abs CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 232 of 2438

The primary functions of the (CAB) are:

² (1) Detect wheel locking tendencies.

² (2) Control fluid modulation to the brakes while in

Anti-Lock mode.

² (3) Monitor the system for proper operation.

² (4) Provide communication to the DRB II while in

diagnostic mode. The (CAB) continuously monitors the speed of each

wheel, through the signals generated at the Wheel

Speed Sensors, to determine if any wheel is begin-

ning to lock. When a wheel locking tendency is de-

tected, the (CAB) will isolate the master cylinder

from the wheel brakes. This is done by activating the

Isolation Valves. The (CAB) then commands the ap-

propriate Build or Decay valves to modulate brake

fluid pressure in some or all of the hydraulic circuits.

The fluid used for modulation comes from the booster

servo circuit. The (CAB) continues to control pres-

sure in individual hydraulic circuits until a locking

tendency is no longer present. The (ABS) system is constantly monitored by the

(CAB) for proper operation. If the (CAB) detects a

fault, it can disable the Anti-Lock braking function.

Depending on the fault, the (CAB) will light one or

both of the brake warning lamps. The (CAB) contains a System Diagnostic Program

which triggers the brake system warning lamps

when a system fault is detected. Faults are stored in

a diagnostic program memory. There are 19 fault

codes that may be stored in the (CAB) and displayed

through the DRB II. These fault codes will remain in

the (CAB) memory even after the ignition has been

turned off. These fault codes will remain in memory

until they are cleared with the DRB II, or automati-

cally erased from the memory after (50) ignition

switch on/off cycles.

CONTROLLER ANTI-LOCK BRAKE (INPUTS)

² Four wheel speed sensors.

² Boost pressure transducer.

² Primary pressure transducer.

² Low fluid level switch.

² Differential pressure switch.

² Parking brake switch.

² Dual function pressure switch (warning pressure

only)

² Stop lamp switch.

² Ignition switch.

² System relay voltage.

² Ground.

² Low Accumulator

CONTROLLER ANTI-LOCK BRAKE (OUTPUTS)

²Ten modulator valves-3 decay, 3 build and 4 isola-

tion.

² Red Brake warning lamp.

² Amber Anti-Lock Warning Lamp.

² System relay actuation. ²

Diagnostic communication.

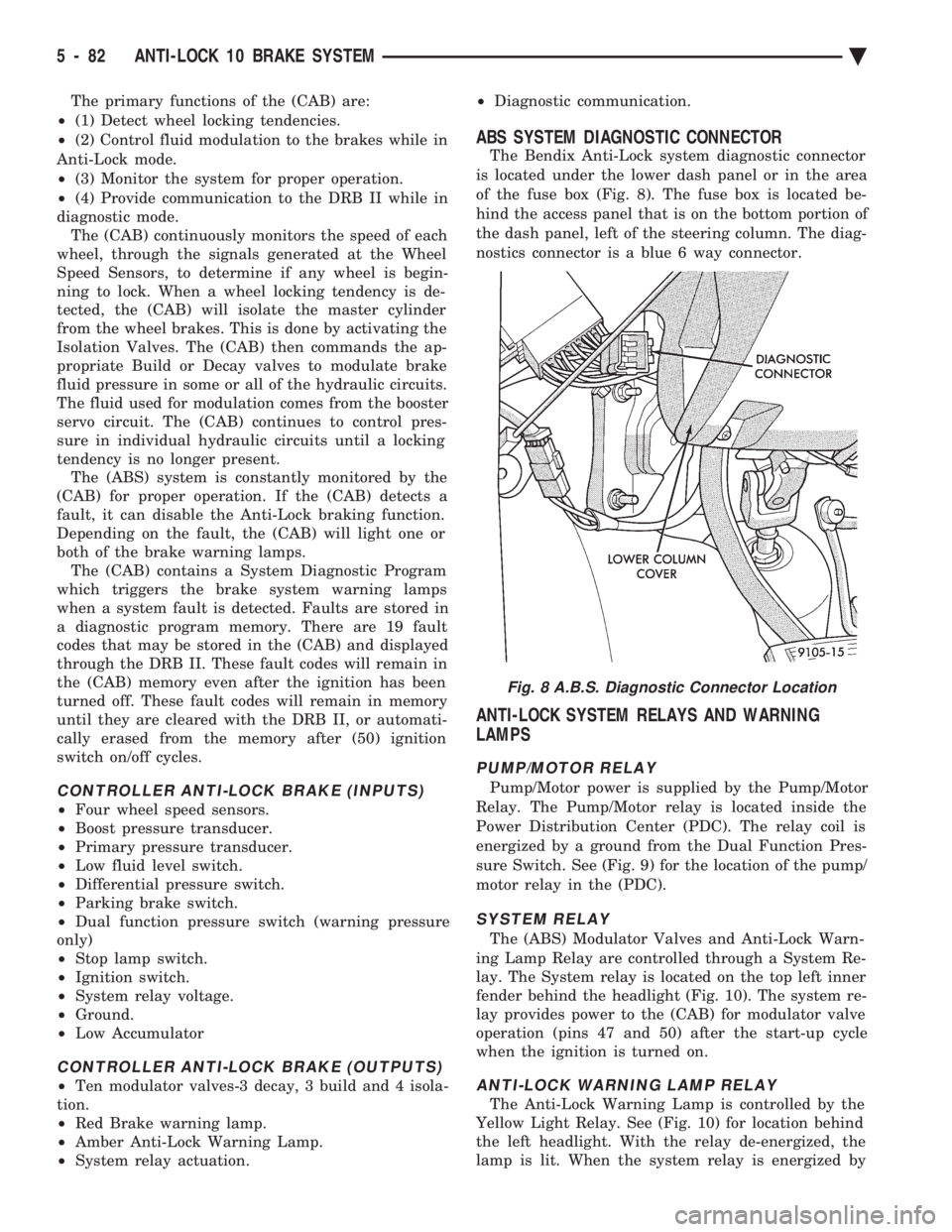

ABS SYSTEM DIAGNOSTIC CONNECTOR

The Bendix Anti-Lock system diagnostic connector

is located under the lower dash panel or in the area

of the fuse box (Fig. 8). The fuse box is located be-

hind the access panel that is on the bottom portion of

the dash panel, left of the steering column. The diag-

nostics connector is a blue 6 way connector.

