service CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2384 of 2438

(4) If pin #13 shows continuity, repair circuit C02

and retest. (5) If no continuity is shown, replace the ATC con-

trol and retest.

DIAGNOSTIC TROUBLE CODE 7ÐBLOWER DRIVE SIGNAL NOT HIGH

First check the 4-way connector to the power

module for correct installation (1) With the ignition ON, check for ignition volt-

age to the power module pin #1 from the ATC con-

trol. If ignition is present at the power module,

proceed to step 3. If not proceed to step 2. (2) With the 21-way connector still connected and

the ignition ON, check for power module ignition

feed at the control pin #12. If ignition is not present,

replace the control. If ignition voltage is present, re-

pair the open in the wire between the control pin

#12 and power module pin #1. Retest system. (3) Turn ignition OFF and disconnect the 21-way

connector. Measure the resistance between pins #2

and #12. The resistance should read between 2,600

and 2,800 ohms. If correct, replace the ATC control.

If not correct, proceed to step 4. (4) Remove the 4-way connector from the power

module. Check for continuity between the ATC con-

trol pin #2 and power module pin #2. If no continu-

ity is shown, repair the wire for an open. If

continuity is shown, replace the power module and

retest.

DIAGNOSTIC TROUBLE CODE 8ÐA/D CONVERTOR INTERNAL FAILURE

Diagnostics will indicate a Diagnostic Trouble Code

8 if the internal reference voltage of the A/D Conver-

tor is not correct. This Diagnostic Trouble Code is

not serviceable. If a Diagnostic Trouble Code 8 oc-

curs, the computer control head must be replaced.

DIAGNOSTIC TROUBLE CODE 9ÐSUN LOAD SENSOR FAILURE

(1) Unplug the 21-way connector from the control

and check pin #19 for continuity to chassis ground.

If continuity is present, repair the wire shorted to

ground. If no continuity is present, proceed to step 2. (2) Plug the 21-way connector back in. Remove pin

#19 from the 21 way connector and run diagnostics

again. If Diagnostic Trouble Code 9 is still present,

replace the control. If code 9 is not present, replace

the sun sensor.

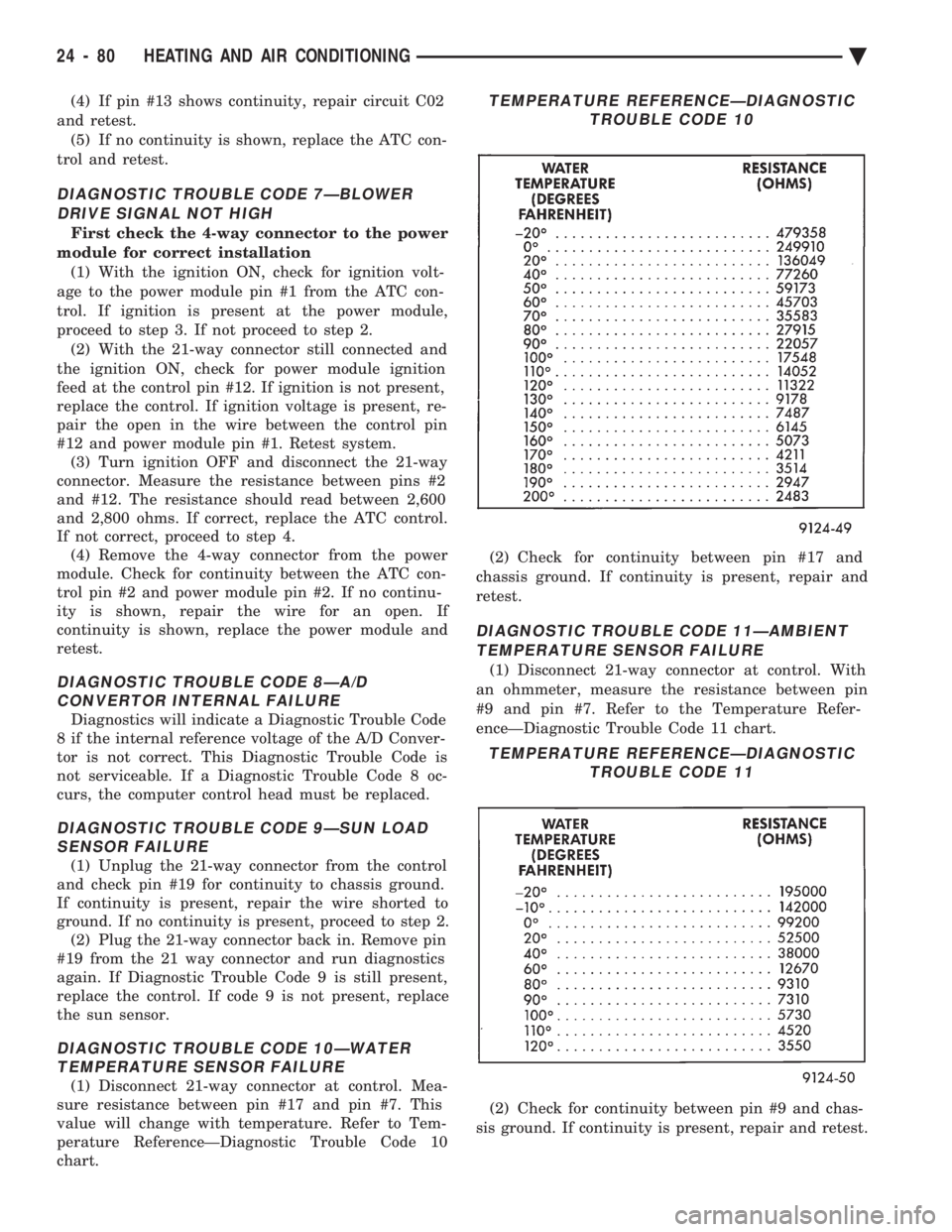

DIAGNOSTIC TROUBLE CODE 10ÐWATER TEMPERATURE SENSOR FAILURE

(1) Disconnect 21-way connector at control. Mea-

sure resistance between pin #17 and pin #7. This

value will change with temperature. Refer to Tem-

perature ReferenceÐDiagnostic Trouble Code 10

chart. (2) Check for continuity between pin #17 and

chassis ground. If continuity is present, repair and

retest.

DIAGNOSTIC TROUBLE CODE 11ÐAMBIENT TEMPERATURE SENSOR FAILURE

(1) Disconnect 21-way connector at control. With

an ohmmeter, measure the resistance between pin

#9 and pin #7. Refer to the Temperature Refer-

enceÐDiagnostic Trouble Code 11 chart.

