CHEVROLET EXPRESS CARGO VAN 2003 1.G Owners Manual

Manufacturer: CHEVROLET, Model Year: 2003, Model line: EXPRESS CARGO VAN, Model: CHEVROLET EXPRESS CARGO VAN 2003 1.GPages: 386, PDF Size: 2.73 MB

Page 331 of 386

Uniform Tire Quality Grading

Quality grades can be found where applicable on the

tire sidewall between tread shoulder and maximum

section width. For example:

Treadwear 200 Traction AA Temperature A

The following information relates to the system

developed by the United States National Highway

Traffic Safety Administration, which grades tires by

treadwear, traction and temperature performance.

(This applies only to vehicles sold in the United States.)

The grades are molded on the sidewalls of most

passenger car tires. The Uniform Tire Quality Grading

system does not apply to deep tread, winter-type

snow tires, space-saver or temporary use spare tires,

tires with nominal rim diameters of 10 to 12 inches

(25 to 30 cm), or to some limited-production tires.

While the tires available on General Motors passenger

cars and light trucks may vary with respect to these

grades, they must also conform to federal safety

requirements and additional General Motors Tire

Performance Criteria (TPC) standards.

Treadwear

The treadwear grade is a comparative rating based on

the wear rate of the tire when tested under controlled

conditions on a speci®ed government test course.

For example, a tire graded 150 would wear one and

a half (1.5) times as well on the government course as

a tire graded 100. The relative performance of tires

depends upon the actual conditions of their use,

however, and may depart signi®cantly from the norm

due to variations in driving habits, service practices and

differences in road characteristics and climate.

Traction ± AA, A, B, C

The traction grades, from highest to lowest, are AA, A,

B, and C. Those grades represent the tire's ability

to stop on wet pavement as measured under controlled

conditions on speci®ed government test surfaces of

asphalt and concrete. A tire marked C may have poor

traction performance. Warning: The traction grade

assigned to this tire is based on straight-ahead braking

traction tests, and does not include acceleration,

cornering, hydroplaning, or peak traction characteristics.

5-61

Page 332 of 386

Temperature ± A, B, C

The temperature grades are A (the highest), B, and C,

representing the tire's resistance to the generation

of heat and its ability to dissipate heat when tested

under controlled conditions on a speci®ed indoor

laboratory test wheel. Sustained high temperature can

cause the material of the tire to degenerate and

reduce tire life, and excessive temperature can lead to

sudden tire failure. The grade C corresponds to a

level of performance which all passenger car tires must

meet under the Federal Motor Vehicle Safety Standard

No. 109. Grades B and A represent higher levels of

performance on the laboratory test wheel than the

minimum required by law.

Warning: The temperature grade for this tire is

established for a tire that is properly in¯ated and not

overloaded. Excessive speed, underin¯ation, or

excessive loading, either separately or in combination,

can cause heat buildup and possible tire failure.

Wheel Alignment and Tire Balance

The wheels on your vehicle were aligned and balanced

carefully at the factory to give you the longest tire life

and best overall performance.Scheduled wheel alignment and wheel balancing are

not needed. However, if you notice unusual tire wear or

your vehicle pulling one way or the other, the alignment

may need to be reset. If you notice your vehicle

vibrating when driving on a smooth road, your wheels

may need to be rebalanced.

Wheel Replacement

Replace any wheel that is bent, cracked, or badly rusted

or corroded. If wheel nuts keep coming loose, the

wheel, wheel bolts and wheel nuts should be replaced.

If the wheel leaks air, replace it (except some

aluminum wheels, which can sometimes be repaired).

See your dealer if any of these conditions exist.

Your dealer will know the kind of wheel you need.

Each new wheel should have the same load-carrying

capacity, diameter, width, offset and be mounted

the same way as the one it replaces.

If you need to replace any of your wheels, wheel bolts

or wheel nuts, replace them only with new GM

original equipment parts. This way, you will be sure to

have the right wheel, wheel bolts and wheel nuts

for your vehicle.

5-62

Page 333 of 386

{CAUTION:

Using the wrong replacement wheels, wheel

bolts or wheel nuts on your vehicle can be

dangerous. It could affect the braking and

handling of your vehicle, make your tires lose

air and make you lose control. You could have

a collision in which you or others could be

injured. Always use the correct wheel, wheel

bolts and wheel nuts for replacement.

Notice:The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or

odometer calibration, headlamp aim, bumper height,

vehicle ground clearance and tire or tire chain

clearance to the body and chassis.

