CHEVROLET KODIAK 2005 Owners Manual

Manufacturer: CHEVROLET, Model Year: 2005, Model line: KODIAK, Model: CHEVROLET KODIAK 2005Pages: 374, PDF Size: 5.46 MB

Page 271 of 374

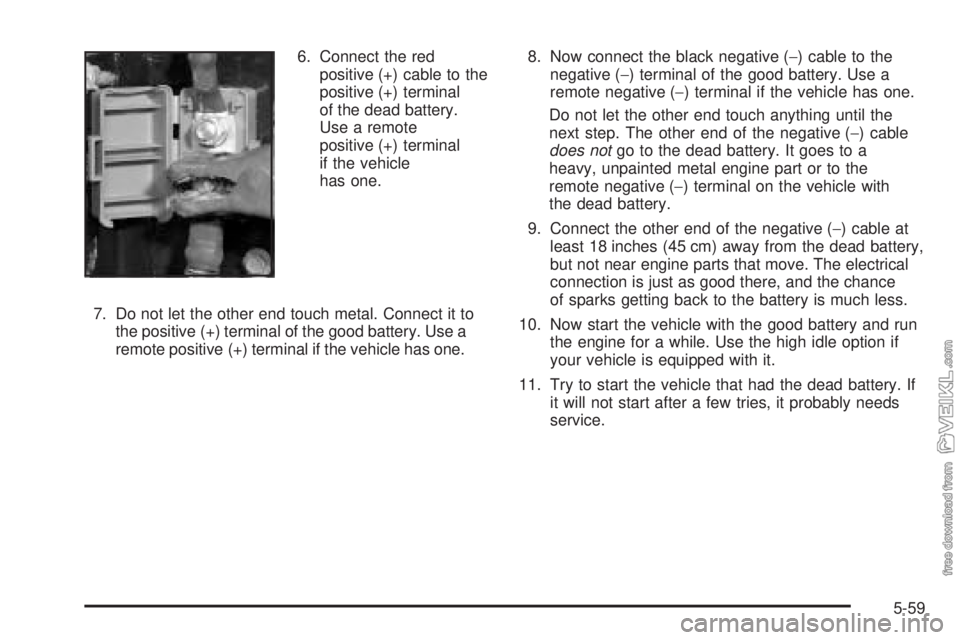

6. Connect the red

positive (+) cable to the

positive (+) terminal

of the dead battery.

Use a remote

positive (+) terminal

if the vehicle

has one.

7. Do not let the other end touch metal. Connect it to

the positive (+) terminal of the good battery. Use a

remote positive (+) terminal if the vehicle has one.8. Now connect the black negative (−) cable to the

negative (−) terminal of the good battery. Use a

remote negative (−) terminal if the vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (−) cable

does notgo to the dead battery. It goes to a

heavy, unpainted metal engine part or to the

remote negative (−) terminal on the vehicle with

the dead battery.

9. Connect the other end of the negative (−) cable at

least 18 inches (45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is just as good there, and the chance

of sparks getting back to the battery is much less.

10. Now start the vehicle with the good battery and run

the engine for a while. Use the high idle option if

your vehicle is equipped with it.

11. Try to start the vehicle that had the dead battery. If

it will not start after a few tries, it probably needs

service.

5-59

Page 272 of 374

Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting may

occur and damage the vehicle. The repairs would

not be covered by your warranty. Always connect

and remove the jumper cables in the correct

order, making sure that the cables do not touch

each other or other metal.

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (−) Terminal

B. Good Battery or Remote Positive (+) and Remote

Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalTo disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the positive (+) remote terminal cover to its

original position.

Rear Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant and when to change it.

SeeScheduled Maintenance on page 6-5.

Notice:If you drive your vehicle through deep

water that is higher than the front or rear axle, water

may enter the axle housing and cause the axle

lubricant to break down. This could damage

the gears inside. Avoid driving your vehicle through

deep water. Jumper Cable Removal

5-60

Page 273 of 374

You should avoid driving your vehicle through deep

puddles or standing water. If you must drive through

water that is higher than the front or rear axle, see your

dealer immediately afterward to have the condition of

the axle lubricant checked.

