brake light CHEVROLET DYNASTY 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 302 of 2438

(2) The voltage output from each of the wheel

speed sensors is verified to be within the correct op-

erating range. If a vehicle is not set in motion within 3 minutes

from the time the ignition switch is turned to the on

position. The solenoid valve test is bypassed but the

pump/motor is activated briefly to verify that it is op-

erating correctly.

WARNING SYSTEMS OPERATION

The ABS system uses an Amber Antilock Warning

Lamp, located in the instrument cluster. The purpose

of the warning lamp is discussed in detail below. The Amber Antilock Warning Light will turn on

whenever the CAB detects a condition which results

in a shutdown of the Antilock brake system. The

Amber Antilock Warning Lamp is normally on until

the CAB completes its self tests and turns the lamp

off (approximately 1-2 seconds). When the Amber

Antilock Warning Light is on, only the Antilock

brake function of the brake system if affected. The

standard brake system and the ability to stop the car

will not be affected when only the Amber Antilock

Warning Light is on.

NORMAL OPERATION OF WARNING LAMP

With ignition key turned to the Crank position, the

Red Brake Warning Lamp and Amber Antilock

Warning Lamp will turn on as a bulb check. The

Amber Antilock Warning Lamp will stay on for 1-2

seconds then turn off, once verification of Antilock

Brake System self diagnosis is completed.

ANTILOCK BRAKE SYSTEM COMPONENTS

The following is a detailed description of the Ben-

dix Antilock 4 Brake System components. For infor-

mation on servicing the Four Wheel Disc Brake

System, see the standard Brake section in the Front

Wheel Drive Car, chassis service manual.

MODULATOR ASSEMBLY

WARNING: THE ONLY COMPONENTS OF THE

MODULATOR ASSSEMBLY THAT ARE SERVICE-

ABLE, ARE THE 2 PROPORTIONING VALVES,

BLEED SCREWS AND THREAD SAVERS. THE RE-

MAINING COMPONENTS OF THE MODULATOR AS-

SEMBLY ARE NOT INTENDED TO BE

SERVICEABLE ITEMS. NO ATTEMPT SHOULD BE

MADE TO REMOVE OR SERVICE ANY OTHER COM-

PONENTS OF THE MODEULATOR ASSEMBLY.

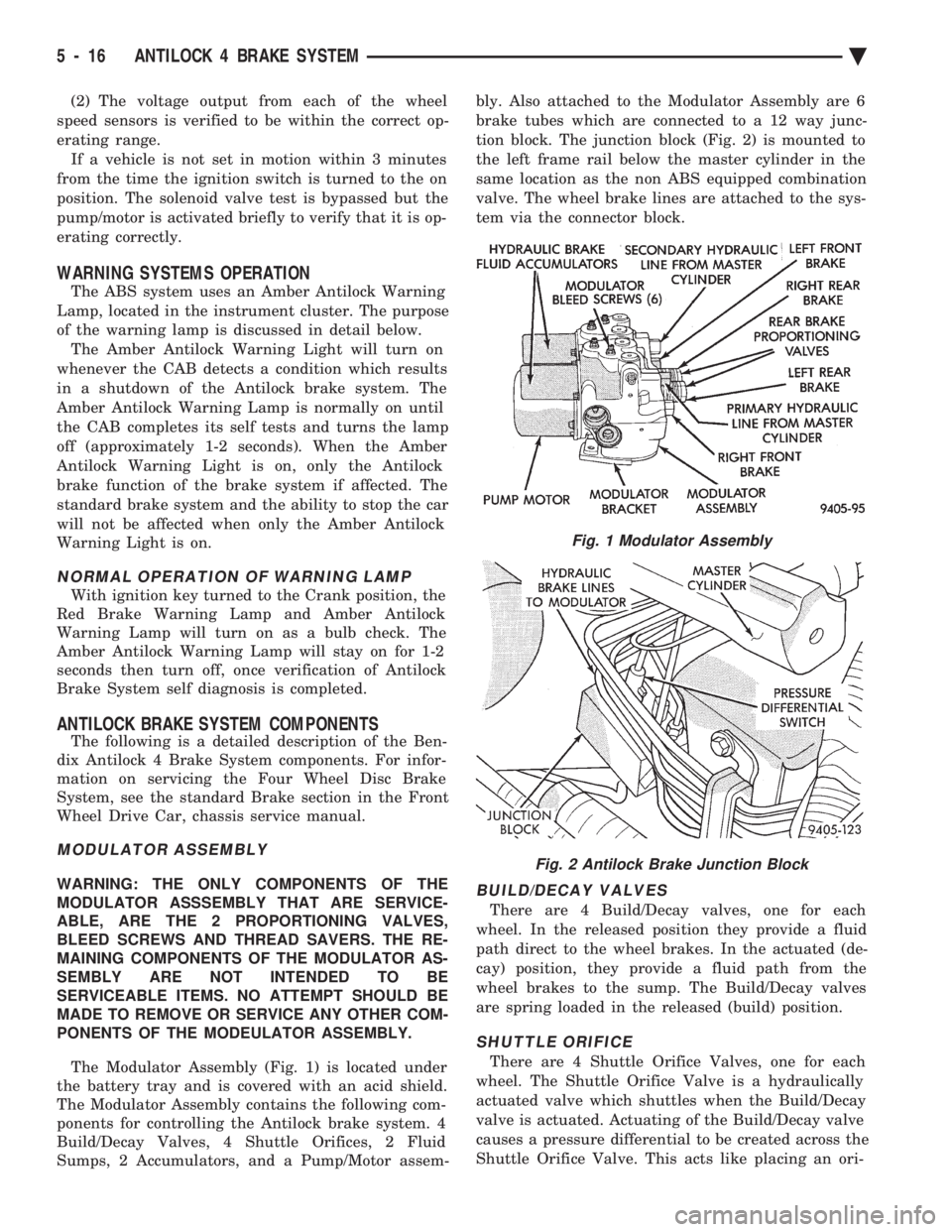

The Modulator Assembly (Fig. 1) is located under

the battery tray and is covered with an acid shield.

The Modulator Assembly contains the following com-

ponents for controlling the Antilock brake system. 4

Build/Decay Valves, 4 Shuttle Orifices, 2 Fluid

Sumps, 2 Accumulators, and a Pump/Motor assem- bly. Also attached to the Modulator Assembly are 6

