brake light CHEVROLET DYNASTY 1993 Manual PDF

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 1284 of 2438

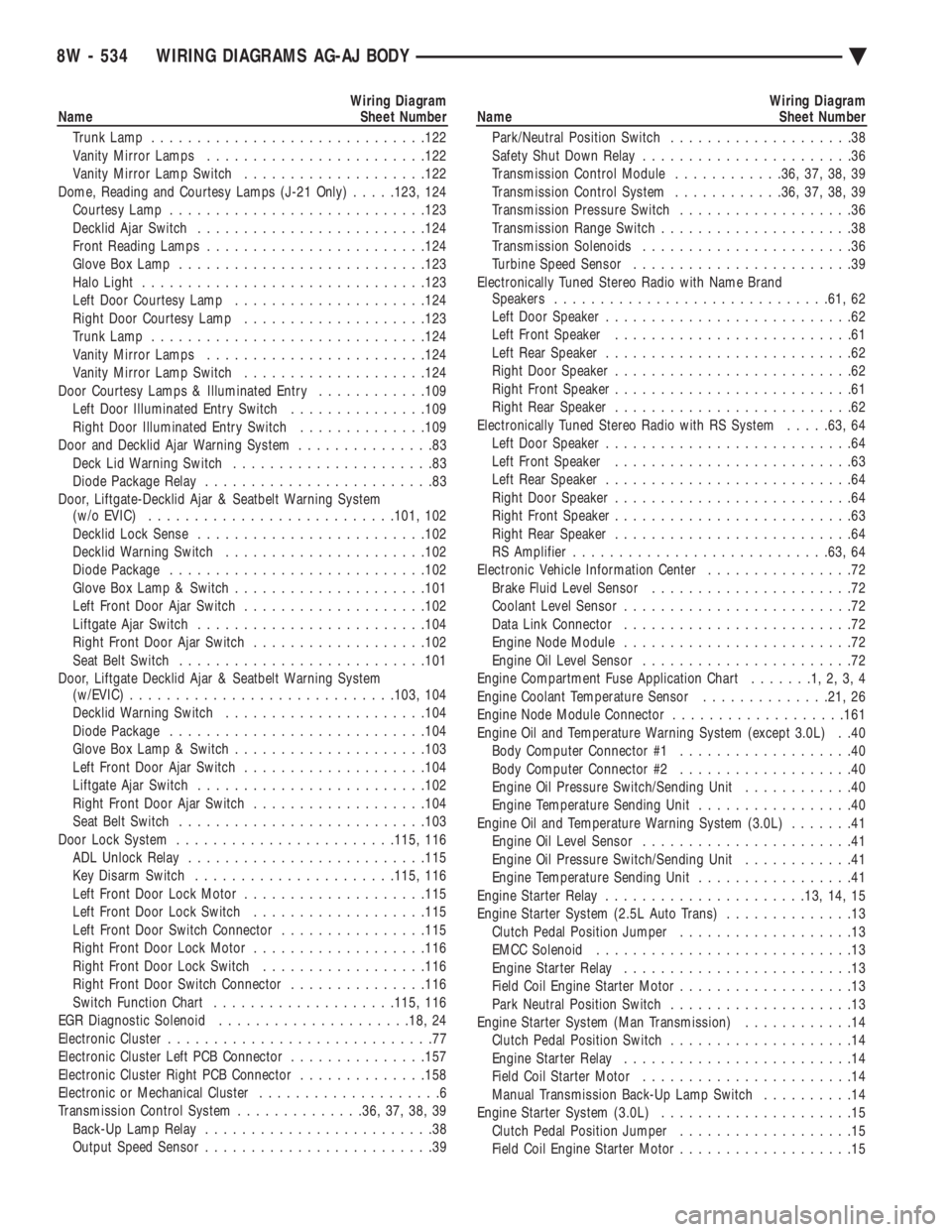

Wiring Diagram

Name Sheet Number

Trunk Lamp ............................. .122

Vanity Mirror Lamps ....................... .122

Vanity Mirror Lamp Switch ................... .122

Dome, Reading and Courtesy Lamps (J-21 Only) .....123, 124

Courtesy Lamp ........................... .123

Decklid Ajar Switch ........................ .124

Front Reading Lamps ....................... .124

Glove Box Lamp .......................... .123

Halo Light .............................. .123

Left Door Courtesy Lamp .................... .124

Right Door Courtesy Lamp ................... .123

Trunk Lamp ............................. .124

Vanity Mirror Lamps ....................... .124

Vanity Mirror Lamp Switch ................... .124

Door Courtesy Lamps & Illuminated Entry ............109

Left Door Illuminated Entry Switch ...............109

Right Door Illuminated Entry Switch ..............109

Door and Decklid Ajar Warning System ...............83

Deck Lid Warning Switch ......................83

Diode Package Relay .........................83

Door, Liftgate-Decklid Ajar & Seatbelt Warning System (w/o EVIC) .......................... .101, 102

Decklid Lock Sense ........................ .102

Decklid Warning Switch ..................... .102

Diode Package ........................... .102

Glove Box Lamp & Switch .................... .101

Left Front Door Ajar Switch ................... .102

Liftgate Ajar Switch ........................ .104

Right Front Door Ajar Switch ...................102

Seat Belt Switch .......................... .101

Door, Liftgate Decklid Ajar & Seatbelt Warning System (w/EVIC) ............................ .103, 104

Decklid Warning Switch ..................... .104

Diode Package ........................... .104

Glove Box Lamp & Switch .................... .103

Left Front Door Ajar Switch ................... .104

Liftgate Ajar Switch ........................ .102

Right Front Door Ajar Switch ...................104

Seat Belt Switch .......................... .103

Door Lock System ....................... .115, 116

ADL Unlock Relay ......................... .115

Key Disarm Switch ..................... .115, 116

Left Front Door Lock Motor ................... .115

Left Front Door Lock Switch ...................115

Left Front Door Switch Connector ................115

Right Front Door Lock Motor ...................116

Right Front Door Lock Switch ..................116

Right Front Door Switch Connector ...............116

Switch Function Chart ................... .115, 116

EGR Diagnostic Solenoid .................... .18, 24

Electronic Cluster .............................77

Electronic Cluster Left PCB Connector ...............157

Electronic Cluster Right PCB Connector ..............158

Electronic or Mechanical Cluster ....................6

Transmission Control System ..............36, 37, 38, 39

Back-Up Lamp Relay .........................38

Output Speed Sensor .........................39Wiring Diagram

Name Sheet Number

Park/Neutral Position Switch ....................38

Safety Shut Down Relay .......................36

Transmission Control Module ............36, 37, 38, 39

Transmission Control System ............36, 37, 38, 39

Transmission Pressure Switch ...................36

Transmission Range Switch .....................38

Transmission Solenoids .......................36

Turbine Speed Sensor ........................39

Electronically Tuned Stereo Radio with Name Brand Speakers ............................. .61, 62

Left Door Speaker ...........................62

Left Front Speaker ..........................61

Left Rear Speaker ...........................62

Right Door Speaker ..........................62

Right Front Speaker ..........................61

Right Rear Speaker ..........................62

Electronically Tuned Stereo Radio with RS System .....63, 64

Left Door Speaker ...........................64

Left Front Speaker ..........................63

Left Rear Speaker ...........................64

Right Door Speaker ..........................64

Right Front Speaker ..........................63

Right Rear Speaker ..........................64

RS Amplifier ........................... .63, 64

Electronic Vehicle Information Center ................72

Brake Fluid Level Sensor ......................72

Coolant Level Sensor .........................72

Data Link Connector .........................72

Engine Node Module .........................72

Engine Oil Level Sensor .......................72

Engine Compartment Fuse Application Chart .......1,2,3,4

Engine Coolant Temperature Sensor ..............21, 26

Engine Node Module Connector ...................161

Engine Oil and Temperature Warning System (except 3.0L) . .40 Body Computer Connector #1 ...................40

