maintenance CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1576 of 2438

shaft end play. A sintered iron (TBI engine and steel

billet Turbo III engines) timing belt sprocket is

mounted on the cam nose, and a hydrodynamic oil

seal is used for oil control at the front of the cam-

shaft. ACCESSORY SHAFT: The iron accessory shaft

has two bearing journals and is housed in the for-

ward facing side of the block. A hydrodynamic seal,

installed in an aluminum housing attached to the

block, provides retention, shaft thrust, and oil con-

trol. The accessory shaft is driven by the timing belt

through a sintered iron (TBI engine and steel billet

Turbo III engines) sprocket mounted on the nose of

the accessory shaft. The accessory shaft in turn

drives the oil pump and distributor on 2.2/2.5L and

2.5L FFV and the oil pump only on Turbo III. VALVES: The valves are actuated by roller cam

followers which pivot on stationary hydraulic lash

adjusters. The valve train with 40.6 mm (1.60 inch)

diameter intake valves and 35.4 mm (1.39 inch) di-

ameter exhaust valves employ viton rubber valve

stem seals except 2.5L FFv . the 2.5L FFV valve

stem seals are made of special rubber compound

which resist the deteriorating effects of methanol

fuel by-products that enter the oil during combus-

tion. Valve springs, spring retainers, and locks are

conventional. For Turbo III engines the valves are

actuated by roller tipped rocker arms with hydraulic

lash adjusters which pivot on a shaft. The valve train

with 33.88 mm (1.33 in.) diameter intake valves are

arranged in line opposite of the 29.26 mm (1.15 in.)

diameter exhaust valves employ locking valve stem

seals. Valve springs, spring retainers, and locks are

not interchangeable with other engines. BALANCE SHAFTS: 2.2 Turbo III and 2.5L en-

gines are equipped with two counter rotating balance

shafts installed in a carrier attached to the lower

crankcase. The shafts are interconnect through

gears. These gears are driven by a short chain from

the crankshaft, to rotate at two times crankshaft

speed. This counterbalances certain engine recipro-

cating forces. INTAKE MANIFOLDS:

All intake manifolds are

aluminum castings, attached to the cylinder head

with eight bolts. N.A. engines use a four branch de-

sign. This long branch fan design enhances low and

midspeed torque. It also features an integrally cast

water crossover passage to warm incoming fuel/air

mixture, plus an EGR mounting boss and PCV inlet. The Turbo III engine intake manifold is a log type

with tuned runners. The manifold is machined to ac-

cept fuel injectors near the ports of each cylinder. EXHAUST MANIFOLDS: The exhaust manifolds

are made of nodular cast iron for strength and high

temperatures. All naturally aspirated (N.A.) and tur-

bocharged engines exit exhaust gasses through a ma-

chined, articulated joint connection to the exhaust

pipe. 2.2/2.5L and 2.5L FFV manifolds intermesh

with the intake manifold at the cylinder head. N.A. engines use a four branch design with cylin-

ders one and four joined and cylinder two and three

joined to exit at the outlet. The Turbo III engine exhaust manifold also carries

the turbocharger. This manifold has a modified log

type collector with exhaust gasses directed to and

through the turbocharger to exit the conical (articu-

lated joint) outlet machined into the turbocharger ex-

haust elbow. ENGINE LUBRICATION: Refer to Group 0 Lu-

brication and Maintenance for recommended oil to be

used in various engine application. System is full

flow filtration, pressure feed type. The oil pump is

mounted within the crankcase and driven by the ac-

cessory shaft. Pressurized oil is then routed through

the main oil gallery, running the length of the cylin-

der block, supplying main and rod bearings with fur-

ther routing (for 2.2L turbo III and 2.5L engines) to

the lower balance shaft assemblies. Pistons are lubri-

cated from directed holes in the connecting rod as-

semblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

9 - 10 2.2/2.5L ENGINE Ä

Page 1697 of 2438

EXHAUST SYSTEM AND INTAKE MANIFOLD

CONTENTS

page page

GENERAL INFORMATION .................. 1

SERVICE PROCEDURES ................... 4 TORQUE SPECIFICATION

................. 25

GENERAL INFORMATION

Throughout this group, references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual.