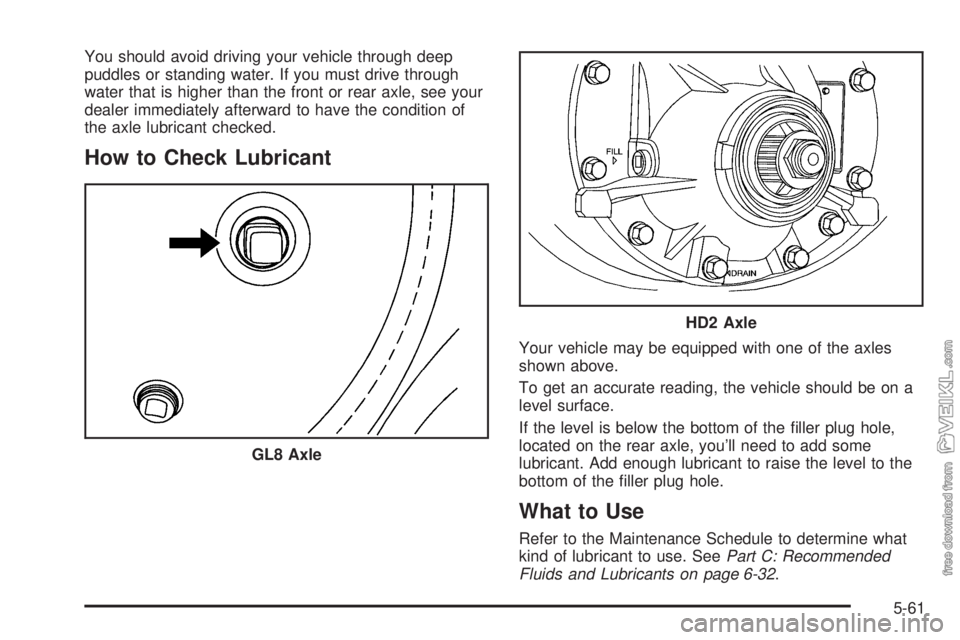

How to Check Lubricant

Your vehicle may be equipped with one of the axles

shown above.

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the filler plug hole,

located on the rear axle, you’ll need to add some

lubricant. Add enough lubricant to raise the level to the

bottom of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart C: Recommended

Fluids and Lubricants on page 6-32. GL8 Axle

HD2 Axle

5-61

Page 274 of 374

Rear Axle Shift Motor

When to Check and Change Fluid

If you have an optional air-shift two-speed, controlled

traction, or locking differential type rear axle, a good time

to check the fluid level in the axle shift motor is when

the rear axle lubricant is checked. Use refrigerant

oil (shift motor only).

How to Check Fluid

Remove the plug on the front plate of the axle shift

motor, add enough fluid to raise the level to the bottom

of the filler plug hole, then replace the plug.

What to Use

Refer to your Maintenance Schedule to determine what

kind of lubricant to use. SeePart C: Recommended

Fluids and Lubricants on page 6-32.

Four-Wheel Drive

Transfer Case

When to Check Lubricant

It is not necessary to regularly check transfer case fluid

unless you suspect there is a leak or you hear an

unusual noise. A fluid loss could indicate a problem.

Have it inspected and repaired.

How to Check Lubricant

A. Fill Plug

B. Drain Plug

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the fill plug hole,

located on the transfer case, you’ll need to add some

lubricant. Add enough lubricant to raise the level to

the bottom of the fill plug hole. Use care not to

overtighten the plug.

5-62

Page 275 of 374

When to Change Lubricant

Refer to the Maintenance Schedule to determine how

often to change the lubricant. SeeScheduled

Maintenance on page 6-5.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart C: Recommended

Fluids and Lubricants on page 6-32.

