brake light CHEVROLET DYNASTY 1993 Manual Online

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1823 of 2438

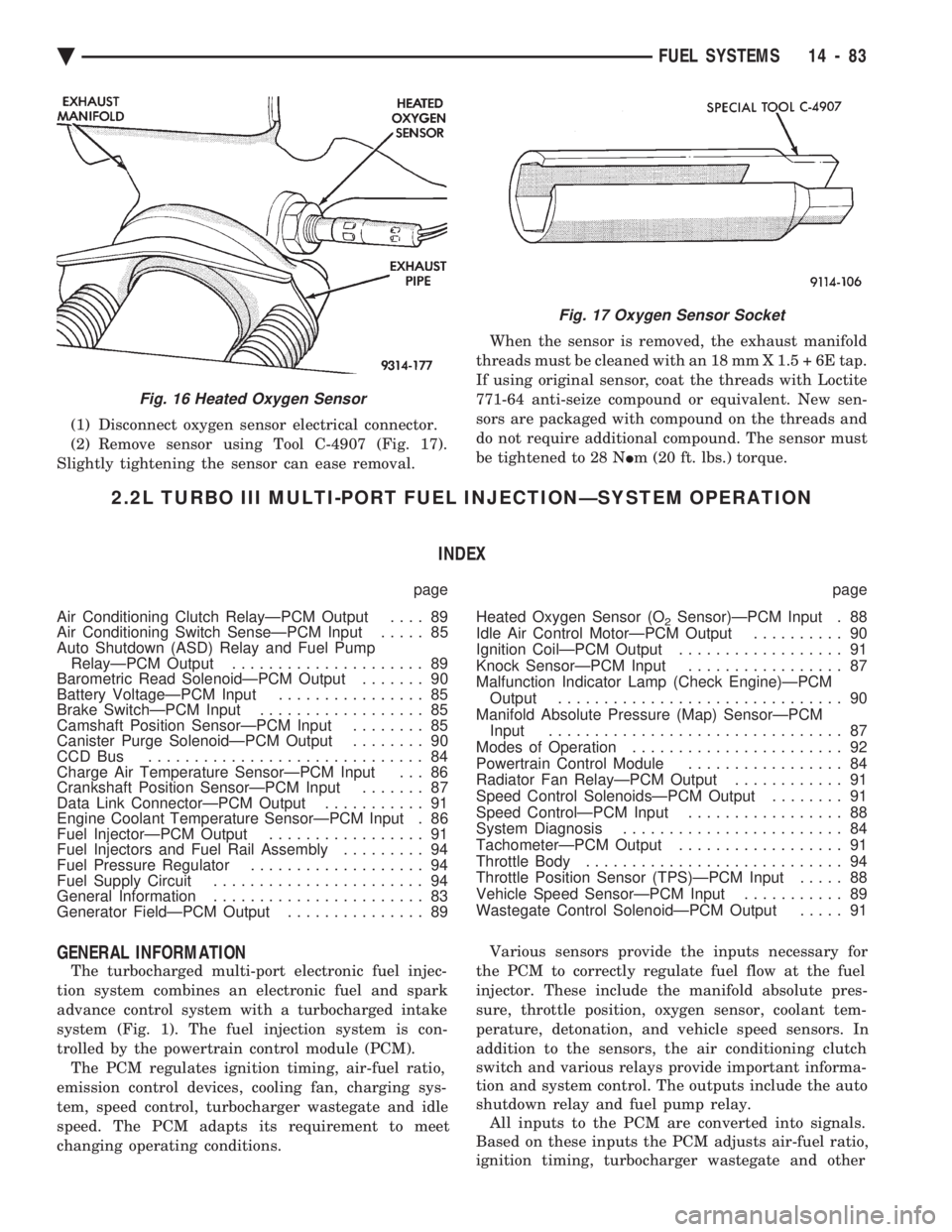

(1) Disconnect oxygen sensor electrical connector.