ANTI-LOCK SYSTEM RELAYS AND WARNING

LAMPS

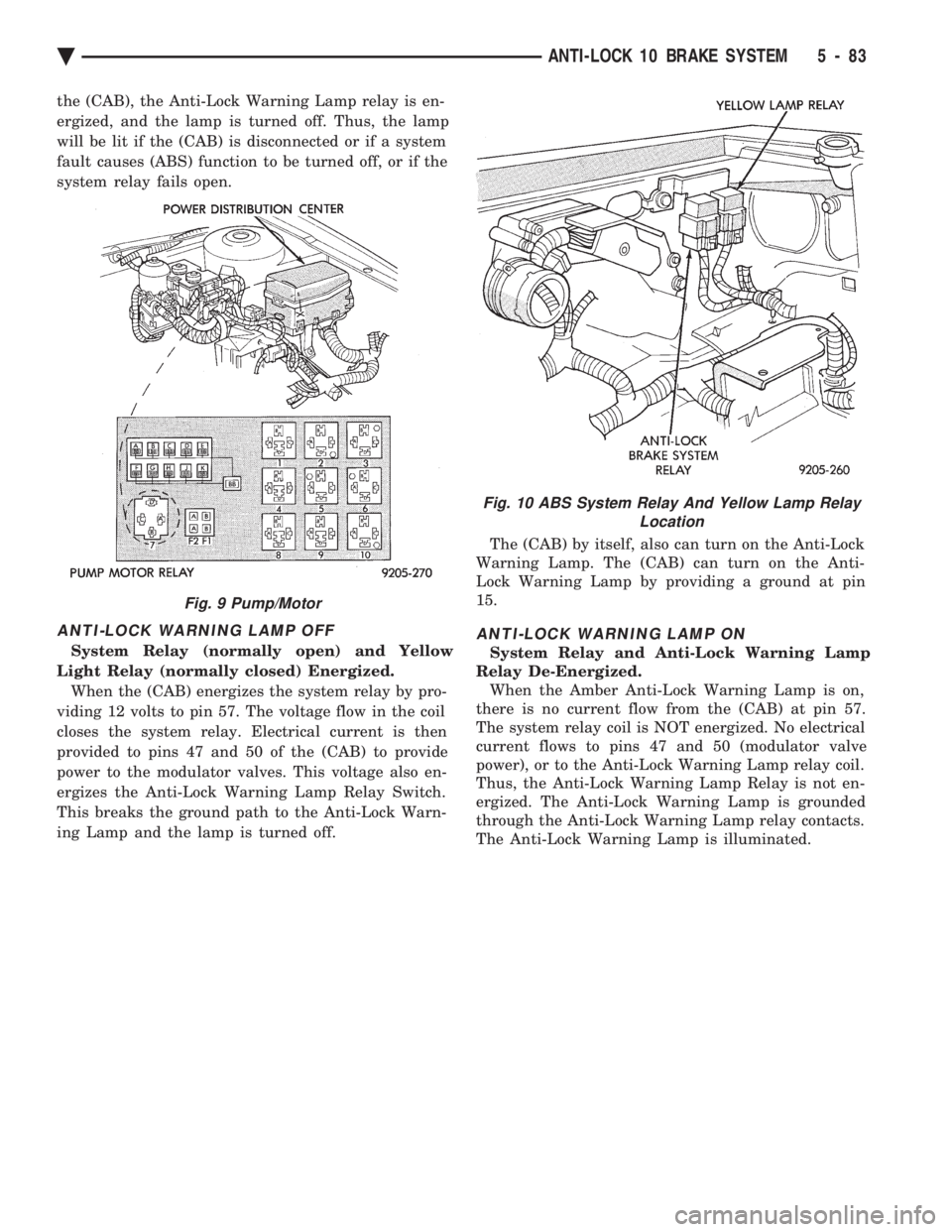

PUMP/MOTOR RELAY

Pump/Motor power is supplied by the Pump/Motor

Relay. The Pump/Motor relay is located inside the

Power Distribution Center (PDC). The relay coil is

energized by a ground from the Dual Function Pres-

sure Switch. See (Fig. 9) for the location of the pump/

motor relay in the (PDC).

SYSTEM RELAY

The (ABS) Modulator Valves and Anti-Lock Warn-

ing Lamp Relay are controlled through a System Re-

lay. The System relay is located on the top left inner

fender behind the headlight (Fig. 10). The system re-

lay provides power to the (CAB) for modulator valve

operation (pins 47 and 50) after the start-up cycle

when the ignition is turned on.

ANTI-LOCK WARNING LAMP RELAY

The Anti-Lock Warning Lamp is controlled by the

Yellow Light Relay. See (Fig. 10) for location behind

the left headlight. With the relay de-energized, the

lamp is lit. When the system relay is energized by

Fig. 8 A.B.S. Diagnostic Connector Location

5 - 82 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 233 of 2438

the (CAB), the Anti-Lock Warning Lamp relay is en-

ergized, and the lamp is turned off. Thus, the lamp

will be lit if the (CAB) is disconnected or if a system

fault causes (ABS) function to be turned off, or if the

system relay fails open.

ANTI-LOCK WARNING LAMP OFF

System Relay (normally open) and Yellow

Light Relay (normally closed) Energized. When the (CAB) energizes the system relay by pro-

viding 12 volts to pin 57. The voltage flow in the coil

closes the system relay. Electrical current is then

provided to pins 47 and 50 of the (CAB) to provide

power to the modulator valves. This voltage also en-

ergizes the Anti-Lock Warning Lamp Relay Switch.

This breaks the ground path to the Anti-Lock Warn-

ing Lamp and the lamp is turned off. The (CAB) by itself, also can turn on the Anti-Lock

Warning Lamp. The (CAB) can turn on the Anti-

Lock Warning Lamp by providing a ground at pin

15.

ANTI-LOCK WARNING LAMP ON

System Relay and Anti-Lock Warning Lamp

Relay De-Energized. When the Amber Anti-Lock Warning Lamp is on,

there is no current flow from the (CAB) at pin 57.

The system relay coil is NOT energized. No electrical

current flows to pins 47 and 50 (modulator valve

power), or to the Anti-Lock Warning Lamp relay coil.

Thus, the Anti-Lock Warning Lamp Relay is not en-

ergized. The Anti-Lock Warning Lamp is grounded

through the Anti-Lock Warning Lamp relay contacts.

The Anti-Lock Warning Lamp is illuminated.