Body Computer Connector #2 ...................40

Engine Oil Pressure Switch/Sending Unit ............40

Engine Temperature Sending Unit .................40

Engine Oil and Temperature Warning System (3.0L) .......41

Engine Oil Level Sensor .......................41

Engine Oil Pressure Switch/Sending Unit ............41

Engine Temperature Sending Unit .................41

Engine Starter Relay ..................... .13, 14, 15

Engine Starter System (2.5L Auto Trans) ..............13

Clutch Pedal Position Jumper ...................13

EMCC Solenoid ............................13

Engine Starter Relay .........................13

Field Coil Engine Starter Motor ...................13

Park Neutral Position Switch ....................13

Engine Starter System (Man Transmission) ............14

Clutch Pedal Position Switch ....................14

Engine Starter Relay .........................14

Field Coil Starter Motor .......................14

Manual Transmission Back-Up Lamp Switch ..........14

Engine Starter System (3.0L) .....................15

Clutch Pedal Position Jumper ...................15

Field Coil Engine Starter Motor ...................15

8W - 534 WIRING DIAGRAMS AG-AJ BODY Ä

Page 1288 of 2438

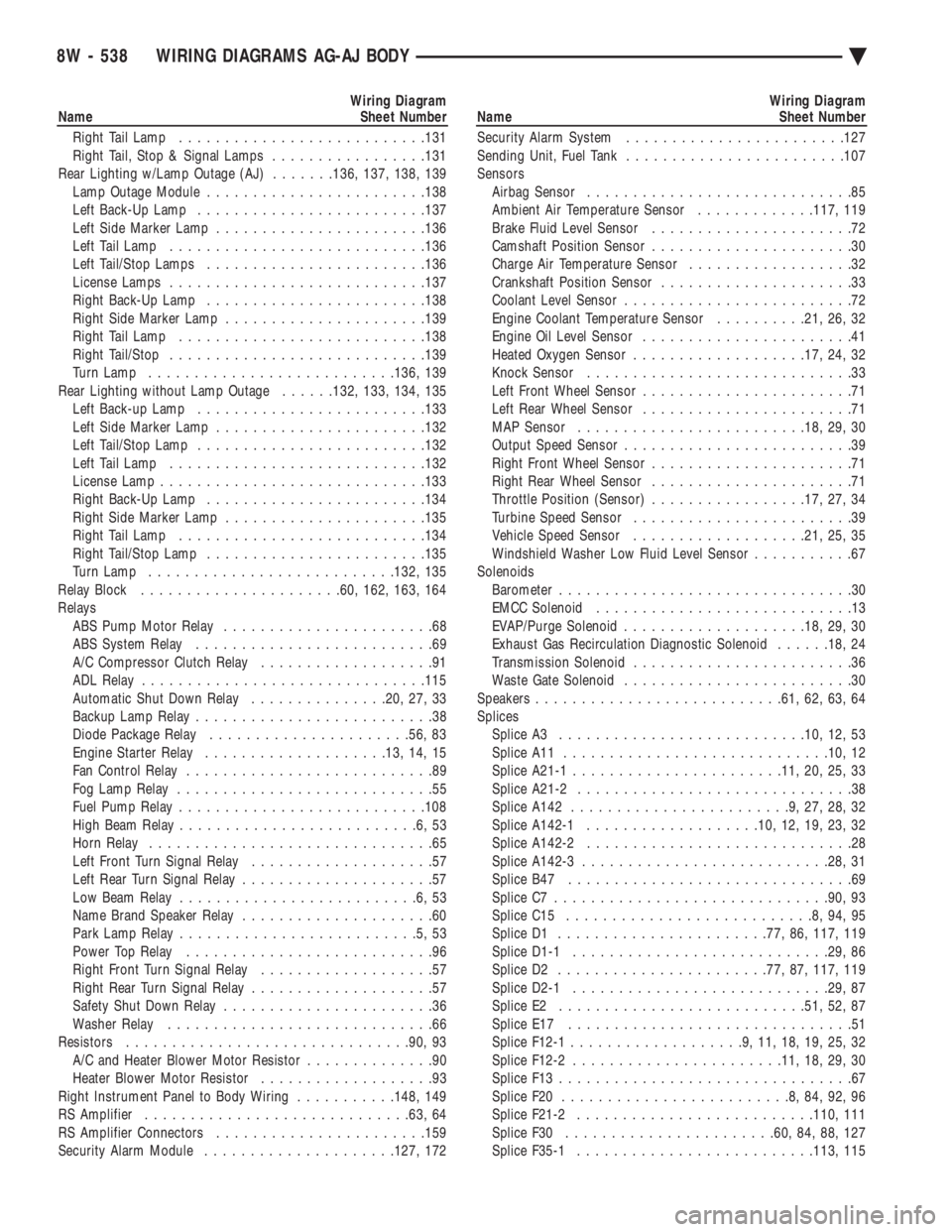

Wiring Diagram

Name Sheet Number

Right Tail Lamp .......................... .131

Right Tail, Stop & Signal Lamps .................131

Rear Lighting w/Lamp Outage (AJ) .......136, 137, 138, 139

Lamp Outage Module ....................... .138

Left Back-Up Lamp ........................ .137

Left Side Marker Lamp ...................... .136

Left Tail Lamp ........................... .136

Left Tail/Stop Lamps ....................... .136

License Lamps ........................... .137

Right Back-Up Lamp ....................... .138

Right Side Marker Lamp ..................... .139

Right Tail Lamp .......................... .138

Right Tail/Stop ........................... .139

Turn Lamp .......................... .136, 139

Rear Lighting without Lamp Outage ......132, 133, 134, 135

Left Back-up Lamp ........................ .133

Left Side Marker Lamp ...................... .132

Left Tail/Stop Lamp ........................ .132

Left Tail Lamp ........................... .132

License Lamp ............................ .133

Right Back-Up Lamp ....................... .134

Right Side Marker Lamp ..................... .135

Right Tail Lamp .......................... .134

Right Tail/Stop Lamp ....................... .135

Turn Lamp .......................... .132, 135

Relay Block ..................... .60, 162, 163, 164

Relays ABS Pump Motor Relay .......................68

ABS System Relay ..........................69

A/C Compressor Clutch Relay ...................91

ADL Relay .............................. .115

Automatic Shut Down Relay ...............20, 27, 33

Backup Lamp Relay ..........................38

Diode Package Relay ..................... .56, 83

Engine Starter Relay ................... .13, 14, 15

Fan Control Relay ...........................89

Fog Lamp Relay ............................55

Fuel Pump Relay .......................... .108

High Beam Relay ..........................6,53

Horn Relay ...............................65

Left Front Turn Signal Relay ....................57

Left Rear Turn Signal Relay .....................57

Low Beam Relay ..........................6,53

Name Brand Speaker Relay .....................60

Park Lamp Relay ..........................5,53

Power Top Relay ...........................96

Right Front Turn Signal Relay ...................57

Right Rear Turn Signal Relay ....................57

Safety Shut Down Relay .......................36

Washer Relay .............................66

Resistors .............................. .90, 93

A/C and Heater Blower Motor Resistor ..............90

Heater Blower Motor Resistor ...................93

Right Instrument Panel to Body Wiring ...........148, 149

RS Amplifier ............................ .63, 64

RS Amplifier Connectors ...................... .159

Security Alarm Module .................... .127, 172Wiring Diagram

Name Sheet Number

Security Alarm System ....................... .127

Sending Unit, Fuel Tank ....................... .107

Sensors Airbag Sensor .............................85

Ambient Air Temperature Sensor .............117, 119

Brake Fluid Level Sensor ......................72

Camshaft Position Sensor ......................30

Charge Air Temperature Sensor ..................32

Crankshaft Position Sensor .....................33

Coolant Level Sensor .........................72

Engine Coolant Temperature Sensor ..........21, 26, 32

Engine Oil Level Sensor .......................41

Heated Oxygen Sensor .................. .17, 24, 32

Knock Sensor .............................33

Left Front Wheel Sensor .......................71

Left Rear Wheel Sensor .......................71

MAP Sensor ........................ .18, 29, 30

Output Speed Sensor .........................39

Right Front Wheel Sensor ......................71

Right Rear Wheel Sensor ......................71

Throttle Position (Sensor) .................17, 27, 34

Turbine Speed Sensor ........................39

Vehicle Speed Sensor .................. .21, 25, 35

Windshield Washer Low Fluid Level Sensor ...........67

Solenoids Barometer ................................30

EMCC Solenoid ............................13

EVAP/Purge Solenoid ................... .18, 29, 30

Exhaust Gas Recirculation Diagnostic Solenoid ......18, 24

Transmission Solenoid ........................36

Waste Gate Solenoid .........................30

Speakers .......................... .61, 62, 63, 64

Splices Splice A3 .......................... .10, 12, 53

Splice A11 ............................ .10, 12

Splice A21-1 ...................... .11, 20, 25, 33

Splice A21-2 ..............................38