Front Axle

When to Check Lubricant

It is not necessary to regularly check front axle fluid

unless you suspect there is a leak or you hear an

unusual noise. A fluid loss could indicate a problem.

Have it inspected and repaired.

Notice:If you drive your vehicle through deep

water that is higher than the front or rear axle, water

may enter the axle housing and cause the axle

lubricant to break down. This could damage the

gears inside. Avoid driving your vehicle through

deep water.

You should avoid driving your vehicle through deep

puddles or standing water. If you must drive through

water that is higher than the front or rear axle, see your

dealer immediately afterward to have the condition of

the axle lubricant checked.

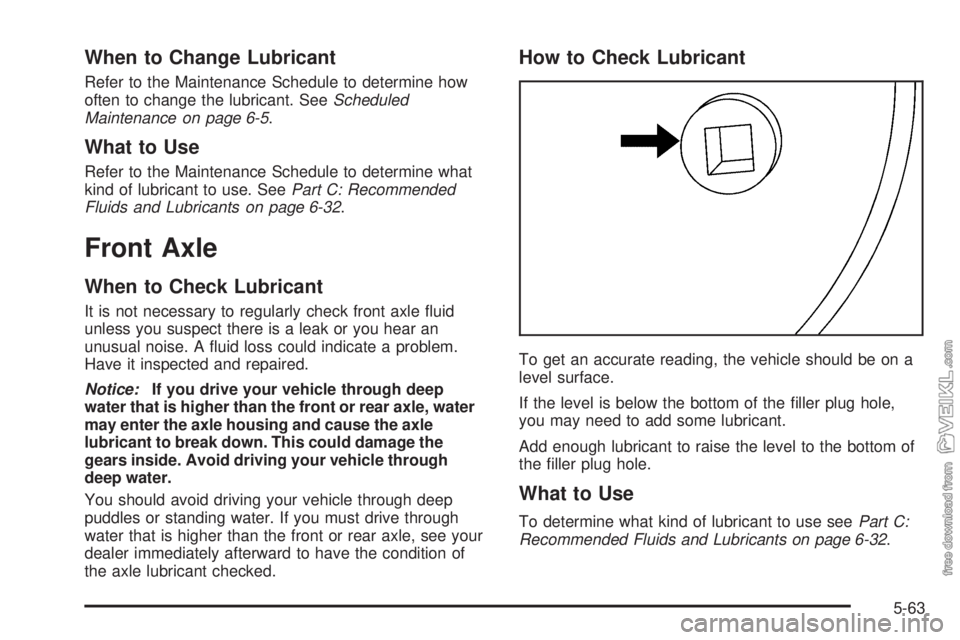

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the filler plug hole,

you may need to add some lubricant.

Add enough lubricant to raise the level to the bottom of

the filler plug hole.

What to Use

To determine what kind of lubricant to use seePart C:

Recommended Fluids and Lubricants on page 6-32.

5-63

Page 276 of 374

Noise Control System

Tampering with Noise Control

System Prohibited

The following information relates to compliance with

federal noise emission standards for vehicles with a

Gross Vehicle Weight Rating (GVWR) of more than

10,000 lbs (4 536 kg). The Maintenance Schedule

provides information on maintaining the noise control

system to minimize degradation of the noise emission

control system during the life of your vehicle. The noise

control system warranty is given in your warranty booklet.

These standards apply only to vehicles sold in the

United States.

Federal law prohibits the following acts or the

causing thereof:

1. The removal or rendering inoperative by any person,

other than for purposes of maintenance, repair or

replacement, of any device or element of design

incorporated into any new vehicle for the purpose of

noise control, prior to its sale or delivery to the

ultimate purchaser or while it is in use; or

2. The use of the vehicle after such device or element

of design has been removed or rendered inoperative

by any person.Among those acts presumed to constitute tampering are

the acts listed below.

Insulation:

•

Removal of the noise shields or any underhood

insulation.

Engine:

•

Removal or rendering engine speed governor (if

equipped) inoperative so as to allow engine

speed to exceed manufacturer specifications.

