engine CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 2229 of 2438

(4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

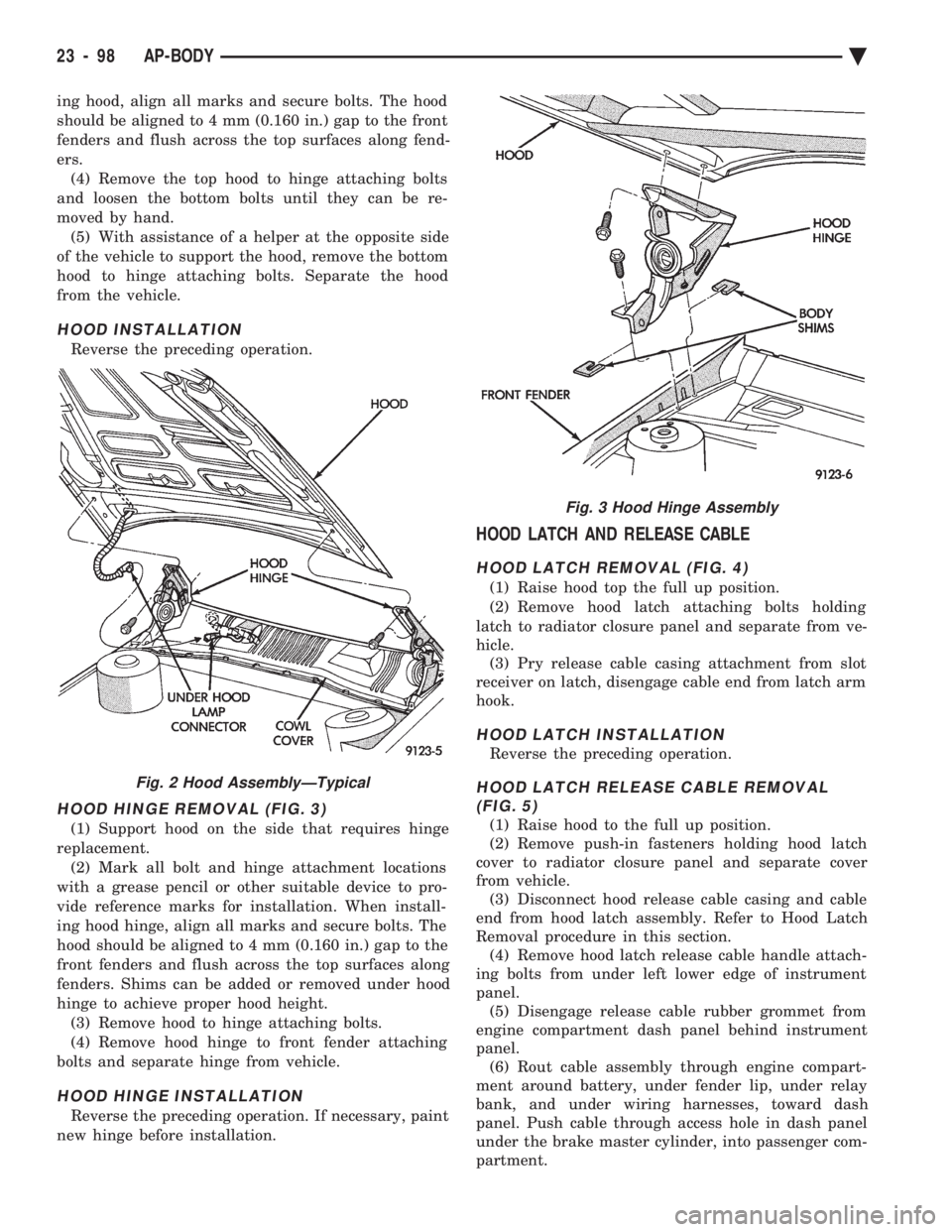

COWL COVER

REMOVAL (FIG. 5)

(1) Raise hood to full up position.

(2) Disconnect windshield washer hoses from wiper

arms. (3) Remove windshield wiper arm assemblies. Re-

fer to Group 8K, Windshield Wiper and Washer Sys-

tems. (4) Remove plastic expanding type fasteners hold-

ing cowl cover to cowl, below windshield. (5) Lift back of cowl cover and slide cover rearward

from under dash panel to hood seal and separate

cover from vehicle.

INSTALLATION

Reverse the preceding operation.

