CHEVROLET EXPRESS CARGO VAN 2003 1.G Owners Manual

Manufacturer: CHEVROLET, Model Year: 2003, Model line: EXPRESS CARGO VAN, Model: CHEVROLET EXPRESS CARGO VAN 2003 1.GPages: 386, PDF Size: 2.73 MB

Page 311 of 386

Jump Starting

If your battery has run down, you may want to use

another vehicle and some jumper cables to start your

vehicle. Be sure to follow the steps below to do it safely.

{CAUTION:

Batteries can hurt you. They can be dangerous

because:

·They contain acid that can burn you.

·They contain gas that can explode or

ignite.

·They contain enough electricity to

burn you.

If you don't follow these steps exactly, some

or all of these things can hurt you.

Notice:Ignoring these steps could result in costly

damage to your vehicle that wouldn't be covered

by your warranty.

Trying to start your vehicle by pushing or pulling it

won't work, and it could damage your vehicle.1. Check the other vehicle. It must have a 12-volt

battery with a negative ground system.

Notice:If the other system isn't a 12-volt system

with a negative ground, both vehicles can be

damaged.

2. Get the vehicles close enough so the jumper cables

can reach, but be sure the vehicles aren't touching

each other. If they are, it could cause a ground

connection you don't want. You wouldn't be able to

start your vehicle, and the bad grounding could

damage the electrical systems.

To avoid the possibility of the vehicles rolling, set

the parking brake ®rmly on both vehicles involved in

the jump start procedure. Put an automatic

transmission in PARK (P) or a manual transmission

in NEUTRAL before setting the parking brake.

Notice:If you leave your radio on, it could be badly

damaged. The repairs wouldn't be covered by

your warranty.

3. Turn off the ignition on both vehicles. Unplug

unnecessary accessories plugged into the cigarette

lighter or in the accessory power outlet. Turn off

the radio and all lamps that aren't needed. This will

avoid sparks and help save both batteries. And it

could save your radio!

5-41

Page 312 of 386

4. Open the hoods and locate the positive (+) and

negative (-) terminal locations of the other vehicle.

Your vehicle has a remote positive (+) jump

starting terminal and a remote negative (-) jump

starting terminal. You should always use these

remote terminals instead of the terminals on the

battery.

The remote positive (+) terminal is located behind a

red plastic cover near the engine accessory drive

bracket on the driver's side below the alternator. To

uncover the remote positive (+) terminal, open

the red plastic cover.

The remote negative (-) terminal is located on the

engine drive bracket on all V8 engines and it is

marked ªGND.º

On V6 engines the remote negative (-) terminal is

located on a tab attached to the engine accessory

drive bracket where it is marked ªGND.º

{CAUTION:

Using a match near a battery can cause battery

gas to explode. People have been hurt doing

this, and some have been blinded. Use a

¯ashlight if you need more light.

Be sure the battery has enough water. You

don't need to add water to the ACDelco

ž

battery installed in your new vehicle. But if a

battery has ®ller caps, be sure the right

amount of ¯uid is there. If it is low, add water

to take care of that ®rst. If you don't, explosive

gas could be present.

Battery ¯uid contains acid that can burn you.

Don't get it on you. If you accidentally get it in

your eyes or on your skin, ¯ush the place with

water and get medical help immediately.

5-42

Page 313 of 386

{CAUTION:

Fans or other moving engine parts can injure

you badly. Keep your hands away from moving

parts once the engine is running.

5. Check that the jumper cables don't have loose or

missing insulation. If they do, you could get a

shock. The vehicles could be damaged, too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go to

positive (+) or to a remote positive (+) terminal if

the vehicle has one. Negative (-) will go to a heavy,

unpainted metal engine part or to a remote

negative (-) terminal if the vehicle has one.

