battery replacement CHEVROLET DYNASTY 1993 Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1751 of 2438

fuel tube enters the fitting, the retainer locks the shoul-

der of the nipple in place and the O-rings seal the tube.

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

When installing fuel tubes, route them in the holders

along the frame rail, fuel tank and the rear of the en-

gine.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from the battery.

(2) Perform the Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section. (3) Remove any loose dirt from quick connect fit-

tings.

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY FUEL SPILLAGE.

(4) Push the quick connect fitting toward the fuel

tube while depressing the built-in release tool. Then

slightly twist the fitting and pull it off the fuel tube

(Fig. 14). (5) Cover the fitting to prevent contamination.

TUBE/FITTING SERVICE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

If a quick connect fitting needs service, the follow-

ing procedure must be followed: (1) Disconnect the battery negative battery cable.

(2) Perform the Fuel System Pressure Release Pro-

cedure.

WARNING: WRAP SHOP TOWELS AROUND HOSES

TO CATCH ANY FUEL SPILLAGE. (3) Remove the quick connect fitting from the fuel

tube by pushing in on the plastic ring located on the

end of the fitting. Gently pull the fitting from the

fuel tube. (4) Cut off the crimp ferrules at each end of the

hose, taking care not to damage the quick connect

fitting or the fuel tube. (5) Discard the ferrules and hose.

WARNING: FUEL SYSTEM HOSES AND TUBES DE-

SIGNED FOR GASOLINE ONLY VEHICLES CANNOT

BE USED ON FLEXIBLE FUEL VEHICLES. WHEN

SERVICING THE FUEL SYSTEM OF A FLEXIBLE

FUEL VEHICLE, ONLY USE ORIGINAL EQUIPMENT

OR EQUIVALENT REPLACEMENT COMPONENTS.

(6) Replace the hose using original equipment or

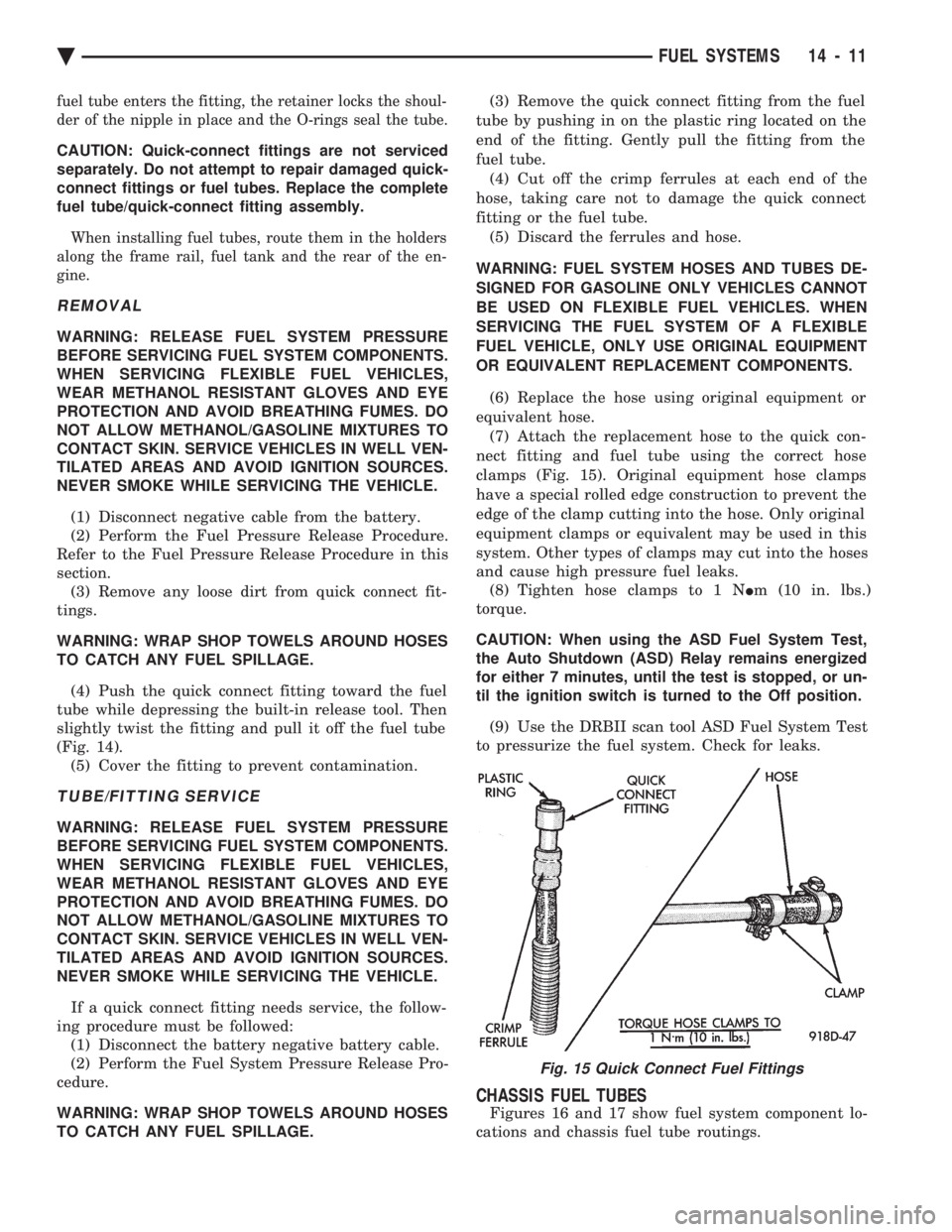

equivalent hose. (7) Attach the replacement hose to the quick con-

nect fitting and fuel tube using the correct hose

clamps (Fig. 15). Original equipment hose clamps

have a special rolled edge construction to prevent the

edge of the clamp cutting into the hose. Only original

equipment clamps or equivalent may be used in this

system. Other types of clamps may cut into the hoses

and cause high pressure fuel leaks. (8) Tighten hose clamps to 1 N Im (10 in. lbs.)

torque.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(9) Use the DRBII scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

CHASSIS FUEL TUBES

Figures 16 and 17 show fuel system component lo-

cations and chassis fuel tube routings.

Fig. 15 Quick Connect Fuel Fittings

Ä FUEL SYSTEMS 14 - 11

Page 1755 of 2438

WARNING: FUEL FILLER TUBE CAPS DESIGNED

FOR GASOLINE ONLY VEHICLES CANNOT BE

USED ON FLEXIBLE FUEL AA-BODY VEHICLES.

WHEN SERVICING THE FUEL SYSTEM OF A FLEX-

IBLE FUEL VEHICLE, ONLY USE ORIGINAL EQUIP-

MENT OR EQUIVALENT REPLACEMENT

COMPONENTS.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐEXCEPT 2.2L/2.5L TBI AND 3.0L

