water pump CHEVROLET DYNASTY 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 353 of 2438

INSPECTION Replace water pump body assembly if it has any of

these defects: (1) Cracks or damage on the body.

(2) Water leaks from the shaft seal, evident by

coolant traces below the vent hole. (3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the hous-

ing.

ASSEMBLY

Body assembly and housing are serviced as separate

components. (1) Install new O-ring gasket in body O-ring groove.

(2) Assemble pump body to housing and tighten nine

screws to 12 N Im (105 in. lbs.) (Fig. 2).

(3) Rotate pump by hand to check for freedom of

movement. (4) Position water pump pulley to water pump.In-

stall three screws and tighten to 30 N Im (250 in. lbs.).

(5) Position new O-ring in housing to block O-ring

groove.

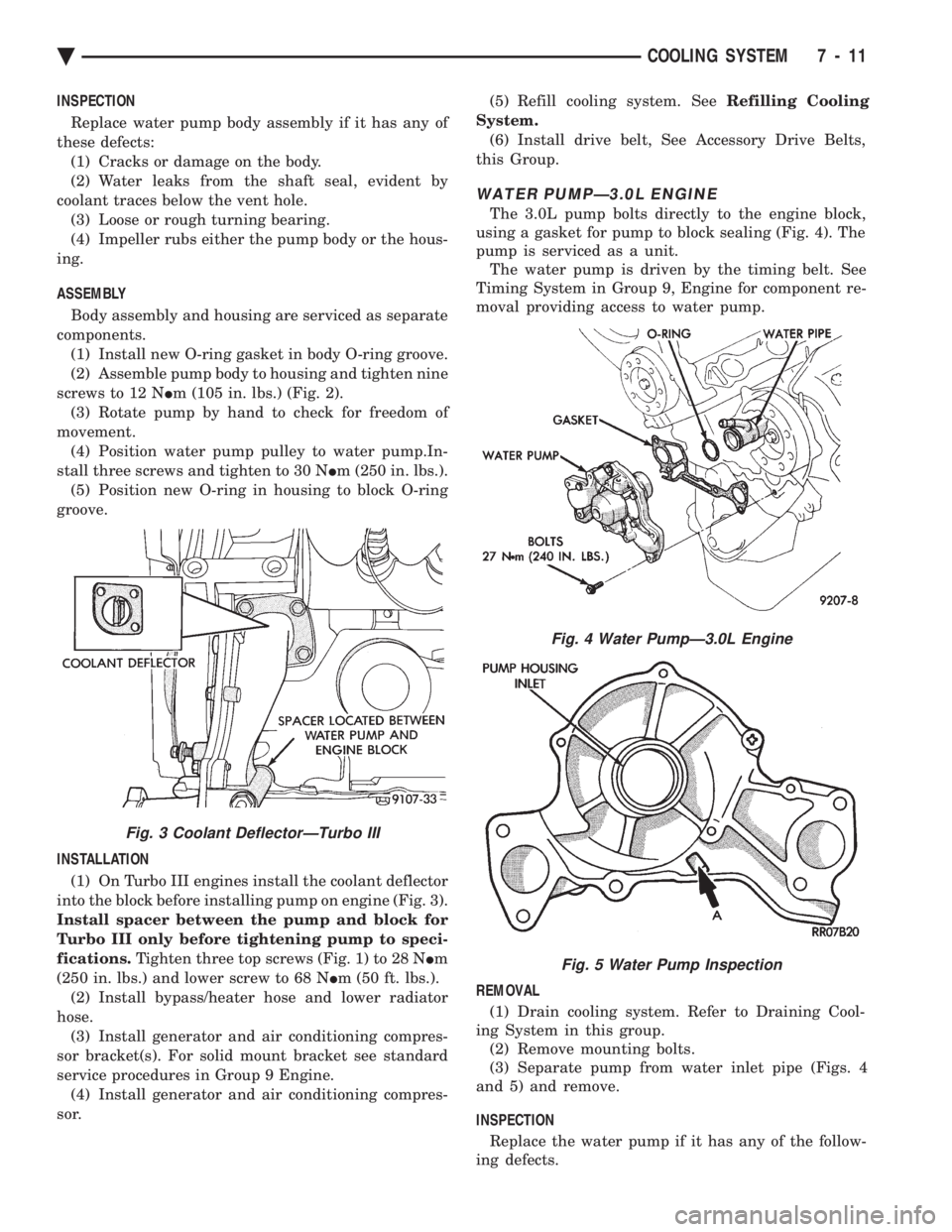

INSTALLATION (1) On Turbo III engines install the coolant deflector

into the block before installing pump on engine (Fig. 3).

Install spacer between the pump and block for

Turbo III only before tightening pump to speci-

fications. Tighten three top screws (Fig. 1) to 28 N Im

(250 in. lbs.) and lower screw to 68 N Im (50 ft. lbs.).

(2) Install bypass/heater hose and lower radiator

hose. (3) Install generator and air conditioning compres-

sor bracket(s). For solid mount bracket see standard

service procedures in Group 9 Engine. (4) Install generator and air conditioning compres-

sor. (5) Refill cooling system. See

Refilling Cooling

System. (6) Install drive belt, See Accessory Drive Belts,

this Group.

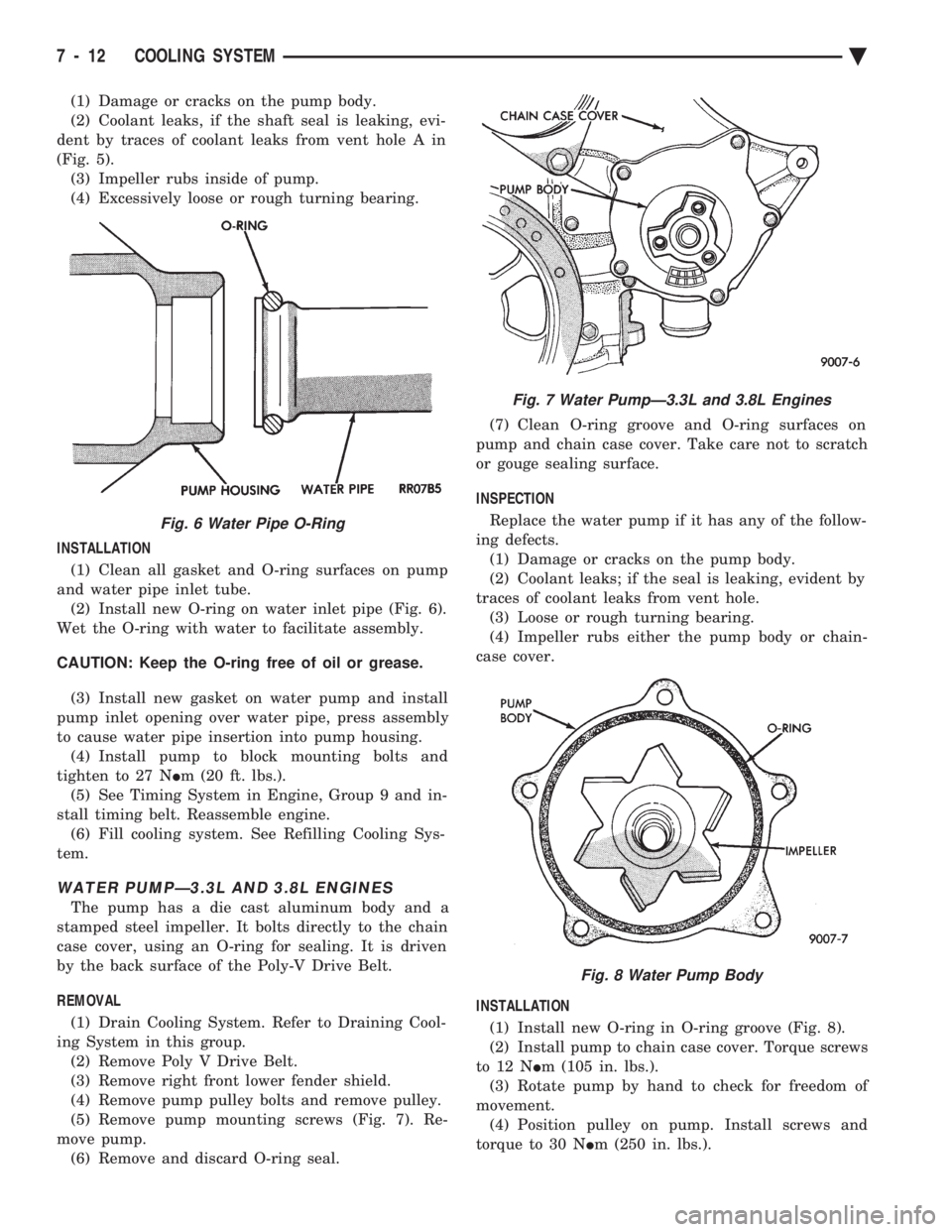

WATER PUMPÐ3.0L ENGINE

The 3.0L pump bolts directly to the engine block,

using a gasket for pump to block sealing (Fig. 4). The

pump is serviced as a unit. The water pump is driven by the timing belt. See

Timing System in Group 9, Engine for component re-

moval providing access to water pump.

