wheel CHEVROLET EXPRESS 1997 1.G Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1997, Model line: EXPRESS, Model: CHEVROLET EXPRESS 1997 1.GPages: 386, PDF Size: 20.32 MB

Page 227 of 386

Downloaded from www.Manualslib.com manuals search engine I

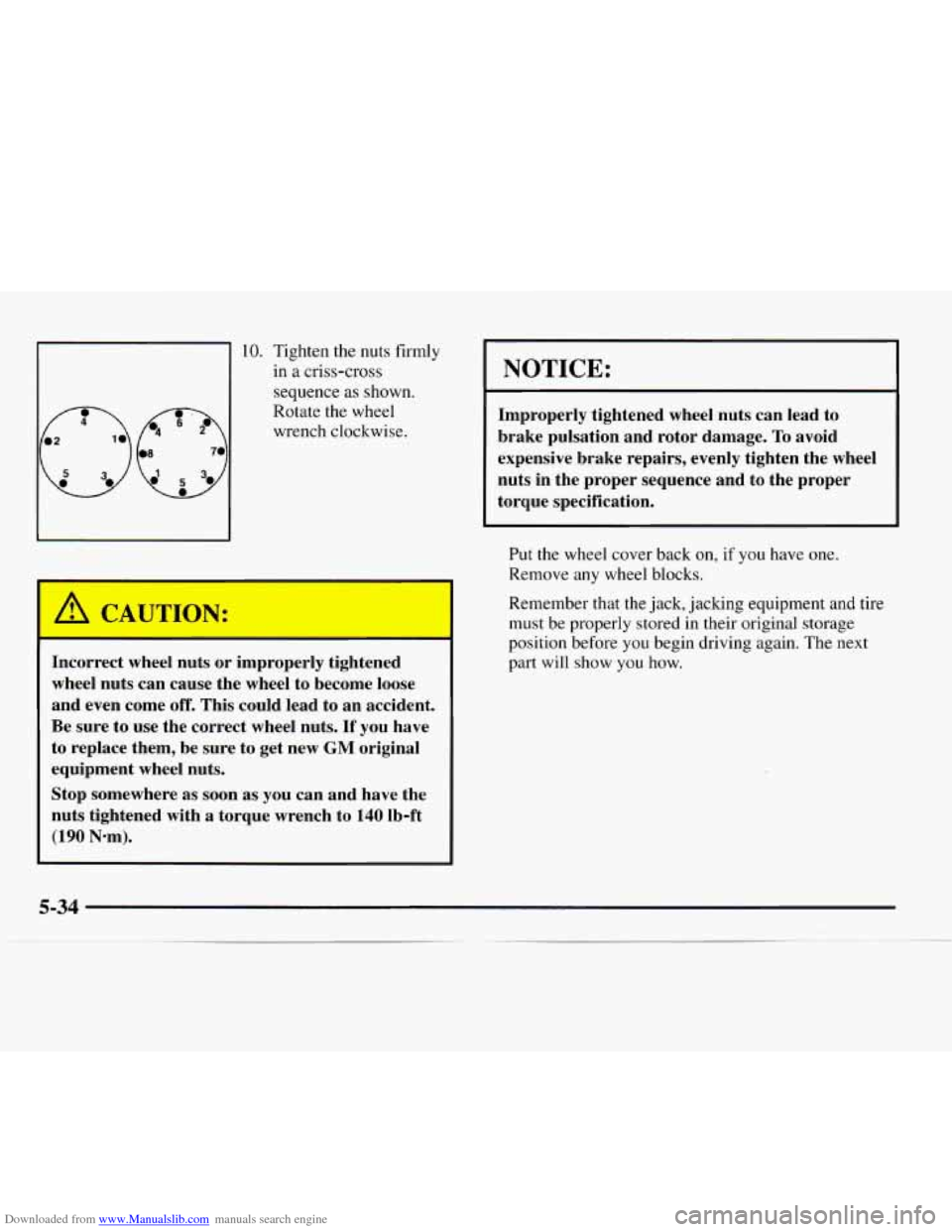

10. Tighten the nuts firmly in

a criss-cross

sequence

as shown.

(f3, e

Rotate the wheel

wrench clockwise.