FRONT END SPLASH SHIELDS

FRONT WHEELHOUSE SPLASH SHIELD REMOVAL (FIG. 6)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

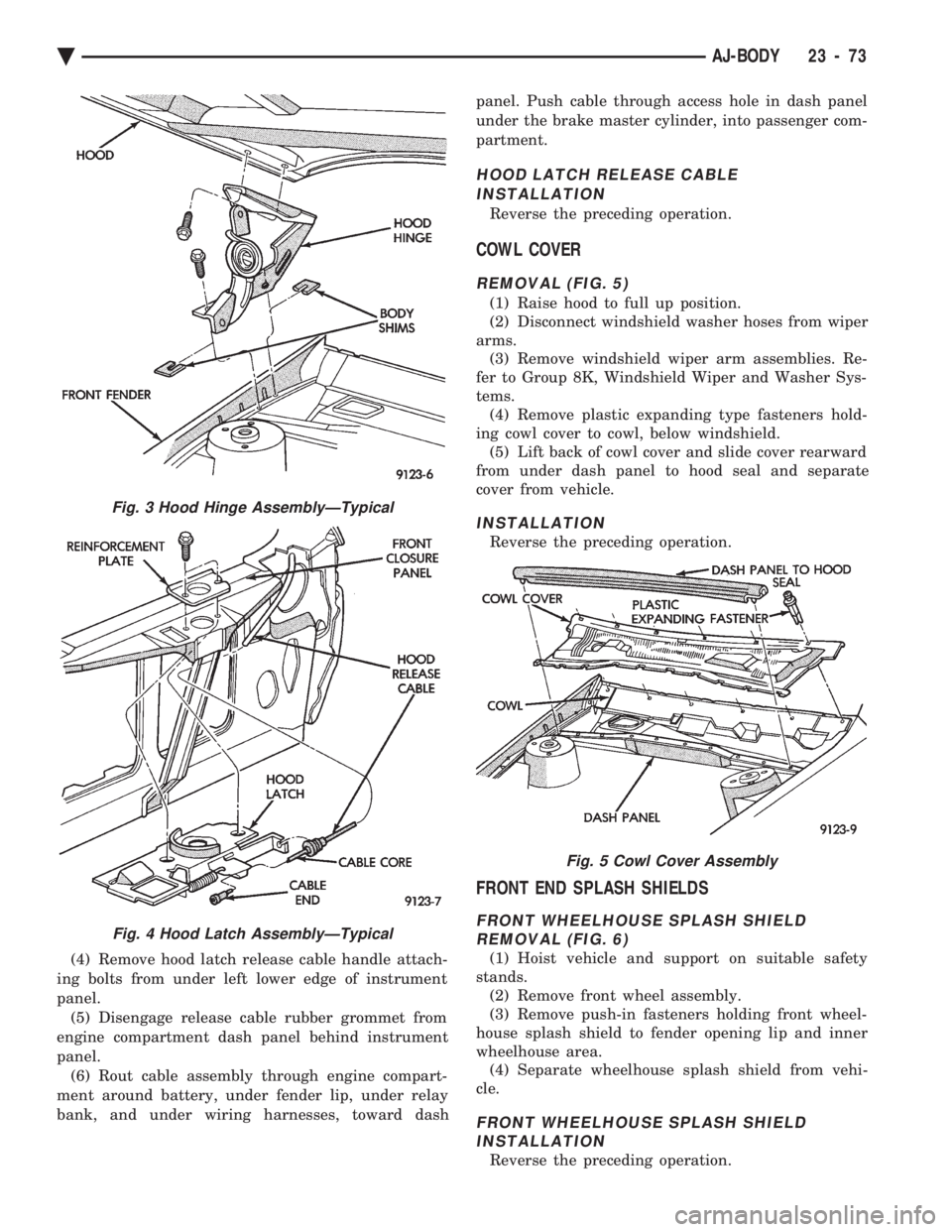

Fig. 3 Hood Hinge AssemblyÐTypical

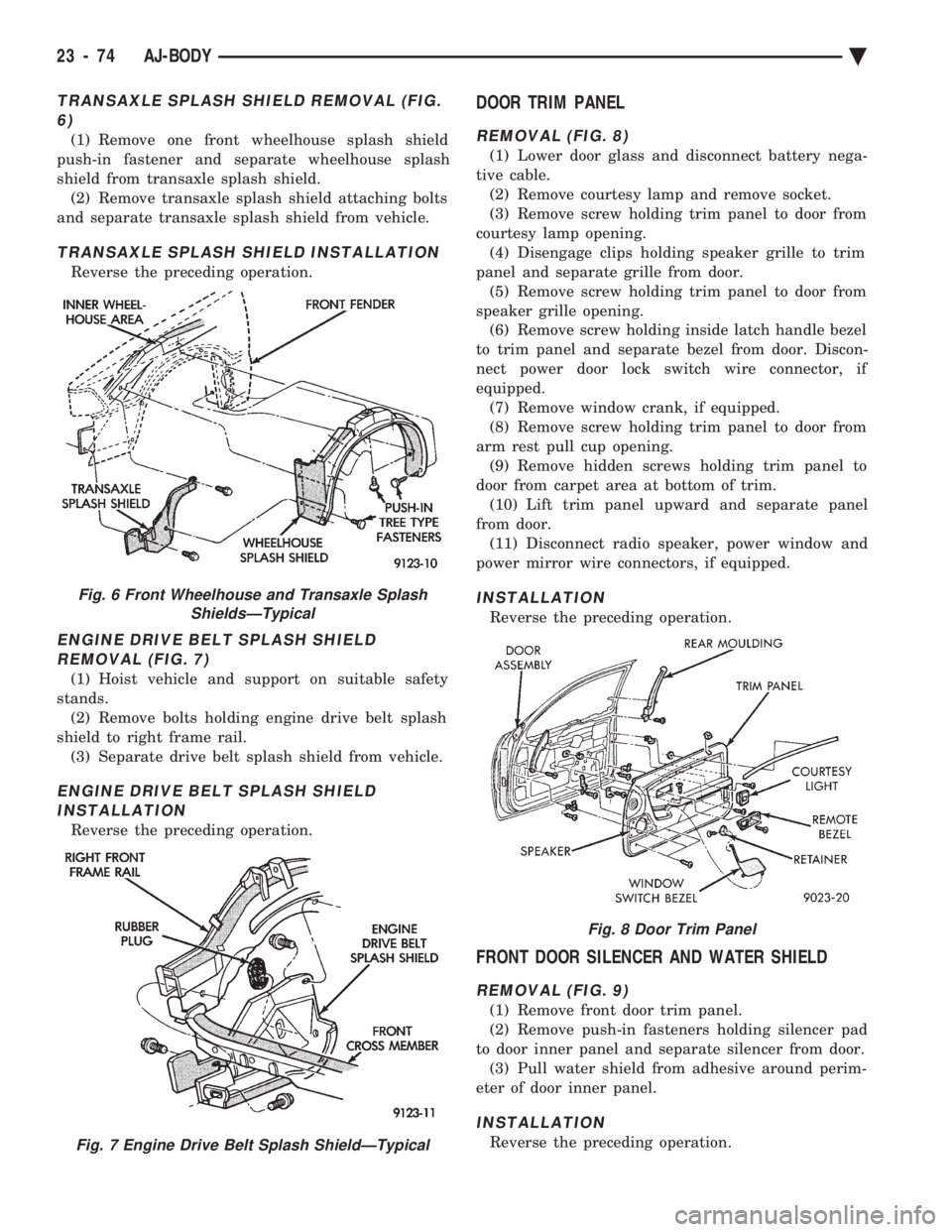

Fig. 4 Hood Latch AssemblyÐTypical

Fig. 5 Cowl Cover Assembly

Ä AJ-BODY 23 - 73

Page 2230 of 2438

TRANSAXLE SPLASH SHIELD REMOVAL (FIG. 6)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

