tow CHEVROLET EXPRESS CARGO VAN 2007 1.G Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2007, Model line: EXPRESS CARGO VAN, Model: CHEVROLET EXPRESS CARGO VAN 2007 1.GPages: 458, PDF Size: 2.62 MB

Page 284 of 458

Turn Signals When Towing a Trailer

When you tow a trailer, your vehicle has to have

extra wiring and a heavy-duty turn signal

flasher (included in the optional trailering package).

The arrows on your instrument panel will flash

whenever you signal a turn or lane change.

Properly hooked up, the trailer lamps will also

flash, telling other drivers you’re about to

turn, change lanes or stop.

When towing a trailer, the arrows on your

instrument panel will flash for turns even if the bulbs

on the trailer are burned out. Thus, you may think

drivers behind you are seeing your signal when

they are not. It’s important to check occasionally to

be sure the trailer bulbs are still working.

Driving On Grades

Reduce speed and shift to a lower gearbefore

you start down a long or steep downgrade. If you

don’t shift down, you might have to use your

brakes so much that they would get hot and no

longer work well.

You can tow in DRIVE (D). You may want to shift

the transmission to THIRD (3) or a lower gear

under heavy loads and/or hilly conditions.

When towing at high altitude on steep uphill

grades, consider the following: Engine coolant will

boil at a lower temperature than at normal

altitudes. If you turn your engine off immediately

after towing at high altitude on steep uphill grades,

your vehicle may show signs similar to engine

overheating. To avoid this, let the engine run while

parked (preferably on level ground) with the

automatic transmission in PARK (P) for a few

minutes before turning the engine off. If you do get

the overheat warning, seeEngine Overheating

on page 315.

284

Page 286 of 458

Maintenance When Trailer Towing

Your vehicle will need service more often when

you’re pulling a trailer. See the Maintenance

Schedule for more on this. Things that are

especially important in trailer operation are

automatic transmission fluid (don’t overfill), engine

oil, axle lubricant, belt, cooling system and

brake system. Each of these is covered in this

manual, and the Index will help you find them

quickly. If you’re trailering, it’s a good idea

to review these sections before you start your trip.

Check periodically to see that all hitch nuts and

bolts are tight.

Trailer Wiring Harness

The optional heavy-duty trailer wiring package

includes a seven-wire harness assembly at the rear

of the vehicle and a four-wire harness assembly

under the left hand side of the instrument panel.

The seven-wire harness assembly is taped together

and located in a frame pocket at the driver side rear

left corner of the frame. The seven-wire harness

includes a 30-amp feed wire.Both harnesses come without connectors and

should be wired by a qualified electrical technician.

The technician can use the following color code

chart when connecting the wiring harness to your

trailer and trailer brake controller.

Seven-Wire Harness

•Light Green: Back-up lamps

•Brown: Parking lamps

•Yellow: Left stoplamp and turn signal

•Dark Green: Right stoplamp and turn signal

•Dark Blue: Use for electric trailer brakes

•Red/Black Stripe: Trailer accessory

•White (heavy gage): Ground wire

Four-Wire Harness (Trailer Brake Controller)

•Black: Ground

•Red/White Stripe: Fused Battery

•Dark Blue: Trailer Brake Feed

•Light Blue: Fused Stoplamp/CHMSL

286

Page 303 of 458

A. Battery. SeeBattery on page 329.

B. Radiator Pressure Cap. SeeRadiator Pressure

Cap on page 315.

C. Coolant Recovery Tank. SeeCooling System

on page 317.

D. Automatic Transmission Fluid Dipstick. See

“Checking the Fluid Level” underAutomatic

Transmission Fluid on page 309.

E. Engine Oil Fill Cap. See “When to Add Engine

Oil” underEngine Oil (Gasoline Engine) on

page 303.

F. Engine Oil Dipstick. See “Checking Engine Oil”

underEngine Oil (Gasoline Engine) on

page 303.

G. Engine Air Cleaner/Filter. SeeEngine

Air Cleaner/Filter on page 308.

H. Power Steering Fluid Reservoir. SeePower

Steering Fluid on page 323.

I. Brake Master Cylinder Reservoir. See “Brake

Fluid” underBrakes on page 325.

J. Windshield Washer Fluid Reservoir. See

“Adding Washer Fluid” underWindshield

Washer Fluid on page 324.Engine Oil (Gasoline Engine)

If your vehicle has a diesel engine, see “Engine

Oil” in the DURAMAX®Diesel Engine Supplement.

Checking Engine Oil

It is a good idea to check the engine oil every time

you get fuel. In order to get an accurate reading,

the oil must be warm and the vehicle must be

on level ground.