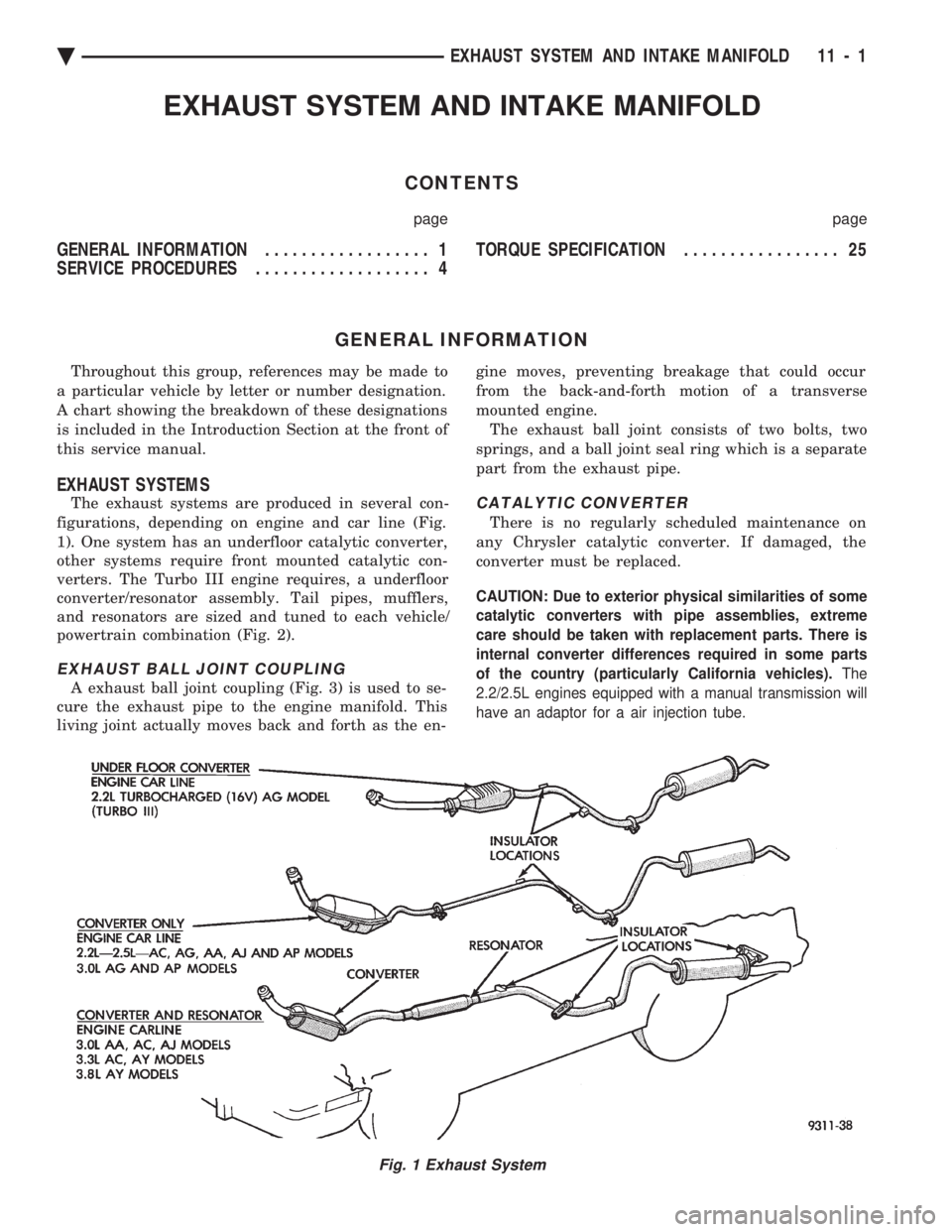

EXHAUST SYSTEMS

The exhaust systems are produced in several con-

figurations, depending on engine and car line (Fig.

1). One system has an underfloor catalytic converter,

other systems require front mounted catalytic con-

verters. The Turbo III engine requires, a underfloor

converter/resonator assembly. Tail pipes, mufflers,

and resonators are sized and tuned to each vehicle/

powertrain combination (Fig. 2).

EXHAUST BALL JOINT COUPLING

A exhaust ball joint coupling (Fig. 3) is used to se-

cure the exhaust pipe to the engine manifold. This

living joint actually moves back and forth as the en- gine moves, preventing breakage that could occur

from the back-and-forth motion of a transverse

mounted engine. The exhaust ball joint consists of two bolts, two

springs, and a ball joint seal ring which is a separate

part from the exhaust pipe.

