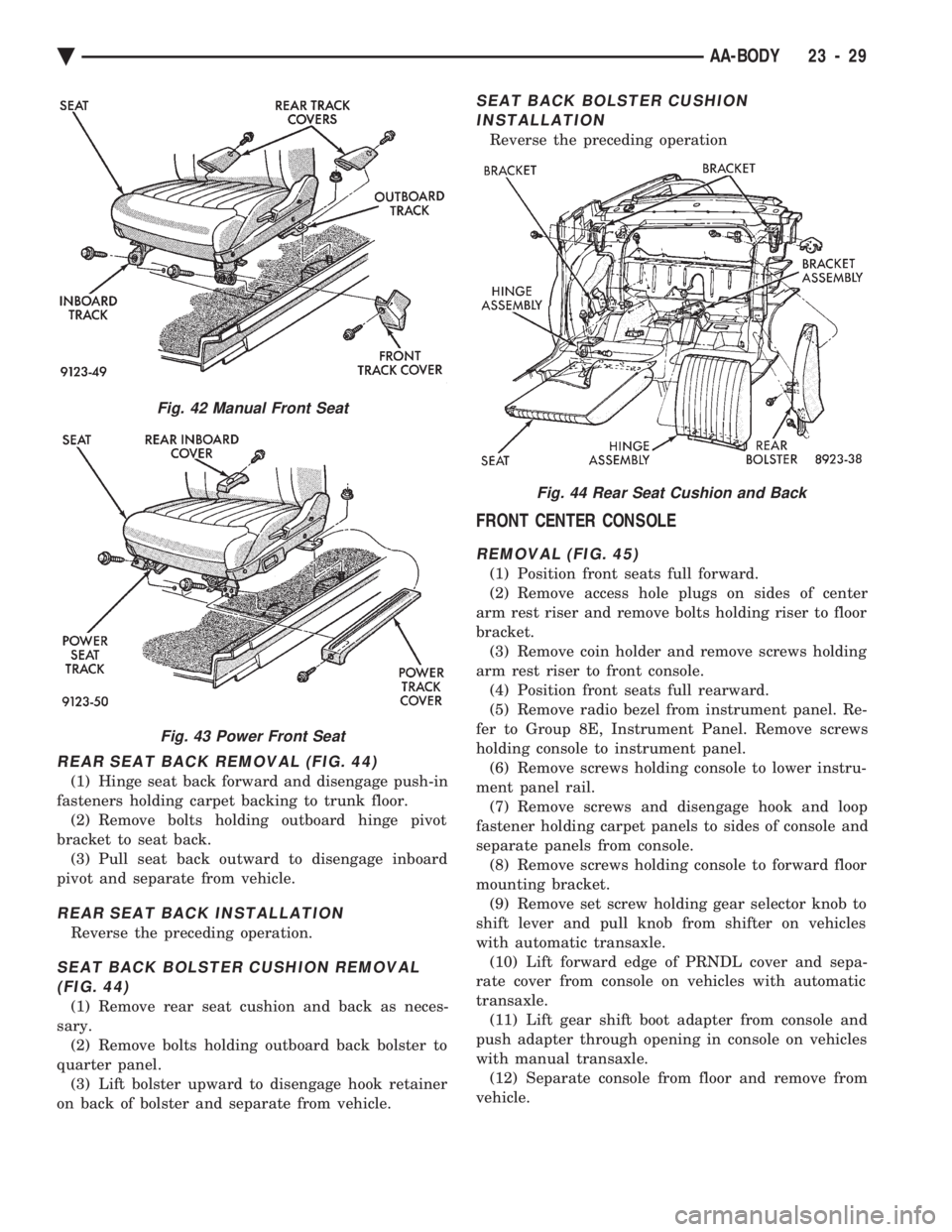

REAR SEAT BACK REMOVAL (FIG. 44)

(1) Hinge seat back forward and disengage push-in

fasteners holding carpet backing to trunk floor. (2) Remove bolts holding outboard hinge pivot

bracket to seat back. (3) Pull seat back outward to disengage inboard

pivot and separate from vehicle.

REAR SEAT BACK INSTALLATION

Reverse the preceding operation.

SEAT BACK BOLSTER CUSHION REMOVAL (FIG. 44)

(1) Remove rear seat cushion and back as neces-

sary. (2) Remove bolts holding outboard back bolster to

quarter panel. (3) Lift bolster upward to disengage hook retainer

on back of bolster and separate from vehicle.

SEAT BACK BOLSTER CUSHION INSTALLATION

Reverse the preceding operation

FRONT CENTER CONSOLE

REMOVAL (FIG. 45)

(1) Position front seats full forward.

(2) Remove access hole plugs on sides of center

arm rest riser and remove bolts holding riser to floor

bracket. (3) Remove coin holder and remove screws holding

arm rest riser to front console. (4) Position front seats full rearward.