brake tubes which are connected to a 12 way junc-

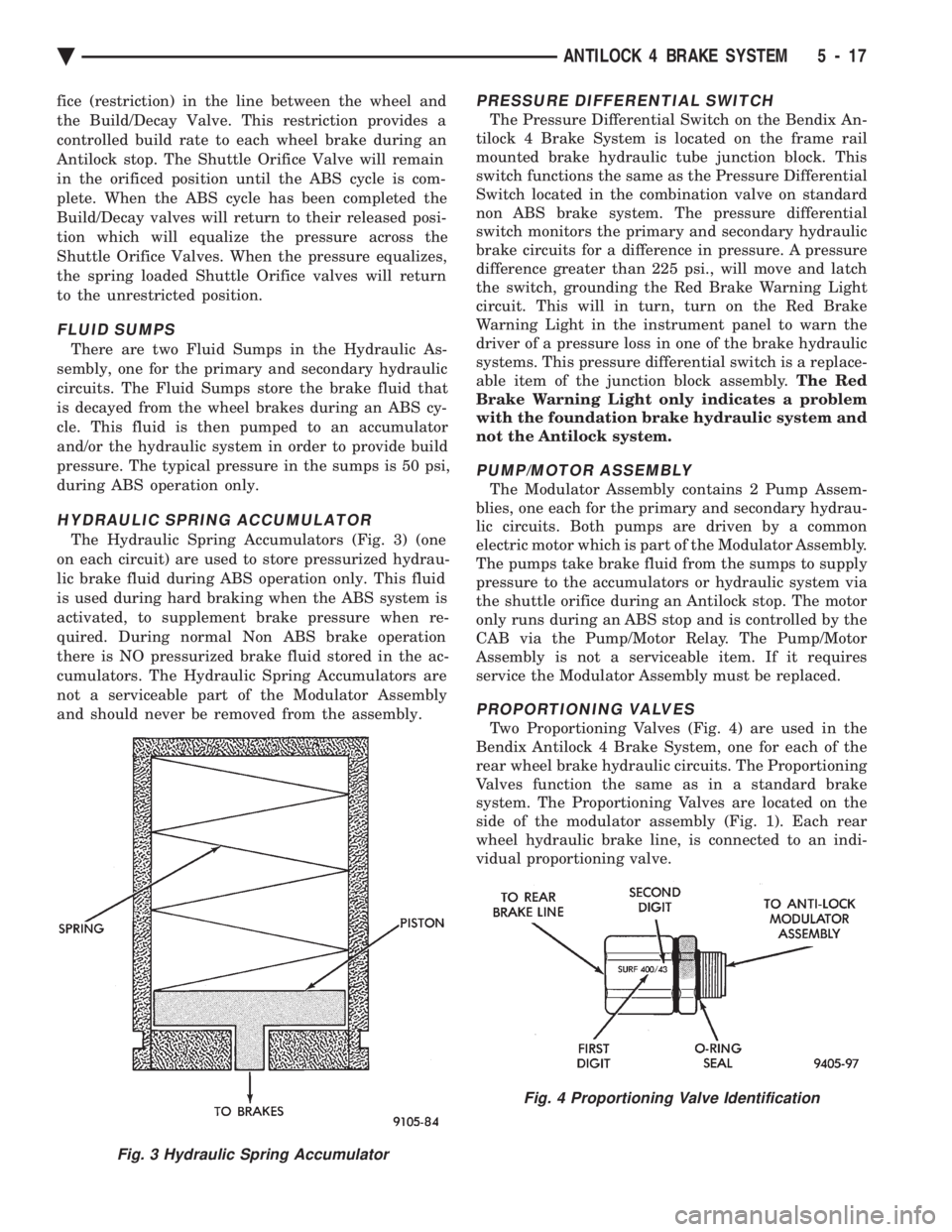

tion block. The junction block (Fig. 2) is mounted to

the left frame rail below the master cylinder in the

same location as the non ABS equipped combination

valve. The wheel brake lines are attached to the sys-

tem via the connector block.BUILD/DECAY VALVES

There are 4 Build/Decay valves, one for each

wheel. In the released position they provide a fluid

path direct to the wheel brakes. In the actuated (de-

cay) position, they provide a fluid path from the

wheel brakes to the sump. The Build/Decay valves

are spring loaded in the released (build) position.

SHUTTLE ORIFICE

There are 4 Shuttle Orifice Valves, one for each

wheel. The Shuttle Orifice Valve is a hydraulically

actuated valve which shuttles when the Build/Decay

valve is actuated. Actuating of the Build/Decay valve

causes a pressure differential to be created across the

Shuttle Orifice Valve. This acts like placing an ori-

Fig. 1 Modulator Assembly

Fig. 2 Antilock Brake Junction Block

5 - 16 ANTILOCK 4 BRAKE SYSTEM Ä

Page 303 of 2438

fice (restriction) in the line between the wheel and

the Build/Decay Valve. This restriction provides a

controlled build rate to each wheel brake during an

Antilock stop. The Shuttle Orifice Valve will remain

in the orificed position until the ABS cycle is com-

plete. When the ABS cycle has been completed the

Build/Decay valves will return to their released posi-

tion which will equalize the pressure across the

Shuttle Orifice Valves. When the pressure equalizes,

the spring loaded Shuttle Orifice valves will return

to the unrestricted position.

FLUID SUMPS

There are two Fluid Sumps in the Hydraulic As-

sembly, one for the primary and secondary hydraulic

circuits. The Fluid Sumps store the brake fluid that

is decayed from the wheel brakes during an ABS cy-

cle. This fluid is then pumped to an accumulator

and/or the hydraulic system in order to provide build

pressure. The typical pressure in the sumps is 50 psi,

during ABS operation only.

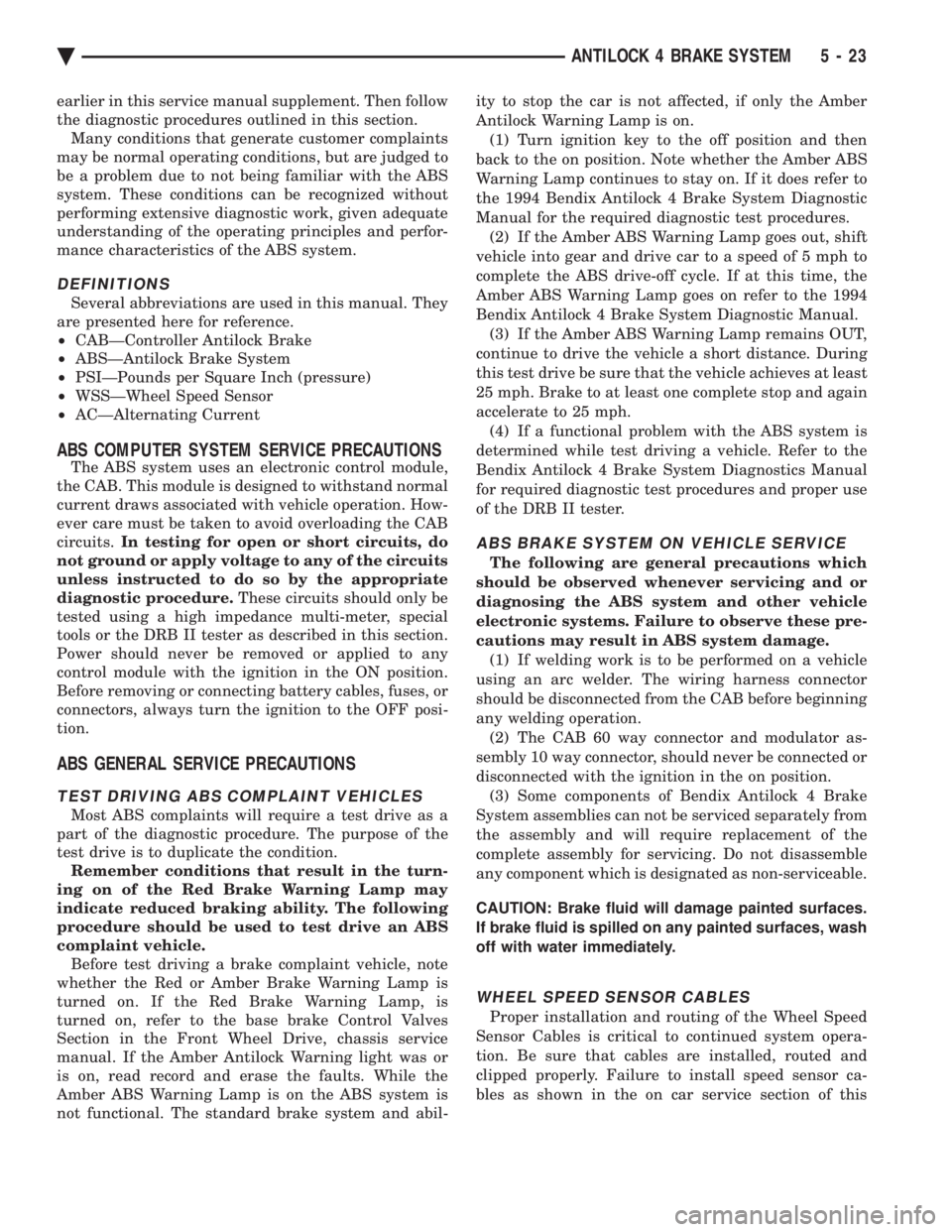

HYDRAULIC SPRING ACCUMULATOR

The Hydraulic Spring Accumulators (Fig. 3) (one

on each circuit) are used to store pressurized hydrau-

lic brake fluid during ABS operation only. This fluid

is used during hard braking when the ABS system is

activated, to supplement brake pressure when re-

quired. During normal Non ABS brake operation

there is NO pressurized brake fluid stored in the ac-

cumulators. The Hydraulic Spring Accumulators are

not a serviceable part of the Modulator Assembly

and should never be removed from the assembly.

PRESSURE DIFFERENTIAL SWITCH

The Pressure Differential Switch on the Bendix An-

tilock 4 Brake System is located on the frame rail

mounted brake hydraulic tube junction block. This

switch functions the same as the Pressure Differential

Switch located in the combination valve on standard

non ABS brake system. The pressure differential

switch monitors the primary and secondary hydraulic

brake circuits for a difference in pressure. A pressure

difference greater than 225 psi., will move and latch

the switch, grounding the Red Brake Warning Light

circuit. This will in turn, turn on the Red Brake

Warning Light in the instrument panel to warn the

driver of a pressure loss in one of the brake hydraulic

systems. This pressure differential switch is a replace-

able item of the junction block assembly. The Red

Brake Warning Light only indicates a problem

with the foundation brake hydraulic system and

not the Antilock system.

