wiring CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1936 of 2438

INSTALL (1) Install power steering pump back in vehicle,

laying it on the steering gear. Do not mount it to the

power steering pump bracket. (2) Install generator back on the lower generator

bracket and install bolt and nut (Fig. 19). Do not

tighten bolt at this time. (3) Install the generator bracket back on engine and

intake manifold. Loosely install the 4 generator

bracket to engine attaching bolts (Fig. 19). Be sure

the SPACER (Fig. 18) is installed between the

engine mounting strut and the generator

bracket. (4) Temporarily install the serpentine belt tensioner

bolt through both generator brackets. This will align

all generator bracket mounting holes (Fig. 15). Then

torque the 4 generator bracket to engine and intake manifold mounting bolts to 54 N

Im (40 ft.

lbs.). Then remove the serpentine belt tensioner from

bracket. It will be installed on the bracket in a

later step. (5) Tighten the bolt holding the engine bracket as-

sembly to the engine support assembly (Fig. 18) to 150

N Im (110 ft. lbs.).

(6) Attach the engine wiring harness routing clip to

the generator bracket. (7) Install the generator to generator bracket attach-

ing bolt (Fig. 19). Torque bolt to 54 N Im (40 ft. lbs.).

Tighten the lower generator pivot bolt to 54 N Im (40 ft.

lbs.). (8) Install the power steering pump fluid reservoir

and tube/hose assembly onto the power steering pump

bracket and generator bracket (Fig. 17). Torque the 2

bolts holding the reservoir to the generator bracket to

5N Im (45 in. lbs.). Torque the 1 bolt holding the

tube/hose assembly to the power steering pump

bracket to 12 N Im (105 in. lbs.).

(9) Raise vehicle See Hoisting, Group 0.

(10) Install the strut assembly power

steering/generator bracket to engine (Fig. 16). Torque

the nut and bolt holding the strut assembly to bracket

and the exhaust manifold stud to 54 N Im (40 ft. lbs).

(11) Install the serpentine drive belt tensioner onto

the power steering/generator bracket (Fig. 15). Install

the tensioner to bracket retaining nut and torque to 54

N Im (40 ft. lbs.).

(12) Install the power steering pump on bracket, by

aligning the 3 mounting holes in pump with mounting

holes in bracket (Fig. 14). Install the 3 power steering

pump to bracket mounting bolts. Torque power steer-

ing pump mounting bolts to 54 N Im (40 ft. lbs.).

(13) Install the support strut, engine block to power

steering pump on pump stud (Fig. 14). Install the nut

and bolt holding the strut to the power steering pump

and engine block and torque to 54 N Im (40 ft. lbs.).

(14) Install the power steering fluid pressure line

onto the output fitting of the power steering pump (Fig.

12). Torque the pressure line pump fitting nut to 31

N Im (275 in. lbs.). Before connecting the pressure

line to power steering pump inspect the O-ring

on the pressure line for damage. (15) Install vehicle's wiring harness connector (if

applicable to vehicle being serviced) onto the power

steering pressure switch (Fig. 11). (16) Install the power steering fluid, low pressure

return hose on the power steering pump low pressure

fitting (Fig. 12). Then install the hose from the remote

reservoir onto the power steering pump (Fig. 13). Be

sure all hose clamps are properly reinstalled. (17) Install right front tire and wheel on vehicle.

Install the wheel stud nuts and torque to 129 N Im (95

ft. lbs.).

Fig. 18 Engine Bracket Support Assembly

Fig. 19 Generator Mounting

19 - 18 STEERING Ä

Page 1937 of 2438

(18) Lower vehicle.

(19) Install the serpentine drive belt. Refer to (Fig.

10) for correct serpentine belt routing. See Cooling,

Group 7 for detailed installation procedure.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(20) Fill power steering pump reservoir to correct

fluid level. (21) Connect the negative battery cable on the

negative battery post. (22) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

TURBO III

REMOVE

(1) Disconnect the battery (-) negative cable from

the battery and isolate cable. (2) Raise vehicle See Hoisting, Group 0. Put oil

drain pan under vehicle to catch power steering

fluid. (3) Remove the right front underhood splash shield

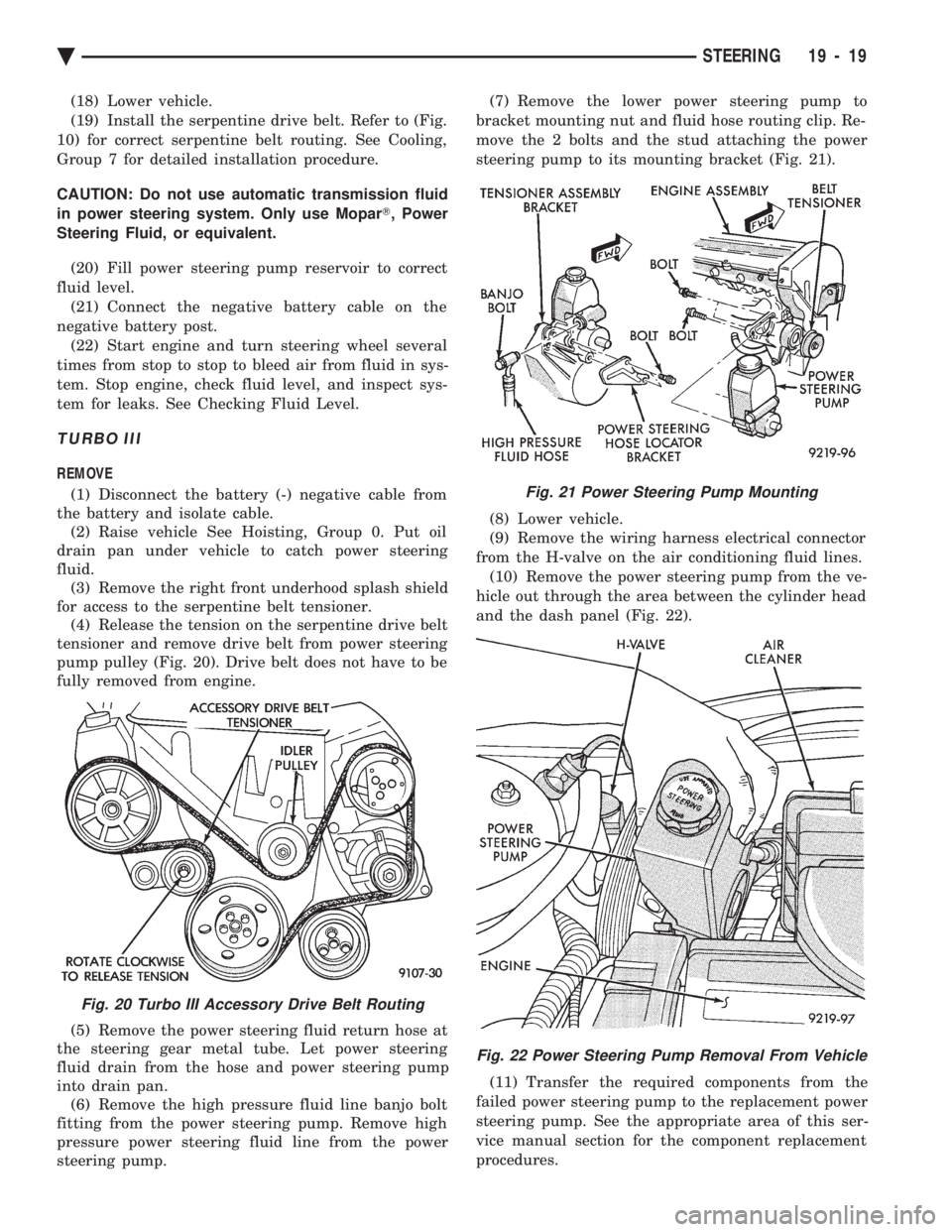

for access to the serpentine belt tensioner. (4) Release the tension on the serpentine drive belt

tensioner and remove drive belt from power steering

pump pulley (Fig. 20). Drive belt does not have to be

fully removed from engine.

