cooling CHEVROLET KODIAK 2004 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2004, Model line: KODIAK, Model: CHEVROLET KODIAK 2004Pages: 366, PDF Size: 6.87 MB

Page 246 of 366

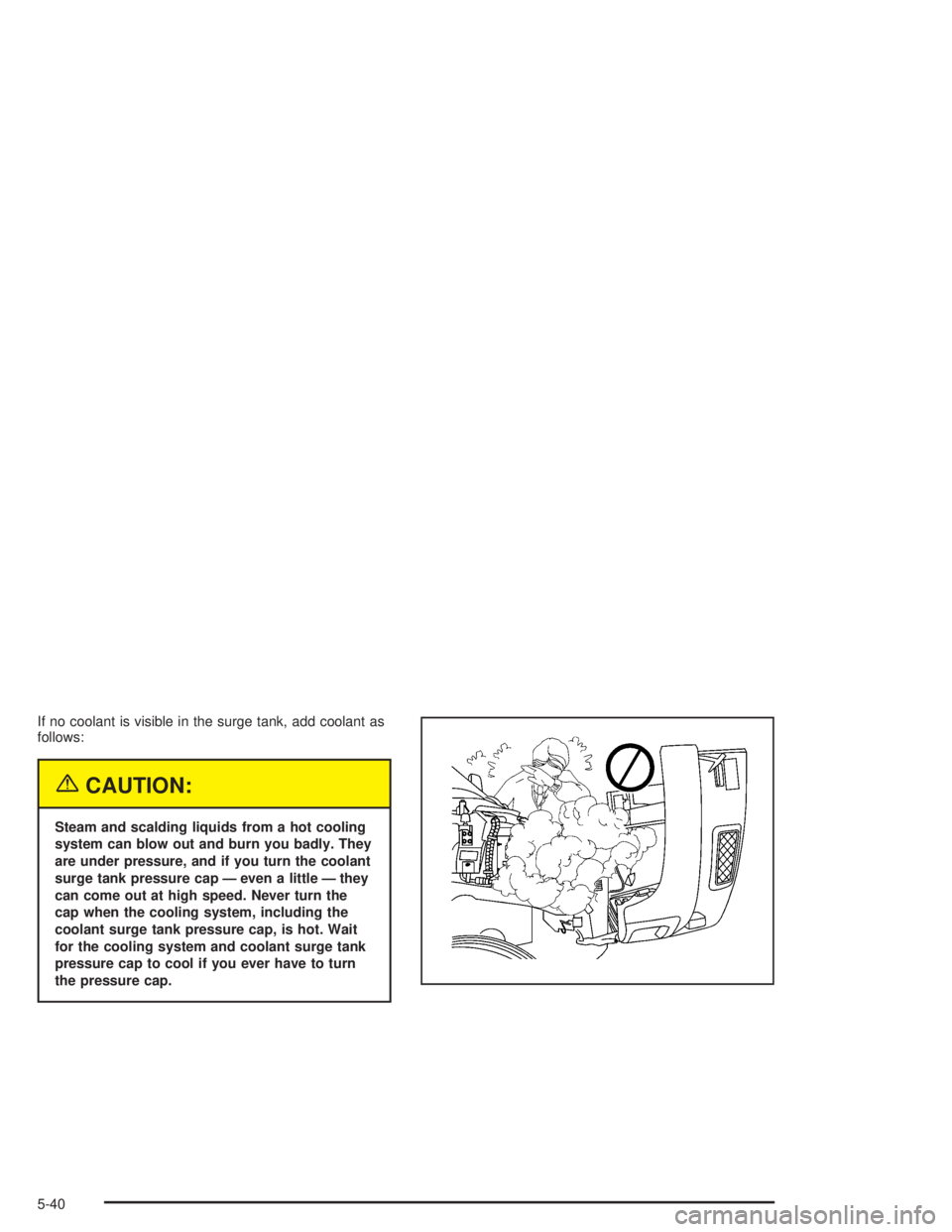

If no coolant is visible in the surge tank, add coolant as

follows:

{CAUTION:

Steam and scalding liquids from a hot cooling

system can blow out and burn you badly. They

are under pressure, and if you turn the coolant

surge tank pressure cap — even a little — they

can come out at high speed. Never turn the

cap when the cooling system, including the

coolant surge tank pressure cap, is hot. Wait

for the cooling system and coolant surge tank

pressure cap to cool if you ever have to turn

the pressure cap.