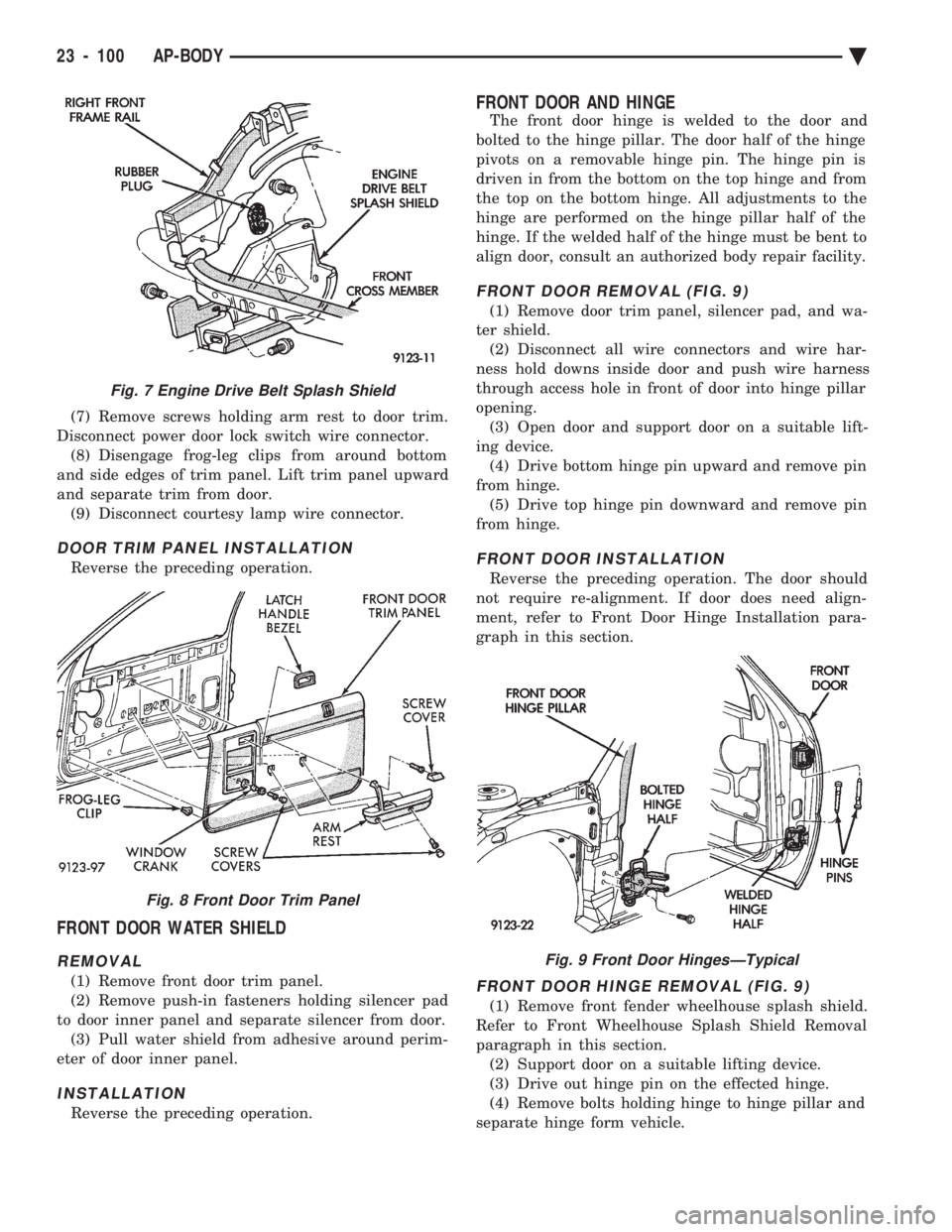

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 7)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

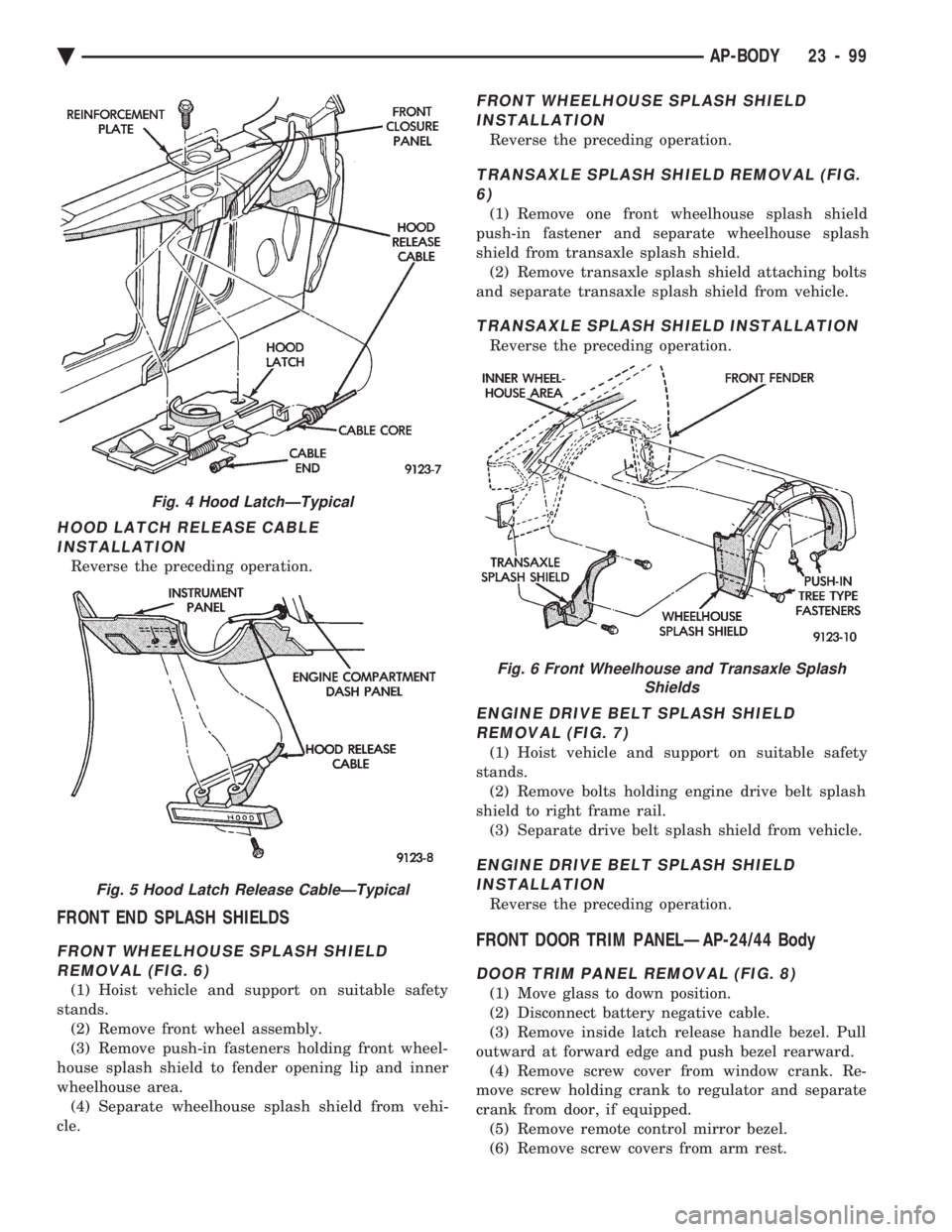

DOOR TRIM PANEL

REMOVAL (FIG. 8)

(1) Lower door glass and disconnect battery nega-

tive cable. (2) Remove courtesy lamp and remove socket.

(3) Remove screw holding trim panel to door from

courtesy lamp opening. (4) Disengage clips holding speaker grille to trim

panel and separate grille from door. (5) Remove screw holding trim panel to door from

speaker grille opening. (6) Remove screw holding inside latch handle bezel

to trim panel and separate bezel from door. Discon-

nect power door lock switch wire connector, if

equipped. (7) Remove window crank, if equipped.