Splice A142 ........................9,27,28,32

Splice A142-1 .................. .10, 12, 19, 23, 32

Splice A142-2 .............................28

Splice A142-3 .......................... .28, 31

Splice B47 ...............................69

Splice C7 ............................. .90, 93

Splice C15 ...........................8,94,95

Splice D1 ...................... .77, 86, 117, 119

Splice D1-1 ........................... .29, 86

Splice D2 ...................... .77, 87, 117, 119

Splice D2-1 ........................... .29, 87

Splice E2 .......................... .51, 52, 87

Splice E17 ...............................51

Splice F12-1 ...................9,11,18,19,25,32

Splice F12-2 ...................... .11, 18, 29, 30

Splice F13 ................................67

Splice F20 .........................8,84,92,96

Splice F21-2 ......................... .110, 111

Splice F30 ...................... .60, 84, 88, 127

Splice F35-1 ......................... .113, 115

8W - 538 WIRING DIAGRAMS AG-AJ BODY Ä

Page 1290 of 2438

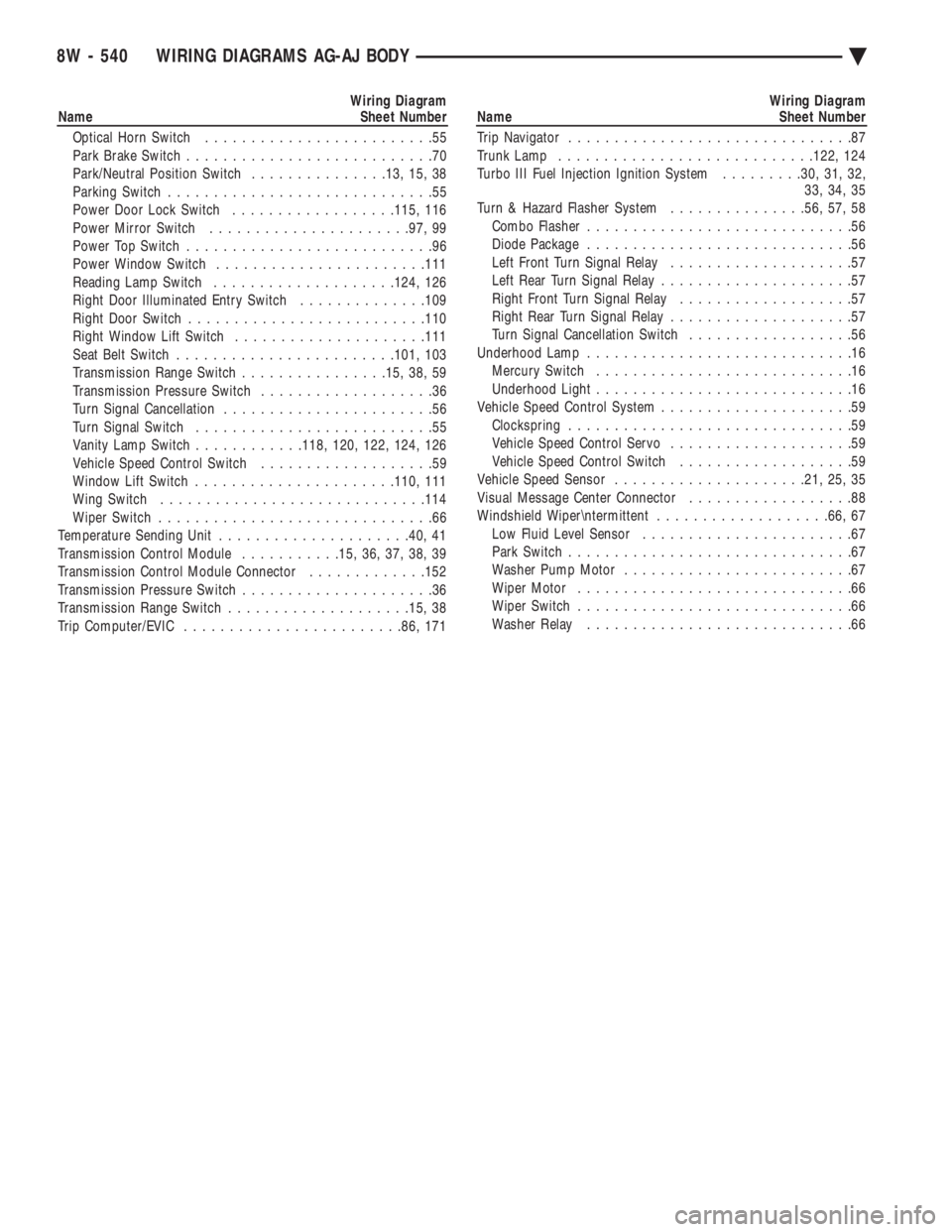

Wiring Diagram

Name Sheet Number

Optical Horn Switch .........................55

Park Brake Switch ...........................70

Park/Neutral Position Switch ...............13, 15, 38

Parking Switch .............................55

Power Door Lock Switch ..................115, 116

Power Mirror Switch ..................... .97, 99

Power Top Switch ...........................96

Power Window Switch ...................... .111

Reading Lamp Switch ................... .124, 126

Right Door Illuminated Entry Switch ..............109

Right Door Switch ......................... .110

Right Window Lift Switch .................... .111

Seat Belt Switch ....................... .101, 103

Transmission Range Switch ................15, 38, 59

Transmission Pressure Switch ...................36

Turn Signal Cancellation .......................56

Turn Signal Switch ..........................55

Vanity Lamp Switch ............118, 120, 122, 124, 126

Vehicle Speed Control Switch ...................59

Window Lift Switch ..................... .110, 111

Wing Switch ............................ .114

Wiper Switch ..............................66

Temperature Sending Unit .................... .40, 41

Transmission Control Module ...........15, 36, 37, 38, 39

Transmission Control Module Connector .............152

Transmission Pressure Switch .....................36

Transmission Range Switch ................... .15, 38

Trip Computer/EVIC ....................... .86, 171Wiring Diagram

Name Sheet Number

Trip Navigator ...............................87

Trunk Lamp ........................... .122, 124

Turbo III Fuel Injection Ignition System .........30, 31, 32,

33, 34, 35

Turn & Hazard Flasher System ...............56, 57, 58

Combo Flasher .............................56

Diode Package .............................56

Left Front Turn Signal Relay ....................57

Left Rear Turn Signal Relay .....................57

Right Front Turn Signal Relay ...................57

Right Rear Turn Signal Relay ....................57

Turn Signal Cancellation Switch ..................56

Underhood Lamp .............................16

Mercury Switch ............................16

Underhood Light ............................16

Vehicle Speed Control System .....................59

Clockspring ...............................59

Vehicle Speed Control Servo ....................59

Vehicle Speed Control Switch ...................59

Vehicle Speed Sensor .................... .21, 25, 35

Visual Message Center Connector ..................88

Windshield Wiper

termittent ...................66, 67

Low Fluid Level Sensor .......................67

Park Switch ...............................67

Washer Pump Motor .........................67

Wiper Motor ..............................66

Wiper Switch ..............................66

Washer Relay .............................66

8W - 540 WIRING DIAGRAMS AG-AJ BODY Ä

Page 1467 of 2438

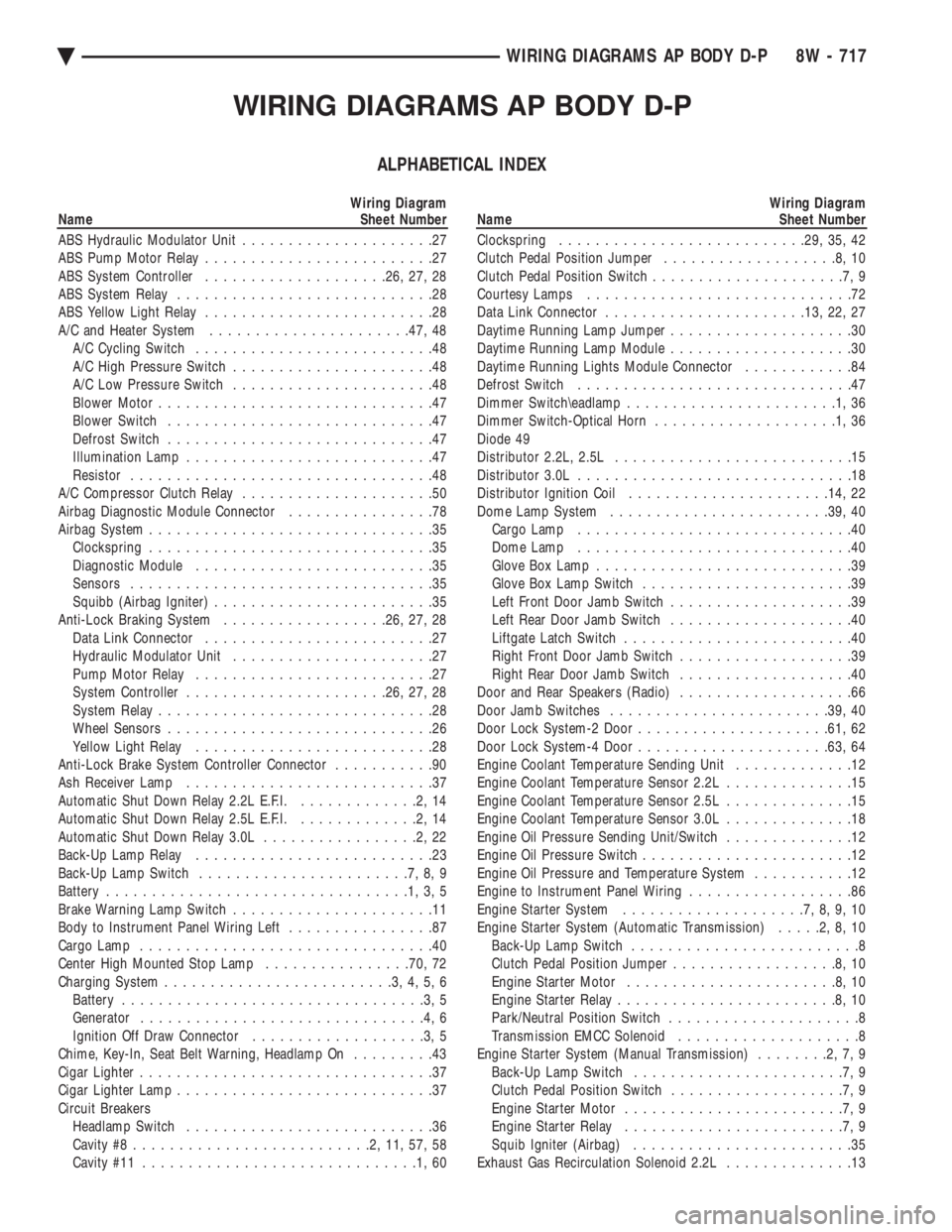

WIRING DIAGRAMS AP BODY D-P

ALPHABETICAL INDEX

Wiring Diagram

Name Sheet Number

ABS Hydraulic Modulator Unit .....................27

ABS Pump Motor Relay .........................27

ABS System Controller ................... .26, 27, 28

ABS System Relay ............................28

ABS Yellow Light Relay .........................28

A/C and Heater System ..................... .47, 48

A/C Cycling Switch ..........................48

A/C High Pressure Switch ......................48

A/C Low Pressure Switch ......................48

Blower Motor ..............................47

Blower Switch .............................47

Defrost Switch .............................47

Illumination Lamp ...........................47

Resistor .................................48

A/C Compressor Clutch Relay .....................50

Airbag Diagnostic Module Connector ................78

Airbag System ...............................35

Clockspring ...............................35

Diagnostic Module ..........................35

Sensors .................................35

Squibb (Airbag Igniter) ........................35

Anti-Lock Braking System ..................26, 27, 28

Data Link Connector .........................27

Hydraulic Modulator Unit ......................27

Pump Motor Relay ..........................27

System Controller ..................... .26, 27, 28

System Relay ..............................28

Wheel Sensors .............................26

Yellow Light Relay ..........................28

Anti-Lock Brake System Controller Connector ...........90

Ash Receiver Lamp ...........................37

Automatic Shut Down Relay 2.2L E.F.I. .............2,14

Automatic Shut Down Relay 2.5L E.F.I. .............2,14

Automatic Shut Down Relay 3.0L .................2,22

