CHEVROLET KODIAK 2008 Owners Manual

Manufacturer: CHEVROLET, Model Year: 2008, Model line: KODIAK, Model: CHEVROLET KODIAK 2008Pages: 384, PDF Size: 5.4 MB

Page 351 of 384

At Least Twice a Year

Wiper Blade Check

Inspect wiper blades for wear, cracking, or

contamination. Clean the windshield and wiper blades, if

contaminated. Replace wiper blades that are worn or

damaged. SeeWindshield Wiper Blade Replacement on

page 5-76andWindshield and Wiper Blades on

page 5-98for more information.

Weatherstrip Lubrication

Silicone grease on weatherstrips will make them last

longer, seal better, and not stick or squeak. Apply

silicone grease with a clean cloth. During very cold,

damp weather more frequent application may be

required. Part C tells you what to use.

Body Lubrication Service

Lubricate all exposed surfaces such as door checks,

door lock bolts, lock strike plates, door hinge bushings,

latches, and dovetail bumper wedges. Where oil holes

are provided, a dripless oil can be used. The seat

adjusters, seat track, door weatherstrips, and rubber cap

bumpers should also be lubricated. Part C tells you what

to use. More frequent lubrication may be required when

exposed to a corrosive environment.

Parking Brake Check

Park on a fairly steep hill and hold the vehicle with the

parking brake only. This checks holding ability. See

Parking Brake (With Hydraulic Brakes) on page 2-38or

Parking Brake (With Air Brakes) on page 2-41.

Starter Switch Check

{CAUTION:

When you are doing this inspection, the

vehicle could move suddenly. If the vehicle

moves, you or others could be injured.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular

brakes.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. On automatic transmission vehicles, try to start the

engine in each gear. The starter should work only

in PARK (P) or NEUTRAL (N). If the starter works in

any other position, your vehicle needs service. On

manual transmission vehicles, the starter should

work only when the clutch pedal is all the way down.

6-27

Page 352 of 384

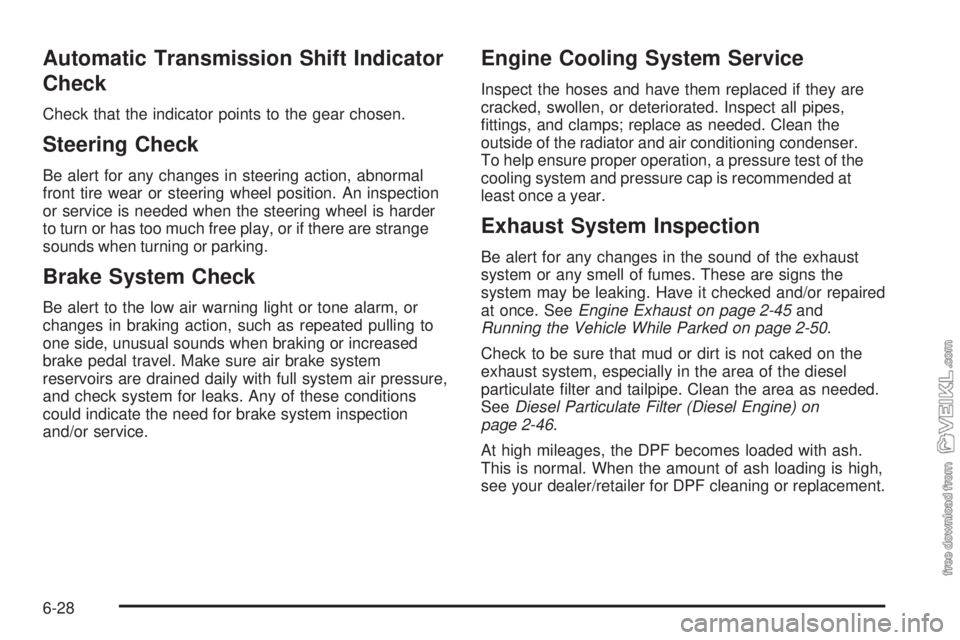

Automatic Transmission Shift Indicator

Check

Check that the indicator points to the gear chosen.

