water pump CHEVROLET DYNASTY 1993 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1805 of 2438

The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera-

tion. The PCM will enrichen the air/fuel ratio to

increase performance and compensate for increased

combustion chamber temperature. The PCM determines the methanol content of the

fuel from the methanol concentration sensor input.

IGNITION SWITCH OFF MODE

This is an OPEN LOOP mode. When the ignition

switch is turned to the OFF position, the following

occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

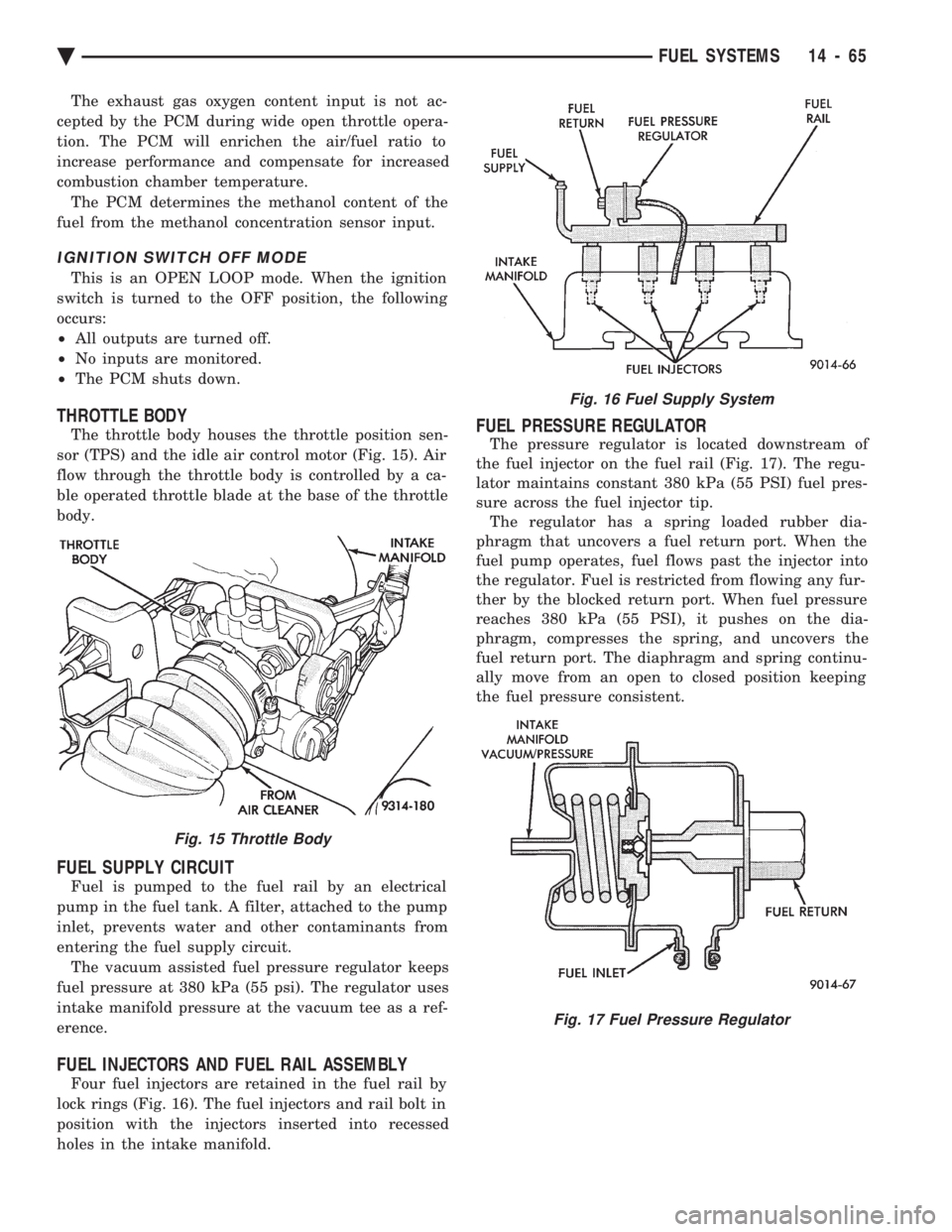

THROTTLE BODY

The throttle body houses the throttle position sen-

sor (TPS) and the idle air control motor (Fig. 15). Air

flow through the throttle body is controlled by a ca-

ble operated throttle blade at the base of the throttle

body.