(8) Remove screw holding trim panel to door from

arm rest pull cup opening. (9) Remove hidden screws holding trim panel to

door from carpet area at bottom of trim. (10) Lift trim panel upward and separate panel

from door. (11) Disconnect radio speaker, power window and

power mirror wire connectors, if equipped.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR SILENCER AND WATER SHIELD

REMOVAL (FIG. 9)

(1) Remove front door trim panel.

(2) Remove push-in fasteners holding silencer pad

to door inner panel and separate silencer from door. (3) Pull water shield from adhesive around perim-

eter of door inner panel.

INSTALLATION

Reverse the preceding operation.

Fig. 6 Front Wheelhouse and Transaxle Splash ShieldsÐTypical

Fig. 7 Engine Drive Belt Splash ShieldÐTypical

Fig. 8 Door Trim Panel

23 - 74 AJ-BODY Ä

Page 2254 of 2438

ing hood, align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.(4) Remove the top hood to hinge attaching bolts

and loosen the bottom bolts until they can be re-

moved by hand. (5) With assistance of a helper at the opposite side

of the vehicle to support the hood, remove the bottom

hood to hinge attaching bolts. Separate the hood

from the vehicle.

HOOD INSTALLATION

Reverse the preceding operation.

HOOD HINGE REMOVAL (FIG. 3)

(1) Support hood on the side that requires hinge

replacement. (2) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When install-

ing hood hinge, align all marks and secure bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders. Shims can be added or removed under hood

hinge to achieve proper hood height. (3) Remove hood to hinge attaching bolts.

(4) Remove hood hinge to front fender attaching

bolts and separate hinge from vehicle.

HOOD HINGE INSTALLATION

Reverse the preceding operation. If necessary, paint

new hinge before installation.

HOOD LATCH AND RELEASE CABLE

HOOD LATCH REMOVAL (FIG. 4)

(1) Raise hood top the full up position.

(2) Remove hood latch attaching bolts holding

latch to radiator closure panel and separate from ve-

hicle. (3) Pry release cable casing attachment from slot

receiver on latch, disengage cable end from latch arm

hook.

HOOD LATCH INSTALLATION

Reverse the preceding operation.

HOOD LATCH RELEASE CABLE REMOVAL (FIG. 5)

(1) Raise hood to the full up position.

(2) Remove push-in fasteners holding hood latch

cover to radiator closure panel and separate cover

from vehicle. (3) Disconnect hood release cable casing and cable

end from hood latch assembly. Refer to Hood Latch

Removal procedure in this section. (4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash

panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

Fig. 2 Hood AssemblyÐTypical

Fig. 3 Hood Hinge Assembly

23 - 98 AP-BODY Ä

Page 2255 of 2438

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

FRONT END SPLASH SHIELDS

FRONT WHEELHOUSE SPLASH SHIELDREMOVAL (FIG. 6)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

TRANSAXLE SPLASH SHIELD REMOVAL (FIG.6)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 7)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

FRONT DOOR TRIM PANELÐAP-24/44 Body

DOOR TRIM PANEL REMOVAL (FIG. 8)

(1) Move glass to down position.

(2) Disconnect battery negative cable.

(3) Remove inside latch release handle bezel. Pull

outward at forward edge and push bezel rearward. (4) Remove screw cover from window crank. Re-

move screw holding crank to regulator and separate

crank from door, if equipped. (5) Remove remote control mirror bezel.

(6) Remove screw covers from arm rest.

Fig. 4 Hood LatchÐTypical

Fig. 5 Hood Latch Release CableÐTypical

Fig. 6 Front Wheelhouse and Transaxle Splash Shields

Ä AP-BODY 23 - 99

Page 2256 of 2438

(7) Remove screws holding arm rest to door trim.

Disconnect power door lock switch wire connector. (8) Disengage frog-leg clips from around bottom

and side edges of trim panel. Lift trim panel upward

and separate trim from door. (9) Disconnect courtesy lamp wire connector.

DOOR TRIM PANEL INSTALLATION

Reverse the preceding operation.

FRONT DOOR WATER SHIELD

REMOVAL

(1) Remove front door trim panel.

(2) Remove push-in fasteners holding silencer pad

to door inner panel and separate silencer from door. (3) Pull water shield from adhesive around perim-

eter of door inner panel.

INSTALLATION

Reverse the preceding operation.