(5) Remove the power steering fluid return hose at

the steering gear metal tube. Let power steering

fluid drain from the hose and power steering pump

into drain pan. (6) Remove the high pressure fluid line banjo bolt

fitting from the power steering pump. Remove high

pressure power steering fluid line from the power

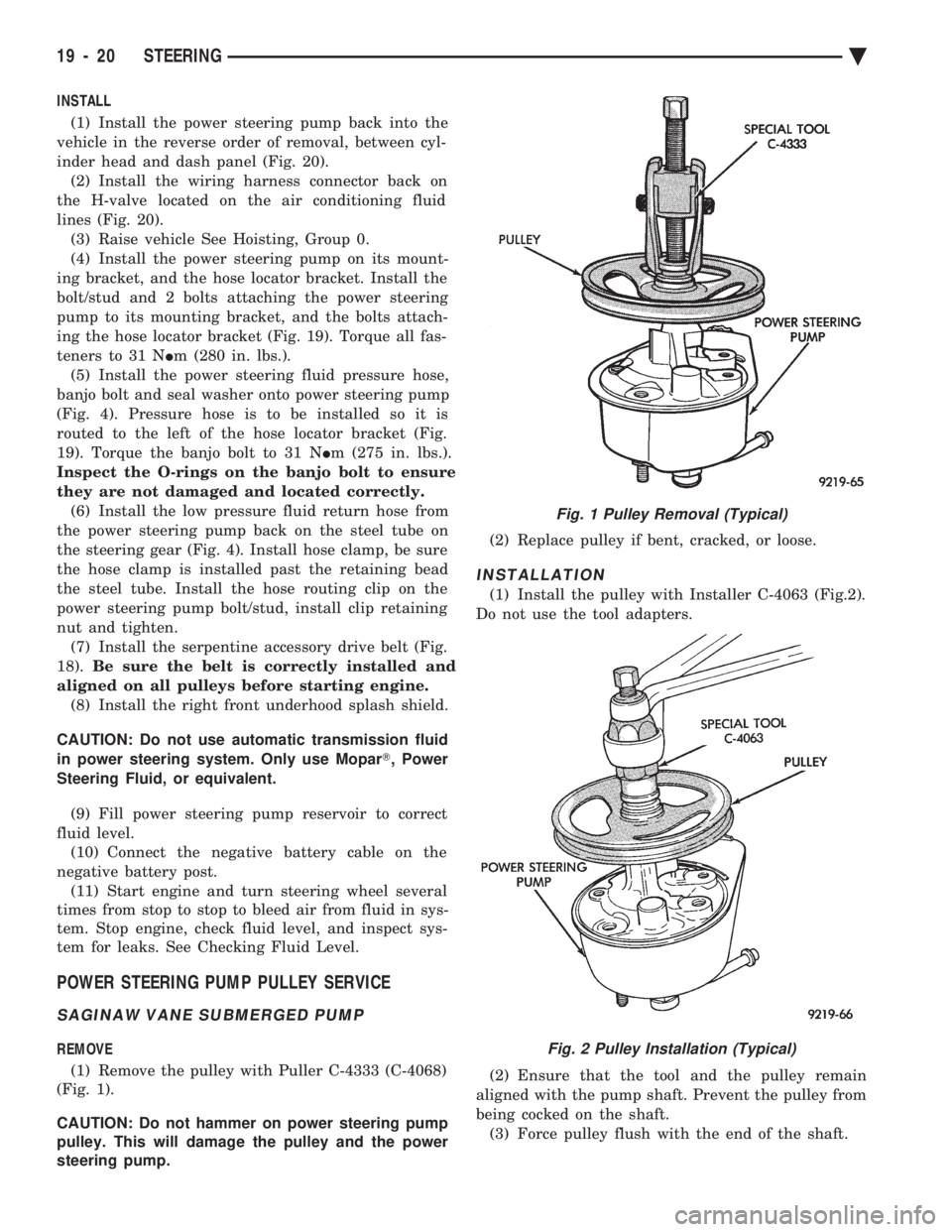

steering pump. (7) Remove the lower power steering pump to

bracket mounting nut and fluid hose routing clip. Re-

move the 2 bolts and the stud attaching the power

steering pump to its mounting bracket (Fig. 21).

(8) Lower vehicle.

(9) Remove the wiring harness electrical connector

from the H-valve on the air conditioning fluid lines. (10) Remove the power steering pump from the ve-

hicle out through the area between the cylinder head

and the dash panel (Fig. 22).

(11) Transfer the required components from the

failed power steering pump to the replacement power

steering pump. See the appropriate area of this ser-

vice manual section for the component replacement

procedures.

Fig. 20 Turbo III Accessory Drive Belt Routing

Fig. 21 Power Steering Pump Mounting

Fig. 22 Power Steering Pump Removal From Vehicle

Ä STEERING 19 - 19

Page 1938 of 2438

INSTALL (1) Install the power steering pump back into the

vehicle in the reverse order of removal, between cyl-

inder head and dash panel (Fig. 20). (2) Install the wiring harness connector back on

the H-valve located on the air conditioning fluid

lines (Fig. 20). (3) Raise vehicle See Hoisting, Group 0.

(4) Install the power steering pump on its mount-

ing bracket, and the hose locator bracket. Install the

bolt/stud and 2 bolts attaching the power steering

pump to its mounting bracket, and the bolts attach-

ing the hose locator bracket (Fig. 19). Torque all fas-

teners to 31 N Im (280 in. lbs.).

(5) Install the power steering fluid pressure hose,

banjo bolt and seal washer onto power steering pump

(Fig. 4). Pressure hose is to be installed so it is

routed to the left of the hose locator bracket (Fig.

19). Torque the banjo bolt to 31 N Im (275 in. lbs.).

Inspect the O-rings on the banjo bolt to ensure

they are not damaged and located correctly. (6) Install the low pressure fluid return hose from

the power steering pump back on the steel tube on

the steering gear (Fig. 4). Install hose clamp, be sure

the hose clamp is installed past the retaining bead

the steel tube. Install the hose routing clip on the

power steering pump bolt/stud, install clip retaining

nut and tighten. (7) Install the serpentine accessory drive belt (Fig.

