lock CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 2368 of 2438

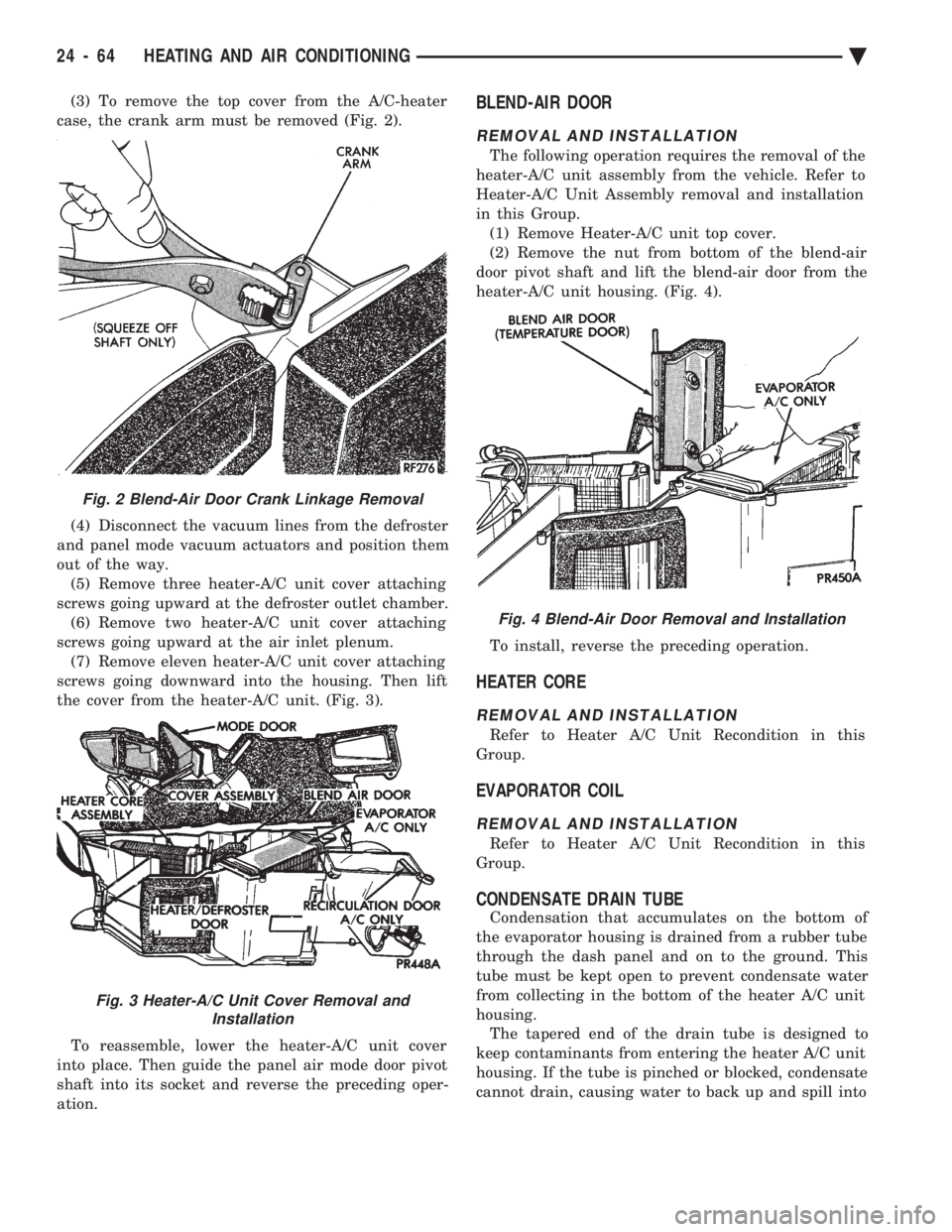

(3) To remove the top cover from the A/C-heater

case, the crank arm must be removed (Fig. 2).

(4) Disconnect the vacuum lines from the defroster

and panel mode vacuum actuators and position them

out of the way. (5) Remove three heater-A/C unit cover attaching

screws going upward at the defroster outlet chamber. (6) Remove two heater-A/C unit cover attaching

screws going upward at the air inlet plenum. (7) Remove eleven heater-A/C unit cover attaching

screws going downward into the housing. Then lift

the cover from the heater-A/C unit. (Fig. 3).