CATALYTIC CONVERTER

There is no regularly scheduled maintenance on

any Chrysler catalytic converter. If damaged, the

converter must be replaced.

CAUTION: Due to exterior physical similarities of some

catalytic converters with pipe assemblies, extreme

care should be taken with replacement parts. There is

internal converter differences required in some parts

of the country (particularly California vehicles). The

2.2/2.5L engines equipped with a manual transmission will

have an adaptor for a air injection tube.

Fig. 1 Exhaust System

Ä EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 1

Page 1739 of 2438

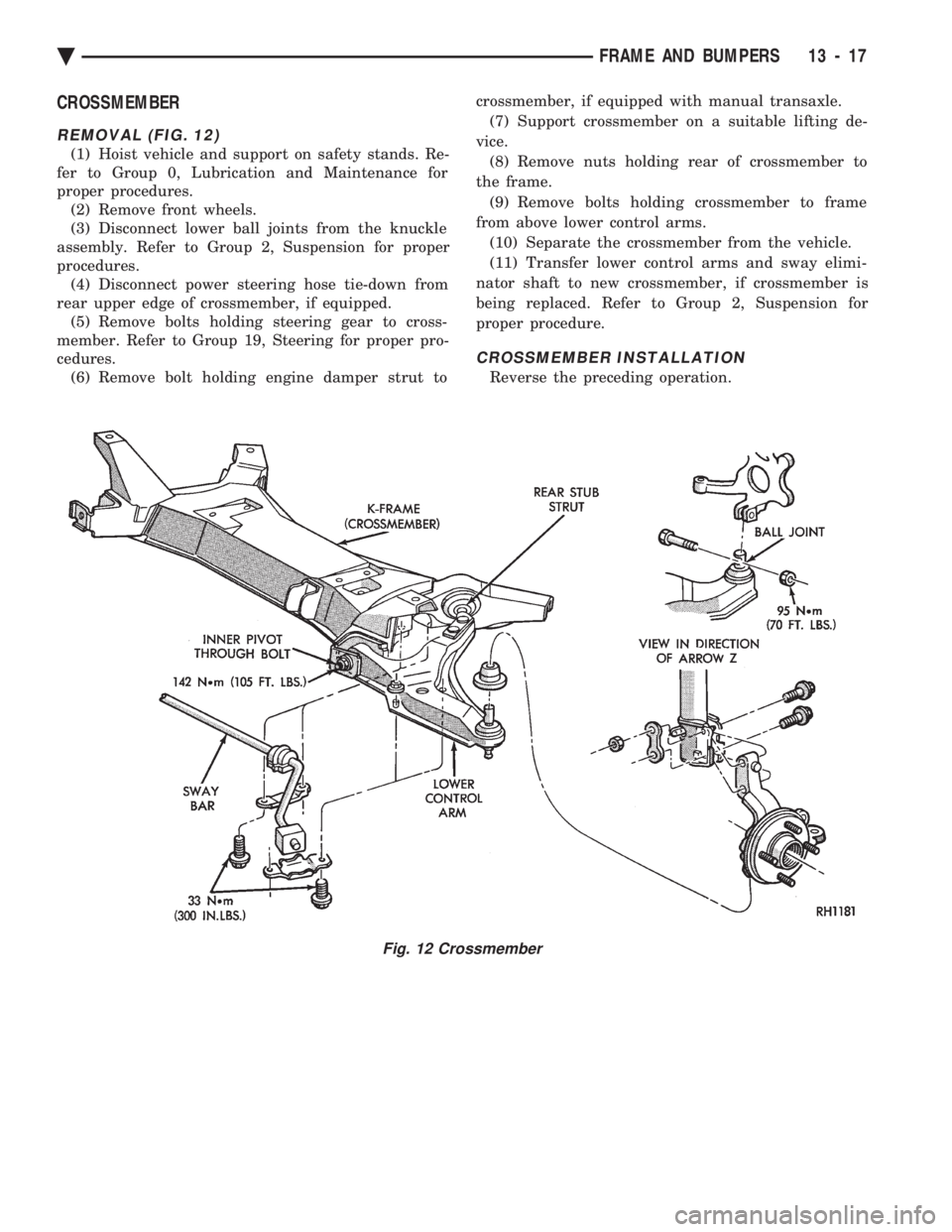

CROSSMEMBER

REMOVAL (FIG. 12)

(1) Hoist vehicle and support on safety stands. Re-

fer to Group 0, Lubrication and Maintenance for

proper procedures. (2) Remove front wheels.