(2) Check for continuity between pin #9 and chas-

sis ground. If continuity is present, repair and retest.

TEMPERATURE REFERENCEÐDIAGNOSTIC TROUBLE CODE 10

TEMPERATURE REFERENCEÐDIAGNOSTICTROUBLE CODE 11

24 - 80 HEATING AND AIR CONDITIONING Ä

Page 2386 of 2438

of the 5-way connector. If continuity is not present,

repair circuit for an open. If present, continue to step

4.(4) Install 5-way connector back into the mode

door actuator. Then check for continuity between

pins #7 and #16 of the 21-way connector. If continu-

ity is present, replace the ATC control. If continuity

is not present, replace the mode door actuator.

DIAGNOSTIC TROUBLE CODE 19ÐMODE DOOR FEEDBACK SHORTED TO GROUND

(1) Remove the 21-way connector from the control,

and the 5 way connector from the mode door actua-

tor. (2) Check for continuity between pin #16 of the

21-way connector and chassis ground. If present, re-

pair circuit for short to ground. If not present, con-

tinue to step 3. (3) Plug in the 5-way connector and measure resis-

tance between pins #7 and #16 of the 21-way con-

nector. If the resistance is less than 10 ohms, replace

the actuator. If not, replace the control head.

DIAGNOSTIC TROUBLE CODE 20ÐBLEND DOOR MOVED DURING MODE DOOR TEST

(1) Remove the 21-way connector from the control

and the 5-way connector from the three actuators. (2) Check for continuity between pin #4 of the 21-

way connector and pin #4 of each actuator. If conti-

nuity is not present for a particular actuator circuit,

repair that circuit and retest system. If continuity is

present for all circuits, continue to step 3. (3) Plug in the 5-way connectors and check for re-

sistance between pins #4 and #6 of the 21-way con-

nector for the blend air actuator. Then check pins #4

and #5 of the 21-way connector for the mode actua-

tor. The resistance should be between 20-50 ohms. If

either of the actuators do not pass the resistance

tests, replace that particular actuator and retest the

system. If both pass the resistance test, replace the

ATC control.

DIAGNOSTIC TROUBLE CODE 21ÐROM CHECK SUM ERROR

During the Diagnostics test, the computer will ver-

ify it's own internal program. If it finds any part to

be bad, a Diagnostic Trouble Code 21 will be set.

This Diagnostic Trouble Code is not serviceable. If a

Fail Code 21 occurs, the ATC Control Module must

be replaced.

DIAGNOSTIC TROUBLE CODE 22ÐCOMPUTER ERROR

If incorrect data is found in the ATC Control com-

puter module, a Diagnostic Trouble Code 22 will be

set. This Fail Code is not serviceable. If a Diagnostic

Trouble Code 22 occurs, the ATC Control Module

must be replaced.

DIAGNOSTIC TROUBLE CODE 23ÐBLEND

DOOR FEEDBACK FAILED

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 23 will be stored within

the ATC Control, and must be cleared after the fail-

ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 from ATC Control. Follow service procedures for Diagnostic Trouble

Codes 14 and 15 when repairing.

DIAGNOSTIC TROUBLE CODE 24ÐMODE DOOR FEEDBACK FAILED

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 24 will be stored within

the ATC Control, and must be cleared after the fail-

ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 From ATC Control. Follow service procedures for Diagnostic Trouble

Codes 18 and 19 when repairing.

DIAGNOSTIC TROUBLE CODE 25ÐAMBIENT TEMPERATURE SENSOR FAILURE

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 25 will be stored within

the ATC Control, and must be cleared after the fail-

ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 from ATC Control. Follow service procedures for Diagnostic Trouble

Code 11 when repairing.

DIAGNOSTIC TROUBLE CODE 26ÐIN-CAR TEMPERATURE SENSOR/ASPIRATOR FAILED

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

24 - 82 HEATING AND AIR CONDITIONING Ä

Page 2387 of 2438

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 26 will be stored within

the ATC Control, and must be cleared after the fail-

ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 from ATC Control. Follow service procedures for Diagnostic Trouble

Code 12 when repairing.

DIAGNOSTIC TROUBLE CODE 27ÐSUN LOAD SENSOR FAILED

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 27 will be stored within

the ATC Control, and must be cleared after the fail-

ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 from ATC Control. Follow service procedures for Diagnostic Trouble

Code 12 when repairing.

DIAGNOSTIC TROUBLE CODE 28ÐWATER TEMPERATURE SENSOR FAILED

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 28 will be stored within

the ATC Control and must be cleared after the fail- ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 from ATC Control. Follow service procedures for Diagnostic Trouble

Code 10 when repairing.

ERASING DIAGNOSTIC TROUBLE CODES

Diagnostic Trouble Codes 23 through 28 are stored

within the ATC in the computer memory. These

codes may be erased from the memory after the cor-

rect repairs have been made. Intermittent Diagnostic

Trouble Codes 23 through 28 will be stored until

they are erased. (1) Run the DIAGNOSTIC TEST.

(2) Depress the PANEL button to access all Diag-

nostic Trouble Codes. When the Display begins flash-

ing alternating zeros, you can do three things:

² Do nothing, and in five seconds control will return

to normal ATC operation. All codes will remain

stored in the control.

² Depress any button within five seconds, other than

A/C, and stop the test immediately. Control will re-

turn to normal ATC operation.

² Depress the A/C button within five seconds, and

proceed to the erasing procedure. By depressing the

A/C button, you will not erase any Diagnostic Trou-

ble Codes. You will only access the next part of the

procedure. Proceed to step 3. (3) After you depress the A/C button the display

will alternate E's. This is for ERASE. You can now

do two things:

² Do nothing, and in five seconds, all Diagnostic

Trouble Codes from 23 through 28 will be erased

from the ATC control.

² Depress any button within five seconds, and Diag-

nostic Trouble Codes will not be erased. Control will return to normal ATC operation.

Ä HEATING AND AIR CONDITIONING 24 - 83

Page 2389 of 2438

EMISSION CONTROL SYSTEMS

CONTENTS

page page

EVAPORATIVE EMISSION CONTROLS ....... 1EXHAUST EMISSION CONTROLS .......... 17

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter designation. The Intro- duction Section at the front of this manual contains a

chart showing the breakdown of the designations.