A CA "TION:

I

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to become loose

and even come

off. This could lead to an accident.

Be sure to use the correct wheel nuts.

If you have

to replace them, be sure to get new

GM original

equipment wheel nuts.

Stop somewhere as soon as you can and have the

nuts tightened with

a torque wrench to 140 Ib-ft

(190 N*m).

NOTICE:

Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage.

To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque specification.

Put the wheel cover back on, if you have one.

Remove

any wheel blocks.

Remember that the jack, jacking equipment and tire

must be properly stored in their original storage

position before you begin driving again. The next

part will show you how.

5-34

Page 228 of 386

Downloaded from www.Manualslib.com manuals search engine Storing a Flat or Spare Tire and Tools

-m

Storing a jack, a tire or other equipment in the

passenger compartment

of the vehicle could

cause injury. In

a sudden stop or collision, loose

equipment could strike someone. Store all these

in the proper place.

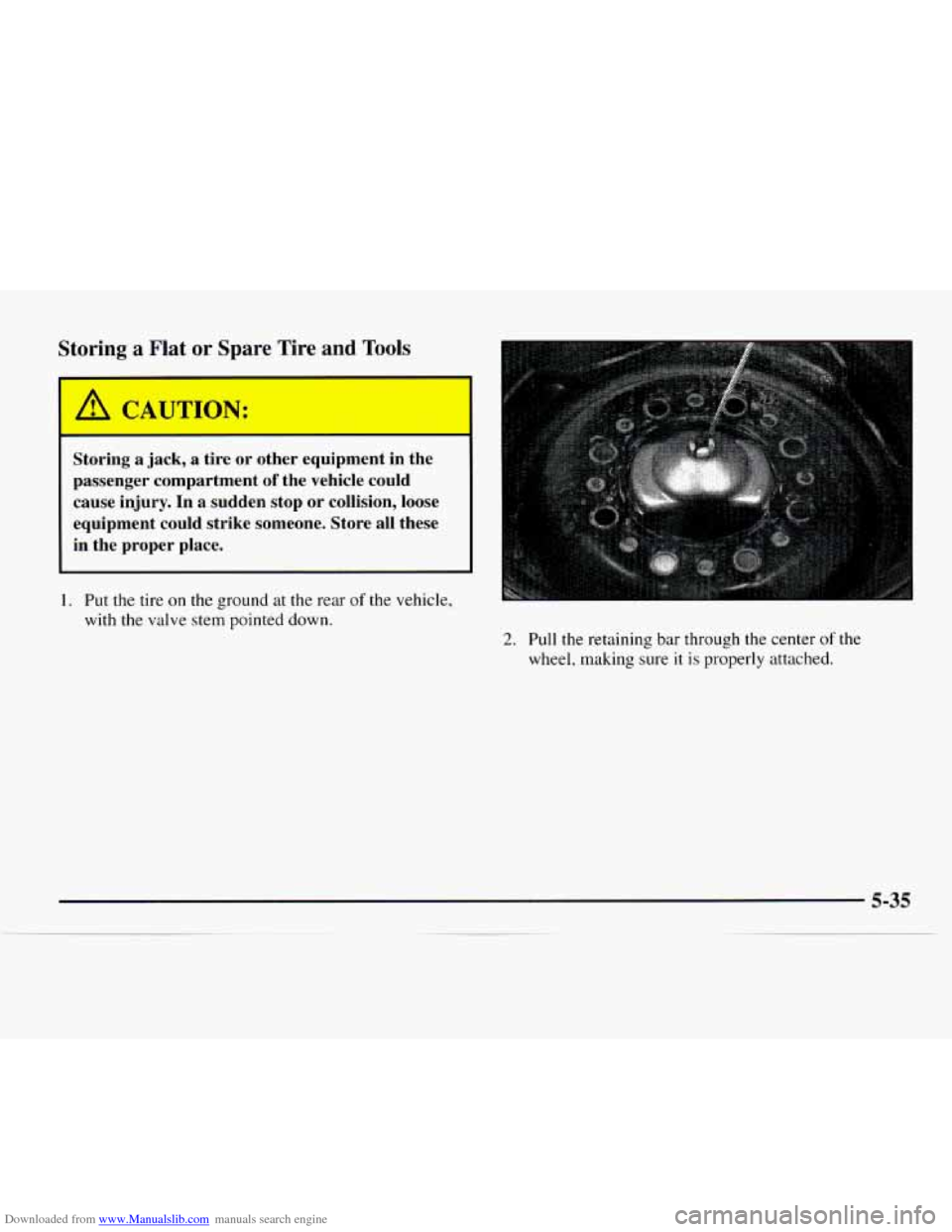

1. Put the tire on the ground at the rear of the vehicle,

with the valve stem pointed down.