18). Be sure the belt is correctly installed and

aligned on all pulleys before starting engine. (8) Install the right front underhood splash shield.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(9) Fill power steering pump reservoir to correct

fluid level. (10) Connect the negative battery cable on the

negative battery post. (11) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

POWER STEERING PUMP PULLEY SERVICE

SAGINAW VANE SUBMERGED PUMP

REMOVE

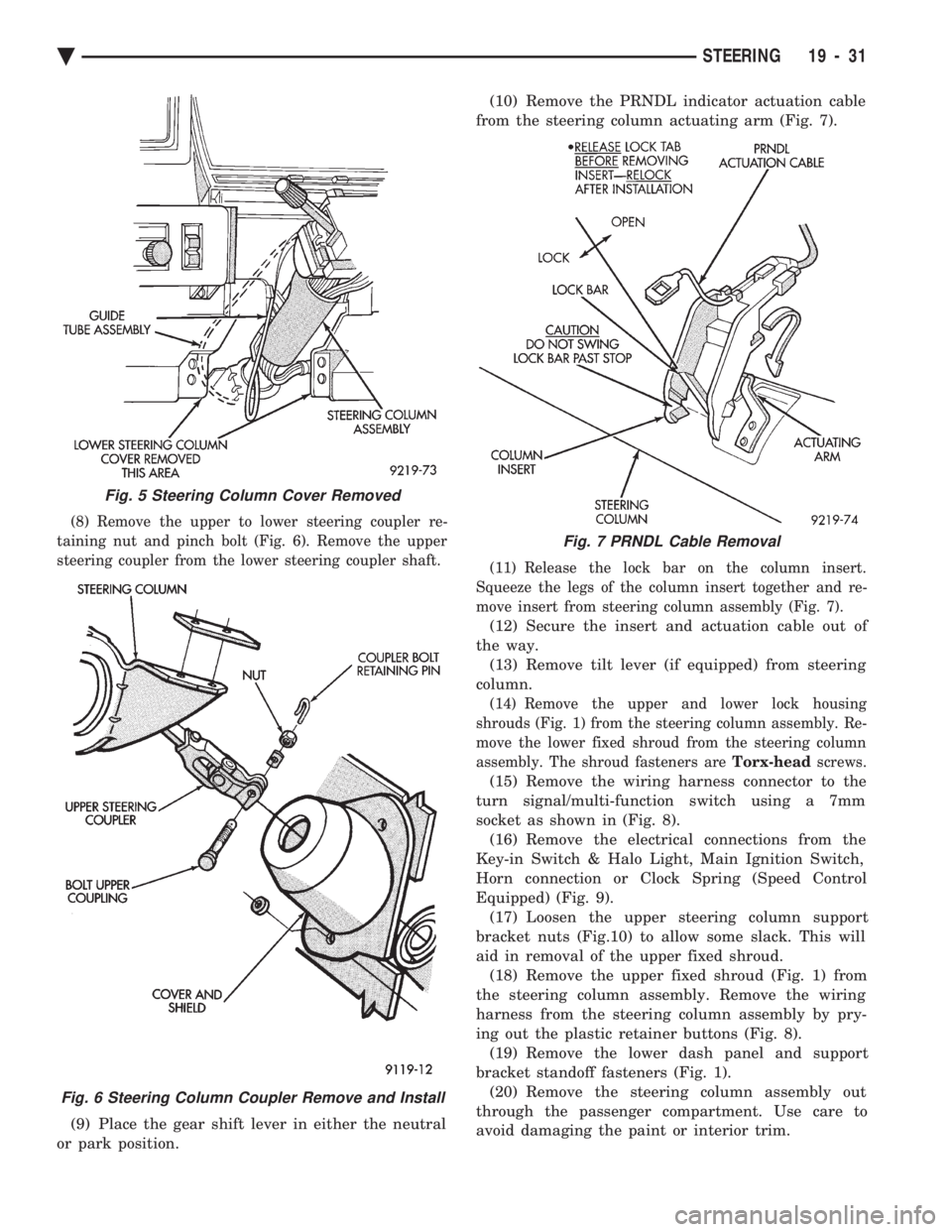

(1) Remove the pulley with Puller C-4333 (C-4068)

(Fig. 1).

CAUTION: Do not hammer on power steering pump

pulley. This will damage the pulley and the power

steering pump. (2) Replace pulley if bent, cracked, or loose.

INSTALLATION

(1) Install the pulley with Installer C-4063 (Fig.2).

Do not use the tool adapters.

(2) Ensure that the tool and the pulley remain

aligned with the pump shaft. Prevent the pulley from

being cocked on the shaft. (3) Force pulley flush with the end of the shaft.

Fig. 1 Pulley Removal (Typical)

Fig. 2 Pulley Installation (Typical)

19 - 20 STEERING Ä

Page 1949 of 2438

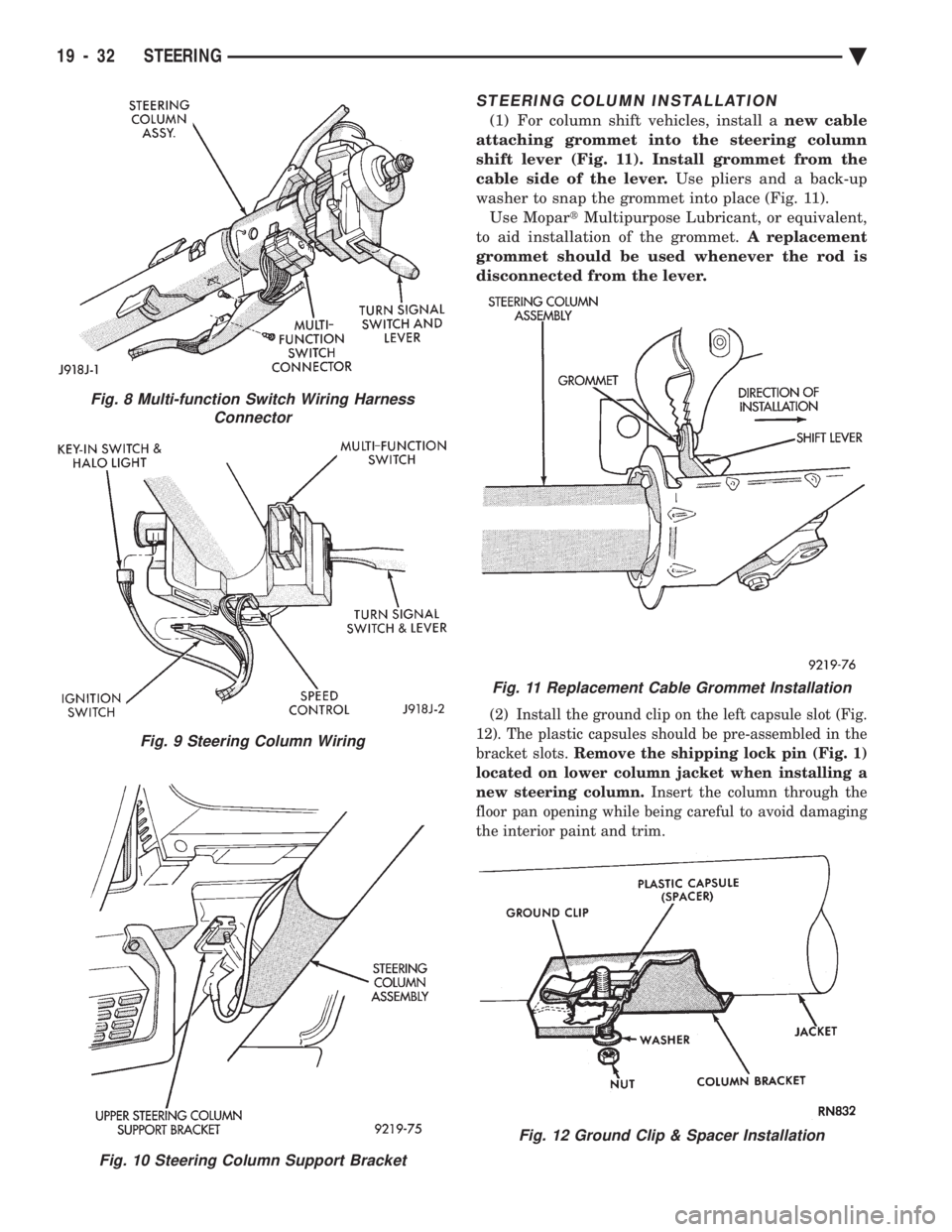

(8) Remove the upper to lower steering coupler re-

taining nut and pinch bolt (Fig. 6). Remove the upper

steering coupler from the lower steering coupler shaft.