5-40

Page 247 of 366

{CAUTION:

Adding only plain water to your cooling

system can be dangerous. Plain water, or

some other liquid such as alcohol, can boil

before the proper coolant mixture will. Your

vehicle’s coolant warning system is set for the

proper coolant mixture. With plain water or the

wrong mixture, your engine could get too hot

but you would not get the overheat warning.

Your engine could catch �re and you or others

could be burned. Use a 50/50 mixture of clean,

drinkable water and DEX-COOL

®coolant.

Notice:In cold weather, water can freeze and crack

the engine, radiator, heater core and other parts.

Use the recommended coolant and the proper

coolant mixture.

{CAUTION:

You can be burned if you spill coolant on hot

engine parts. Coolant contains ethylene glycol

and it will burn if the engine parts are hot

enough. Do not spill coolant on a hot engine.

1. Park the vehicle on a level surface. You can

remove the coolant surge tank pressure cap

when the cooling system, including the coolant

surge tank pressure cap and upper radiator hose, is

no longer hot. Turn the pressure cap slowly

counterclockwise (left) about one full turn. If you

hear a hiss, wait for that to stop. A hiss means there

is still some pressure left.

2. Then keep turning the pressure cap slowly, and

remove it.

5-41

Page 248 of 366

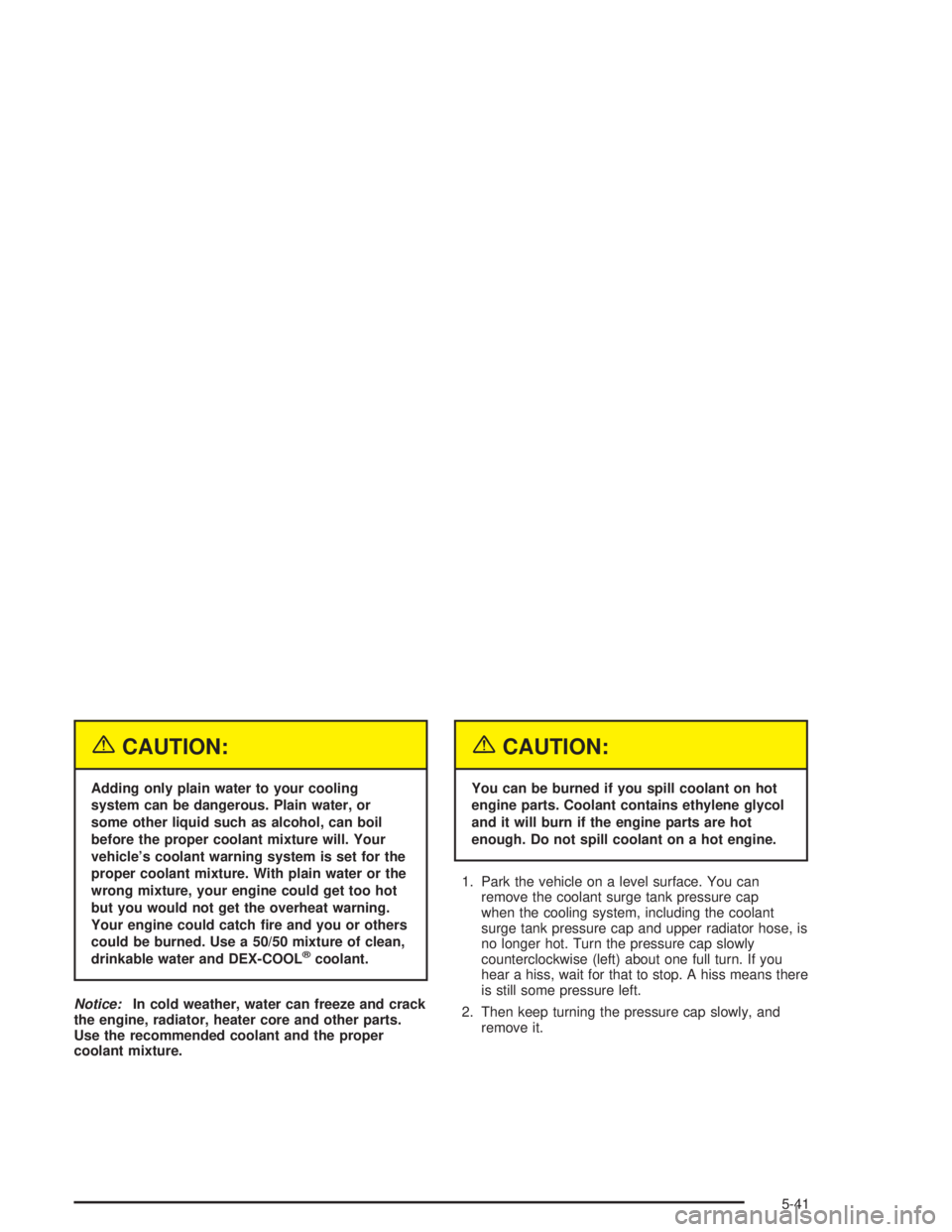

3. Then fill the coolant surge tank with the proper

mixture, to the FULL mark.4. With the coolant surge tank pressure cap off, start

the engine and let it run until you can feel the upper

radiator hose getting hot. Watch out for the

engine cooling fan.

By this time, the coolant level inside the coolant

surge tank may be lower. If the level is lower,

add more of the proper mixture to the coolant