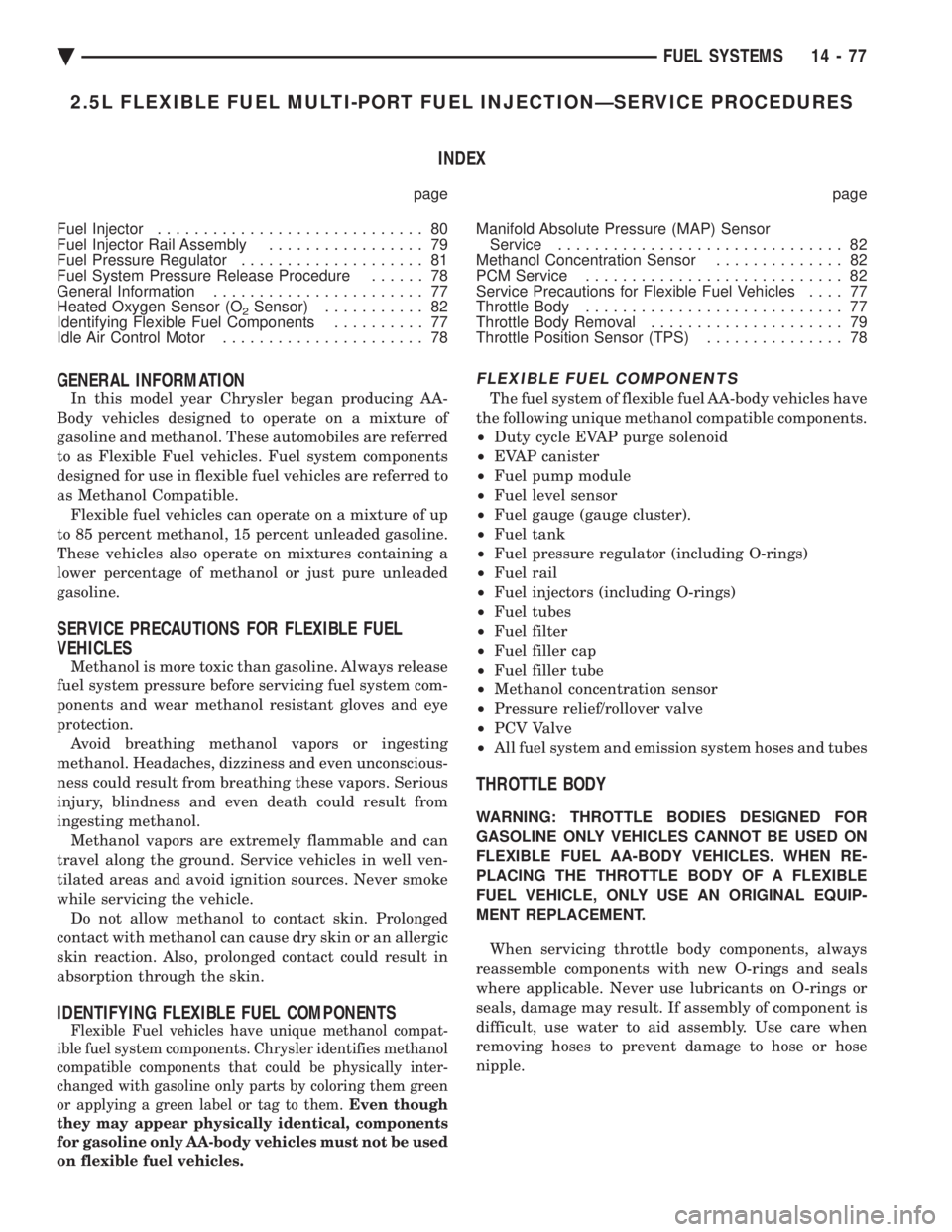

FUEL SUPPLY CIRCUIT

Fuel is pumped to the fuel rail by an electrical

pump in the fuel tank. A filter, attached to the pump

inlet, prevents water and other contaminants from

entering the fuel supply circuit. The vacuum assisted fuel pressure regulator keeps

fuel pressure at 380 kPa (55 psi). The regulator uses

intake manifold pressure at the vacuum tee as a ref-

erence.

FUEL INJECTORS AND FUEL RAIL ASSEMBLY

Four fuel injectors are retained in the fuel rail by

lock rings (Fig. 16). The fuel injectors and rail bolt in

position with the injectors inserted into recessed

holes in the intake manifold.

FUEL PRESSURE REGULATOR

The pressure regulator is located downstream of

the fuel injector on the fuel rail (Fig. 17). The regu-

lator maintains constant 380 kPa (55 PSI) fuel pres-

sure across the fuel injector tip. The regulator has a spring loaded rubber dia-

phragm that uncovers a fuel return port. When the

fuel pump operates, fuel flows past the injector into

the regulator. Fuel is restricted from flowing any fur-

ther by the blocked return port. When fuel pressure

reaches 380 kPa (55 PSI), it pushes on the dia-

phragm, compresses the spring, and uncovers the

fuel return port. The diaphragm and spring continu-

ally move from an open to closed position keeping

the fuel pressure consistent.

Fig. 15 Throttle Body

Fig. 16 Fuel Supply System

Fig. 17 Fuel Pressure Regulator

Ä FUEL SYSTEMS 14 - 65

Page 1817 of 2438

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES INDEX

page page

Fuel Injector ............................. 80

Fuel Injector Rail Assembly ................. 79

Fuel Pressure Regulator .................... 81

Fuel System Pressure Release Procedure ...... 78

General Information ....................... 77

Heated Oxygen Sensor (O

2Sensor) ........... 82

Identifying Flexible Fuel Components .......... 77

Idle Air Control Motor ...................... 78 Manifold Absolute Pressure (MAP) Sensor

Service ............................... 82

Methanol Concentration Sensor .............. 82

PCM Service ............................ 82

Service Precautions for Flexible Fuel Vehicles .... 77

Throttle Body ............................ 77

Throttle Body Removal ..................... 79

Throttle Position Sensor (TPS) ............... 78

GENERAL INFORMATION

In this model year Chrysler began producing AA-

Body vehicles designed to operate on a mixture of

gasoline and methanol. These automobiles are referred

to as Flexible Fuel vehicles. Fuel system components

designed for use in flexible fuel vehicles are referred to

as Methanol Compatible. Flexible fuel vehicles can operate on a mixture of up

to 85 percent methanol, 15 percent unleaded gasoline.

These vehicles also operate on mixtures containing a

lower percentage of methanol or just pure unleaded

gasoline.

SERVICE PRECAUTIONS FOR FLEXIBLE FUEL

VEHICLES

Methanol is more toxic than gasoline. Always release

fuel system pressure before servicing fuel system com-

ponents and wear methanol resistant gloves and eye

protection. Avoid breathing methanol vapors or ingesting

methanol. Headaches, dizziness and even unconscious-

ness could result from breathing these vapors. Serious

injury, blindness and even death could result from

ingesting methanol. Methanol vapors are extremely flammable and can

travel along the ground. Service vehicles in well ven-

tilated areas and avoid ignition sources. Never smoke

while servicing the vehicle. Do not allow methanol to contact skin. Prolonged

contact with methanol can cause dry skin or an allergic

skin reaction. Also, prolonged contact could result in

absorption through the skin.

IDENTIFYING FLEXIBLE FUEL COMPONENTS

Flexible Fuel vehicles have unique methanol compat-

ible fuel system components. Chrysler identifies methanol

compatible components that could be physically inter-

changed with gasoline only parts by coloring them green

or applying a green label or tag to them. Even though

they may appear physically identical, components

for gasoline only AA-body vehicles must not be used

on flexible fuel vehicles.

FLEXIBLE FUEL COMPONENTS

The fuel system of flexible fuel AA-body vehicles have

the following unique methanol compatible components.

² Duty cycle EVAP purge solenoid

² EVAP canister

² Fuel pump module

² Fuel level sensor

² Fuel gauge (gauge cluster).

² Fuel tank

² Fuel pressure regulator (including O-rings)

² Fuel rail

² Fuel injectors (including O-rings)

² Fuel tubes

² Fuel filter

² Fuel filler cap

² Fuel filler tube

² Methanol concentration sensor

² Pressure relief/rollover valve

² PCV Valve

² All fuel system and emission system hoses and tubes

THROTTLE BODY

WARNING: THROTTLE BODIES DESIGNED FOR

GASOLINE ONLY VEHICLES CANNOT BE USED ON

FLEXIBLE FUEL AA-BODY VEHICLES. WHEN RE-

PLACING THE THROTTLE BODY OF A FLEXIBLE

FUEL VEHICLE, ONLY USE AN ORIGINAL EQUIP-

MENT REPLACEMENT.

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. Never use lubricants on O-rings or

seals, damage may result. If assembly of component is

difficult, use water to aid assembly. Use care when

removing hoses to prevent damage to hose or hose

nipple.

Ä FUEL SYSTEMS 14 - 77

Page 1834 of 2438

THROTTLE BODY

The throttle body assembly is located on the left

end of the intake manifold plenum (Fig. 20). The

throttle body houses the throttle position sensor and

the idle air control motor. Air flow through the throt-

tle body is controlled by a cable operated throttle

blade located in the base of the throttle body.