(9) Place the gear shift lever in either the neutral

or park position. (10) Remove the PRNDL indicator actuation cable

from the steering column actuating arm (Fig. 7).

(11) Release the lock bar on the column insert.

Squeeze the legs of the column insert together and re-

move insert from steering column assembly (Fig. 7).

(12) Secure the insert and actuation cable out of

the way. (13) Remove tilt lever (if equipped) from steering

column.

(14) Remove the upper and lower lock housing

shrouds (Fig. 1) from the steering column assembly. Re-

move the lower fixed shroud from the steering column

assembly. The shroud fasteners are Torx-headscrews.

(15) Remove the wiring harness connector to the

turn signal/multi-function switch using a 7mm

socket as shown in (Fig. 8). (16) Remove the electrical connections from the

Key-in Switch & Halo Light, Main Ignition Switch,

Horn connection or Clock Spring (Speed Control

Equipped) (Fig. 9). (17) Loosen the upper steering column support

bracket nuts (Fig.10) to allow some slack. This will

aid in removal of the upper fixed shroud. (18) Remove the upper fixed shroud (Fig. 1) from

the steering column assembly. Remove the wiring

harness from the steering column assembly by pry-

ing out the plastic retainer buttons (Fig. 8). (19) Remove the lower dash panel and support

bracket standoff fasteners (Fig. 1). (20) Remove the steering column assembly out

through the passenger compartment. Use care to

avoid damaging the paint or interior trim.

Fig. 5 Steering Column Cover Removed

Fig. 6 Steering Column Coupler Remove and Install

Fig. 7 PRNDL Cable Removal

Ä STEERING 19 - 31

Page 1950 of 2438

STEERING COLUMN INSTALLATION

(1) For column shift vehicles, install a new cable

attaching grommet into the steering column

shift lever (Fig. 11). Install grommet from the

cable side of the lever. Use pliers and a back-up

washer to snap the grommet into place (Fig. 11). Use Mopar tMultipurpose Lubricant, or equivalent,

to aid installation of the grommet. A replacement

grommet should be used whenever the rod is

disconnected from the lever.

(2) Install the ground clip on the left capsule slot (Fig.

12). The plastic capsules should be pre-assembled in the

bracket slots. Remove the shipping lock pin (Fig. 1)

located on lower column jacket when installing a

new steering column. Insert the column through the

floor pan opening while being careful to avoid damaging

the interior paint and trim.

Fig. 8 Multi-function Switch Wiring Harness Connector

Fig. 9 Steering Column Wiring

Fig. 10 Steering Column Support Bracket

Fig. 11 Replacement Cable Grommet Installation

Fig. 12 Ground Clip & Spacer Installation

19 - 32 STEERING Ä

Page 1951 of 2438

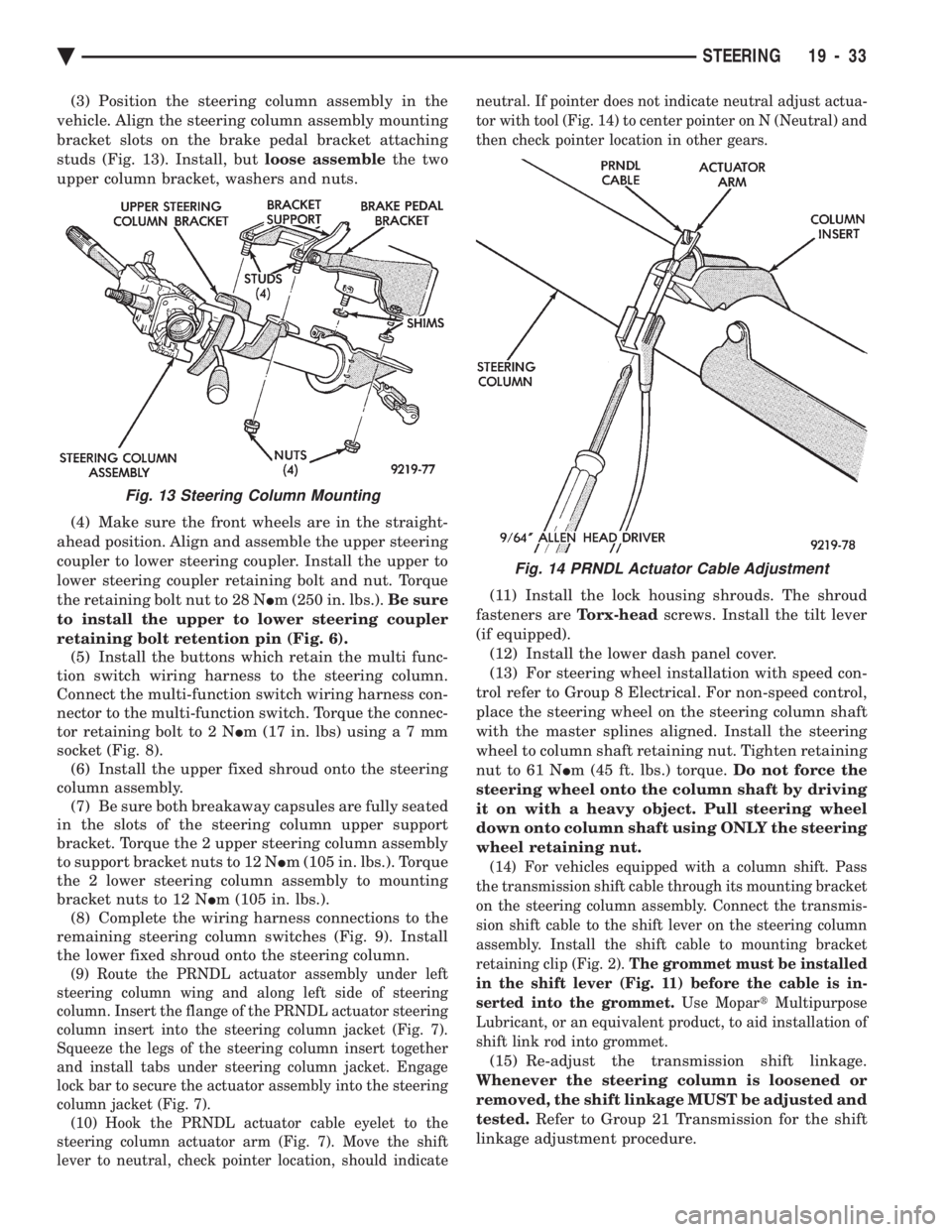

(3) Position the steering column assembly in the

vehicle. Align the steering column assembly mounting

bracket slots on the brake pedal bracket attaching

studs (Fig. 13). Install, but loose assemblethe two

upper column bracket, washers and nuts.