surge tank until the level reaches slightly above the

FULL mark.

5-42

Page 249 of 366

5. Then replace the

pressure cap. Be sure

the pressure cap is

hand-tight and

fully seated.

Engine Fan Noise

Your vehicle has a clutched engine cooling fan. When

the clutch is engaged, the fan spins faster to provide

more air to cool the engine. In most everyday driving

conditions, the clutch is not fully engaged. This improves

fuel economy and reduces fan noise. Under heavy

vehicle loading, trailer towing and/or high outside

temperatures, the fan speed increases when the clutch

engages. So you may hear an increase in fan noise.

This is normal and should not be mistaken as thetransmission slipping or making extra shifts. It is merely

the cooling system functioning properly. The fan will

slow down when additional cooling is not required and

the clutch disengages.

You may also hear this fan noise when you start the

engine. It will go away as the fan clutch disengages.

Power Steering Fluid

See your Maintenance Schedule for when to check your

power steering fluid.

How To Check Power Steering Fluid

Check your power steering fluid only when the engine is

warm. If the engine isn’t warm, you probably won’t

get an accurate reading.

If the fluid level is between the MIN and MAX marks,

you have enough. If you need fluid, add only enough of

the proper fluid to bring it in between the MIN and

MAX marks.

5-43

Page 273 of 366

6. Install a new gasket whenever you take out the

cylinder. Use only one gasket and spread a light

film of clean oil on it before installation.

7. Put in the new cylinder. Turn it clockwise until it just

starts to contact the gasket.

8. Tighten the cylinder another half turn (180 degrees).

Don’t over-tighten.