Fan and Drive:

•

Removal of fan clutch (if equipped) or rendering

clutch inoperative.

•Removal of the fan shroud (if equipped).

Air Intake:

•

Removal of the air cleaner silencer.

•Modification of the air cleaner.

Exhaust:

•

Removal of the muffler and/or resonator.

•Removal of the exhaust pipes and exhaust

pipe clamps.

5-64

Page 277 of 374

Bulb Replacement

It is recommended that all bulbs be replaced by your

dealer.

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected at least

twice a year for wear or cracking. SeeWiper Blade

CheckunderAt Least Twice a Year on page 6-28for

more information.

Replacement blades come in different types and are

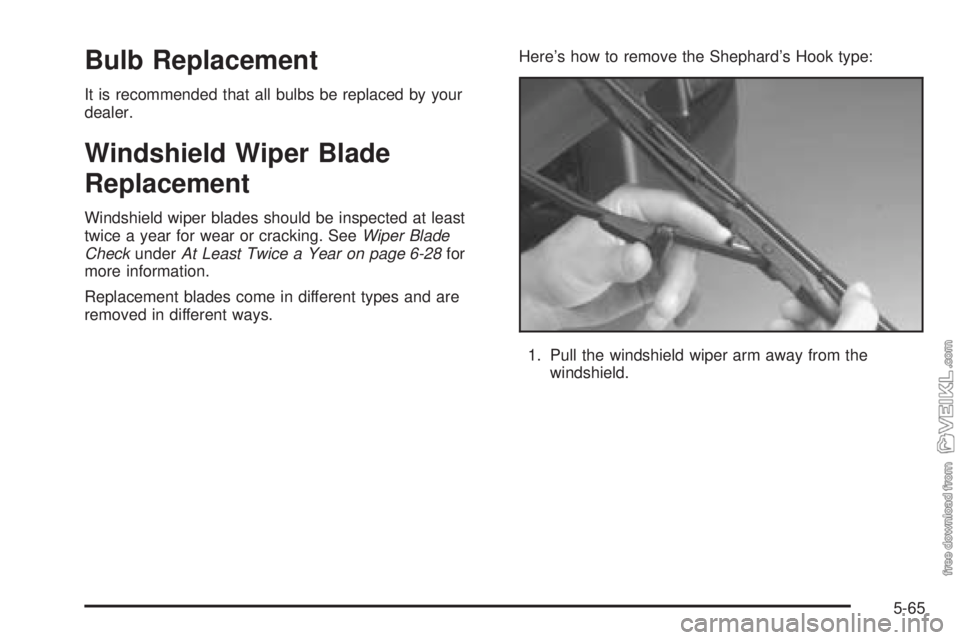

removed in different ways.Here’s how to remove the Shephard’s Hook type:

1. Pull the windshield wiper arm away from the

windshield.