(4) Make sure the front wheels are in the straight-

ahead position. Align and assemble the upper steering

coupler to lower steering coupler. Install the upper to

lower steering coupler retaining bolt and nut. Torque

the retaining bolt nut to 28 N Im (250 in. lbs.). Be sure

to install the upper to lower steering coupler

retaining bolt retention pin (Fig. 6). (5) Install the buttons which retain the multi func-

tion switch wiring harness to the steering column.

Connect the multi-function switch wiring harness con-

nector to the multi-function switch. Torque the connec-

tor retaining bolt to 2 N Im (17 in. lbs) usin ga7mm

socket (Fig. 8). (6) Install the upper fixed shroud onto the steering

column assembly. (7) Be sure both breakaway capsules are fully seated

in the slots of the steering column upper support

bracket. Torque the 2 upper steering column assembly

to support bracket nuts to 12 N Im (105 in. lbs.). Torque

the 2 lower steering column assembly to mounting

bracket nuts to 12 N Im (105 in. lbs.).

(8) Complete the wiring harness connections to the

remaining steering column switches (Fig. 9). Install

the lower fixed shroud onto the steering column.

(9) Route the PRNDL actuator assembly under left

steering column wing and along left side of steering

column. Insert the flange of the PRNDL actuator steering

column insert into the steering column jacket (Fig. 7).

Squeeze the legs of the steering column insert together

and install tabs under steering column jacket. Engage

lock bar to secure the actuator assembly into the steering

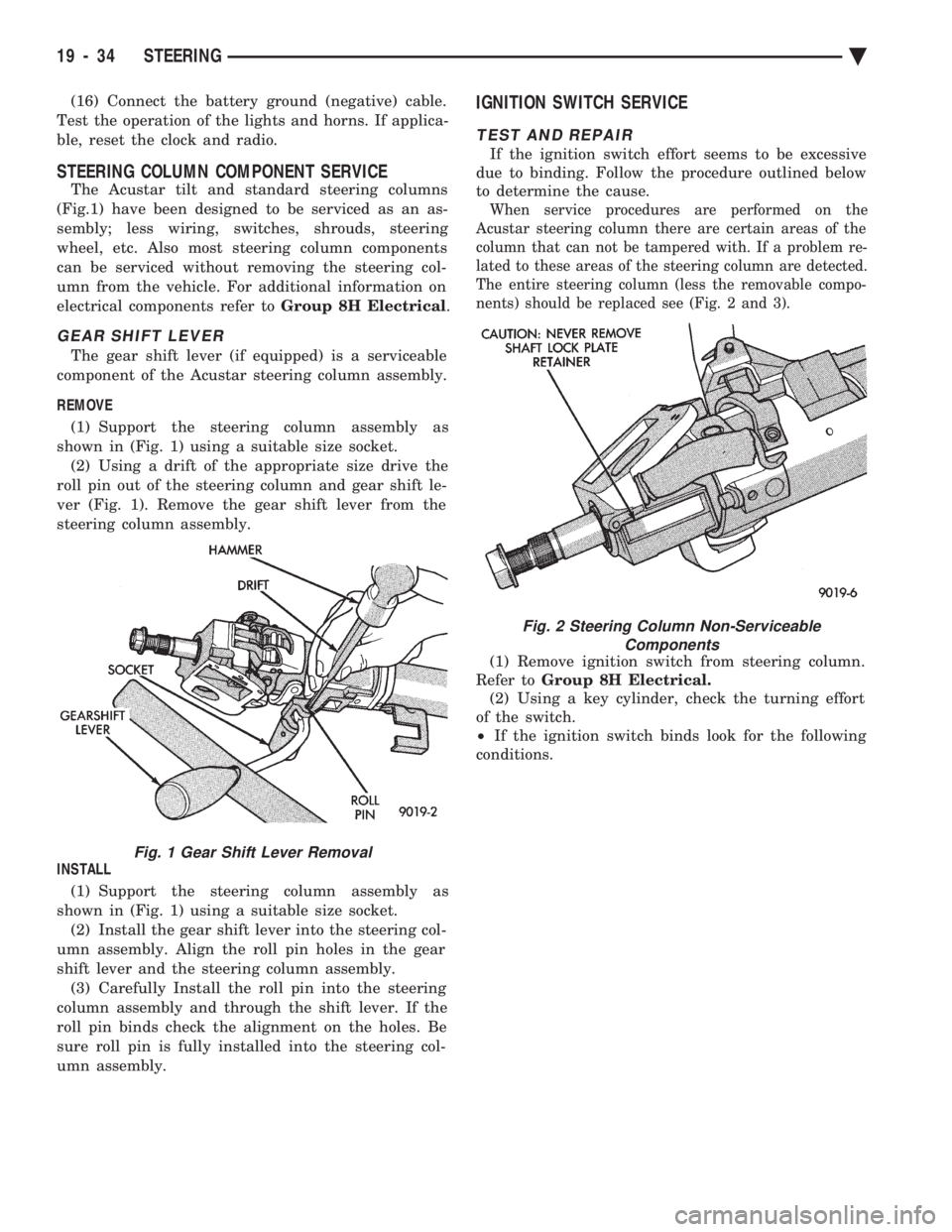

column jacket (Fig. 7). (10) Hook the PRNDL actuator cable eyelet to the

steering column actuator arm (Fig. 7). Move the shift

lever to neutral, check pointer location, should indicate neutral. If pointer does not indicate neutral adjust actua-

tor with tool (Fig. 14) to center pointer on N (Neutral) and

then check pointer location in other gears.

(11) Install the lock housing shrouds. The shroud

fasteners are Torx-headscrews. Install the tilt lever

(if equipped). (12) Install the lower dash panel cover.

(13) For steering wheel installation with speed con-

trol refer to Group 8 Electrical. For non-speed control,

place the steering wheel on the steering column shaft

with the master splines aligned. Install the steering

wheel to column shaft retaining nut. Tighten retaining

nut to 61 N Im (45 ft. lbs.) torque. Do not force the

steering wheel onto the column shaft by driving

it on with a heavy object. Pull steering wheel

down onto column shaft using ONLY the steering

wheel retaining nut.

(14) For vehicles equipped with a column shift. Pass

the transmission shift cable through its mounting bracket

on the steering column assembly. Connect the transmis-

sion shift cable to the shift lever on the steering column

assembly. Install the shift cable to mounting bracket

retaining clip (Fig. 2). The grommet must be installed

in the shift lever (Fig. 11) before the cable is in-

serted into the grommet. Use MopartMultipurpose

Lubricant, or an equivalent product, to aid installation of

shift link rod into grommet.

(15) Re-adjust the transmission shift linkage.

Whenever the steering column is loosened or

removed, the shift linkage MUST be adjusted and

tested. Refer to Group 21 Transmission for the shift

linkage adjustment procedure.

Fig. 13 Steering Column Mounting

Fig. 14 PRNDL Actuator Cable Adjustment

Ä STEERING 19 - 33

Page 1952 of 2438

(16) Connect the battery ground (negative) cable.

Test the operation of the lights and horns. If applica-

ble, reset the clock and radio.

STEERING COLUMN COMPONENT SERVICE

The Acustar tilt and standard steering columns

(Fig.1) have been designed to be serviced as an as-

sembly; less wiring, switches, shrouds, steering

wheel, etc. Also most steering column components

can be serviced without removing the steering col-

umn from the vehicle. For additional information on

electrical components refer to Group 8H Electrical.

GEAR SHIFT LEVER

The gear shift lever (if equipped) is a serviceable

component of the Acustar steering column assembly.