9. Retighten the cylinder clamp.

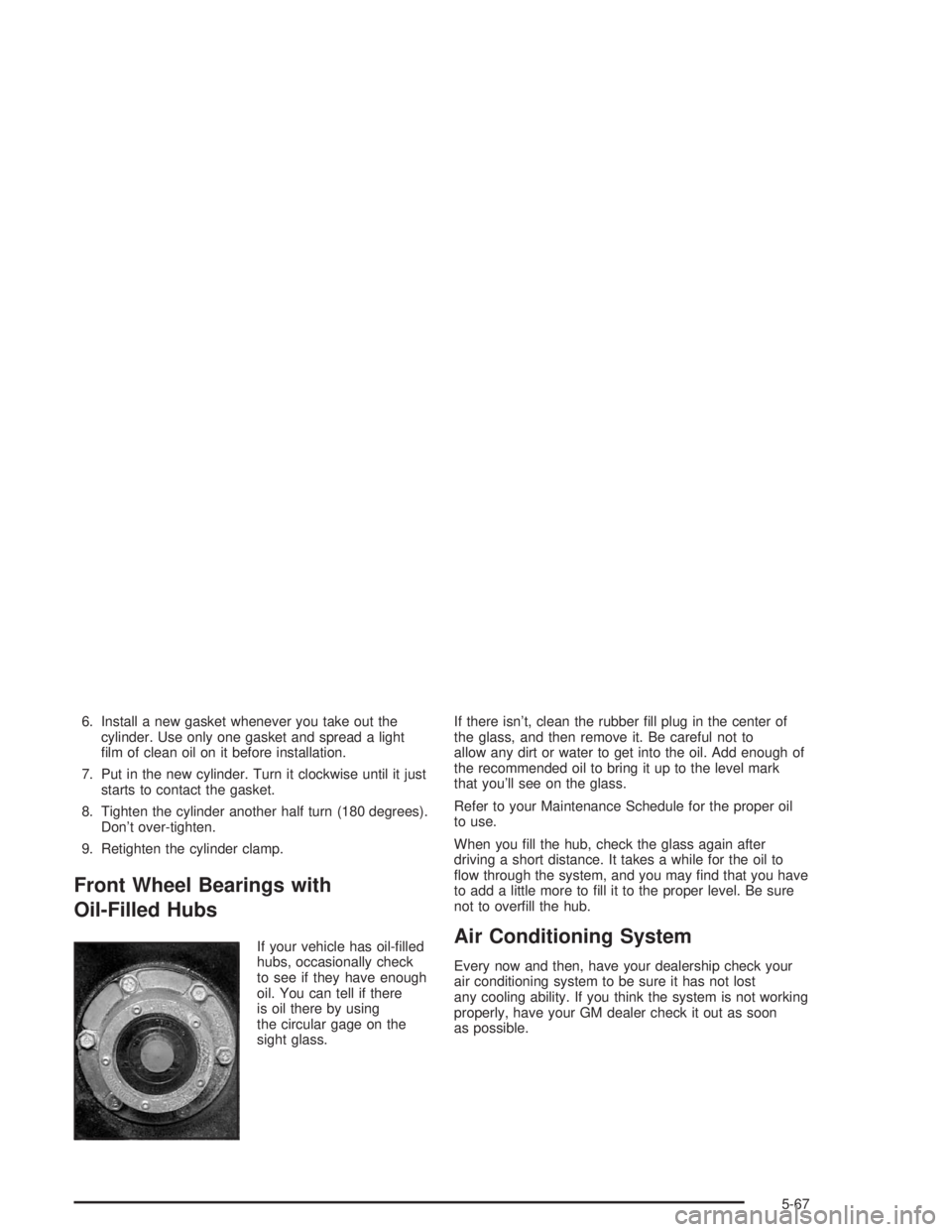

Front Wheel Bearings with

Oil-Filled Hubs

If your vehicle has oil-filled

hubs, occasionally check

to see if they have enough

oil. You can tell if there

is oil there by using

the circular gage on the

sight glass.If there isn’t, clean the rubber fill plug in the center of

the glass, and then remove it. Be careful not to

allow any dirt or water to get into the oil. Add enough of

the recommended oil to bring it up to the level mark

that you’ll see on the glass.

Refer to your Maintenance Schedule for the proper oil

to use.

When you fill the hub, check the glass again after

driving a short distance. It takes a while for the oil to

flow through the system, and you may find that you have

to add a little more to fill it to the proper level. Be sure

not to overfill the hub.Air Conditioning System

Every now and then, have your dealership check your

air conditioning system to be sure it has not lost

any cooling ability. If you think the system is not working

properly, have your GM dealer check it out as soon

as possible.

5-67

Page 280 of 366

Wheel Replacement

Replace any wheel that is bent, cracked or badly rusted

or corroded. If wheel nuts keep coming loose, replace

the wheel. If the wheel leaks air, replace it.

Your dealer will know the kind of wheel you need.

Each new wheel should have the same load-carrying

capacity, diameter, width, offset and be mounted

the same way as the one it replaces.

If you need to replace any of your wheels, wheel bolts

or wheel nuts, replace them only with new GM

original equipment parts. This way, you will be sure to

have the right wheel, wheel bolts and wheel nuts

for your vehicle.

{CAUTION:

A leaking wheel could fail without warning.

A wheel designed for tubeless tires could be

leaking because it is damaged. Don’t use

an inner tube or some other thing to try to

stop the leaking. Get a new wheel or the

proper type.

{CAUTION:

Without the correct wheel, you may not be able

to stop properly, and you could have other

problems like a tire air-out. You could have a

collision. If you don’t go to your dealer to get a

new wheel, be sure you get the correct one.

Each new wheel should match the original

wheel in load-carrying capacity, in�ation

pressure capacity, diameter, width, offset and

mounting con�guration.

Using wheels and tires with higher load-carrying limits

than the original wheels and tires doesn’t change

the GAWR or the GVWR of your vehicle. See “Loading

Your Vehicle” for more information.

Notice:The wrong wheel can cause trouble in

bearing life, brake cooling, speedometer/odometer

calibration, headlamp aim, bumper height, vehicle

ground clearance, stopping distance and tire

clearance to the body and chassis. You could also

have other problems like a tire air-out.