REMOVAL (1) Drain cooling system. Refer to Draining Cool-

ing System in this group. (2) Remove mounting bolts.

(3) Separate pump from water inlet pipe (Figs. 4

and 5) and remove.

INSPECTION Replace the water pump if it has any of the follow-

ing defects.

Fig. 4 Water PumpÐ3.0L Engine

Fig. 5 Water Pump Inspection

Fig. 3 Coolant DeflectorÐTurbo III

Ä COOLING SYSTEM 7 - 11

Page 354 of 2438

(1) Damage or cracks on the pump body.

(2) Coolant leaks, if the shaft seal is leaking, evi-

dent by traces of coolant leaks from vent hole A in

(Fig. 5). (3) Impeller rubs inside of pump.

(4) Excessively loose or rough turning bearing.

INSTALLATION (1) Clean all gasket and O-ring surfaces on pump

and water pipe inlet tube. (2) Install new O-ring on water inlet pipe (Fig. 6).

Wet the O-ring with water to facilitate assembly.

CAUTION: Keep the O-ring free of oil or grease.

(3) Install new gasket on water pump and install

pump inlet opening over water pipe, press assembly

to cause water pipe insertion into pump housing. (4) Install pump to block mounting bolts and

tighten to 27 N Im (20 ft. lbs.).

(5) See Timing System in Engine, Group 9 and in-

stall timing belt. Reassemble engine. (6) Fill cooling system. See Refilling Cooling Sys-

tem.

WATER PUMPÐ3.3L AND 3.8L ENGINES

The pump has a die cast aluminum body and a

stamped steel impeller. It bolts directly to the chain

case cover, using an O-ring for sealing. It is driven

by the back surface of the Poly-V Drive Belt.

REMOVAL (1) Drain Cooling System. Refer to Draining Cool-

ing System in this group. (2) Remove Poly V Drive Belt.

(3) Remove right front lower fender shield.

(4) Remove pump pulley bolts and remove pulley.

(5) Remove pump mounting screws (Fig. 7). Re-

move pump. (6) Remove and discard O-ring seal. (7) Clean O-ring groove and O-ring surfaces on

pump and chain case cover. Take care not to scratch

or gouge sealing surface.

INSPECTION

Replace the water pump if it has any of the follow-

ing defects. (1) Damage or cracks on the pump body.

(2) Coolant leaks; if the seal is leaking, evident by

traces of coolant leaks from vent hole. (3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or chain-

case cover.

INSTALLATION

(1) Install new O-ring in O-ring groove (Fig. 8).

(2) Install pump to chain case cover. Torque screws

to 12 N Im (105 in. lbs.).

(3) Rotate pump by hand to check for freedom of

movement. (4) Position pulley on pump. Install screws and

torque to 30 N Im (250 in. lbs.).

Fig. 6 Water Pipe O-Ring

Fig. 7 Water PumpÐ3.3L and 3.8L Engines

Fig. 8 Water Pump Body

7 - 12 COOLING SYSTEM Ä

Page 355 of 2438

(5) Install drive belt. See Accessory Drive Belts

this group. (6) Install right front lower fender shield.

(7) Refill Cooling System. See Refilling Cooling

System in this section.

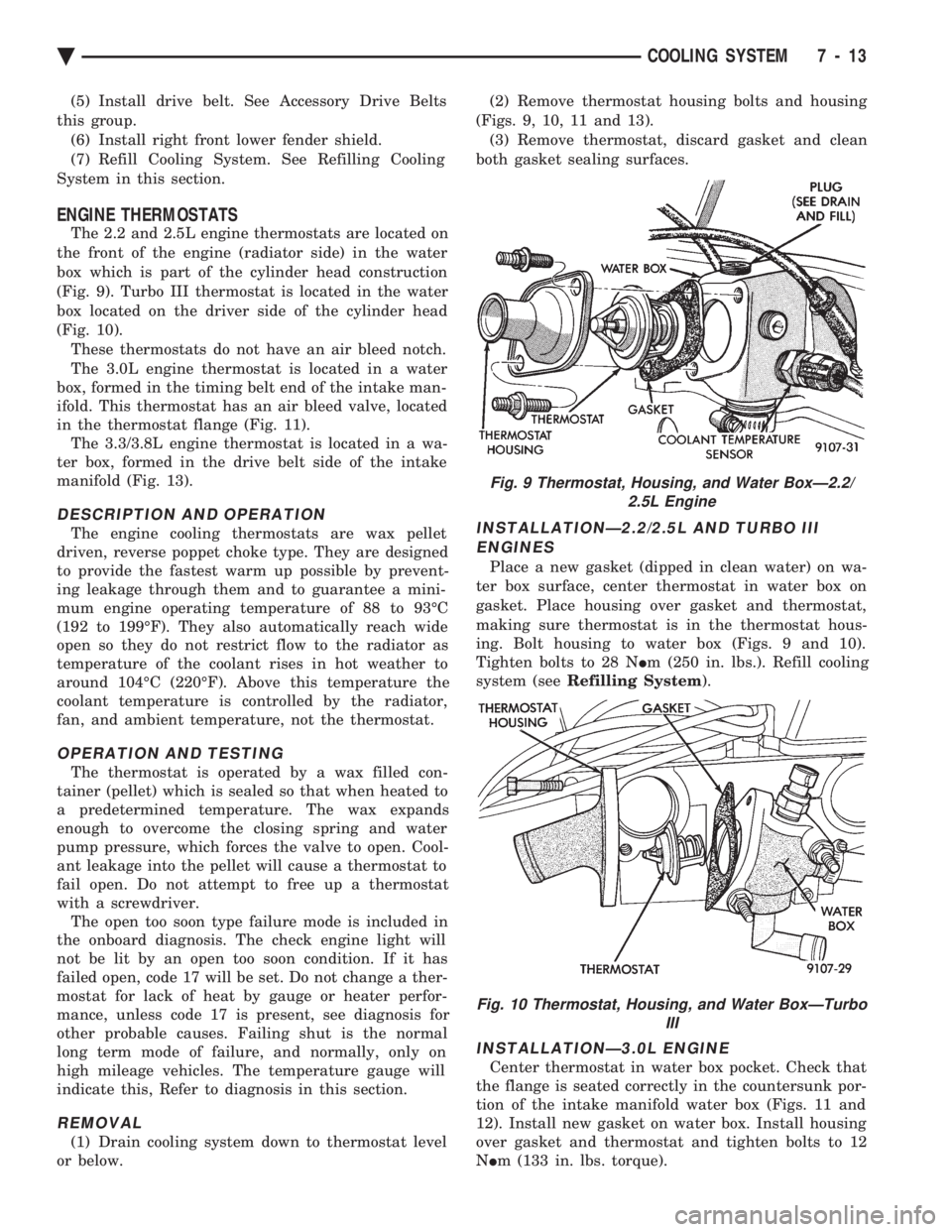

ENGINE THERMOSTATS

The 2.2 and 2.5L engine thermostats are located on

the front of the engine (radiator side) in the water

box which is part of the cylinder head construction

(Fig. 9). Turbo III thermostat is located in the water

box located on the driver side of the cylinder head

(Fig. 10). These thermostats do not have an air bleed notch.