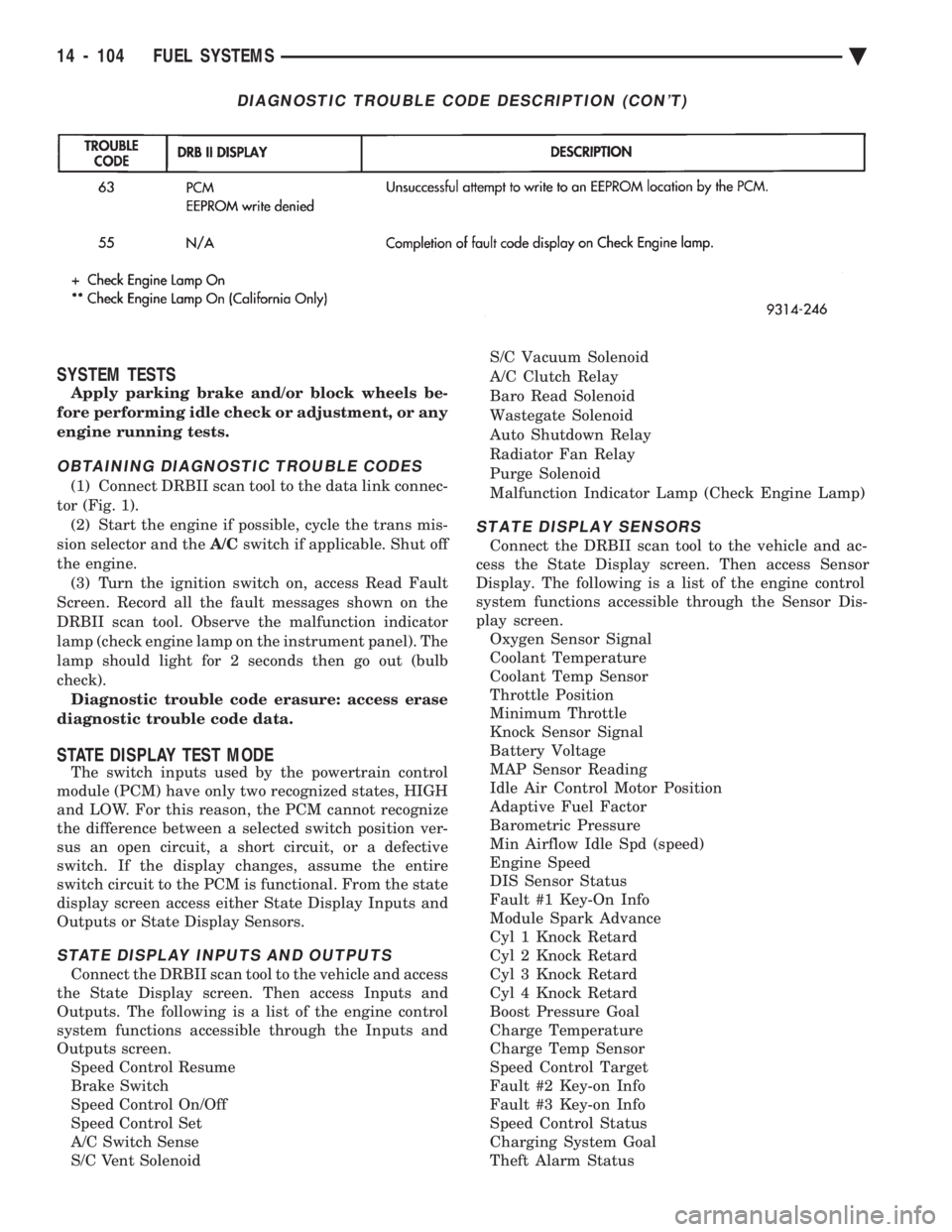

(2) Remove sensor using Tool C-4907 (Fig. 17).

Slightly tightening the sensor can ease removal. When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E tap.

If using original sensor, coat the threads with Loctite

771-64 anti-seize compound or equivalent. New sen-

sors are packaged with compound on the threads and

do not require additional compound. The sensor must

be tightened to 28 N Im (20 ft. lbs.) torque.

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION

INDEX

page page

Air Conditioning Clutch RelayÐPCM Output .... 89

Air Conditioning Switch SenseÐPCM Input ..... 85

Auto Shutdown (ASD) Relay and Fuel Pump RelayÐPCM Output ..................... 89

Barometric Read SolenoidÐPCM Output ....... 90

Battery VoltageÐPCM Input ................ 85

Brake SwitchÐPCM Input .................. 85

Camshaft Position SensorÐPCM Input ........ 85

Canister Purge SolenoidÐPCM Output ........ 90

CCD Bus .............................. 84

Charge Air Temperature SensorÐPCM Input . . . 86

Crankshaft Position SensorÐPCM Input ....... 87

Data Link ConnectorÐPCM Output ........... 91

Engine Coolant Temperature SensorÐPCM Input . 86

Fuel InjectorÐPCM Output ................. 91

Fuel Injectors and Fuel Rail Assembly ......... 94

Fuel Pressure Regulator ................... 94

Fuel Supply Circuit ....................... 94

General Information ....................... 83

Generator FieldÐPCM Output ............... 89 Heated Oxygen Sensor (O

2Sensor)ÐPCM Input . 88

Idle Air Control MotorÐPCM Output .......... 90

Ignition CoilÐPCM Output .................. 91

Knock SensorÐPCM Input ................. 87

Malfunction Indicator Lamp (Check Engine)ÐPCM Output ............................... 90

Manifold Absolute Pressure (Map) SensorÐPCM Input ................................ 87