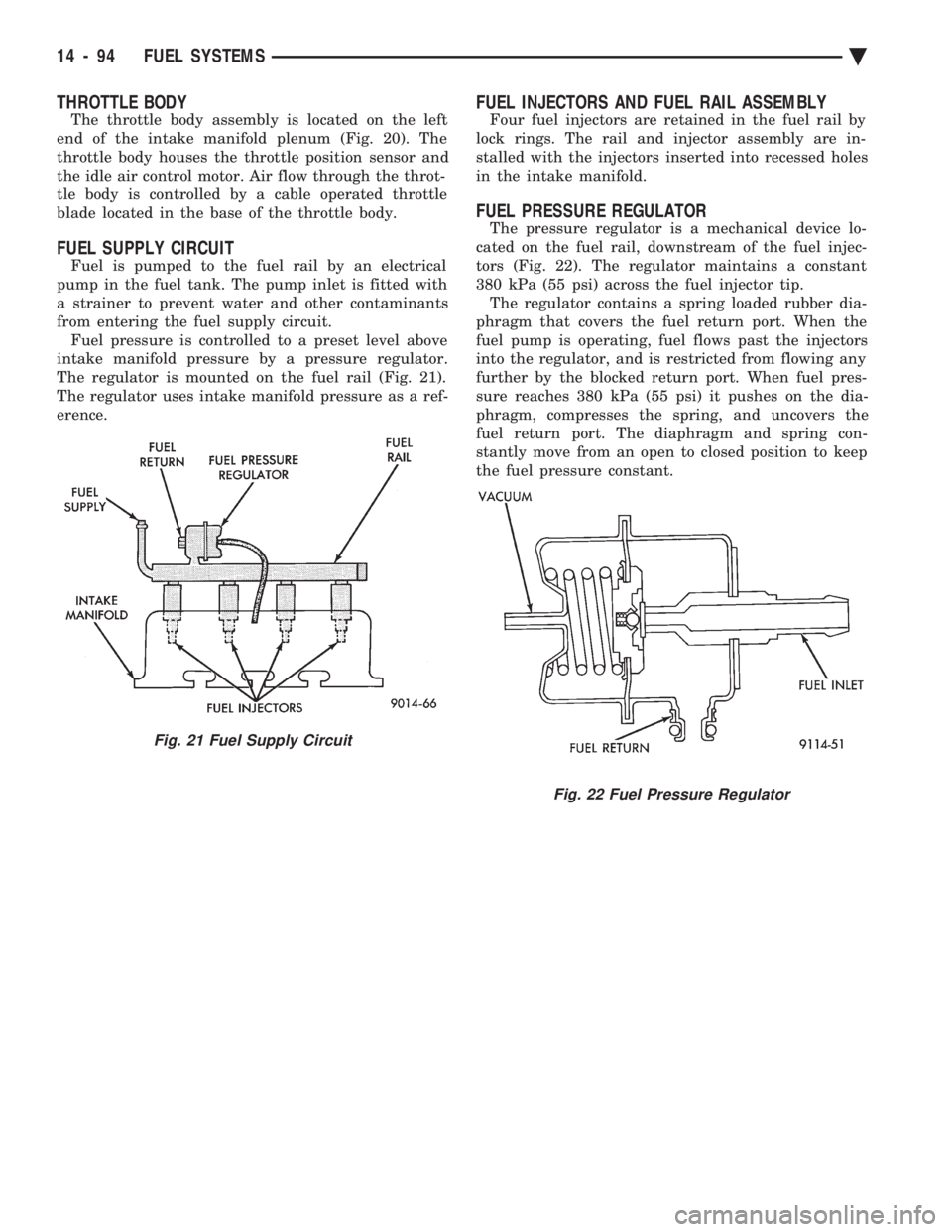

FUEL SUPPLY CIRCUIT

Fuel is pumped to the fuel rail by an electrical

pump in the fuel tank. The pump inlet is fitted with

a strainer to prevent water and other contaminants

from entering the fuel supply circuit. Fuel pressure is controlled to a preset level above

intake manifold pressure by a pressure regulator.

The regulator is mounted on the fuel rail (Fig. 21).

The regulator uses intake manifold pressure as a ref-

erence.

FUEL INJECTORS AND FUEL RAIL ASSEMBLY

Four fuel injectors are retained in the fuel rail by

lock rings. The rail and injector assembly are in-

stalled with the injectors inserted into recessed holes

in the intake manifold.

FUEL PRESSURE REGULATOR

The pressure regulator is a mechanical device lo-

cated on the fuel rail, downstream of the fuel injec-

tors (Fig. 22). The regulator maintains a constant

380 kPa (55 psi) across the fuel injector tip. The regulator contains a spring loaded rubber dia-

phragm that covers the fuel return port. When the

fuel pump is operating, fuel flows past the injectors

into the regulator, and is restricted from flowing any

further by the blocked return port. When fuel pres-

sure reaches 380 kPa (55 psi) it pushes on the dia-

phragm, compresses the spring, and uncovers the

fuel return port. The diaphragm and spring con-

stantly move from an open to closed position to keep

the fuel pressure constant.

Fig. 21 Fuel Supply Circuit

Fig. 22 Fuel Pressure Regulator

14 - 94 FUEL SYSTEMS Ä

Page 1847 of 2438

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES INDEX

page page

Fuel Injector Rail Assembly ................ 109

Fuel Injectors .......................... 110

Fuel Pressure Regulator .................. 111

Fuel System Pressure Release Procedure ..... 107

Heated Oxygen Sensor (O

2Sensor) ......... 112

Idle Air Control Motor .................... 108

Manifold Absolute Pressure (MAP) Sensor Service .............................. 111 PCM Service