PUMP/MOTOR ASSEMBLY

The Modulator Assembly contains 2 Pump Assem-

blies, one each for the primary and secondary hydrau-

lic circuits. Both pumps are driven by a common

electric motor which is part of the Modulator Assembly.

The pumps take brake fluid from the sumps to supply

pressure to the accumulators or hydraulic system via

the shuttle orifice during an Antilock stop. The motor

only runs during an ABS stop and is controlled by the

CAB via the Pump/Motor Relay. The Pump/Motor

Assembly is not a serviceable item. If it requires

service the Modulator Assembly must be replaced.

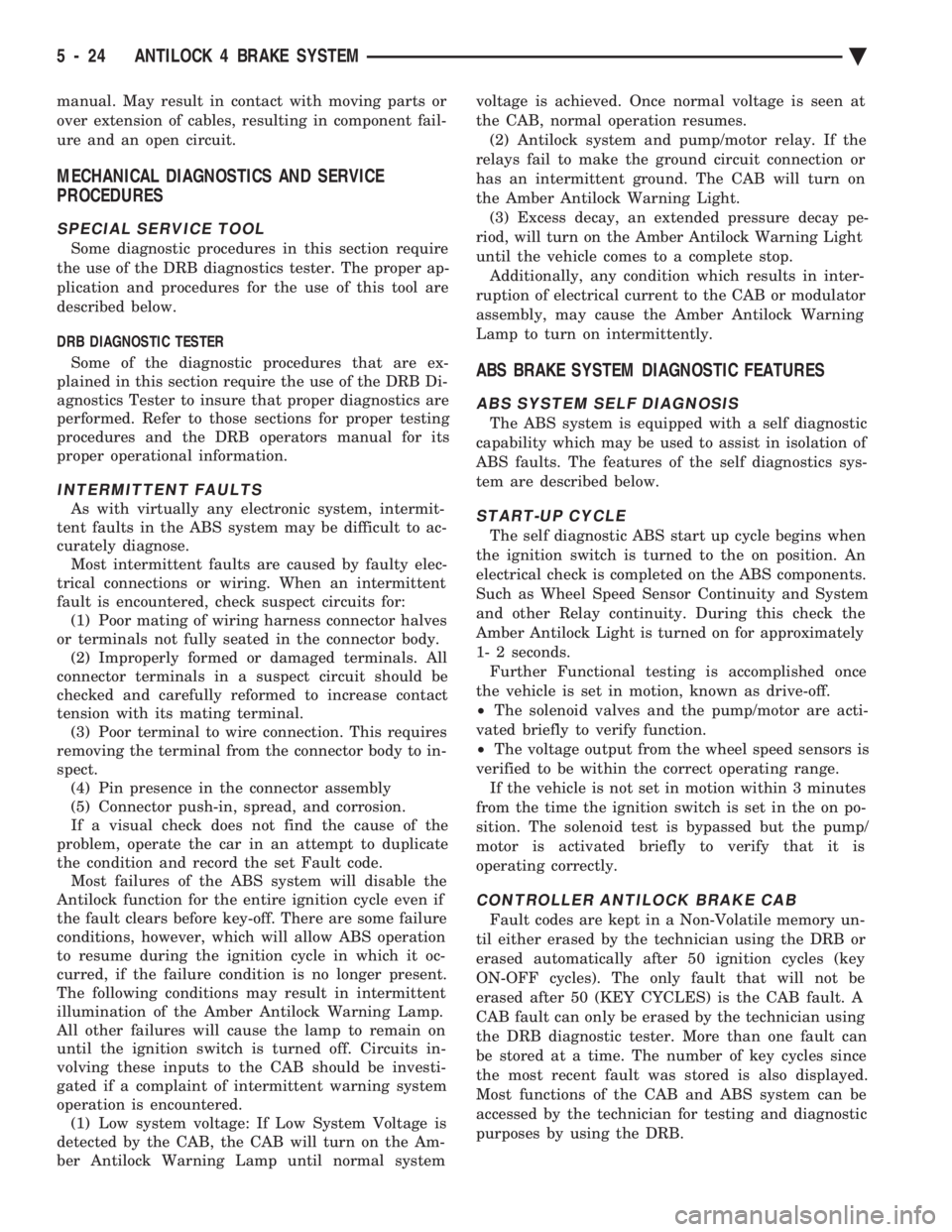

PROPORTIONING VALVES

Two Proportioning Valves (Fig. 4) are used in the

Bendix Antilock 4 Brake System, one for each of the

rear wheel brake hydraulic circuits. The Proportioning

Valves function the same as in a standard brake

system. The Proportioning Valves are located on the

side of the modulator assembly (Fig. 1). Each rear

wheel hydraulic brake line, is connected to an indi-

vidual proportioning valve.

Fig. 3 Hydraulic Spring Accumulator

Fig. 4 Proportioning Valve Identification

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 17

Page 309 of 2438

earlier in this service manual supplement. Then follow

the diagnostic procedures outlined in this section. Many conditions that generate customer complaints

may be normal operating conditions, but are judged to

be a problem due to not being familiar with the ABS

system. These conditions can be recognized without

performing extensive diagnostic work, given adequate

understanding of the operating principles and perfor-

mance characteristics of the ABS system.

DEFINITIONS

Several abbreviations are used in this manual. They

are presented here for reference.

² CABÐController Antilock Brake

² ABSÐAntilock Brake System

² PSIÐPounds per Square Inch (pressure)

² WSSÐWheel Speed Sensor

² ACÐAlternating Current

ABS COMPUTER SYSTEM SERVICE PRECAUTIONS

The ABS system uses an electronic control module,

the CAB. This module is designed to withstand normal

current draws associated with vehicle operation. How-

ever care must be taken to avoid overloading the CAB

circuits. In testing for open or short circuits, do

not ground or apply voltage to any of the circuits

unless instructed to do so by the appropriate

diagnostic procedure. These circuits should only be

tested using a high impedance multi-meter, special

tools or the DRB II tester as described in this section.

Power should never be removed or applied to any

control module with the ignition in the ON position.

Before removing or connecting battery cables, fuses, or

connectors, always turn the ignition to the OFF posi-

tion.

ABS GENERAL SERVICE PRECAUTIONS

TEST DRIVING ABS COMPLAINT VEHICLES

Most ABS complaints will require a test drive as a

part of the diagnostic procedure. The purpose of the

test drive is to duplicate the condition. Remember conditions that result in the turn-

ing on of the Red Brake Warning Lamp may

indicate reduced braking ability. The following

procedure should be used to test drive an ABS

complaint vehicle. Before test driving a brake complaint vehicle, note

whether the Red or Amber Brake Warning Lamp is

turned on. If the Red Brake Warning Lamp, is

turned on, refer to the base brake Control Valves

Section in the Front Wheel Drive, chassis service

manual. If the Amber Antilock Warning light was or

is on, read record and erase the faults. While the

Amber ABS Warning Lamp is on the ABS system is

not functional. The standard brake system and abil- ity to stop the car is not affected, if only the Amber

Antilock Warning Lamp is on.

(1) Turn ignition key to the off position and then

back to the on position. Note whether the Amber ABS

Warning Lamp continues to stay on. If it does refer to

the 1994 Bendix Antilock 4 Brake System Diagnostic

Manual for the required diagnostic test procedures. (2) If the Amber ABS Warning Lamp goes out, shift

vehicle into gear and drive car to a speed of 5 mph to

complete the ABS drive-off cycle. If at this time, the

Amber ABS Warning Lamp goes on refer to the 1994

Bendix Antilock 4 Brake System Diagnostic Manual. (3) If the Amber ABS Warning Lamp remains OUT,

continue to drive the vehicle a short distance. During

this test drive be sure that the vehicle achieves at least

25 mph. Brake to at least one complete stop and again

accelerate to 25 mph. (4) If a functional problem with the ABS system is

determined while test driving a vehicle. Refer to the

Bendix Antilock 4 Brake System Diagnostics Manual

for required diagnostic test procedures and proper use

of the DRB II tester.

ABS BRAKE SYSTEM ON VEHICLE SERVICE

The following are general precautions which

should be observed whenever servicing and or

diagnosing the ABS system and other vehicle

electronic systems. Failure to observe these pre-

cautions may result in ABS system damage. (1) If welding work is to be performed on a vehicle

using an arc welder. The wiring harness connector

should be disconnected from the CAB before beginning

any welding operation. (2) The CAB 60 way connector and modulator as-

sembly 10 way connector, should never be connected or

disconnected with the ignition in the on position. (3) Some components of Bendix Antilock 4 Brake

System assemblies can not be serviced separately from

the assembly and will require replacement of the

complete assembly for servicing. Do not disassemble

any component which is designated as non-serviceable.