Whenever a wheel, wheel bolt or wheel nut is replaced

on a dual wheel setup, check the wheel nut torque

after 100, 1,000 and 6,000 miles (160, 1 600 and

10 000 km) of driving. For proper torque, see ªWheel Nut

Torqueº under

Capacities and Speci®cations on

page 5-97.

See

Changing a Flat Tire on page 5-65for more

information.

Used Replacement Wheels

{CAUTION:

Putting a used wheel on your vehicle is

dangerous. You can't know how it's been used

or how far it's been driven. It could fail

suddenly and cause a crash. If you have to

replace a wheel, use a new GM original

equipment wheel.

Tire Chains

Notice:Use tire chains only where legal and only

when you must. Use chains that are the proper size

for your tires. Install them on the tires of the rear

axle. Tighten them as tightly as possible with

the ends securely fastened. Drive slowly and follow

the chain manufacturer's instructions. If you can

hear the chains contacting your vehicle, stop

and retighten them. If the contact continues, slow

down until it stops. Driving too fast or spinning the

wheels with chains on will damage your vehicle.

5-63

Page 334 of 386

If a Tire Goes Flat

It's unusual for a tire to ªblowoutº while you're driving,

especially if you maintain your tires properly. If air goes

out of a tire, it's much more likely to leak out slowly.

But if you should ever have a ªblowout,º here are a few

tips about what to expect and what to do:

If a front tire fails, the ¯at tire will create a drag that

pulls the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel ®rmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you'd use

in a skid. In any rear blowout, remove your foot from the

accelerator pedal. Get the vehicle under control by

steering the way you want the vehicle to go. It may be

very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.{CAUTION:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without

the appropriate safety equipment and training.

The jack provided with your vehicle is

designed only for changing a ¯at tire. If it is

used for anything else, you or others could be

badly injured or killed if the vehicle slips off

the jack. Use the jack provided with your

vehicle only for changing a ¯at tire.

If a tire goes ¯at, the next part shows how to use your

jacking equipment to change a ¯at tire safely.

5-64

Page 335 of 386

Changing a Flat Tire

If a tire goes ¯at, avoid further tire and wheel damage

by driving slowly to a level place. Turn on your

hazard warning ¯ashers.

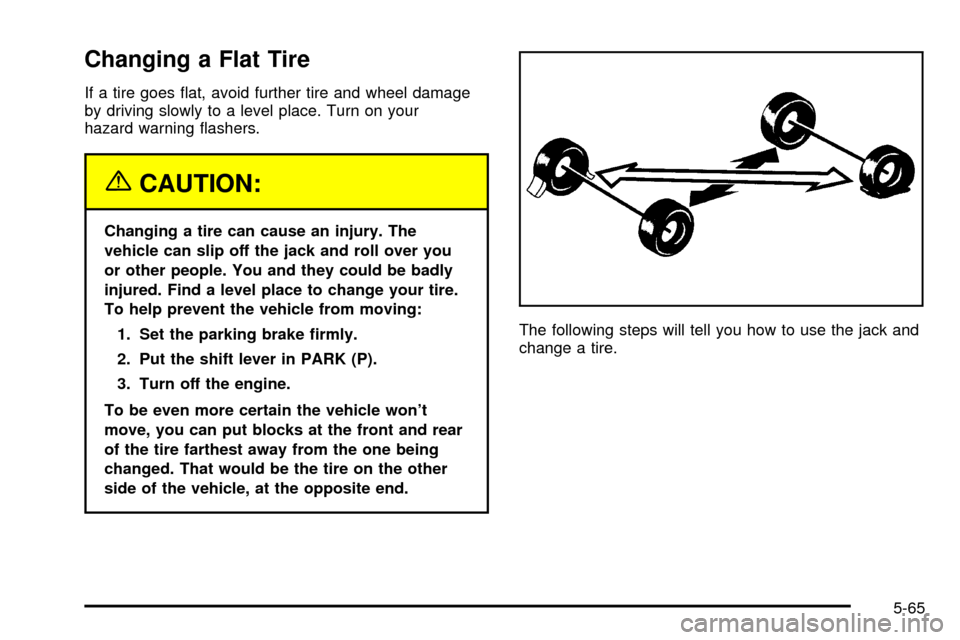

{CAUTION:

Changing a tire can cause an injury. The

vehicle can slip off the jack and roll over you

or other people. You and they could be badly

injured. Find a level place to change your tire.