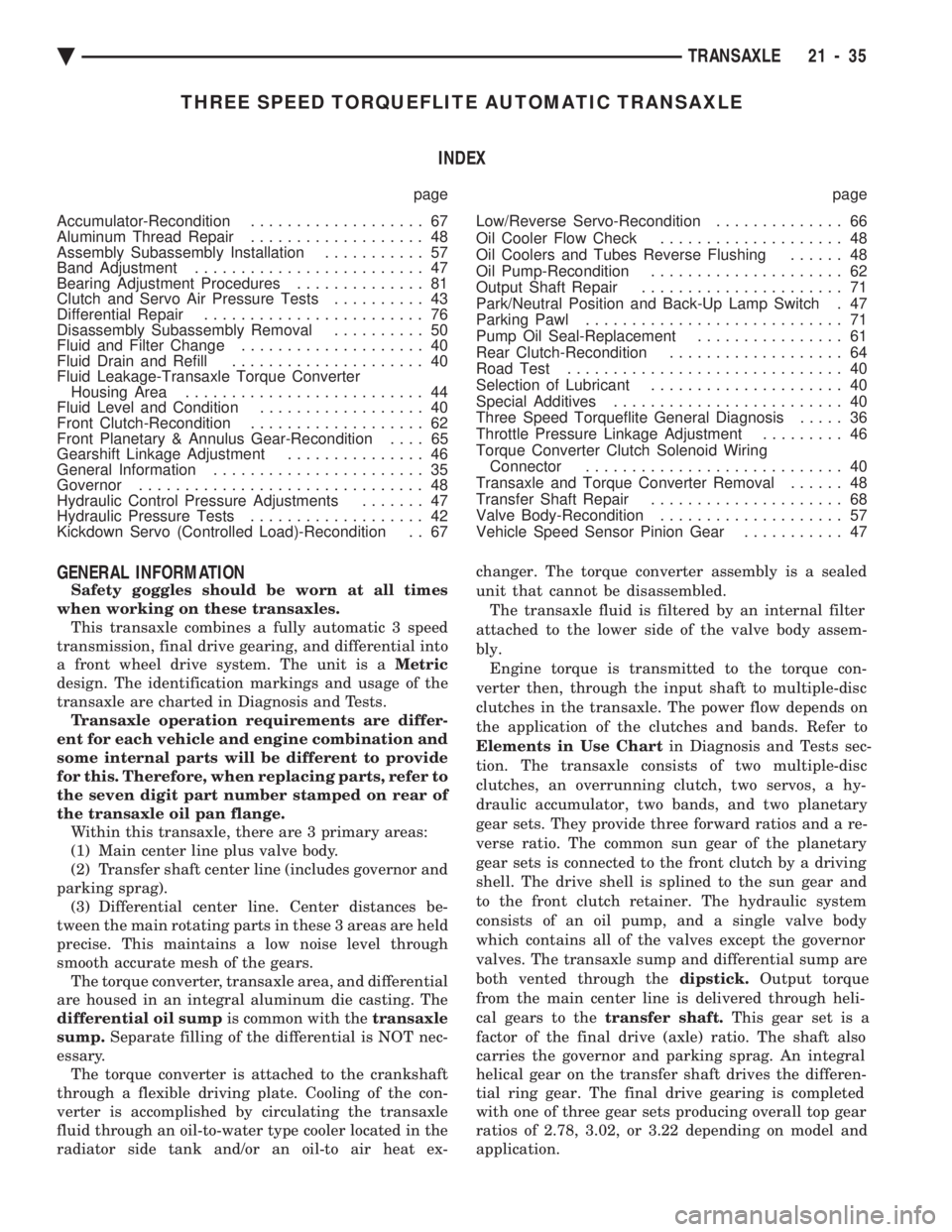

REMOVE (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Using a drift of the appropriate size drive the

roll pin out of the steering column and gear shift le-

ver (Fig. 1). Remove the gear shift lever from the

steering column assembly.

INSTALL (1) Support the steering column assembly as

shown in (Fig. 1) using a suitable size socket. (2) Install the gear shift lever into the steering col-

umn assembly. Align the roll pin holes in the gear

shift lever and the steering column assembly. (3) Carefully Install the roll pin into the steering

column assembly and through the shift lever. If the

roll pin binds check the alignment on the holes. Be

sure roll pin is fully installed into the steering col-

umn assembly.

IGNITION SWITCH SERVICE

TEST AND REPAIR

If the ignition switch effort seems to be excessive

due to binding. Follow the procedure outlined below

to determine the cause.

When service procedures are performed on the

Acustar steering column there are certain areas of the

column that can not be tampered with. If a problem re-

lated to these areas of the steering column are detected.

The entire steering column (less the removable compo-

nents) should be replaced see (Fig. 2 and 3).

(1) Remove ignition switch from steering column.

Refer to Group 8H Electrical.

(2) Using a key cylinder, check the turning effort

of the switch.

² If the ignition switch binds look for the following

conditions.