Modes of Operation ....................... 92

Powertrain Control Module ................. 84

Radiator Fan RelayÐPCM Output ............ 91

Speed Control SolenoidsÐPCM Output ........ 91

Speed ControlÐPCM Input ................. 88

System Diagnosis ........................ 84

TachometerÐPCM Output .................. 91

Throttle Body ............................ 94

Throttle Position Sensor (TPS)ÐPCM Input ..... 88

Vehicle Speed SensorÐPCM Input ........... 89

Wastegate Control SolenoidÐPCM Output ..... 91

GENERAL INFORMATION

The turbocharged multi-port electronic fuel injec-

tion system combines an electronic fuel and spark

advance control system with a turbocharged intake

system (Fig. 1). The fuel injection system is con-

trolled by the powertrain control module (PCM). The PCM regulates ignition timing, air-fuel ratio,

emission control devices, cooling fan, charging sys-

tem, speed control, turbocharger wastegate and idle

speed. The PCM adapts its requirement to meet

changing operating conditions. Various sensors provide the inputs necessary for

the PCM to correctly regulate fuel flow at the fuel

injector. These include the manifold absolute pres-

sure, throttle position, oxygen sensor, coolant tem-

perature, detonation, and vehicle speed sensors. In

addition to the sensors, the air conditioning clutch

switch and various relays provide important informa-

tion and system control. The outputs include the auto

shutdown relay and fuel pump relay. All inputs to the PCM are converted into signals.

Based on these inputs the PCM adjusts air-fuel ratio,

ignition timing, turbocharger wastegate and other

Fig. 16 Heated Oxygen Sensor

Fig. 17 Oxygen Sensor Socket

Ä FUEL SYSTEMS 14 - 83

Page 1844 of 2438

SYSTEM TESTS

Apply parking brake and/or block wheels be-

fore performing idle check or adjustment, or any

engine running tests.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link connec-

tor (Fig. 1). (2) Start the engine if possible, cycle the trans mis-

sion selector and the A/Cswitch if applicable. Shut off

the engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel). The

lamp should light for 2 seconds then go out (bulb

check). Diagnostic trouble code erasure: access erase

diagnostic trouble code data.

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the display changes, assume the entire

switch circuit to the PCM is functional. From the state

display screen access either State Display Inputs and

Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid S/C Vacuum Solenoid

A/C Clutch Relay

Baro Read Solenoid

Wastegate Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Oxygen Sensor Signal

Coolant Temperature

Coolant Temp Sensor

Throttle Position

Minimum Throttle

Knock Sensor Signal

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Spd (speed)

Engine Speed

DIS Sensor Status

Fault #1 Key-On Info

Module Spark Advance

Cyl 1 Knock Retard

Cyl 2 Knock Retard

Cyl 3 Knock Retard

Cyl 4 Knock Retard

Boost Pressure Goal

Charge Temperature

Charge Temp Sensor

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Charging System Goal

Theft Alarm Status

DIAGNOSTIC TROUBLE CODE DESCRIPTION (CON'T)

14 - 104 FUEL SYSTEMS Ä

Page 1855 of 2438

The PCM adjusts ignition timing based on the fol-

lowing inputs.

² engine coolant temperature

² engine speed (distributor pick-up)

² manifold absolute pressure

² throttle position

The Automatic Shut Down (ASD) and Fuel Pump

relays are mounted externally, but turned on and off

by the PCM through the same circuit. The distributor pick-up signal is sent to the PCM.

If the PCM does not receive a distributor signal

within approximately one second of engine cranking,

the ASD relay and fuel pump relay are deactivated.

When these relays are deactivated, power is shut off

to the fuel injector, ignition coil, oxygen sensor heat-

ing element and fuel pump. The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the distributor pick-up and vehicle

speed sensor. The PCM also provides a 5.0 volts sup-

ply for the coolant temperature sensor, manifold ab-

solute pressure sensor and throttle position sensor.

AIR CONDITIONING SWITCH SENSE (AA, AG, AJ

BODY)ÐPCM INPUT

When the air conditioning or defrost switch is in

the ON position and the low pressure and high pres-

sure switches are closed, the PCM receives an input

for air conditioning. After receiving this input, the

PCM activates the A/C compressor clutch by ground-

ing the A/C clutch relay. The PCM also adjusts idle

speed to a scheduled RPM to compensate for in-

creased engine load.

AIR CONDITIONING SWITCH SENSE (AC

BODY)ÐPCM INPUT

When the air conditioning or defrost switch is in

the ON position and the low pressure, high pressure

and ambient temperature switches are closed, the

PCM receives an input for air conditioning. After re-

ceiving this input, the PCM activates the A/C com-

pressor clutch by grounding the A/C clutch relay.

The PCM also adjusts idle speed to a scheduled RPM

to compensate for increased engine load.

BATTERY VOLTAGEÐPCM INPUT

The PCM monitors the battery voltage input to de-

termine fuel injector pulse width and generator field

control. If battery voltage is low, the PCM will in-

crease injector pulse width.

BRAKE SWITCHÐPCM INPUT

When the brake switch is activated, the PCM re-

ceives an input indicating that the brakes are being

applied. After receiving this input the PCM main-

tains idle speed to a scheduled RPM through the idle

air control motor. The brake switch is mounted on

the brake pedal support bracket.