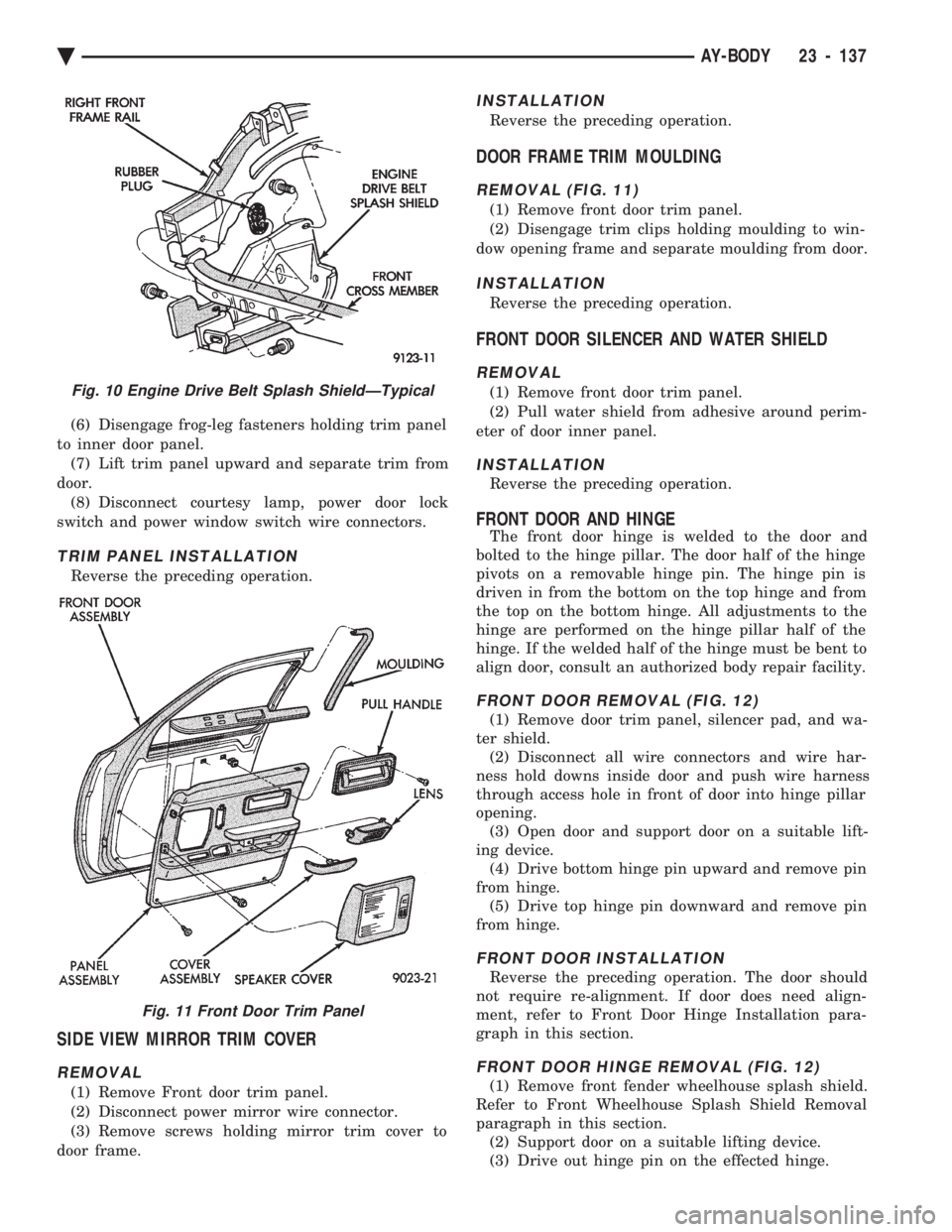

FRONT DOOR AND HINGE

The front door hinge is welded to the door and

bolted to the hinge pillar. The door half of the hinge

pivots on a removable hinge pin. The hinge pin is

driven in from the bottom on the top hinge and from

the top on the bottom hinge. All adjustments to the

hinge are performed on the hinge pillar half of the

hinge. If the welded half of the hinge must be bent to

align door, consult an authorized body repair facility.

FRONT DOOR REMOVAL (FIG. 9)

(1) Remove door trim panel, silencer pad, and wa-

ter shield. (2) Disconnect all wire connectors and wire har-

ness hold downs inside door and push wire harness

through access hole in front of door into hinge pillar

opening. (3) Open door and support door on a suitable lift-

ing device. (4) Drive bottom hinge pin upward and remove pin

from hinge. (5) Drive top hinge pin downward and remove pin

from hinge.

FRONT DOOR INSTALLATION

Reverse the preceding operation. The door should

not require re-alignment. If door does need align-

ment, refer to Front Door Hinge Installation para-

graph in this section.

FRONT DOOR HINGE REMOVAL (FIG. 9)

(1) Remove front fender wheelhouse splash shield.

Refer to Front Wheelhouse Splash Shield Removal

paragraph in this section. (2) Support door on a suitable lifting device.

(3) Drive out hinge pin on the effected hinge.

(4) Remove bolts holding hinge to hinge pillar and

separate hinge form vehicle.

Fig. 7 Engine Drive Belt Splash Shield

Fig. 8 Front Door Trim Panel

Fig. 9 Front Door HingesÐTypical

23 - 100 AP-BODY Ä

Page 2292 of 2438

HOOD LATCH RELEASE CABLE REMOVAL (FIG. 8)

(1) Raise hood to the full up position.

(2) Remove push-in fasteners holding hood latch

cover to radiator closure panel and separate cover

from vehicle. (3) Disconnect hood release cable casing and cable

end from hood latch assembly. Refer to Hood Latch

Removal procedure in this section. (4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash

panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

HOOD LATCH RELEASE CABLE INSTALLATION

Reverse the preceding operation.

FRONT END SPLASH SHIELDS

FRONT WHEELHOUSE SPLASH SHIELDREMOVAL (FIG. 9)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove front wheel assembly.

(3) Remove push-in fasteners holding front wheel-

house splash shield to fender opening lip and inner

wheelhouse area. (4) Separate wheelhouse splash shield from vehi-

cle.

FRONT WHEELHOUSE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

TRANSAXLE SPLASH SHIELD REMOVAL (FIG.9)

(1) Remove one front wheelhouse splash shield

push-in fastener and separate wheelhouse splash

shield from transaxle splash shield. (2) Remove transaxle splash shield attaching bolts

and separate transaxle splash shield from vehicle.

TRANSAXLE SPLASH SHIELD INSTALLATION

Reverse the preceding operation.

ENGINE DRIVE BELT SPLASH SHIELD REMOVAL (FIG. 10)

(1) Hoist vehicle and support on suitable safety

stands. (2) Remove bolts holding engine drive belt splash

shield to right frame rail. (3) Separate drive belt splash shield from vehicle.

ENGINE DRIVE BELT SPLASH SHIELDINSTALLATION

Reverse the preceding operation.

FRONT DOOR TRIM PANEL

TRIM PANEL REMOVAL (FIG. 11)

(1) Disengage frog-leg fasteners holding power seat

switch/speaker bezel to door trim. Separate bezel

from trim panel. (2) Disconnect power seat switch wire connector.

(3) Remove screws holding trim panel to door from

around speaker and power seat switch. (4) Remove screws holding pull handle to door trim

and separate pull handle from door. (5) Remove hidden screws holding trim panel to in-

ner door panel from behind carpet insert.

Fig. 8 Hood Latch Release CableÐTypical

Fig. 9 Front Wheelhouse and Transaxle Splash Shields

23 - 136 AY-BODY Ä

Page 2293 of 2438

(6) Disengage frog-leg fasteners holding trim panel

to inner door panel. (7) Lift trim panel upward and separate trim from

door. (8) Disconnect courtesy lamp, power door lock

switch and power window switch wire connectors.

TRIM PANEL INSTALLATION

Reverse the preceding operation.

SIDE VIEW MIRROR TRIM COVER

REMOVAL

(1) Remove Front door trim panel.

(2) Disconnect power mirror wire connector.

(3) Remove screws holding mirror trim cover to

door frame.

INSTALLATION

Reverse the preceding operation.

DOOR FRAME TRIM MOULDING

REMOVAL (FIG. 11)

(1) Remove front door trim panel.

(2) Disengage trim clips holding moulding to win-

dow opening frame and separate moulding from door.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR SILENCER AND WATER SHIELD

REMOVAL

(1) Remove front door trim panel.

(2) Pull water shield from adhesive around perim-

eter of door inner panel.

INSTALLATION

Reverse the preceding operation.

FRONT DOOR AND HINGE

The front door hinge is welded to the door and

bolted to the hinge pillar. The door half of the hinge

pivots on a removable hinge pin. The hinge pin is

driven in from the bottom on the top hinge and from

the top on the bottom hinge. All adjustments to the

hinge are performed on the hinge pillar half of the

hinge. If the welded half of the hinge must be bent to

align door, consult an authorized body repair facility.