5-65

Page 278 of 374

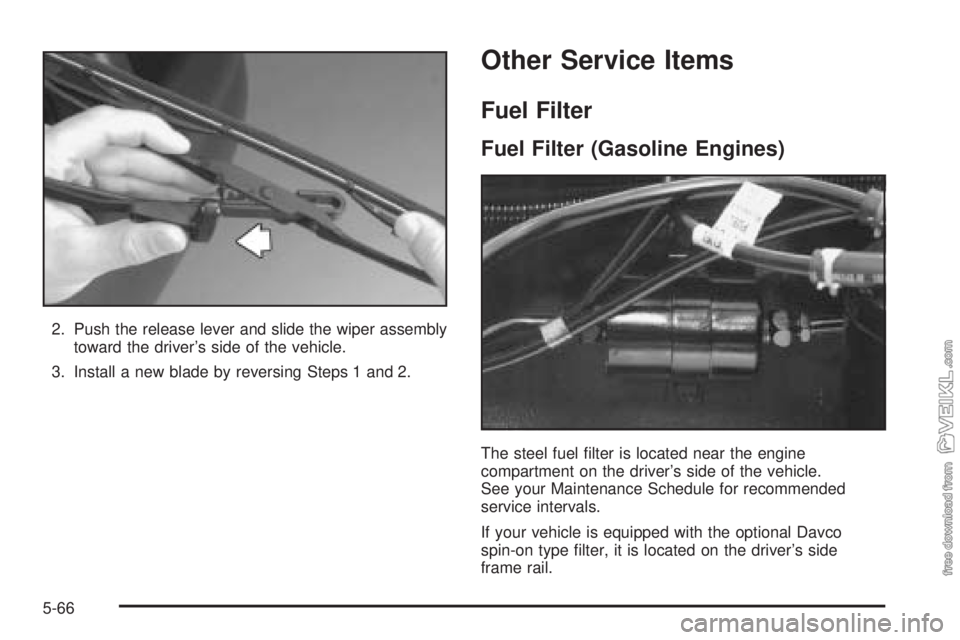

2. Push the release lever and slide the wiper assembly

toward the driver’s side of the vehicle.

3. Install a new blade by reversing Steps 1 and 2.

Other Service Items

Fuel Filter

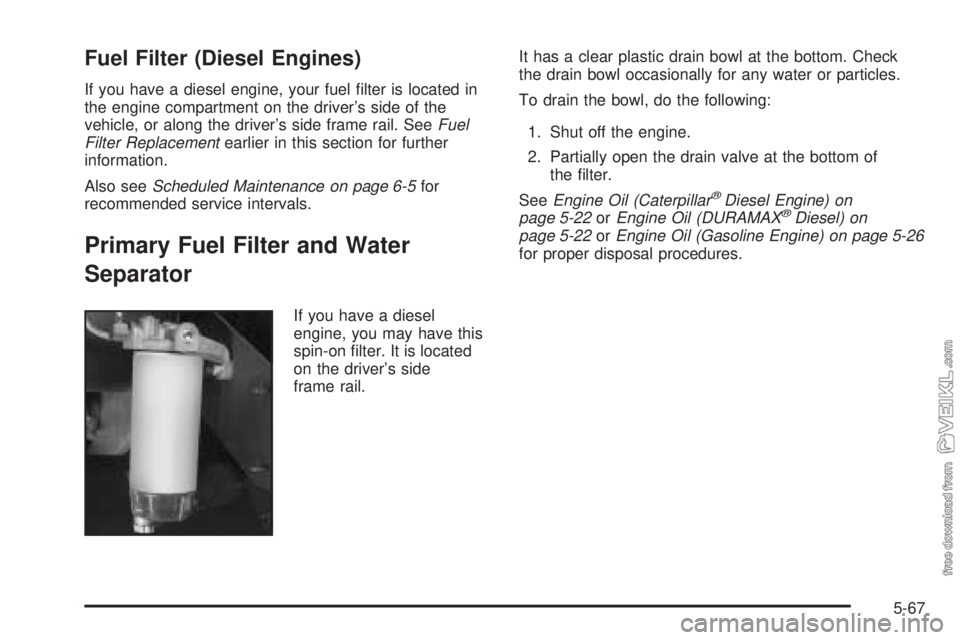

Fuel Filter (Gasoline Engines)

The steel fuel filter is located near the engine

compartment on the driver’s side of the vehicle.

See your Maintenance Schedule for recommended

service intervals.

If your vehicle is equipped with the optional Davco

spin-on type filter, it is located on the driver’s side

frame rail.

5-66

Page 279 of 374

Fuel Filter (Diesel Engines)

If you have a diesel engine, your fuel filter is located in

the engine compartment on the driver’s side of the

vehicle, or along the driver’s side frame rail. SeeFuel

Filter Replacementearlier in this section for further

information.

Also seeScheduled Maintenance on page 6-5for

recommended service intervals.