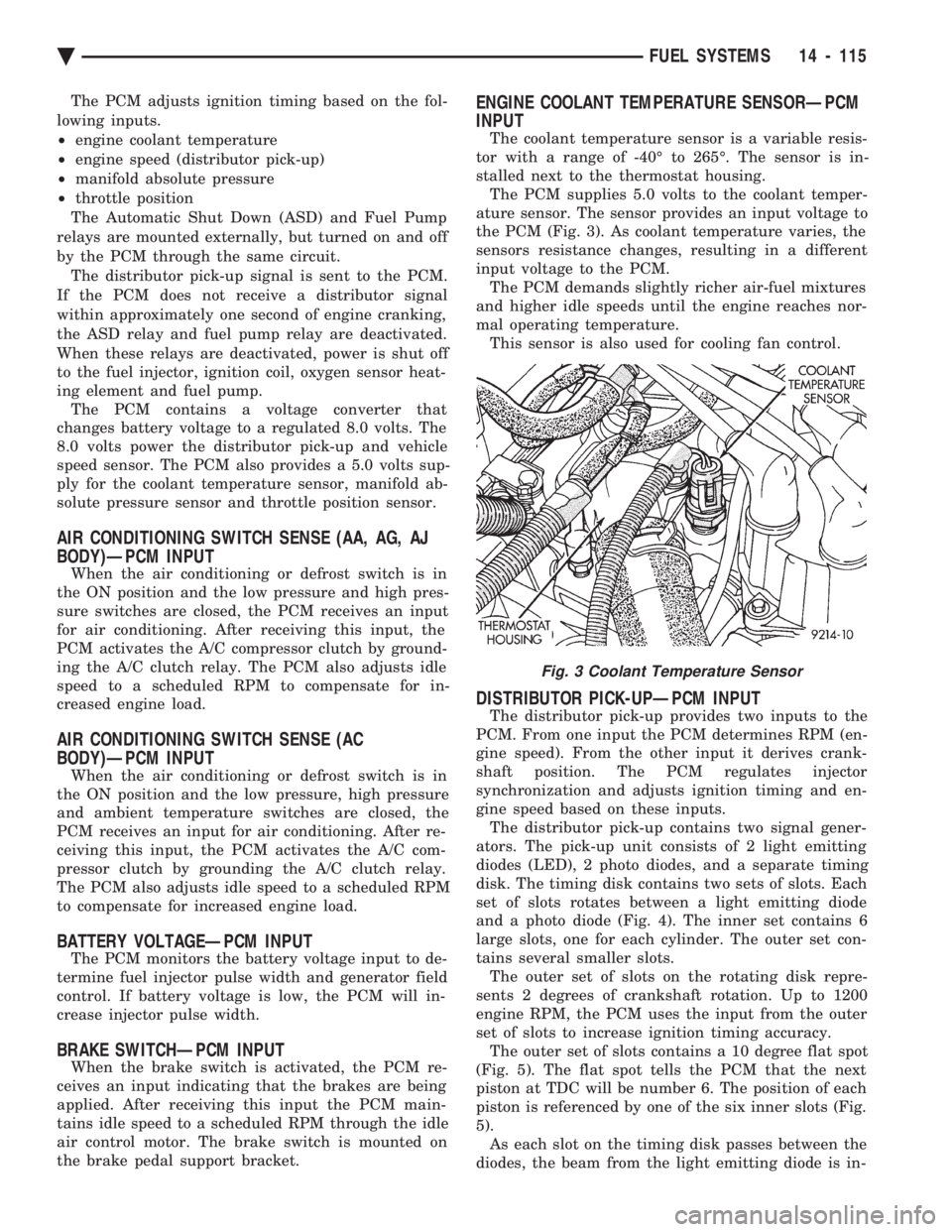

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The coolant temperature sensor is a variable resis-

tor with a range of -40É to 265É. The sensor is in-

stalled next to the thermostat housing. The PCM supplies 5.0 volts to the coolant temper-

ature sensor. The sensor provides an input voltage to

the PCM (Fig. 3). As coolant temperature varies, the

sensors resistance changes, resulting in a different

input voltage to the PCM. The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature. This sensor is also used for cooling fan control.

DISTRIBUTOR PICK-UPÐPCM INPUT

The distributor pick-up provides two inputs to the

PCM. From one input the PCM determines RPM (en-

gine speed). From the other input it derives crank-

shaft position. The PCM regulates injector

synchronization and adjusts ignition timing and en-

gine speed based on these inputs. The distributor pick-up contains two signal gener-

ators. The pick-up unit consists of 2 light emitting

diodes (LED), 2 photo diodes, and a separate timing

disk. The timing disk contains two sets of slots. Each

set of slots rotates between a light emitting diode

and a photo diode (Fig. 4). The inner set contains 6

large slots, one for each cylinder. The outer set con-

tains several smaller slots. The outer set of slots on the rotating disk repre-

sents 2 degrees of crankshaft rotation. Up to 1200

engine RPM, the PCM uses the input from the outer

set of slots to increase ignition timing accuracy. The outer set of slots contains a 10 degree flat spot

(Fig. 5). The flat spot tells the PCM that the next

piston at TDC will be number 6. The position of each

piston is referenced by one of the six inner slots (Fig.