FRONT DOOR REMOVAL (FIG. 12)

(1) Remove door trim panel, silencer pad, and wa-

ter shield. (2) Disconnect all wire connectors and wire har-

ness hold downs inside door and push wire harness

through access hole in front of door into hinge pillar

opening. (3) Open door and support door on a suitable lift-

ing device. (4) Drive bottom hinge pin upward and remove pin

from hinge. (5) Drive top hinge pin downward and remove pin

from hinge.

FRONT DOOR INSTALLATION

Reverse the preceding operation. The door should

not require re-alignment. If door does need align-

ment, refer to Front Door Hinge Installation para-

graph in this section.

FRONT DOOR HINGE REMOVAL (FIG. 12)

(1) Remove front fender wheelhouse splash shield.

Refer to Front Wheelhouse Splash Shield Removal

paragraph in this section. (2) Support door on a suitable lifting device.

(3) Drive out hinge pin on the effected hinge.

Fig. 10 Engine Drive Belt Splash ShieldÐTypical

Fig. 11 Front Door Trim Panel

Ä AY-BODY 23 - 137

Page 2305 of 2438

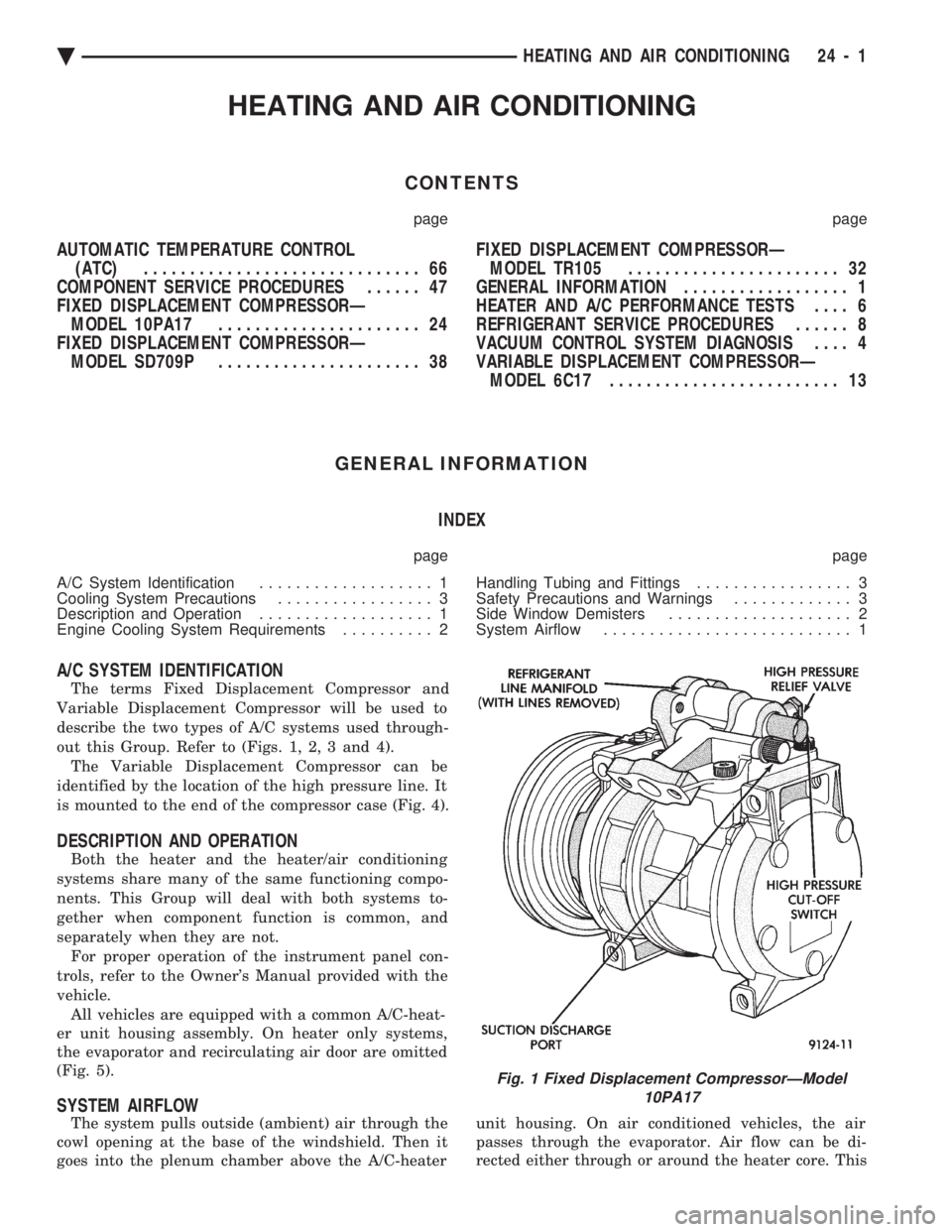

HEATING AND AIR CONDITIONING

CONTENTS

page page

AUTOMATIC TEMPERATURE CONTROL (ATC) .............................. 66

COMPONENT SERVICE PROCEDURES ...... 47

FIXED DISPLACEMENT COMPRESSORÐ MODEL 10PA17 ...................... 24

FIXED DISPLACEMENT COMPRESSORÐ MODEL SD709P ...................... 38 FIXED DISPLACEMENT COMPRESSORÐ

MODEL TR105 ....................... 32

GENERAL INFORMATION .................. 1

HEATER AND A/C PERFORMANCE TESTS .... 6

REFRIGERANT SERVICE PROCEDURES ...... 8