(3) Disconnect lower ball joints from the knuckle

assembly. Refer to Group 2, Suspension for proper

procedures. (4) Disconnect power steering hose tie-down from

rear upper edge of crossmember, if equipped. (5) Remove bolts holding steering gear to cross-

member. Refer to Group 19, Steering for proper pro-

cedures. (6) Remove bolt holding engine damper strut to crossmember, if equipped with manual transaxle.

(7) Support crossmember on a suitable lifting de-

vice. (8) Remove nuts holding rear of crossmember to

the frame. (9) Remove bolts holding crossmember to frame

from above lower control arms. (10) Separate the crossmember from the vehicle.

(11) Transfer lower control arms and sway elimi-

nator shaft to new crossmember, if crossmember is

being replaced. Refer to Group 2, Suspension for

proper procedure.

CROSSMEMBER INSTALLATION

Reverse the preceding operation.

Fig. 12 Crossmember

Ä FRAME AND BUMPERS 13 - 17

Page 2158 of 2438

BODY DIAGNOSTIC PROCEDURES INDEX

page page

Water Leaks ............................. 2 Wind Noise.............................. 3

WATER LEAKS

Water leaks can be caused by poor sealing, improper

body component alignment, body seam porosity, miss-

ing plugs, or blocked drain holes. Centrifugal and

gravitational force can cause water to drip from an

area somewhat distant from the actual leak point,

making leak detection difficult. All body sealing points

should be water tight in normal wet driving conditions.

Water flowing downward from the front of the vehicle

should not enter the passenger or luggage compart-

ment. Moving sealing surfaces will not always seal

water tight under all conditions. At times, side glass,

door, or convertible top seals will allow water to enter

the passenger compartment during high pressure

washing or hard driving rain (severe) conditions. Over

compensating on door, glass, or top adjustments to stop

a water leak that occurs under severe conditions, can

cause premature seal wear and excessive closing or

latching effort. After a repair procedure has been

performed, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear and body components are aligned and

sealed. If component alignment or sealing is necessary,

refer to the appropriate section of this group for proper

procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA, PERSONAL IN-

JURY CAN RESULT.

When a determination has been made on the condi-

tions that a water leak occurs, simulate the conditions

as closely as possible.

² If a leak occurs when the car is parked in a steady

light rain, flood the leak area with a open ended garden

hose.

² If a leak occurs at highway speeds in a steady rain,

test the leak area with a stream or fan spray of water

from a garden hose with an adjustable nozzle. Direct

the spray in the direction comparable to actual condi-

tions. ²

If a leak seems to occur only when the vehicle is

parked on an incline, hoist the end or side of the vehicle

to simulate this condition before water testing. This

method can also be used when the leak occurs when the

vehicle accelerates, stops, or turns. If the leak occurs

on acceleration, hoist the front of the vehicle. If the

leak occurs when braking, hoist the back of the vehicle.

If the leak occurs on left turns, hoist the left side of the

vehicle. If the leak occurs on right turns, hoist the right

side of the vehicle. For hoisting recommendations refer

to Group 0, Lubrication and Maintenance, General

Information section.

WATER LEAK DETECTION

To detect a water leak point of entry, perform a water

test and watch for water tracks or droplets forming on

the inside if the vehicle. If necessary remove interior

trim covers or panels to gain visual access to the leak

area. If the hose can not be positioned without being

held, have someone help perform the water test. Some water leaks must be tested for a considerable

length of time to become apparent. When a leak ap-

pears, determine the highest point of the water track or

drop. The highest point usually will indicate the point

of entry. After leak point has been determined, repair

the leak and water test to verify that leak has stopped. Locating the entry point of water that is leaking into

a cavity between panels can be difficult. The trapped

water splashes or runs from the cavity it is dammed up

in, often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on a incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use a