To reassemble, lower the heater-A/C unit cover

into place. Then guide the panel air mode door pivot

shaft into its socket and reverse the preceding oper-

ation.BLEND-AIR DOOR

REMOVAL AND INSTALLATION

The following operation requires the removal of the

heater-A/C unit assembly from the vehicle. Refer to

Heater-A/C Unit Assembly removal and installation

in this Group. (1) Remove Heater-A/C unit top cover.

(2) Remove the nut from bottom of the blend-air

door pivot shaft and lift the blend-air door from the

heater-A/C unit housing. (Fig. 4).

To install, reverse the preceding operation.

HEATER CORE

REMOVAL AND INSTALLATION

Refer to Heater A/C Unit Recondition in this

Group.

EVAPORATOR COIL

REMOVAL AND INSTALLATION

Refer to Heater A/C Unit Recondition in this

Group.

CONDENSATE DRAIN TUBE

Condensation that accumulates on the bottom of

the evaporator housing is drained from a rubber tube

through the dash panel and on to the ground. This

tube must be kept open to prevent condensate water

from collecting in the bottom of the heater A/C unit

housing. The tapered end of the drain tube is designed to

keep contaminants from entering the heater A/C unit

housing. If the tube is pinched or blocked, condensate

cannot drain, causing water to back up and spill into

Fig. 2 Blend-Air Door Crank Linkage Removal

Fig. 3 Heater-A/C Unit Cover Removal and Installation

Fig. 4 Blend-Air Door Removal and Installation

24 - 64 HEATING AND AIR CONDITIONING Ä

Page 2370 of 2438

AUTOMATIC TEMPERATURE CONTROL (ATC) INDEX

page page

Ambient Temperature Sensor ............... 67

ATC Computer/Control Panel ................ 66

Blend-Air Door Actuator .................... 69

Computer Aided Diagnostic Tests ............ 72

Diagnostic Trouble Code Definitions .......... 73

Diagnostic Trouble Code Service Procedures . . . 74

Erasing Diagnostic Trouble Codes ............ 83

Fresh/Recirc Door Actuator ................. 68 General InformationÐComponent Operation