CAUTION: Brake fluid will damage painted surfaces.

If brake fluid is spilled on any painted surfaces, wash

off with water immediately.

WHEEL SPEED SENSOR CABLES

Proper installation and routing of the Wheel Speed

Sensor Cables is critical to continued system opera-

tion. Be sure that cables are installed, routed and

clipped properly. Failure to install speed sensor ca-

bles as shown in the on car service section of this

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 23

Page 310 of 2438

manual. May result in contact with moving parts or

over extension of cables, resulting in component fail-

ure and an open circuit.

MECHANICAL DIAGNOSTICS AND SERVICE

PROCEDURES

SPECIAL SERVICE TOOL

Some diagnostic procedures in this section require

the use of the DRB diagnostics tester. The proper ap-

plication and procedures for the use of this tool are

described below.

DRB DIAGNOSTIC TESTER

Some of the diagnostic procedures that are ex-

plained in this section require the use of the DRB Di-

agnostics Tester to insure that proper diagnostics are

performed. Refer to those sections for proper testing

procedures and the DRB operators manual for its

proper operational information.

INTERMITTENT FAULTS

As with virtually any electronic system, intermit-

tent faults in the ABS system may be difficult to ac-

curately diagnose. Most intermittent faults are caused by faulty elec-

trical connections or wiring. When an intermittent

fault is encountered, check suspect circuits for: (1) Poor mating of wiring harness connector halves

or terminals not fully seated in the connector body. (2) Improperly formed or damaged terminals. All

connector terminals in a suspect circuit should be

checked and carefully reformed to increase contact

tension with its mating terminal. (3) Poor terminal to wire connection. This requires

removing the terminal from the connector body to in-

spect. (4) Pin presence in the connector assembly

(5) Connector push-in, spread, and corrosion.

If a visual check does not find the cause of the

problem, operate the car in an attempt to duplicate

the condition and record the set Fault code. Most failures of the ABS system will disable the

Antilock function for the entire ignition cycle even if

the fault clears before key-off. There are some failure

conditions, however, which will allow ABS operation

to resume during the ignition cycle in which it oc-

curred, if the failure condition is no longer present.

The following conditions may result in intermittent

illumination of the Amber Antilock Warning Lamp.

All other failures will cause the lamp to remain on

until the ignition switch is turned off. Circuits in-

volving these inputs to the CAB should be investi-

gated if a complaint of intermittent warning system

operation is encountered. (1) Low system voltage: If Low System Voltage is

detected by the CAB, the CAB will turn on the Am-

ber Antilock Warning Lamp until normal system voltage is achieved. Once normal voltage is seen at

the CAB, normal operation resumes.

(2) Antilock system and pump/motor relay. If the

relays fail to make the ground circuit connection or

has an intermittent ground. The CAB will turn on

the Amber Antilock Warning Light. (3) Excess decay, an extended pressure decay pe-

riod, will turn on the Amber Antilock Warning Light

until the vehicle comes to a complete stop. Additionally, any condition which results in inter-

ruption of electrical current to the CAB or modulator

assembly, may cause the Amber Antilock Warning

Lamp to turn on intermittently.

ABS BRAKE SYSTEM DIAGNOSTIC FEATURES

ABS SYSTEM SELF DIAGNOSIS

The ABS system is equipped with a self diagnostic

capability which may be used to assist in isolation of

ABS faults. The features of the self diagnostics sys-

tem are described below.

START-UP CYCLE

The self diagnostic ABS start up cycle begins when

the ignition switch is turned to the on position. An

electrical check is completed on the ABS components.

Such as Wheel Speed Sensor Continuity and System

and other Relay continuity. During this check the

Amber Antilock Light is turned on for approximately

1- 2 seconds. Further Functional testing is accomplished once

the vehicle is set in motion, known as drive-off.

² The solenoid valves and the pump/motor are acti-

vated briefly to verify function.

² The voltage output from the wheel speed sensors is

verified to be within the correct operating range. If the vehicle is not set in motion within 3 minutes

from the time the ignition switch is set in the on po-

sition. The solenoid test is bypassed but the pump/

motor is activated briefly to verify that it is

operating correctly.

CONTROLLER ANTILOCK BRAKE CAB

Fault codes are kept in a Non-Volatile memory un-

til either erased by the technician using the DRB or

erased automatically after 50 ignition cycles (key

ON-OFF cycles). The only fault that will not be

erased after 50 (KEY CYCLES) is the CAB fault. A

CAB fault can only be erased by the technician using

the DRB diagnostic tester. More than one fault can

be stored at a time. The number of key cycles since

the most recent fault was stored is also displayed.

Most functions of the CAB and ABS system can be

accessed by the technician for testing and diagnostic

purposes by using the DRB.

5 - 24 ANTILOCK 4 BRAKE SYSTEM Ä

Page 311 of 2438

LATCHING VERSUS NON-LATCHING ABS FAULTS

Some faults detected by the CAB are latching; the

fault is latched and ABS is disabled until the igni-

tion switch is reset. Thus ABS is disabled even if the

original fault has disappeared. Other faults are non-

latching; any warning lights that are turned on, are

only turned on as long as the fault condition exists.

As soon as the condition goes away, the Antilock

Warning Light is turned off. Although a fault code

will be set in most cases.

BENDIX ANTILOCK 4 BRAKE SYSTEM DIAGNOSTICS

Bendix Antilock 4 Brake System Diagnostics, be-

yond basic mechanical diagnostics, covered earlier in

this section, are accomplished by using the DRB scan

tool. See testing procedures outlined in the 1994 Ben-

dix Antilock 4 Diagnostics Manual. Please refer to the above mentioned manual for

any further electronic diagnostics and service proce-

dures that are required on the Bendix Antilock 4

Brake System.

ON-CAR ABS BRAKE SYSTEM SERVICE

GENERAL SERVICE PRECAUTIONS

The following are general cautions which should be

observed when servicing the Bendix Antilock 4

Brake System and other vehicle electronic systems.

Failure to observe these precautions may result in

Antilock Brake System component damage. If welding work is to be performed on a vehicle us-

ing an electric arc welder, disconnect the 60 way wir-

ing harness connector from the CAB, prior to

performing the welding operation. The wiring harness connector should never be con-

nected or disconnected from the CAB with the igni-

tion key in the ON or Run position. (3) Most components making up the assemblies of

the Bendix Antilock 4 Brake System can not be ser-

viced separately from those assemblies. This will re-

quire replacement of the complete assembly for the

servicing of these components. Do not disassemble

any component from an assembly which is desig-

nated as non-serviceable.

CHECKING BRAKE FLUID LEVEL

CAUTION: Only use brake fluid conforming to DOT

3 specifications, such as Mopar or Equivalent. Do

not use any fluid which contains a petroleum base.

Do not use a container which has been used for pe-

troleum based fluids or a container which is wet

with water. Petroleum based fluids will cause swell-

ing and distortion of rubber parts in the hydraulic

brake system. Water will mix with brake fluid, low-

ering the boiling point of the brake fluid, possibly causing brake fluid to boil resulting in brake fade.

Keep all brake fluid containers capped to prevent

contamination. Remove the front cap of the master

cylinder reservoir and fill to the bottom of the split

ring.

For the specific procedure for the inspection of

brake fluid level and adding of brake to the reser-

voir. Refer to the Service Adjustments Section in this

group of the service manual.

BLEEDING BENDIX ANTILOCK 4 BRAKE SYSTEM

The base brakes and Antilock Brake System must

be bled anytime air is permitted to enter the hydrau-

lic system, due to disconnection of brake lines, hoses

or components. If the Antilock Modulator Assembly is removed

from the vehicle, both the Base Brake System and

the Antilock Brake System must be bled using the

appropriate procedure. It is important to note that

excessive air in the brake system will cause a soft or

spongy feeling brake pedal. During brake bleeding operations, ensure that

brake fluid level remains close to the FULL level in

the reservoir. Check brake fluid level periodically

during bleeding procedure, adding DOT 3 brake fluid

as required.

CAUTION: The base brake and Antilock brake hy-

draulic systems, on the Bendix Antilock 4 Brake

System, can NOT be bled using any type of brake

pressure bleeding equipment. This type of bleeding

equipment does not develop the pressure required

in the brake hydraulic system, to adequately bleed

all trapped air. The only approved method for bleed-

ing air out of the hydraulic system on vehicles

equipped with the Bendix Antilock 4 Brake System,

is the manual procedure of pressurizing the hydrau-

lic system using constant, moderate to heavy foot

pressure on the brake pedal.