2. Pull the retaining bar through the center of the

wheel, making sure

it is properly attached.

Page 229 of 386

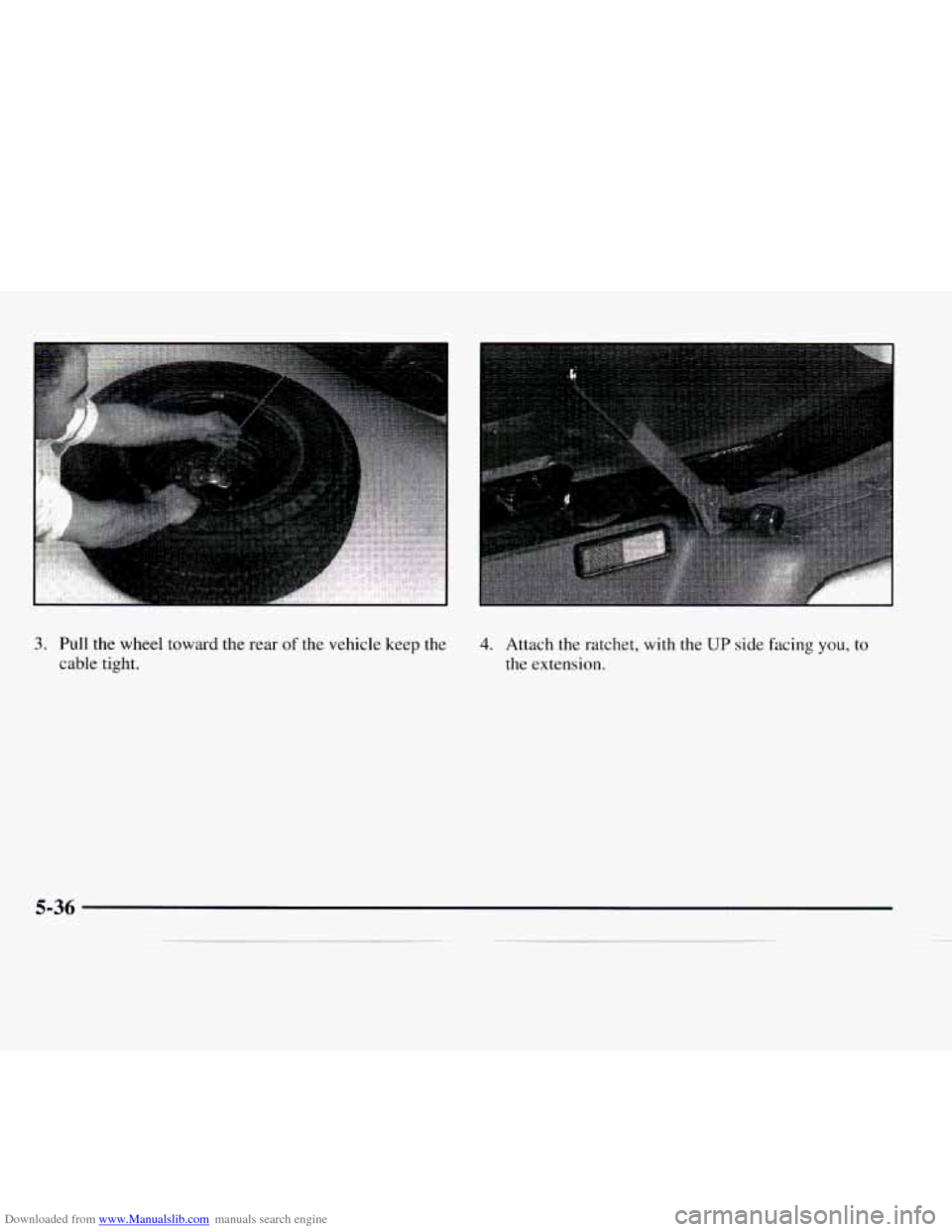

Downloaded from www.Manualslib.com manuals search engine 3. Pull the wheel toward the rear of the vehicle keep the

cable tight. 4. Attach the ratchet, with the UP side facing you, to

the extension.