EVAPORATIVE EMISSION CONTROLS

INDEX

page page

Canister Purge SolenoidÐExcept 3.0L and 2.5L MPI ............................. 13

Crankcase Vent Filter ..................... 16

Duty Cycle EVAP Purge Solenoid ............ 13

Evaporation Control System ................ 13 PCV Valve Test

......................... 15

Positive Crankcase Ventilation (PCV) Systems . . 15

Pressure-Vacuum Filler Cap ................ 14

Vacuum Schematics ....................... 2

Vehicle Emission Control Information Label ...... 1

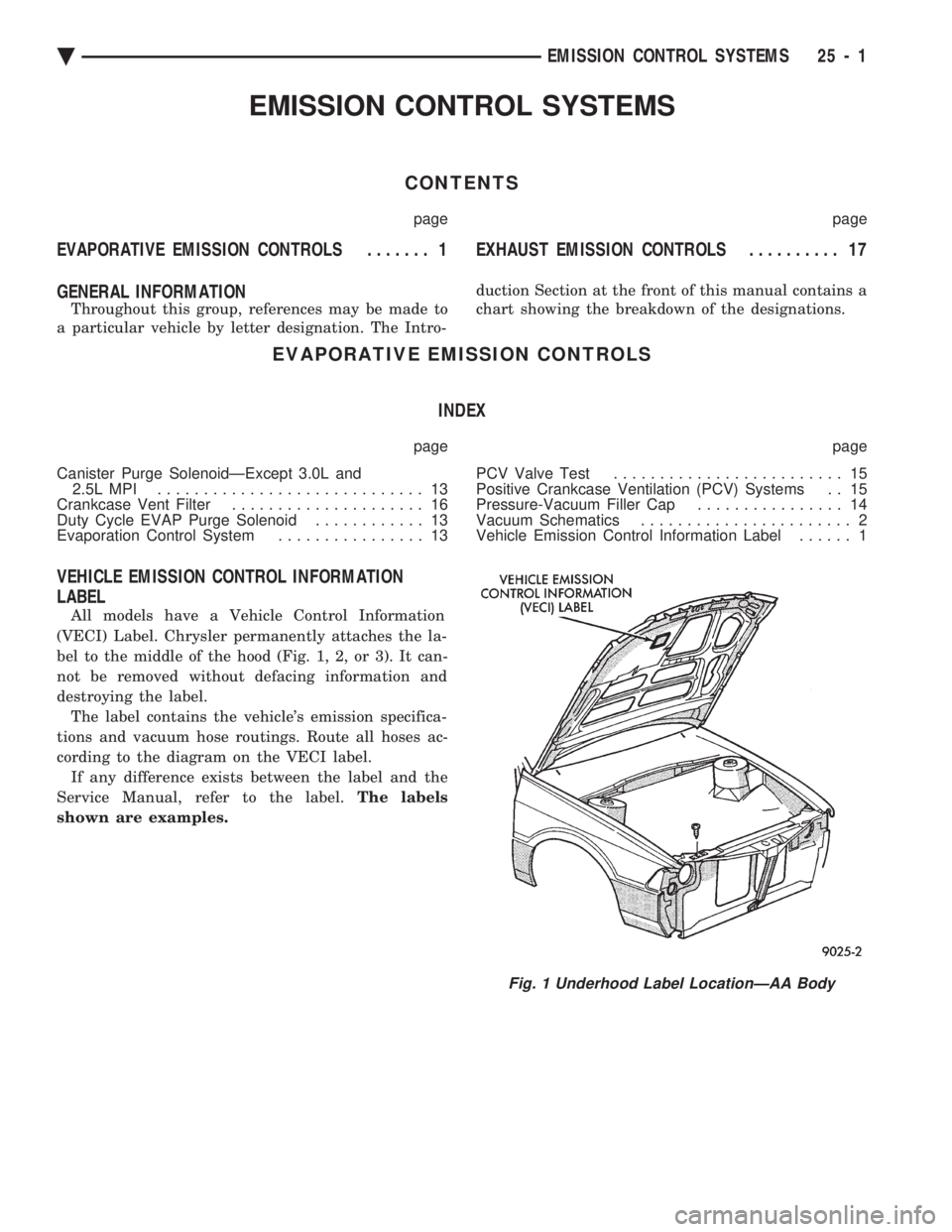

VEHICLE EMISSION CONTROL INFORMATION

LABEL

All models have a Vehicle Control Information

(VECI) Label. Chrysler permanently attaches the la-

bel to the middle of the hood (Fig. 1, 2, or 3). It can-

not be removed without defacing information and

destroying the label. The label contains the vehicle's emission specifica-

tions and vacuum hose routings. Route all hoses ac-

cording to the diagram on the VECI label. If any difference exists between the label and the

Service Manual, refer to the label. The labels

shown are examples.

Fig. 1 Underhood Label LocationÐAA Body

Ä EMISSION CONTROL SYSTEMS 25 - 1

Page 2390 of 2438

VACUUM SCHEMATICS

If any difference exists between the vacuum sche-

matics on the VECI label and the schematics in the

Service Manual, refer to the label.

Fig. 2 Underhood Label LocationÐAC, AP and AY BodiesFig. 3 Underhood Label LocationÐAG and AJBodies