The Bendix Antilock 4 Brake System must be bled

as two independent brake systems. The non ABS por-

tion of the brake system is to be bled the same as

any non ABS system. Refer to the Service Adjust-

ments section in this manual for the proper bleeding

procedure to be used. The Bendix Antilock 4 Brake

System can only be bled using a manual method of

pressurizing the brakes hydraulic system. The Antilock portion of brake system MUST be

bled separately. This bleeding procedure requires the

use of the DRB Diagnostic tester and the bleeding se-

quence procedure outlined below.

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 25

Page 313 of 2438

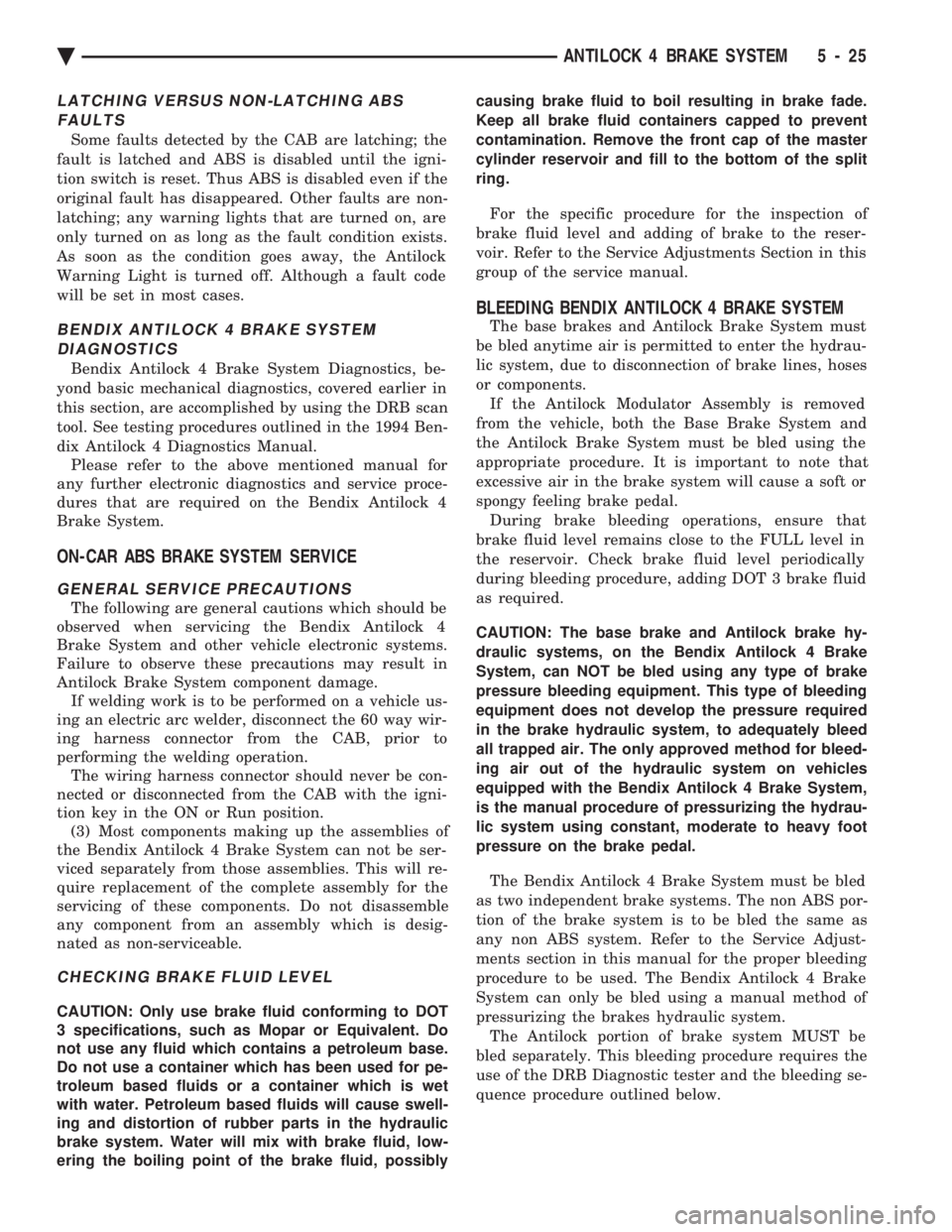

(4) After brake pedal bottoms, close and tighten

bleed screw and release brake pedal. Do not release

brake pedal prior to closing and tightening bleed

screw. (5) Continue bleeding secondary check valve circuit,

repeating steps 2 through 4, until a clear, bubble free

flow of brake fluid is evident. (6) When air is bled from primary check valve cir-

cuit, tighten bleed screw and remove bleed hose from

bleed screw. Do not remove bleed hose before

tightening bleed screw, air may re-enter modula-

tor. (7) Torque modulator assembly primary bleed screw

to9N Im (80 in. lbs.).

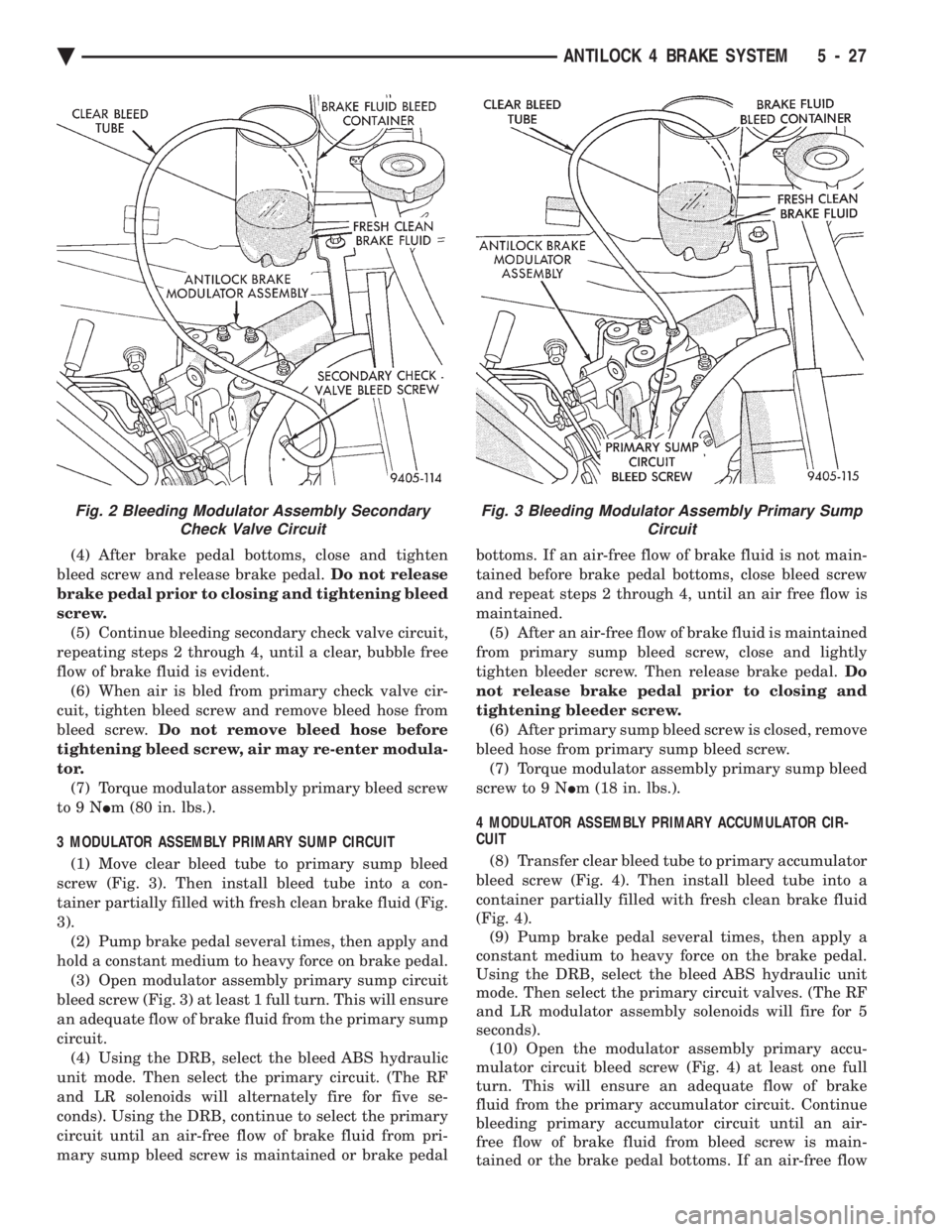

3 MODULATOR ASSEMBLY PRIMARY SUMP CIRCUIT (1) Move clear bleed tube to primary sump bleed

screw (Fig. 3). Then install bleed tube into a con-

tainer partially filled with fresh clean brake fluid (Fig.