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

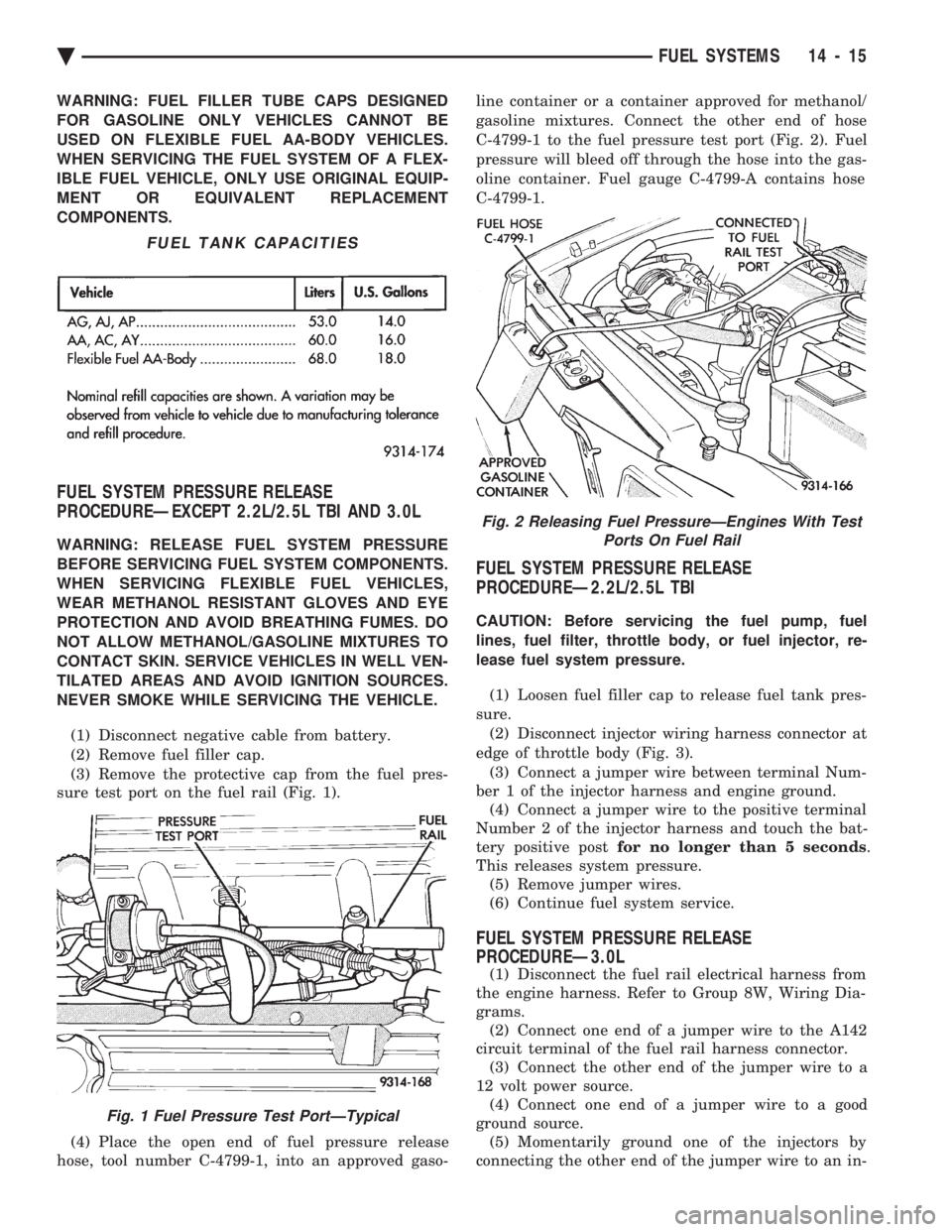

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 1).

(4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso- line container or a container approved for methanol/

gasoline mixtures. Connect the other end of hose

C-4799-1 to the fuel pressure test port (Fig. 2). Fuel

pressure will bleed off through the hose into the gas-

oline container. Fuel gauge C-4799-A contains hose

C-4799-1.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.2L/2.5L TBI

CAUTION: Before servicing the fuel pump, fuel

lines, fuel filter, throttle body, or fuel injector, re-

lease fuel system pressure.

(1) Loosen fuel filler cap to release fuel tank pres-

sure. (2) Disconnect injector wiring harness connector at

edge of throttle body (Fig. 3). (3) Connect a jumper wire between terminal Num-

ber 1 of the injector harness and engine ground. (4) Connect a jumper wire to the positive terminal

Number 2 of the injector harness and touch the bat-

tery positive post for no longer than 5 seconds .

This releases system pressure. (5) Remove jumper wires.

(6) Continue fuel system service.

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ3.0L

(1) Disconnect the fuel rail electrical harness from

the engine harness. Refer to Group 8W, Wiring Dia-

grams. (2) Connect one end of a jumper wire to the A142

circuit terminal of the fuel rail harness connector. (3) Connect the other end of the jumper wire to a

12 volt power source. (4) Connect one end of a jumper wire to a good

ground source. (5) Momentarily ground one of the injectors by

connecting the other end of the jumper wire to an in-

FUEL TANK CAPACITIES

Fig. 1 Fuel Pressure Test PortÐTypical

Fig. 2 Releasing Fuel PressureÐEngines With Test Ports On Fuel Rail

Ä FUEL SYSTEMS 14 - 15

Page 1758 of 2438

INSTALLATION

WARNING: FUEL TANKS DESIGNED FOR GASO-

LINE ONLY VEHICLES CANNOT BE USED ON

FLEXIBLE FUEL AA-BODY VEHICLES. WHEN SER-

VICING THE FUEL SYSTEM OF A FLEXIBLE FUEL

VEHICLE, ONLY USE ORIGINAL EQUIPMENT OR

EQUIVALENT REPLACEMENT COMPONENTS. (1) Position fuel tank on transmission jack. Con-

nect vapor separator/rollover valve hose and position

insulator pad on fuel tank. Position vapor vent so

that it is not pinched between tank and floor pan

during installation. (2) Raise tank and fuel filler tube carefully into

position. Use a light coating of power steering fluid

to ease fuel filler tube installation. Ensure filler tube

grommet is not damaged. Verify that the tube is in-

stalled correctly. (3) Tighten fuel tank strap nuts to 23 N Im (250 in.

lbs.) torque. Remove transmission jack. Ensure

straps are not twisted or bent. (4) Lubricate the metal tubes on the fuel pump

with clean 30 weight engine oil. Install the quick

connect fuel fittings. Refer to Quick Connect Fittings

in the Fuel Delivery section of this Group. (5) Attach electrical connector to fuel pump mod-

ule and level sensor unit. (6) Lower the vehicle.

(7) Attach filler tube to filler neck opening in

quarter panel. Tighten quarter panel screws to 2

N Im (17 in. lbs.) torque.

(8) Fill fuel tank, install filler cap, and connect

battery cable.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(9) Use the DRBII scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

FUEL PUMP MODULE

Refer to the Fuel Delivery section of this group.

METHANOL CONCENTRATION SENSOR

Refer to the Fuel Delivery section of this group.