(5) Remove radio bezel from instrument panel. Re-

fer to Group 8E, Instrument Panel. Remove screws

holding console to instrument panel. (6) Remove screws holding console to lower instru-

ment panel rail. (7) Remove screws and disengage hook and loop

fastener holding carpet panels to sides of console and

separate panels from console. (8) Remove screws holding console to forward floor

mounting bracket. (9) Remove set screw holding gear selector knob to

shift lever and pull knob from shifter on vehicles

with automatic transaxle. (10) Lift forward edge of PRNDL cover and sepa-

rate cover from console on vehicles with automatic

transaxle. (11) Lift gear shift boot adapter from console and

push adapter through opening in console on vehicles

with manual transaxle. (12) Separate console from floor and remove from

vehicle.

Fig. 42 Manual Front Seat

Fig. 43 Power Front Seat

Fig. 44 Rear Seat Cushion and Back

Ä AA-BODY 23 - 29

Page 2243 of 2438

QUARTER WINDOW

REMOVAL

(1) Disengage snaps holding sling well to rear deck

panel. (2) From each side of vehicle, Disengage clips hold-

ing sling well to belt reinforcement brace. Drape

sling well over rear seat back into passenger com-

partment. (3) Remove screw holding quarter trim panel and

door weatherstrip to door opening. (4) Remove the cowl trim and scuff plate covers.

(5) Remove the rear seat cushion.

(6) Disconnect rear speaker wire connectors.

(7) Remove screws holding seat back to floor

brackets and rear shoulder belt retractors (Fig. 1).

Separate rear seat back from vehicle. (8) Remove screws holding quarter trim to quarter

panel at the boot latches. (9) Remove screws holding quarter trim to floor

pan kick up. (10) Separate quarter trim from rear reinforce-

ment. Position trim panel out of quarter window re-

moval path (Fig. 3). (11) Raise quarter window approximately 100 mm

(4 in.) from the down position. (12) Remove bolt holding glass stabilizer bumper

to top of quarter panel opening. (13) Disconnect power window motor wire connec-

tor. (14) Remove bolts holding quarter window assem-

bly to quarter panel and lift the assembly through

the opening at the top of the quarter panel.

INSTALLATION

Reverse the preceding operation. Align the quarter

glass to have adequate pressure on the weatherstrips

for proper sealing. Insert sling well drain tubes into

the holes in the floor pan.