3). (2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open modulator assembly primary sump circuit

bleed screw (Fig. 3) at least 1 full turn. This will ensure

an adequate flow of brake fluid from the primary sump

circuit. (4) Using the DRB, select the bleed ABS hydraulic

unit mode. Then select the primary circuit. (The RF

and LR solenoids will alternately fire for five se-

conds). Using the DRB, continue to select the primary

circuit until an air-free flow of brake fluid from pri-

mary sump bleed screw is maintained or brake pedal bottoms. If an air-free flow of brake fluid is not main-

tained before brake pedal bottoms, close bleed screw

and repeat steps 2 through 4, until an air free flow is

maintained.

(5) After an air-free flow of brake fluid is maintained

from primary sump bleed screw, close and lightly

tighten bleeder screw. Then release brake pedal. Do

not release brake pedal prior to closing and

tightening bleeder screw. (6) After primary sump bleed screw is closed, remove

bleed hose from primary sump bleed screw. (7) Torque modulator assembly primary sump bleed

screw to 9 N Im (18 in. lbs.).

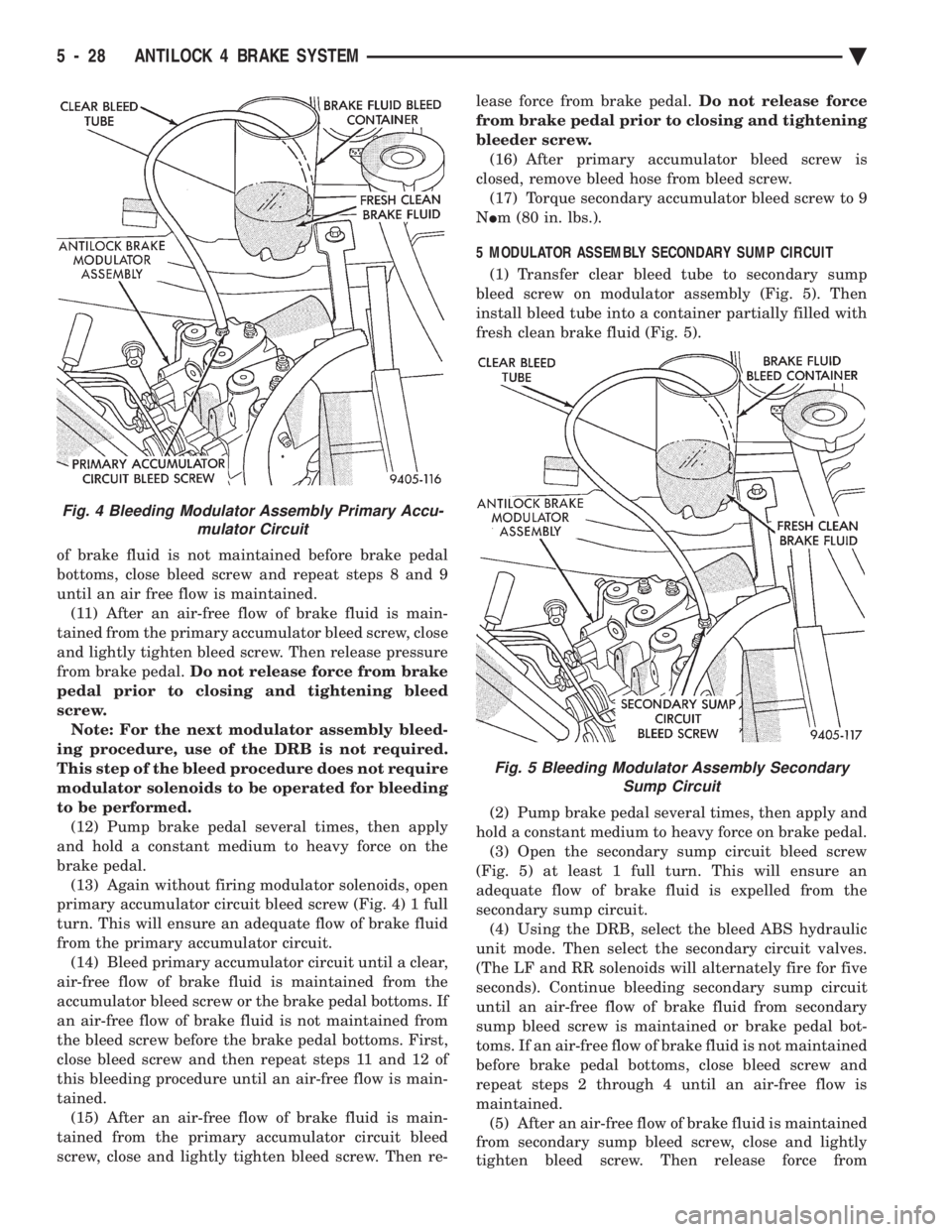

4 MODULATOR ASSEMBLY PRIMARY ACCUMULATOR CIR-

CUIT

(8) Transfer clear bleed tube to primary accumulator

bleed screw (Fig. 4). Then install bleed tube into a

container partially filled with fresh clean brake fluid

(Fig. 4). (9) Pump brake pedal several times, then apply a

constant medium to heavy force on the brake pedal.

Using the DRB, select the bleed ABS hydraulic unit

mode. Then select the primary circuit valves. (The RF

and LR modulator assembly solenoids will fire for 5

seconds). (10) Open the modulator assembly primary accu-

mulator circuit bleed screw (Fig. 4) at least one full

turn. This will ensure an adequate flow of brake

fluid from the primary accumulator circuit. Continue

bleeding primary accumulator circuit until an air-

free flow of brake fluid from bleed screw is main-

tained or the brake pedal bottoms. If an air-free flow

Fig. 3 Bleeding Modulator Assembly Primary Sump CircuitFig. 2 Bleeding Modulator Assembly SecondaryCheck Valve Circuit

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 27

Page 314 of 2438

of brake fluid is not maintained before brake pedal

bottoms, close bleed screw and repeat steps 8 and 9

until an air free flow is maintained.(11) After an air-free flow of brake fluid is main-

tained from the primary accumulator bleed screw, close

and lightly tighten bleed screw. Then release pressure

from brake pedal. Do not release force from brake

pedal prior to closing and tightening bleed

screw. Note: For the next modulator assembly bleed-

ing procedure, use of the DRB is not required.

This step of the bleed procedure does not require

modulator solenoids to be operated for bleeding

to be performed. (12) Pump brake pedal several times, then apply

and hold a constant medium to heavy force on the

brake pedal. (13) Again without firing modulator solenoids, open

primary accumulator circuit bleed screw (Fig. 4) 1 full

turn. This will ensure an adequate flow of brake fluid

from the primary accumulator circuit. (14) Bleed primary accumulator circuit until a clear,

air-free flow of brake fluid is maintained from the

accumulator bleed screw or the brake pedal bottoms. If

an air-free flow of brake fluid is not maintained from

the bleed screw before the brake pedal bottoms. First,

close bleed screw and then repeat steps 11 and 12 of

this bleeding procedure until an air-free flow is main-

tained. (15) After an air-free flow of brake fluid is main-

tained from the primary accumulator circuit bleed

screw, close and lightly tighten bleed screw. Then re- lease force from brake pedal.

Do not release force

from brake pedal prior to closing and tightening

bleeder screw. (16) After primary accumulator bleed screw is

closed, remove bleed hose from bleed screw. (17) Torque secondary accumulator bleed screw to 9

N Im (80 in. lbs.).