VACUUM CONTROL SYSTEM DIAGNOSIS .... 4

VARIABLE DISPLACEMENT COMPRESSORÐ MODEL 6C17 ......................... 13

GENERAL INFORMATION INDEX

page page

A/C System Identification ................... 1

Cooling System Precautions ................. 3

Description and Operation ................... 1

Engine Cooling System Requirements .......... 2 Handling Tubing and Fittings

................. 3

Safety Precautions and Warnings ............. 3

Side Window Demisters .................... 2

System Airflow ........................... 1

A/C SYSTEM IDENTIFICATION

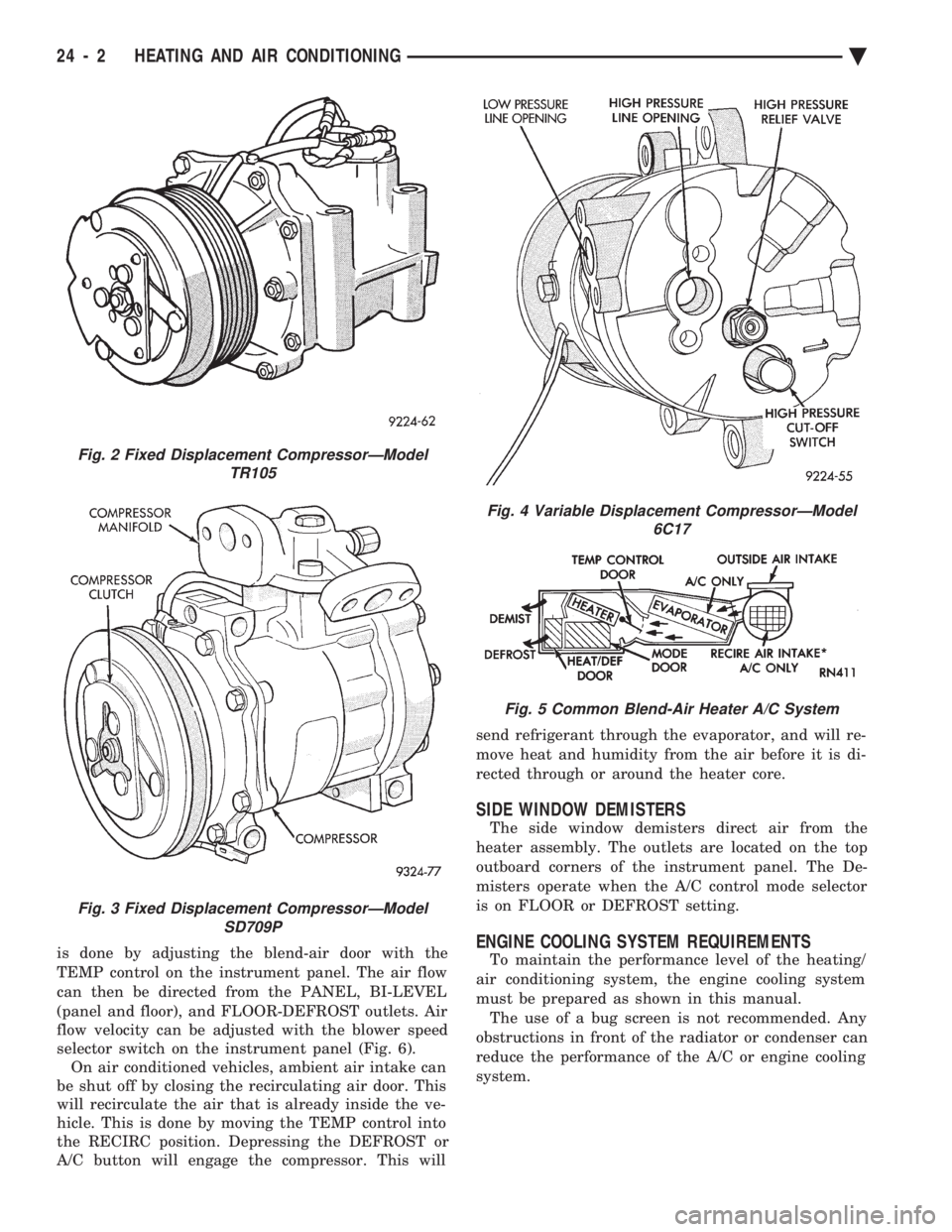

The terms Fixed Displacement Compressor and

Variable Displacement Compressor will be used to

describe the two types of A/C systems used through-

out this Group. Refer to (Figs. 1, 2, 3 and 4). The Variable Displacement Compressor can be

identified by the location of the high pressure line. It

is mounted to the end of the compressor case (Fig. 4).

DESCRIPTION AND OPERATION

Both the heater and the heater/air conditioning

systems share many of the same functioning compo-

nents. This Group will deal with both systems to-

gether when component function is common, and

separately when they are not. For proper operation of the instrument panel con-

trols, refer to the Owner's Manual provided with the

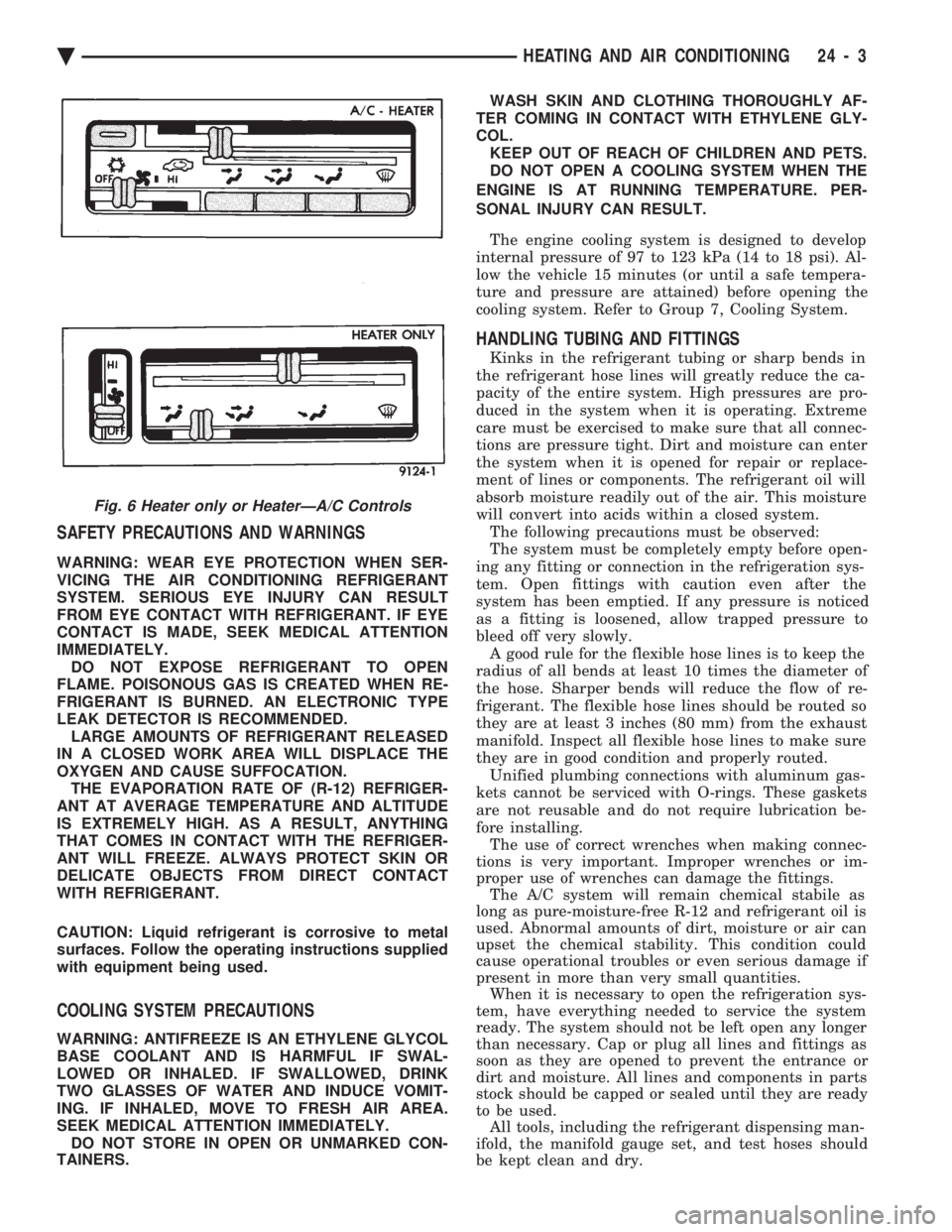

vehicle. All vehicles are equipped with a common A/C-heat-

er unit housing assembly. On heater only systems,

the evaporator and recirculating air door are omitted

(Fig. 5).