........................... 111

Throttle Body ........................... 107

Throttle Body Removal ................... 108

Throttle Position Sensor (TPS) ............. 107

Wastegate and Canister Purge Solenoid Service . 111

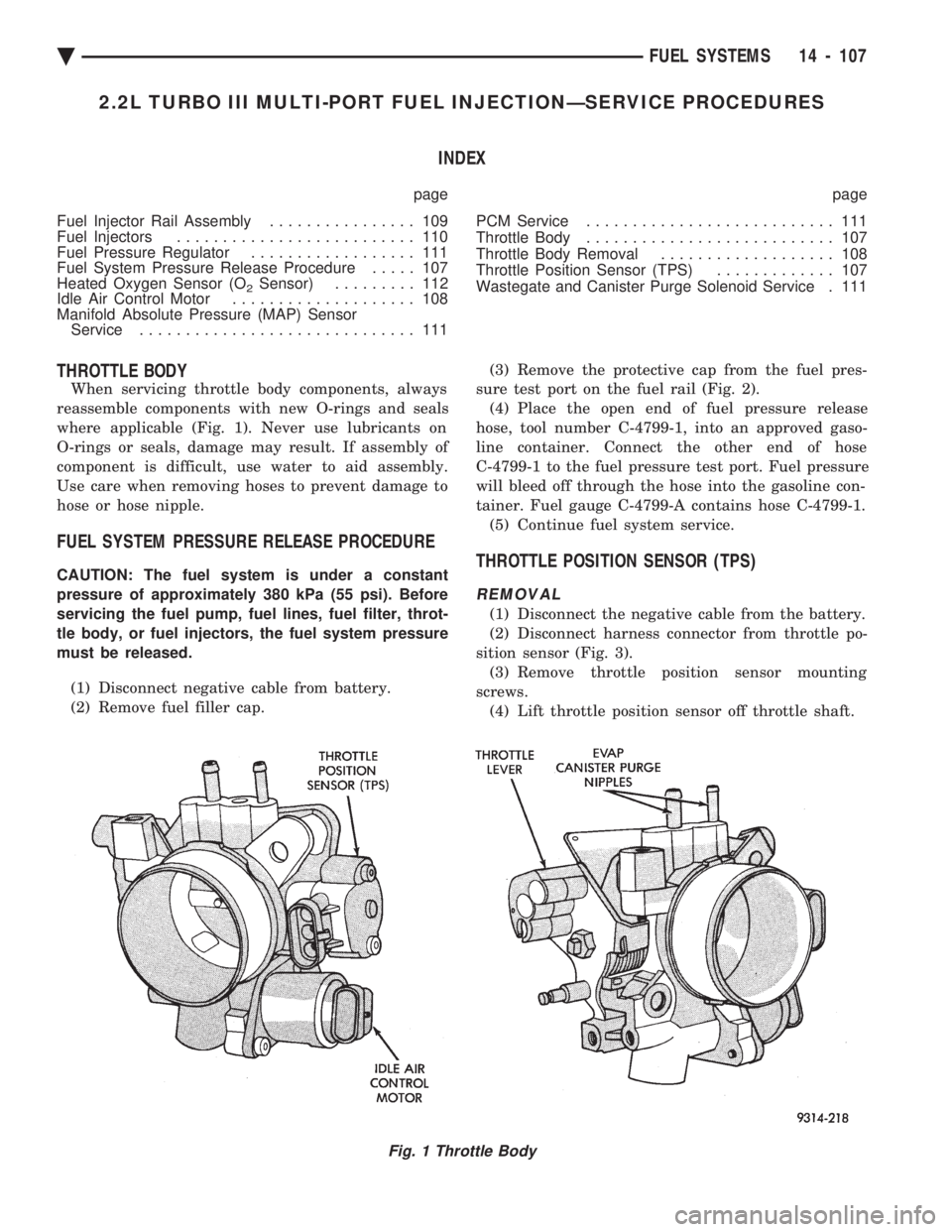

THROTTLE BODY

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable (Fig. 1). Never use lubricants on

O-rings or seals, damage may result. If assembly of

component is difficult, use water to aid assembly.

Use care when removing hoses to prevent damage to

hose or hose nipple.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

CAUTION: The fuel system is under a constant

pressure of approximately 380 kPa (55 psi). Before

servicing the fuel pump, fuel lines, fuel filter, throt-

tle body, or fuel injectors, the fuel system pressure

must be released.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap. (3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 2). (4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso-

line container. Connect the other end of hose

C-4799-1 to the fuel pressure test port. Fuel pressure

will bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1. (5) Continue fuel system service.THROTTLE POSITION SENSOR (TPS)

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Disconnect harness connector from throttle po-

sition sensor (Fig. 3). (3) Remove throttle position sensor mounting

screws. (4) Lift throttle position sensor off throttle shaft.

Fig. 1 Throttle Body

Ä FUEL SYSTEMS 14 - 107

Page 1863 of 2438

The PCM may receive a closed throttle input from

the throttle position sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. The PCM may reduce injector

firing to once per engine revolution. This helps main-

tain better control of the air-fuel mixture. During a deceleration condition, the PCM grounds

the exhaust gas recirculation (EGR) solenoid. When

the PCM grounds the solenoid, preventing EGR.

WIDE OPEN THROTTLE MODE This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

² engine coolant temperature

² crankshaft position (distributor pick-up)

² manifold absolute pressure

² engine speed (distributor pick-up)

² throttle position

When the PCM senses wide open throttle condition

through the throttle position sensor (TPS) it will:

² Provide a ground for the electrical EGR transducer

(EET) solenoid. When the PCM grounds the solenoid,

the EGR system stops operating.

² De-energize the air conditioning relay. This dis-

ables the air conditioning system. The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera- tion. The PCM will adjust injector pulse width to

supply a predetermined amount of additional fuel.