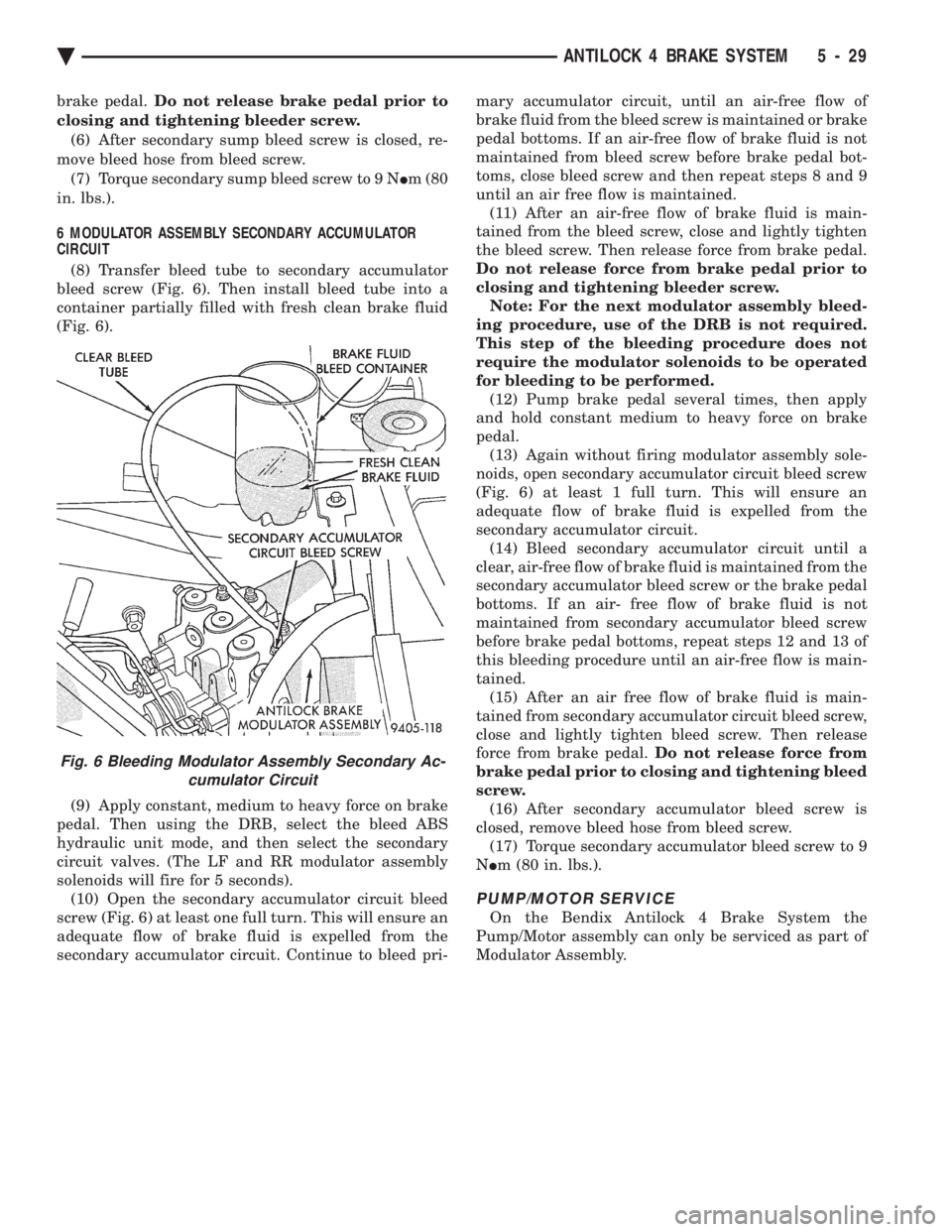

5 MODULATOR ASSEMBLY SECONDARY SUMP CIRCUIT (1) Transfer clear bleed tube to secondary sump

bleed screw on modulator assembly (Fig. 5). Then

install bleed tube into a container partially filled with

fresh clean brake fluid (Fig. 5).

(2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open the secondary sump circuit bleed screw

(Fig. 5) at least 1 full turn. This will ensure an

adequate flow of brake fluid is expelled from the

secondary sump circuit. (4) Using the DRB, select the bleed ABS hydraulic

unit mode. Then select the secondary circuit valves.

(The LF and RR solenoids will alternately fire for five

seconds). Continue bleeding secondary sump circuit

until an air-free flow of brake fluid from secondary

sump bleed screw is maintained or brake pedal bot-

toms. If an air-free flow of brake fluid is not maintained

before brake pedal bottoms, close bleed screw and

repeat steps 2 through 4 until an air-free flow is

maintained. (5) After an air-free flow of brake fluid is maintained

from secondary sump bleed screw, close and lightly

tighten bleed screw. Then release force from

Fig. 4 Bleeding Modulator Assembly Primary Accu- mulator Circuit

Fig. 5 Bleeding Modulator Assembly SecondarySump Circuit

5 - 28 ANTILOCK 4 BRAKE SYSTEM Ä

Page 315 of 2438

brake pedal. Do not release brake pedal prior to

closing and tightening bleeder screw. (6) After secondary sump bleed screw is closed, re-

move bleed hose from bleed screw. (7) Torque secondary sump bleed screw to 9 N Im (80

in. lbs.).

6 MODULATOR ASSEMBLY SECONDARY ACCUMULATOR

CIRCUIT

(8) Transfer bleed tube to secondary accumulator

bleed screw (Fig. 6). Then install bleed tube into a

container partially filled with fresh clean brake fluid

(Fig. 6).

(9) Apply constant, medium to heavy force on brake

pedal. Then using the DRB, select the bleed ABS

hydraulic unit mode, and then select the secondary

circuit valves. (The LF and RR modulator assembly

solenoids will fire for 5 seconds). (10) Open the secondary accumulator circuit bleed

screw (Fig. 6) at least one full turn. This will ensure an

adequate flow of brake fluid is expelled from the

secondary accumulator circuit. Continue to bleed pri- mary accumulator circuit, until an air-free flow of

brake fluid from the bleed screw is maintained or brake

pedal bottoms. If an air-free flow of brake fluid is not

maintained from bleed screw before brake pedal bot-

toms, close bleed screw and then repeat steps 8 and 9

until an air free flow is maintained. (11) After an air-free flow of brake fluid is main-

tained from the bleed screw, close and lightly tighten

the bleed screw. Then release force from brake pedal.

Do not release force from brake pedal prior to

closing and tightening bleeder screw. Note: For the next modulator assembly bleed-

ing procedure, use of the DRB is not required.

This step of the bleeding procedure does not

require the modulator solenoids to be operated

for bleeding to be performed. (12) Pump brake pedal several times, then apply

and hold constant medium to heavy force on brake

pedal. (13) Again without firing modulator assembly sole-

noids, open secondary accumulator circuit bleed screw

(Fig. 6) at least 1 full turn. This will ensure an

adequate flow of brake fluid is expelled from the

secondary accumulator circuit. (14) Bleed secondary accumulator circuit until a

clear, air-free flow of brake fluid is maintained from the

secondary accumulator bleed screw or the brake pedal

bottoms. If an air- free flow of brake fluid is not

maintained from secondary accumulator bleed screw

before brake pedal bottoms, repeat steps 12 and 13 of

this bleeding procedure until an air-free flow is main-

tained. (15) After an air free flow of brake fluid is main-

tained from secondary accumulator circuit bleed screw,

close and lightly tighten bleed screw. Then release

force from brake pedal. Do not release force from

brake pedal prior to closing and tightening bleed

screw. (16) After secondary accumulator bleed screw is

closed, remove bleed hose from bleed screw. (17) Torque secondary accumulator bleed screw to 9

N Im (80 in. lbs.).

PUMP/MOTOR SERVICE

On the Bendix Antilock 4 Brake System the

Pump/Motor assembly can only be serviced as part of

Modulator Assembly.