5-36

Page 230 of 386

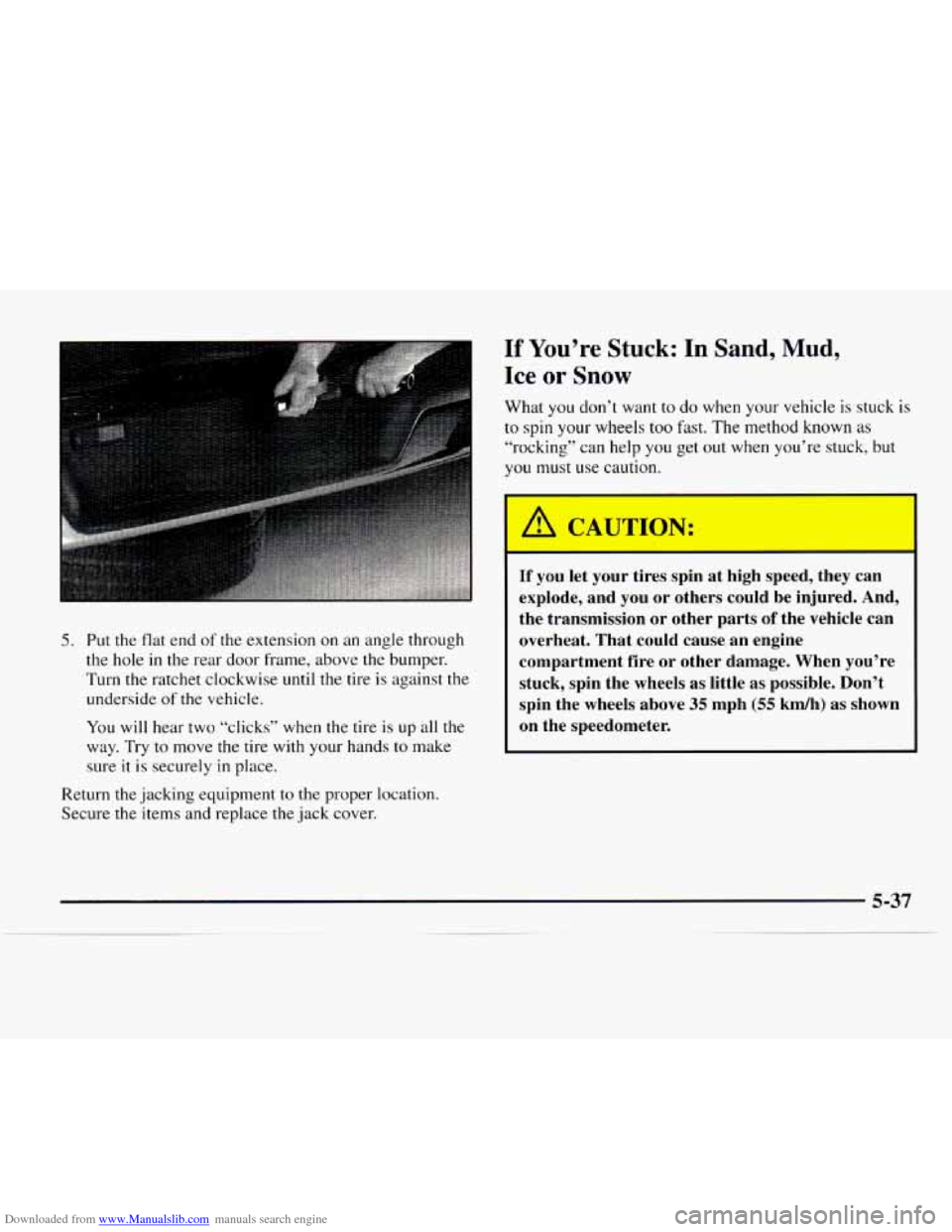

Downloaded from www.Manualslib.com manuals search engine 5. Put the flat end of the extension on an angle through

the hole in the rear door frame, above the bumper.