25 - 2 EMISSION CONTROL SYSTEMS Ä

Page 2401 of 2438

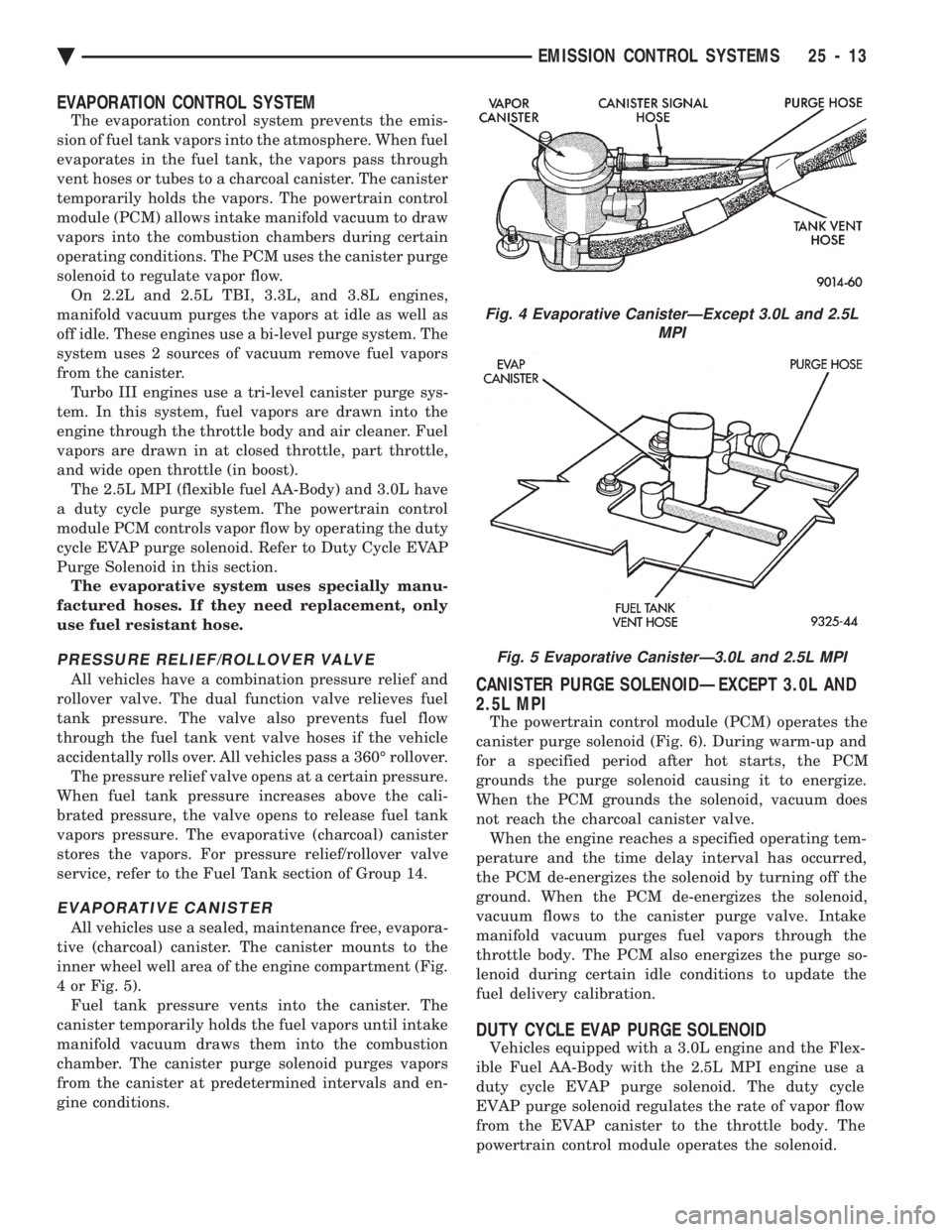

EVAPORATION CONTROL SYSTEM

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When fuel

evaporates in the fuel tank, the vapors pass through

vent hoses or tubes to a charcoal canister. The canister

temporarily holds the vapors. The powertrain control

module (PCM) allows intake manifold vacuum to draw

vapors into the combustion chambers during certain

operating conditions. The PCM uses the canister purge

solenoid to regulate vapor flow. On 2.2L and 2.5L TBI, 3.3L, and 3.8L engines,

manifold vacuum purges the vapors at idle as well as

off idle. These engines use a bi-level purge system. The

system uses 2 sources of vacuum remove fuel vapors

from the canister. Turbo III engines use a tri-level canister purge sys-

tem. In this system, fuel vapors are drawn into the

engine through the throttle body and air cleaner. Fuel

vapors are drawn in at closed throttle, part throttle,

and wide open throttle (in boost). The 2.5L MPI (flexible fuel AA-Body) and 3.0L have

a duty cycle purge system. The powertrain control

module PCM controls vapor flow by operating the duty

cycle EVAP purge solenoid. Refer to Duty Cycle EVAP

Purge Solenoid in this section. The evaporative system uses specially manu-

factured hoses. If they need replacement, only

use fuel resistant hose.

PRESSURE RELIEF/ROLLOVER VALVE

All vehicles have a combination pressure relief and

rollover valve. The dual function valve relieves fuel

tank pressure. The valve also prevents fuel flow

through the fuel tank vent valve hoses if the vehicle

accidentally rolls over. All vehicles pass a 360É rollover. The pressure relief valve opens at a certain pressure.

When fuel tank pressure increases above the cali-

brated pressure, the valve opens to release fuel tank

vapors pressure. The evaporative (charcoal) canister

stores the vapors. For pressure relief/rollover valve

service, refer to the Fuel Tank section of Group 14.

EVAPORATIVE CANISTER

All vehicles use a sealed, maintenance free, evapora-

tive (charcoal) canister. The canister mounts to the

inner wheel well area of the engine compartment (Fig.

4 or Fig. 5). Fuel tank pressure vents into the canister. The

canister temporarily holds the fuel vapors until intake

manifold vacuum draws them into the combustion

chamber. The canister purge solenoid purges vapors

from the canister at predetermined intervals and en-

gine conditions.

CANISTER PURGE SOLENOIDÐEXCEPT 3.0L AND

2.5L MPI

The powertrain control module (PCM) operates the

canister purge solenoid (Fig. 6). During warm-up and

for a specified period after hot starts, the PCM

grounds the purge solenoid causing it to energize.

When the PCM grounds the solenoid, vacuum does

not reach the charcoal canister valve. When the engine reaches a specified operating tem-

perature and the time delay interval has occurred,

the PCM de-energizes the solenoid by turning off the

ground. When the PCM de-energizes the solenoid,

vacuum flows to the canister purge valve. Intake

manifold vacuum purges fuel vapors through the

throttle body. The PCM also energizes the purge so-

lenoid during certain idle conditions to update the

fuel delivery calibration.

DUTY CYCLE EVAP PURGE SOLENOID

Vehicles equipped with a 3.0L engine and the Flex-

ible Fuel AA-Body with the 2.5L MPI engine use a

duty cycle EVAP purge solenoid. The duty cycle

EVAP purge solenoid regulates the rate of vapor flow

from the EVAP canister to the throttle body. The

powertrain control module operates the solenoid.