IGNITION SWITCH OFF MODE

When the ignition switch is turned to the OFF po-

sition, the following occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

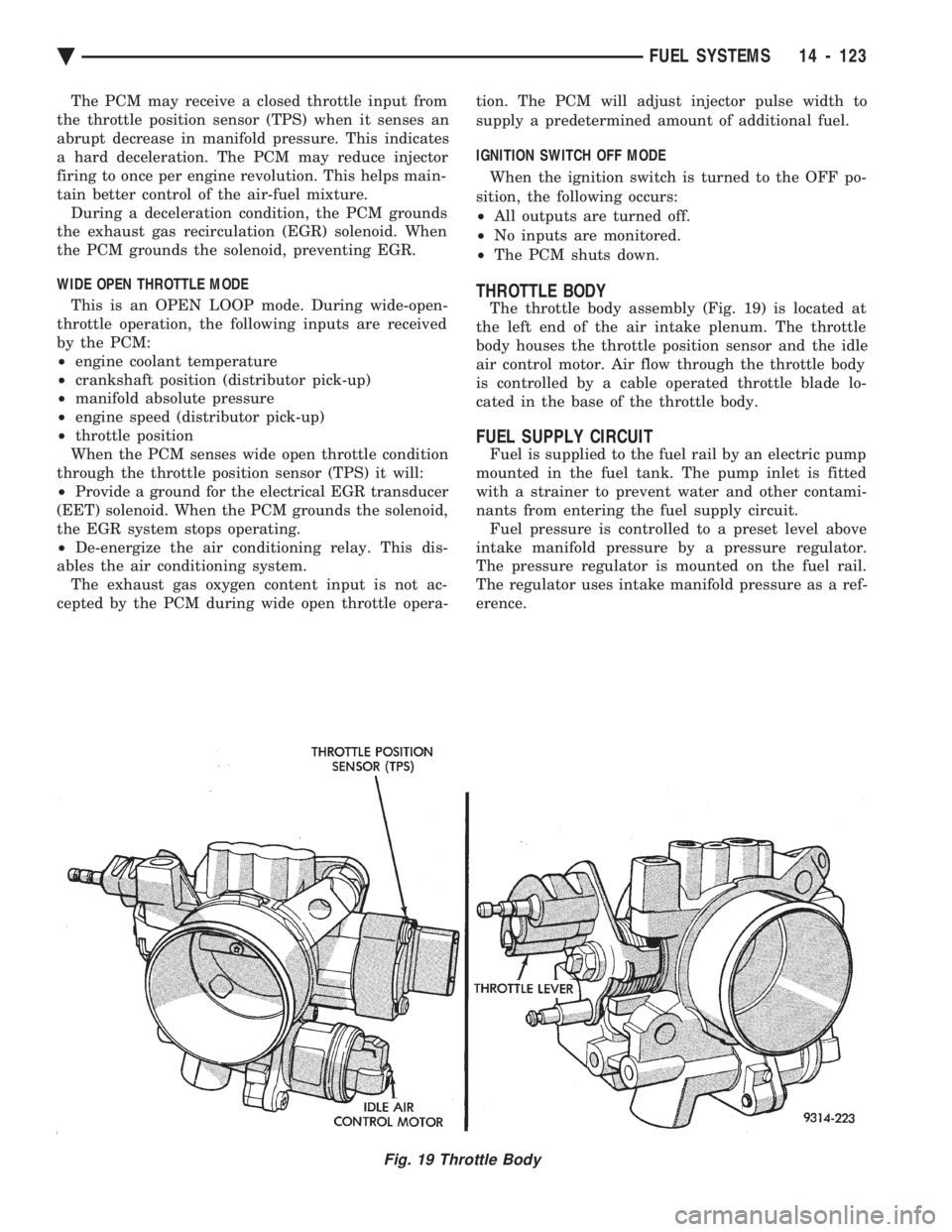

THROTTLE BODY

The throttle body assembly (Fig. 19) is located at

the left end of the air intake plenum. The throttle

body houses the throttle position sensor and the idle

air control motor. Air flow through the throttle body

is controlled by a cable operated throttle blade lo-

cated in the base of the throttle body.

FUEL SUPPLY CIRCUIT

Fuel is supplied to the fuel rail by an electric pump

mounted in the fuel tank. The pump inlet is fitted

with a strainer to prevent water and other contami-

nants from entering the fuel supply circuit. Fuel pressure is controlled to a preset level above

intake manifold pressure by a pressure regulator.

The pressure regulator is mounted on the fuel rail.

The regulator uses intake manifold pressure as a ref-

erence.

Fig. 19 Throttle Body

Ä FUEL SYSTEMS 14 - 123

Page 1878 of 2438

3.0L MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES INDEX

page page

Idle Air Control Motor .................... 138

Canister Purge Solenoid Service ............ 143

Fuel Injector Rail Assembly ................ 139

Fuel Injectors .......................... 142

Fuel Pressure Regulator Service ............ 141

Fuel System Pressure Release Procedure ..... 138 Heated Oxygen Sensor (O

2Sensor)

......... 144

Manifold Absolute Pressure (MAP) Sensor ..... 143

PCM ................................. 143

Throttle Body ........................... 138

Throttle Body Service .................... 138

Throttle Position Sensor .................. 138

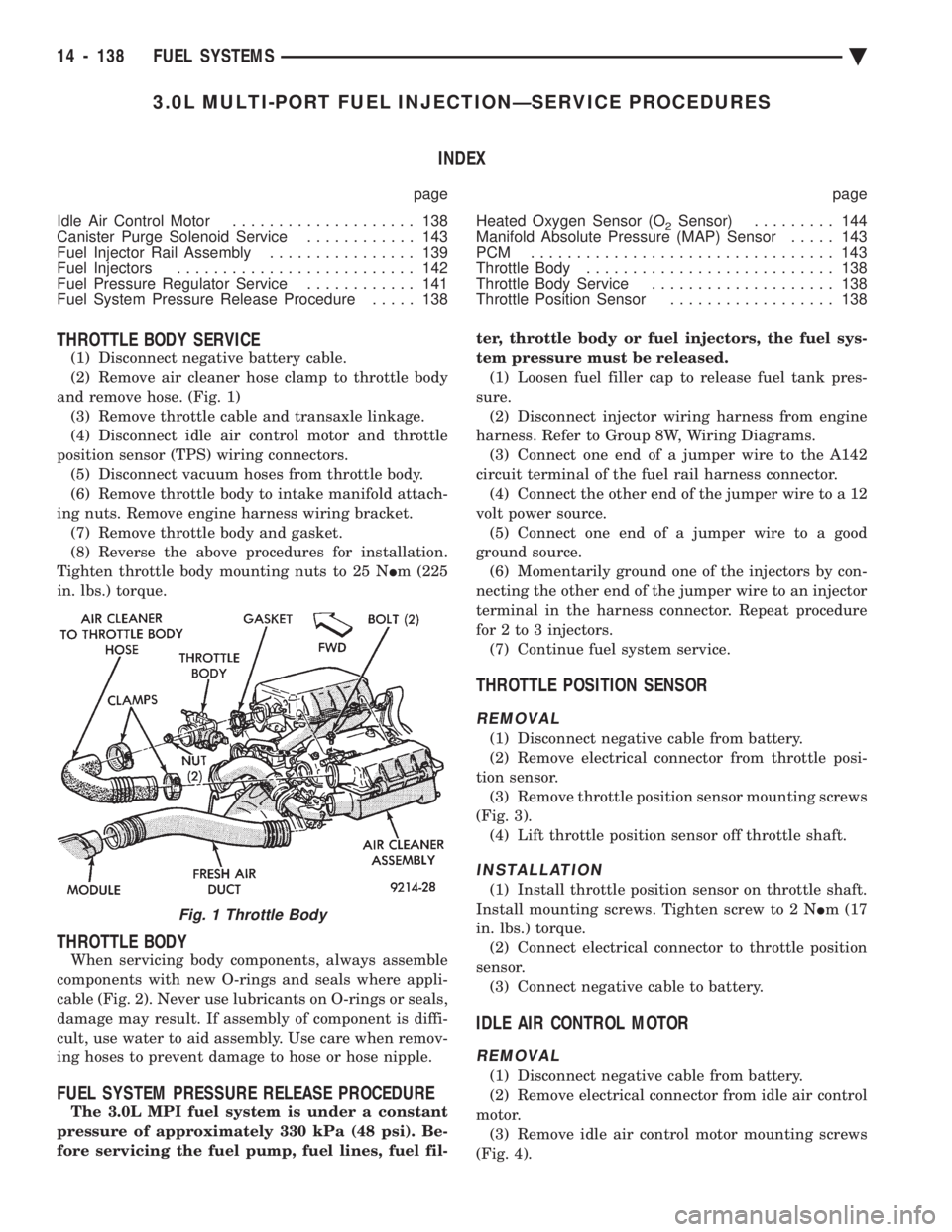

THROTTLE BODY SERVICE

(1) Disconnect negative battery cable.

(2) Remove air cleaner hose clamp to throttle body

and remove hose. (Fig. 1) (3) Remove throttle cable and transaxle linkage.

(4) Disconnect idle air control motor and throttle

position sensor (TPS) wiring connectors. (5) Disconnect vacuum hoses from throttle body.