Turn the ratchet clockwise until the tire is against the

underside

of the vehicle.

You will hear two “clicks” when the tire is up all the

way. Try to move the tire with your hands to make

sure

it is securely in place.

Return the jacking equipment to the proper location.

Secure the items and replace the jack cover.

If You’re Stuck: In Sand, Mud,

Ice or Snow

What you don’t want to do when your vehicle is stuck is

to spin your wheels too fast. The method known as

“rocking” can help you get out when you’re stuck, but

you

must use caution.

I

A CAUTION:

If you let your tires spin at high speed, they can

explode, and you or others could be injured. And,

the transmission

or other parts of the vehicle can

overheat. That could cause an engine

compartment fire or other damage. When you’re

stuck, spin the wheels

as little as possible. Don’t

spin the wheels above

35 mph (55 kmk) as shown

on the speedometer.

Page 231 of 386

Downloaded from www.Manualslib.com manuals search engine NOTICE:

Spinning your wheels can destroy parts of your

vehicle as

well as the tires. If you spin the wheels

too fast while shifting

your transmission back

and forth, you can destroy your transmission.

For information about using tire chains on your vehicle,

see “Tire Chains” in the Index.

Rocking Your Vehicle To Get It Out

First, turn your steering wheel left and right. That will

clear the area around your front wheels. Then shift back

and forth between REVERSE (R) and a forward gear,

spinning

the wheels as little as possible. Release the

accelerator pedal while you shift, and press lightly

on

the accelerator pedal when the transmission is in gear.

If that doesn’t get you out after a few tries,

you may

need to be towed out. If you do need

to be towed out,

see “Towing Your Vehicle” in the Index.

Page 234 of 386

Downloaded from www.Manualslib.com manuals search engine Section 6 Service and Appearance Care

Here you will find information about the care of your vehicle. This section begins with service and fuel information,

and then it shows how to check important fluid and lubricant levels. There

is also technical information about your

vehicle, and

a part devoted to its appearance care.

6-2

6-3

6-5

6-5

6-7

6-1 1

6-12 6-17

6-18

6-22

6-22

6-25

6-26 6-26

6-27

6-28 6-32 Service

Fuel (Gasoline Engine)

Fuels in Foreign Countries

Filling Your Tank

Checking Things Under the Hood

Noise Control System

Engine Oil (Gasoline Engine)

Air Cleaner (Gasoline Engines)

Automatic Transmission Fluid

Rear Axle

Engine Coolant Radiator Pressure Cap

Thermostat Power Steering Fluid

Windshield Washer Fluid

Brakes

Battery 6-32

6-32

6-40

6-4

1

6-49

6-50

6-54

6-55

6-55

6-55

6-56

6-57

6-5 8

6-59

6-63

6-66

6-67 Bulb Replacement

Halogen Bulbs

Windshield Wiper Blade Replacement

Tires Appearance Care

Cleaning the Inside

of Your Vehicle

Cleaning the Outside of Your Vehicle

Cleaning Aluminum Wheels

(If Equipped)

Cleaning Tires Sheet Metal Damage

Finish Damage

Appearance Care Materials Chart

Vehicle Identification Number (VIN)

Electrical System

Capacities and Specifications

Air Conditioning Refrigerants

Lamp and Bulb Data

Page 264 of 386

Downloaded from www.Manualslib.com manuals search engine Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does

not mean something is wrong with

your brakes.

Properly torqued wheel

nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly torque wheel nuts in the

proper sequence to

GM specifications.

Your rear drum brakes don’t have wear indicators, but

if you ever hear a rear brake rubbing noise, have the

rear brake linings inspected. Also, the rear brake drums

should be removed and inspected each time the tires

are removed for rotation or changing. When you have

the front brake pads replaced, have the rear brakes

inspected,

too.

Brake linings should always be replaced as complete

axle sets.

See “Brake System Inspection” in Section

7 of this

manual under Part

C “Periodic Maintenance

Inspections”.

Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or if there is a rapid increase in pedal

travel. This could be

a sign of brake trouble.