.... 66

In-Car Temperature Sensor/Aspirator Assembly . . 70

Manual A/C Mode ........................ 66

Mode Door Actuator ...................... 69

NonÐComputer Aided Diagnostic Tests ....... 72

Power Module ........................... 67

Sun Sensor ............................. 71

Water Temperature Sensor ................. 71

GENERAL INFORMATIONÐCOMPONENT

OPERATION

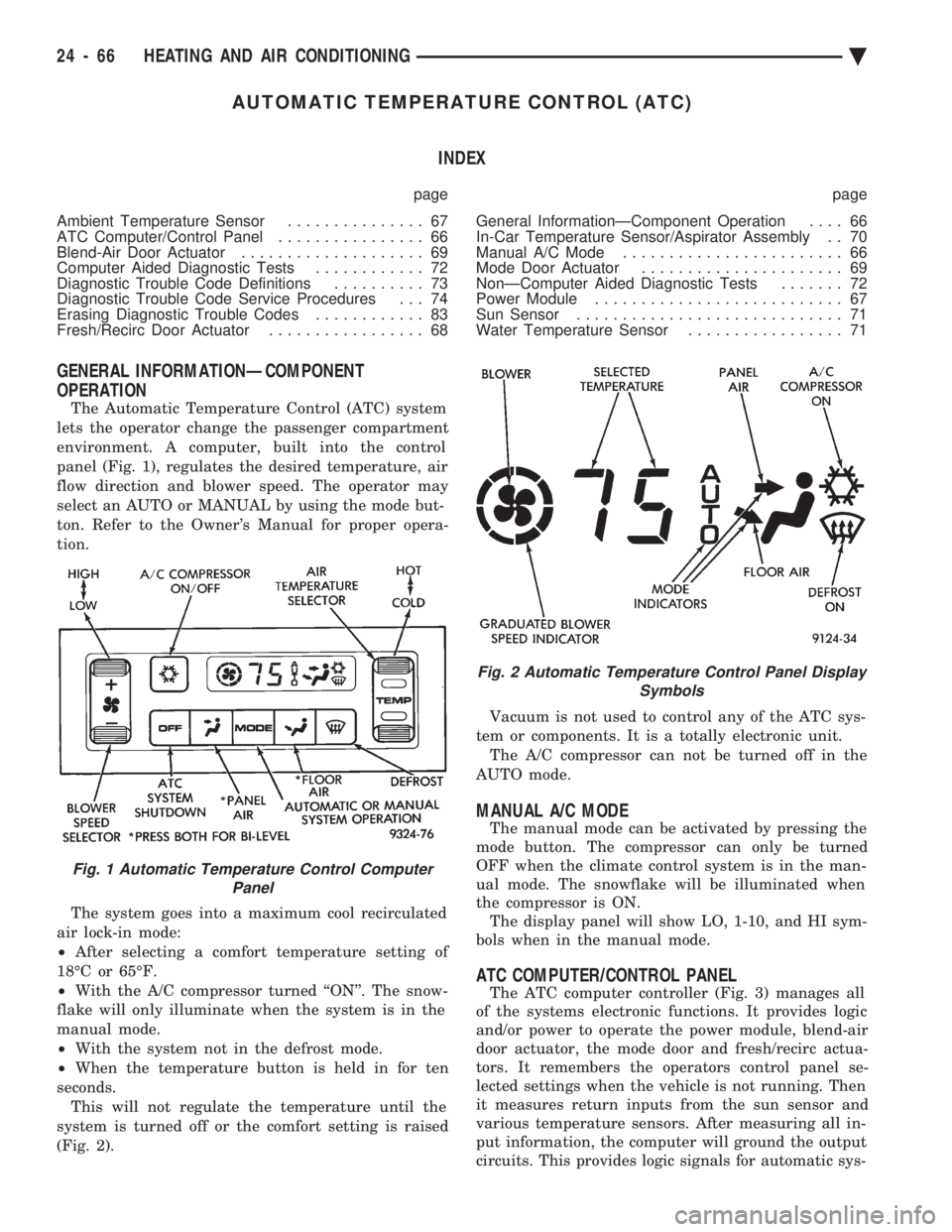

The Automatic Temperature Control (ATC) system

lets the operator change the passenger compartment

environment. A computer, built into the control

panel (Fig. 1), regulates the desired temperature, air

flow direction and blower speed. The operator may

select an AUTO or MANUAL by using the mode but-

ton. Refer to the Owner's Manual for proper opera-

tion.

The system goes into a maximum cool recirculated

air lock-in mode:

² After selecting a comfort temperature setting of

18ÉC or 65ÉF.

² With the A/C compressor turned ``ON''. The snow-

flake will only illuminate when the system is in the

manual mode.

² With the system not in the defrost mode.

² When the temperature button is held in for ten

seconds. This will not regulate the temperature until the

system is turned off or the comfort setting is raised

(Fig. 2). Vacuum is not used to control any of the ATC sys-

tem or components. It is a totally electronic unit. The A/C compressor can not be turned off in the

AUTO mode.

MANUAL A/C MODE

The manual mode can be activated by pressing the

mode button. The compressor can only be turned

OFF when the climate control system is in the man-

ual mode. The snowflake will be illuminated when

the compressor is ON. The display panel will show LO, 1-10, and HI sym-

bols when in the manual mode.

ATC COMPUTER/CONTROL PANEL

The ATC computer controller (Fig. 3) manages all

of the systems electronic functions. It provides logic

and/or power to operate the power module, blend-air

door actuator, the mode door and fresh/recirc actua-

tors. It remembers the operators control panel se-

lected settings when the vehicle is not running. Then

it measures return inputs from the sun sensor and

various temperature sensors. After measuring all in-

put information, the computer will ground the output

circuits. This provides logic signals for automatic sys-

Fig. 1 Automatic Temperature Control Computer Panel

Fig. 2 Automatic Temperature Control Panel Display Symbols

24 - 66 HEATING AND AIR CONDITIONING Ä

Page 2373 of 2438

To install, reverse the preceding operation.