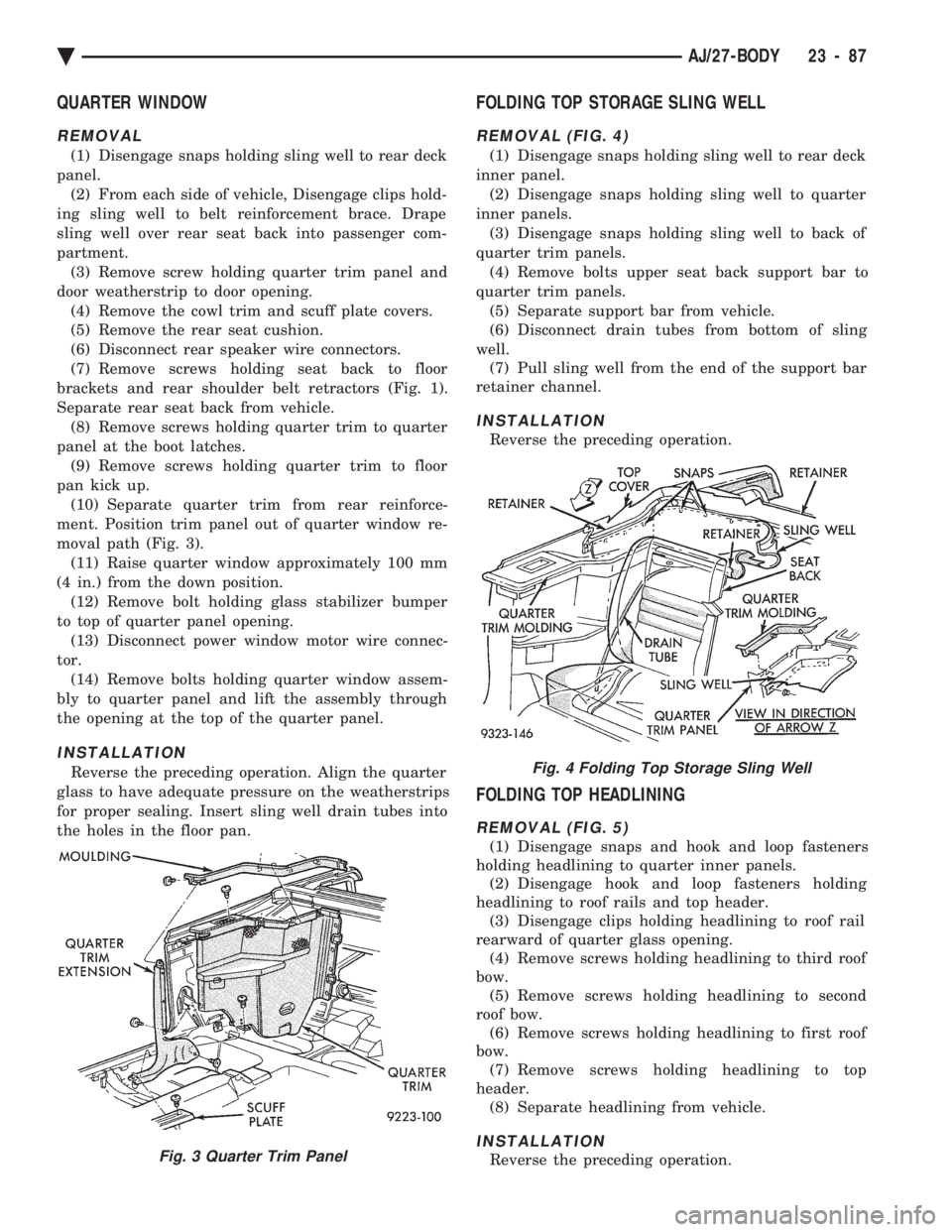

FOLDING TOP STORAGE SLING WELL

REMOVAL (FIG. 4)

(1) Disengage snaps holding sling well to rear deck

inner panel. (2) Disengage snaps holding sling well to quarter

inner panels. (3) Disengage snaps holding sling well to back of

quarter trim panels. (4) Remove bolts upper seat back support bar to

quarter trim panels. (5) Separate support bar from vehicle.

(6) Disconnect drain tubes from bottom of sling

well. (7) Pull sling well from the end of the support bar

retainer channel.

INSTALLATION

Reverse the preceding operation.

FOLDING TOP HEADLINING

REMOVAL (FIG. 5)

(1) Disengage snaps and hook and loop fasteners

holding headlining to quarter inner panels. (2) Disengage hook and loop fasteners holding

headlining to roof rails and top header. (3) Disengage clips holding headlining to roof rail

rearward of quarter glass opening. (4) Remove screws holding headlining to third roof

bow. (5) Remove screws holding headlining to second

roof bow. (6) Remove screws holding headlining to first roof

bow. (7) Remove screws holding headlining to top

header. (8) Separate headlining from vehicle.

INSTALLATION

Reverse the preceding operation.Fig. 3 Quarter Trim Panel

Fig. 4 Folding Top Storage Sling Well

Ä AJ/27-BODY 23 - 87

Page 2269 of 2438

REAR SEAT BACK INSTALLATION

Reverse the preceding operation.