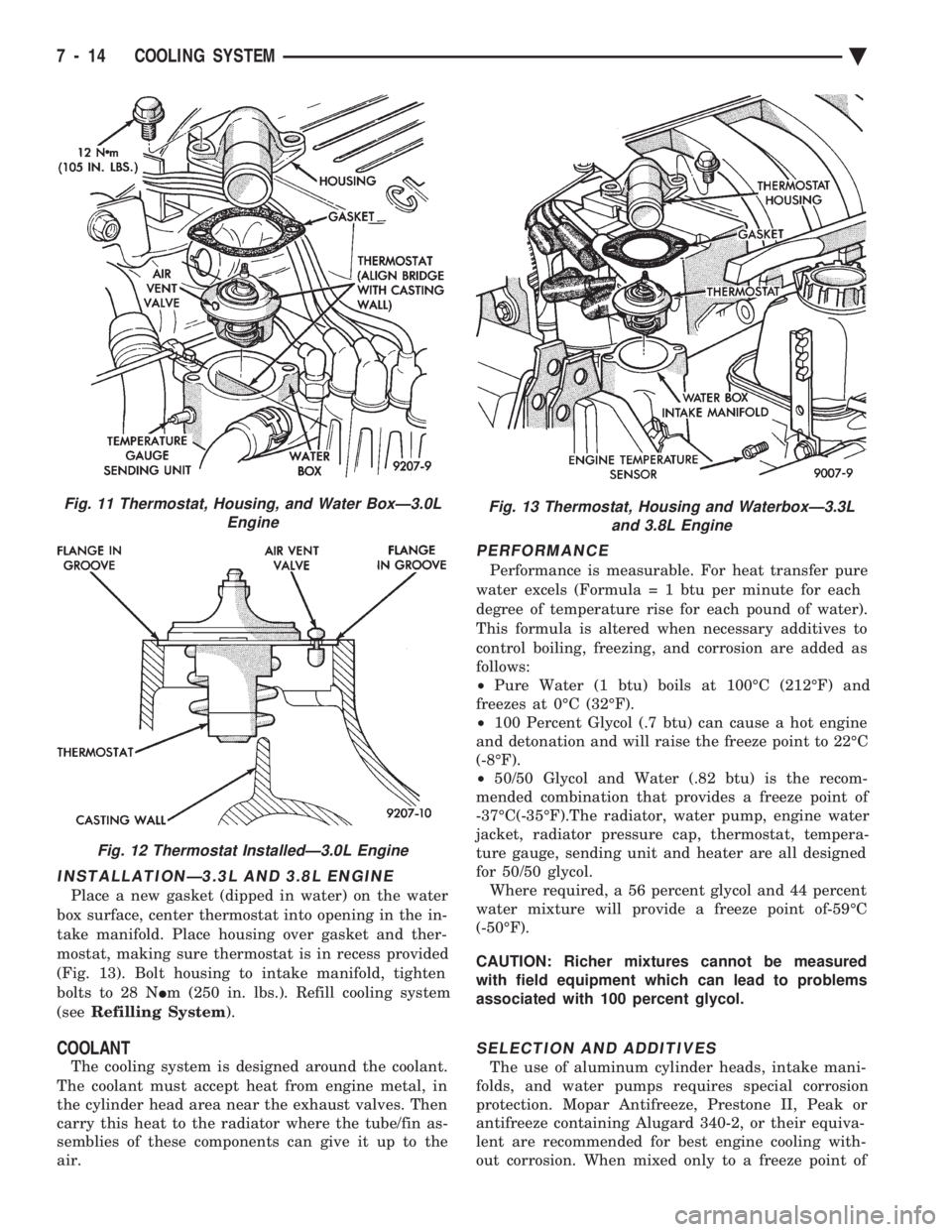

The 3.0L engine thermostat is located in a water

box, formed in the timing belt end of the intake man-

ifold. This thermostat has an air bleed valve, located

in the thermostat flange (Fig. 11). The 3.3/3.8L engine thermostat is located in a wa-

ter box, formed in the drive belt side of the intake

manifold (Fig. 13).

DESCRIPTION AND OPERATION

The engine cooling thermostats are wax pellet

driven, reverse poppet choke type. They are designed

to provide the fastest warm up possible by prevent-

ing leakage through them and to guarantee a mini-

mum engine operating temperature of 88 to 93ÉC

(192 to 199ÉF). They also automatically reach wide

open so they do not restrict flow to the radiator as

temperature of the coolant rises in hot weather to

around 104ÉC (220ÉF). Above this temperature the

coolant temperature is controlled by the radiator,

fan, and ambient temperature, not the thermostat.

OPERATION AND TESTING

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed so that when heated to

a predetermined temperature. The wax expands

enough to overcome the closing spring and water

pump pressure, which forces the valve to open. Cool-

ant leakage into the pellet will cause a thermostat to

fail open. Do not attempt to free up a thermostat

with a screwdriver. The open too soon type failure mode is included in

the onboard diagnosis. The check engine light will

not be lit by an open too soon condition. If it has

failed open, code 17 will be set. Do not change a ther-

mostat for lack of heat by gauge or heater perfor-

mance, unless code 17 is present, see diagnosis for

other probable causes. Failing shut is the normal

long term mode of failure, and normally, only on

high mileage vehicles. The temperature gauge will

indicate this, Refer to diagnosis in this section.

REMOVAL

(1) Drain cooling system down to thermostat level

or below. (2) Remove thermostat housing bolts and housing

(Figs. 9, 10, 11 and 13). (3) Remove thermostat, discard gasket and clean

both gasket sealing surfaces.

INSTALLATIONÐ2.2/2.5L AND TURBO III ENGINES

Place a new gasket (dipped in clean water) on wa-

ter box surface, center thermostat in water box on

gasket. Place housing over gasket and thermostat,

making sure thermostat is in the thermostat hous-

ing. Bolt housing to water box (Figs. 9 and 10).

Tighten bolts to 28 N Im (250 in. lbs.). Refill cooling

system (see Refilling System ).

INSTALLATIONÐ3.0L ENGINE

Center thermostat in water box pocket. Check that

the flange is seated correctly in the countersunk por-

tion of the intake manifold water box (Figs. 11 and

12). Install new gasket on water box. Install housing

over gasket and thermostat and tighten bolts to 12

N Im (133 in. lbs. torque).

Fig. 9 Thermostat, Housing, and Water BoxÐ2.2/

2.5L Engine

Fig. 10 Thermostat, Housing, and Water BoxÐTurbo III

Ä COOLING SYSTEM 7 - 13

Page 356 of 2438

INSTALLATIONÐ3.3L AND 3.8L ENGINE

Place a new gasket (dipped in water) on the water

box surface, center thermostat into opening in the in-

take manifold. Place housing over gasket and ther-

mostat, making sure thermostat is in recess provided

(Fig. 13). Bolt housing to intake manifold, tighten

bolts to 28 N Im (250 in. lbs.). Refill cooling system

(see Refilling System ).

COOLANT

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves. Then

carry this heat to the radiator where the tube/fin as-

semblies of these components can give it up to the

air.

PERFORMANCE

Performance is measurable. For heat transfer pure

water excels (Formul a = 1 btu per minute for each

degree of temperature rise for each pound of water).

This formula is altered when necessary additives to

control boiling, freezing, and corrosion are added as

follows:

² Pure Water (1 btu) boils at 100ÉC (212ÉF) and

freezes at 0ÉC (32ÉF).

² 100 Percent Glycol (.7 btu) can cause a hot engine

and detonation and will raise the freeze point to 22ÉC

(-8ÉF).

² 50/50 Glycol and Water (.82 btu) is the recom-

mended combination that provides a freeze point of

-37ÉC(-35ÉF).The radiator, water pump, engine water

jacket, radiator pressure cap, thermostat, tempera-

ture gauge, sending unit and heater are all designed

for 50/50 glycol. Where required, a 56 percent glycol and 44 percent

water mixture will provide a freeze point of-59ÉC

(-50ÉF).

CAUTION: Richer mixtures cannot be measured

with field equipment which can lead to problems

associated with 100 percent glycol.