(6) Remove throttle body to intake manifold attach-

ing nuts. Remove engine harness wiring bracket. (7) Remove throttle body and gasket.

(8) Reverse the above procedures for installation.

Tighten throttle body mounting nuts to 25 N Im (225

in. lbs.) torque.

THROTTLE BODY

When servicing body components, always assemble

components with new O-rings and seals where appli-

cable (Fig. 2). Never use lubricants on O-rings or seals,

damage may result. If assembly of component is diffi-

cult, use water to aid assembly. Use care when remov-

ing hoses to prevent damage to hose or hose nipple.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

The 3.0L MPI fuel system is under a constant

pressure of approximately 330 kPa (48 psi). Be-

fore servicing the fuel pump, fuel lines, fuel fil- ter, throttle body or fuel injectors, the fuel sys-

tem pressure must be released. (1) Loosen fuel filler cap to release fuel tank pres-

sure. (2) Disconnect injector wiring harness from engine

harness. Refer to Group 8W, Wiring Diagrams. (3) Connect one end of a jumper wire to the A142

circuit terminal of the fuel rail harness connector. (4) Connect the other end of the jumper wire to a 12

volt power source. (5) Connect one end of a jumper wire to a good

ground source. (6) Momentarily ground one of the injectors by con-

necting the other end of the jumper wire to an injector

terminal in the harness connector. Repeat procedure

for 2 to 3 injectors. (7) Continue fuel system service.

THROTTLE POSITION SENSOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from throttle posi-

tion sensor. (3) Remove throttle position sensor mounting screws

(Fig. 3). (4) Lift throttle position sensor off throttle shaft.

INSTALLATION

(1) Install throttle position sensor on throttle shaft.

Install mounting screws. Tighten screw to 2 N Im (17

in. lbs.) torque. (2) Connect electrical connector to throttle position

sensor. (3) Connect negative cable to battery.

IDLE AIR CONTROL MOTOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from idle air control

motor. (3) Remove idle air control motor mounting screws

(Fig. 4).

Fig. 1 Throttle Body

14 - 138 FUEL SYSTEMS Ä

Page 1895 of 2438

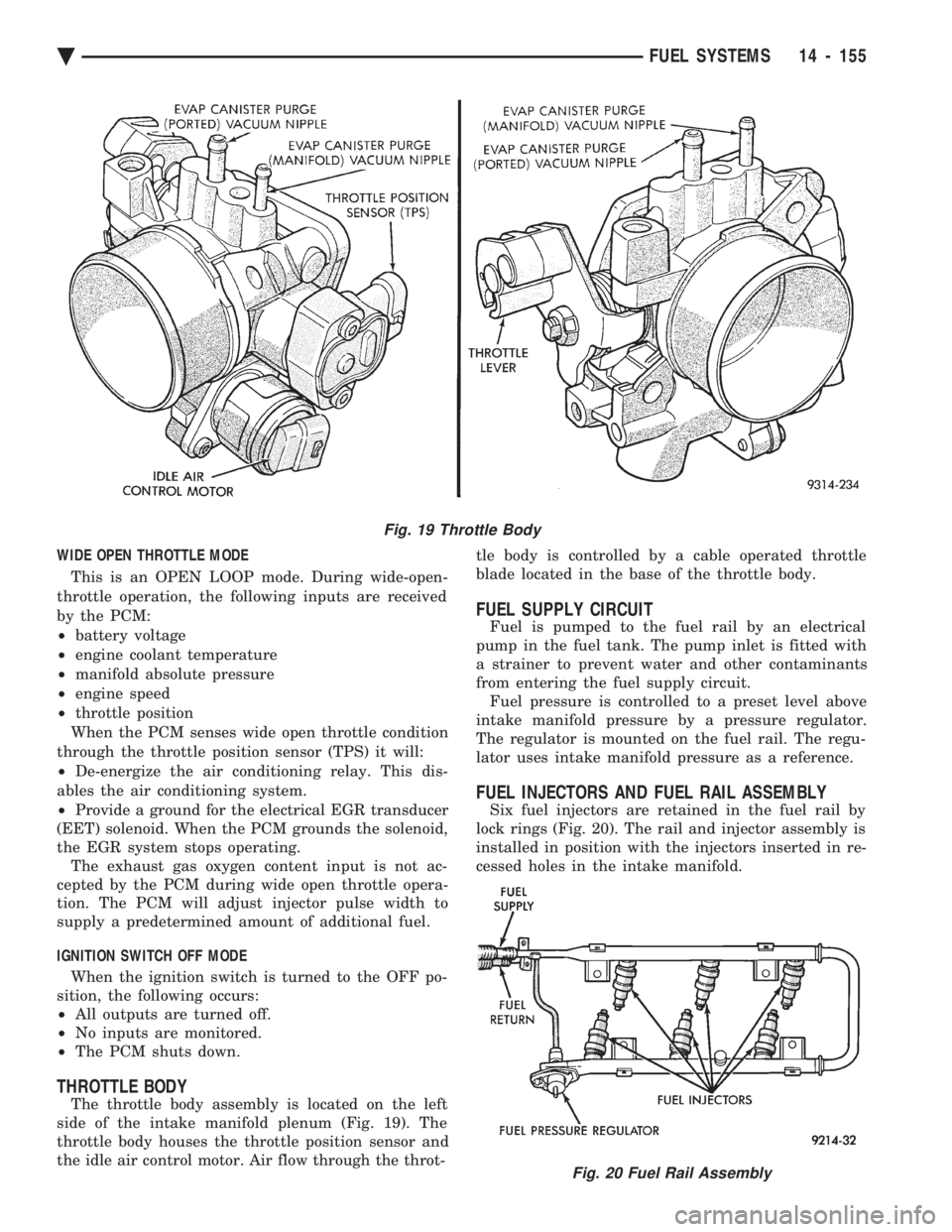

WIDE OPEN THROTTLE MODE This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

² battery voltage

² engine coolant temperature

² manifold absolute pressure

² engine speed

² throttle position

When the PCM senses wide open throttle condition

through the throttle position sensor (TPS) it will:

² De-energize the air conditioning relay. This dis-

ables the air conditioning system.

² Provide a ground for the electrical EGR transducer

(EET) solenoid. When the PCM grounds the solenoid,

the EGR system stops operating. The exhaust gas oxygen content input is not ac-

cepted by the PCM during wide open throttle opera-

tion. The PCM will adjust injector pulse width to

supply a predetermined amount of additional fuel.

IGNITION SWITCH OFF MODE When the ignition switch is turned to the OFF po-

sition, the following occurs:

² All outputs are turned off.

² No inputs are monitored.

² The PCM shuts down.

THROTTLE BODY

The throttle body assembly is located on the left

side of the intake manifold plenum (Fig. 19). The

throttle body houses the throttle position sensor and

the idle air control motor. Air flow through the throt- tle body is controlled by a cable operated throttle

blade located in the base of the throttle body.