Brake Adjustment

Every time you make a brake stop, your disc brakes

adjust for wear.

If your brake pedal goes down farther than normal, your

rear drum brakes may need adjustment. Adjust them by

backing up and firmly applying the brakes a few times.

Replacing Brake System Parts

The braking system on a modern vehicle is complex.

Its many parts have to be

of top quality and work well

together if the vehicle is to have really good braking.

Your vehicle was designed and tested with top-quality

GM brake parts. When you replace parts of your braking

system

-- for example, when your brake linings wear

down and you have

to have new ones put in -- be sure

you get new approved

GM replacement parts. If you

don’t, your brakes may no longer work properly. For

example,

if someone puts in brake linings that are wrong

for your vehicle, the balance between your front and

rear brakes can change

-- for the worse. The braking

performance you’ve come to expect can change in many

other ways

if someone puts in the wrong replacement

brake parts.

Page 276 of 386

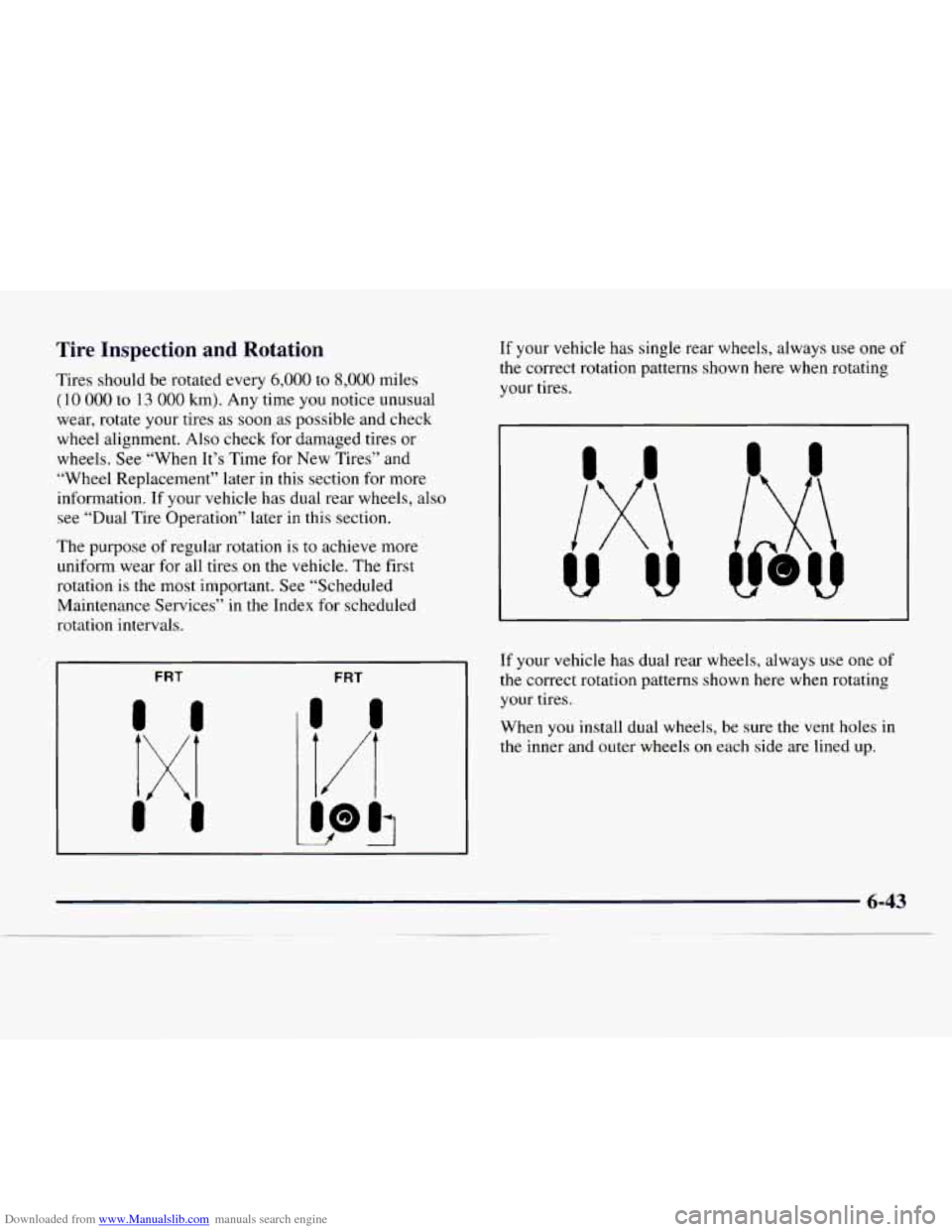

Downloaded from www.Manualslib.com manuals search engine Tire Inspection and Rotation