SELECTION AND ADDITIVES

The use of aluminum cylinder heads, intake mani-

folds, and water pumps requires special corrosion

protection. Mopar Antifreeze, Prestone II, Peak or

antifreeze containing Alugard 340-2, or their equiva-

lent are recommended for best engine cooling with-

out corrosion. When mixed only to a freeze point of

Fig. 11 Thermostat, Housing, and Water BoxÐ3.0L Engine

Fig. 12 Thermostat InstalledÐ3.0L Engine

Fig. 13 Thermostat, Housing and WaterboxÐ3.3Land 3.8L Engine

7 - 14 COOLING SYSTEM Ä

Page 357 of 2438

-37ÉC (-35ÉF) to -59ÉC (-50ÉF). If it looses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed solution.

SERVICE

Coolant should be changed at 52,500 miles or three

years, whichever occurs first, then every two years or

30,000 miles.

ROUTINE LEVEL CHECK

Do not remove radiator cap for routine coolant

level inspections. The coolant reserve system provides a quick visual

method for determining the coolant level without re-

moving the radiator cap. Simply observe, with the

engine idling and warmed up to normal operating

temperature, that the level of the coolant in the reserve

tank (Figs. 5 and 6) is between the minimum and

maximum marks.

ADDING ADDITIONAL COOLANT

The radiator cap should not be removed. When

additional coolant is needed to maintain this level, it

should be added to the coolant reserve tank. Use only

50/50 concentration of ethylene glycol type antifreeze

and water.

SERVICE COOLANT LEVEL

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator. When servicing requires a coolant level check in the

radiator, the engine must be offand notunder pres-

sure. Drain several ounces of coolant from the radiator

drain cock while observing the Coolant Recovery Sys-

tem (CRS) Tank. Coolant level in the CRS tank should

drop slightly. Then remove the radiator cap. The radia-

tor should be full to the top. If not, and the coolant level

in the CRS tank is at the MIN mark there is a air leak

in the CRS system. Check hose or hose connections to

the CRS tank, radiator filler neck or the pressure cap

seal to the radiator filler neck for leaks.

LOW COOLANT LEVEL AERATION

Low coolant level in a cross flow radiator will equal-

ize in both tanks with engine off. With engine at

running operating temperature the high pressure inlet

tank runs full and the low pressure outlet tank drops.

If this level drops below the top of the transmission oil

cooler, air will be sucked into the water pump:

² Transmission oil will become hotter.

² High reading shown on the temperature gauge.

² Air in the coolant will also cause loss of flow through

the heater.

² Exhaust gas leaks into the coolant can also cause the

same problems.

DEAERATION

Air can only be removed from the system by gather-

ing under the pressure cap. On the next heat up it will

be pushed past the pressure cap into the CRS tank by

thermal expansion of the coolant. It then escapes to the

atmosphere in the CRS tank and is replaced with solid

coolant on cool down.

COOLING SYSTEM DRAIN, CLEAN, FLUSH AND

REFILL

Drain, flush, and fill the cooling system at the

mileage or time intervals specified in the Maintenance

Schedule in this Group. If the solution is dirty or rusty

or contains a considerable amount of sediment, clean

and flush with a reliable cooling system cleaner. Care

should be taken in disposing of the used engine coolant

from your vehicle. Check governmental regulations for

disposal of used engine coolant.

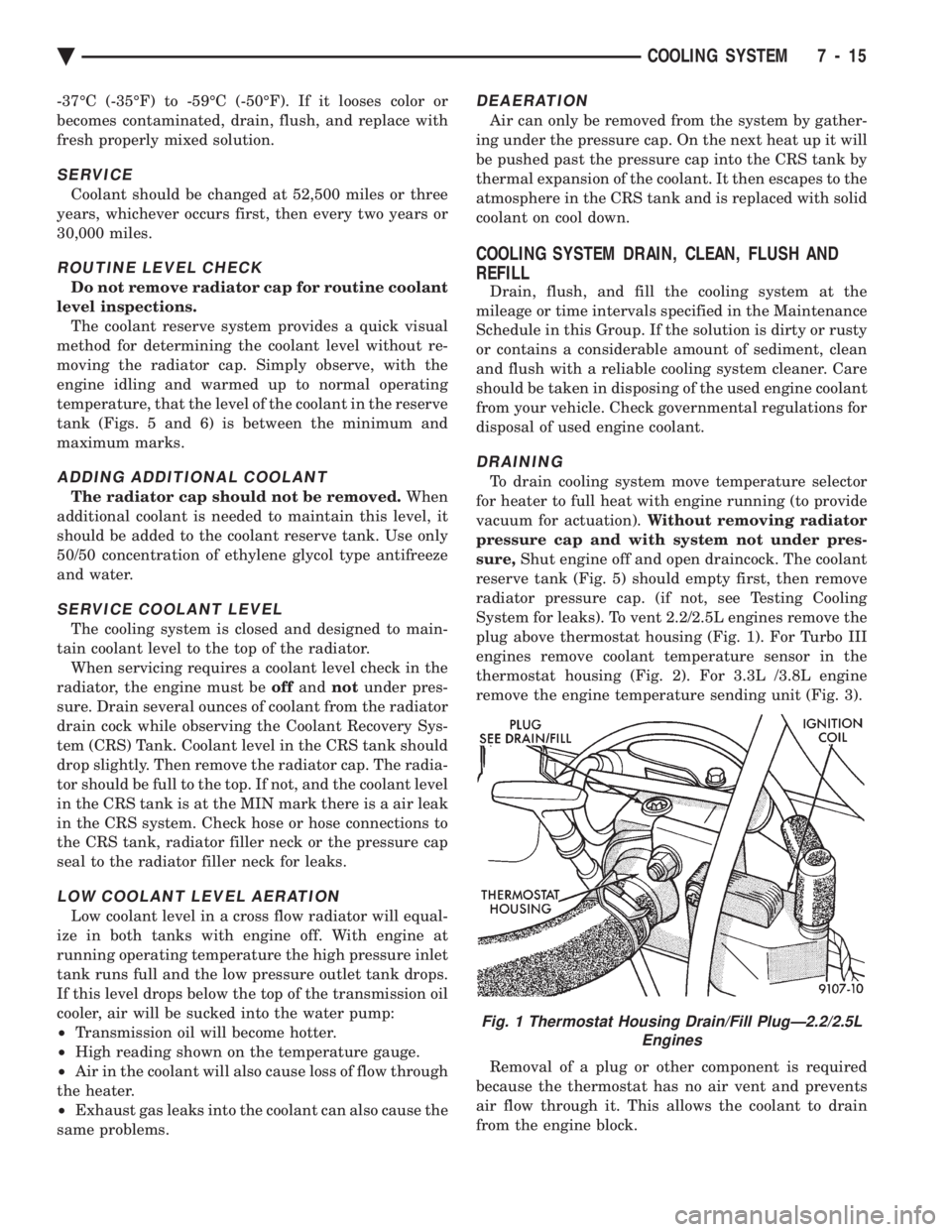

DRAINING

To drain cooling system move temperature selector

for heater to full heat with engine running (to provide

vacuum for actuation). Without removing radiator

pressure cap and with system not under pres-

sure, Shut engine off and open draincock. The coolant

reserve tank (Fig. 5) should empty first, then remove

radiator pressure cap. (if not, see Testing Cooling

System for leaks). To vent 2.2/2.5L engines remove the

plug above thermostat housing (Fig. 1). For Turbo III

engines remove coolant temperature sensor in the

thermostat housing (Fig. 2). For 3.3L /3.8L engine

remove the engine temperature sending unit (Fig. 3).

Removal of a plug or other component is required

because the thermostat has no air vent and prevents

air flow through it. This allows the coolant to drain

from the engine block.