5-74

Page 300 of 366

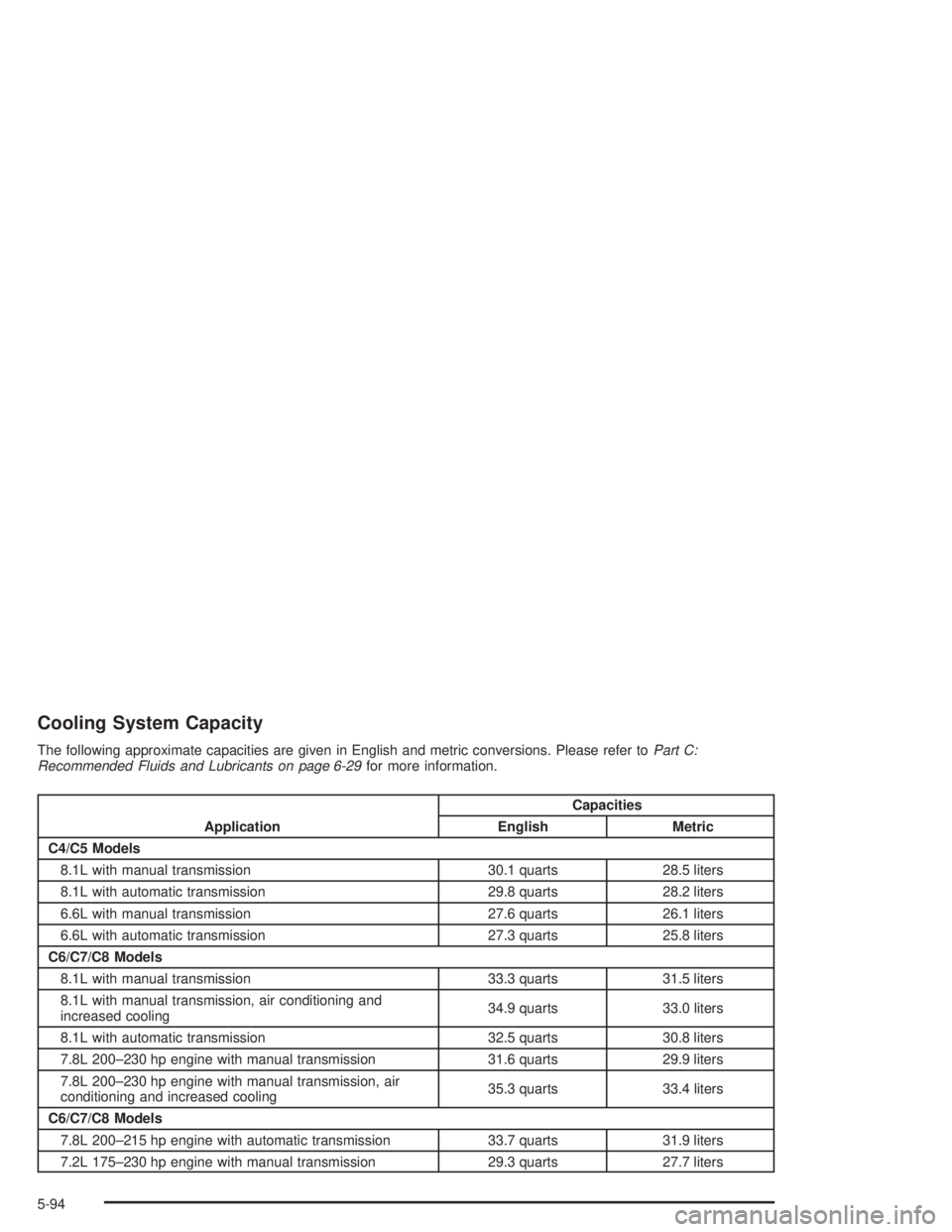

Cooling System Capacity

The following approximate capacities are given in English and metric conversions. Please refer toPart C:

Recommended Fluids and Lubricants on page 6-29for more information.