5). As each slot on the timing disk passes between the

diodes, the beam from the light emitting diode is in-

Fig. 3 Coolant Temperature Sensor

Ä FUEL SYSTEMS 14 - 115

Page 1874 of 2438

SYSTEM TESTS

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link connec-

tor located in the engine compartment near the pow-

ertrain control module (PCM). (2) Start the engine if possible, cycle the transaxle

selector and the A/Cswitch if applicable. Shut off the

engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (Check Engine lamp on the instrument panel).

The lamp should light for 3 seconds then go out (bulb

check). Diagnostic trouble code erasure; access erase

diagnostic trouble code data

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the change is displayed, it can be assumed

that the entire switch circuit to the PCM is functional.

From the state display screen access either State

Display Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle. Access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid

S/C Vacuum Solenoid

A/C Clutch Relay

EGR Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Torque Converter Clutch Solenoid

Malfunction Indicator Lamp (Check Engine Lamp)

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Battery Temperature

Oxygen Sensor Signal

Engine Coolant Temperature

Engine Coolant Temp Sensor

Throttle Position

Minimum Throttle

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idle Speed

Engine Speed

Fault #1 Key-On Info

Module Spark Advance

Speed Control Target

Fault #2 Key-on Info

Fault #3 Key-on Info

Speed Control Status

Speed Control Switch Voltage

Charging System Goal

Theft Alarm Status

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The circuit actuation test mode checks for proper

operation of output circuits or devices which the pow-

ertrain control module (PCM) cannot internally rec-

ognize. The PCM can attempt to activate these

outputs and allow an observer to verify proper oper-

ation. Most of the tests provide an audible or visual

indication of device operation (click of relay contacts,

spray fuel, etc.). Except for intermittent conditions, if

a device functions properly during testing, assume

the device, its associated wiring, and driver circuit

working correctly.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the engine control system functions accessible

through Actuators screens. Stop All Tests

Ignition Coil #1

Fuel Injector #1

Fuel Injector #2

Fuel Injector #3

14 - 134 FUEL SYSTEMS Ä

Page 1903 of 2438

line. However, these could result in a rich or lean

condition causing an oxygen sensor fault to be stored in

the PCM. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket and

crankshaft sprocket. However, these could result in a

rich or lean condition causing an oxygen sensor fault to

be stored in the PCM. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Malfunctions - The PCM cannot

determine if a fuel injector is clogged, the needle is

sticking or the wrong injector is installed. However,

these could result in a rich or lean condition causing an

oxygen sensor fault to be stored in the PCM. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM will not detect a

restricted, plugged or loaded evaporative purge canis-

ter. Vacuum Assist - Leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices are not monitored by the PCM. How-

ever, these could result in a MAP sensor fault being

stored in the PCM. PCM System Ground - The PCM cannot determine

a poor system ground. However, a diagnostic trouble

code may be generated as a result of this condition. PCM Connector Engagement - The PCM cannot

determine spread or damaged connector pins. How-

ever, a diagnostic trouble code may be generated as a

result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device with estab-

lished high and low limits for the device. If the input

voltage is not within limits and other diagnostic

trouble code criteria are met, a diagnostic trouble code

will be stored in memory. Other diagnostic trouble code

criteria might include engine RPM limits or input

voltages from other sensors or switches that must be

present before a fault condition can be verified.

DIAGNOSTIC TROUBLE CODE DESCRIPTION

A diagnostic trouble code indicates that the power-

train control module (PCM) has recognized an abnor- mal condition in the system. Diagnostic trouble codes

can be obtained from the malfunction indicator lamp

(Check Engine lamp on the instrument panel) or from

the DRBII scan tool. Diagnostic trouble codes indicate

the results of a failure but do not identify the failed

component directly.

SYSTEM TESTS

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE.