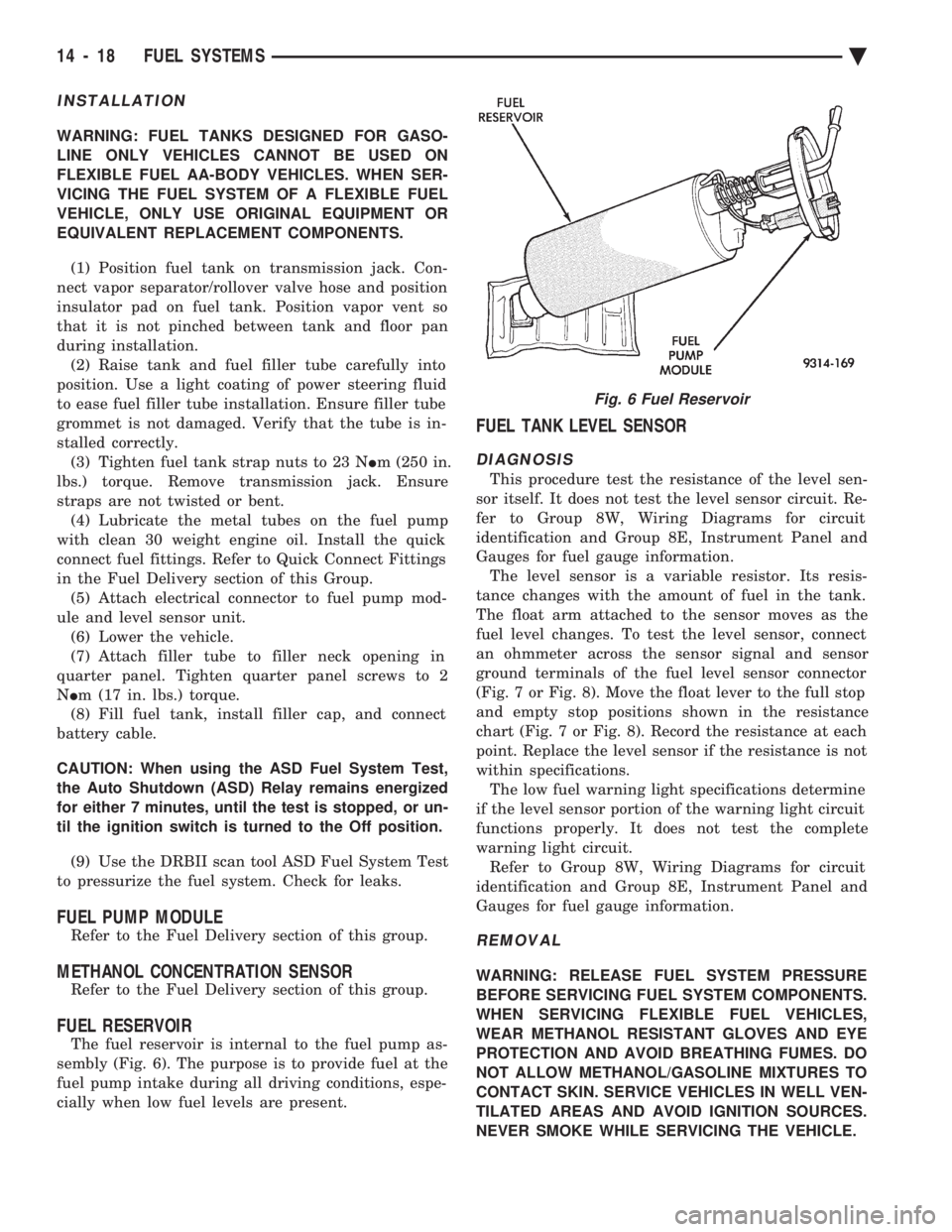

FUEL RESERVOIR

The fuel reservoir is internal to the fuel pump as-

sembly (Fig. 6). The purpose is to provide fuel at the

fuel pump intake during all driving conditions, espe-

cially when low fuel levels are present.

FUEL TANK LEVEL SENSOR

DIAGNOSIS

This procedure test the resistance of the level sen-

sor itself. It does not test the level sensor circuit. Re-

fer to Group 8W, Wiring Diagrams for circuit

identification and Group 8E, Instrument Panel and

Gauges for fuel gauge information. The level sensor is a variable resistor. Its resis-

tance changes with the amount of fuel in the tank.

The float arm attached to the sensor moves as the

fuel level changes. To test the level sensor, connect

an ohmmeter across the sensor signal and sensor

ground terminals of the fuel level sensor connector

(Fig. 7 or Fig. 8). Move the float lever to the full stop

and empty stop positions shown in the resistance

chart (Fig. 7 or Fig. 8). Record the resistance at each

point. Replace the level sensor if the resistance is not

within specifications. The low fuel warning light specifications determine

if the level sensor portion of the warning light circuit

functions properly. It does not test the complete

warning light circuit. Refer to Group 8W, Wiring Diagrams for circuit

identification and Group 8E, Instrument Panel and

Gauges for fuel gauge information.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

Fig. 6 Fuel Reservoir

14 - 18 FUEL SYSTEMS Ä

Page 1819 of 2438

(3) Remove idle air control motor mounting screws.

(4) Remove idle air control motor from throttle

body (make certain that the O-ring is on motor).

INSTALLATION

(1) New idle air control motors have a new O-ring

installed on them. If pintle measures more than 1

inch (25 mm) it must be retracted. Use the IDLE

AIR CONTROL MOTOR OPEN/CLOSE mode of the

DRBII scan tool (battery must be reconnected for this

operation). (2) Carefully place idle air control motor into

throttle body. (3) Install 2 mounting screws. Tighten screws to 2

N Im (17 in. lbs.) torque.

(4) Connect harness connector to motor.

(5) Connect negative cable to battery.

THROTTLE BODY REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove clamp from air hose. Remove hose (Fig.

1). (3) Remove accelerator cable.

(4) Disconnect idle air control motor and throttle

position sensor (TPS) electrical connectors. (5) Remove throttle body mounting nuts.

(6) Remove throttle body and gasket.

(7) Reverse the above procedures for installation.

FUEL INJECTOR RAIL ASSEMBLY

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

WHEN SERVICING FLEXIBLE FUEL VEHICLES,

WEAR METHANOL RESISTANT GLOVES AND EYE

PROTECTION AND AVOID BREATHING FUMES. DO

NOT ALLOW METHANOL/GASOLINE MIXTURES TO

CONTACT SKIN. SERVICE VEHICLES IN WELL VEN-

TILATED AREAS AND AVOID IGNITION SOURCES.

NEVER SMOKE WHILE SERVICING THE VEHICLE.