Fig. 4 Evaporative CanisterÐExcept 3.0L and 2.5L MPI

Fig. 5 Evaporative CanisterÐ3.0L and 2.5L MPI

Ä EMISSION CONTROL SYSTEMS 25 - 13

Page 2404 of 2438

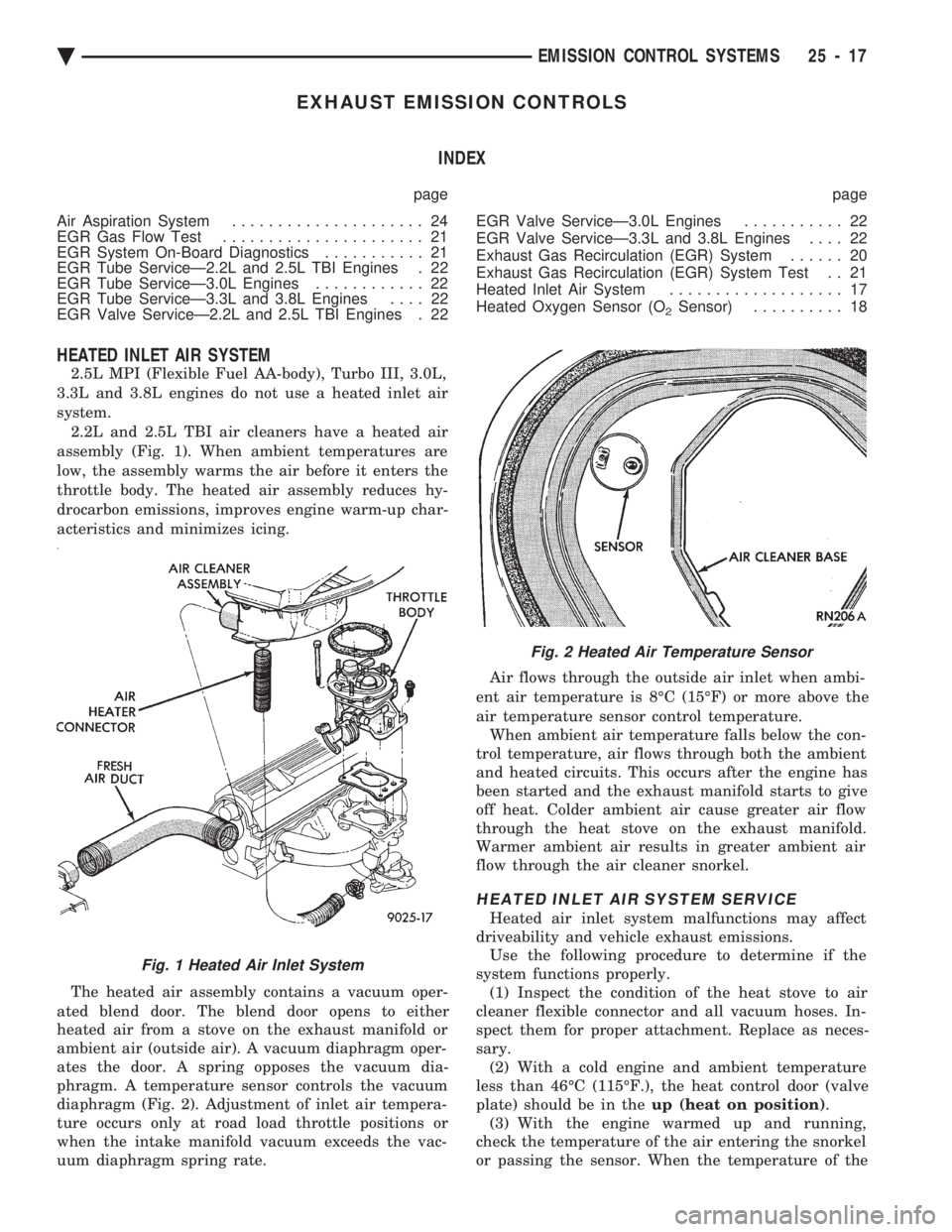

CRANKCASE VENT FILTER

All engines have a crankcase vent filter. The filter

cleans outside air before it enters the PCV system.

On 2.5L engines, the filter mounts to the upper shell

assembly of the air cleaner. On 2.5L MPI (Flexible

Fuel AA-body) and Turbo III engines, the filter at-

taches to the inside of the filter element box, next to

the filter element. On 3.0L engines, it attaches to the

inside of the filter element box under the filter ele- ment. On the 3.3L engines, the filter mounts to the

bottom of the filter element box. Refer to Group 0 for

mileage intervals and service procedures.