To help prevent the vehicle from moving:

1. Set the parking brake ®rmly.

2. Put the shift lever in PARK (P).

3. Turn off the engine.

To be even more certain the vehicle won't

move, you can put blocks at the front and rear

of the tire farthest away from the one being

changed. That would be the tire on the other

side of the vehicle, at the opposite end.The following steps will tell you how to use the jack and

change a tire.

5-65

Page 336 of 386

Removing the Spare Tire and Tools

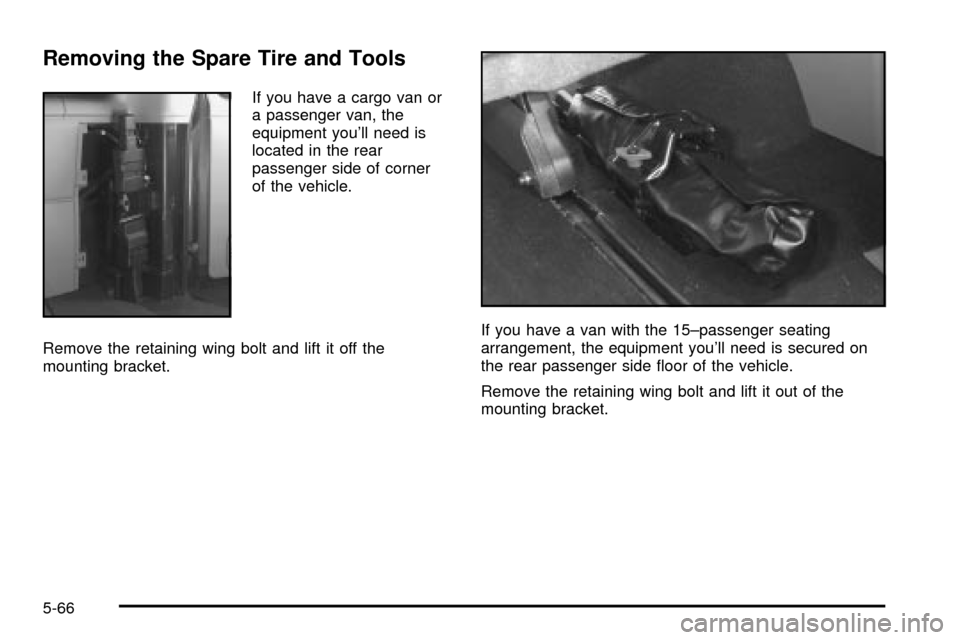

If you have a cargo van or

a passenger van, the

equipment you'll need is

located in the rear

passenger side of corner

of the vehicle.

Remove the retaining wing bolt and lift it off the

mounting bracket.If you have a van with the 15±passenger seating

arrangement, the equipment you'll need is secured on

the rear passenger side ¯oor of the vehicle.

Remove the retaining wing bolt and lift it out of the

mounting bracket.

5-66

Page 337 of 386

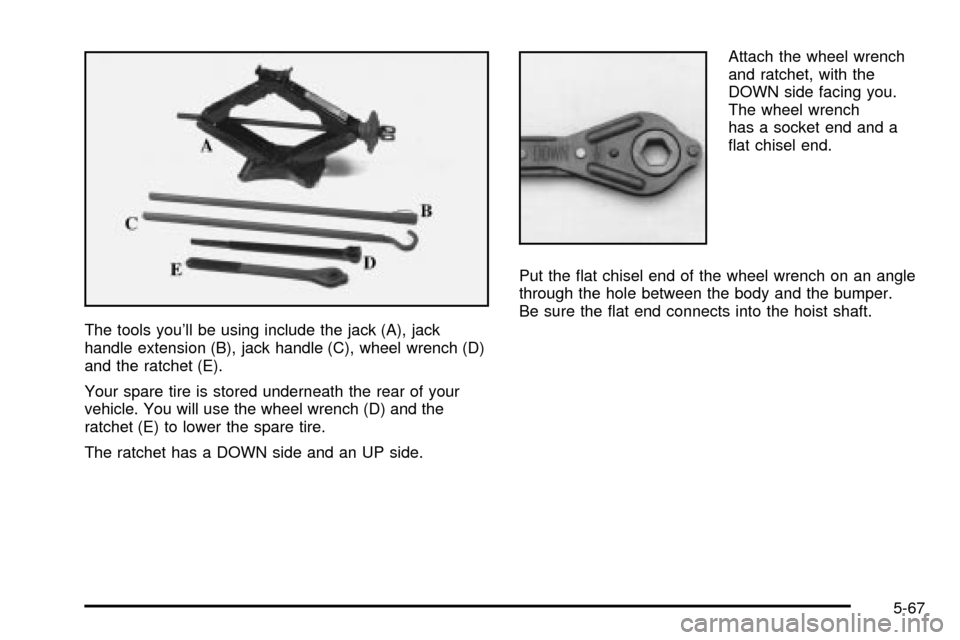

The tools you'll be using include the jack (A), jack

handle extension (B), jack handle (C), wheel wrench (D)

and the ratchet (E).