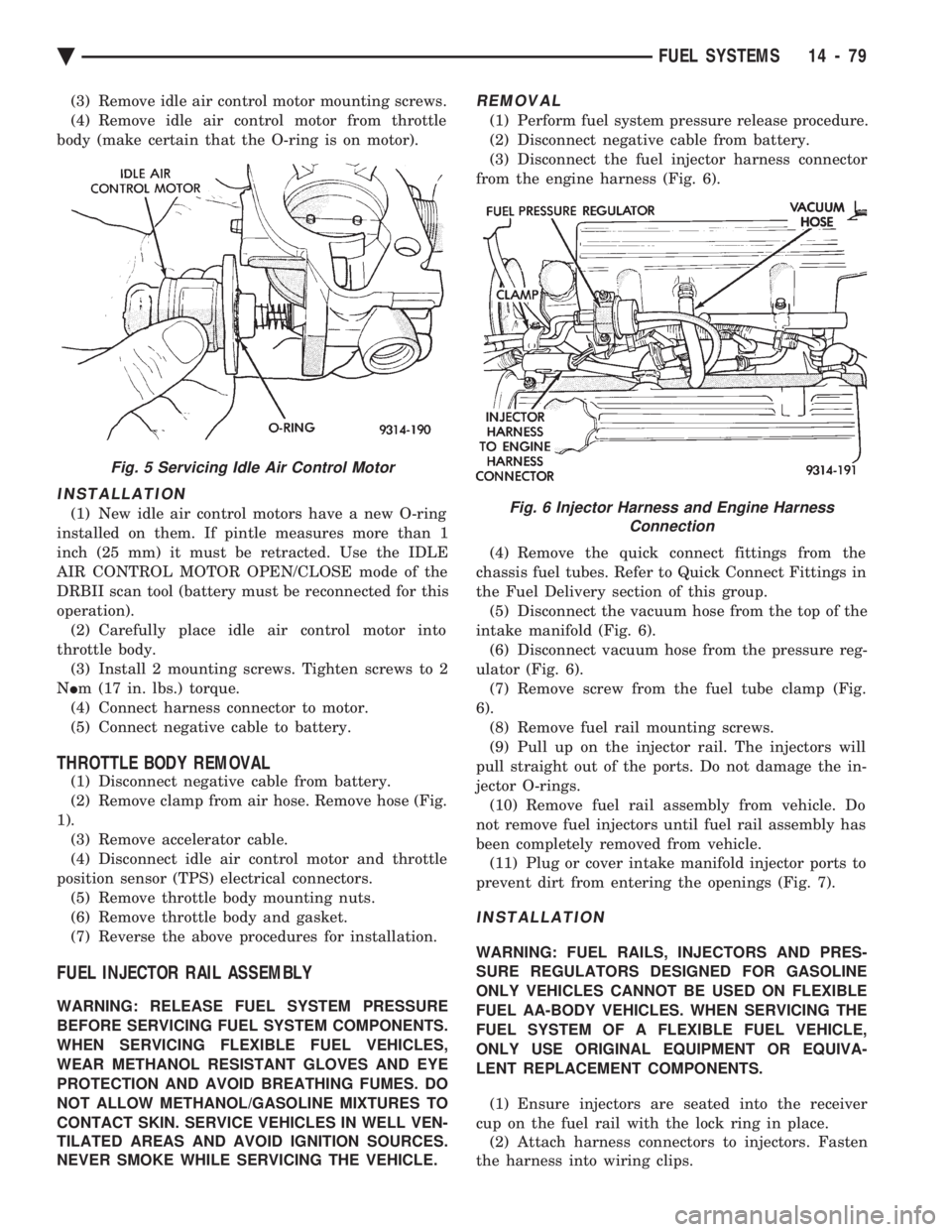

REMOVAL

(1) Perform fuel system pressure release procedure.

(2) Disconnect negative cable from battery.

(3) Disconnect the fuel injector harness connector

from the engine harness (Fig. 6).

(4) Remove the quick connect fittings from the

chassis fuel tubes. Refer to Quick Connect Fittings in

the Fuel Delivery section of this group. (5) Disconnect the vacuum hose from the top of the

intake manifold (Fig. 6). (6) Disconnect vacuum hose from the pressure reg-

ulator (Fig. 6). (7) Remove screw from the fuel tube clamp (Fig.

6). (8) Remove fuel rail mounting screws.

(9) Pull up on the injector rail. The injectors will

pull straight out of the ports. Do not damage the in-

jector O-rings. (10) Remove fuel rail assembly from vehicle. Do

not remove fuel injectors until fuel rail assembly has

been completely removed from vehicle. (11) Plug or cover intake manifold injector ports to

prevent dirt from entering the openings (Fig. 7).

INSTALLATION

WARNING: FUEL RAILS, INJECTORS AND PRES-

SURE REGULATORS DESIGNED FOR GASOLINE

ONLY VEHICLES CANNOT BE USED ON FLEXIBLE

FUEL AA-BODY VEHICLES. WHEN SERVICING THE

FUEL SYSTEM OF A FLEXIBLE FUEL VEHICLE,

ONLY USE ORIGINAL EQUIPMENT OR EQUIVA-

LENT REPLACEMENT COMPONENTS.

(1) Ensure injectors are seated into the receiver

cup on the fuel rail with the lock ring in place. (2) Attach harness connectors to injectors. Fasten

the harness into wiring clips.

Fig. 5 Servicing Idle Air Control Motor

Fig. 6 Injector Harness and Engine Harness Connection

Ä FUEL SYSTEMS 14 - 79

Page 1822 of 2438

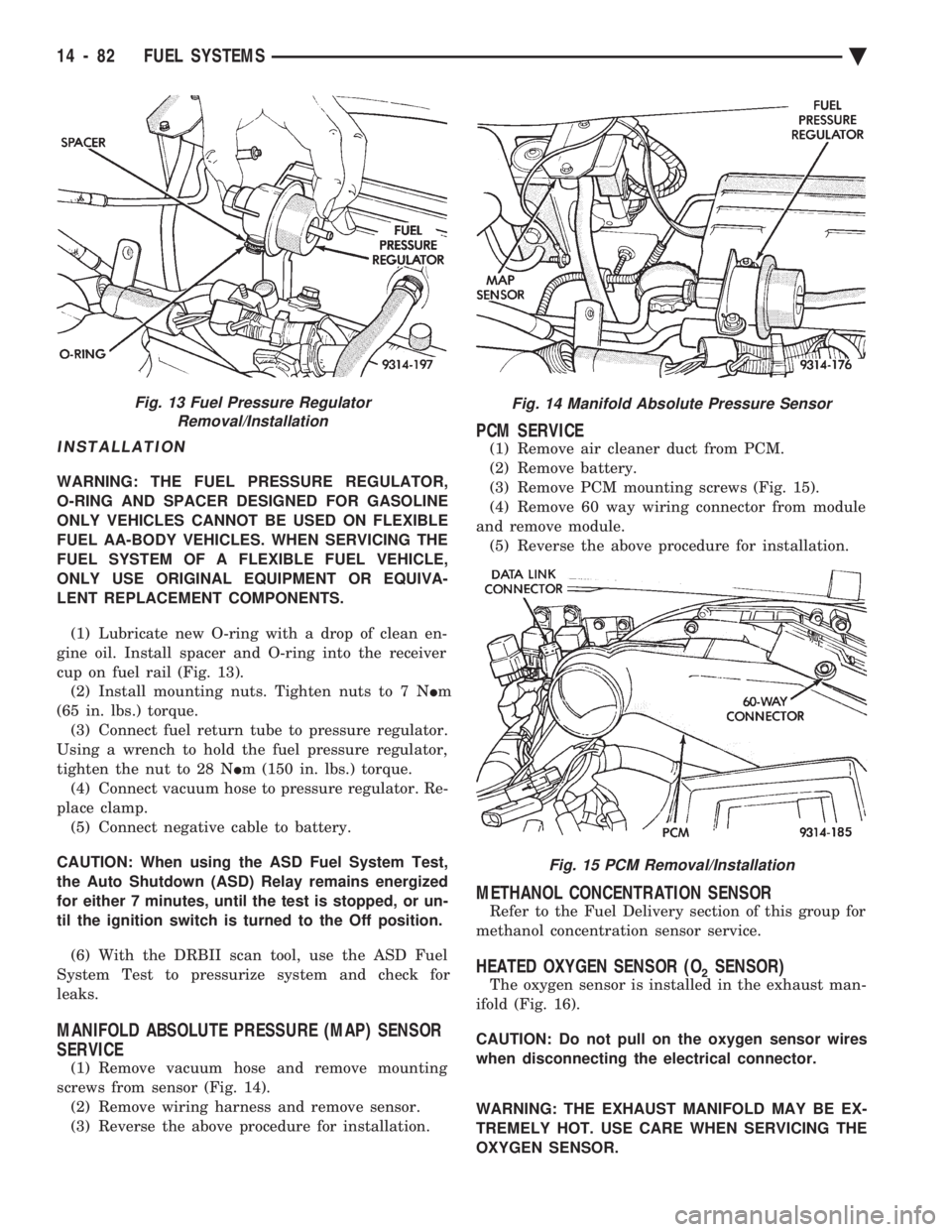

INSTALLATION

WARNING: THE FUEL PRESSURE REGULATOR,

O-RING AND SPACER DESIGNED FOR GASOLINE

ONLY VEHICLES CANNOT BE USED ON FLEXIBLE

FUEL AA-BODY VEHICLES. WHEN SERVICING THE

FUEL SYSTEM OF A FLEXIBLE FUEL VEHICLE,

ONLY USE ORIGINAL EQUIPMENT OR EQUIVA-

LENT REPLACEMENT COMPONENTS.

(1) Lubricate new O-ring with a drop of clean en-

gine oil. Install spacer and O-ring into the receiver

cup on fuel rail (Fig. 13). (2) Install mounting nuts. Tighten nuts to 7 N Im

(65 in. lbs.) torque. (3) Connect fuel return tube to pressure regulator.

Using a wrench to hold the fuel pressure regulator,

tighten the nut to 28 N Im (150 in. lbs.) torque.

(4) Connect vacuum hose to pressure regulator. Re-

place clamp. (5) Connect negative cable to battery.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or un-

til the ignition switch is turned to the Off position.