suitable mirror to gain visual access. A mirror can also

be used to deflect light to a limited access area to assist

in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can be

detected without water testing. Position the vehicle in

a brightly light area. From inside the darkened lug-

gage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the lug-

23 - 2 BODY Ä

Page 2401 of 2438

EVAPORATION CONTROL SYSTEM

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When fuel

evaporates in the fuel tank, the vapors pass through

vent hoses or tubes to a charcoal canister. The canister

temporarily holds the vapors. The powertrain control

module (PCM) allows intake manifold vacuum to draw

vapors into the combustion chambers during certain

operating conditions. The PCM uses the canister purge

solenoid to regulate vapor flow. On 2.2L and 2.5L TBI, 3.3L, and 3.8L engines,

manifold vacuum purges the vapors at idle as well as

off idle. These engines use a bi-level purge system. The

system uses 2 sources of vacuum remove fuel vapors

from the canister. Turbo III engines use a tri-level canister purge sys-

tem. In this system, fuel vapors are drawn into the

engine through the throttle body and air cleaner. Fuel

vapors are drawn in at closed throttle, part throttle,

and wide open throttle (in boost). The 2.5L MPI (flexible fuel AA-Body) and 3.0L have

a duty cycle purge system. The powertrain control

module PCM controls vapor flow by operating the duty

cycle EVAP purge solenoid. Refer to Duty Cycle EVAP

Purge Solenoid in this section. The evaporative system uses specially manu-

factured hoses. If they need replacement, only

use fuel resistant hose.

PRESSURE RELIEF/ROLLOVER VALVE

All vehicles have a combination pressure relief and

rollover valve. The dual function valve relieves fuel

tank pressure. The valve also prevents fuel flow

through the fuel tank vent valve hoses if the vehicle

accidentally rolls over. All vehicles pass a 360É rollover. The pressure relief valve opens at a certain pressure.

When fuel tank pressure increases above the cali-

brated pressure, the valve opens to release fuel tank

vapors pressure. The evaporative (charcoal) canister

stores the vapors. For pressure relief/rollover valve

service, refer to the Fuel Tank section of Group 14.