Fig. 9 Pump/Motor

Fig. 10 ABS System Relay And Yellow Lamp Relay Location

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 83

Page 235 of 2438

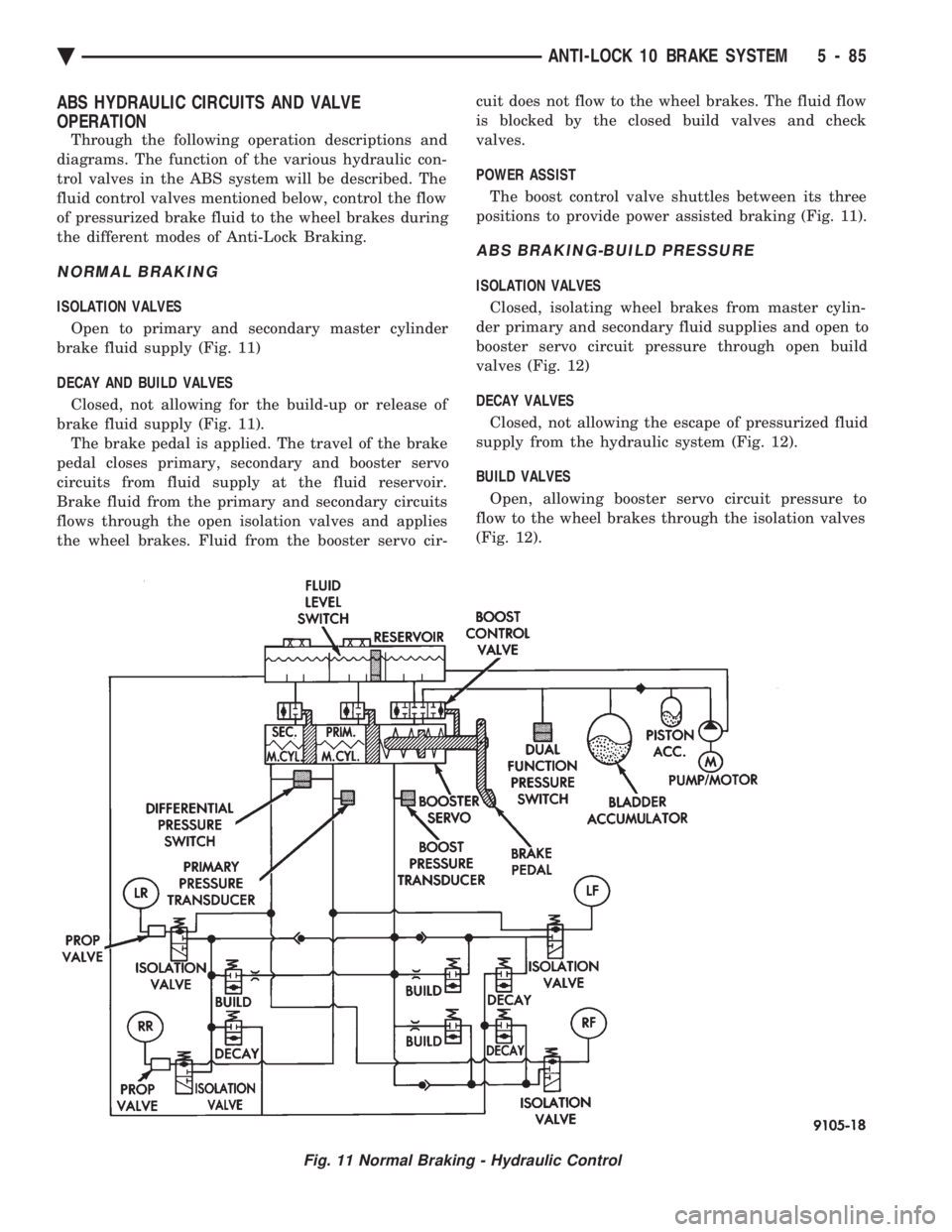

ABS HYDRAULIC CIRCUITS AND VALVE

OPERATION

Through the following operation descriptions and

diagrams. The function of the various hydraulic con-

trol valves in the ABS system will be described. The

fluid control valves mentioned below, control the flow

of pressurized brake fluid to the wheel brakes during

the different modes of Anti-Lock Braking.

NORMAL BRAKING

ISOLATION VALVES

Open to primary and secondary master cylinder

brake fluid supply (Fig. 11)

DECAY AND BUILD VALVES

Closed, not allowing for the build-up or release of

brake fluid supply (Fig. 11). The brake pedal is applied. The travel of the brake

pedal closes primary, secondary and booster servo

circuits from fluid supply at the fluid reservoir.

Brake fluid from the primary and secondary circuits

flows through the open isolation valves and applies

the wheel brakes. Fluid from the booster servo cir- cuit does not flow to the wheel brakes. The fluid flow

is blocked by the closed build valves and check

valves.

POWER ASSIST

The boost control valve shuttles between its three

positions to provide power assisted braking (Fig. 11).

ABS BRAKING-BUILD PRESSURE

ISOLATION VALVES

Closed, isolating wheel brakes from master cylin-

der primary and secondary fluid supplies and open to

booster servo circuit pressure through open build

valves (Fig. 12)

DECAY VALVES

Closed, not allowing the escape of pressurized fluid

supply from the hydraulic system (Fig. 12).

BUILD VALVES

Open, allowing booster servo circuit pressure to

flow to the wheel brakes through the isolation valves

(Fig. 12).

Fig. 11 Normal Braking - Hydraulic Control

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 85

Page 236 of 2438

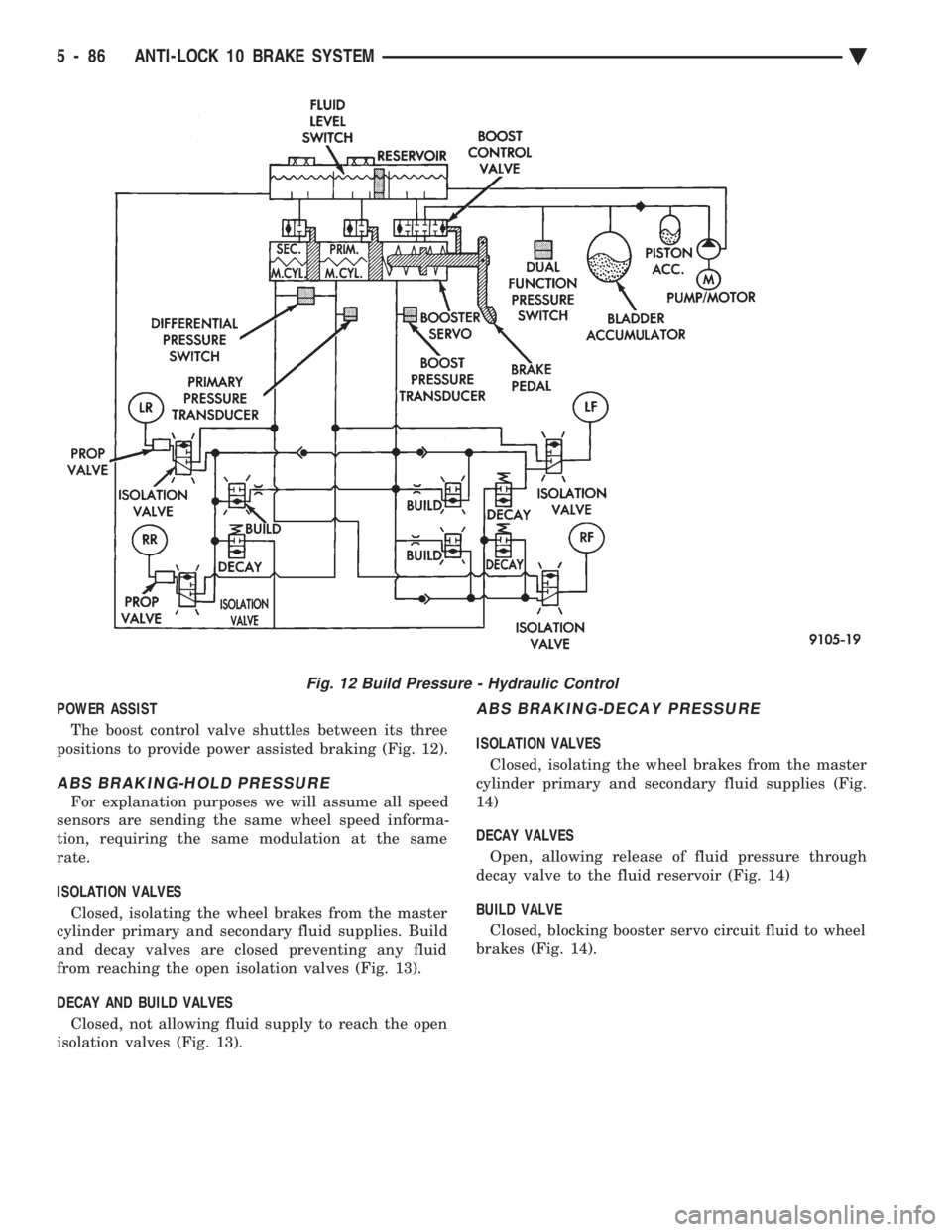

POWER ASSIST The boost control valve shuttles between its three

positions to provide power assisted braking (Fig. 12).