(6) With the DRBII scan tool, use the ASD Fuel

System Test to pressurize system and check for

leaks.

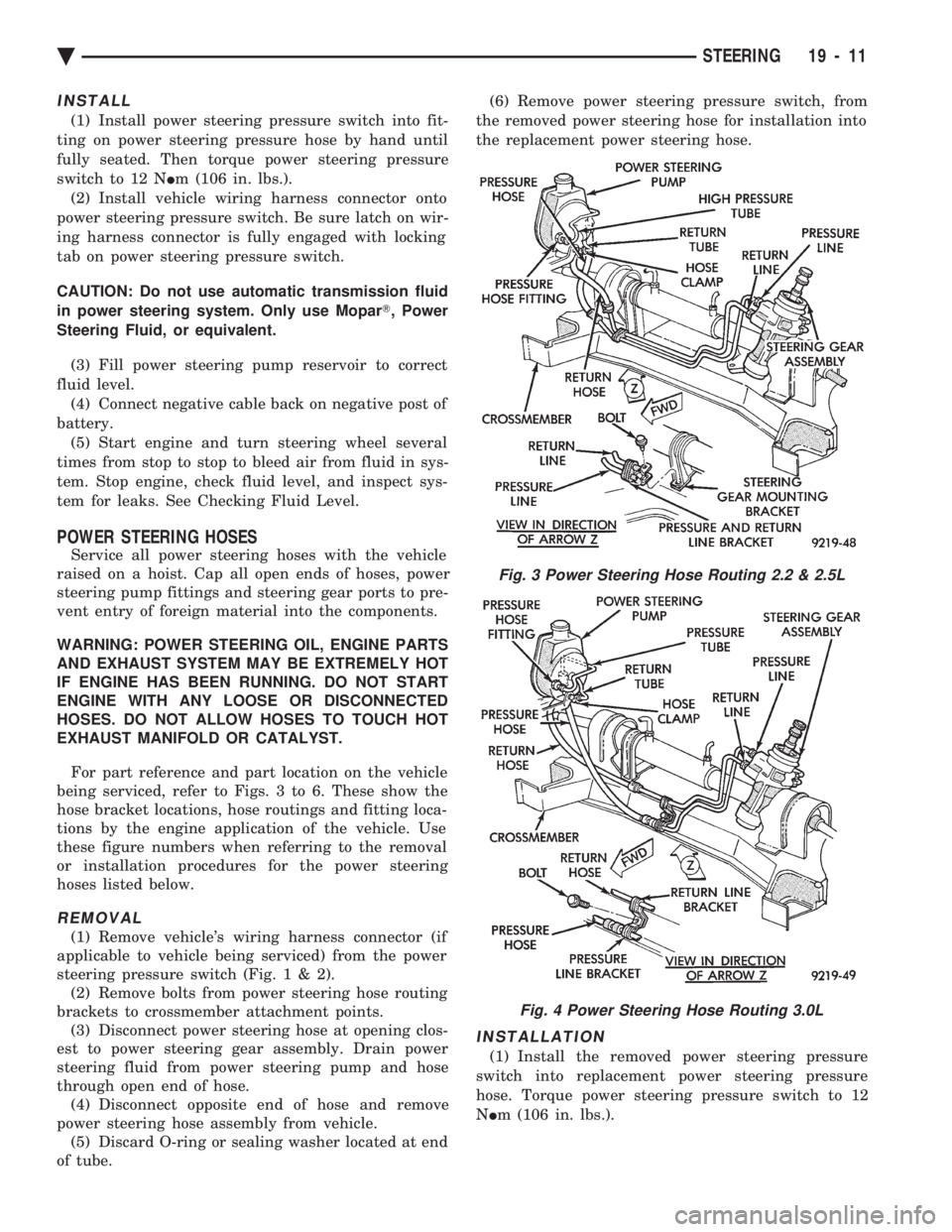

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

SERVICE

(1) Remove vacuum hose and remove mounting

screws from sensor (Fig. 14). (2) Remove wiring harness and remove sensor.

(3) Reverse the above procedure for installation.

PCM SERVICE

(1) Remove air cleaner duct from PCM.

(2) Remove battery.

(3) Remove PCM mounting screws (Fig. 15).

(4) Remove 60 way wiring connector from module

and remove module. (5) Reverse the above procedure for installation.

METHANOL CONCENTRATION SENSOR

Refer to the Fuel Delivery section of this group for

methanol concentration sensor service.

HEATED OXYGEN SENSOR (O2SENSOR)

The oxygen sensor is installed in the exhaust man-

ifold (Fig. 16).

CAUTION: Do not pull on the oxygen sensor wires

when disconnecting the electrical connector.

WARNING: THE EXHAUST MANIFOLD MAY BE EX-

TREMELY HOT. USE CARE WHEN SERVICING THE

OXYGEN SENSOR.

Fig. 13 Fuel Pressure Regulator Removal/InstallationFig. 14 Manifold Absolute Pressure Sensor

Fig. 15 PCM Removal/Installation

14 - 82 FUEL SYSTEMS Ä

Page 1929 of 2438

INSTALL

(1) Install power steering pressure switch into fit-

ting on power steering pressure hose by hand until

fully seated. Then torque power steering pressure

switch to 12 N Im (106 in. lbs.).

(2) Install vehicle wiring harness connector onto

power steering pressure switch. Be sure latch on wir-

ing harness connector is fully engaged with locking

tab on power steering pressure switch.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(3) Fill power steering pump reservoir to correct