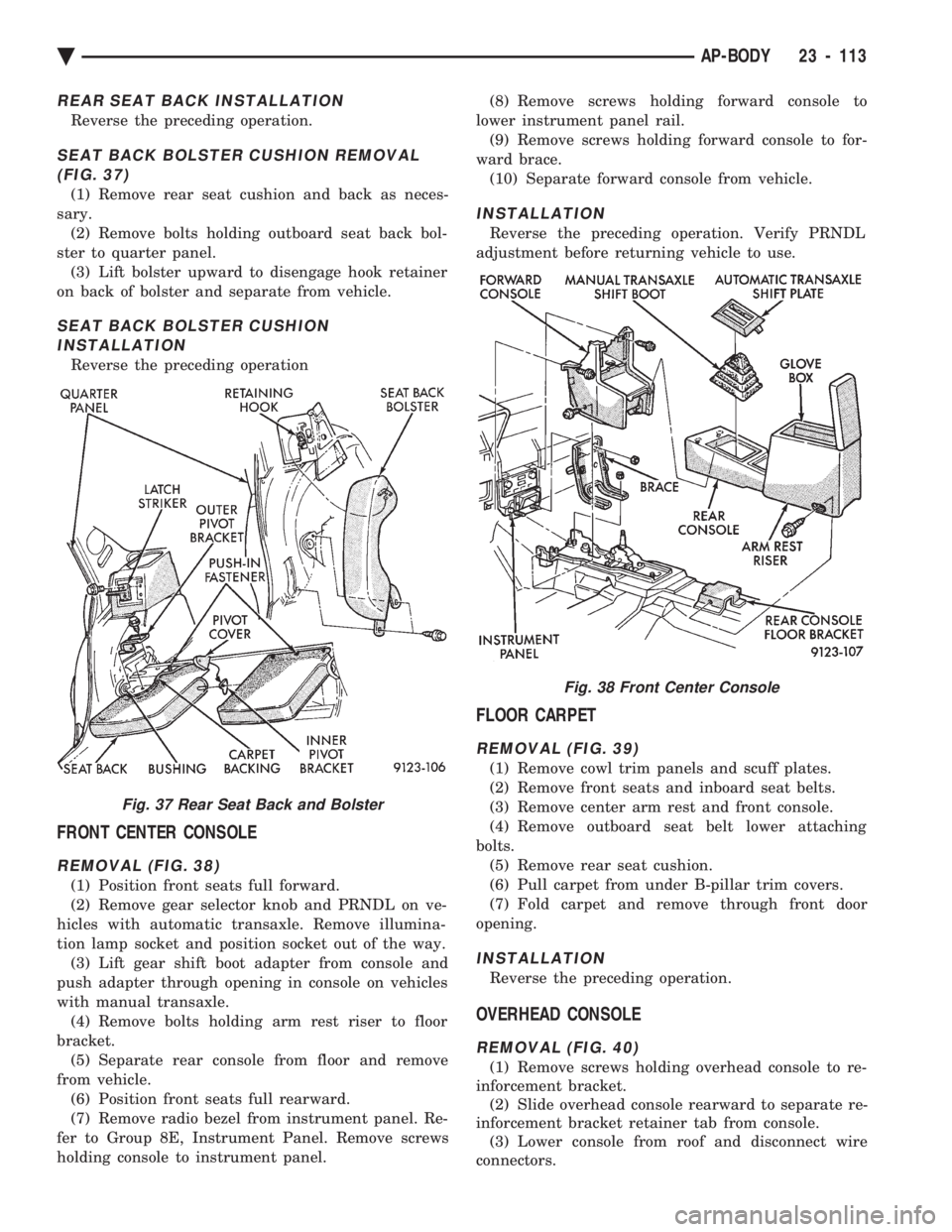

SEAT BACK BOLSTER CUSHION REMOVAL (FIG. 37)

(1) Remove rear seat cushion and back as neces-

sary. (2) Remove bolts holding outboard seat back bol-

ster to quarter panel. (3) Lift bolster upward to disengage hook retainer

on back of bolster and separate from vehicle.

SEAT BACK BOLSTER CUSHION INSTALLATION

Reverse the preceding operation

FRONT CENTER CONSOLE

REMOVAL (FIG. 38)

(1) Position front seats full forward.

(2) Remove gear selector knob and PRNDL on ve-

hicles with automatic transaxle. Remove illumina-

tion lamp socket and position socket out of the way. (3) Lift gear shift boot adapter from console and

push adapter through opening in console on vehicles

with manual transaxle. (4) Remove bolts holding arm rest riser to floor

bracket. (5) Separate rear console from floor and remove

from vehicle. (6) Position front seats full rearward.

(7) Remove radio bezel from instrument panel. Re-

fer to Group 8E, Instrument Panel. Remove screws

holding console to instrument panel. (8) Remove screws holding forward console to

lower instrument panel rail. (9) Remove screws holding forward console to for-

ward brace. (10) Separate forward console from vehicle.

INSTALLATION

Reverse the preceding operation. Verify PRNDL

adjustment before returning vehicle to use.

FLOOR CARPET

REMOVAL (FIG. 39)

(1) Remove cowl trim panels and scuff plates.

(2) Remove front seats and inboard seat belts.

(3) Remove center arm rest and front console.

(4) Remove outboard seat belt lower attaching

bolts. (5) Remove rear seat cushion.

(6) Pull carpet from under B-pillar trim covers.

(7) Fold carpet and remove through front door

opening.

INSTALLATION

Reverse the preceding operation.

OVERHEAD CONSOLE

REMOVAL (FIG. 40)

(1) Remove screws holding overhead console to re-

inforcement bracket. (2) Slide overhead console rearward to separate re-

inforcement bracket retainer tab from console. (3) Lower console from roof and disconnect wire

connectors.