ApplicationCapacities

English Metric

C4/C5 Models

8.1L with manual transmission 30.1 quarts 28.5 liters

8.1L with automatic transmission 29.8 quarts 28.2 liters

6.6L with manual transmission 27.6 quarts 26.1 liters

6.6L with automatic transmission 27.3 quarts 25.8 liters

C6/C7/C8 Models

8.1L with manual transmission 33.3 quarts 31.5 liters

8.1L with manual transmission, air conditioning and

increased cooling34.9 quarts 33.0 liters

8.1L with automatic transmission 32.5 quarts 30.8 liters

7.8L 200–230 hp engine with manual transmission 31.6 quarts 29.9 liters

7.8L 200–230 hp engine with manual transmission, air

conditioning and increased cooling35.3 quarts 33.4 liters

C6/C7/C8 Models

7.8L 200–215 hp engine with automatic transmission 33.7 quarts 31.9 liters

7.2L 175–230 hp engine with manual transmission 29.3 quarts 27.7 liters

5-94

Page 301 of 366

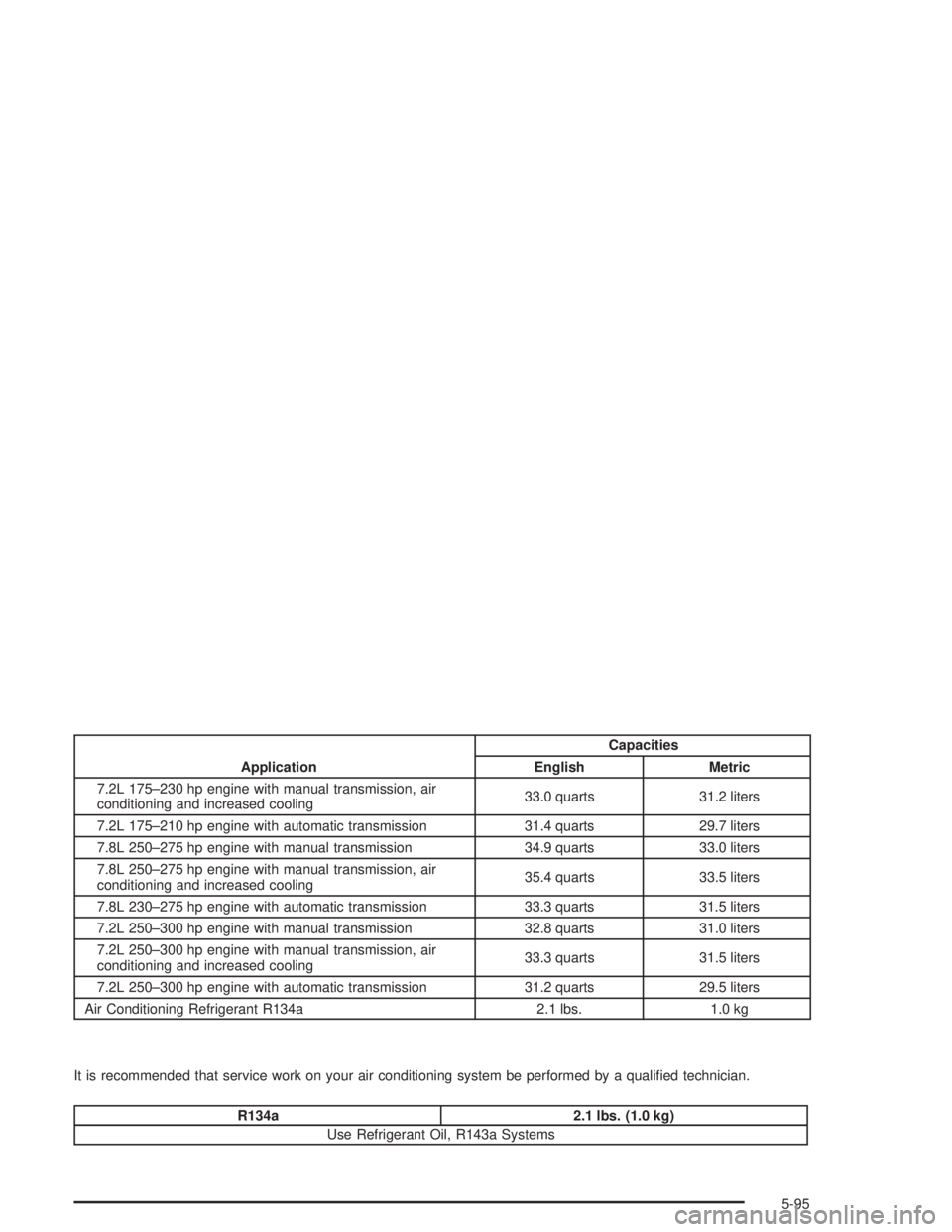

ApplicationCapacities

English Metric

7.2L 175–230 hp engine with manual transmission, air

conditioning and increased cooling33.0 quarts 31.2 liters