Fig. 1 Thermostat Housing Drain/Fill PlugÐ2.2/2.5L Engines

Ä COOLING SYSTEM 7 - 15

Page 360 of 2438

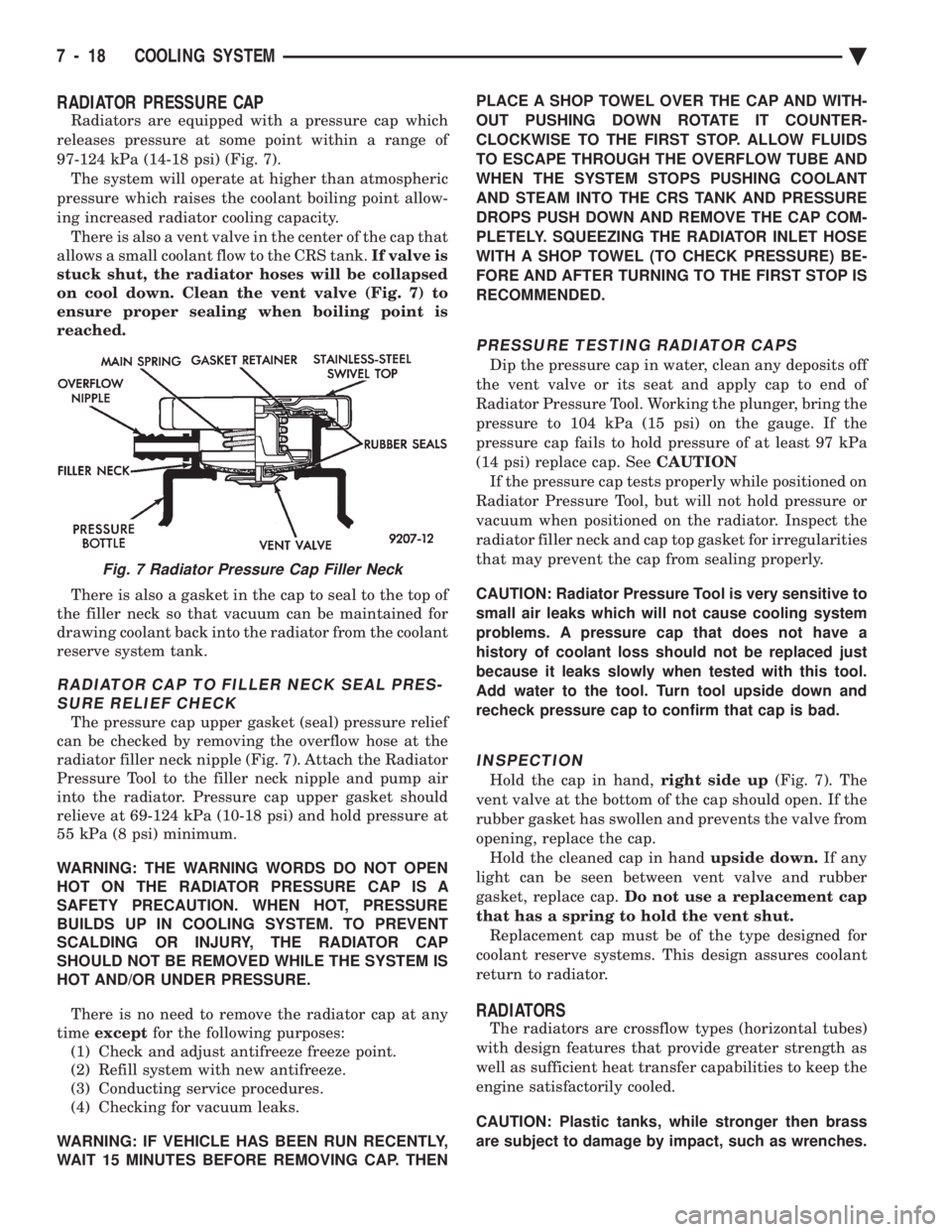

RADIATOR PRESSURE CAP

Radiators are equipped with a pressure cap which

releases pressure at some point within a range of

97-124 kPa (14-18 psi) (Fig. 7). The system will operate at higher than atmospheric

pressure which raises the coolant boiling point allow-

ing increased radiator cooling capacity. There is also a vent valve in the center of the cap that

allows a small coolant flow to the CRS tank. If valve is

stuck shut, the radiator hoses will be collapsed

on cool down. Clean the vent valve (Fig. 7) to

ensure proper sealing when boiling point is

reached.

There is also a gasket in the cap to seal to the top of

the filler neck so that vacuum can be maintained for

drawing coolant back into the radiator from the coolant

reserve system tank.

RADIATOR CAP TO FILLER NECK SEAL PRES- SURE RELIEF CHECK

The pressure cap upper gasket (seal) pressure relief

can be checked by removing the overflow hose at the

radiator filler neck nipple (Fig. 7). Attach the Radiator

Pressure Tool to the filler neck nipple and pump air

into the radiator. Pressure cap upper gasket should

relieve at 69-124 kPa (10-18 psi) and hold pressure at

55 kPa (8 psi) minimum.

WARNING: THE WARNING WORDS DO NOT OPEN

HOT ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM IS

HOT AND/OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

time except for the following purposes:

(1) Check and adjust antifreeze freeze point.

(2) Refill system with new antifreeze.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN PLACE A SHOP TOWEL OVER THE CAP AND WITH-

OUT PUSHING DOWN ROTATE IT COUNTER-

CLOCKWISE TO THE FIRST STOP. ALLOW FLUIDS

TO ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COM-

PLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE) BE-

FORE AND AFTER TURNING TO THE FIRST STOP IS

RECOMMENDED.

PRESSURE TESTING RADIATOR CAPS

Dip the pressure cap in water, clean any deposits off

the vent valve or its seat and apply cap to end of

Radiator Pressure Tool. Working the plunger, bring the

pressure to 104 kPa (15 psi) on the gauge. If the

pressure cap fails to hold pressure of at least 97 kPa

(14 psi) replace cap. See CAUTION

If the pressure cap tests properly while positioned on

Radiator Pressure Tool, but will not hold pressure or

vacuum when positioned on the radiator. Inspect the

radiator filler neck and cap top gasket for irregularities

that may prevent the cap from sealing properly.

CAUTION: Radiator Pressure Tool is very sensitive to

small air leaks which will not cause cooling system

problems. A pressure cap that does not have a

history of coolant loss should not be replaced just

because it leaks slowly when tested with this tool.

Add water to the tool. Turn tool upside down and

recheck pressure cap to confirm that cap is bad.

INSPECTION

Hold the cap in hand, right side up(Fig. 7). The

vent valve at the bottom of the cap should open. If the

rubber gasket has swollen and prevents the valve from

opening, replace the cap. Hold the cleaned cap in hand upside down.If any

light can be seen between vent valve and rubber

gasket, replace cap. Do not use a replacement cap

that has a spring to hold the vent shut. Replacement cap must be of the type designed for

coolant reserve systems. This design assures coolant

return to radiator.

RADIATORS

The radiators are crossflow types (horizontal tubes)

with design features that provide greater strength as

well as sufficient heat transfer capabilities to keep the

engine satisfactorily cooled.

CAUTION: Plastic tanks, while stronger then brass

are subject to damage by impact, such as wrenches.