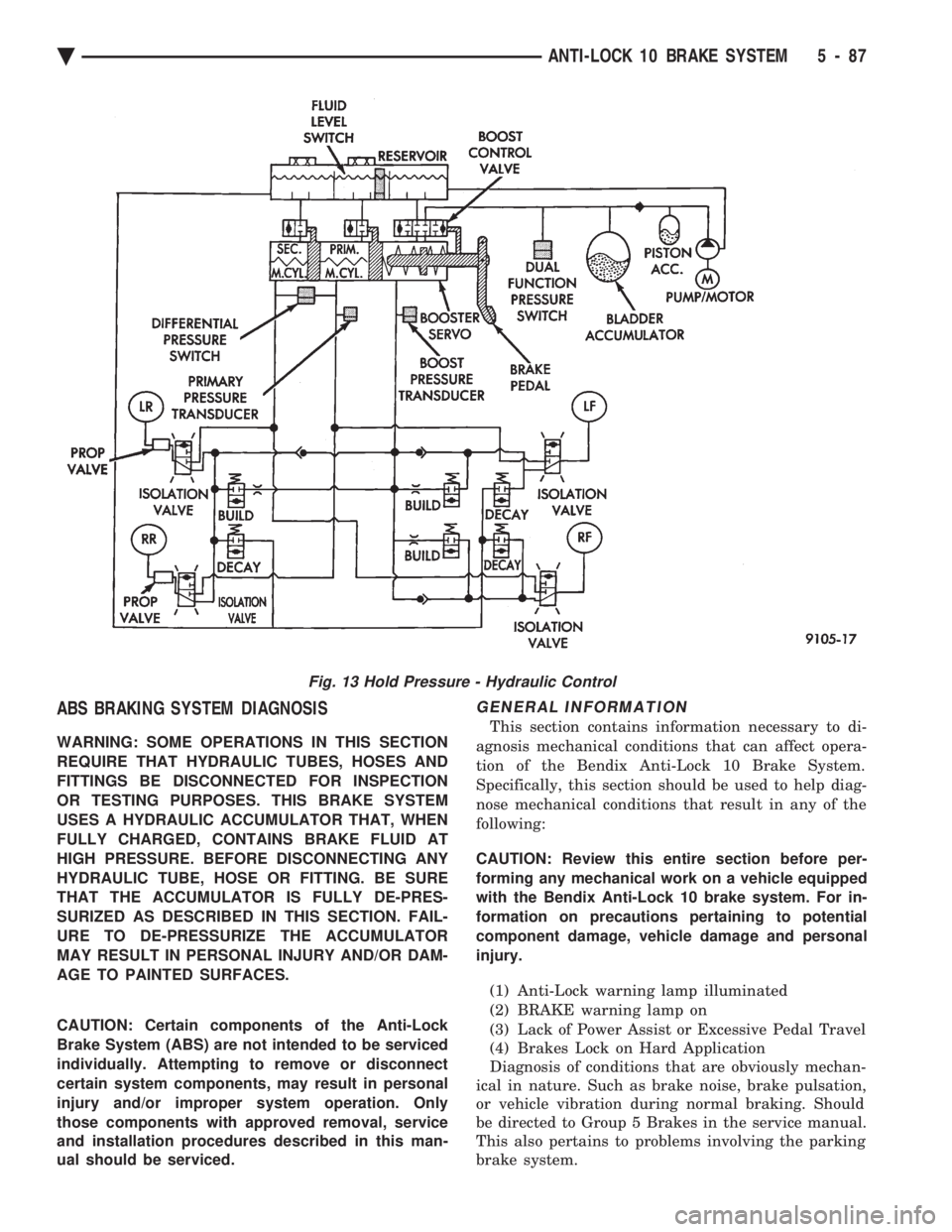

ABS BRAKING-HOLD PRESSURE

For explanation purposes we will assume all speed

sensors are sending the same wheel speed informa-

tion, requiring the same modulation at the same

rate.

ISOLATION VALVES Closed, isolating the wheel brakes from the master

cylinder primary and secondary fluid supplies. Build

and decay valves are closed preventing any fluid

from reaching the open isolation valves (Fig. 13).

DECAY AND BUILD VALVES Closed, not allowing fluid supply to reach the open

isolation valves (Fig. 13).

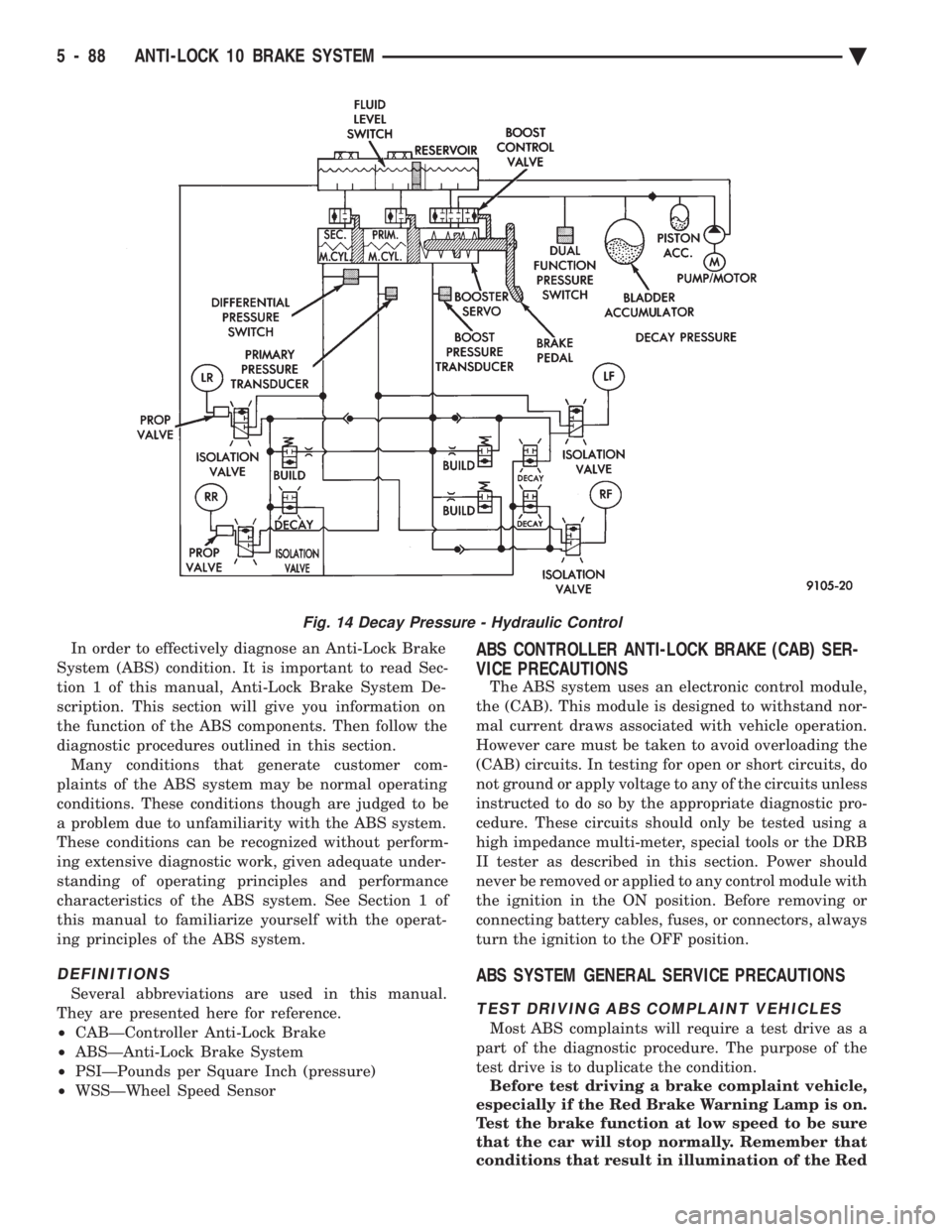

ABS BRAKING-DECAY PRESSURE

ISOLATION VALVES

Closed, isolating the wheel brakes from the master

cylinder primary and secondary fluid supplies (Fig.