7.2L 175–210 hp engine with automatic transmission 31.4 quarts 29.7 liters

7.8L 250–275 hp engine with manual transmission 34.9 quarts 33.0 liters

7.8L 250–275 hp engine with manual transmission, air

conditioning and increased cooling35.4 quarts 33.5 liters

7.8L 230–275 hp engine with automatic transmission 33.3 quarts 31.5 liters

7.2L 250–300 hp engine with manual transmission 32.8 quarts 31.0 liters

7.2L 250–300 hp engine with manual transmission, air

conditioning and increased cooling33.3 quarts 31.5 liters

7.2L 250–300 hp engine with automatic transmission 31.2 quarts 29.5 liters

Air Conditioning Refrigerant R134a 2.1 lbs. 1.0 kg

It is recommended that service work on your air conditioning system be performed by a qualified technician.

R134a 2.1 lbs. (1.0 kg)

Use Refrigerant Oil, R143a Systems

5-95

Page 316 of 366

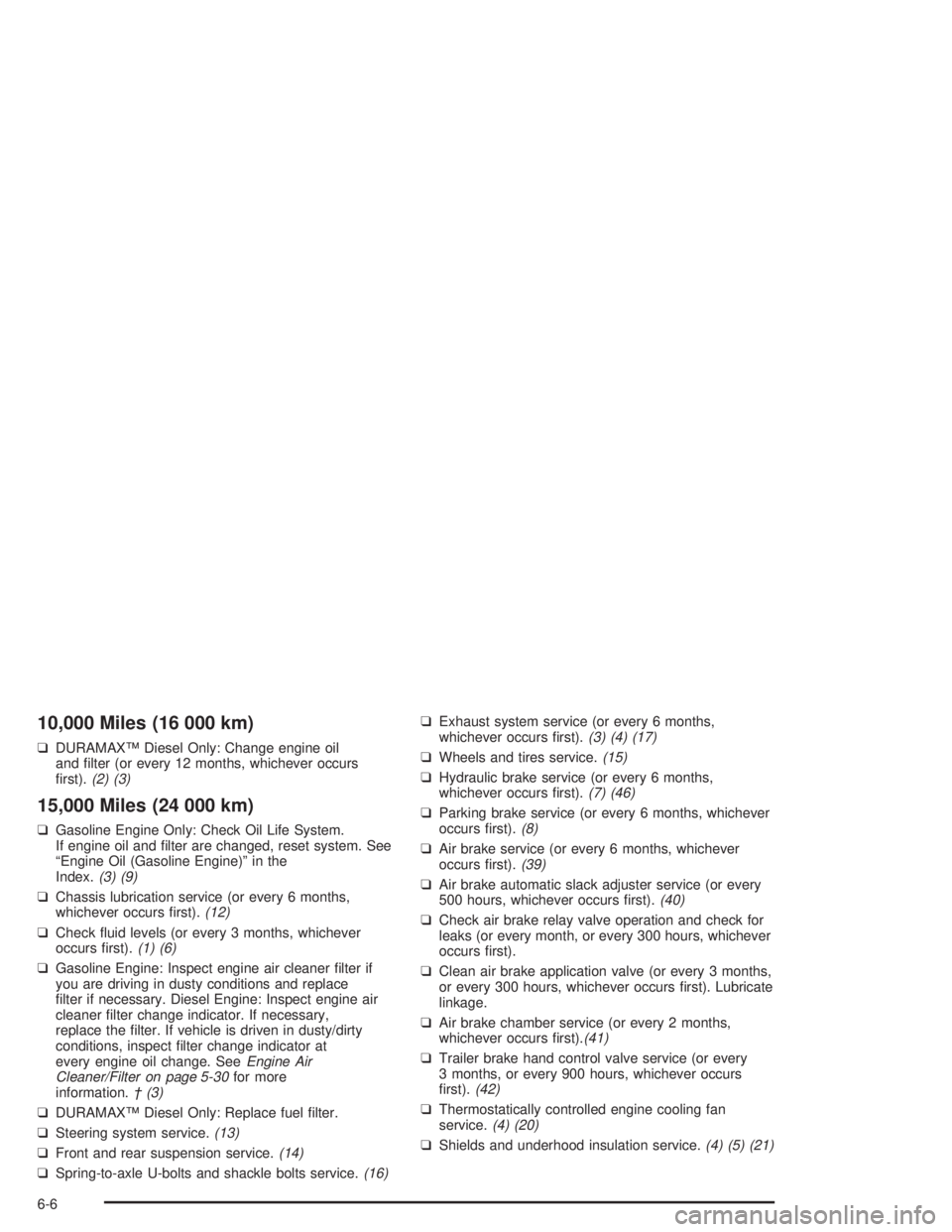

10,000 Miles (16 000 km)

❑DURAMAX™ Diesel Only: Change engine oil

and filter (or every 12 months, whichever occurs

first).(2) (3)

15,000 Miles (24 000 km)

❑Gasoline Engine Only: Check Oil Life System.