Fig. 7 Radiator Pressure Cap Filler Neck

7 - 18 COOLING SYSTEM Ä

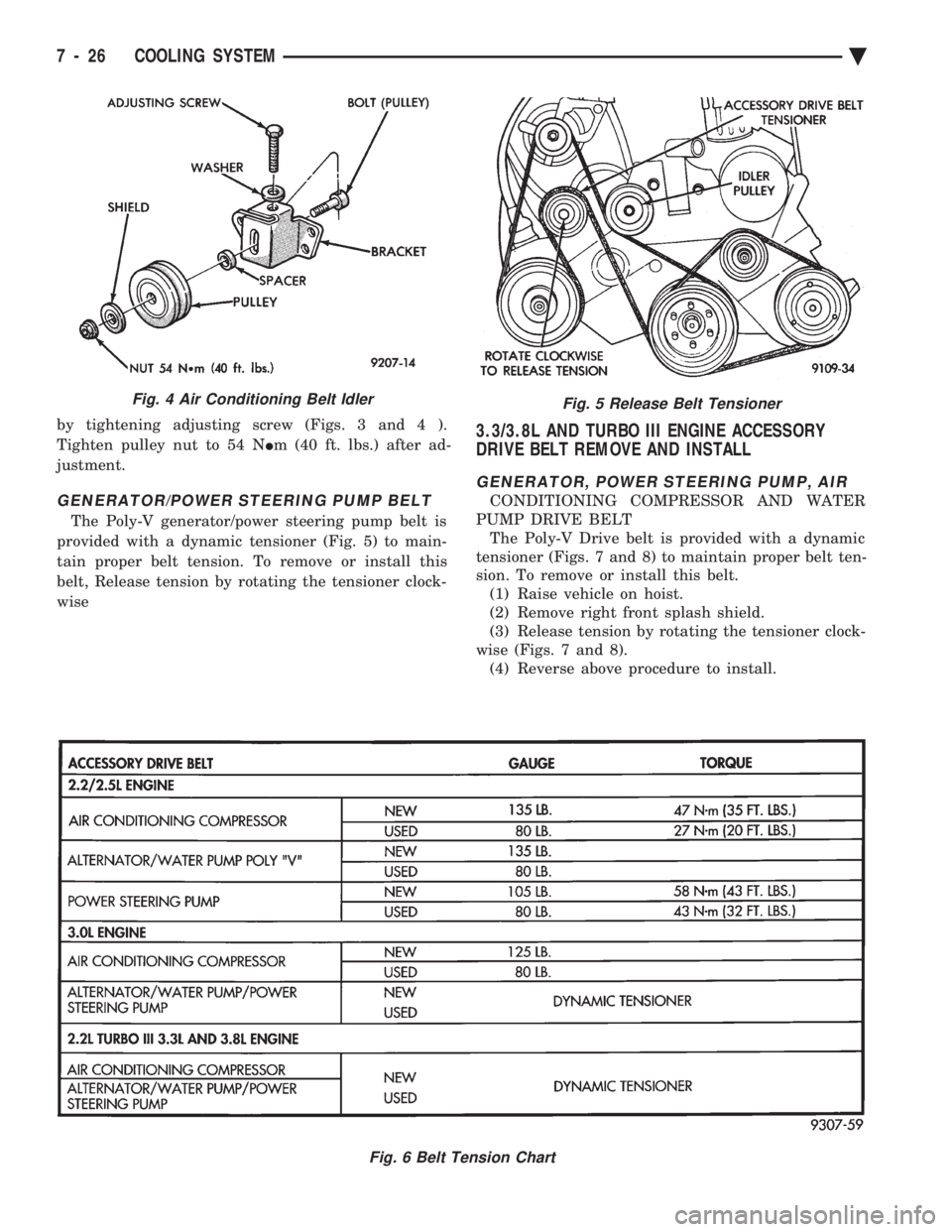

Page 368 of 2438

by tightening adjusting screw (Figs. 3 and 4 ).

Tighten pulley nut to 54 N Im (40 ft. lbs.) after ad-

justment.

GENERATOR/POWER STEERING PUMP BELT

The Poly-V generator/power steering pump belt is

provided with a dynamic tensioner (Fig. 5) to main-

tain proper belt tension. To remove or install this

belt, Release tension by rotating the tensioner clock-

wise

3.3/3.8L AND TURBO III ENGINE ACCESSORY

DRIVE BELT REMOVE AND INSTALL

GENERATOR, POWER STEERING PUMP, AIR

CONDITIONING COMPRESSOR AND WATER

PUMP DRIVE BELT The Poly-V Drive belt is provided with a dynamic

tensioner (Figs. 7 and 8) to maintain proper belt ten-

sion. To remove or install this belt. (1) Raise vehicle on hoist.

(2) Remove right front splash shield.

(3) Release tension by rotating the tensioner clock-

wise (Figs. 7 and 8). (4) Reverse above procedure to install.