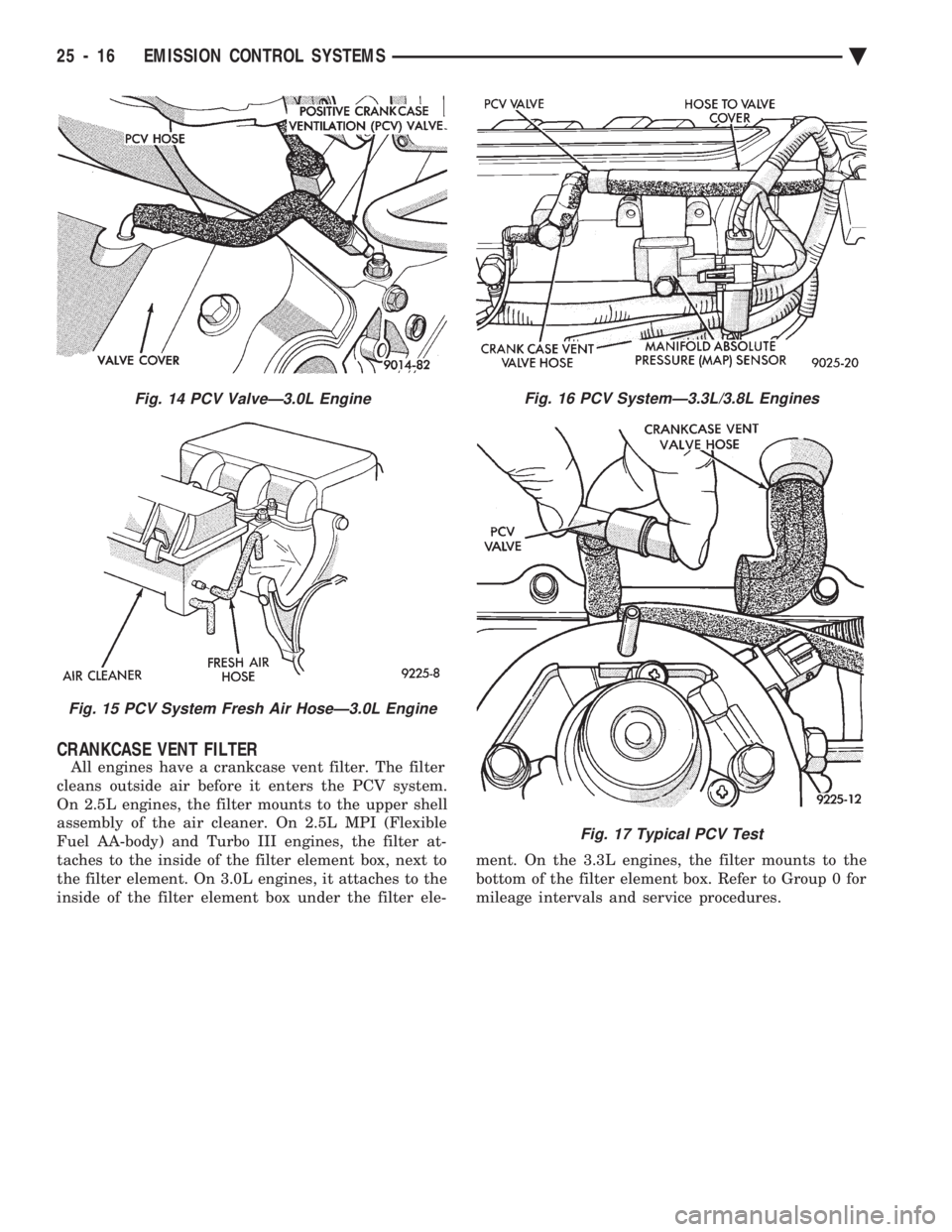

Fig. 14 PCV ValveÐ3.0L Engine

Fig. 15 PCV System Fresh Air HoseÐ3.0L Engine

Fig. 16 PCV SystemÐ3.3L/3.8L Engines

Fig. 17 Typical PCV Test

25 - 16 EMISSION CONTROL SYSTEMS Ä

Page 2405 of 2438

EXHAUST EMISSION CONTROLS INDEX

page page

Air Aspiration System ..................... 24

EGR Gas Flow Test ...................... 21

EGR System On-Board Diagnostics ........... 21

EGR Tube ServiceÐ2.2L and 2.5L TBI Engines . 22

EGR Tube ServiceÐ3.0L Engines ............ 22

EGR Tube ServiceÐ3.3L and 3.8L Engines .... 22

EGR Valve ServiceÐ2.2L and 2.5L TBI Engines . 22 EGR Valve ServiceÐ3.0L Engines

........... 22

EGR Valve ServiceÐ3.3L and 3.8L Engines .... 22

Exhaust Gas Recirculation (EGR) System ...... 20

Exhaust Gas Recirculation (EGR) System Test . . 21

Heated Inlet Air System ................... 17

Heated Oxygen Sensor (O

2Sensor) .......... 18

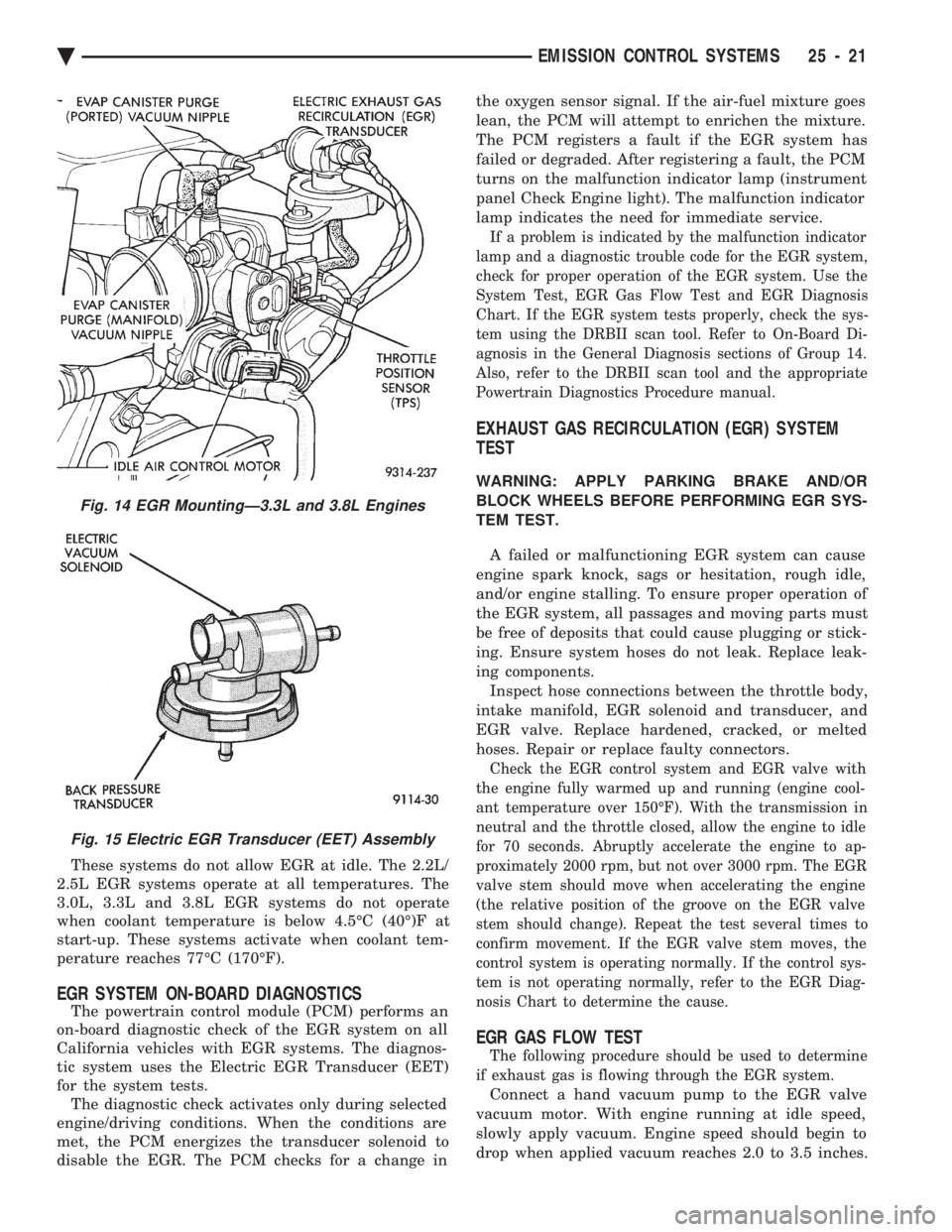

HEATED INLET AIR SYSTEM

2.5L MPI (Flexible Fuel AA-body), Turbo III, 3.0L,

3.3L and 3.8L engines do not use a heated inlet air

system. 2.2L and 2.5L TBI air cleaners have a heated air

assembly (Fig. 1). When ambient temperatures are

low, the assembly warms the air before it enters the

throttle body. The heated air assembly reduces hy-

drocarbon emissions, improves engine warm-up char-

acteristics and minimizes icing.