Back-Up Lamp Relay ..........................23

Back-Up Lamp Switch .......................7,8,9

Battery .................................1,3,5

Brake Warning Lamp Switch ......................11

Body to Instrument Panel Wiring Left ................87

Cargo Lamp ................................40

Center High Mounted Stop Lamp ................70, 72

Charging System .........................3,4,5,6

Battery .................................3,5

Generator ...............................4,6

Ignition Off Draw Connector ...................3,5

Chime, Key-In, Seat Belt Warning, Headlamp On .........43

Cigar Lighter ................................37

Cigar Lighter Lamp ............................37

Circuit Breakers Headlamp Switch ...........................36

Cavity #8 ..........................2,11,57,58

Cavity #11 ..............................1,60Wiring Diagram

Name Sheet Number

Clockspring .......................... .29, 35, 42

Clutch Pedal Position Jumper ...................8,10

Clutch Pedal Position Switch .....................7,9

Courtesy Lamps .............................72

Data Link Connector ..................... .13, 22, 27

Daytime Running Lamp Jumper ....................30

Daytime Running Lamp Module ....................30

Daytime Running Lights Module Connector ............84

Defrost Switch ..............................47

Dimmer Switch\eadlamp .......................1,36

Dimmer Switch-Optical Horn ....................1,36

Diode 49

Distributor 2.2L, 2.5L ..........................15

Distributor 3.0L ..............................18

Distributor Ignition Coil ..................... .14, 22

Dome Lamp System ....................... .39, 40

Cargo Lamp ..............................40

Dome Lamp ..............................40

Glove Box Lamp ............................39

Glove Box Lamp Switch .......................39

Left Front Door Jamb Switch ....................39

Left Rear Door Jamb Switch ....................40

Liftgate Latch Switch .........................40

Right Front Door Jamb Switch ...................39

Right Rear Door Jamb Switch ...................40

Door and Rear Speakers (Radio) ...................66

Door Jamb Switches ....................... .39, 40

Door Lock System-2 Door .................... .61, 62

Door Lock System-4 Door .................... .63, 64

Engine Coolant Temperature Sending Unit .............12

Engine Coolant Temperature Sensor 2.2L ..............15

Engine Coolant Temperature Sensor 2.5L ..............15

Engine Coolant Temperature Sensor 3.0L ..............18

Engine Oil Pressure Sending Unit/Switch ..............12

Engine Oil Pressure Switch .......................12

Engine Oil Pressure and Temperature System ...........12

Engine to Instrument Panel Wiring ..................86

Engine Starter System ....................7,8,9,10

Engine Starter System (Automatic Transmission) .....2,8,10

Back-Up Lamp Switch .........................8

Clutch Pedal Position Jumper ..................8,10

Engine Starter Motor .......................8,10

Engine Starter Relay ........................8,10

Park/Neutral Position Switch .....................8

Transmission EMCC Solenoid ....................8

Engine Starter System (Manual Transmission) ........2,7,9

Back-Up Lamp Switch .......................7,9

Clutch Pedal Position Switch ...................7,9

Engine Starter Motor ........................7,9

Engine Starter Relay ........................7,9

Squib Igniter (Airbag) ........................35

Exhaust Gas Recirculation Solenoid 2.2L ..............13

Ä WIRING DIAGRAMS AP BODY D-P 8W - 717

Page 1469 of 2438

Wiring Diagram

Name Sheet Number

Horn (Lo-note) .............................42

Horn Relay ...............................42

Horn Switch ..............................42

Idle Air Control Motor ...................... .16, 20

Ignition Coil 2.2L E.F.I. .........................14

Ignition Coil 2.5L E.F.I. .........................14

Ignition Coil 3.0L .............................22

Ignition Off-Draw Connector .....................3,5

Ignition Switch .............................2,11

Brake Warning Lamp Switch ....................11

Park Brake Switch ...........................11

Injector ...................................13

Instrument Panel Illumination Lamps ...........45, 46, 47

Instrument Panel to Left Body Wiring ................88

Instrument Panel to Engine Wiring ..................85

Intermittent Wiper System .................... .53, 54

Control Unit ...............................54

Park Switch ...............................54

Washer Low Fluid Level Sensor ..................53

Washer Pump Motor .........................53

Wiper Motor ..............................54

Wiper Switch ..............................53

Key-In, Seat Belt Warning, Headlamp On, Chime .........43

Lamps Air Conditioning and Heater Switch Lamp ............47

Ash Receiver Lamp ..........................37

Back-Up Lamps .................... .69, 70, 71, 72

Cargo Lamp ..............................40

Center High Mounted Stop Lamp ...............70, 72

Cigar Lighter Lamp ..........................37

Courtesy Lamps ............................72

Dome Lamp ..............................40

Fog Lamp ....................... .31, 32, 33, 34

Glove Box Lamp ............................39

Halo Lamp ...............................44

Headlamp-Aero .................... .31, 32, 33, 34

Heated Rear Window Switch Lamp ................67

Heater Switch Lamp .........................46

Illumination Lamps ....................... .46, 47

License Lamp .......................... .70, 72

Park Lamps-Front .................. .31, 32, 33, 34

Side Marker Lamps-Front ..............31, 32, 33, 34

Side Marker Lamps-Rear ...............69, 70, 71, 72

Stop Lamps ...............................29

Tail/Stop/Turn Signal Lamps-Rear .........69, 70, 71, 72