FUEL SUPPLY CIRCUIT

Fuel is pumped to the fuel rail by an electrical

pump in the fuel tank. The pump inlet is fitted with

a strainer to prevent water and other contaminants

from entering the fuel supply circuit. Fuel pressure is controlled to a preset level above

intake manifold pressure by a pressure regulator.

The regulator is mounted on the fuel rail. The regu-

lator uses intake manifold pressure as a reference.

FUEL INJECTORS AND FUEL RAIL ASSEMBLY

Six fuel injectors are retained in the fuel rail by

lock rings (Fig. 20). The rail and injector assembly is

installed in position with the injectors inserted in re-

cessed holes in the intake manifold.

Fig. 19 Throttle Body

Fig. 20 Fuel Rail Assembly

Ä FUEL SYSTEMS 14 - 155

Page 1909 of 2438

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES INDEX

page page

Camshaft Position Sensor Service ........... 176

Crankshaft Position Sensor ................ 176

EVAP Canister Purge Solenoid Service ....... 175

Fuel Injector ........................... 174

Fuel Injector Rail Assembly ................ 170

Fuel Pressure Regulator .................. 173

Fuel System Pressure Release Procedure ..... 169 Heated Oxygen Sensor (O

2Sensor) Service . . . 177

Idle Air Control Motor .................... 170

Manifold Absolute Pressure (MAP) Sensor ..... 175

PCM Service ........................... 175

Throttle Body ........................... 169

Throttle Body Removal ................... 169

Throttle Position Sensor .................. 169

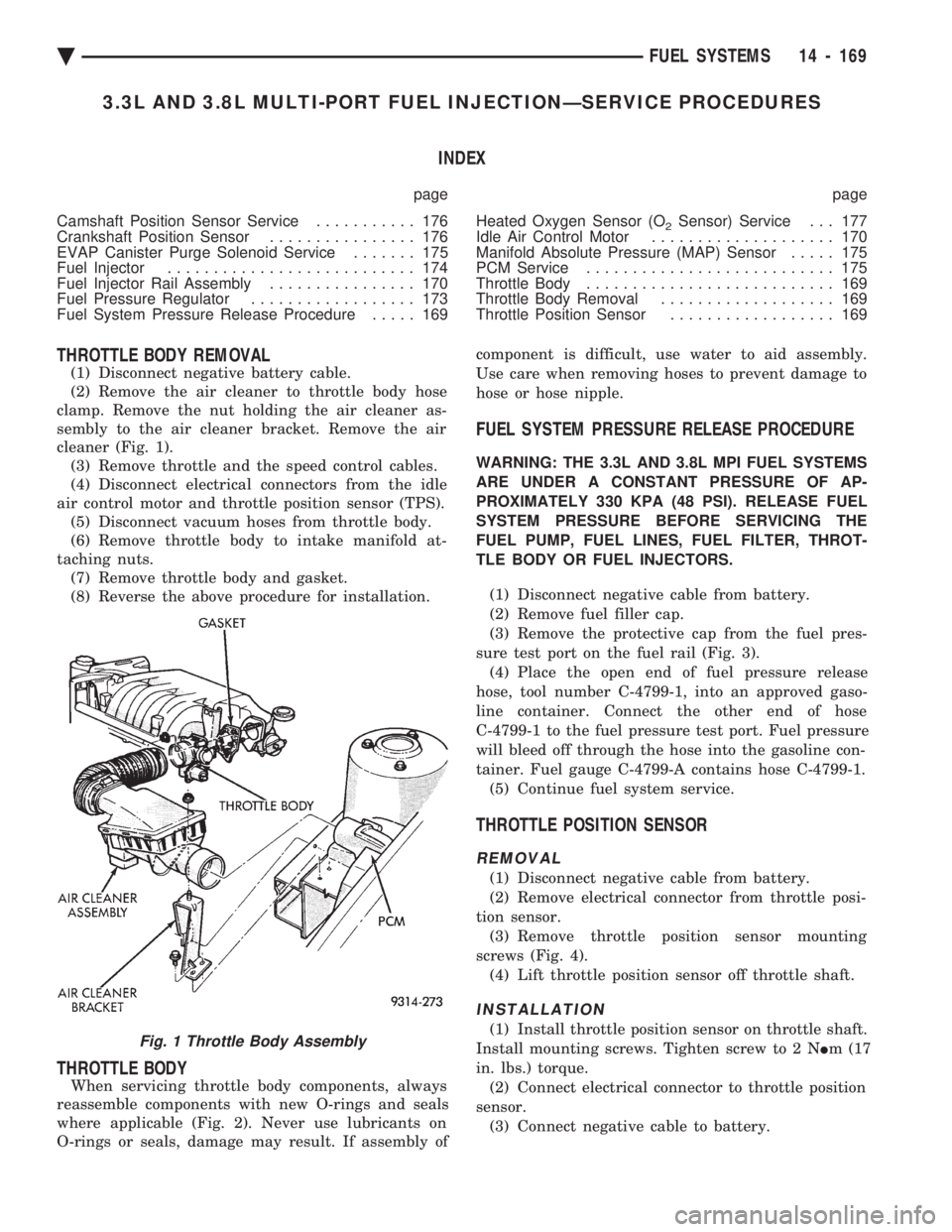

THROTTLE BODY REMOVAL

(1) Disconnect negative battery cable.

(2) Remove the air cleaner to throttle body hose

clamp. Remove the nut holding the air cleaner as-

sembly to the air cleaner bracket. Remove the air

cleaner (Fig. 1). (3) Remove throttle and the speed control cables.

(4) Disconnect electrical connectors from the idle

air control motor and throttle position sensor (TPS). (5) Disconnect vacuum hoses from throttle body.

(6) Remove throttle body to intake manifold at-

taching nuts. (7) Remove throttle body and gasket.

(8) Reverse the above procedure for installation.

THROTTLE BODY

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable (Fig. 2). Never use lubricants on

O-rings or seals, damage may result. If assembly of component is difficult, use water to aid assembly.

Use care when removing hoses to prevent damage to

hose or hose nipple.

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

WARNING: THE 3.3L AND 3.8L MPI FUEL SYSTEMS

ARE UNDER A CONSTANT PRESSURE OF AP-

PROXIMATELY 330 KPA (48 PSI). RELEASE FUEL

SYSTEM PRESSURE BEFORE SERVICING THE

FUEL PUMP, FUEL LINES, FUEL FILTER, THROT-

TLE BODY OR FUEL INJECTORS.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 3). (4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso-

line container. Connect the other end of hose

C-4799-1 to the fuel pressure test port. Fuel pressure

will bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1. (5) Continue fuel system service.

THROTTLE POSITION SENSOR

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from throttle posi-

tion sensor. (3) Remove throttle position sensor mounting

screws (Fig. 4). (4) Lift throttle position sensor off throttle shaft.