The heated air assembly contains a vacuum oper-

ated blend door. The blend door opens to either

heated air from a stove on the exhaust manifold or

ambient air (outside air). A vacuum diaphragm oper-

ates the door. A spring opposes the vacuum dia-

phragm. A temperature sensor controls the vacuum

diaphragm (Fig. 2). Adjustment of inlet air tempera-

ture occurs only at road load throttle positions or

when the intake manifold vacuum exceeds the vac-

uum diaphragm spring rate. Air flows through the outside air inlet when ambi-

ent air temperature is 8ÉC (15ÉF) or more above the

air temperature sensor control temperature. When ambient air temperature falls below the con-

trol temperature, air flows through both the ambient

and heated circuits. This occurs after the engine has

been started and the exhaust manifold starts to give

off heat. Colder ambient air cause greater air flow

through the heat stove on the exhaust manifold.

Warmer ambient air results in greater ambient air

flow through the air cleaner snorkel.

HEATED INLET AIR SYSTEM SERVICE

Heated air inlet system malfunctions may affect

driveability and vehicle exhaust emissions. Use the following procedure to determine if the

system functions properly. (1) Inspect the condition of the heat stove to air

cleaner flexible connector and all vacuum hoses. In-

spect them for proper attachment. Replace as neces-

sary. (2) With a cold engine and ambient temperature

less than 46ÉC (115ÉF.), the heat control door (valve

plate) should be in the up (heat on position).

(3) With the engine warmed up and running,

check the temperature of the air entering the snorkel

or passing the sensor. When the temperature of the

Fig. 1 Heated Air Inlet System

Fig. 2 Heated Air Temperature Sensor

Ä EMISSION CONTROL SYSTEMS 25 - 17

Page 2409 of 2438

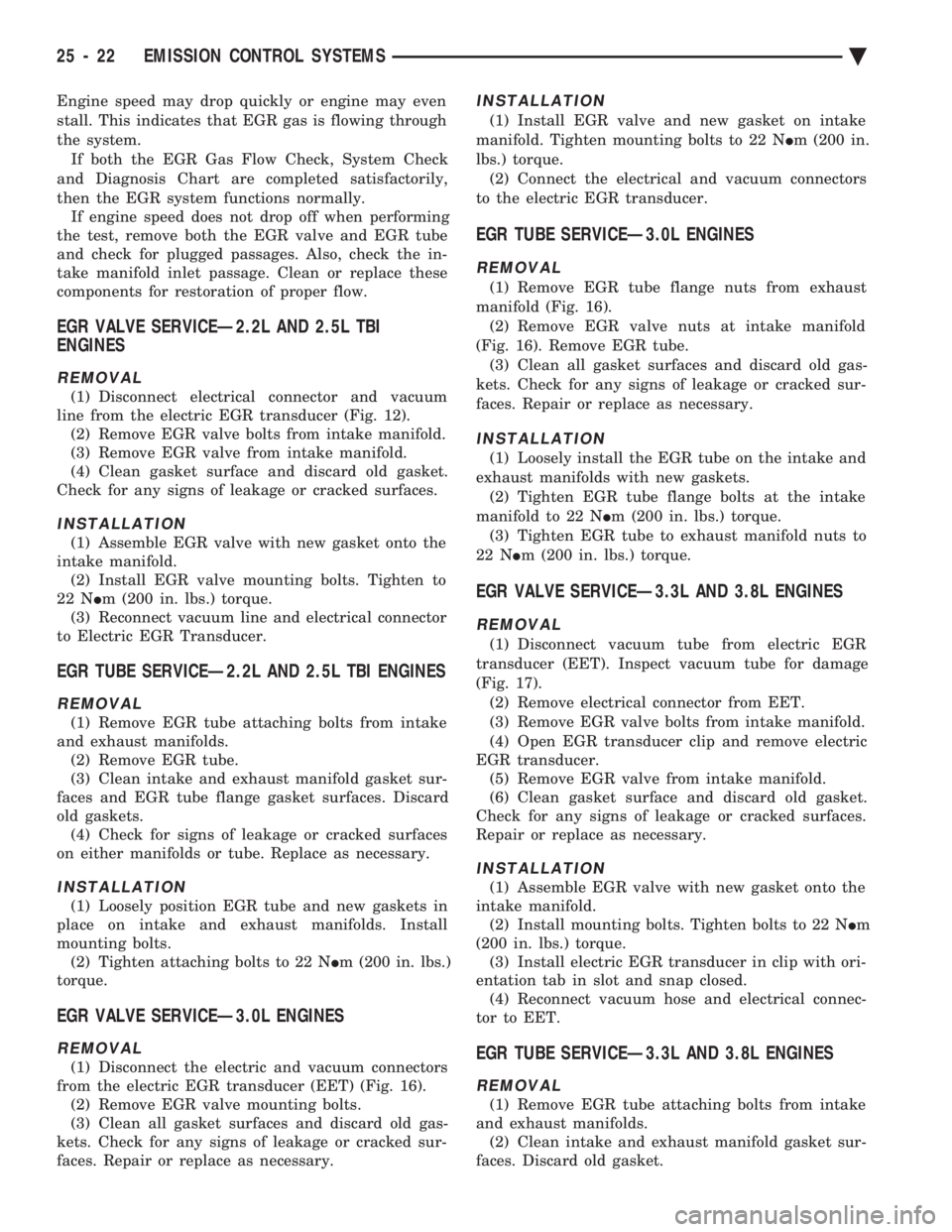

These systems do not allow EGR at idle. The 2.2L/

2.5L EGR systems operate at all temperatures. The

3.0L, 3.3L and 3.8L EGR systems do not operate

when coolant temperature is below 4.5ÉC (40É)F at

start-up. These systems activate when coolant tem-

perature reaches 77ÉC (170ÉF).

EGR SYSTEM ON-BOARD DIAGNOSTICS

The powertrain control module (PCM) performs an

on-board diagnostic check of the EGR system on all

California vehicles with EGR systems. The diagnos-

tic system uses the Electric EGR Transducer (EET)

for the system tests. The diagnostic check activates only during selected

engine/driving conditions. When the conditions are

met, the PCM energizes the transducer solenoid to

disable the EGR. The PCM checks for a change in the oxygen sensor signal. If the air-fuel mixture goes

lean, the PCM will attempt to enrichen the mixture.

The PCM registers a fault if the EGR system has

failed or degraded. After registering a fault, the PCM

turns on the malfunction indicator lamp (instrument

panel Check Engine light). The malfunction indicator

lamp indicates the need for immediate service.