Transmission Range Lamp .....................37

Turn Signal Lamps-Front ...............31, 32, 33, 34

Underhood Lamp ...........................12

Left Body to Instrument Panel Wiring ................87

Left Front Wheel Sensor ........................26

Left Rear Wheel Sensor .........................26

Liftgate Latch Switch ..........................40

MAP Sensor ............................ .15, 20

Mercury Switch ..............................12

Mirrors-Power ........................... .55, 56

Modules Airbag Diagnostic Module ......................35Wiring Diagram

Name Sheet Number

Daytime Running Lamps Module .................30

Fuse Block Module ..........................76

Powertrain Control Module ...........13, 14, 15, 16, 17,

18, 19, 20, 21, 22, 29

Relay Module ..............................77

Transmission Control Module ...............23, 24, 25

Motors Blower Motor .......................... .46, 47

Engine Starter ........................7,8,9,10

Fuel Pump Motor ...........................68

Idle Air Control Motor ..................... .16, 20

Power Door Locks-2 Door .................. .61, 62

Power Door Locks-4 Door .................. .63, 64

Power Mirror ..............................56

Power Seat ...............................60

Power Window-2 Door ........................57

Power Window-4 Door ........................58

Radiator Fan Motor ...................... .45, 49

Washer Pump Motor .........................53

Wiper ..................................54

Optical Horn ..............................1,36

Overhead Console ............................41

A/C Ambient Temperature Sensor .................41

Power Door Lock System-2 Door ................61, 62

Connector and Door Lock Switch Function .........61, 62

Left Front Door Motor ........................61

Left Front Door Switch ........................61

Right Front Door Motor .......................62

Right Front Door Switch .......................62

Power Door Lock System-4 Door ................63, 64

Left Front Door Motor ........................63

Left Front Door Switch ........................63

Left Rear Door Motor ........................63

Right Front Door Motor .......................64

Right Front Door Switch .......................64

Right Rear Door Motor .......................64

Power Mirrors ........................... .55, 56

Dual Mirror Control Switch .....................55

Left Motors ...............................56

Power Mirror Switch .........................55

Right Motors ..............................56

Switch Function ............................55

Power Seat System-Left Bucket ....................60

Powertrain Control Module ............13, 14, 15, 16, 17,

18, 19, 20, 21, 22

Powertrain Control Module Connector .............79, 80

Power Window Connector and Switch Functions .........59

Power Window System-2 Door ....................57

Console Master Switch ........................57

Left Front Motor ............................57

Right Front Motor ...........................57

Power Window System-4 Door ....................58

Console Master Switch ........................58

Left Front Motor ............................58

Left Rear Motor ............................58

Left Rear Switch ............................58

Right Front Motor ...........................58

Ä WIRING DIAGRAMS AP BODY D-P 8W - 719

Page 1766 of 2438

it de-activates the ASD relay and fuel pump relay.

When these relays are deactivated, power is shut off

from the fuel injector, fuel pump, ignition coil, and

oxygen sensor heater element. The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts to

power the distributor pick-up and vehicle speed sen-

sor. The PCM also provides a 5.0 volts supply for the

coolant temperature sensor, manifold absolute pres-

sure sensor and throttle position sensor.

AIR CONDITIONING SWITCH SENSEÐPCM INPUT

ALL VEHICLES EXCEPT AC-BODY

When the air conditioning or defrost switch is put

in the ON position and the low pressure and high

pressure switches are closed, the PCM receives an in-

put indicating that the air conditioning has been se-

lected. After receiving this input, the PCM activates

the A/C compressor clutch by grounding the A/C

clutch relay. The PCM also adjusts idle speed to a

scheduled RPM to compensate for increased engine

load.

AC-BODY VEHICLES

When the air conditioning or defrost switch is put

in the ON position and the low pressure switch, high

pressure switch and electronic cycling switch close,

the PCM receives an air conditioning select input.

After receiving this input, the PCM activates the

A/C compressor clutch by grounding the A/C com-

pressor clutch relay. The PCM also adjusts idle speed

to a scheduled RPM to compensate for increased en-

gine load.

BATTERY VOLTAGEÐPCM INPUT

The PCM monitors the battery voltage input to de-

termine fuel injector pulse width and generator field

control. If battery voltage is low, the PCM increases

injector pulse width.

BRAKE SWITCHÐPCM INPUT

When the brake switch is activated, the PCM re-

ceives an input indicating that the brakes are being

applied. After receiving the input, the PCM vents the

speed control servo. Venting the servo turns the

speed control system off.

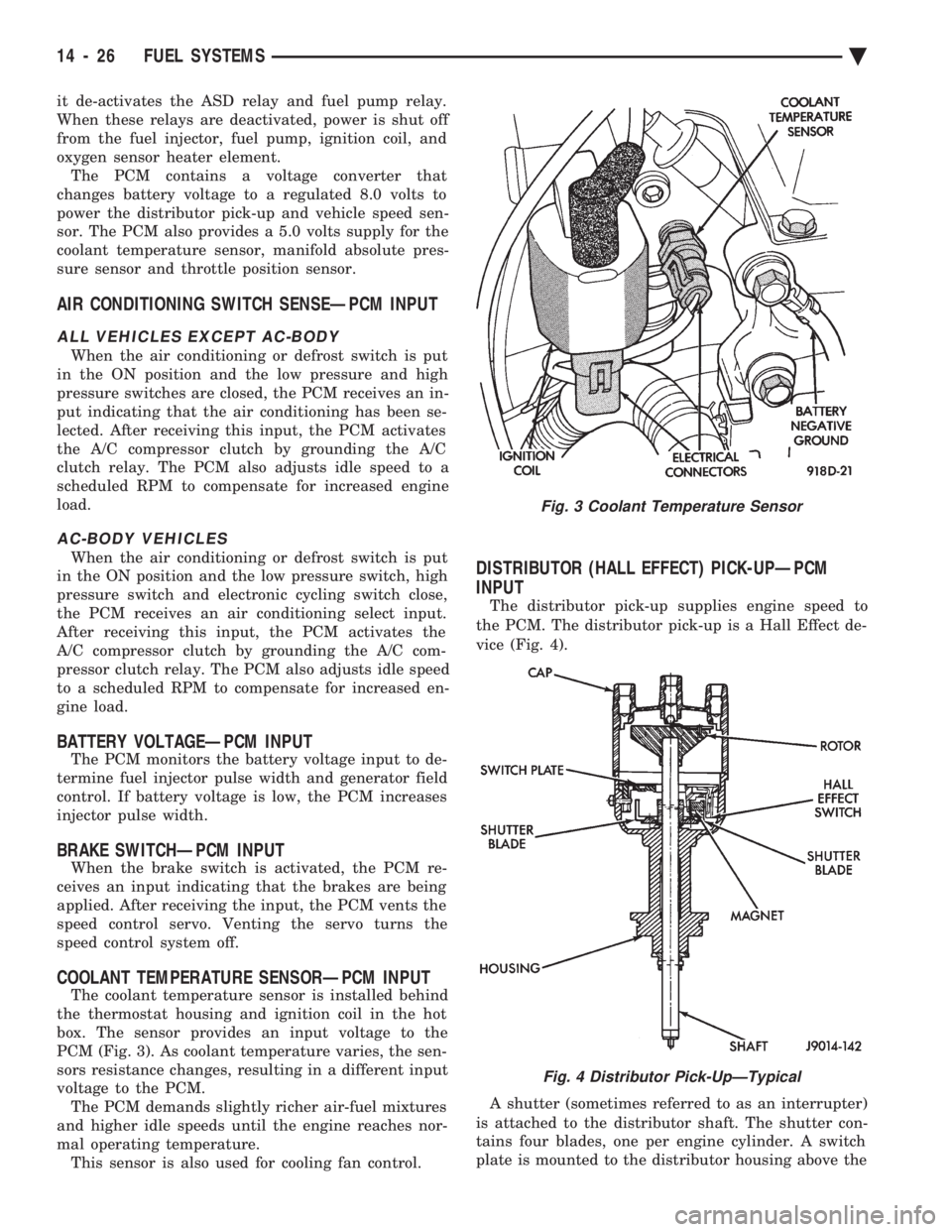

COOLANT TEMPERATURE SENSORÐPCM INPUT

The coolant temperature sensor is installed behind

the thermostat housing and ignition coil in the hot

box. The sensor provides an input voltage to the

PCM (Fig. 3). As coolant temperature varies, the sen-

sors resistance changes, resulting in a different input

voltage to the PCM. The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature. This sensor is also used for cooling fan control.

DISTRIBUTOR (HALL EFFECT) PICK-UPÐPCM

INPUT

The distributor pick-up supplies engine speed to

the PCM. The distributor pick-up is a Hall Effect de-

vice (Fig. 4).