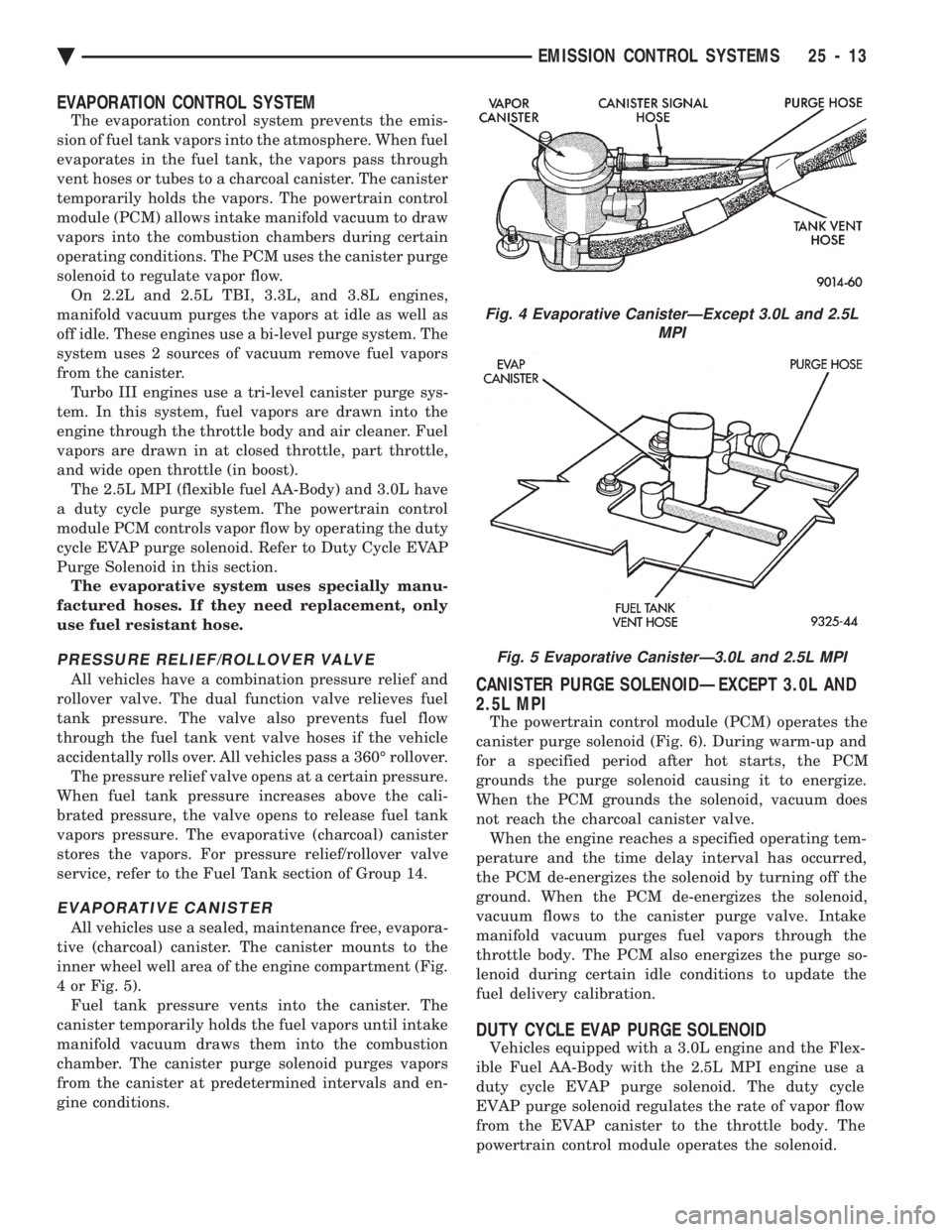

EVAPORATIVE CANISTER

All vehicles use a sealed, maintenance free, evapora-

tive (charcoal) canister. The canister mounts to the

inner wheel well area of the engine compartment (Fig.

4 or Fig. 5). Fuel tank pressure vents into the canister. The

canister temporarily holds the fuel vapors until intake

manifold vacuum draws them into the combustion

chamber. The canister purge solenoid purges vapors

from the canister at predetermined intervals and en-

gine conditions.

CANISTER PURGE SOLENOIDÐEXCEPT 3.0L AND

2.5L MPI

The powertrain control module (PCM) operates the

canister purge solenoid (Fig. 6). During warm-up and

for a specified period after hot starts, the PCM

grounds the purge solenoid causing it to energize.

When the PCM grounds the solenoid, vacuum does

not reach the charcoal canister valve. When the engine reaches a specified operating tem-

perature and the time delay interval has occurred,

the PCM de-energizes the solenoid by turning off the

ground. When the PCM de-energizes the solenoid,

vacuum flows to the canister purge valve. Intake

manifold vacuum purges fuel vapors through the

throttle body. The PCM also energizes the purge so-

lenoid during certain idle conditions to update the

fuel delivery calibration.

DUTY CYCLE EVAP PURGE SOLENOID

Vehicles equipped with a 3.0L engine and the Flex-

ible Fuel AA-Body with the 2.5L MPI engine use a

duty cycle EVAP purge solenoid. The duty cycle

EVAP purge solenoid regulates the rate of vapor flow

from the EVAP canister to the throttle body. The

powertrain control module operates the solenoid.