fluid level. (4) Connect negative cable back on negative post of

battery. (5) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

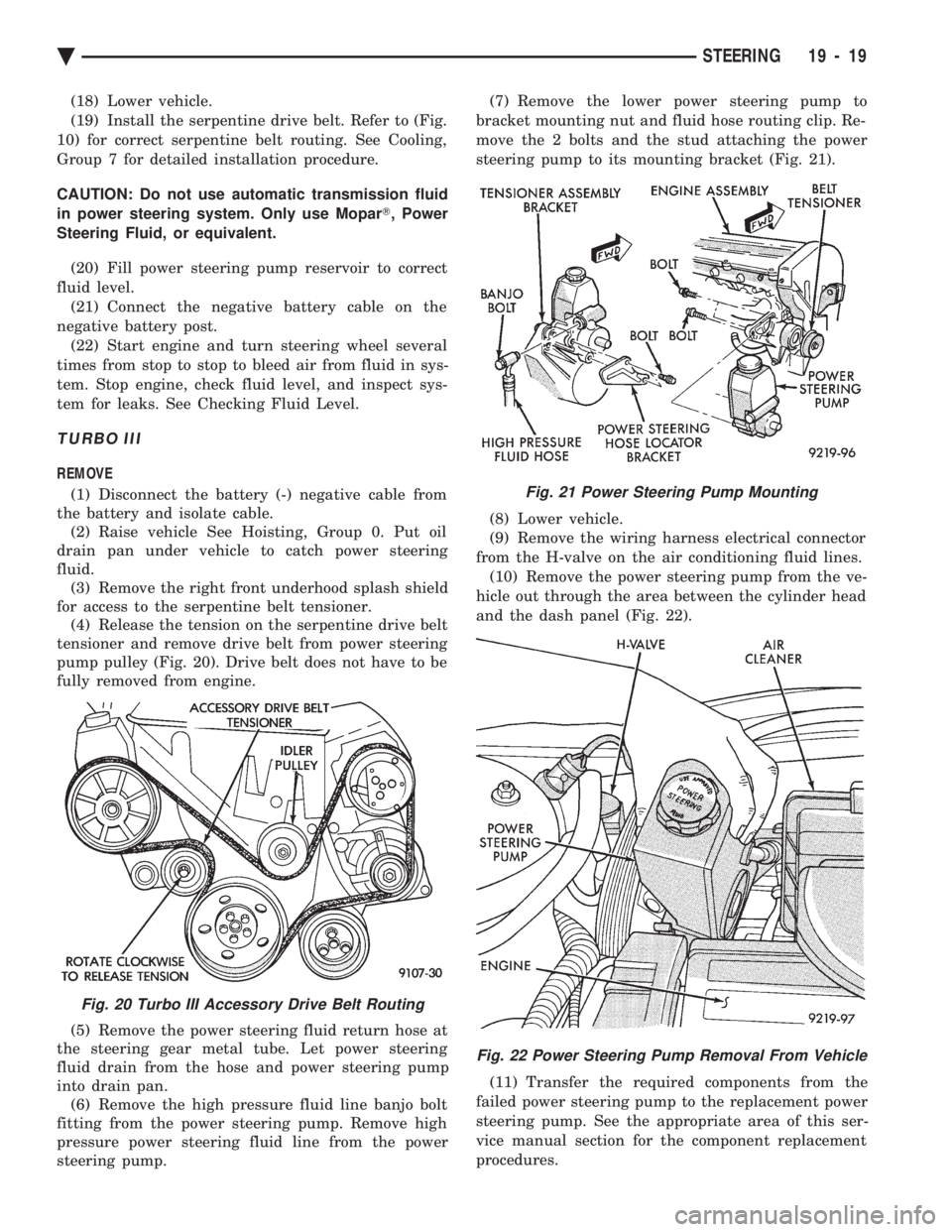

POWER STEERING HOSES

Service all power steering hoses with the vehicle

raised on a hoist. Cap all open ends of hoses, power

steering pump fittings and steering gear ports to pre-

vent entry of foreign material into the components.

WARNING: POWER STEERING OIL, ENGINE PARTS

AND EXHAUST SYSTEM MAY BE EXTREMELY HOT

IF ENGINE HAS BEEN RUNNING. DO NOT START

ENGINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

For part reference and part location on the vehicle

being serviced, refer to Figs. 3 to 6. These show the

hose bracket locations, hose routings and fitting loca-

tions by the engine application of the vehicle. Use

these figure numbers when referring to the removal

or installation procedures for the power steering

hoses listed below.

REMOVAL

(1) Remove vehicle's wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig .1&2).

(2) Remove bolts from power steering hose routing

brackets to crossmember attachment points. (3) Disconnect power steering hose at opening clos-

est to power steering gear assembly. Drain power

steering fluid from power steering pump and hose

through open end of hose. (4) Disconnect opposite end of hose and remove

power steering hose assembly from vehicle. (5) Discard O-ring or sealing washer located at end

of tube. (6) Remove power steering pressure switch, from

the removed power steering hose for installation into

the replacement power steering hose.

INSTALLATION

(1) Install the removed power steering pressure

switch into replacement power steering pressure

hose. Torque power steering pressure switch to 12

N Im (106 in. lbs.).

Fig. 3 Power Steering Hose Routing 2.2 & 2.5L

Fig. 4 Power Steering Hose Routing 3.0L

Ä STEERING 19 - 11

Page 1937 of 2438

(18) Lower vehicle.

(19) Install the serpentine drive belt. Refer to (Fig.

10) for correct serpentine belt routing. See Cooling,

Group 7 for detailed installation procedure.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar T, Power

Steering Fluid, or equivalent.

(20) Fill power steering pump reservoir to correct

fluid level. (21) Connect the negative battery cable on the

negative battery post. (22) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

TURBO III

REMOVE

(1) Disconnect the battery (-) negative cable from

the battery and isolate cable. (2) Raise vehicle See Hoisting, Group 0. Put oil

drain pan under vehicle to catch power steering

fluid. (3) Remove the right front underhood splash shield

for access to the serpentine belt tensioner. (4) Release the tension on the serpentine drive belt

tensioner and remove drive belt from power steering

pump pulley (Fig. 20). Drive belt does not have to be

fully removed from engine.

(5) Remove the power steering fluid return hose at

the steering gear metal tube. Let power steering

fluid drain from the hose and power steering pump

into drain pan. (6) Remove the high pressure fluid line banjo bolt

fitting from the power steering pump. Remove high

pressure power steering fluid line from the power

steering pump. (7) Remove the lower power steering pump to

bracket mounting nut and fluid hose routing clip. Re-

move the 2 bolts and the stud attaching the power

steering pump to its mounting bracket (Fig. 21).

(8) Lower vehicle.

(9) Remove the wiring harness electrical connector

from the H-valve on the air conditioning fluid lines. (10) Remove the power steering pump from the ve-

hicle out through the area between the cylinder head

and the dash panel (Fig. 22).

(11) Transfer the required components from the

failed power steering pump to the replacement power

steering pump. See the appropriate area of this ser-

vice manual section for the component replacement

procedures.

Fig. 20 Turbo III Accessory Drive Belt Routing

Fig. 21 Power Steering Pump Mounting

Fig. 22 Power Steering Pump Removal From Vehicle

Ä STEERING 19 - 19

Page 2195 of 2438

ing hood, align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.(4) Remove the top hood to hinge bolts and loosen

the bottom bolts until they can be removed by hand. (5) With assistance of a helper at the opposite side

of the vehicle to support the hood, remove the bottom

hood to hinge bolts. Separate the hood from the ve-

hicle.

HOOD INSTALLATION

Reverse the preceding operation.