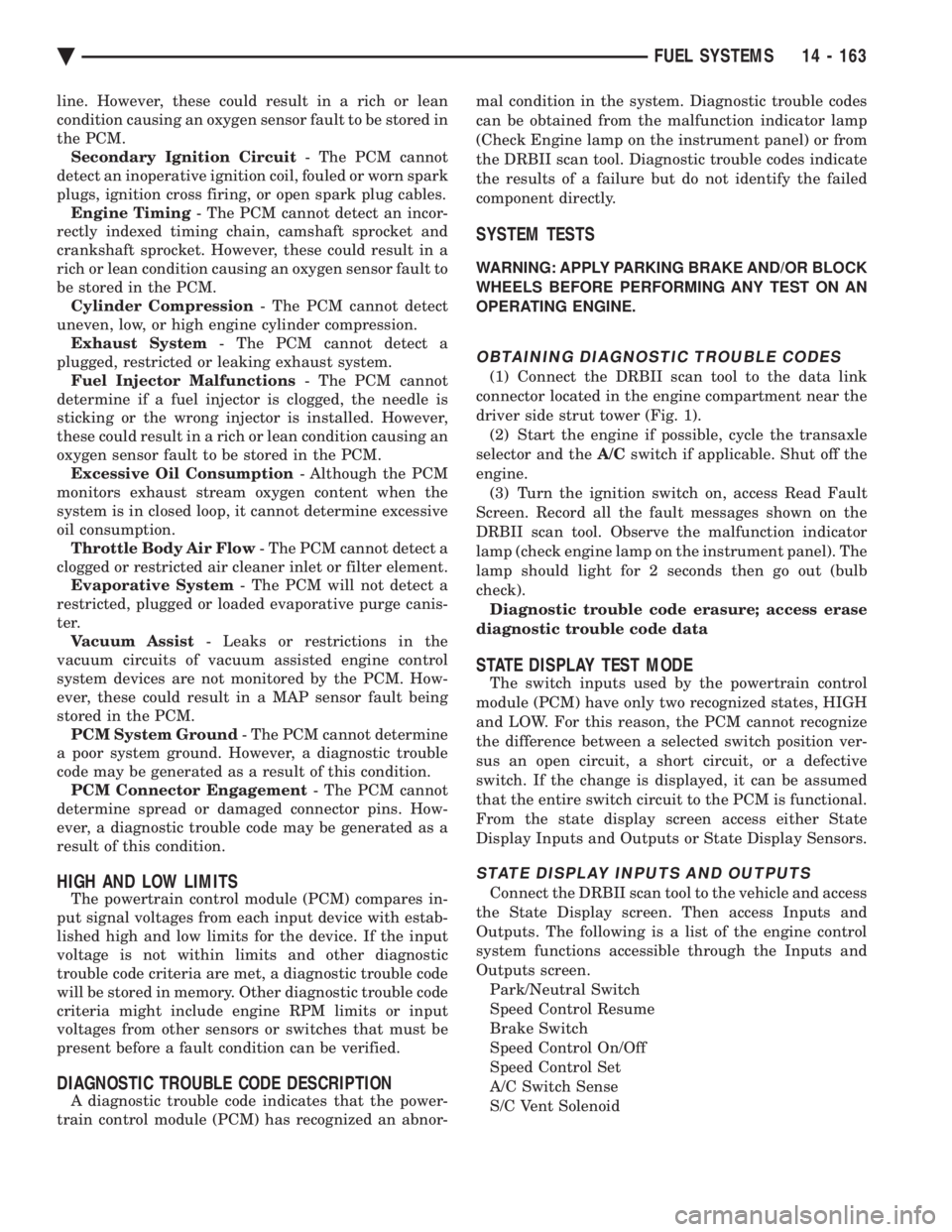

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect the DRBII scan tool to the data link

connector located in the engine compartment near the

driver side strut tower (Fig. 1). (2) Start the engine if possible, cycle the transaxle

selector and the A/Cswitch if applicable. Shut off the

engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel). The

lamp should light for 2 seconds then go out (bulb

check). Diagnostic trouble code erasure; access erase

diagnostic trouble code data

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states, HIGH

and LOW. For this reason, the PCM cannot recognize

the difference between a selected switch position ver-

sus an open circuit, a short circuit, or a defective

switch. If the change is displayed, it can be assumed

that the entire switch circuit to the PCM is functional.

From the state display screen access either State

Display Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and access

the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C Vent Solenoid

Ä FUEL SYSTEMS 14 - 163

Page 2366 of 2438

AA BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION. Refer to Group 8E and Group 23 for component re-

moval and installation when performing this opera-

tion. (1) Perform steps 1 through 7 of Blower Motor re-

moval and installation. (2) Remove relay panel above glove compartment

opening. (3) Disconnect the A/C vacuum line connector and

radio noise capacitor connectors. (4) Remove left windshield pillar trim cover.

(5) Remove left lower side cowl trim cover.

(6) Remove hood release handle mechanism attach-

ing screws. (7) Remove steering column trim covers.

(8) Disconnect parking brake release mechanism

connecting rod. Gain access through fuse panel open-

ing. (9) Remove lower left instrument panel silencer.

(10) Remove lower left instrument panel reinforce-

ment. (11) Remove instrument panel center (radio) bezel.

(12) Remove forward floor console.

(13) Remove the radio.

(14) Remove the heater-A/C control.

(15) Remove cigar lighter.