14)

DECAY VALVES Open, allowing release of fluid pressure through

decay valve to the fluid reservoir (Fig. 14)

BUILD VALVE Closed, blocking booster servo circuit fluid to wheel

brakes (Fig. 14).

Fig. 12 Build Pressure - Hydraulic Control

5 - 86 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 237 of 2438

ABS BRAKING SYSTEM DIAGNOSIS

WARNING: SOME OPERATIONS IN THIS SECTION

REQUIRE THAT HYDRAULIC TUBES, HOSES AND

FITTINGS BE DISCONNECTED FOR INSPECTION

OR TESTING PURPOSES. THIS BRAKE SYSTEM

USES A HYDRAULIC ACCUMULATOR THAT, WHEN

FULLY CHARGED, CONTAINS BRAKE FLUID AT

HIGH PRESSURE. BEFORE DISCONNECTING ANY

HYDRAULIC TUBE, HOSE OR FITTING. BE SURE

THAT THE ACCUMULATOR IS FULLY DE-PRES-

SURIZED AS DESCRIBED IN THIS SECTION. FAIL-

URE TO DE-PRESSURIZE THE ACCUMULATOR

MAY RESULT IN PERSONAL INJURY AND/OR DAM-

AGE TO PAINTED SURFACES.

CAUTION: Certain components of the Anti-Lock

Brake System (ABS) are not intended to be serviced

individually. Attempting to remove or disconnect

certain system components, may result in personal

injury and/or improper system operation. Only

those components with approved removal, service

and installation procedures described in this man-

ual should be serviced.

GENERAL INFORMATION

This section contains information necessary to di-

agnosis mechanical conditions that can affect opera-

tion of the Bendix Anti-Lock 10 Brake System.

Specifically, this section should be used to help diag-

nose mechanical conditions that result in any of the

following:

CAUTION: Review this entire section before per-

forming any mechanical work on a vehicle equipped

with the Bendix Anti-Lock 10 brake system. For in-

formation on precautions pertaining to potential

component damage, vehicle damage and personal

injury.

(1) Anti-Lock warning lamp illuminated

(2) BRAKE warning lamp on

(3) Lack of Power Assist or Excessive Pedal Travel

(4) Brakes Lock on Hard Application

Diagnosis of conditions that are obviously mechan-

ical in nature. Such as brake noise, brake pulsation,

or vehicle vibration during normal braking. Should

be directed to Group 5 Brakes in the service manual.

This also pertains to problems involving the parking

brake system.

Fig. 13 Hold Pressure - Hydraulic Control

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 87

Page 238 of 2438

In order to effectively diagnose an Anti-Lock Brake

System (ABS) condition. It is important to read Sec-

tion 1 of this manual, Anti-Lock Brake System De-

scription. This section will give you information on

the function of the ABS components. Then follow the

diagnostic procedures outlined in this section. Many conditions that generate customer com-

plaints of the ABS system may be normal operating

conditions. These conditions though are judged to be

a problem due to unfamiliarity with the ABS system.

These conditions can be recognized without perform-

ing extensive diagnostic work, given adequate under-

standing of operating principles and performance

characteristics of the ABS system. See Section 1 of

this manual to familiarize yourself with the operat-

ing principles of the ABS system.

DEFINITIONS

Several abbreviations are used in this manual.

They are presented here for reference.

² CABÐController Anti-Lock Brake

² ABSÐAnti-Lock Brake System

² PSIÐPounds per Square Inch (pressure)

² WSSÐWheel Speed Sensor

ABS CONTROLLER ANTI-LOCK BRAKE (CAB) SER-

VICE PRECAUTIONS

The ABS system uses an electronic control module,

the (CAB). This module is designed to withstand nor-

mal current draws associated with vehicle operation.

However care must be taken to avoid overloading the

(CAB) circuits. In testing for open or short circuits, do

not ground or apply voltage to any of the circuits unless

instructed to do so by the appropriate diagnostic pro-

cedure. These circuits should only be tested using a

high impedance multi-meter, special tools or the DRB

II tester as described in this section. Power should

never be removed or applied to any control module with

the ignition in the ON position. Before removing or

connecting battery cables, fuses, or connectors, always

turn the ignition to the OFF position.

ABS SYSTEM GENERAL SERVICE PRECAUTIONS

TEST DRIVING ABS COMPLAINT VEHICLES

Most ABS complaints will require a test drive as a

part of the diagnostic procedure. The purpose of the

test drive is to duplicate the condition. Before test driving a brake complaint vehicle,

especially if the Red Brake Warning Lamp is on.

Test the brake function at low speed to be sure

that the car will stop normally. Remember that

conditions that result in illumination of the Red

Fig. 14 Decay Pressure - Hydraulic Control

5 - 88 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 239 of 2438

Brake Warning Lamp may indicate reduced

braking ability. The following procedure should

be used to test drive an ABS complaint:(1) Ignition on. Turn the ignition to the ON position

without starting the car and wait until the Red Brake

Warning Lamp and Amber Anti-Lock Warning Lamp

turn off. This will allow the pump to charge the

accumulator to operating pressure. If the warning

lamp(s) do not turn off, go to step 3. (2) Ignition off for 15 seconds.

(3) Start car. Wait for displays to return to normal

operating mode before proceeding. (4) With Shift lever in PARK, slowly depress brake

pedal and release. (5) Drive vehicle a short distance. During this test

drive, be sure that the vehicle achieves at least 20 mph.

Then brake to at least one complete stop and accelerate

slowly back up to at least 20 mph. (6) If a functional problem with the A.B.S. system is

determined while test driving a vehicle. Refer to the

Bendix Anti-Lock 10 Diagnostics Manual for required

test procedures and proper use of the DRB II tester.

CAUTION: The following are general precautions that

should be observed when servicing and diagnosing

the ABS system and/or other vehicle systems. Failure

to observe these precautions may result in ABS

system damage.

(1) If welding work is to be performed on the vehicle

using an arc welder, the (CAB) should be disconnected

before the welding operation begins. (2) The (CAB) and hydraulic assembly 10 way con-

nectors should never be connected or disconnected with

the ignition on. (3) Some components of the ABS system are not

serviced separately and must be serviced as complete

assemblies. Do not disassemble any component which

is designated as non-serviceable. (4) Always de-pressurize the Hydraulic Accu-

mulator when performing any work that re-

quires disconnecting any hydraulic tube, flex

hose or fitting. The ABS system uses brake fluid

at high pressure. Failure to de-pressurize the

accumulator may result in personal injury

and/or damage to painted surfaces. Brake fluid will damage painted surfaces. If brake

fluid is spilled on any painted surfaces, wash off with

water immediately.