The engine oil dipstick handle is a yellow loop.

SeeEngine Compartment Overview on page 302

for the location of the engine oil dipstick.

1. Turn off the engine and give the oil several

minutes to drain back into the oil pan. If you

do not do this, the oil dipstick might not

show the actual level.

2. Pull out the dipstick and clean it with a paper

towel or cloth, then push it back in all the

way. Remove it again, keeping the tip down,

and check the level.

303

Page 311 of 458

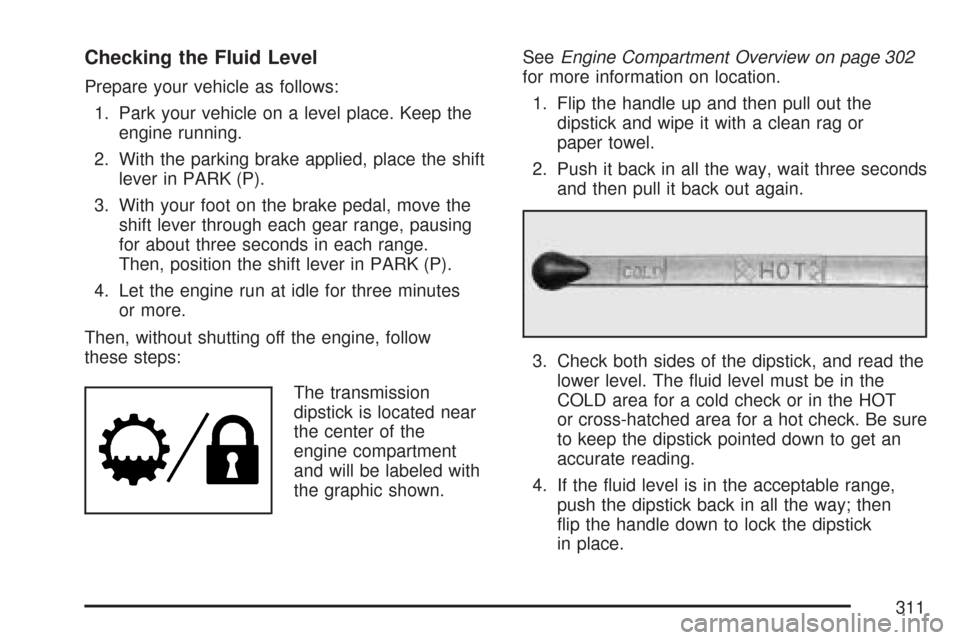

Checking the Fluid Level

Prepare your vehicle as follows:

1. Park your vehicle on a level place. Keep the

engine running.

2. With the parking brake applied, place the shift

lever in PARK (P).

3. With your foot on the brake pedal, move the

shift lever through each gear range, pausing

for about three seconds in each range.

Then, position the shift lever in PARK (P).

4. Let the engine run at idle for three minutes

or more.

Then, without shutting off the engine, follow

these steps:

The transmission

dipstick is located near

the center of the

engine compartment

and will be labeled with

the graphic shown.SeeEngine Compartment Overview on page 302

for more information on location.

1. Flip the handle up and then pull out the

dipstick and wipe it with a clean rag or

paper towel.

2. Push it back in all the way, wait three seconds

and then pull it back out again.

3. Check both sides of the dipstick, and read the

lower level. The fluid level must be in the

COLD area for a cold check or in the HOT

or cross-hatched area for a hot check. Be sure

to keep the dipstick pointed down to get an

accurate reading.

4. If the fluid level is in the acceptable range,

push the dipstick back in all the way; then

flip the handle down to lock the dipstick

in place.

311

Page 316 of 458

If Steam Is Coming From Your Engine

{CAUTION:

Steam from an overheated engine can

burn you badly, even if you just open the

hood. Stay away from the engine if you

see or hear steam coming from it. Just

turn it off and get everyone away from

the vehicle until it cools down. Wait until

there is no sign of steam or coolant

before you open the hood.

If you keep driving when your engine is

overheated, the liquids in it can catch �re.

You or others could be badly burned.

Stop your engine if it overheats, and get

out of the vehicle until the engine is cool.

Notice:If your engine catches �re because

you keep driving with no coolant, your vehicle

can be badly damaged. The costly repairs

would not be covered by your warranty.

If No Steam Is Coming From

Your Engine

If you get an engine overheat warning but see

or hear no steam, the problem may not be

too serious. Sometimes the engine can get a

little too hot when you:

•Climb a long hill on a hot day.

•Stop after high-speed driving.

•Idle for long periods in traffic.