INSTALLATION

(1) Install throttle position sensor on throttle shaft.

Install mounting screws. Tighten screw to 2 N Im (17

in. lbs.) torque. (2) Connect electrical connector to throttle position

sensor. (3) Connect negative cable to battery.Fig. 1 Throttle Body Assembly

Ä FUEL SYSTEMS 14 - 169

Page 1995 of 2438

THREE SPEED TORQUEFLITE AUTOMATIC TRANSAXLE INDEX

page page

Accumulator-Recondition ................... 67

Aluminum Thread Repair ................... 48

Assembly Subassembly Installation ........... 57

Band Adjustment ......................... 47

Bearing Adjustment Procedures .............. 81

Clutch and Servo Air Pressure Tests .......... 43

Differential Repair ........................ 76

Disassembly Subassembly Removal .......... 50

Fluid and Filter Change .................... 40

Fluid Drain and Refill ..................... 40

Fluid Leakage-Transaxle Torque Converter Housing Area .......................... 44

Fluid Level and Condition .................. 40

Front Clutch-Recondition ................... 62

Front Planetary & Annulus Gear-Recondition .... 65

Gearshift Linkage Adjustment ............... 46

General Information ....................... 35

Governor ............................... 48

Hydraulic Control Pressure Adjustments ....... 47

Hydraulic Pressure Tests ................... 42

Kickdown Servo (Controlled Load)-Recondition . . 67 Low/Reverse Servo-Recondition

.............. 66

Oil Cooler Flow Check .................... 48

Oil Coolers and Tubes Reverse Flushing ...... 48

Oil Pump-Recondition ..................... 62

Output Shaft Repair ...................... 71

Park/Neutral Position and Back-Up Lamp Switch . 47

Parking Pawl ............................ 71

Pump Oil Seal-Replacement ................ 61

Rear Clutch-Recondition ................... 64

Road Test .............................. 40

Selection of Lubricant ..................... 40

Special Additives ......................... 40

Three Speed Torqueflite General Diagnosis ..... 36

Throttle Pressure Linkage Adjustment ......... 46

Torque Converter Clutch Solenoid Wiring Connector ............................ 40

Transaxle and Torque Converter Removal ...... 48

Transfer Shaft Repair ..................... 68

Valve Body-Recondition .................... 57

Vehicle Speed Sensor Pinion Gear ........... 47

GENERAL INFORMATION

Safety goggles should be worn at all times

when working on these transaxles. This transaxle combines a fully automatic 3 speed

transmission, final drive gearing, and differential into

a front wheel drive system. The unit is a Metric

design. The identification markings and usage of the

transaxle are charted in Diagnosis and Tests. Transaxle operation requirements are differ-

ent for each vehicle and engine combination and

some internal parts will be different to provide

for this. Therefore, when replacing parts, refer to

the seven digit part number stamped on rear of

the transaxle oil pan flange. Within this transaxle, there are 3 primary areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor and

parking sprag). (3) Differential center line. Center distances be-

tween the main rotating parts in these 3 areas are held

precise. This maintains a low noise level through

smooth accurate mesh of the gears. The torque converter, transaxle area, and differential

are housed in an integral aluminum die casting. The

differential oil sump is common with thetransaxle

sump. Separate filling of the differential is NOT nec-

essary. The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through an oil-to-water type cooler located in the

radiator side tank and/or an oil-to air heat ex- changer. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assem-

bly. Engine torque is transmitted to the torque con-

verter then, through the input shaft to multiple-disc

clutches in the transaxle. The power flow depends on

the application of the clutches and bands. Refer to

Elements in Use Chart in Diagnosis and Tests sec-

tion. The transaxle consists of two multiple-disc

clutches, an overrunning clutch, two servos, a hy-

draulic accumulator, two bands, and two planetary

gear sets. They provide three forward ratios and a re-

verse ratio. The common sun gear of the planetary

gear sets is connected to the front clutch by a driving

shell. The drive shell is splined to the sun gear and

to the front clutch retainer. The hydraulic system

consists of an oil pump, and a single valve body

which contains all of the valves except the governor

valves. The transaxle sump and differential sump are

both vented through the dipstick.Output torque

from the main center line is delivered through heli-

cal gears to the transfer shaft.This gear set is a

factor of the final drive (axle) ratio. The shaft also

carries the governor and parking sprag. An integral

helical gear on the transfer shaft drives the differen-

tial ring gear. The final drive gearing is completed

with one of three gear sets producing overall top gear

ratios of 2.78, 3.02, or 3.22 depending on model and

application.

Ä TRANSAXLE 21 - 35

Page 2000 of 2438

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. Before removing the dipstick, wipe all dirt off of the

protective disc and the dipstick handle. The torque converter will fill in both the PPark or N

Neutral positions. Place the selector lever in PPark to

check fluid level. Inspect fluid level on dipstick every six months.

Allow the engine to idle for at least one minute

with vehicle on level ground. This will assure

complete oil level stabilization between differen-

tial and transmission. A properly filled transaxle

will read near the addmark when fluid temperature is

21 degrees Celsius (70 degrees Fahrenheit). When the

transaxle reaches operating temperature the fluid

should be in the HOTregion.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause overheating,

fluid oxidation, and varnishing, which can interfere

with normal valve, clutch, and servo operation. Foam-

ing can also result in fluid escaping from the transaxle

vent (dipstick handle) where it may be mistaken for a

leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. MOPAR tATF PLUS (Automatic

Transmission Fluid-Type 7176) should be used to aid in

assuring optimum transmission performance. Fluids of

the type labeled DEXRON II Automatic Transmission

Fluid should be used only if the recommended fluid is

not available. It is important that the transmission

fluid be maintained at the prescribed level using the

recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transmission, other than the

automatic transmission fluid listed above. An ex- ception to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only

fluids of the type labeled MOPAR tATF PLUS

(Automatic Transmission fluid) Type 7176 should

be used. A band adjustment and filter change

should be made at the time of the oil change. The

magnet (on the inside of the oil pan) should also

be cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason,

the fluid and filter should be changed, and the

band(s) adjusted.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication, Group

0). Place a drain container with a large opening, under

transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner to

break it loose allowing fluid to drain, then remove the

oil pan. (3) Install a new filter and gasket on bottom of the

valve body and tighten retaining screws to 5 N Im (40

in. lbs.). (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive sealant. Tighten oil pan

bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Auto-

matic Transmission Fluid) Type 7176 through the

dipstick opening. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the HOT

region (Fig. 1). To prevent dirt from entering transaxle, make cer-

tain that dipstick is full seated into the dipstick open-

ing.

TORQUE CONVERTER CLUTCH SOLENOID WIRING

CONNECTOR

If wiring connector is unplugged, the torque con-

verter clutch will not operate (Fig. 2).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjustments

have been checked and approved. During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

21 - 40 TRANSAXLE Ä