Tires should be rotated every 6,000 to 8,000 miles

(10 000 to 13 000 km). Any time you notice unusual

wear, rotate your tires as soon as possible and check

wheel alignment. Also check for damaged tires or

wheels. See “When It’s Time for New Tires” and

“Wheel Replacement” later in

this section for more

information. If your vehicle has dual rear wheels, also

see “Dual Tire Operation” later in this section.

The purpose of regular rotation is to achieve more

uniform wear for

all tires on the vehicle. The first

rotation is the most important. See “Scheduled

Maintenance Services’’

in the Index for scheduled

rotation intervals.

I FRT FRT

If your vehicle has single rear wheels, always use one of

the correct rotation patterns shown here when rotating

your tires.

If your vehicle has dual rear wheels, always use one

of

the correct rotation patterns shown here when rotating

your tires.

When you install dual wheels, be sure the vent holes in

the inner and outer wheels on each side are lined

up.

Page 277 of 386

Downloaded from www.Manualslib.com manuals search engine After the tires have been rotated, adjust the front and rear

inflation pressures as shown on the Certificatioflire label.

Make certain that

all wheel nuts are properly tightened.

See “Wheel Nut Torque” in the Index.

1

Rust or dirt on a wheel, or on the parts to which

it is fastened, can make wheel nuts become loose

after

a time. The wheel could come off and cause

an accident. When you change

a wheel, remove

any rust or dirt from places where the wheel

attaches to the vehicle. In

an emergency, you can

use a cloth or a paper towel to do this; but be

sure to use

a scraper or wire brush later, if you

need to, to get all the rust or dirt

off. (See

“Changing a Flat Tire” in the Index.) When

It’s Time

for New Tires

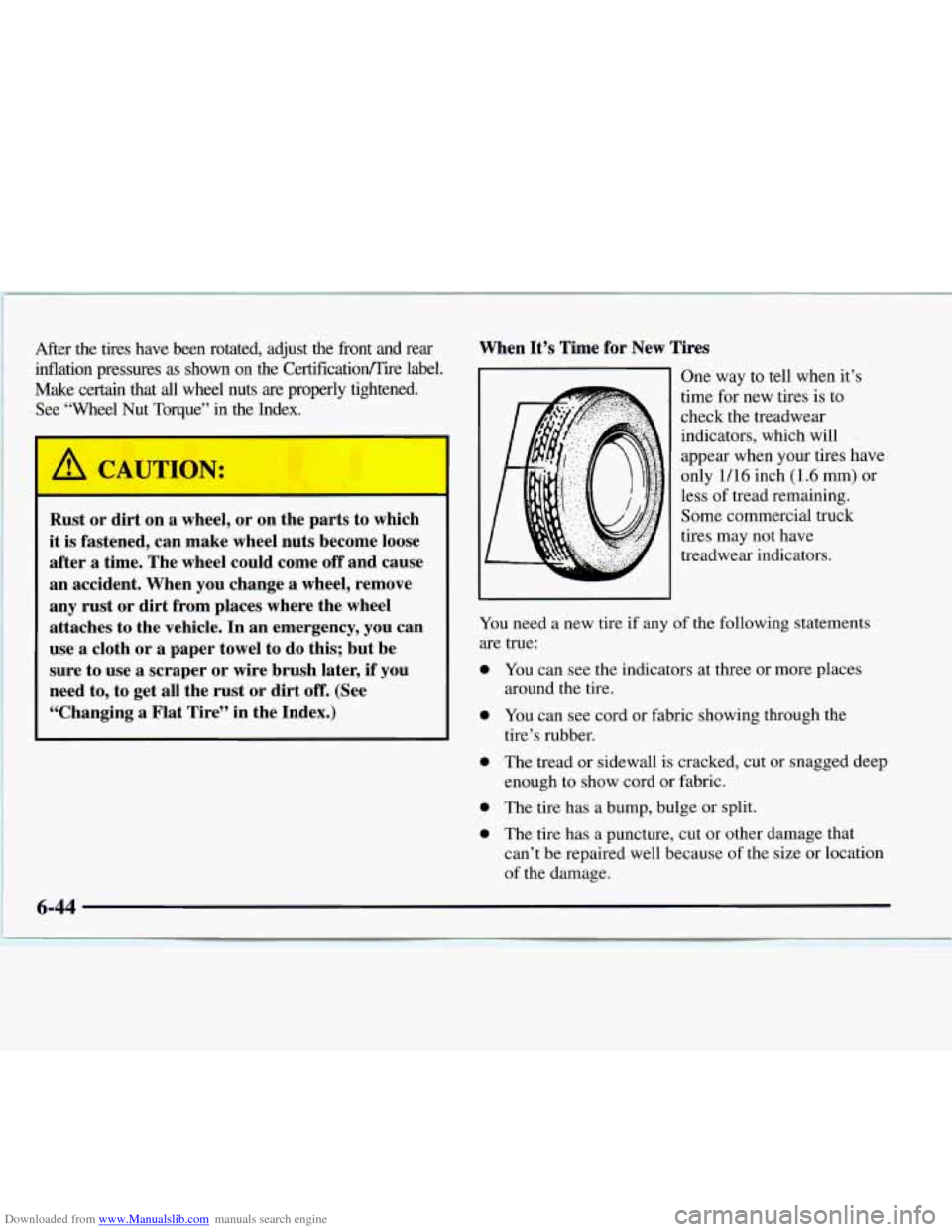

One way to tell when it’s

time for new tires is to

check the treadwear

indicators, which will

appear when your tires have

only

1/16 inch (1.6 mm) or

less

of tread remaining.

Some commercial truck

tires may not have

treadwear indicators.

You need

a new tire if any of the following statements

are true:

0 You can see the indicators at three or more places