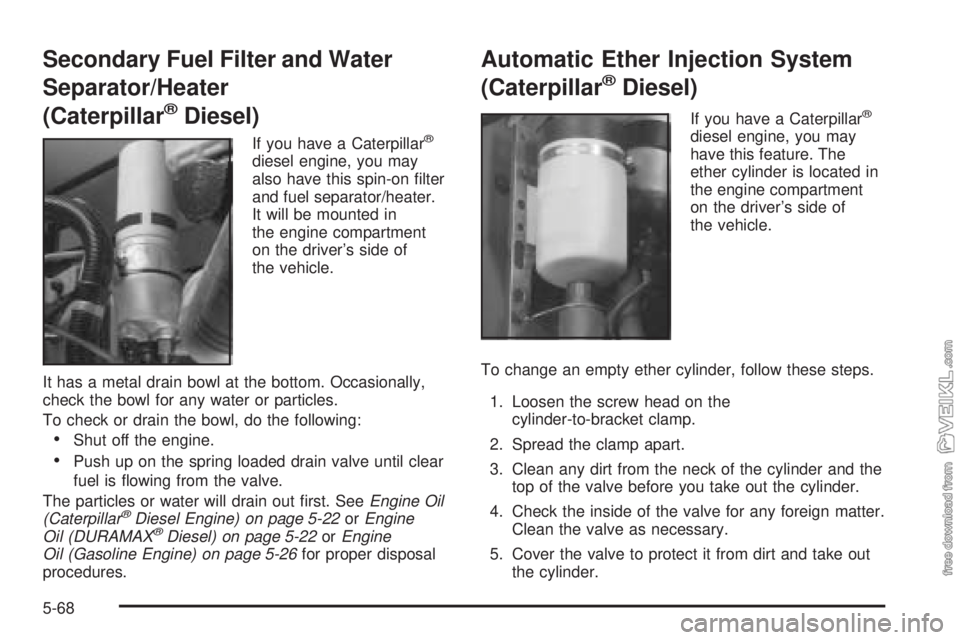

Primary Fuel Filter and Water

Separator

If you have a diesel

engine, you may have this

spin-on filter. It is located

on the driver’s side

frame rail.It has a clear plastic drain bowl at the bottom. Check

the drain bowl occasionally for any water or particles.

To drain the bowl, do the following:

1. Shut off the engine.

2. Partially open the drain valve at the bottom of

the filter.

SeeEngine Oil (Caterpillar

®Diesel Engine) on

page 5-22orEngine Oil (DURAMAX®Diesel) on

page 5-22orEngine Oil (Gasoline Engine) on page 5-26

for proper disposal procedures.

5-67

Page 280 of 374

Secondary Fuel Filter and Water

Separator/Heater

(Caterpillar

®Diesel)

If you have a Caterpillar®

diesel engine, you may

also have this spin-on filter

and fuel separator/heater.

It will be mounted in

the engine compartment

on the driver’s side of

the vehicle.

It has a metal drain bowl at the bottom. Occasionally,

check the bowl for any water or particles.

To check or drain the bowl, do the following:

•Shut off the engine.

•Push up on the spring loaded drain valve until clear

fuel is flowing from the valve.

The particles or water will drain out first. SeeEngine Oil

(Caterpillar

®Diesel Engine) on page 5-22orEngine

Oil (DURAMAX®Diesel) on page 5-22orEngine

Oil (Gasoline Engine) on page 5-26for proper disposal

procedures.

Automatic Ether Injection System

(Caterpillar

®Diesel)

If you have a Caterpillar®

diesel engine, you may

have this feature. The

ether cylinder is located in

the engine compartment

on the driver’s side of

the vehicle.

To change an empty ether cylinder, follow these steps.

1. Loosen the screw head on the

cylinder-to-bracket clamp.

2. Spread the clamp apart.

3. Clean any dirt from the neck of the cylinder and the

top of the valve before you take out the cylinder.

4. Check the inside of the valve for any foreign matter.

Clean the valve as necessary.

5. Cover the valve to protect it from dirt and take out

the cylinder.

5-68