DE-PRESSURIZING HYDRAULIC ACCUMULA- TOR

The ABS pump/motor assembly keeps the hydraulic

accumulator charged between approximately 11,032

and 13,790 kPa (1600 and 2000 psi) anytime key is in the ON position. The pump/motor assembly

cannot run if the ignition is off or either battery ca-

ble is disconnected. Unless otherwise specified, the hydraulic accumu-

lator should be de-pressurized before disassembling

any portion of the hydraulic system. The following

procedure should be used to de-pressurize the hy-

draulic accumulator: (1) With ignition off, or either battery cable discon-

nected, pump the brake pedal a minimum of 40 times

using approximately 50 pounds of pedal force. A no-

ticeable change in pedal feel will occur when the ac-

cumulator becomes discharged. (2) When a definite increase in pedal effort is felt,

pump the pedal a few additional times. This will in-

sure removal of all hydraulic pressure from the

brake system.

WHEEL SPEED SENSOR CABLES

Proper installation of wheel speed sensor cables is

critical to continued ABS system operation. Be sure

that cables are installed and routed properly. Failure

to install cables in their retainers, as shown in Sec-

tion 3 of this manual. May result in contact with

moving parts or over extension of cables, resulting in

an open circuit.

MECHANICAL DIAGNOSTICS AND SERVICE

PROCEDURES

SPECIAL SERVICE TOOLS

Some diagnostic procedures in this section require

the use of special service tools. Each of these tools is

described below.

DRB II DIAGNOSTIC TESTER

Some of the diagnostic procedures that are ex-

plained in this section require the use of the DRB II

DIAGNOSTICS TESTER to insure that proper diag-

nostics are performed. Refer to those sections for

proper testing procedures and the DRB II manual for

its proper operational information.

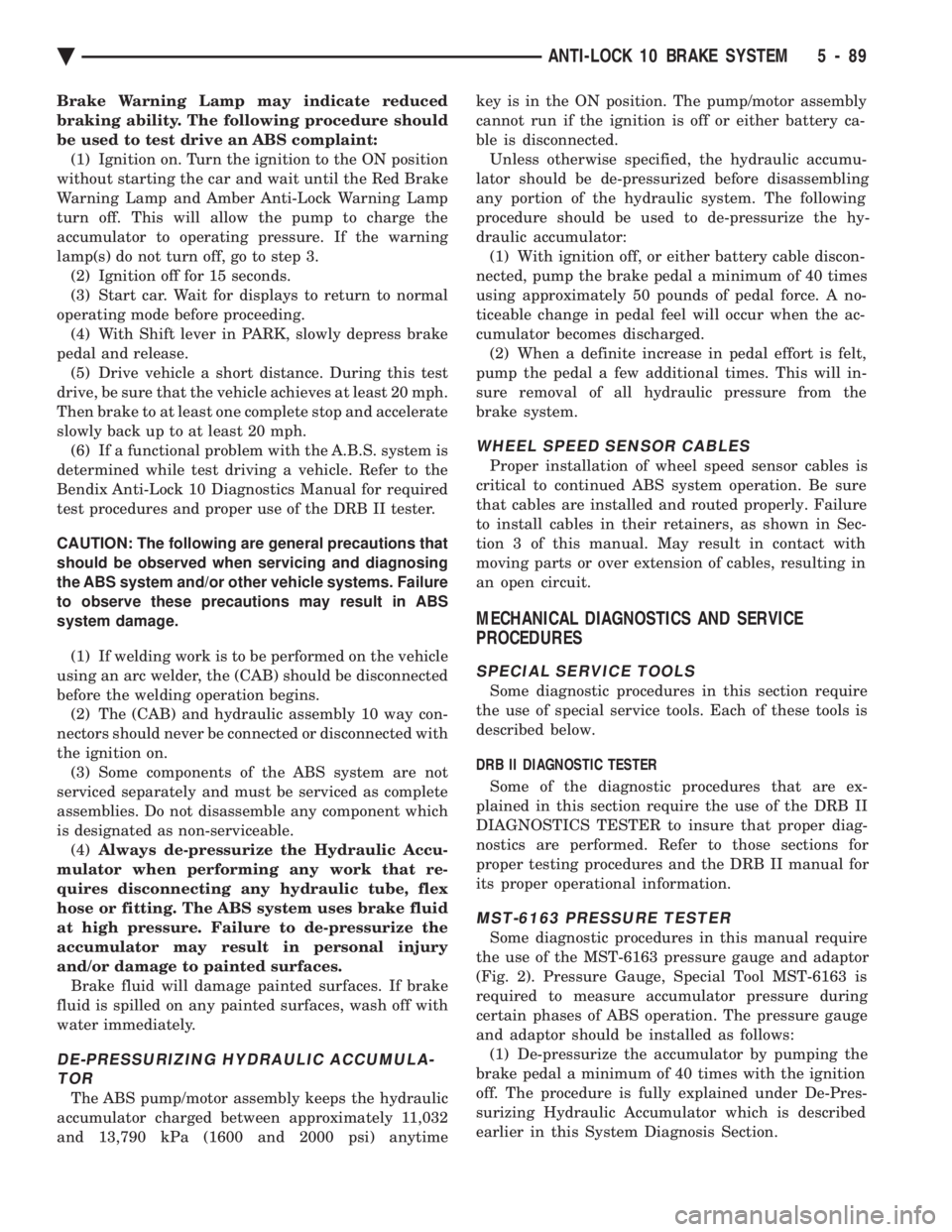

MST-6163 PRESSURE TESTER

Some diagnostic procedures in this manual require

the use of the MST-6163 pressure gauge and adaptor

(Fig. 2). Pressure Gauge, Special Tool MST-6163 is

required to measure accumulator pressure during

certain phases of ABS operation. The pressure gauge

and adaptor should be installed as follows: (1) De-pressurize the accumulator by pumping the

brake pedal a minimum of 40 times with the ignition

off. The procedure is fully explained under De-Pres-

surizing Hydraulic Accumulator which is described

earlier in this System Diagnosis Section.

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 89

Page 240 of 2438

WARNING: FAILURE TO DE-PRESSURIZE THE AC-

CUMULATOR PRIOR TO PERFORMING THIS OPER-

ATION MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES. (2) Remove hydraulic assembly accumulator port

plug,located on right hand side of hydraulic assembly

(Fig. 1).

(3) Install pressure gauge to hydraulic assembly

adaptor into accumulator port of hydraulic assembly

(Fig. 2). Then torque adaptor to 10 N Im (7.5 ft. lbs.).

(4) Install adaptor onto the pressure gauge hose

(Fig. 2) and tighten the fitting to 15 N Im (11 ft. lbs.)

torque. (5) Install pressure gauge and hose adaptor assem-

bly onto the adaptor installed in the hydraulic as-

sembly accumulator port. Then install the retaining

clip into the grove on the accumulator port adaptor

(Fig. 2). MAKE SURE THAT THE RETAINING

CLIP IS INSTALLED ON THE ACCUMULATOR

PORT ADAPTOR BEFORE RE-PRESSURIZING

THE HYDRAULIC SYSTEM.

WARNING: BEFORE REMOVING PRESSURE

GAUGE AND ADAPTOR, BE SURE TO DE-PRES-

SURIZE THE HYDRAULIC ASSEMBLY. THEN IN-

STALL AND TIGHTEN ACCUMULATOR PORT PLUG

TO 12 N IM (9 FT. LBS.).

It is not necessary to bleed the hydraulic assembly

or brake system after installation and removal of the

pressure gauge. Unless additional tubes, hoses, or fit-

tings were removed or loosened.