0 You can see cord or fabric showing through the

around the tire.

tire’s rubber.

0 The tread or sidewall is cracked, cut or snagged deep

enough

to show cord or fabric.

0 The tire has a bump, bulge or split.

0 The tire has a puncture, cut or other damage that

can’t be repaired well because

of the size or location

of the damage.

6-44

, , , .

Page 278 of 386

Downloaded from www.Manualslib.com manuals search engine Dual Tire Operation

When the vehicle is new, or whenever a wheel, wheel

bolt or wheel nut is replaced, check the wheel

nut torque

after

100, 1,000 and 6,000 miles ( 160, 1 600 and

10 000 km) of driving. For proper torque, see “Wheel

Nut Torque’’ in

the Index.

The outer tire on a dual wheel setup generally wears

faster than the inner tire. Your tires will wear more

evenly and last longer if you rotate the tires periodically.

If you’re going to be doing a lot

of driving on

high-crown roads, you can reduce tire wear by adding

5 psi (35 kPa) to the tire pressure in the outer tires. Be

sure

to return to the recommended pressures when no

longer driving under those conditions. See “Changing a

Flat Tire” in the Index for more information.

A CAUTION:

Buying New Tires

To find out what kind and size of tires you need, look at

the Certificationrnire label.

The tires installed

on your vehicle when it was new had

a Tire Performance Criteria Specification (TPC Spec)

number

on each tire’s sidewall. When you get new tires,

get ones with that same TPC Spec number. That way

your vehicle will continue

to have tires that are designed

to give proper endurance, handling, speed rating,

traction, ride and other things during normal service on

your vehicle. If your tires have an all-season tread

design, the TPC number will be followed by

an “MS”

(for mud and snow).

If you ever replace your tires with those not having a

TPC Spec number, make sure they are the same size,

load range, speed rating and construction type (bias,

bias-belted or radial) as your original tires.

If you operate your vehicle with a tire that is

badly underinflated, the tire can overheat. An

overheated tire can lose air suddenly or catch

fire.

You or others could be injured. Be sure all

tires (including the spare) are properly inflated.