(16) Remove message center/trip computer, if

equipped. (17) Disconnect side window demister tubes from

top of heat A/C unit. (18) Remove steering column upper attaching bolts

and allow the steering wheel to rest on the driver

seat cushion. (19) Remove upper instrument panel (defroster

outlet) cover. (20) Remove upper instrument panel attaching

screws from below the windshield opening. (21) Loosen (do not remove) the left lower cowl in-

strument panel attaching screw. (22) Remove the right lower cowl instrument panel

attaching screw.

CAUTION: Protect the passenger seat cover from

soiling or damage using a suitable cover.

(23) Carefully pull the right side of the instrument

panel away from the vehicle. Allow the instrument

panel to rest on the passenger seat cushion.

CAUTION: Before proceeding with the next opera-

tion, review the Safety Precautions and Warnings at

the front of this Group. (24) From the engine compartment, drain the cool-

ing system and disconnect the heater hoses from the

heater core nipples. Plug the nipples to avoid spilling

coolant inside the vehicle. (25) Disconnect the refrigerant lines from the ex-

pansion-valve at the dash panel on the right side of

the vehicle. Seal the refrigerant lines to prevent con-

tamination. (26) Remove the expansion valve from the evapo-

rator plate. Seal the valve to avoid contamination. (27) Remove the condensate drain tube.

(28) Remove heater-A/C unit to dash panel attach-

ing nuts. (29) From inside the vehicle, pull rearward on the

heater-A/C unit to clear the dash panel silencer and

remove the unit from the vehicle. To install, reverse the preceding operation. Refill

cooling system and test for leaks. Evacuate and

charge the refrigerant system and test overall perfor-

mance.

AG, AJ BODY PROCEDURE

WARNING: IF EQUIPPED WITH A/C, THE REFRIG-

ERATION SYSTEM MUST BE COMPLETELY EMPTY

BEFORE PROCEEDING WITH THIS OPERATION.

(1) Disconnect the battery negative cable.

(2) Drain the coolant from cooling system. Refer to

Group 7, Cooling System. (3) Remove the air conditioner expansion valve (if

equipped). (4) Disconnect the heater hoses from heater core.

Then plug or cap the tubes on heater core. This will

prevent spilling coolant into the interior of vehicle

during unit removal. (5) Remove the condensate drain tube.

(6) Disconnect the A/C-heater vacuum supply line

from vacuum supply nipple (in the engine compart-

ment). (7) Remove the four A/C-heater assembly-to-dash

panel attaching nuts. (8) Remove the passenger side front seat. Refer to

Group 23, Body. (9) Remove the kick panel/sill cover at right door

opening. (10) Remove the body computer (Fig. 6) located at

the lower right section of the right front door pillar. (11) Remove the glove box assembly. Refer to

Group 8E, Instrument Panel. (12) Remove the carpeted panels from both sides of

the console. (13) Un-clip the radio antenna cable from the

metal support (Fig. 6) located behind and below the

glove box opening. (14) Instrument panel removal is not necessary to

remove the A/C-heater assembly from the vehicle.