A shutter (sometimes referred to as an interrupter)

is attached to the distributor shaft. The shutter con-

tains four blades, one per engine cylinder. A switch

plate is mounted to the distributor housing above the

Fig. 3 Coolant Temperature Sensor

Fig. 4 Distributor Pick-UpÐTypical

14 - 26 FUEL SYSTEMS Ä

Page 1785 of 2438

SYSTEMS TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING A TEST

WITH THE ENGINE OPERATING.

OBTAINING DIAGNOSTIC TROUBLE CODES

(1) Connect DRBII scan tool to the data link con-

nector located in the engine compartment near the

powertrain control module (PCM). (2) Start the engine if possible, cycle the transaxle

selector and the A/Cswitch if applicable. Shut off

the engine. (3) Turn the ignition switch on, access Read Fault

Screen. Record all the fault messages shown on the

DRBII scan tool. Observe the malfunction indicator

lamp (check engine lamp on the instrument panel).

The lamp should light for 3 seconds then go out (bulb

check).

STATE DISPLAY TEST MODE

The switch inputs used by the powertrain control

module (PCM) have only two recognized states,

HIGH and LOW. For this reason, the PCM cannot

recognize the difference between a selected switch po-

sition versus an open circuit, a short circuit, or a de-

fective switch. If the change is displayed, it can be

assumed that the entire switch circuit to the PCM is

functional. From the state display screen access ei-

ther State Display Inputs and Outputs or State Dis-

play Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Inputs and

Outputs. The following is a list of the engine control

system functions accessible through the Inputs and

Outputs screen. Park/Neutral Switch (automatic transaxle only)

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

A/C Switch Sense

S/C (Speed Control) Vent Solenoid

S/C (Speed Control) Vacuum Solenoid

Torque Converter Clutch Solenoid (3 speed auto-

matic transaxle)

A/C Clutch Relay

EGR Solenoid

Auto Shutdown Relay

Radiator Fan Relay

Purge Solenoid

Malfunction Indicator (Check Engine) Lamp

STATE DISPLAY SENSORS

Connect the DRBII scan tool to the vehicle and ac-

cess the State Display screen. Then access Sensor

Display. The following is a list of the engine control

system functions accessible through the Sensor Dis-

play screen. Oxygen Sensor Signal

Coolant Temperature

Coolant Temp Sensor

Throttle Position

Minimum Throttle

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Added Adaptive Fuel

Adaptive Fuel Factor

Barometric Pressure

Min Airflow Idl Spd

Engine Speed

Fault #1 Key-On Info

Module Spark Advance

Speed Control Target

Fault #2 Key-On Info

Fault #3 Key-On Info

Speed Control Status

Charging System Goal

Theft Alarm Status

Speed Control Switch Voltage

Map Sensor Voltage

Vehicle Speed

Oxygen Sensor State

MAP Gauge Reading

Throttle Opening (percentage)

Total Spark Advance

CIRCUIT ACTUATION TEST MODE

The circuit actuation test mode checks for proper

operation of output circuits or devices which the pow-

ertrain control module (PCM) cannot internally rec-

ognize. The PCM can attempt to activate these

outputs and allow an observer to verify proper oper-

ation. Most of the tests provide an audible or visual

indication of device operation (click of relay contacts,

spray fuel, etc.). With the exception of an intermit-

tent condition, if a device functions properly during

its test, it can be assumed that the device, its associ-

ated wiring, and its driver circuit are in working or-

der.

OBTAINING CIRCUIT ACTUATION TEST

Connect the DRBII scan tool to the vehicle and ac-

cess the Actuators screen. The following is a list of

the engine control system functions accessible

through Actuators screens. Stop All Tests

Ignition Coil #1

Fuel Injector #1

Idle Air Control Motor Open/Close

Ä FUEL SYSTEMS 14 - 45

Page 1795 of 2438

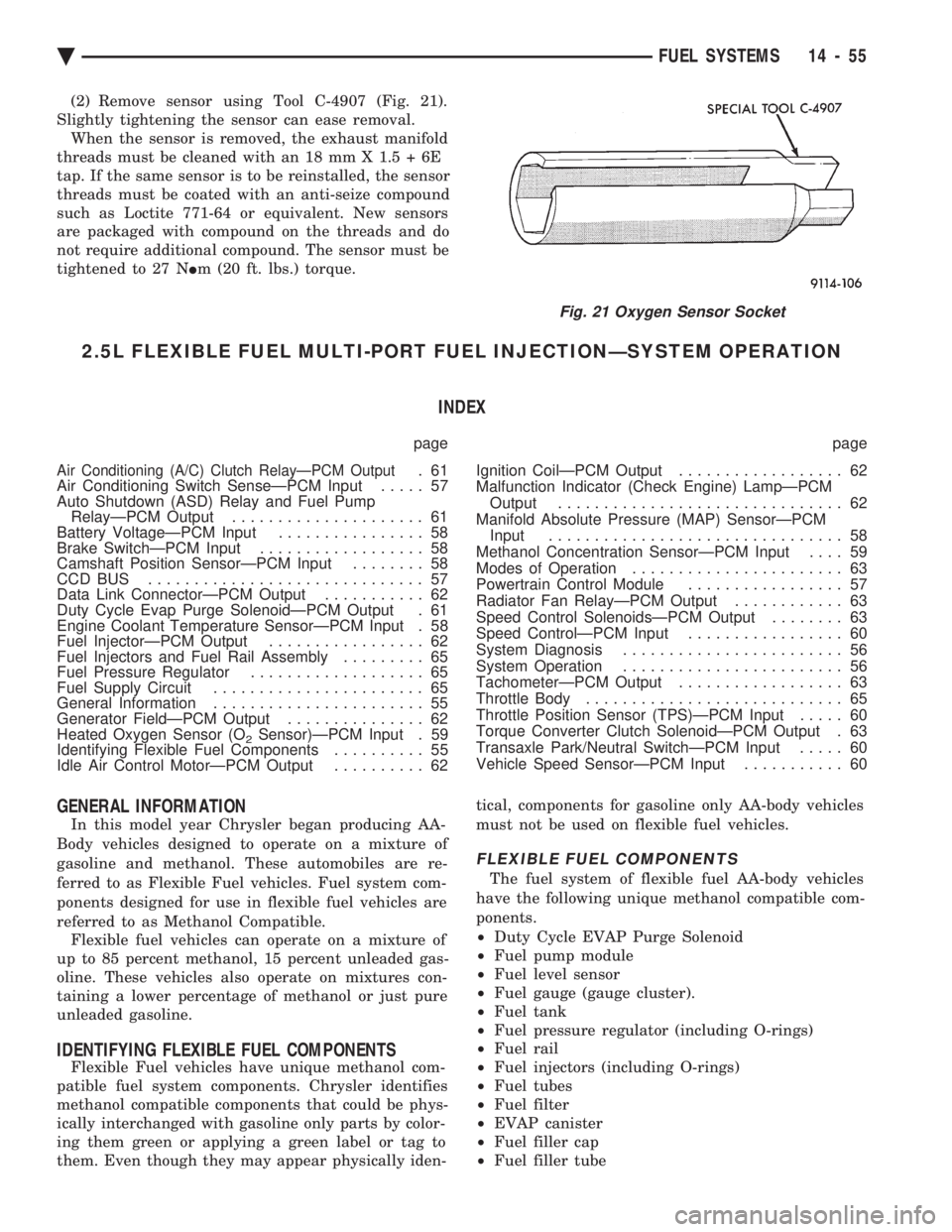

(2) Remove sensor using Tool C-4907 (Fig. 21).

Slightly tightening the sensor can ease removal. When the sensor is removed, the exhaust manifold

threads must be cleaned with an 18 mm X 1.5 + 6E

tap. If the same sensor is to be reinstalled, the sensor

threads must be coated with an anti-seize compound

such as Loctite 771-64 or equivalent. New sensors

are packaged with compound on the threads and do

not require additional compound. The sensor must be

tightened to 27 N Im (20 ft. lbs.) torque.