Fig. 37 Rear Seat Back and Bolster

Fig. 38 Front Center Console

Ä AP-BODY 23 - 113

Page 2315 of 2438

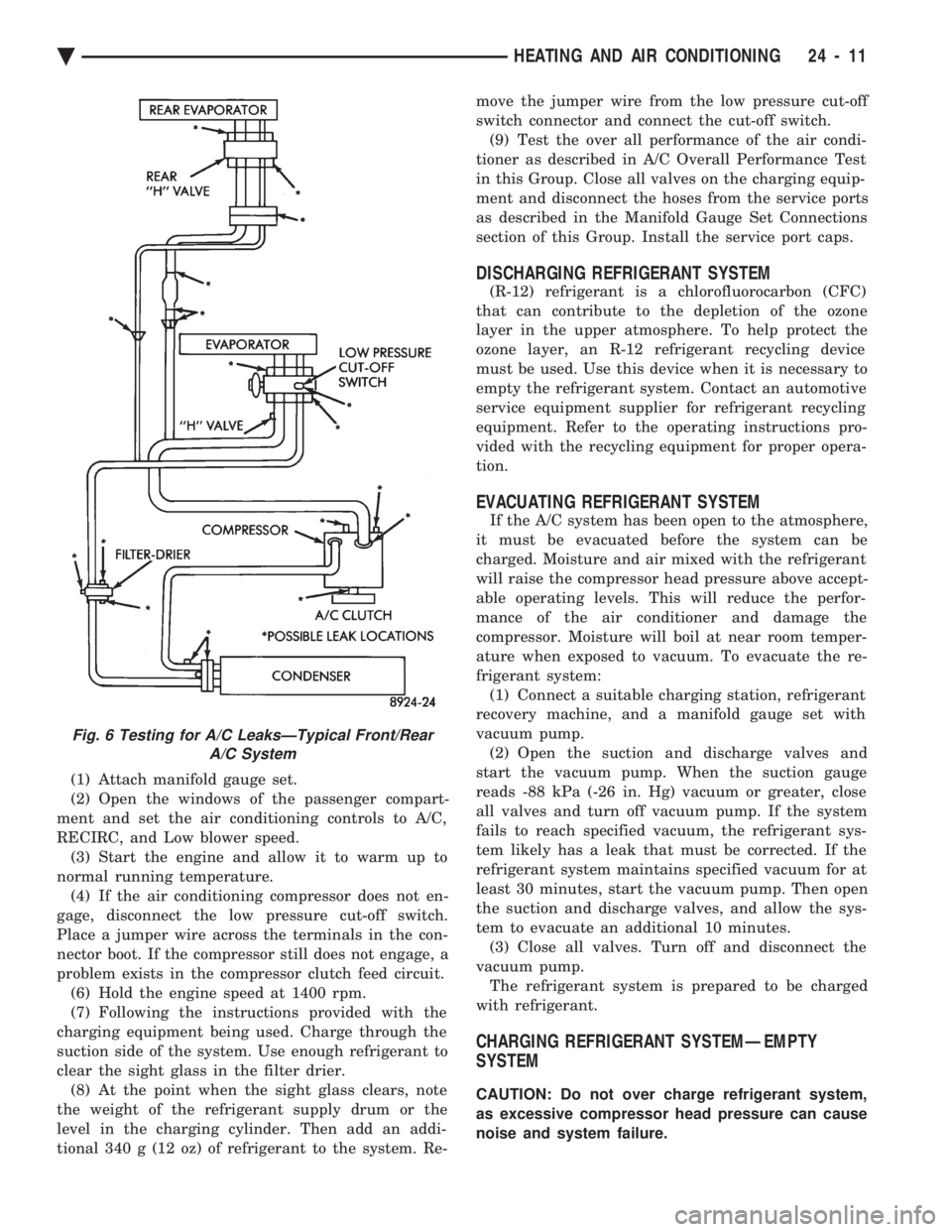

(1) Attach manifold gauge set.

(2) Open the windows of the passenger compart-

ment and set the air conditioning controls to A/C,

RECIRC, and Low blower speed. (3) Start the engine and allow it to warm up to

normal running temperature. (4) If the air conditioning compressor does not en-

gage, disconnect the low pressure cut-off switch.

Place a jumper wire across the terminals in the con-

nector boot. If the compressor still does not engage, a

problem exists in the compressor clutch feed circuit. (6) Hold the engine speed at 1400 rpm.

(7) Following the instructions provided with the

charging equipment being used. Charge through the

suction side of the system. Use enough refrigerant to

clear the sight glass in the filter drier. (8) At the point when the sight glass clears, note

the weight of the refrigerant supply drum or the

level in the charging cylinder. Then add an addi-

tional 340 g (12 oz) of refrigerant to the system. Re- move the jumper wire from the low pressure cut-off

switch connector and connect the cut-off switch.

(9) Test the over all performance of the air condi-

tioner as described in A/C Overall Performance Test

in this Group. Close all valves on the charging equip-

ment and disconnect the hoses from the service ports

as described in the Manifold Gauge Set Connections

section of this Group. Install the service port caps.

DISCHARGING REFRIGERANT SYSTEM

(R-12) refrigerant is a chlorofluorocarbon (CFC)

that can contribute to the depletion of the ozone

layer in the upper atmosphere. To help protect the

ozone layer, an R-12 refrigerant recycling device

must be used. Use this device when it is necessary to

empty the refrigerant system. Contact an automotive

service equipment supplier for refrigerant recycling

equipment. Refer to the operating instructions pro-

vided with the recycling equipment for proper opera-

tion.

EVACUATING REFRIGERANT SYSTEM

If the A/C system has been open to the atmosphere,

it must be evacuated before the system can be

charged. Moisture and air mixed with the refrigerant

will raise the compressor head pressure above accept-

able operating levels. This will reduce the perfor-

mance of the air conditioner and damage the

compressor. Moisture will boil at near room temper-

ature when exposed to vacuum. To evacuate the re-

frigerant system: (1) Connect a suitable charging station, refrigerant

recovery machine, and a manifold gauge set with

vacuum pump. (2) Open the suction and discharge valves and

start the vacuum pump. When the suction gauge

reads -88 kPa (-26 in. Hg) vacuum or greater, close

all valves and turn off vacuum pump. If the system

fails to reach specified vacuum, the refrigerant sys-

tem likely has a leak that must be corrected. If the

refrigerant system maintains specified vacuum for at

least 30 minutes, start the vacuum pump. Then open

the suction and discharge valves, and allow the sys-

tem to evacuate an additional 10 minutes. (3) Close all valves. Turn off and disconnect the

vacuum pump. The refrigerant system is prepared to be charged

with refrigerant.