Steering Check

Be alert for any changes in steering action, abnormal

front tire wear or steering wheel position. An inspection

or service is needed when the steering wheel is harder

to turn or has too much free play, or if there are strange

sounds when turning or parking.

Brake System Check

Be alert to the low air warning light or tone alarm, or

changes in braking action, such as repeated pulling to

one side, unusual sounds when braking or increased

brake pedal travel. Make sure air brake system

reservoirs are drained daily with full system air pressure,

and check system for leaks. Any of these conditions

could indicate the need for brake system inspection

and/or service.

Engine Cooling System Service

Inspect the hoses and have them replaced if they are

cracked, swollen, or deteriorated. Inspect all pipes,

fittings, and clamps; replace as needed. Clean the

outside of the radiator and air conditioning condenser.

To help ensure proper operation, a pressure test of the

cooling system and pressure cap is recommended at

least once a year.

Exhaust System Inspection

Be alert for any changes in the sound of the exhaust

system or any smell of fumes. These are signs the

system may be leaking. Have it checked and/or repaired

at once. SeeEngine Exhaust on page 2-45and

Running the Vehicle While Parked on page 2-50.

Check to be sure that mud or dirt is not caked on the

exhaust system, especially in the area of the diesel

particulate filter and tailpipe. Clean the area as needed.

SeeDiesel Particulate Filter (Diesel Engine) on

page 2-46.

At high mileages, the DPF becomes loaded with ash.

This is normal. When the amount of ash loading is high,

see your dealer/retailer for DPF cleaning or replacement.

6-28

Page 353 of 384

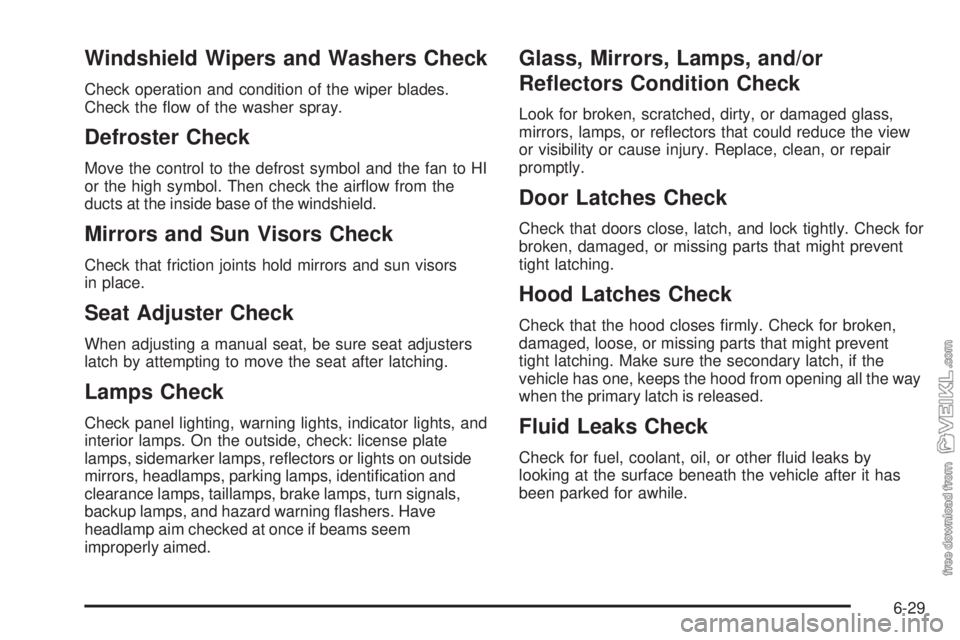

Windshield Wipers and Washers Check

Check operation and condition of the wiper blades.

Check the flow of the washer spray.