If engine oil and filter are changed, reset system. See

“Engine Oil (Gasoline Engine)” in the

Index.(3) (9)

❑Chassis lubrication service (or every 6 months,

whichever occurs first).(12)

❑Check fluid levels (or every 3 months, whichever

occurs first).(1) (6)

❑Gasoline Engine: Inspect engine air cleaner filter if

you are driving in dusty conditions and replace

filter if necessary. Diesel Engine: Inspect engine air

cleaner filter change indicator. If necessary,

replace the filter. If vehicle is driven in dusty/dirty

conditions, inspect filter change indicator at

every engine oil change. SeeEngine Air

Cleaner/Filter on page 5-30for more

information.† (3)

❑DURAMAX™ Diesel Only: Replace fuel filter.

❑Steering system service.(13)

❑Front and rear suspension service.(14)

❑Spring-to-axle U-bolts and shackle bolts service.(16)❑Exhaust system service (or every 6 months,

whichever occurs first).(3) (4) (17)

❑Wheels and tires service.(15)

❑Hydraulic brake service (or every 6 months,

whichever occurs first).(7) (46)

❑Parking brake service (or every 6 months, whichever

occurs first).(8)

❑Air brake service (or every 6 months, whichever

occurs first).(39)

❑Air brake automatic slack adjuster service (or every

500 hours, whichever occurs first).(40)

❑Check air brake relay valve operation and check for

leaks (or every month, or every 300 hours, whichever

occurs first).

❑Clean air brake application valve (or every 3 months,

or every 300 hours, whichever occurs first). Lubricate

linkage.

❑Air brake chamber service (or every 2 months,

whichever occurs first).(41)

❑Trailer brake hand control valve service (or every

3 months, or every 900 hours, whichever occurs

first).(42)

❑Thermostatically controlled engine cooling fan

service.(4) (20)

❑Shields and underhood insulation service.(4) (5) (21)

6-6

Page 317 of 366

20,000 Miles (32 000 km)

❑DURAMAX™ Diesel Only: Change engine oil

and filter (or every 12 months, whichever occurs

first).(2) (3)

❑Air compressor dry element pleated paper air strainer

service (or every 2 months or every 800 hours,

whichever occurs first).

22,500 Miles (36 000 km)

❑Gasoline Engine Only: Check Oil Life System. If

engine oil and filter are changed, reset system. See

“Engine Oil (Gasoline Engine)” in the Index.(3) (9)

❑Check fluid levels (or every 3 months, whichever

occurs first).(1) (6)

❑Chassis lubrication service (or every 6 months,

whichever occurs first).(12)

❑Inspect door hinge pins and bushings and replace as

necessary.

❑Cooling system service. Clean the cooling system filter

cap with clean water, clean the core, pressure test the

cap and the system for proper pressure capability and

inspect condition of cooling and heater hoses and

clamps. Replace hoses if cracked, swollen or

damaged.

❑Wheel bearing (grease type) service (or every

24 months, whichever occurs first, and whenever hubs

are removed).(23) (46)❑Wheels and tires service.(15)

❑Hydraulic brake service (or every 6 months, whichever

occurs first).(7) (46)

❑Parking brake service (or every 6 months, whichever

occurs first).(8)

❑Air brake service (or every 6 months, whichever

occurs first).(39)

❑Air brake automatic slack adjuster service (or every

500 hours, whichever occurs first).(40)

❑Check air brake relay valve operation and check for

leaks (or every month, or every 300 hours, whichever

occurs first).

❑Clean air brake application valve (or every 3 months,

or every 300 hours, whichever occurs first). Lubricate

linkage.

❑Air brake chamber service (or every 2 months,

whichever occurs first).(41)

❑Trailer brake hand control valve service (or every

3 months, or every 900 hours, whichever occurs

first).(42)

❑Air intake system service (or every 24 months,

whichever occurs first).(4) (5) (24)

❑Evaporative Control System service (if equipped) (or

every 24 months, whichever occurs first).(3) (26) †

❑Rear axle air shift motor service.(11)

6-7