CHARGING REFRIGERANT SYSTEMÐEMPTY

SYSTEM

CAUTION: Do not over charge refrigerant system,

as excessive compressor head pressure can cause

noise and system failure.

Fig. 6 Testing for A/C LeaksÐTypical Front/Rear A/C System

Ä HEATING AND AIR CONDITIONING 24 - 11

Page 2352 of 2438

WARNING: AVOID RADIATOR/CONDENSER FAN

BLADES WHEN WORKING IN THE RADIATOR

AREA. FAN IS CONTROLLED BY TEMPERATURE

AND CAN START ANY TIME IGNITION IS ON. PER-

SONAL INJURY CAN RESULT.

(1) Disconnect fan control switch wire connector.

(2) Using a suitable jumper wire, jump across ter-

minals in wire connector. (3) Connect a suitable continuity tester across fan

control switch terminals. (4) Start engine and set idle at 1300 rpm. The ra-

diator fan should run constantly. (5) Set the A/C controls to A/C and high blower.

(6) If the high pressure gauge reads below 1102

kPa (160 psi) there should be no continuity across

the switch terminals.

CAUTION: Do not allow engine to overheat when ra-

diator air flow is blocked.

(7) Block radiator air flow with a suitable cover to

increase the high side pressure to at least 1585 kPa

(230 psi). Electrical continuity should be detected

across the fan control switch terminals. (8) Remove cover from front of vehicle to allow

high side pressure to decrease. When pressure drops

below 1102 kPa (160 psi), continuity should cease. If fan control switch is defective, replace it.

REMOVAL AND INSTALLATION

CAUTION: Refrigerant removal is not necessary

when removing the Condenser Fan Control Switch.

However, a small amount of refrigerant will vent

from the switch port. Review the refrigerant han-

dling section of Safety Precautions and Warnings in

the General Information section of this Group.

(1) Disconnect wire connector from condenser fan

control switch. (2) Loosen and quickly rotate the switch counter-

clockwise and separate from the high pressure line

switch port. To install, reverse the preceding operation.