Fig. 1 Gear Shift Lever Removal

Fig. 2 Steering Column Non-Serviceable Components

19 - 34 STEERING Ä

Page 1995 of 2438

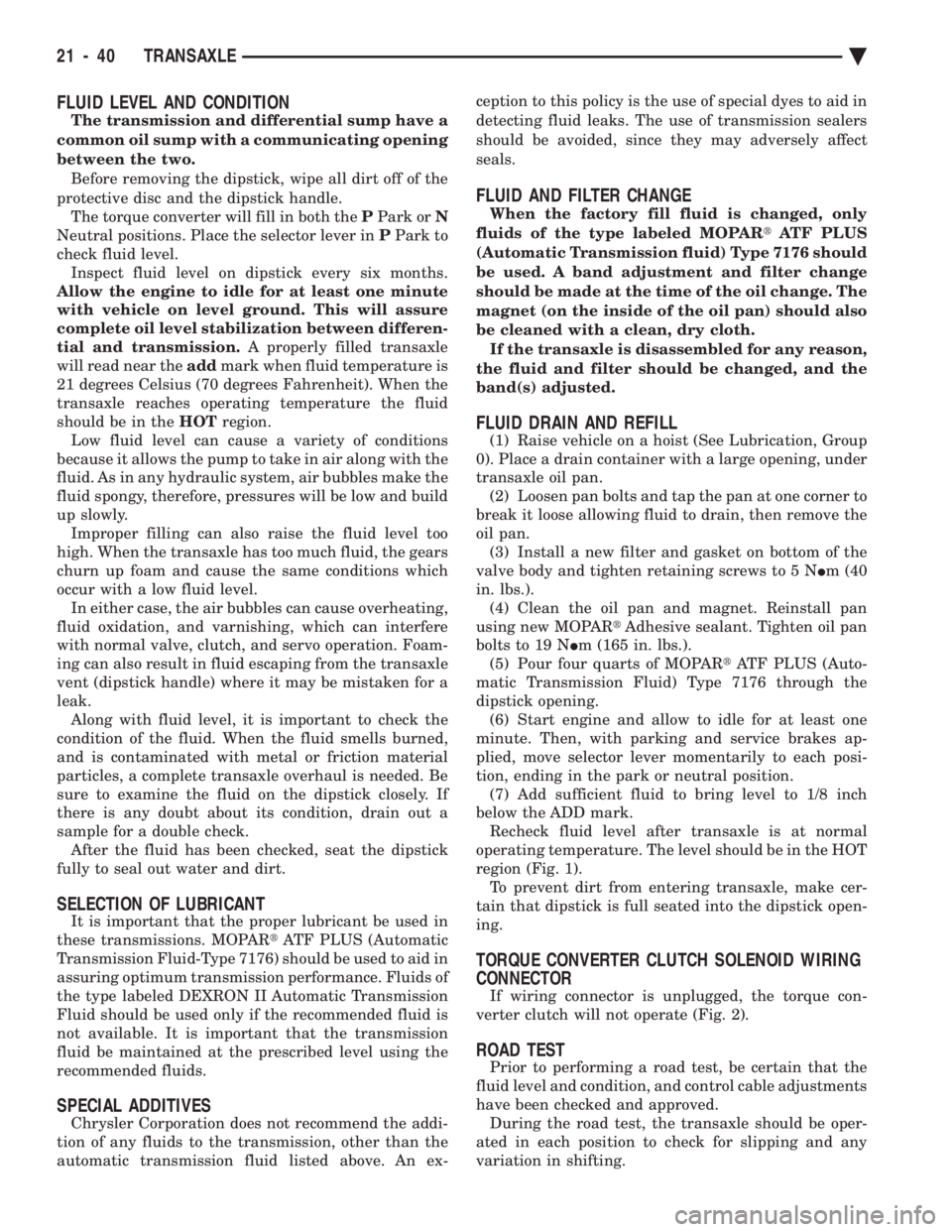

THREE SPEED TORQUEFLITE AUTOMATIC TRANSAXLE INDEX

page page

Accumulator-Recondition ................... 67

Aluminum Thread Repair ................... 48

Assembly Subassembly Installation ........... 57

Band Adjustment ......................... 47

Bearing Adjustment Procedures .............. 81

Clutch and Servo Air Pressure Tests .......... 43

Differential Repair ........................ 76

Disassembly Subassembly Removal .......... 50

Fluid and Filter Change .................... 40

Fluid Drain and Refill ..................... 40

Fluid Leakage-Transaxle Torque Converter Housing Area .......................... 44

Fluid Level and Condition .................. 40

Front Clutch-Recondition ................... 62

Front Planetary & Annulus Gear-Recondition .... 65

Gearshift Linkage Adjustment ............... 46

General Information ....................... 35

Governor ............................... 48

Hydraulic Control Pressure Adjustments ....... 47

Hydraulic Pressure Tests ................... 42

Kickdown Servo (Controlled Load)-Recondition . . 67 Low/Reverse Servo-Recondition

.............. 66

Oil Cooler Flow Check .................... 48

Oil Coolers and Tubes Reverse Flushing ...... 48

Oil Pump-Recondition ..................... 62

Output Shaft Repair ...................... 71

Park/Neutral Position and Back-Up Lamp Switch . 47

Parking Pawl ............................ 71

Pump Oil Seal-Replacement ................ 61

Rear Clutch-Recondition ................... 64

Road Test .............................. 40

Selection of Lubricant ..................... 40

Special Additives ......................... 40

Three Speed Torqueflite General Diagnosis ..... 36

Throttle Pressure Linkage Adjustment ......... 46

Torque Converter Clutch Solenoid Wiring Connector ............................ 40

Transaxle and Torque Converter Removal ...... 48

Transfer Shaft Repair ..................... 68

Valve Body-Recondition .................... 57

Vehicle Speed Sensor Pinion Gear ........... 47

GENERAL INFORMATION

Safety goggles should be worn at all times

when working on these transaxles. This transaxle combines a fully automatic 3 speed

transmission, final drive gearing, and differential into

a front wheel drive system. The unit is a Metric

design. The identification markings and usage of the

transaxle are charted in Diagnosis and Tests. Transaxle operation requirements are differ-

ent for each vehicle and engine combination and

some internal parts will be different to provide

for this. Therefore, when replacing parts, refer to

the seven digit part number stamped on rear of

the transaxle oil pan flange. Within this transaxle, there are 3 primary areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor and

parking sprag). (3) Differential center line. Center distances be-

tween the main rotating parts in these 3 areas are held

precise. This maintains a low noise level through

smooth accurate mesh of the gears. The torque converter, transaxle area, and differential

are housed in an integral aluminum die casting. The

differential oil sump is common with thetransaxle

sump. Separate filling of the differential is NOT nec-

essary. The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through an oil-to-water type cooler located in the

radiator side tank and/or an oil-to air heat ex- changer. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assem-

bly. Engine torque is transmitted to the torque con-

verter then, through the input shaft to multiple-disc

clutches in the transaxle. The power flow depends on

the application of the clutches and bands. Refer to

Elements in Use Chart in Diagnosis and Tests sec-

tion. The transaxle consists of two multiple-disc

clutches, an overrunning clutch, two servos, a hy-

draulic accumulator, two bands, and two planetary

gear sets. They provide three forward ratios and a re-

verse ratio. The common sun gear of the planetary

gear sets is connected to the front clutch by a driving

shell. The drive shell is splined to the sun gear and

to the front clutch retainer. The hydraulic system

consists of an oil pump, and a single valve body

which contains all of the valves except the governor

valves. The transaxle sump and differential sump are

both vented through the dipstick.Output torque

from the main center line is delivered through heli-

cal gears to the transfer shaft.This gear set is a

factor of the final drive (axle) ratio. The shaft also

carries the governor and parking sprag. An integral

helical gear on the transfer shaft drives the differen-

tial ring gear. The final drive gearing is completed

with one of three gear sets producing overall top gear

ratios of 2.78, 3.02, or 3.22 depending on model and

application.

Ä TRANSAXLE 21 - 35

Page 2000 of 2438

FLUID LEVEL AND CONDITION

The transmission and differential sump have a

common oil sump with a communicating opening

between the two. Before removing the dipstick, wipe all dirt off of the

protective disc and the dipstick handle. The torque converter will fill in both the PPark or N

Neutral positions. Place the selector lever in PPark to

check fluid level. Inspect fluid level on dipstick every six months.

Allow the engine to idle for at least one minute

with vehicle on level ground. This will assure

complete oil level stabilization between differen-

tial and transmission. A properly filled transaxle

will read near the addmark when fluid temperature is

21 degrees Celsius (70 degrees Fahrenheit). When the

transaxle reaches operating temperature the fluid

should be in the HOTregion.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with the

fluid. As in any hydraulic system, air bubbles make the

fluid spongy, therefore, pressures will be low and build

up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the gears

churn up foam and cause the same conditions which

occur with a low fluid level. In either case, the air bubbles can cause overheating,

fluid oxidation, and varnishing, which can interfere

with normal valve, clutch, and servo operation. Foam-

ing can also result in fluid escaping from the transaxle

vent (dipstick handle) where it may be mistaken for a

leak. Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed. Be

sure to examine the fluid on the dipstick closely. If

there is any doubt about its condition, drain out a

sample for a double check. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. MOPAR tATF PLUS (Automatic

Transmission Fluid-Type 7176) should be used to aid in

assuring optimum transmission performance. Fluids of

the type labeled DEXRON II Automatic Transmission

Fluid should be used only if the recommended fluid is

not available. It is important that the transmission

fluid be maintained at the prescribed level using the

recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the addi-

tion of any fluids to the transmission, other than the

automatic transmission fluid listed above. An ex- ception to this policy is the use of special dyes to aid in

detecting fluid leaks. The use of transmission sealers

should be avoided, since they may adversely affect

seals.