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION

INDEX

page page

Air Conditioning (A/C) Clutch RelayÐPCM Output.61

Air Conditioning Switch SenseÐPCM Input ..... 57

Auto Shutdown (ASD) Relay and Fuel Pump RelayÐPCM Output ..................... 61

Battery VoltageÐPCM Input ................ 58

Brake SwitchÐPCM Input .................. 58

Camshaft Position SensorÐPCM Input ........ 58

CCD BUS .............................. 57

Data Link ConnectorÐPCM Output ........... 62

Duty Cycle Evap Purge SolenoidÐPCM Output . 61

Engine Coolant Temperature SensorÐPCM Input . 58

Fuel InjectorÐPCM Output ................. 62

Fuel Injectors and Fuel Rail Assembly ......... 65

Fuel Pressure Regulator ................... 65

Fuel Supply Circuit ....................... 65

General Information ....................... 55

Generator FieldÐPCM Output ............... 62

Heated Oxygen Sensor (O

2Sensor)ÐPCM Input . 59

Identifying Flexible Fuel Components .......... 55

Idle Air Control MotorÐPCM Output .......... 62 Ignition CoilÐPCM Output

.................. 62

Malfunction Indicator (Check Engine) LampÐPCM Output ............................... 62

Manifold Absolute Pressure (MAP) SensorÐPCM Input ................................ 58

Methanol Concentration SensorÐPCM Input .... 59

Modes of Operation ....................... 63

Powertrain Control Module ................. 57

Radiator Fan RelayÐPCM Output ............ 63

Speed Control SolenoidsÐPCM Output ........ 63

Speed ControlÐPCM Input ................. 60

System Diagnosis ........................ 56

System Operation ........................ 56

TachometerÐPCM Output .................. 63

Throttle Body ............................ 65

Throttle Position Sensor (TPS)ÐPCM Input ..... 60

Torque Converter Clutch SolenoidÐPCM Output . 63

Transaxle Park/Neutral SwitchÐPCM Input ..... 60

Vehicle Speed SensorÐPCM Input ........... 60

GENERAL INFORMATION

In this model year Chrysler began producing AA-

Body vehicles designed to operate on a mixture of

gasoline and methanol. These automobiles are re-

ferred to as Flexible Fuel vehicles. Fuel system com-

ponents designed for use in flexible fuel vehicles are

referred to as Methanol Compatible. Flexible fuel vehicles can operate on a mixture of

up to 85 percent methanol, 15 percent unleaded gas-

oline. These vehicles also operate on mixtures con-

taining a lower percentage of methanol or just pure

unleaded gasoline.

IDENTIFYING FLEXIBLE FUEL COMPONENTS

Flexible Fuel vehicles have unique methanol com-

patible fuel system components. Chrysler identifies

methanol compatible components that could be phys-

ically interchanged with gasoline only parts by color-

ing them green or applying a green label or tag to

them. Even though they may appear physically iden- tical, components for gasoline only AA-body vehicles

must not be used on flexible fuel vehicles.

FLEXIBLE FUEL COMPONENTS

The fuel system of flexible fuel AA-body vehicles

have the following unique methanol compatible com-

ponents.

² Duty Cycle EVAP Purge Solenoid

² Fuel pump module

² Fuel level sensor

² Fuel gauge (gauge cluster).

² Fuel tank

² Fuel pressure regulator (including O-rings)

² Fuel rail

² Fuel injectors (including O-rings)

² Fuel tubes

² Fuel filter

² EVAP canister

² Fuel filler cap

² Fuel filler tube

Fig. 21 Oxygen Sensor Socket

Ä FUEL SYSTEMS 14 - 55

Page 1798 of 2438

A/C clutch relay. To compensate for increased engine

load, the PCM also adjusts idle speed to a scheduled

RPM.

BATTERY VOLTAGEÐPCM INPUT

The powertrain control module (PCM) monitors the

battery voltage input to determine fuel injector pulse

width and generator field control. If battery voltage

is low, the PCM increases injector pulse width to

compensate.

BRAKE SWITCHÐPCM INPUT

When the brake switch activates, the powertrain

control module (PCM) receives an input indicating

that the brakes are being applied. After receiving the

input, the PCM vents the speed control servo. Vent-

ing the servo turns the speed control system off.

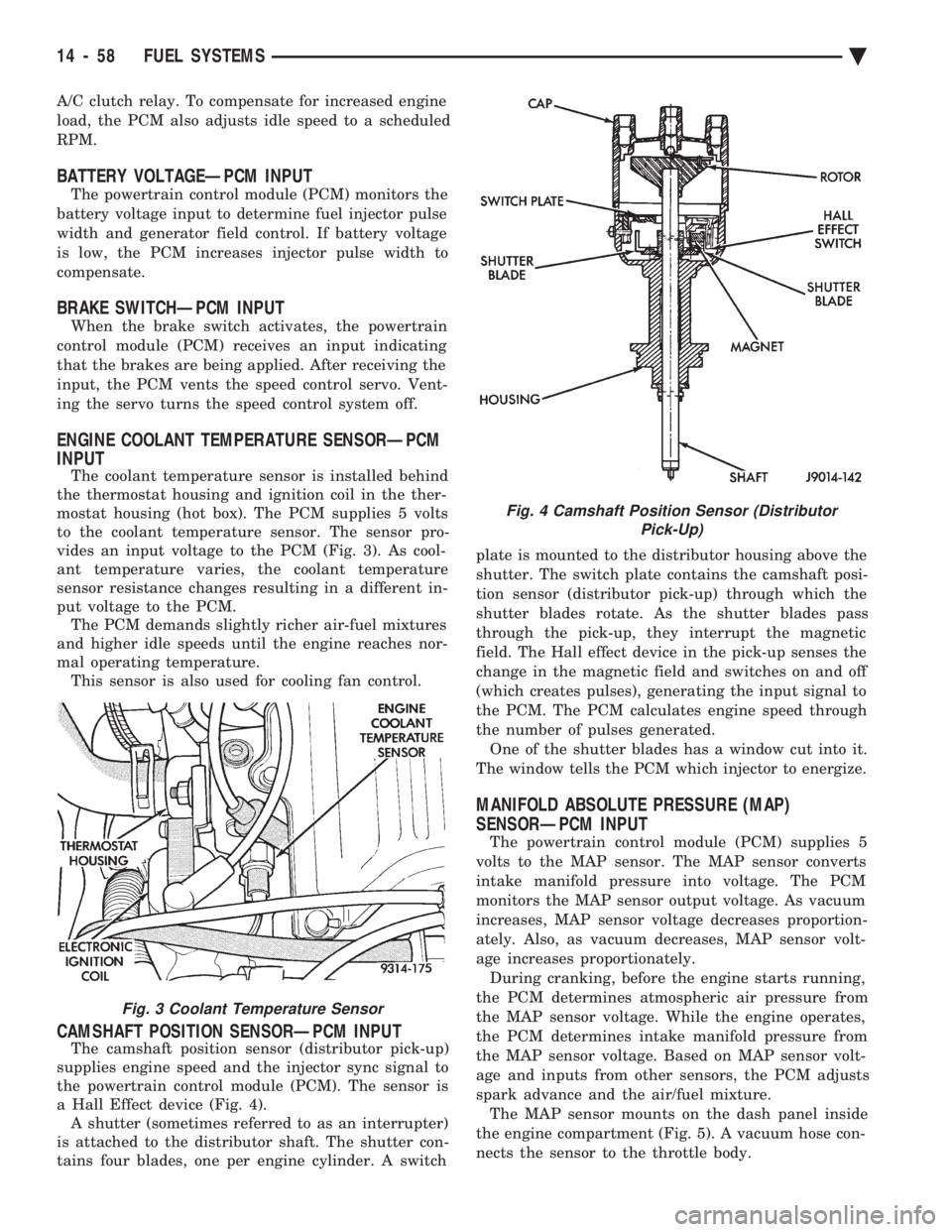

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The coolant temperature sensor is installed behind

the thermostat housing and ignition coil in the ther-

mostat housing (hot box). The PCM supplies 5 volts

to the coolant temperature sensor. The sensor pro-

vides an input voltage to the PCM (Fig. 3). As cool-

ant temperature varies, the coolant temperature

sensor resistance changes resulting in a different in-

put voltage to the PCM. The PCM demands slightly richer air-fuel mixtures

and higher idle speeds until the engine reaches nor-

mal operating temperature. This sensor is also used for cooling fan control.