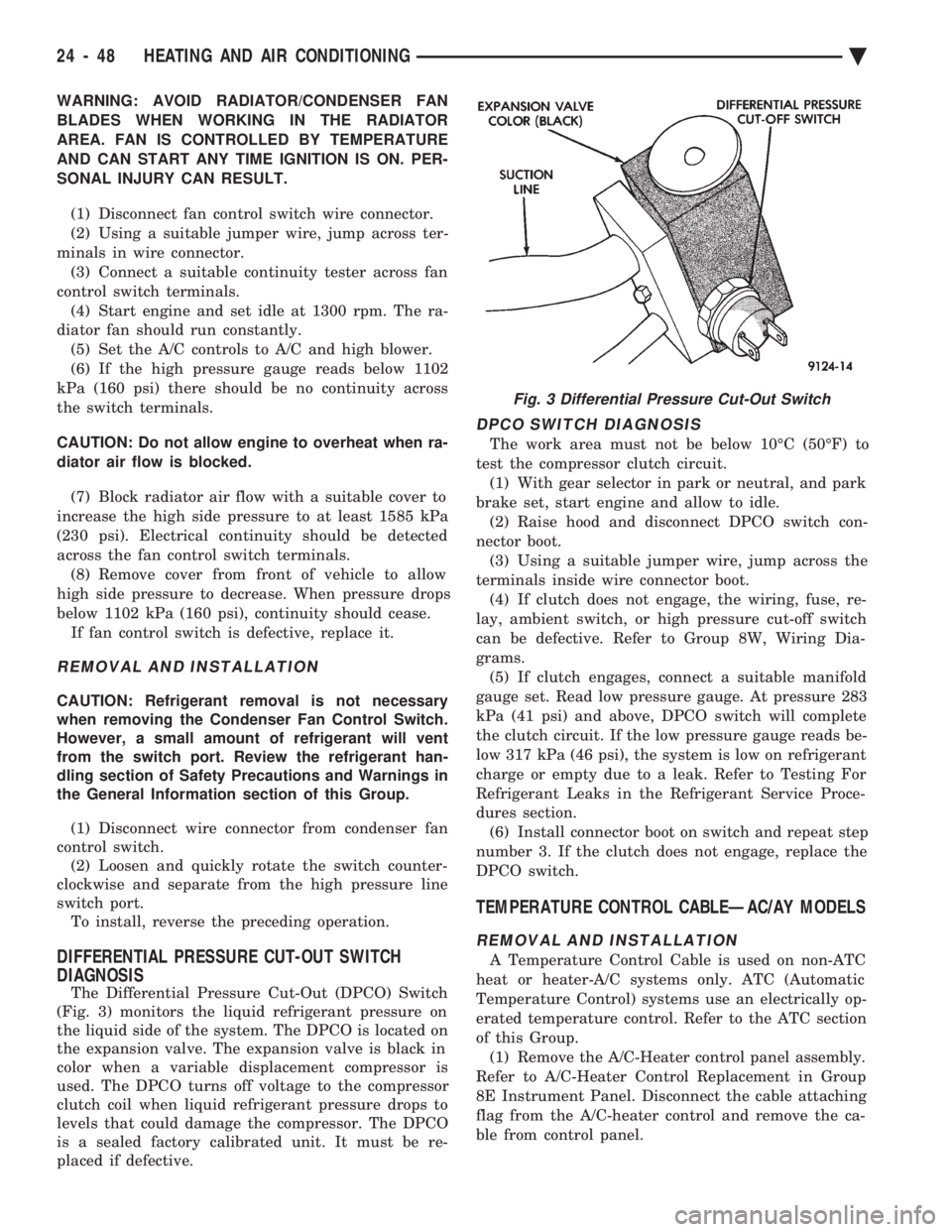

DIFFERENTIAL PRESSURE CUT-OUT SWITCH

DIAGNOSIS

The Differential Pressure Cut-Out (DPCO) Switch

(Fig. 3) monitors the liquid refrigerant pressure on

the liquid side of the system. The DPCO is located on

the expansion valve. The expansion valve is black in

color when a variable displacement compressor is

used. The DPCO turns off voltage to the compressor

clutch coil when liquid refrigerant pressure drops to

levels that could damage the compressor. The DPCO

is a sealed factory calibrated unit. It must be re-

placed if defective.

DPCO SWITCH DIAGNOSIS

The work area must not be below 10ÉC (50ÉF) to

test the compressor clutch circuit. (1) With gear selector in park or neutral, and park

brake set, start engine and allow to idle. (2) Raise hood and disconnect DPCO switch con-

nector boot. (3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot. (4) If clutch does not engage, the wiring, fuse, re-

lay, ambient switch, or high pressure cut-off switch

can be defective. Refer to Group 8W, Wiring Dia-

grams. (5) If clutch engages, connect a suitable manifold

gauge set. Read low pressure gauge. At pressure 283

kPa (41 psi) and above, DPCO switch will complete

the clutch circuit. If the low pressure gauge reads be-

low 317 kPa (46 psi), the system is low on refrigerant

charge or empty due to a leak. Refer to Testing For

Refrigerant Leaks in the Refrigerant Service Proce-

dures section. (6) Install connector boot on switch and repeat step

number 3. If the clutch does not engage, replace the

DPCO switch.

TEMPERATURE CONTROL CABLEÐAC/AY MODELS

REMOVAL AND INSTALLATION

A Temperature Control Cable is used on non-ATC

heat or heater-A/C systems only. ATC (Automatic

Temperature Control) systems use an electrically op-

erated temperature control. Refer to the ATC section

of this Group. (1) Remove the A/C-Heater control panel assembly.

Refer to A/C-Heater Control Replacement in Group

8E Instrument Panel. Disconnect the cable attaching

flag from the A/C-heater control and remove the ca-

ble from control panel.

Fig. 3 Differential Pressure Cut-Out Switch

24 - 48 HEATING AND AIR CONDITIONING Ä

Page 2358 of 2438

housing) through the hole in the housing. Feed the

wire harness and connector through the opening and

into the housing (Fig. 19). (3) Work through the air inlet opening (to the left of

the blower motor wheel). Pull the fin-sensing cycling

switch from the A/C evaporator (Fig. 20). The metal

probe on the switch is pushed into the evapora-

tor approximately three inches.

To install, reverse the preceding operation. The

switch probe should not be installed in the original

location (hole). Insert the probe in the evaporator coil

approximately 5 mm (3 to 4 fins) to the right or left of

the position it was removed. This will insure correct

temperature sensing and system performance. Exces-

sive force should not be required for probe insertion.

Care should be taken not to damage the A/C evaporator

coil or the switch probe.