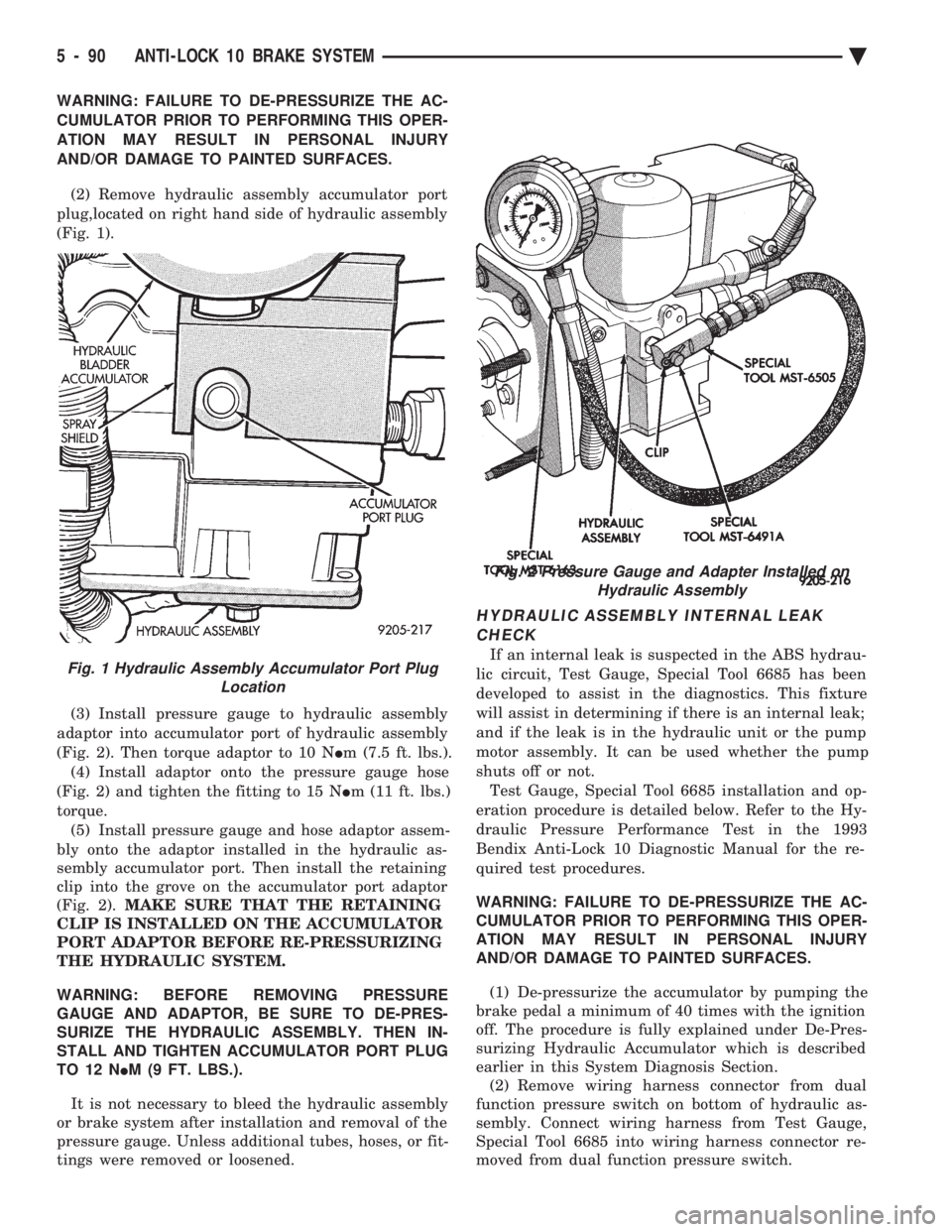

HYDRAULIC ASSEMBLY INTERNAL LEAK

CHECK

If an internal leak is suspected in the ABS hydrau-

lic circuit, Test Gauge, Special Tool 6685 has been

developed to assist in the diagnostics. This fixture

will assist in determining if there is an internal leak;

and if the leak is in the hydraulic unit or the pump

motor assembly. It can be used whether the pump

shuts off or not. Test Gauge, Special Tool 6685 installation and op-

eration procedure is detailed below. Refer to the Hy-

draulic Pressure Performance Test in the 1993

Bendix Anti-Lock 10 Diagnostic Manual for the re-

quired test procedures.

WARNING: FAILURE TO DE-PRESSURIZE THE AC-

CUMULATOR PRIOR TO PERFORMING THIS OPER-

ATION MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(1) De-pressurize the accumulator by pumping the

brake pedal a minimum of 40 times with the ignition

off. The procedure is fully explained under De-Pres-

surizing Hydraulic Accumulator which is described

earlier in this System Diagnosis Section. (2) Remove wiring harness connector from dual

function pressure switch on bottom of hydraulic as-

sembly. Connect wiring harness from Test Gauge,

Special Tool 6685 into wiring harness connector re-

moved from dual function pressure switch.Fig. 1 Hydraulic Assembly Accumulator Port Plug Location

Fig. 2 Pressure Gauge and Adapter Installed onHydraulic Assembly

5 - 90 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 242 of 2438

(11) Remove all special tools previously installed,

from the ABS hydraulic assembly. (12) Install accumulator port plug into hydraulic

assembly. Torque accumulator port plug to 12 N Im(9

ft. lbs.). (13) Install high pressure brake hose from the

pump motor assembly into hydraulic fitting on ABS

hydraulic assembly. Torque high pressure brake hose

tube nut to 16 N Im (145 in. lbs.).

(14) Turn ignition switch to the run position to en-

ergize the pump/motor assembly and pressurize hy-

draulic system. Check for leakage at the hydraulic

assembly to hydraulic bladder accumulator fitting. (15) Again de-pressurize accumulator by pumping

brake pedal a minimum of 40 times. Use procedure

described in De-Pressurizing Hydraulic Accumulator

in this section of the service manual. (16) Then check the brake fluid level in the hy-

draulic assembly reservoir. If brake fluid level is low,

fill reservoir to proper level with Mopar tbrake fluid

or equivalent conforming to DOT 3 requirements.

INTERMITTENT FAULTS

As with almost any electronic system, intermittent

faults in the ABS system may be difficult to accu-

rately diagnose. Most intermittent faults are caused by faulty elec-

trical connections or wiring. When an intermittent

fault is encountered, check suspect circuits for: (1) Poor mating of electrical connector halves, or

electrical terminals not fully seated in the connector

body. (2) Improperly formed or damaged electrical termi-

nals. All connector terminals in a suspect circuit

should be carefully reformed to increase contact ten-

sion. (3) Poor terminal to wire connection. This requires

removing the terminal from the connector body and

inspecting for proper terminal to wire connection. If a visual check does not find the cause of the

problem, operate the vehicle in an attempt to dupli-

cate the condition and record the Fault Code. Most failures of the ABS system will disable the

Anti-Lock function for the entire ignition cycle even

if the fault clears before ignition key-off. There are

some failure conditions however, which will allow

ABS operation to resume during the ignition cycle in

which a failure occurred. If the failure conditions are

no longer present. The following conditions may result in intermittent

illumination of the Red Brake Warning Lamp and/or

Amber Anti-Lock Warning Lamp. All other failures

will cause the lamp(s) to remain on until the ignition

switch is turned off. Circuits and or components in-

volving these inputs to the (CAB) should be investi-

gated if a complaint of intermittent warning system

operation is encountered. ²

Low system voltage. If low system voltage is de-

tected by the (CAB), the (CAB) will turn on the Am-

ber Anti-Lock Warning Lamp until normal system

voltage is achieved. Once normal voltage is seen at

the (CAB), normal operation resumes.