SYSTEM AIRFLOW

The system pulls outside (ambient) air through the

cowl opening at the base of the windshield. Then it

goes into the plenum chamber above the A/C-heater unit housing. On air conditioned vehicles, the air

passes through the evaporator. Air flow can be di-

rected either through or around the heater core. This

Fig. 1 Fixed Displacement CompressorÐModel 10PA17

Ä HEATING AND AIR CONDITIONING 24 - 1

Page 2306 of 2438

is done by adjusting the blend-air door with the

TEMP control on the instrument panel. The air flow

can then be directed from the PANEL, BI-LEVEL

(panel and floor), and FLOOR-DEFROST outlets. Air

flow velocity can be adjusted with the blower speed

selector switch on the instrument panel (Fig. 6). On air conditioned vehicles, ambient air intake can

be shut off by closing the recirculating air door. This

will recirculate the air that is already inside the ve-

hicle. This is done by moving the TEMP control into

the RECIRC position. Depressing the DEFROST or

A/C button will engage the compressor. This will send refrigerant through the evaporator, and will re-

move heat and humidity from the air before it is di-

rected through or around the heater core.

SIDE WINDOW DEMISTERS

The side window demisters direct air from the

heater assembly. The outlets are located on the top

outboard corners of the instrument panel. The De-

misters operate when the A/C control mode selector

is on FLOOR or DEFROST setting.

ENGINE COOLING SYSTEM REQUIREMENTS

To maintain the performance level of the heating/

air conditioning system, the engine cooling system

must be prepared as shown in this manual. The use of a bug screen is not recommended. Any

obstructions in front of the radiator or condenser can

reduce the performance of the A/C or engine cooling

system.

Fig. 2 Fixed Displacement CompressorÐModel TR105

Fig. 3 Fixed Displacement CompressorÐModelSD709P

Fig. 4 Variable Displacement CompressorÐModel 6C17

Fig. 5 Common Blend-Air Heater A/C System

24 - 2 HEATING AND AIR CONDITIONING Ä

Page 2307 of 2438

SAFETY PRECAUTIONS AND WARNINGS

WARNING: WEAR EYE PROTECTION WHEN SER-

VICING THE AIR CONDITIONING REFRIGERANT

SYSTEM. SERIOUS EYE INJURY CAN RESULT

FROM EYE CONTACT WITH REFRIGERANT. IF EYE

CONTACT IS MADE, SEEK MEDICAL ATTENTION

IMMEDIATELY. DO NOT EXPOSE REFRIGERANT TO OPEN

FLAME. POISONOUS GAS IS CREATED WHEN RE-

FRIGERANT IS BURNED. AN ELECTRONIC TYPE

LEAK DETECTOR IS RECOMMENDED. LARGE AMOUNTS OF REFRIGERANT RELEASED

IN A CLOSED WORK AREA WILL DISPLACE THE

OXYGEN AND CAUSE SUFFOCATION. THE EVAPORATION RATE OF (R-12) REFRIGER-

ANT AT AVERAGE TEMPERATURE AND ALTITUDE

IS EXTREMELY HIGH. AS A RESULT, ANYTHING

THAT COMES IN CONTACT WITH THE REFRIGER-

ANT WILL FREEZE. ALWAYS PROTECT SKIN OR

DELICATE OBJECTS FROM DIRECT CONTACT

WITH REFRIGERANT.

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with equipment being used.

COOLING SYSTEM PRECAUTIONS

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT STORE IN OPEN OR UNMARKED CON-

TAINERS. WASH SKIN AND CLOTHING THOROUGHLY AF-

TER COMING IN CONTACT WITH ETHYLENE GLY-

COL. KEEP OUT OF REACH OF CHILDREN AND PETS.

DO NOT OPEN A COOLING SYSTEM WHEN THE

ENGINE IS AT RUNNING TEMPERATURE. PER-

SONAL INJURY CAN RESULT.

The engine cooling system is designed to develop

internal pressure of 97 to 123 kPa (14 to 18 psi). Al-

low the vehicle 15 minutes (or until a safe tempera-

ture and pressure are attained) before opening the

cooling system. Refer to Group 7, Cooling System.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the ca-

pacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil will

absorb moisture readily out of the air. This moisture

will convert into acids within a closed system. The following precautions must be observed:

The system must be completely empty before open-

ing any fitting or connection in the refrigeration sys-

tem. Open fittings with caution even after the

system has been emptied. If any pressure is noticed

as a fitting is loosened, allow trapped pressure to

bleed off very slowly. A good rule for the flexible hose lines is to keep the

radius of all bends at least 10 times the diameter of

the hose. Sharper bends will reduce the flow of re-

frigerant. The flexible hose lines should be routed so

they are at least 3 inches (80 mm) from the exhaust

manifold. Inspect all flexible hose lines to make sure

they are in good condition and properly routed. Unified plumbing connections with aluminum gas-

kets cannot be serviced with O-rings. These gaskets

are not reusable and do not require lubrication be-

fore installing. The use of correct wrenches when making connec-

tions is very important. Improper wrenches or im-

proper use of wrenches can damage the fittings. The A/C system will remain chemical stabile as

long as pure-moisture-free R-12 and refrigerant oil is

used. Abnormal amounts of dirt, moisture or air can

upset the chemical stability. This condition could

cause operational troubles or even serious damage if

present in more than very small quantities. When it is necessary to open the refrigeration sys-

tem, have everything needed to service the system

ready. The system should not be left open any longer

than necessary. Cap or plug all lines and fittings as

soon as they are opened to prevent the entrance or

dirt and moisture. All lines and components in parts

stock should be capped or sealed until they are ready

to be used. All tools, including the refrigerant dispensing man-

ifold, the manifold gauge set, and test hoses should

be kept clean and dry.

Fig. 6 Heater only or HeaterÐA/C Controls

Ä HEATING AND AIR CONDITIONING 24 - 3