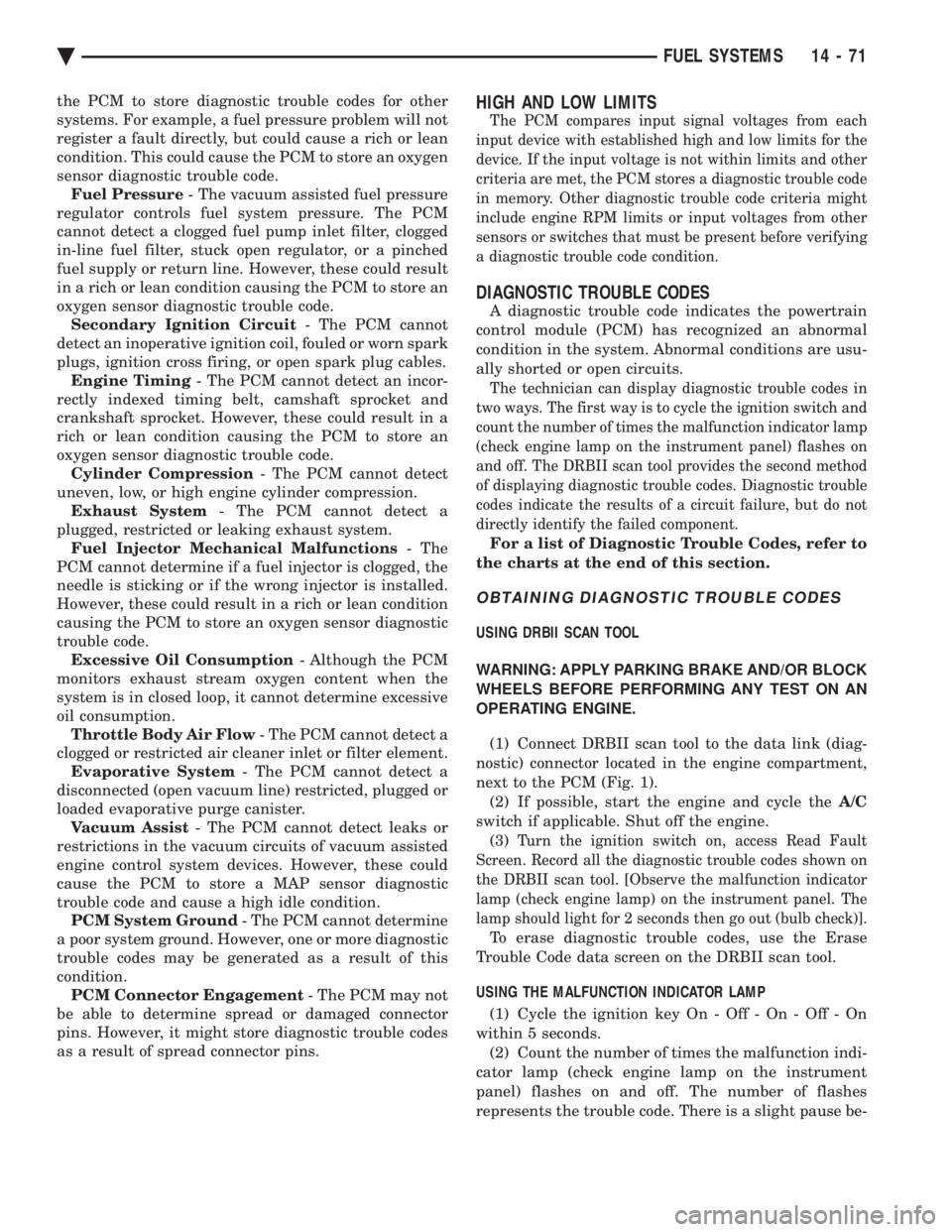

CAMSHAFT POSITION SENSORÐPCM INPUT

The camshaft position sensor (distributor pick-up)

supplies engine speed and the injector sync signal to

the powertrain control module (PCM). The sensor is

a Hall Effect device (Fig. 4). A shutter (sometimes referred to as an interrupter)

is attached to the distributor shaft. The shutter con-

tains four blades, one per engine cylinder. A switch plate is mounted to the distributor housing above the

shutter. The switch plate contains the camshaft posi-

tion sensor (distributor pick-up) through which the

shutter blades rotate. As the shutter blades pass

through the pick-up, they interrupt the magnetic

field. The Hall effect device in the pick-up senses the

change in the magnetic field and switches on and off

(which creates pulses), generating the input signal to

the PCM. The PCM calculates engine speed through

the number of pulses generated. One of the shutter blades has a window cut into it.

The window tells the PCM which injector to energize.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT

The powertrain control module (PCM) supplies 5

volts to the MAP sensor. The MAP sensor converts

intake manifold pressure into voltage. The PCM

monitors the MAP sensor output voltage. As vacuum

increases, MAP sensor voltage decreases proportion-

ately. Also, as vacuum decreases, MAP sensor volt-

age increases proportionately. During cranking, before the engine starts running,

the PCM determines atmospheric air pressure from

the MAP sensor voltage. While the engine operates,

the PCM determines intake manifold pressure from

the MAP sensor voltage. Based on MAP sensor volt-

age and inputs from other sensors, the PCM adjusts

spark advance and the air/fuel mixture. The MAP sensor mounts on the dash panel inside

the engine compartment (Fig. 5). A vacuum hose con-

nects the sensor to the throttle body.

Fig. 3 Coolant Temperature Sensor

Fig. 4 Camshaft Position Sensor (Distributor Pick-Up)

14 - 58 FUEL SYSTEMS Ä

Page 1811 of 2438

the PCM to store diagnostic trouble codes for other

systems. For example, a fuel pressure problem will not

register a fault directly, but could cause a rich or lean

condition. This could cause the PCM to store an oxygen

sensor diagnostic trouble code. Fuel Pressure - The vacuum assisted fuel pressure

regulator controls fuel system pressure. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, stuck open regulator, or a pinched

fuel supply or return line. However, these could result

in a rich or lean condition causing the PCM to store an

oxygen sensor diagnostic trouble code. Secondary Ignition Circuit - The PCM cannot

detect an inoperative ignition coil, fouled or worn spark

plugs, ignition cross firing, or open spark plug cables. Engine Timing - The PCM cannot detect an incor-

rectly indexed timing belt, camshaft sprocket and

crankshaft sprocket. However, these could result in a

rich or lean condition causing the PCM to store an

oxygen sensor diagnostic trouble code. Cylinder Compression - The PCM cannot detect

uneven, low, or high engine cylinder compression. Exhaust System - The PCM cannot detect a

plugged, restricted or leaking exhaust system. Fuel Injector Mechanical Malfunctions - The

PCM cannot determine if a fuel injector is clogged, the

needle is sticking or if the wrong injector is installed.

However, these could result in a rich or lean condition

causing the PCM to store an oxygen sensor diagnostic

trouble code. Excessive Oil Consumption - Although the PCM

monitors exhaust stream oxygen content when the

system is in closed loop, it cannot determine excessive

oil consumption. Throttle Body Air Flow - The PCM cannot detect a

clogged or restricted air cleaner inlet or filter element. Evaporative System - The PCM cannot detect a

disconnected (open vacuum line) restricted, plugged or

loaded evaporative purge canister. Vacuum Assist - The PCM cannot detect leaks or

restrictions in the vacuum circuits of vacuum assisted

engine control system devices. However, these could

cause the PCM to store a MAP sensor diagnostic

trouble code and cause a high idle condition. PCM System Ground - The PCM cannot determine

a poor system ground. However, one or more diagnostic

trouble codes may be generated as a result of this

condition. PCM Connector Engagement - The PCM may not

be able to determine spread or damaged connector

pins. However, it might store diagnostic trouble codes

as a result of spread connector pins.HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for the

device. If the input voltage is not within limits and other

criteria are met, the PCM stores a diagnostic trouble code

in memory. Other diagnostic trouble code criteria might

include engine RPM limits or input voltages from other

sensors or switches that must be present before verifying

a diagnostic trouble code condition.

DIAGNOSTIC TROUBLE CODES

A diagnostic trouble code indicates the powertrain

control module (PCM) has recognized an abnormal

condition in the system. Abnormal conditions are usu-

ally shorted or open circuits.

The technician can display diagnostic trouble codes in

two ways. The first way is to cycle the ignition switch and

count the number of times the malfunction indicator lamp

(check engine lamp on the instrument panel) flashes on

and off. The DRBII scan tool provides the second method

of displaying diagnostic trouble codes. Diagnostic trouble

codes indicate the results of a circuit failure, but do not

directly identify the failed component.

For a list of Diagnostic Trouble Codes, refer to

the charts at the end of this section.

OBTAINING DIAGNOSTIC TROUBLE CODES

USING DRBII SCAN TOOL

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING ANY TEST ON AN

OPERATING ENGINE. (1) Connect DRBII scan tool to the data link (diag-

nostic) connector located in the engine compartment,

next to the PCM (Fig. 1). (2) If possible, start the engine and cycle the A/C

switch if applicable. Shut off the engine. (3)

Turn the ignition switch on, access Read Fault

Screen. Record all the diagnostic trouble codes shown on

the DRBII scan tool. [Observe the malfunction indicator

lamp (check engine lamp) on the instrument panel. The

lamp should light for 2 seconds then go out (bulb check)].

To erase diagnostic trouble codes, use the Erase

Trouble Code data screen on the DRBII scan tool.

USING THE MALFUNCTION INDICATOR LAMP (1) Cycle the ignition key On - Off - On - Off - On

within 5 seconds. (2) Count the number of times the malfunction indi-

cator lamp (check engine lamp on the instrument

panel) flashes on and off. The number of flashes

represents the trouble code. There is a slight pause be-

Ä FUEL SYSTEMS 14 - 71