Don't connect positive (+) to negative (-) or you will

get a short that would damage the battery and

maybe other parts, too. And don't connect

the negative (-) cable to the negative (-) terminal

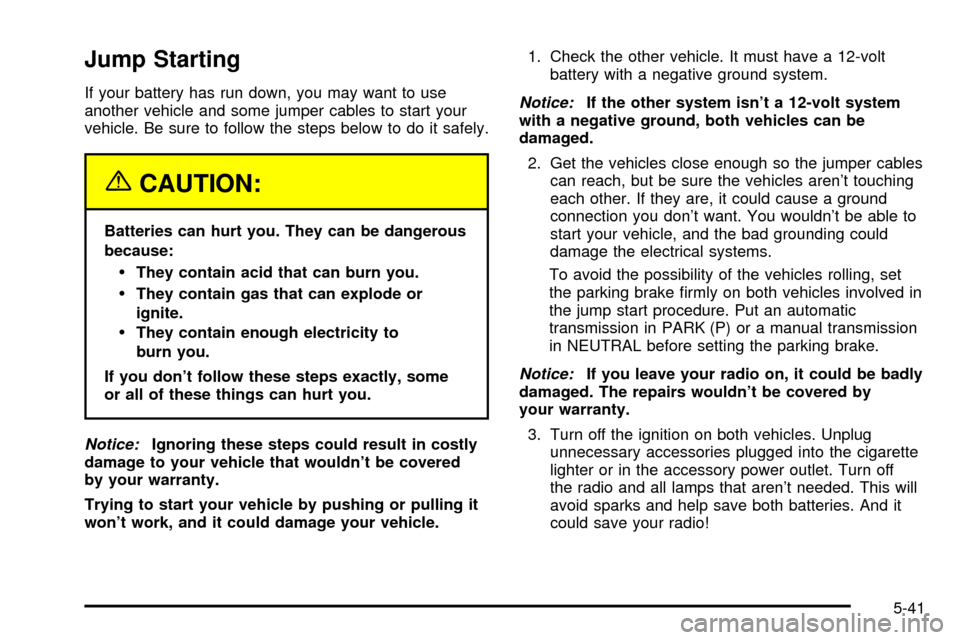

on the dead battery because this can cause sparks.6. Connect the red positive (+) cable to the positive (+)

terminal of the dead battery. Use a remote

positive (+) terminal if the vehicle has one.

5-43

Page 314 of 386

7. Don't let the other end

touch metal. Connect it

to the positive (+)

terminal of the good

battery. Use a remote

positive (+) terminal

if the vehicle has one.

8. Now connect the black

negative (-) cable to

the negative (-)

terminal of the good

battery. Use a remote

negative (-) terminal

if the vehicle has one.Don't let the other end touch anything until the next

step. The other end of the negative (-) cable

doesn't go to the dead battery. It goes to a heavy,

unpainted metal engine part or to a remote

negative (-) terminal on the vehicle with the dead

battery.

9. Connect the other end of the negative (-) cable

to the negative (-) terminal of the dead battery or

to a remote negative (-) terminal if the vehicle

has one.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle with the dead battery. If it

won't start after a few tries, it probably needs

service.

Notice:Damage to your vehicle may result from

electrical shorting if jumper cables are removed

incorrectly. To prevent electrical shorting, take care

that the cables don't touch each other or any

other metal. The repairs wouldn't be covered by

your warranty.

5-44

Page 315 of 386

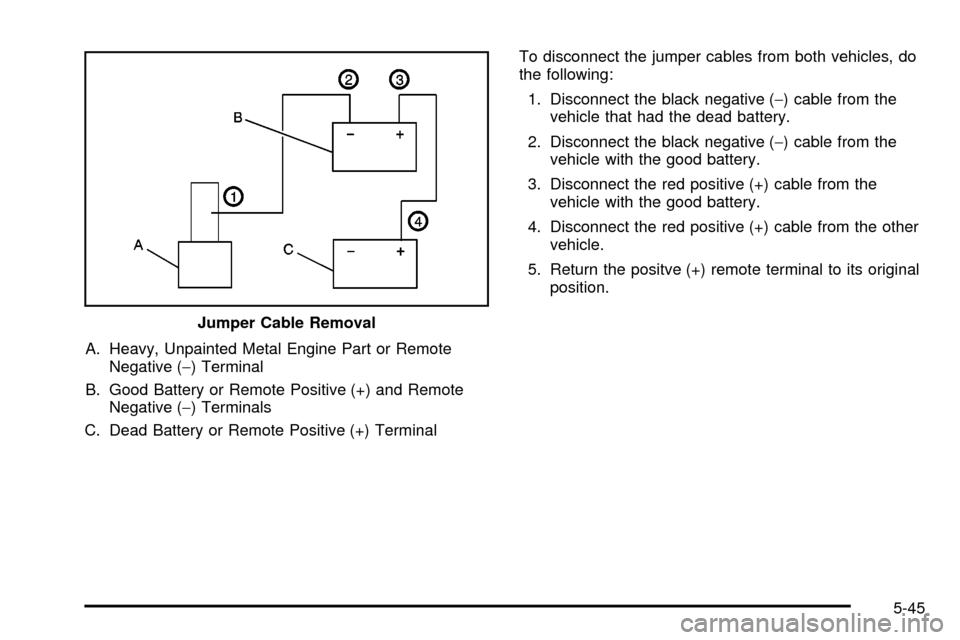

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (-) Terminal

B. Good Battery or Remote Positive (+) and Remote

Negative (-) Terminals

C. Dead Battery or Remote Positive (+) TerminalTo disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (-) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (-) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the positve (+) remote terminal to its original

position.