² Low Brake Fluid. A low brake fluid condition will

cause the Red Brake Warning Lamp to illuminate.

When the fluid sensor again indicates an acceptable

fluid level, the Red Brake Warning Lamp will go out.

This condition may exist during hard cornering or

while the vehicle is on a grade. If the vehicle is in

motion above 3 M.P.H. the Amber Anti-Lock Warn-

ing Lamp will also be turned on.

² Low Accumulator Pressure. Low Accumulator

Pressure will cause both the Red Brake Warning and

Amber Anti-Lock Warning Lamps to illuminate.

Once normal operating pressure is achieved, the

lamps will extinguish and the system will return to

normal operation. Additionally, any condition that results in an inter-

ruption of power to the (CAB) or hydraulic assembly.

May cause the Red Brake Warning and Amber Anti-

Lock Warning Lamps to illuminate intermittently. All the conditions (or faults) mentioned above, can

store a fault code in the (CAB) module.

ABS BRAKE SYSTEM DIAGNOSTIC FEATURES

SYSTEM SELF DIAGNOSIS

The ABS system is equipped with a diagnostic ca-

pability that may be used to assist in isolation of

ABS faults. The features of the diagnostics system

are described below.

CONTROLLER ANTI-LOCK BRAKE (CAB)

Fault codes are kept in a Non-Volatile memory un-

til either erased by the technician using the DRB II

or erased automatically after 50 ignition cycles (key

ON-OFF cycles). The only fault that will not be

erased after 50 (KEY CYCLES) is the (CAB) fault.

The (CAB) fault can only be erased by using the

DRB II diagnostic tester. More than one fault can be

stored at a time. The number of key cycles since the

most recent fault was stored is also displayed. Most

functions of the (CAB) and (ABS) system can be ac-

cessed by the technician for testing and diagnostic

purposes by using the DRB II Diagnostic Tester.

START-UP CYCLE

The START-UP CYCLE takes place immediately

after the ignition switch is turned on. It is an elec-

trical check of basic electrical functions such as the

System Relay and Anti-Lock Warning Lamp Relay.

During this check, the Amber Anti-Lock Warning

Lamp is turned on, then turned off at the end of the

test. The test takes approximatel y1-2seconds to

complete.

5 - 92 ANTI-LOCK 10 BRAKE SYSTEM Ä

Page 243 of 2438

DRIVE-OFF CYCLE

The DRIVE-OFF CYCLE takes place when the ve-

hicle reaches about 3 miles per hour the first time af-

ter an ignition reset. During this test, the modulator

solenoid valves are activated briefly to test their

function. The DRIVE-OFF CYCLE will be bypassed

if you drive-off with the service brake pedal de-

pressed.

LATCHING VERSUS NON-LATCHING FAULTS

Some faults detected by the (CAB) are latching.

The fault is latched and (ABS) function is disabled

until the ignition switch is reset (turned OFF/ON).

Thus (ABS) function is disabled even if the original

fault has disappeared during the ignition cycle in

which it occurred. Other faults are non-latching; any

warning lights that are turned on are only on as long

as the fault condition exists. As soon as the condition

goes away. The Amber Anti-Lock Warning Light is

turned off. Although a fault code will be set in most

cases. (Example:low accumulator fault will not be

stored for a time of 2 minutes after the fault is de-

tected).

BENDIX ABS SYSTEMS DIAGNOSTICS

The Bendix Anti-Lock 10 Brake System diagnos-

tics. Beyond the basic mechanical diagnostics, sys-

tems and components covered earlier in this section,

is accomplished by using the DRB II diagnostic

tester. See testing procedures outlined in the Bendix

Anti-Lock 10 Diagnostics Manual for the 1993 M.Y. Please reference the above mentioned manual. For

any further diagnostic service procedures that are re-

quired on the Bendix Anti-Lock 10 Brake System, re-

quiring the use of the DRB II diagnostic tester.

ON CAR HYDRAULIC ABS COMPONENT SERVICE

WARNING: FAILURE TO FULLY DE-PRESSURIZE

THE HYDRAULIC ACCUMULATOR BEFORE PER-

FORMING HYDRAULIC SYSTEM SERVICE OPERA-

TIONS. COULD RESULT IN INJURY TO SERVICE

PERSONNEL AND OR DAMAGE TO PAINTED SUR-

FACES. SEE SECTION 2 FOR ADDITIONAL WARN-

INGS AND CAUTIONS.

GENERAL SERVICE PRECAUTIONS

The following are general precautions that should

be observed when servicing the Anti-Lock Brake Sys-

tem and/or other vehicle systems. Failure to observe

these precautions may result in Anti-Lock brake sys-

tem damage. If welding work is to be performed on the vehicle,

using an electric arc welder, the (CAB) connector

should be disconnected during the welding operation. The (CAB) or hydraulic assembly connector should

never be connected or disconnected with the ignition

switch in the ONposition.

Many components of the Anti-Lock brake system are

not serviceable and must be replaced as an assembly.

Do not attempt to disassemble any component

that is not designed to be a serviced component.

DE-PRESSURIZING HYDRAULIC ACCUMULA- TOR

The pump/motor assembly will keep the hydraulic

accumulator charged to approximately 11,032 and

13,790 kPa (1600 and 2000 psi) any time that the

ignition is in the ON position. The pump/motor assem-

bly cannot run if the ignition is off or if either battery

cable is disconnected. Unless otherwise specified, the hydraulic accumula-

tor should be de-pressurized before disassembling any

portion of the hydraulic system. The following proce-

dure should be used to relieve the pressure in the

hydraulic accumulator: (1) With ignition off, or either battery cable discon-

nected, pump the brake pedal a minimum of 40 times,

using approximately 222 N (50 lbs.) pedal force. A

noticeable change in pedal feel will occur, when the

accumulator is discharged. (2) When a definite increase in pedal effort is felt,

pump pedal a few additional times. This will insure

removal of all hydraulic pressure from the brake sys-

tem.

CHECKING BRAKE FLUID LEVEL

CAUTION: Use only brake fluid conforming to DOT 3

specifications such as Mopar Tor Equivalent. Do not

use any fluid in the brake hydraulic system, which

contains a petroleum base. Do not use a container

which has been used for petroleum based fluids or a

container that is wet with water. Petroleum based

fluids will cause swelling and distortion of rubber

parts in the hydraulic brake system and water will mix

with brake fluid, lowering the fluid boiling point. Keep

all brake fluid containers tightly capped to prevent

contamination.

The hydraulic assembly is equipped with a plastic

fluid reservoir, with a filter/strainer located in the filler

neck of each reservoir section. The Anti-Lock brake system requires that the hy-

draulic accumulator be de-pressurized when checking

the fluid level. To check the brake fluid level, the

following procedure should be used: (1) With the ignition off, de-pressurize the hydraulic

accumulator by applying the brake pedal approxi-

mately 40 times, using a pedal force of approximately

220 N (50 lbs.). A noticeable change in pedal feel will

occur when the accumulator is de-

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 93