•Tow a trailer. See “Driving on Grades”

underTowing a Trailer on page 269.

If you get the overheat warning with no sign of

steam, try this for a minute or so:

1. In heavy traffic, let the engine idle in

NEUTRAL (N) while stopped. If it is safe to

do so, pull off the road, shift to PARK (P)

or NEUTRAL (N) and let the engine idle.

2. Turn on your heater to full hot at the highest

fan speed and open the windows as

necessary.

316

Page 323 of 458

Engine Fan Noise

Your vehicle has a clutched engine cooling fan.

When the clutch is engaged, the fan spins faster

to provide more air to cool the engine. In most

everyday driving conditions, the fan is spinning

slower and the clutch is not fully engaged.

This improves fuel economy and reduces fan

noise. Under heavy vehicle loading, trailer towing,

and/or high outside temperatures, the fan speed

increases as the clutch more fully engages,

so you may hear an increase in fan noise.

This is normal and should not be mistaken as the

transmission slipping or making extra shifts. It

is merely the cooling system functioning properly.

The fan will slow down when additional cooling

is not required and the clutch partially disengages.

You may also hear this fan noise when you

start the engine. It will go away as the fan

clutch partially disengages.

Power Steering Fluid

The power steering fluid

reservoir is located in

the engine compartment

on the driver’s side of

the vehicle. SeeEngine

Compartment Overview

on page 302for

reservoir location.

When to Check Power Steering Fluid

It is not necessary to regularly check power

steering fluid unless you suspect there is a leak

in the system or you hear an unusual noise.

A fluid loss in this system could indicate a problem.

Have the system inspected and repaired.

323

Page 357 of 458

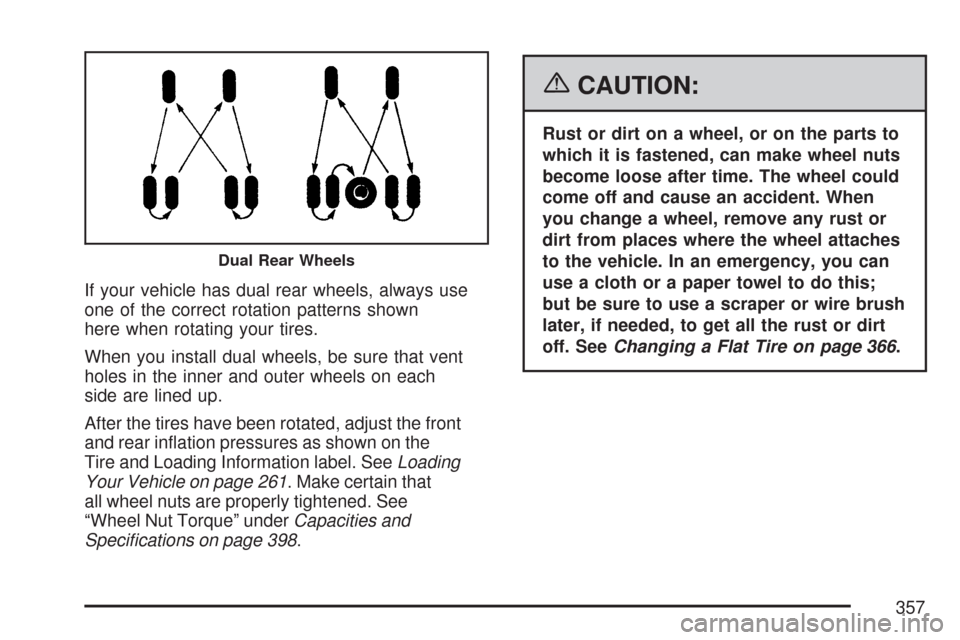

If your vehicle has dual rear wheels, always use

one of the correct rotation patterns shown

here when rotating your tires.

When you install dual wheels, be sure that vent

holes in the inner and outer wheels on each

side are lined up.

After the tires have been rotated, adjust the front

and rear inflation pressures as shown on the

Tire and Loading Information label. SeeLoading

Your Vehicle on page 261. Make certain that

all wheel nuts are properly tightened. See

“Wheel Nut Torque” underCapacities and

Speci�cations on page 398.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after time. The wheel could

come off and cause an accident. When

you change a wheel, remove any rust or

dirt from places where the wheel attaches

to the vehicle. In an emergency, you can

use a cloth or a paper towel to do this;

but be sure to use a scraper or wire brush

later, if needed, to get all the rust or dirt

off. SeeChanging a Flat Tire on page 366.