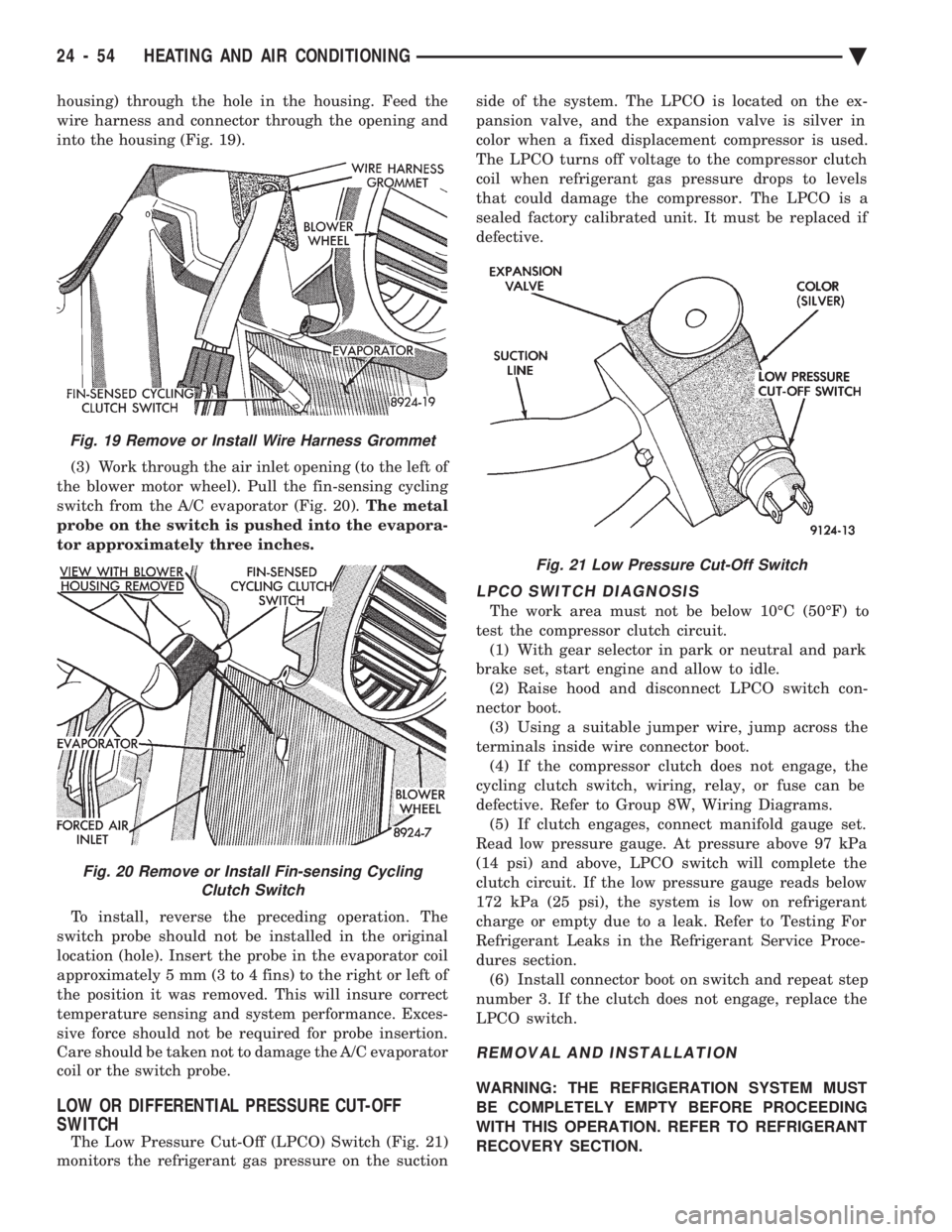

LOW OR DIFFERENTIAL PRESSURE CUT-OFF

SWITCH

The Low Pressure Cut-Off (LPCO) Switch (Fig. 21)

monitors the refrigerant gas pressure on the suction side of the system. The LPCO is located on the ex-

pansion valve, and the expansion valve is silver in

color when a fixed displacement compressor is used.

The LPCO turns off voltage to the compressor clutch

coil when refrigerant gas pressure drops to levels

that could damage the compressor. The LPCO is a

sealed factory calibrated unit. It must be replaced if

defective.

LPCO SWITCH DIAGNOSIS

The work area must not be below 10ÉC (50ÉF) to

test the compressor clutch circuit. (1) With gear selector in park or neutral and park

brake set, start engine and allow to idle. (2) Raise hood and disconnect LPCO switch con-

nector boot. (3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot. (4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams. (5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, LPCO switch will complete the

clutch circuit. If the low pressure gauge reads below

172 kPa (25 psi), the system is low on refrigerant

charge or empty due to a leak. Refer to Testing For

Refrigerant Leaks in the Refrigerant Service Proce-

dures section. (6) Install connector boot on switch and repeat step

number 3. If the clutch does not engage, replace the

LPCO switch.

REMOVAL AND INSTALLATION

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION. REFER TO REFRIGERANT

RECOVERY SECTION.

Fig. 21 Low Pressure Cut-Off Switch

Fig. 19 Remove or Install Wire Harness Grommet

Fig. 20 Remove or Install Fin-sensing Cycling Clutch Switch

24 - 54 HEATING AND AIR CONDITIONING Ä