If a problem is indicated by the malfunction indicator

lamp and a diagnostic trouble code for the EGR system,

check for proper operation of the EGR system. Use the

System Test, EGR Gas Flow Test and EGR Diagnosis

Chart. If the EGR system tests properly, check the sys-

tem using the DRBII scan tool. Refer to On-Board Di-

agnosis in the General Diagnosis sections of Group 14.

Also, refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedure manual.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING EGR SYS-

TEM TEST.

A failed or malfunctioning EGR system can cause

engine spark knock, sags or hesitation, rough idle,

and/or engine stalling. To ensure proper operation of

the EGR system, all passages and moving parts must

be free of deposits that could cause plugging or stick-

ing. Ensure system hoses do not leak. Replace leak-

ing components. Inspect hose connections between the throttle body,

intake manifold, EGR solenoid and transducer, and

EGR valve. Replace hardened, cracked, or melted

hoses. Repair or replace faulty connectors.

Check the EGR control system and EGR valve with

the engine fully warmed up and running (engine cool-

ant temperature over 150ÉF). With the transmission in

neutral and the throttle closed, allow the engine to idle

for 70 seconds. Abruptly accelerate the engine to ap-

proximately 2000 rpm, but not over 3000 rpm. The EGR

valve stem should move when accelerating the engine

(the relative position of the groove on the EGR valve

stem should change). Repeat the test several times to

confirm movement. If the EGR valve stem moves, the

control system is operating normally. If the control sys-

tem is not operating normally, refer to the EGR Diag-

nosis Chart to determine the cause.

EGR GAS FLOW TEST

The following procedure should be used to determine

if exhaust gas is flowing through the EGR system.

Connect a hand vacuum pump to the EGR valve

vacuum motor. With engine running at idle speed,

slowly apply vacuum. Engine speed should begin to

drop when applied vacuum reaches 2.0 to 3.5 inches.

Fig. 14 EGR MountingÐ3.3L and 3.8L Engines

Fig. 15 Electric EGR Transducer (EET) Assembly

Ä EMISSION CONTROL SYSTEMS 25 - 21

Page 2410 of 2438

Engine speed may drop quickly or engine may even

stall. This indicates that EGR gas is flowing through

the system.If both the EGR Gas Flow Check, System Check

and Diagnosis Chart are completed satisfactorily,

then the EGR system functions normally. If engine speed does not drop off when performing

the test, remove both the EGR valve and EGR tube

and check for plugged passages. Also, check the in-

take manifold inlet passage. Clean or replace these

components for restoration of proper flow.

EGR VALVE SERVICEÐ2.2L AND 2.5L TBI

ENGINES

REMOVAL

(1) Disconnect electrical connector and vacuum

line from the electric EGR transducer (Fig. 12). (2) Remove EGR valve bolts from intake manifold.

(3) Remove EGR valve from intake manifold.

(4) Clean gasket surface and discard old gasket.

Check for any signs of leakage or cracked surfaces.

INSTALLATION

(1) Assemble EGR valve with new gasket onto the

intake manifold. (2) Install EGR valve mounting bolts. Tighten to

22 N Im (200 in. lbs.) torque.

(3) Reconnect vacuum line and electrical connector

to Electric EGR Transducer.

EGR TUBE SERVICEÐ2.2L AND 2.5L TBI ENGINES

REMOVAL

(1) Remove EGR tube attaching bolts from intake

and exhaust manifolds. (2) Remove EGR tube.

(3) Clean intake and exhaust manifold gasket sur-

faces and EGR tube flange gasket surfaces. Discard

old gaskets. (4) Check for signs of leakage or cracked surfaces

on either manifolds or tube. Replace as necessary.

INSTALLATION

(1) Loosely position EGR tube and new gaskets in

place on intake and exhaust manifolds. Install

mounting bolts. (2) Tighten attaching bolts to 22 N Im (200 in. lbs.)

torque.

EGR VALVE SERVICEÐ3.0L ENGINES

REMOVAL

(1) Disconnect the electric and vacuum connectors

from the electric EGR transducer (EET) (Fig. 16). (2) Remove EGR valve mounting bolts.

(3) Clean all gasket surfaces and discard old gas-

kets. Check for any signs of leakage or cracked sur-

faces. Repair or replace as necessary.

INSTALLATION

(1) Install EGR valve and new gasket on intake

manifold. Tighten mounting bolts to 22 N Im (200 in.

lbs.) torque. (2) Connect the electrical and vacuum connectors

to the electric EGR transducer.

EGR TUBE SERVICEÐ3.0L ENGINES

REMOVAL

(1) Remove EGR tube flange nuts from exhaust

manifold (Fig. 16). (2) Remove EGR valve nuts at intake manifold

(Fig. 16). Remove EGR tube. (3) Clean all gasket surfaces and discard old gas-

kets. Check for any signs of leakage or cracked sur-

faces. Repair or replace as necessary.

INSTALLATION

(1) Loosely install the EGR tube on the intake and

exhaust manifolds with new gaskets. (2) Tighten EGR tube flange bolts at the intake

manifold to 22 N Im (200 in. lbs.) torque.

(3) Tighten EGR tube to exhaust manifold nuts to

22 N Im (200 in. lbs.) torque.

EGR VALVE SERVICEÐ3.3L AND 3.8L ENGINES

REMOVAL

(1) Disconnect vacuum tube from electric EGR

transducer (EET). Inspect vacuum tube for damage

(Fig. 17). (2) Remove electrical connector from EET.

(3) Remove EGR valve bolts from intake manifold.

(4) Open EGR transducer clip and remove electric

EGR transducer. (5) Remove EGR valve from intake manifold.

(6) Clean gasket surface and discard old gasket.

Check for any signs of leakage or cracked surfaces.

Repair or replace as necessary.

INSTALLATION

(1) Assemble EGR valve with new gasket onto the

intake manifold. (2) Install mounting bolts. Tighten bolts to 22 N Im

(200 in. lbs.) torque. (3) Install electric EGR transducer in clip with ori-

entation tab in slot and snap closed. (4) Reconnect vacuum hose and electrical connec-

tor to EET.

EGR TUBE SERVICEÐ3.3L AND 3.8L ENGINES

REMOVAL

(1) Remove EGR tube attaching bolts from intake

and exhaust manifolds. (2) Clean intake and exhaust manifold gasket sur-

faces. Discard old gasket.

25 - 22 EMISSION CONTROL SYSTEMS Ä