Dual Rear Wheels

357

Page 365 of 458

If a Tire Goes Flat

It is unusual for a tire to blowout while you are

driving, especially if you maintain your vehicle’s

tires properly. If air goes out of a tire, it is

much more likely to leak out slowly. But if you

should ever have a blowout, here are a few tips

about what to expect and what to do:

If a front tire fails, the flat tire will create a drag

that pulls the vehicle toward that side. Take

your foot off the accelerator pedal and grip the

steering wheel firmly. Steer to maintain lane

position, and then gently brake to a stop well

out of the traffic lane.

A rear blowout, particularly on a curve, acts much

like a skid and may require the same correction

you would use in a skid. In any rear blowout

remove your foot from the accelerator pedal.

Get the vehicle under control by steering the

way you want the vehicle to go. It may be very

bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.{CAUTION:

Lifting a vehicle and getting under it to

do maintenance or repairs is dangerous

without the appropriate safety equipment

and training. The jack provided with your

vehicle is designed only for changing a

�at tire. If it is used for anything else, you

or others could be badly injured or killed

if the vehicle slips off the jack. Use the

jack provided with your vehicle only for

changing a �at tire.

If a tire goes flat, the next part shows how to use

the jacking equipment to change a flat tire safely.

365

Page 370 of 458

4. When the tire has been lowered, pull the tire

toward you so you can reach the tire retainer

and pull it up through the wheel opening.

If you have a vehicle which was completed from

a cab and chassis, refer to the information from

the body supplier/installer.

The spare tire is a full-size tire, like the other tires

on your vehicle.

Removing the Flat Tire and

Installing the Spare Tire

If your vehicle has plastic wheel nut caps,

loosen them by turning the wheel wrench

counterclockwise. The wheel nut caps are

designed to remain with the center cap.

Remove the center cap.

If the wheel has a smooth center piece, place

the chisel end of the wheel wrench in the slot

on the wheel and gently pry it out.

1. Do a safety check before proceeding.

SeeChanging a Flat Tire on page 366

for more information.

2. With the DOWN side facing you, use the

ratchet and wheel wrench to loosen all the

wheel nuts. Do not remove them yet.

370

Page 374 of 458

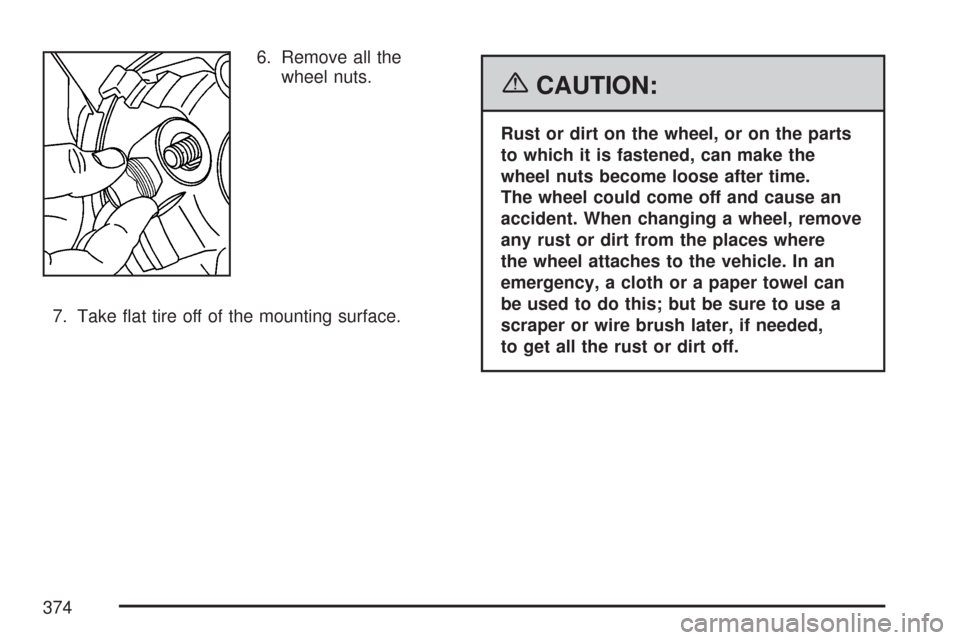

6. Remove all the

wheel nuts.

7. Take flat tire off of the mounting surface.

{CAUTION:

Rust or dirt on the wheel, or on the parts

to which it is fastened, can make the

wheel nuts become loose after time.

The wheel could come off and cause an

accident. When changing a wheel, remove

any rust or dirt from the places where

the wheel attaches to the vehicle. In an

emergency, a cloth or a paper towel can

be used to do this; but be sure to use a

scraper or wire brush later, if needed,

to get all the rust or dirt off.

374