Defroster Check

Move the control to the defrost symbol and the fan to HI

or the high symbol. Then check the airflow from the

ducts at the inside base of the windshield.

Mirrors and Sun Visors Check

Check that friction joints hold mirrors and sun visors

in place.

Seat Adjuster Check

When adjusting a manual seat, be sure seat adjusters

latch by attempting to move the seat after latching.

Lamps Check

Check panel lighting, warning lights, indicator lights, and

interior lamps. On the outside, check: license plate

lamps, sidemarker lamps, reflectors or lights on outside

mirrors, headlamps, parking lamps, identification and

clearance lamps, taillamps, brake lamps, turn signals,

backup lamps, and hazard warning flashers. Have

headlamp aim checked at once if beams seem

improperly aimed.

Glass, Mirrors, Lamps, and/or

Re�ectors Condition Check

Look for broken, scratched, dirty, or damaged glass,

mirrors, lamps, or reflectors that could reduce the view

or visibility or cause injury. Replace, clean, or repair

promptly.

Door Latches Check

Check that doors close, latch, and lock tightly. Check for

broken, damaged, or missing parts that might prevent

tight latching.

Hood Latches Check

Check that the hood closes firmly. Check for broken,

damaged, loose, or missing parts that might prevent

tight latching. Make sure the secondary latch, if the

vehicle has one, keeps the hood from opening all the way

when the primary latch is released.

Fluid Leaks Check

Check for fuel, coolant, oil, or other fluid leaks by

looking at the surface beneath the vehicle after it has

been parked for awhile.

6-29

Page 354 of 384

Underbody Inspection

Corrosive materials used for ice, snow removal, and

dust control can collect on the underbody. If these

materials are not removed, accelerated corrosion (rust)

can occur on underbody parts such as fuel lines, frame,

floor pan, and exhaust system. At least every spring,

flush these materials from the underbody with plain water.

Take care to clean well any areas where mud and other

debris can collect. Sediment packed in closed areas of

the frame should be loosened before being flushed.

Engine Cover Check

Check that the cab’s engine cover and seal, if the

vehicle has one, are not torn or damaged. Be sure that

the cover is clamped down firmly to the floor.

At Least Once a Year

Key Lock Cylinders Service

Lubricate the key lock cylinders with the lubricant

specified in Part C.

Underbody Flushing Service

At least every spring, use plain water to flush any

corrosive materials from the underbody. Take care to

clean thoroughly any areas where mud and other debris

can collect.

Tractor Protection (Breakaway) Valve

Check

On air brake models, remove, disassemble, clean, and

inspect the tractor protection (breakaway) valve.