Fig. 6 Bleeding Modulator Assembly Secondary Ac- cumulator Circuit

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 29

Page 325 of 2438

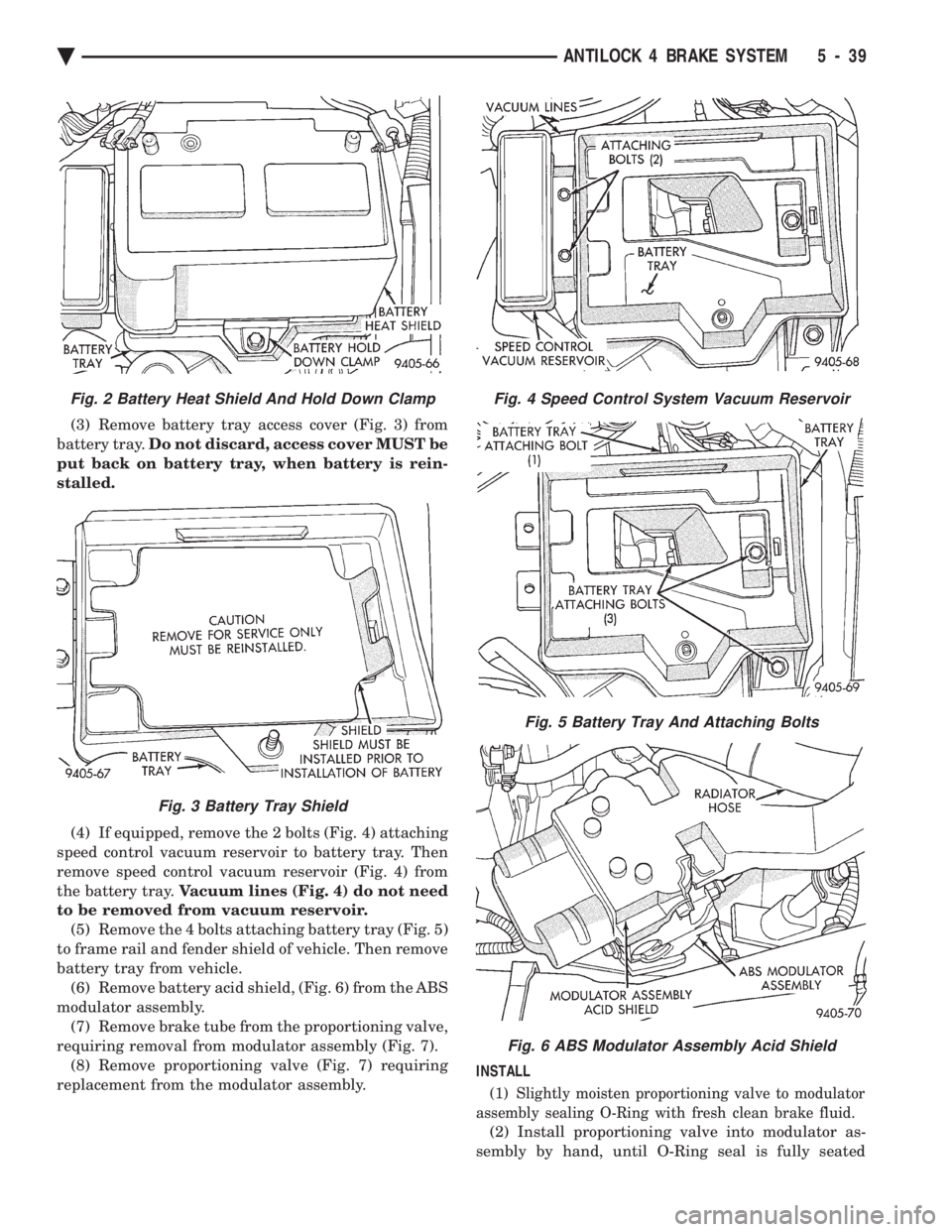

(3) Remove battery tray access cover (Fig. 3) from

battery tray. Do not discard, access cover MUST be

put back on battery tray, when battery is rein-

stalled.

(4) If equipped, remove the 2 bolts (Fig. 4) attaching

speed control vacuum reservoir to battery tray. Then

remove speed control vacuum reservoir (Fig. 4) from

the battery tray. Vacuum lines (Fig. 4) do not need

to be removed from vacuum reservoir. (5) Remove the 4 bolts attaching battery tray (Fig. 5)

to frame rail and fender shield of vehicle. Then remove

battery tray from vehicle. (6) Remove battery acid shield, (Fig. 6) from the ABS

modulator assembly. (7) Remove brake tube from the proportioning valve,

requiring removal from modulator assembly (Fig. 7). (8) Remove proportioning valve (Fig. 7) requiring

replacement from the modulator assembly. INSTALL

(1) Slightly moisten proportioning valve to modulator

assembly sealing O-Ring with fresh clean brake fluid.

(2) Install proportioning valve into modulator as-

sembly by hand, until O-Ring seal is fully seated

Fig. 4 Speed Control System Vacuum Reservoir

Fig. 5 Battery Tray And Attaching Bolts

Fig. 6 ABS Modulator Assembly Acid Shield

Fig. 2 Battery Heat Shield And Hold Down Clamp

Fig. 3 Battery Tray Shield

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 39

Page 385 of 2438

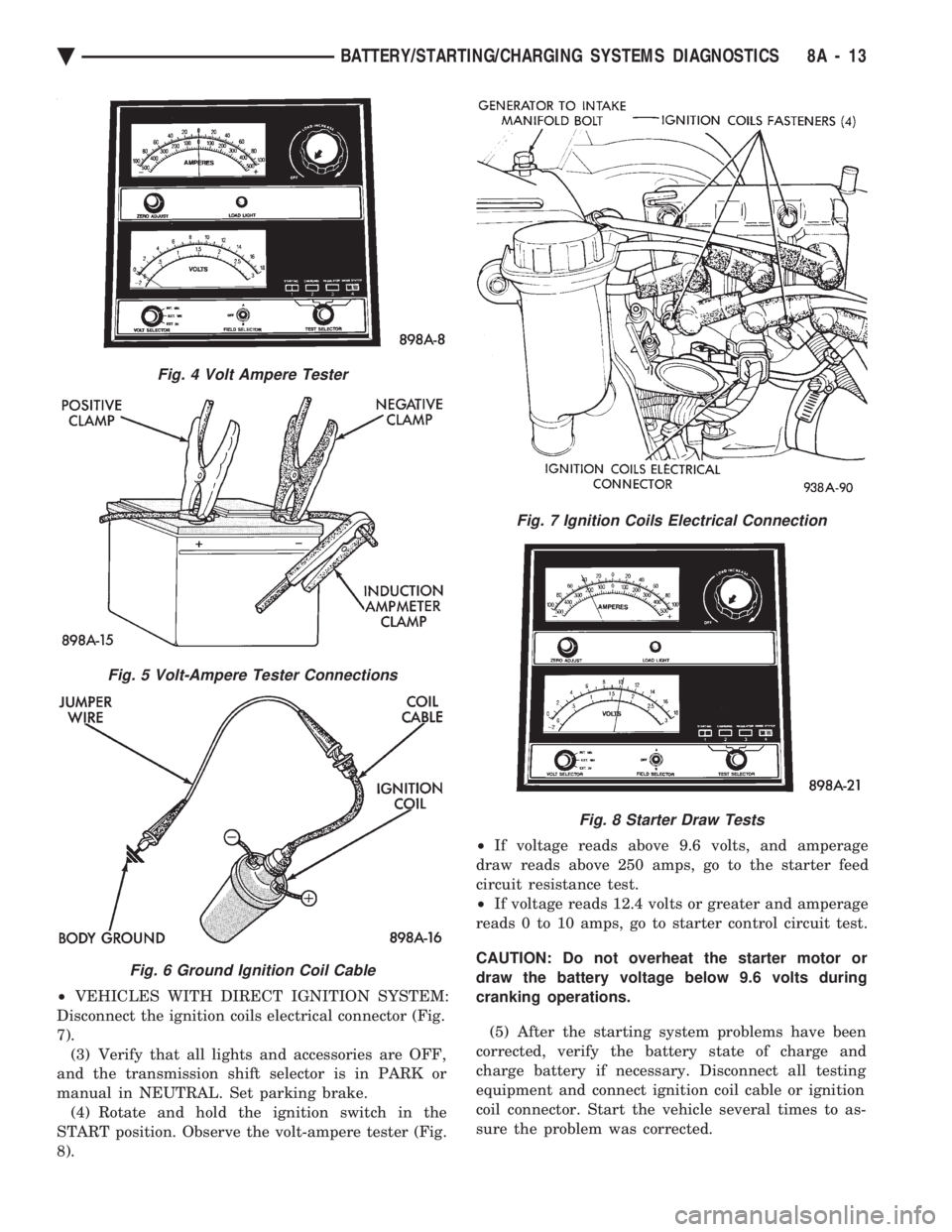

² VEHICLES WITH DIRECT IGNITION SYSTEM:

Disconnect the ignition coils electrical connector (Fig.

7). (3) Verify that all lights and accessories are OFF,

and the transmission shift selector is in PARK or

manual in NEUTRAL. Set parking brake. (4) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

8). ²

If voltage reads above 9.6 volts, and amperage

draw reads above 250 amps, go to the starter feed

circuit resistance test.

² If voltage reads 12.4 volts or greater and amperage

reads 0 to 10 amps, go to starter control circuit test.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(5) After the starting system problems have been

corrected, verify the battery state of charge and

charge battery if necessary. Disconnect all testing

equipment and connect ignition coil cable or ignition

coil connector. Start the vehicle several times to as-

sure the problem was corrected.

Fig. 4 Volt Ampere Tester

Fig. 5 Volt-Ampere Tester Connections

Fig. 6 Ground Ignition Coil Cable

Fig. 7 Ignition Coils Electrical Connection

Fig. 8 Starter Draw Tests

Ä BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 13