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only

fluids of the type labeled MOPAR tATF PLUS

(Automatic Transmission fluid) Type 7176 should

be used. A band adjustment and filter change

should be made at the time of the oil change. The

magnet (on the inside of the oil pan) should also

be cleaned with a clean, dry cloth. If the transaxle is disassembled for any reason,

the fluid and filter should be changed, and the

band(s) adjusted.

FLUID DRAIN AND REFILL

(1) Raise vehicle on a hoist (See Lubrication, Group

0). Place a drain container with a large opening, under

transaxle oil pan. (2) Loosen pan bolts and tap the pan at one corner to

break it loose allowing fluid to drain, then remove the

oil pan. (3) Install a new filter and gasket on bottom of the

valve body and tighten retaining screws to 5 N Im (40

in. lbs.). (4) Clean the oil pan and magnet. Reinstall pan

using new MOPAR tAdhesive sealant. Tighten oil pan

bolts to 19 N Im (165 in. lbs.).

(5) Pour four quarts of MOPAR tATF PLUS (Auto-

matic Transmission Fluid) Type 7176 through the

dipstick opening. (6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes ap-

plied, move selector lever momentarily to each posi-

tion, ending in the park or neutral position. (7) Add sufficient fluid to bring level to 1/8 inch

below the ADD mark. Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the HOT

region (Fig. 1). To prevent dirt from entering transaxle, make cer-

tain that dipstick is full seated into the dipstick open-

ing.

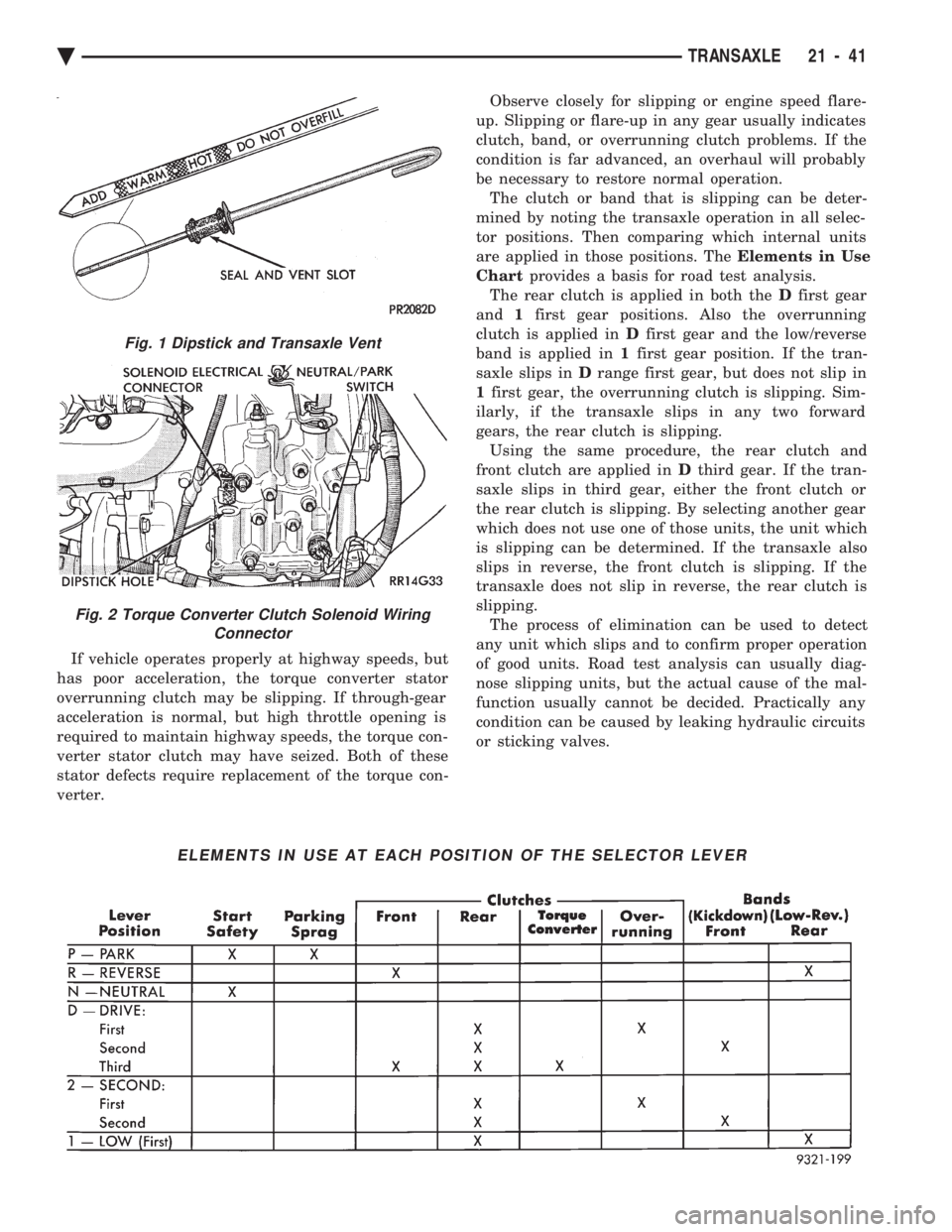

TORQUE CONVERTER CLUTCH SOLENOID WIRING

CONNECTOR

If wiring connector is unplugged, the torque con-

verter clutch will not operate (Fig. 2).

ROAD TEST

Prior to performing a road test, be certain that the

fluid level and condition, and control cable adjustments

have been checked and approved. During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

21 - 40 TRANSAXLE Ä

Page 2001 of 2438

If vehicle operates properly at highway speeds, but

has poor acceleration, the torque converter stator

overrunning clutch may be slipping. If through-gear

acceleration is normal, but high throttle opening is

required to maintain highway speeds, the torque con-

verter stator clutch may have seized. Both of these

stator defects require replacement of the torque con-

verter. Observe closely for slipping or engine speed flare-

up. Slipping or flare-up in any gear usually indicates

clutch, band, or overrunning clutch problems. If the

condition is far advanced, an overhaul will probably

be necessary to restore normal operation. The clutch or band that is slipping can be deter-

mined by noting the transaxle operation in all selec-

tor positions. Then comparing which internal units

are applied in those positions. The Elements in Use

Chart provides a basis for road test analysis.

The rear clutch is applied in both the Dfirst gear

and 1first gear positions. Also the overrunning

clutch is applied in Dfirst gear and the low/reverse

band is applied in 1first gear position. If the tran-

saxle slips in Drange first gear, but does not slip in

1 first gear, the overrunning clutch is slipping. Sim-

ilarly, if the transaxle slips in any two forward

gears, the rear clutch is slipping. Using the same procedure, the rear clutch and

front clutch are applied in Dthird gear. If the tran-

saxle slips in third gear, either the front clutch or

the rear clutch is slipping. By selecting another gear

which does not use one of those units, the unit which

is slipping can be determined. If the transaxle also

slips in reverse, the front clutch is slipping. If the

transaxle does not slip in reverse, the rear clutch is

slipping. The process of elimination can be used to detect

any unit which slips and to confirm proper operation

of good units. Road test analysis can usually diag-

nose slipping units, but the actual cause of the mal-

function usually cannot be decided. Practically any

condition can be caused by leaking hydraulic circuits

or sticking valves.

ELEMENTS IN USE AT EACH POSITION OF THE SELECTOR LEVER

Fig. 1 Dipstick and Transaxle Vent

Fig. 2 Torque Converter Clutch Solenoid Wiring Connector

Ä TRANSAXLE 21 - 41