6-30

Page 355 of 384

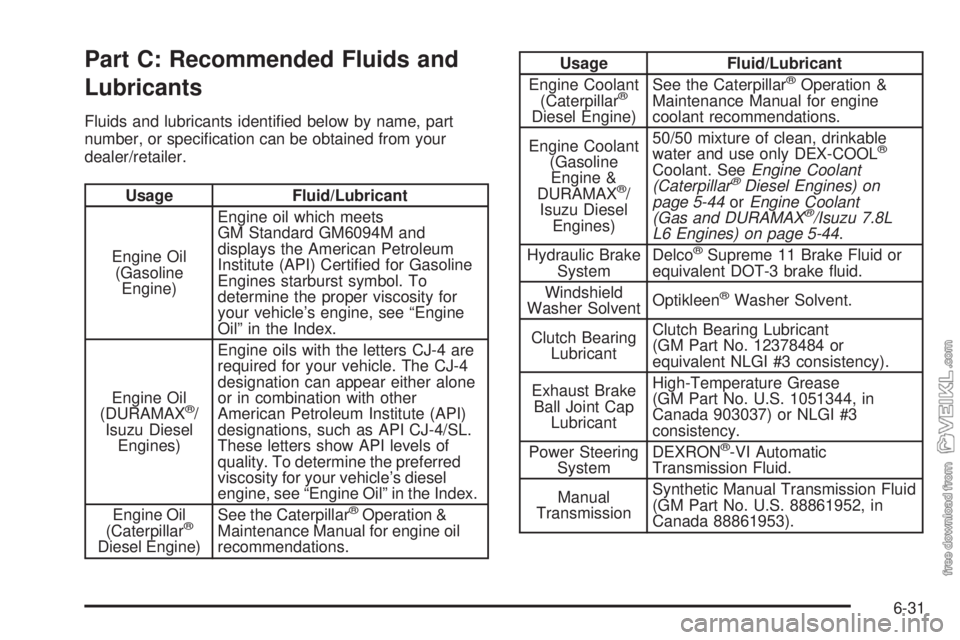

Part C: Recommended Fluids and

Lubricants

Fluids and lubricants identified below by name, part

number, or specification can be obtained from your

dealer/retailer.

Usage Fluid/Lubricant

Engine Oil

(Gasoline

Engine)Engine oil which meets

GM Standard GM6094M and

displays the American Petroleum

Institute (API) Certified for Gasoline

Engines starburst symbol. To

determine the proper viscosity for

your vehicle’s engine, see “Engine

Oil” in the Index.

Engine Oil

(DURAMAX

®/

Isuzu Diesel

Engines)Engine oils with the letters CJ-4 are

required for your vehicle. The CJ-4

designation can appear either alone

or in combination with other

American Petroleum Institute (API)

designations, such as API CJ-4/SL.

These letters show API levels of

quality. To determine the preferred

viscosity for your vehicle’s diesel

engine, see “Engine Oil” in the Index.

Engine Oil

(Caterpillar

®

Diesel Engine)See the Caterpillar

®Operation &

Maintenance Manual for engine oil

recommendations.

Usage Fluid/Lubricant

Engine Coolant

(Caterpillar

®

Diesel Engine)See the Caterpillar

®Operation &

Maintenance Manual for engine

coolant recommendations.

Engine Coolant

(Gasoline

Engine &

DURAMAX

®/

Isuzu Diesel

Engines)50/50 mixture of clean, drinkable

water and use only DEX-COOL

®

Coolant. SeeEngine Coolant

(Caterpillar®Diesel Engines) on

page 5-44orEngine Coolant

(Gas and DURAMAX

®/Isuzu 7.8L

L6 Engines) on page 5-44.

Hydraulic Brake

SystemDelco

®Supreme 11 Brake Fluid or

equivalent DOT-3 brake fluid.

Windshield

Washer SolventOptikleen

®Washer Solvent.

Clutch Bearing

LubricantClutch Bearing Lubricant

(GM Part No. 12378484 or

equivalent NLGI #3 consistency).

Exhaust Brake

Ball Joint Cap

LubricantHigh-Temperature Grease

(GM Part No. U.S. 1051344, in

Canada 903037) or NLGI #3

consistency.

Power Steering

SystemDEXRON

®-VI Automatic

Transmission Fluid.

Manual

TransmissionSynthetic Manual Transmission Fluid

(GM Part No. U.S. 88861952, in

Canada 88861953).