Your spare tire is stored underneath the rear of your

vehicle. You will use the wheel wrench (D) and the

ratchet (E) to lower the spare tire.

The ratchet has a DOWN side and an UP side.Attach the wheel wrench

and ratchet, with the

DOWN side facing you.

The wheel wrench

has a socket end and a

¯at chisel end.

Put the ¯at chisel end of the wheel wrench on an angle

through the hole between the body and the bumper.

Be sure the ¯at end connects into the hoist shaft.

5-67

Page 338 of 386

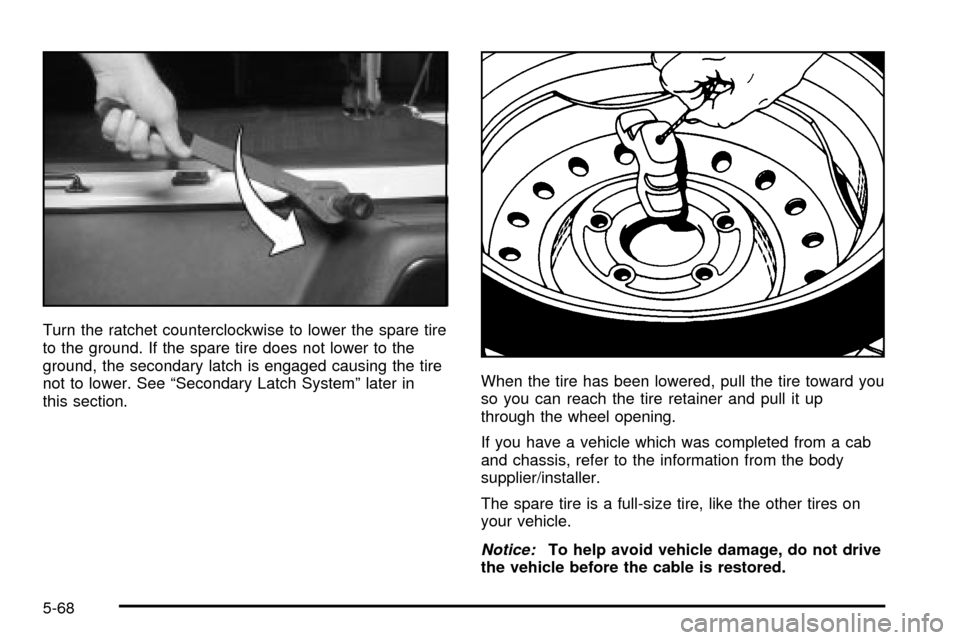

Turn the ratchet counterclockwise to lower the spare tire

to the ground. If the spare tire does not lower to the

ground, the secondary latch is engaged causing the tire

not to lower. See ªSecondary Latch Systemº later in

this section.When the tire has been lowered, pull the tire toward you

so you can reach the tire retainer and pull it up

through the wheel opening.

If you have a vehicle which was completed from a cab

and chassis, refer to the information from the body

supplier/installer.

The spare tire is a full-size tire, like the other tires on

your vehicle.

Notice:To help avoid vehicle damage, do not drive

the vehicle before the cable is restored.