24 - 62 HEATING AND AIR CONDITIONING Ä

Page 2409 of 2438

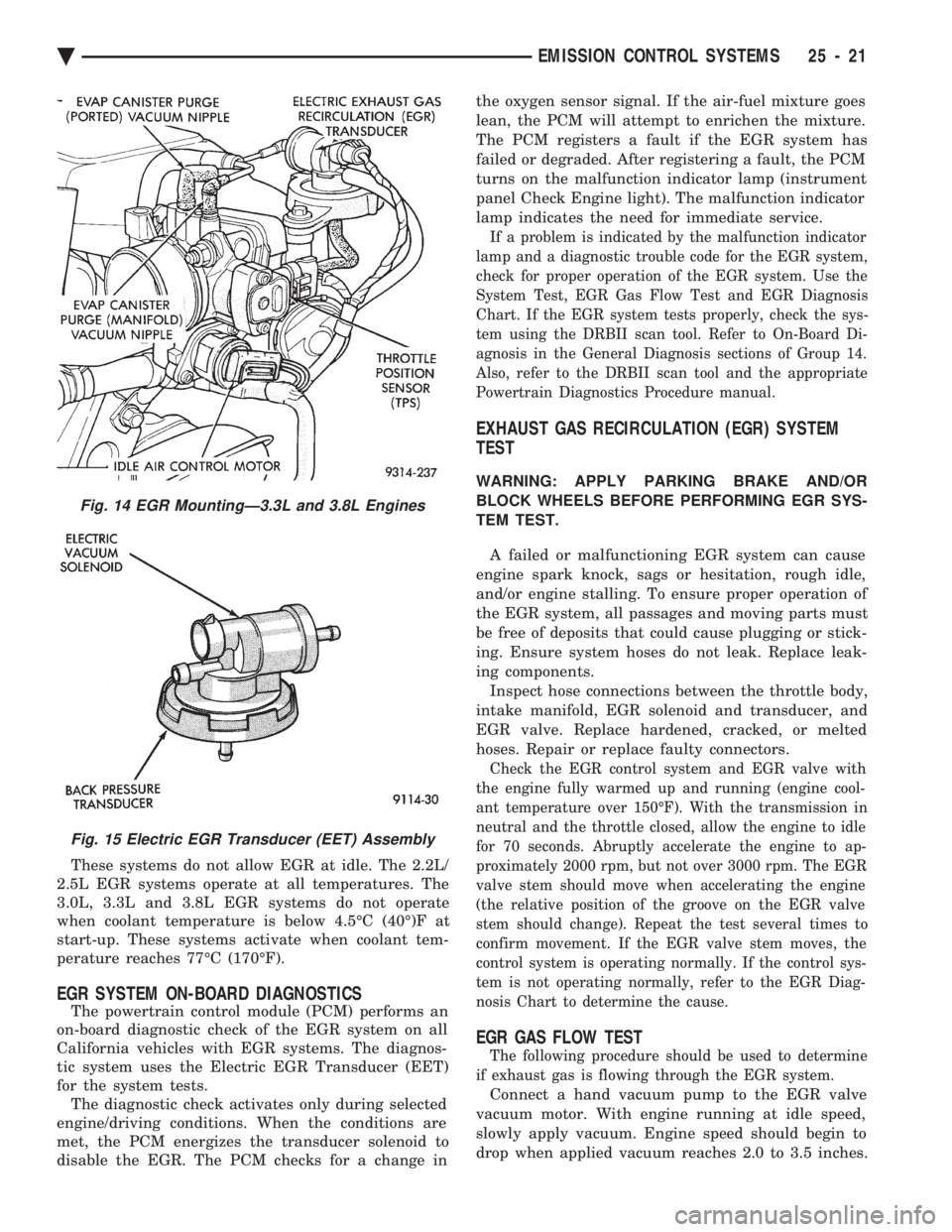

These systems do not allow EGR at idle. The 2.2L/

2.5L EGR systems operate at all temperatures. The

3.0L, 3.3L and 3.8L EGR systems do not operate

when coolant temperature is below 4.5ÉC (40É)F at

start-up. These systems activate when coolant tem-

perature reaches 77ÉC (170ÉF).

EGR SYSTEM ON-BOARD DIAGNOSTICS

The powertrain control module (PCM) performs an

on-board diagnostic check of the EGR system on all

California vehicles with EGR systems. The diagnos-

tic system uses the Electric EGR Transducer (EET)

for the system tests. The diagnostic check activates only during selected

engine/driving conditions. When the conditions are

met, the PCM energizes the transducer solenoid to

disable the EGR. The PCM checks for a change in the oxygen sensor signal. If the air-fuel mixture goes

lean, the PCM will attempt to enrichen the mixture.

The PCM registers a fault if the EGR system has

failed or degraded. After registering a fault, the PCM

turns on the malfunction indicator lamp (instrument

panel Check Engine light). The malfunction indicator

lamp indicates the need for immediate service.

If a problem is indicated by the malfunction indicator

lamp and a diagnostic trouble code for the EGR system,

check for proper operation of the EGR system. Use the

System Test, EGR Gas Flow Test and EGR Diagnosis

Chart. If the EGR system tests properly, check the sys-

tem using the DRBII scan tool. Refer to On-Board Di-

agnosis in the General Diagnosis sections of Group 14.

Also, refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedure manual.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING EGR SYS-

TEM TEST.

A failed or malfunctioning EGR system can cause

engine spark knock, sags or hesitation, rough idle,

and/or engine stalling. To ensure proper operation of

the EGR system, all passages and moving parts must

be free of deposits that could cause plugging or stick-

ing. Ensure system hoses do not leak. Replace leak-

ing components. Inspect hose connections between the throttle body,

intake manifold, EGR solenoid and transducer, and

EGR valve. Replace hardened, cracked, or melted

hoses. Repair or replace faulty connectors.

Check the EGR control system and EGR valve with

the engine fully warmed up and running (engine cool-

ant temperature over 150ÉF). With the transmission in

neutral and the throttle closed, allow the engine to idle

for 70 seconds. Abruptly accelerate the engine to ap-

proximately 2000 rpm, but not over 3000 rpm. The EGR

valve stem should move when accelerating the engine

(the relative position of the groove on the EGR valve

stem should change). Repeat the test several times to

confirm movement. If the EGR valve stem moves, the

control system is operating normally. If the control sys-

tem is not operating normally, refer to the EGR Diag-

nosis Chart to determine the cause.

EGR GAS FLOW TEST

The following procedure should be used to determine

if exhaust gas is flowing through the EGR system.

Connect a hand vacuum pump to the EGR valve

vacuum motor. With engine running at idle speed,

slowly apply vacuum. Engine speed should begin to

drop when applied vacuum reaches 2.0 to 3.5 inches.

Fig. 14 EGR MountingÐ3.3L and 3.8L Engines

Fig. 15 Electric EGR Transducer (EET) Assembly

Ä EMISSION CONTROL SYSTEMS 25 - 21