Fig. 5 Release Belt Tensioner

Fig. 6 Belt Tension Chart

Fig. 4 Air Conditioning Belt Idler

7 - 26 COOLING SYSTEM Ä

Page 1063 of 2438

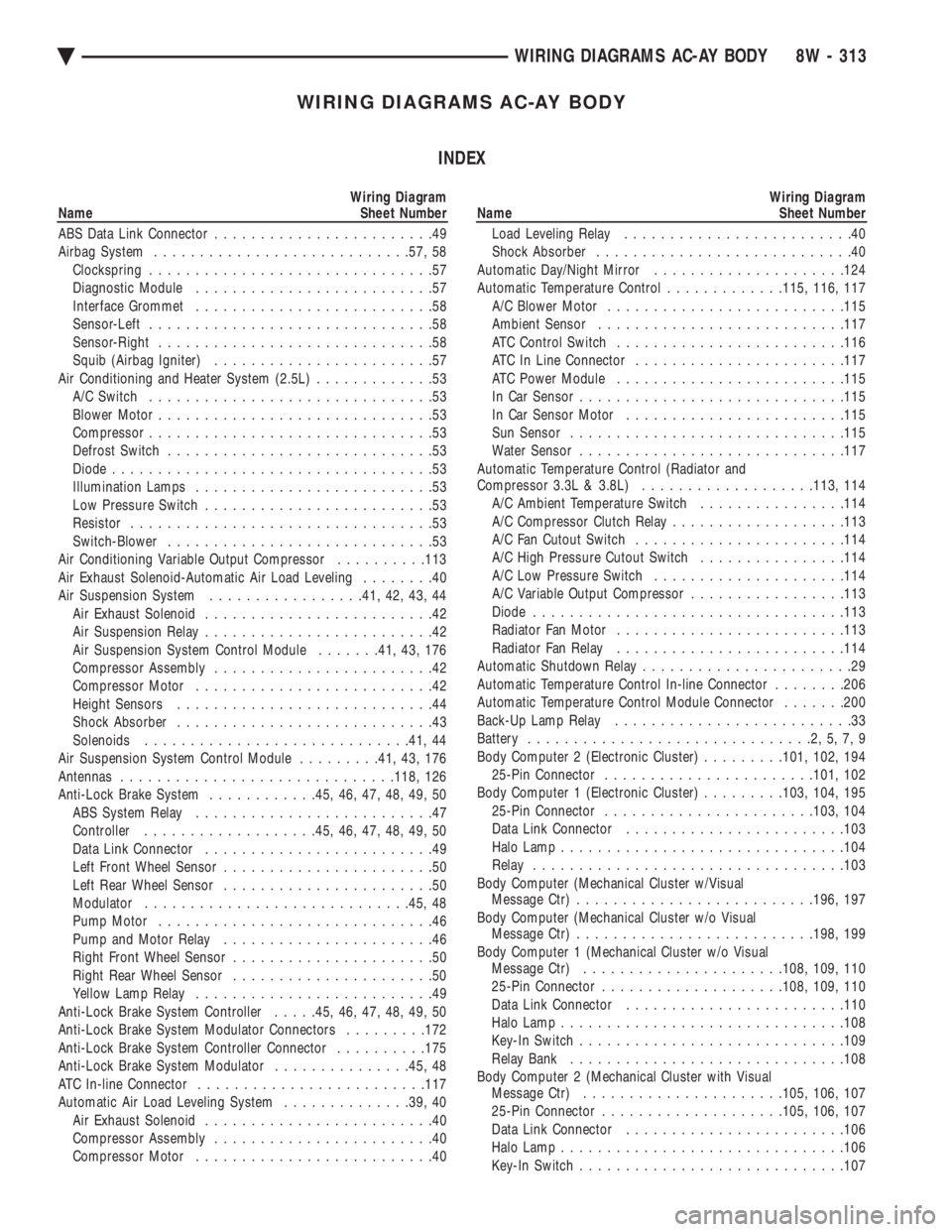

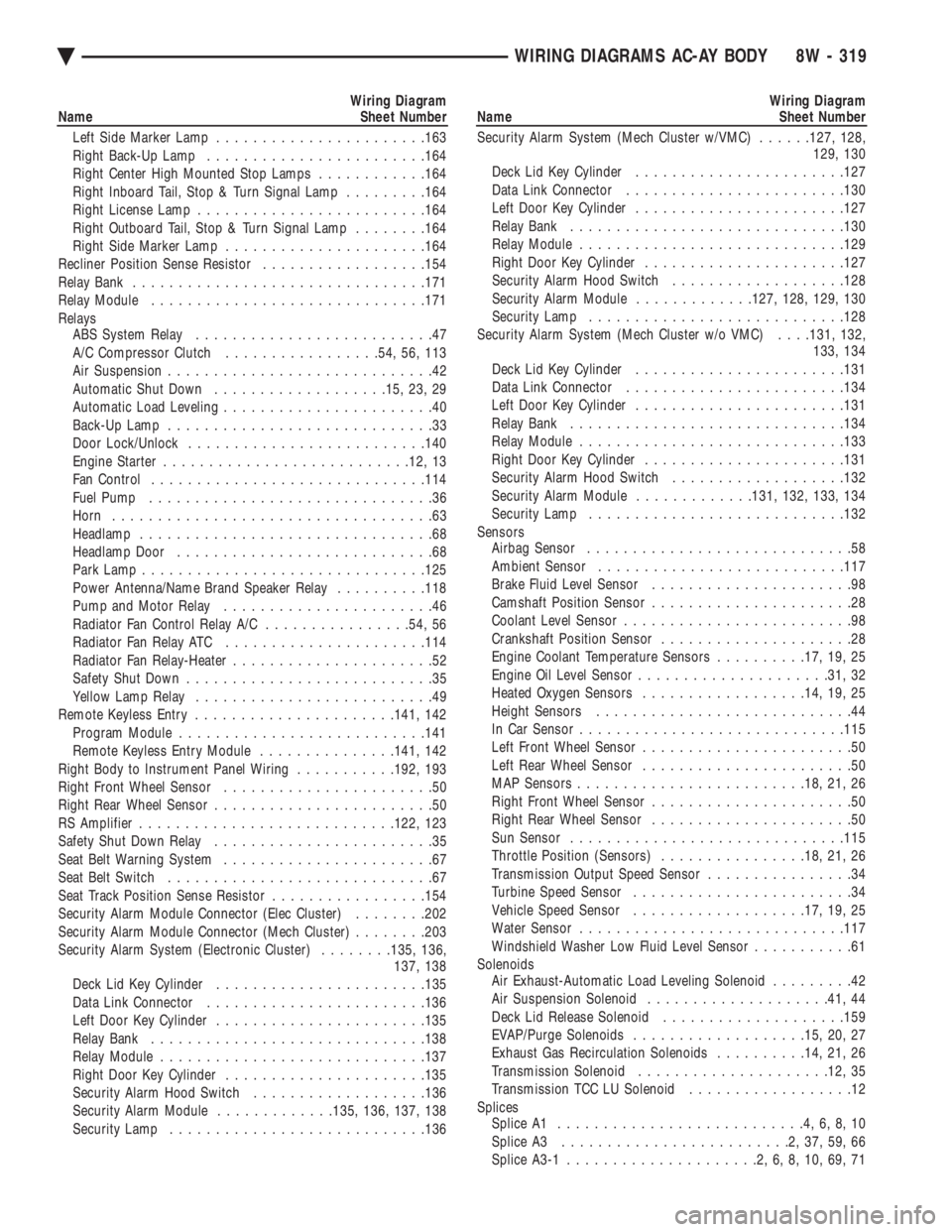

WIRING DIAGRAMS AC-AY BODY INDEX

Wiring Diagram

Name Sheet Number

ABS Data Link Connector ........................49

Airbag System ........................... .57, 58

Clockspring ...............................57

Diagnostic Module ..........................57

Interface Grommet ..........................58

Sensor-Left ...............................58

Sensor-Right ..............................58

Squib (Airbag Igniter) ........................57

Air Conditioning and Heater System (2.5L) .............53

A/C Switch ...............................53

Blower Motor ..............................53

Compressor ...............................53

Defrost Switch .............................53

Diode ...................................53

Illumination Lamps ..........................53

Low Pressure Switch .........................53

Resistor .................................53

Switch-Blower .............................53

Air Conditioning Variable Output Compressor ..........113

Air Exhaust Solenoid-Automatic Air Load Leveling ........40

Air Suspension System .................41, 42, 43, 44

Air Exhaust Solenoid .........................42

Air Suspension Relay .........................42

Air Suspension System Control Module .......41, 43, 176

Compressor Assembly ........................42

Compressor Motor ..........................42

Height Sensors ............................44

Shock Absorber ............................43

Solenoids ............................ .41, 44

Air Suspension System Control Module .........41, 43, 176

Antennas ............................. .118, 126

Anti-Lock Brake System ............45, 46, 47, 48, 49, 50

ABS System Relay ..........................47

Controller .................. .45, 46, 47, 48, 49, 50

Data Link Connector .........................49

Left Front Wheel Sensor .......................50

Left Rear Wheel Sensor .......................50

Modulator ............................ .45, 48

Pump Motor ..............................46

Pump and Motor Relay .......................46

Right Front Wheel Sensor ......................50

Right Rear Wheel Sensor ......................50

Yellow Lamp Relay ..........................49

Anti-Lock Brake System Controller .....45, 46, 47, 48, 49, 50

Anti-Lock Brake System Modulator Connectors .........172

Anti-Lock Brake System Controller Connector ..........175

Anti-Lock Brake System Modulator ...............45, 48

ATC In-line Connector ........................ .117

Automatic Air Load Leveling System ..............39, 40

Air Exhaust Solenoid .........................40

Compressor Assembly ........................40

Compressor Motor ..........................40Wiring Diagram

Name Sheet Number

Load Leveling Relay .........................40

Shock Absorber ............................40

Automatic Day/Night Mirror .................... .124

Automatic Temperature Control .............115, 116, 117

A/C Blower Motor ......................... .115

Ambient Sensor .......................... .117

ATC Control Switch ........................ .116

ATC In Line Connector ...................... .117

ATC Power Module ........................ .115

In Car Senso r............................ .115

In Car Sensor Motor ....................... .115

Sun Sensor ............................. .115

Water Sensor ............................ .117

Automatic Temperature Control (Radiator and

Compressor 3.3L & 3.8L) .................. .113, 114

A/C Ambient Temperature Switch ................114

A/C Compressor Clutch Relay ...................113

A/C Fan Cutout Switch ...................... .114

A/C High Pressure Cutout Switch ................114

A/C Low Pressure Switch .................... .114

A/C Variable Output Compressor .................113

Diode ................................. .113

Radiator Fan Motor ........................ .113

Radiator Fan Relay ........................ .114

Automatic Shutdown Relay .......................29

Automatic Temperature Control In-line Connector ........206

Automatic Temperature Control Module Connector .......200

Back-Up Lamp Relay ..........................33

Battery ...............................2,5,7,9

Body Computer 2 (Electronic Cluster) .........101, 102, 194

25-Pin Connector ...................... .101, 102

Body Computer 1 (Electronic Cluster) .........103, 104, 195

25-Pin Connector ...................... .103, 104

Data Link Connector ....................... .103

Halo Lamp .............................. .104

Relay ................................. .103

Body Computer (Mechanical Cluster w/Visual Message Ctr) ......................... .196, 197

Body Computer (Mechanical Cluster w/o Visual Message Ctr) ......................... .198, 199

Body Computer 1 (Mechanical Cluster w/o Visual Message Ctr) ..................... .108, 109, 110

25-Pin Connector ................... .108, 109, 110

Data Link Connector ....................... .110

Halo Lamp .............................. .108

Key-In Switch ............................ .109

Relay Bank ............................. .108

Body Computer 2 (Mechanical Cluster with Visual Message Ctr) ..................... .105, 106, 107