Fig. 4 Evaporative CanisterÐExcept 3.0L and 2.5L MPI

Fig. 5 Evaporative CanisterÐ3.0L and 2.5L MPI

Ä EMISSION CONTROL SYSTEMS 25 - 13

Page 2421 of 2438

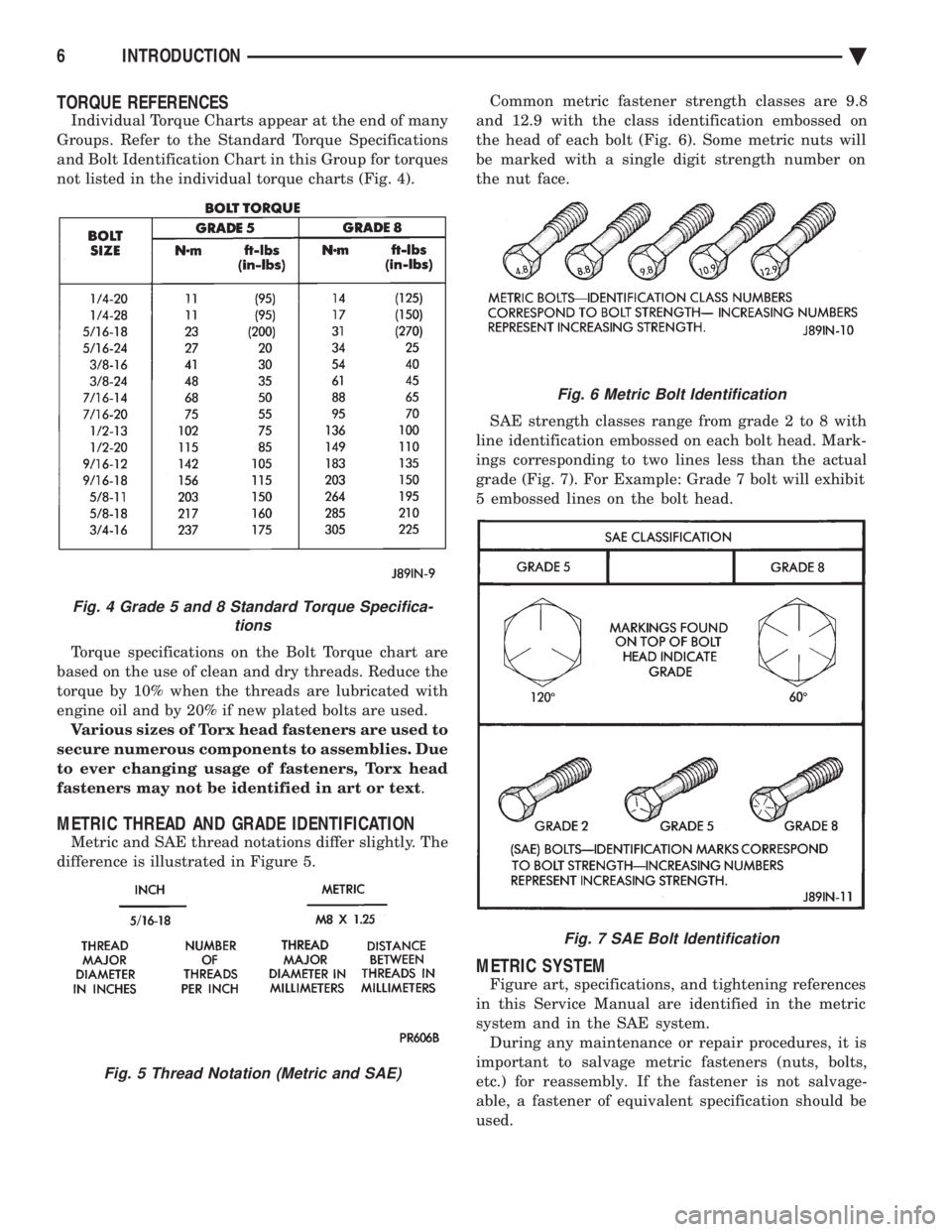

TORQUE REFERENCES

Individual Torque Charts appear at the end of many

Groups. Refer to the Standard Torque Specifications

and Bolt Identification Chart in this Group for torques

not listed in the individual torque charts (Fig. 4).

Torque specifications on the Bolt Torque chart are

based on the use of clean and dry threads. Reduce the

torque by 10% when the threads are lubricated with

engine oil and by 20% if new plated bolts are used. Various sizes of Torx head fasteners are used to

secure numerous components to assemblies. Due

to ever changing usage of fasteners, Torx head

fasteners may not be identified in art or text .

METRIC THREAD AND GRADE IDENTIFICATION

Metric and SAE thread notations differ slightly. The

difference is illustrated in Figure 5. Common metric fastener strength classes are 9.8

and 12.9 with the class identification embossed on

the head of each bolt (Fig. 6). Some metric nuts will

be marked with a single digit strength number on

the nut face.

SAE strength classes range from grade 2 to 8 with

line identification embossed on each bolt head. Mark-

ings corresponding to two lines less than the actual

grade (Fig. 7). For Example: Grade 7 bolt will exhibit

5 embossed lines on the bolt head.

METRIC SYSTEM

Figure art, specifications, and tightening references

in this Service Manual are identified in the metric

system and in the SAE system. During any maintenance or repair procedures, it is

important to salvage metric fasteners (nuts, bolts,

etc.) for reassembly. If the fastener is not salvage-

able, a fastener of equivalent specification should be

used.

Fig. 6 Metric Bolt Identification

Fig. 7 SAE Bolt Identification

Fig. 4 Grade 5 and 8 Standard Torque Specifica- tions

Fig. 5 Thread Notation (Metric and SAE)

6 INTRODUCTION Ä