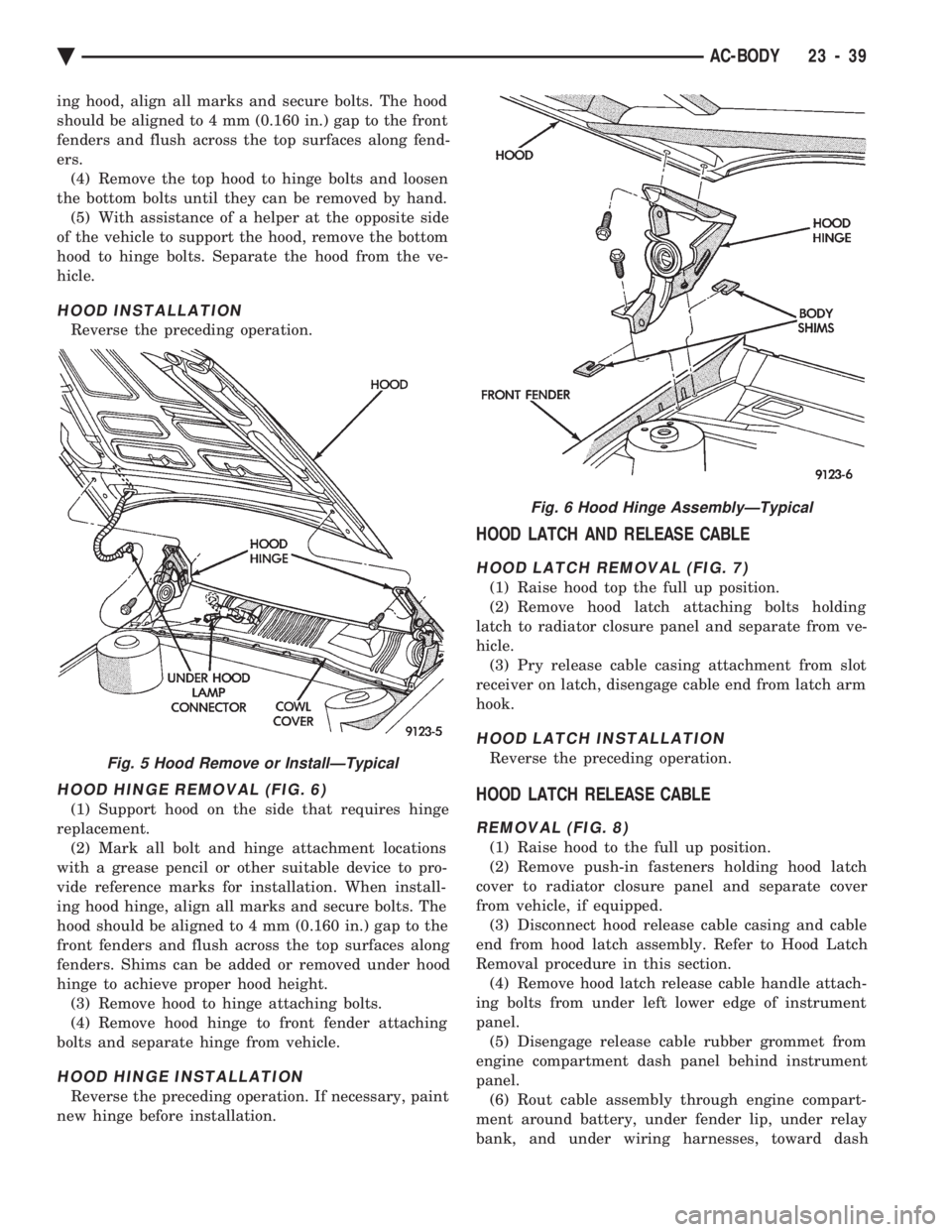

HOOD HINGE REMOVAL (FIG. 6)

(1) Support hood on the side that requires hinge

replacement. (2) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When install-

ing hood hinge, align all marks and secure bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders. Shims can be added or removed under hood

hinge to achieve proper hood height. (3) Remove hood to hinge attaching bolts.

(4) Remove hood hinge to front fender attaching

bolts and separate hinge from vehicle.

HOOD HINGE INSTALLATION

Reverse the preceding operation. If necessary, paint

new hinge before installation.

HOOD LATCH AND RELEASE CABLE

HOOD LATCH REMOVAL (FIG. 7)

(1) Raise hood top the full up position.

(2) Remove hood latch attaching bolts holding

latch to radiator closure panel and separate from ve-

hicle. (3) Pry release cable casing attachment from slot

receiver on latch, disengage cable end from latch arm

hook.

HOOD LATCH INSTALLATION

Reverse the preceding operation.

HOOD LATCH RELEASE CABLE

REMOVAL (FIG. 8)

(1) Raise hood to the full up position.

(2) Remove push-in fasteners holding hood latch

cover to radiator closure panel and separate cover

from vehicle, if equipped. (3) Disconnect hood release cable casing and cable

end from hood latch assembly. Refer to Hood Latch

Removal procedure in this section. (4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash

Fig. 5 Hood Remove or InstallÐTypical

Fig. 6 Hood Hinge AssemblyÐTypical

Ä AC-BODY 23 - 39

Page 2254 of 2438

ing hood, align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.(4) Remove the top hood to hinge attaching bolts

and loosen the bottom bolts until they can be re-

moved by hand. (5) With assistance of a helper at the opposite side

of the vehicle to support the hood, remove the bottom

hood to hinge attaching bolts. Separate the hood

from the vehicle.

HOOD INSTALLATION

Reverse the preceding operation.

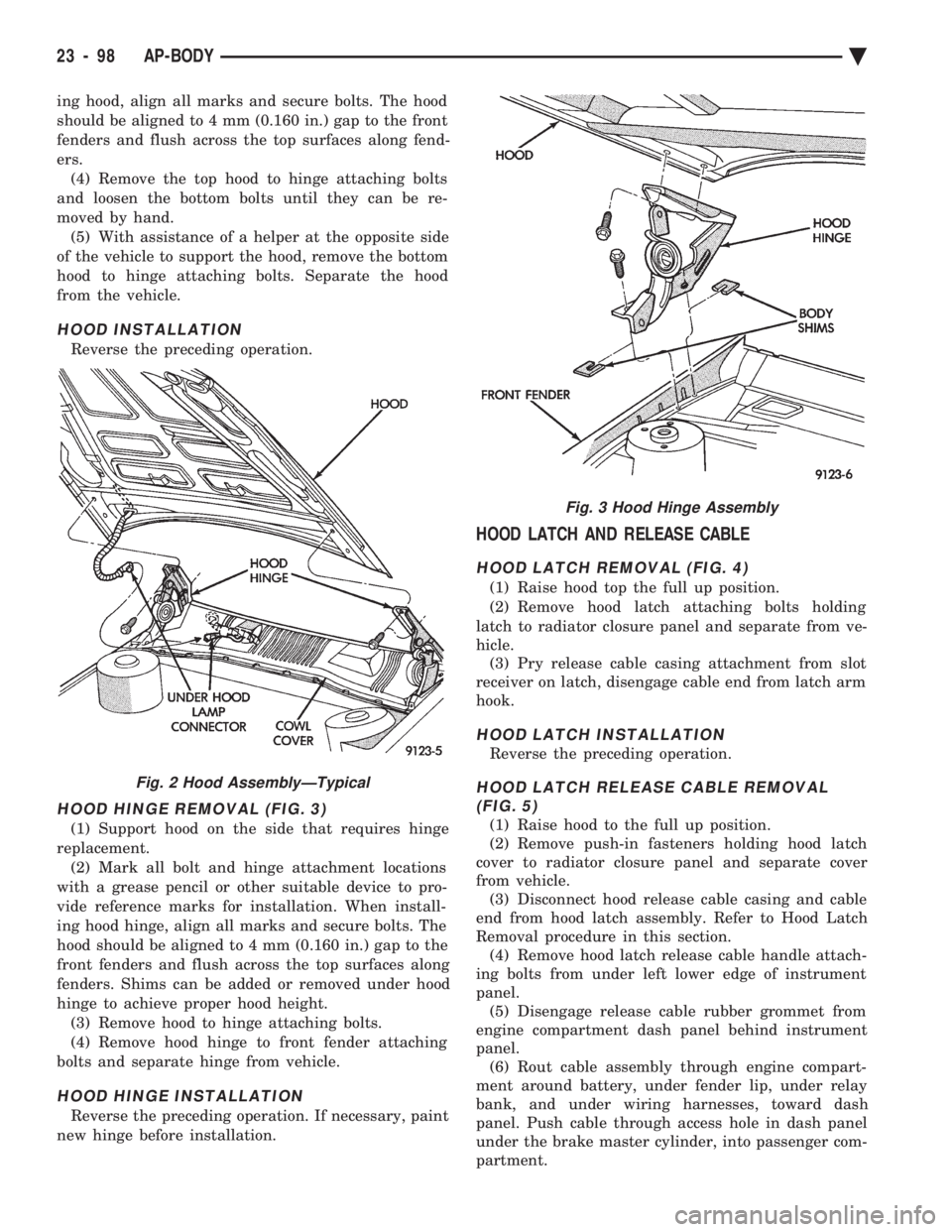

HOOD HINGE REMOVAL (FIG. 3)

(1) Support hood on the side that requires hinge

replacement. (2) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When install-

ing hood hinge, align all marks and secure bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders. Shims can be added or removed under hood

hinge to achieve proper hood height. (3) Remove hood to hinge attaching bolts.

(4) Remove hood hinge to front fender attaching

bolts and separate hinge from vehicle.

HOOD HINGE INSTALLATION

Reverse the preceding operation. If necessary, paint

new hinge before installation.

HOOD LATCH AND RELEASE CABLE

HOOD LATCH REMOVAL (FIG. 4)

(1) Raise hood top the full up position.