Jumper Cable Removal

5-45

Page 316 of 386

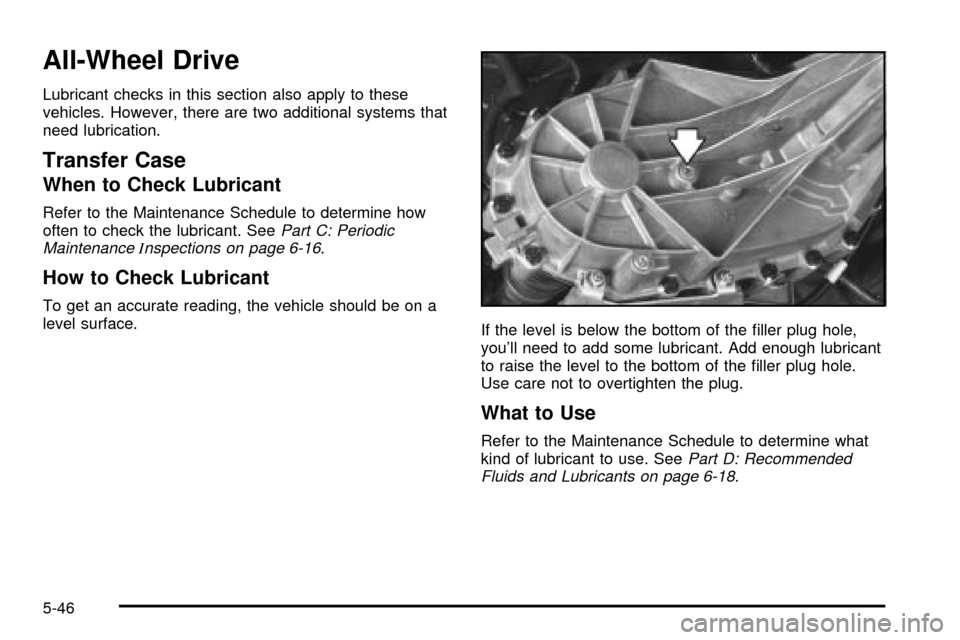

All-Wheel Drive

Lubricant checks in this section also apply to these

vehicles. However, there are two additional systems that

need lubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. SeePart C: Periodic

MaintenanceInspections on page 6-16.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the ®ller plug hole,

you'll need to add some lubricant. Add enough lubricant

to raise the level to the bottom of the ®ller plug hole.

Use care not to overtighten the plug.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart D: Recommended

Fluids and Lubricants on page 6-18.

5-46

Page 317 of 386

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. SeePart A: Scheduled

Maintenance Services on page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If you have the 1500 Series, the proper level is from

5/8 inch (15 mm) to 1 5/8 inch (40 mm) below the

bottom of the ®ller plug hole. The proper level for the

2500 and 3500 Series is from 0 to 1/4 (6 mm) below the

bottom of the ®ller plug hole. Add only enough ¯uid to

reach the proper level.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart D: Recommended

Fluids and Lubricants on page 6-18.

5-47

Page 318 of 386

Front Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it. See

Part A: Scheduled Maintenance Services on page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the

bottom of the ®ller plug

hole, you may need to

add some lubricant.When the differential is cold, add enough lubricant to

raise the level to 3/8 inch (10 mm) below the ®ller

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to the

bottom of the ®ller plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart D: Recommended

Fluids and Lubricants on page 6-18.

5-48

Page 319 of 386

Noise Control System

Tampering with Noise Control

System Prohibited

The following information relates to compliance with

federal noise emission standards for vehicles with

a Gross Vehicle Weight Rating (GVWR) of more than

10,000 lbs (4 536 kg). The Maintenance Schedule

provides information on maintaining the noise control

system to minimize degradation of the noise emission

control system during the life of your vehicle. The noise

control system warranty is given in your warranty

booklet.

These standards apply only to vehicles sold in the

United States.

Federal law prohibits the following acts or the causing

thereof:

1. The removal or rendering inoperative by any

person, other than for purposes of maintenance,

repair or replacement, of any device or element of

design incorporated into any new vehicle for

the purpose of noise control, prior to its sale or

delivery to the ultimate purchaser or while it is in

use; or

2. The use of the vehicle after such device or element

of design has been removed or rendered inoperative

by any person.Among those acts presumed to constitute tampering are

the acts listed below.

Insulation:

·

Removal of the noise shields or any underhood

insulation.

Engine:

·

Removal or rendering engine speed governor

(if equipped) inoperative so as to allow engine

speed to exceed manufacturer speci®cations.

Fan and Drive:

·

Removal of fan clutch (if equipped) or rendering

clutch inoperative.

·Removal of the fan shroud (if equipped).

Air Intake:

·

Removal of the air cleaner silencer.

·Modi®cation of the air cleaner.

Exhaust:

·

Removal of the muffler and/or resonator.

·Removal of the exhaust pipes and exhaust pipe

clamps.

5-49

Page 320 of 386

Bulb Replacement

For any bulb changing procedure not listed in this

section, contact your dealer.

For the type of bulbs, see

Replacement Bulbs on

page 5-54.

Halogen Bulbs

{CAUTION:

Halogen bulbs have pressurized gas inside

and can burst if you drop or scratch the bulb.

You or others could be injured. Be sure to read

and follow the instructions on the bulb

package.

Headlamps

1. Remove the two bolts from the headlamp assembly.

2. Remove the two pins on the top of the headlamp

assembly. To remove the pins, turn the outer pin

clockwise and pull it straight up. To remove

the inner pin, turn it counterclockwise and pull it

straight up.

3. Lift the inboard side of the headlamp to release the

inboard tab from the radiator support.

4. Lift the outboard side of the headlamp to release

the outboard tab from the radiator support.

5. Lower the headlamp to allow the vertical adjustor to

clear tie bar.

6. Turn the headlamp forward and upward to remove

it from the grille.

7. Turn the bulb connector counterclockwise and pull it

out of the housing.

5-50