25-Pin Connector ................... .105, 106, 107

Data Link Connector ....................... .106

Halo Lamp .............................. .106

Key-In Switch ............................ .107

Ä WIRING DIAGRAMS AC-AY BODY 8W - 313

Page 1069 of 2438

Wiring Diagram

Name Sheet Number

Left Side Marker Lamp ...................... .163

Right Back-Up Lamp ....................... .164

Right Center High Mounted Stop Lamps ............164

Right Inboard Tail, Stop & Turn Signal Lamp .........164

Right License Lamp ........................ .164

Right Outboard Tail, Stop & Turn Signal Lamp ........164

Right Side Marker Lamp ..................... .164

Recliner Position Sense Resistor ..................154

Relay Bank ............................... .171

Relay Module ............................. .171

Relays ABS System Relay ..........................47

A/C Compressor Clutch .................54, 56, 113

Air Suspension .............................42

Automatic Shut Down .................. .15, 23, 29

Automatic Load Leveling .......................40

Back-Up Lamp .............................33

Door Lock/Unlock ......................... .140

Engine Starter .......................... .12, 13

Fan Control ............................. .114

Fuel Pump ...............................36

Horn ...................................63

Headlamp ................................68

Headlamp Door ............................68

Park Lamp .............................. .125

Power Antenna/Name Brand Speaker Relay ..........118

Pump and Motor Relay .......................46

Radiator Fan Control Relay A/C ................54, 56

Radiator Fan Relay ATC ..................... .114

Radiator Fan Relay-Heater ......................52

Safety Shut Down ...........................35

Yellow Lamp Relay ..........................49

Remote Keyless Entry ..................... .141, 142

Program Module .......................... .141

Remote Keyless Entry Module ...............141, 142

Right Body to Instrument Panel Wiring ...........192, 193

Right Front Wheel Sensor .......................50

Right Rear Wheel Sensor ........................50

RS Amplifier ........................... .122, 123

Safety Shut Down Relay ........................35

Seat Belt Warning System .......................67

Seat Belt Switch .............................67

Seat Track Position Sense Resistor .................154

Security Alarm Module Connector (Elec Cluster) ........202

Security Alarm Module Connector (Mech Cluster) ........203

Security Alarm System (Electronic Cluster) ........135, 136,

137, 138

Deck Lid Key Cylinder ...................... .135

Data Link Connector ....................... .136

Left Door Key Cylinder ...................... .135

Relay Bank ............................. .138

Relay Module ............................ .137

Right Door Key Cylinder ..................... .135

Security Alarm Hood Switch ...................136

Security Alarm Module .............135, 136, 137, 138

Security Lamp ........................... .136Wiring Diagram

Name Sheet Number

Security Alarm System (Mech Cluster w/VMC) ......127, 128,

129, 130

Deck Lid Key Cylinder ...................... .127

Data Link Connector ....................... .130

Left Door Key Cylinder ...................... .127

Relay Bank ............................. .130

Relay Module ............................ .129

Right Door Key Cylinder ..................... .127

Security Alarm Hood Switch ...................128

Security Alarm Module .............127, 128, 129, 130

Security Lamp ........................... .128

Security Alarm System (Mech Cluster w/o VMC) . . . .131, 132,

133, 134

Deck Lid Key Cylinder ...................... .131

Data Link Connector ....................... .134

Left Door Key Cylinder ...................... .131

Relay Bank ............................. .134

Relay Module ............................ .133

Right Door Key Cylinder ..................... .131

Security Alarm Hood Switch ...................132

Security Alarm Module .............131, 132, 133, 134

Security Lamp ........................... .132

Sensors Airbag Sensor .............................58

Ambient Sensor .......................... .117

Brake Fluid Level Sensor ......................98

Camshaft Position Sensor ......................28

Coolant Level Sensor .........................98

Crankshaft Position Sensor .....................28

Engine Coolant Temperature Sensors ..........17, 19, 25

Engine Oil Level Sensor .................... .31, 32

Heated Oxygen Sensors ................. .14, 19, 25

Height Sensors ............................44

In Car Senso r............................ .115

Left Front Wheel Sensor .......................50

Left Rear Wheel Sensor .......................50

MAP Sensors ........................ .18, 21, 26

Right Front Wheel Sensor ......................50

Right Rear Wheel Sensor ......................50

Sun Sensor ............................. .115

Throttle Position (Sensors) ................18, 21, 26

Transmission Output Speed Sensor ................34

Turbine Speed Sensor ........................34

Vehicle Speed Sensor .................. .17, 19, 25

Water Sensor ............................ .117

Windshield Washer Low Fluid Level Sensor ...........61

Solenoids Air Exhaust-Automatic Load Leveling Solenoid .........42

Air Suspension Solenoid ................... .41, 44

Deck Lid Release Solenoid ................... .159

EVAP/Purge Solenoids .................. .15, 20, 27

Exhaust Gas Recirculation Solenoids ..........14, 21, 26

Transmission Solenoid .................... .12, 35

Transmission TCC LU Solenoid ..................12

Splices Splice A1 ...........................4,6,8,10

Splice A3 .........................2,37,59,66

Splice A3-1 .....................2,6,8,10,69,71

Ä WIRING DIAGRAMS AC-AY BODY 8W - 319

Page 1575 of 2438

Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline. Engine components which are required for safe op-

eration using fuel containing methanol alcohol are

identified by a standard green color and/or display

the statement methanol compatible imprinted on the

component. To ensure continued safe operation, these

components must be serviced only with genuine MO-

PAR replacement parts. Methanol compatible parts for the 2.5L FFV (Flex-

ible Fuel Vehicle) engine include, but are not limited

to; the valve stem oil seals, all piston rings, the oil

fill cap, the fuel injectors, fuel rail, fuel pressure reg-

ulator, hoses and the vacuum control harness hose. BLOCK: All four cylinder cast iron blocks have

cast-in recesses in the bottom of each cylinder bore to

provide connecting rod clearance; especially needed

for 2.5L engines. The bores are also siamese to min-

imize engine length. A coolant passage is drilled

cross-ways through the siamese section to enhance

between the bore cooling on some engine types. A

partial open deck is used for cooling and weight re-

duction with oil filter, water pump, and distributor

mounting bosses molded into the front (radiator side)

of the block. Nominal wall thickness is 4.5 mm. Five

main bearing bulkheads and a block skirt extending

3 mm below the crankshaft center line add to the

blocks high rigidity with light weight. CRANKSHAFT: A nodular cast iron crankshaft is

used in TBI engines. A forged steel crankshaft is

used in the Turbo III engine. All engines have 5 main bearings, with number 3 flanged to control

thrust. The 60 mm diameter main and 50 mm diam-

eter crank pin journals (all) have undercut radiuses

fillets that are deep rolled for added strength. To op-

timize bearing loading 4 counterweights are used.

Hydrodynamic seals (installed in diecast aluminum

retainers) provide end sealing, where the crankshaft

exits the block. Anaerobic gasket material is used for

retainer-to-block sealing. No vibration damper is

used. A sintered iron (TBI engine and steel billet

Turbo III engines) timing belt sprocket is mounted

on the crankshaft nose. This sprocket provides mo-

tive power; via timing belt to the camshaft and inter-

mediate shaft sprockets (also sintered iron (TBI

engine and steel billet Turbo III engines) providing

timed valve, distributor, and oil pump actuation. PISTONS: Some Chrysler pistons have cast-in

steel struts at the pin bosses for autothermic control.

All 2.2L and 2.5L piston tops have cuts to provide

valve clearance. Some pistons are dished to provide

various compression ratios. Standard 2.2L and 2.5L

engines are designed for 9.5:1 and 8.9:1 compression

ratios respectively. The 2.5L piston is dished and is a

lightweight design to enhance engine smoothness.

The 2.2L turbo III uses dished pistons providing a

8.3:1 compression ratio. All standard 2.2/2.5L and

2.5L FFV engines use pressed-in piston pins to at-

tach forged steel connecting rods, 2.2L turbo III en-

gine uses a full floating piston pin and connecting

rod assembly. PISTONS RINGS: The 2.2/2.5L engines share

common piston rings throughout, including molybde-

num filled top ring for reliable compression sealing

and a tapered faced intermediate ring for additional

cylinder pressure control. The 2.5L FFV engine fea-

ture all chrome rings for enhanced long term dura-

bility under multi-fueled conditions. CYLINDER HEAD: The cylinder head is cast alu-

minum with in-line valves. The 2.2/2.5L and 2.5L

FFV valves are arranged with alternating exhaust

and intake. The intake and exhaust ports are located

in the rearward, facing side of the head. The Turbo

III valves are arranged in two inline banks, with the

ports of the bank of two intake valves per cylinder

facing toward the radiator side of engine and ports of

the bank of two exhaust valve per cylinder facing to-

ward the dash panel. The intake ports feed fast-burn

design combustion chambers (2.2/2.5L and 2.5L FFV

only) with the spark plug located close to the center

line of the combustion chamber for optimum effi-

ciency. An integral oil gallery within the cylinder

head supplies oil to the hydraulic lash adjusters,

camshaft, and valve mechanisms. CAMSHAFT: The nodular iron camshaft has five

bearing journals (2.2/2.5L and 2.5L FFV). The Turbo

III employs dual camshafts that have nine bearing

journals. Flanges at the rear journal control cam-

Fig. 1 Engine Identification

Ä 2.2/2.5L ENGINE 9 - 9