(2) Remove hood latch attaching bolts holding

latch to radiator closure panel and separate from ve-

hicle. (3) Pry release cable casing attachment from slot

receiver on latch, disengage cable end from latch arm

hook.

HOOD LATCH INSTALLATION

Reverse the preceding operation.

HOOD LATCH RELEASE CABLE REMOVAL (FIG. 5)

(1) Raise hood to the full up position.

(2) Remove push-in fasteners holding hood latch

cover to radiator closure panel and separate cover

from vehicle. (3) Disconnect hood release cable casing and cable

end from hood latch assembly. Refer to Hood Latch

Removal procedure in this section. (4) Remove hood latch release cable handle attach-

ing bolts from under left lower edge of instrument

panel. (5) Disengage release cable rubber grommet from

engine compartment dash panel behind instrument

panel. (6) Rout cable assembly through engine compart-

ment around battery, under fender lip, under relay

bank, and under wiring harnesses, toward dash

panel. Push cable through access hole in dash panel

under the brake master cylinder, into passenger com-

partment.

Fig. 2 Hood AssemblyÐTypical

Fig. 3 Hood Hinge Assembly

23 - 98 AP-BODY Ä

Page 2338 of 2438

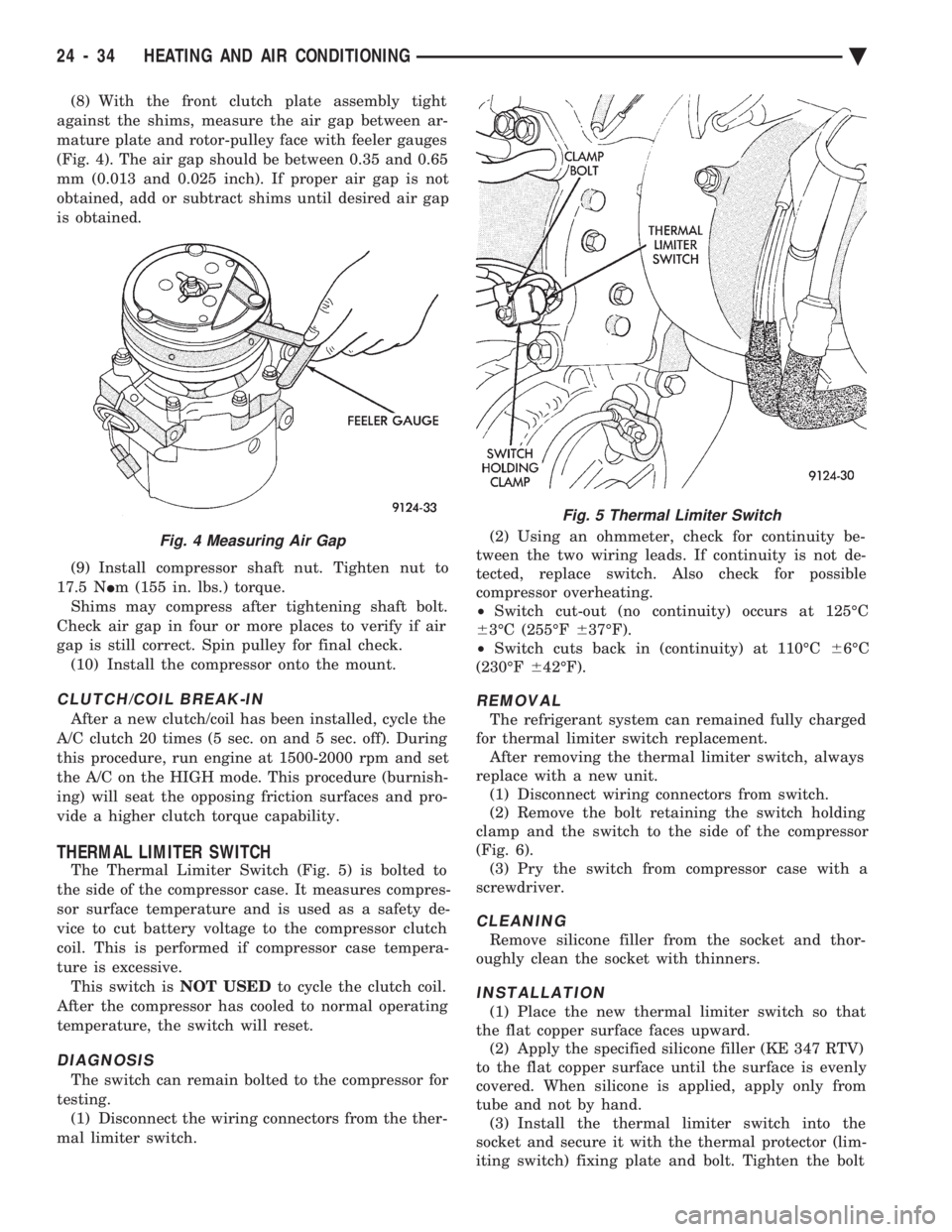

(8) With the front clutch plate assembly tight

against the shims, measure the air gap between ar-

mature plate and rotor-pulley face with feeler gauges

(Fig. 4). The air gap should be between 0.35 and 0.65

mm (0.013 and 0.025 inch). If proper air gap is not

obtained, add or subtract shims until desired air gap

is obtained.

(9) Install compressor shaft nut. Tighten nut to

17.5 N Im (155 in. lbs.) torque.

Shims may compress after tightening shaft bolt.

Check air gap in four or more places to verify if air

gap is still correct. Spin pulley for final check. (10) Install the compressor onto the mount.

CLUTCH/COIL BREAK-IN

After a new clutch/coil has been installed, cycle the

A/C clutch 20 times (5 sec. on and 5 sec. off). During

this procedure, run engine at 1500-2000 rpm and set

the A/C on the HIGH mode. This procedure (burnish-

ing) will seat the opposing friction surfaces and pro-

vide a higher clutch torque capability.

THERMAL LIMITER SWITCH

The Thermal Limiter Switch (Fig. 5) is bolted to

the side of the compressor case. It measures compres-

sor surface temperature and is used as a safety de-

vice to cut battery voltage to the compressor clutch

coil. This is performed if compressor case tempera-

ture is excessive. This switch is NOT USEDto cycle the clutch coil.

After the compressor has cooled to normal operating

temperature, the switch will reset.

DIAGNOSIS

The switch can remain bolted to the compressor for

testing. (1) Disconnect the wiring connectors from the ther-

mal limiter switch. (2) Using an ohmmeter, check for continuity be-

tween the two wiring leads. If continuity is not de-

tected, replace switch. Also check for possible

compressor overheating.

² Switch cut-out (no continuity) occurs at 125ÉC

6 3ÉC (255ÉF 637ÉF).

² Switch cuts back in (continuity) at 110ÉC 66ÉC

(230ÉF 642ÉF).

REMOVAL

The refrigerant system can remained fully charged

for thermal limiter switch replacement. After removing the thermal limiter switch, always

replace with a new unit. (1) Disconnect wiring connectors from switch.

(2) Remove the bolt retaining the switch holding

clamp and the switch to the side of the compressor

(Fig. 6). (3) Pry the switch from compressor case with a

screwdriver.

CLEANING

Remove silicone filler from the socket and thor-

oughly clean the socket with thinners.

INSTALLATION

(1) Place the new thermal limiter switch so that

the flat copper surface faces upward. (2) Apply the specified silicone filler (KE 347 RTV)

to the flat copper surface until the surface is evenly

covered. When silicone is applied, apply only from

tube and not by hand. (3) Install the thermal limiter switch into the

socket and secure it with the thermal protector (lim-

iting switch) fixing plate and bolt. Tighten the bolt

Fig. 4 Measuring Air Gap

Fig. 5 Thermal Limiter Switch

24 - 34 HEATING AND AIR CONDITIONING Ä