6-31

Page 356 of 384

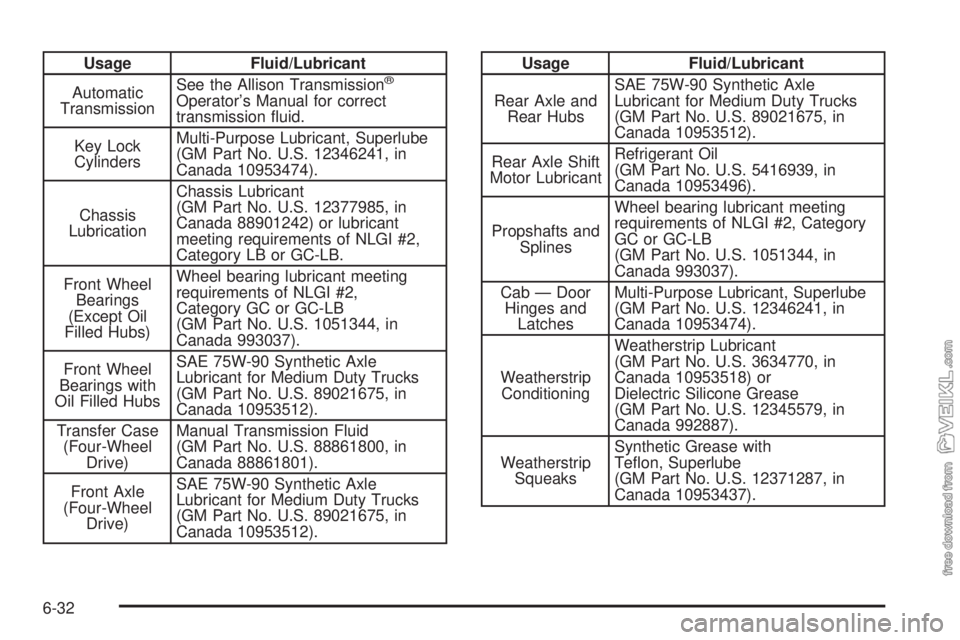

Usage Fluid/Lubricant

Automatic

TransmissionSee the Allison Transmission®

Operator’s Manual for correct

transmission fluid.

Key Lock

CylindersMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474).

Chassis

LubricationChassis Lubricant

(GM Part No. U.S. 12377985, in

Canada 88901242) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Front Wheel

Bearings

(Except Oil

Filled Hubs)Wheel bearing lubricant meeting

requirements of NLGI #2,

Category GC or GC-LB

(GM Part No. U.S. 1051344, in

Canada 993037).

Front Wheel

Bearings with

Oil Filled HubsSAE 75W-90 Synthetic Axle

Lubricant for Medium Duty Trucks

(GM Part No. U.S. 89021675, in

Canada 10953512).

Transfer Case

(Four-Wheel

Drive)Manual Transmission Fluid

(GM Part No. U.S. 88861800, in

Canada 88861801).

Front Axle

(Four-Wheel

Drive)SAE 75W-90 Synthetic Axle

Lubricant for Medium Duty Trucks

(GM Part No. U.S. 89021675, in

Canada 10953512).

Usage Fluid/Lubricant

Rear Axle and

Rear HubsSAE 75W-90 Synthetic Axle

Lubricant for Medium Duty Trucks

(GM Part No. U.S. 89021675, in

Canada 10953512).

Rear Axle Shift

Motor LubricantRefrigerant Oil

(GM Part No. U.S. 5416939, in

Canada 10953496).

Propshafts and

SplinesWheel bearing lubricant meeting

requirements of NLGI #2, Category

GC or GC-LB

(GM Part No. U.S. 1051344, in

Canada 993037).

Cab — Door

Hinges and

LatchesMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474).

Weatherstrip

ConditioningWeatherstrip Lubricant

(GM Part No. U.S. 3634770, in

Canada 10953518) or

Dielectric Silicone Grease

(GM Part No. U.S. 12345579, in

Canada 992887).

Weatherstrip

SqueaksSynthetic Grease with

Teflon, Superlube

(GM Part No. U.S. 12371287, in

Canada 10953437).

6-32

Page 357 of 384

Part D: Maintenance Record

After the scheduled services are performed, record the date, odometer reading and who performed the service, and

any additional information from “Owner Checks and Services” on the following record pages. Also, you should

retain all maintenance receipts.

DateMiles/km Or

HoursServiced By Maintenance Record

6-33

Page 358 of 384

DateMiles/km Or

HoursServiced By Maintenance Record

6-34

Page 359 of 384

DateMiles/km Or

HoursServiced By Maintenance Record

6-35

Page 360 of 384

DateMiles/km Or

HoursServiced By Maintenance Record

6-36