5-68

Page 339 of 386

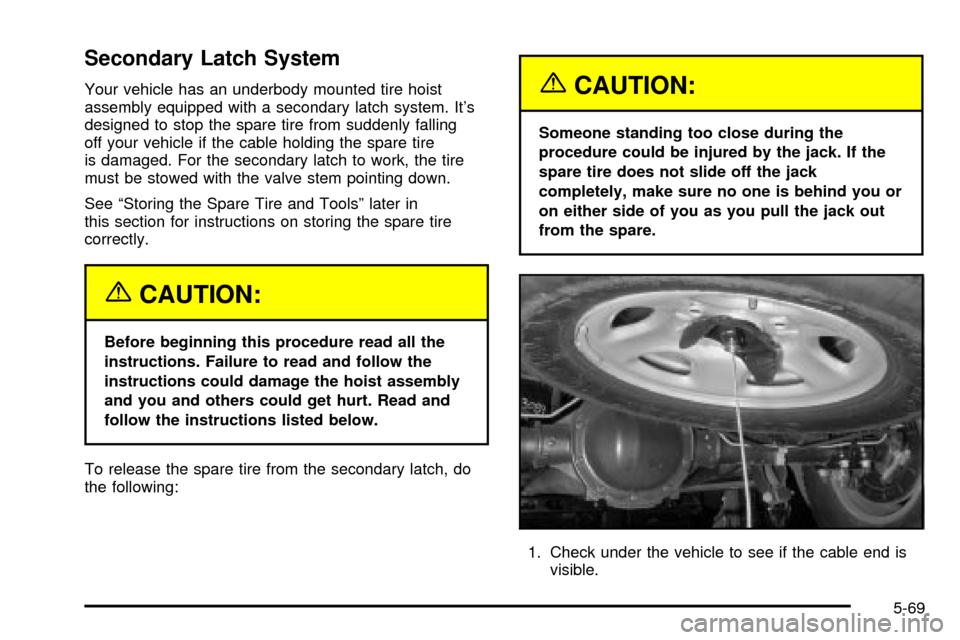

Secondary Latch System

Your vehicle has an underbody mounted tire hoist

assembly equipped with a secondary latch system. It's

designed to stop the spare tire from suddenly falling

off your vehicle if the cable holding the spare tire

is damaged. For the secondary latch to work, the tire

must be stowed with the valve stem pointing down.

See ªStoring the Spare Tire and Toolsº later in

this section for instructions on storing the spare tire

correctly.

{CAUTION:

Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly

and you and others could get hurt. Read and

follow the instructions listed below.

To release the spare tire from the secondary latch, do

the following:

{CAUTION:

Someone standing too close during the

procedure could be injured by the jack. If the

spare tire does not slide off the jack

completely, make sure no one is behind you or

on either side of you as you pull the jack out

from the spare.

1. Check under the vehicle to see if the cable end is

visible.

5-69

Page 340 of 386

2. If the cable is not visible, start this procedure at

Step 6.

3. Turn the wrench counterclockwise until

approximately 6 inches (15 cm) of cable is exposed.

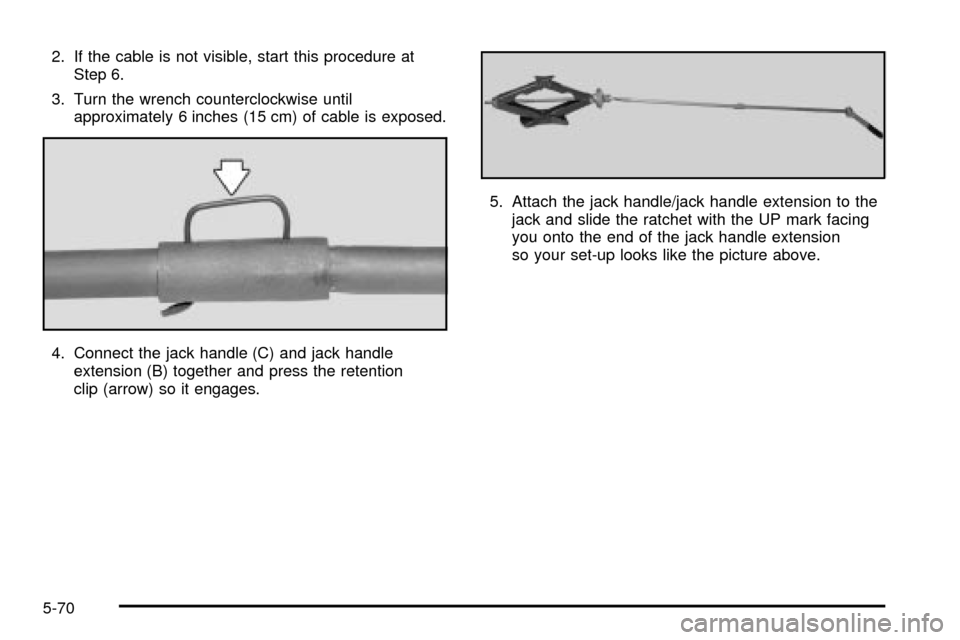

4. Connect the jack handle (C) and jack handle

extension (B) together and press the retention

clip (arrow) so it engages.5. Attach the jack handle/jack handle extension to the

jack and slide the ratchet with the UP mark facing

you onto the end of the jack handle extension

so your set-up looks like the picture above.

5-70