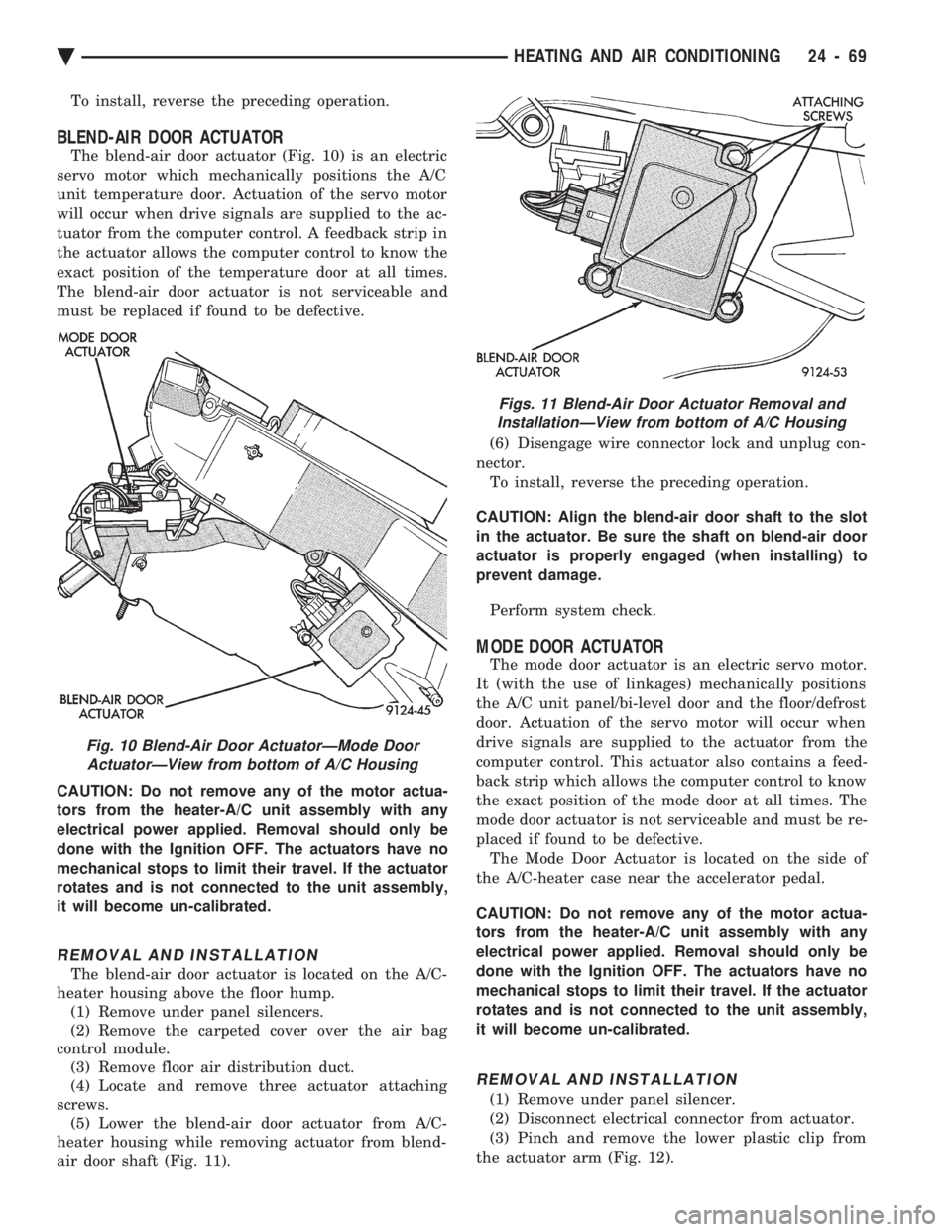

BLEND-AIR DOOR ACTUATOR

The blend-air door actuator (Fig. 10) is an electric

servo motor which mechanically positions the A/C

unit temperature door. Actuation of the servo motor

will occur when drive signals are supplied to the ac-

tuator from the computer control. A feedback strip in

the actuator allows the computer control to know the

exact position of the temperature door at all times.

The blend-air door actuator is not serviceable and

must be replaced if found to be defective.

CAUTION: Do not remove any of the motor actua-

tors from the heater-A/C unit assembly with any

electrical power applied. Removal should only be

done with the Ignition OFF. The actuators have no

mechanical stops to limit their travel. If the actuator

rotates and is not connected to the unit assembly,

it will become un-calibrated.

REMOVAL AND INSTALLATION

The blend-air door actuator is located on the A/C-

heater housing above the floor hump. (1) Remove under panel silencers.

(2) Remove the carpeted cover over the air bag

control module. (3) Remove floor air distribution duct.

(4) Locate and remove three actuator attaching

screws. (5) Lower the blend-air door actuator from A/C-

heater housing while removing actuator from blend-

air door shaft (Fig. 11). (6) Disengage wire connector lock and unplug con-

nector. To install, reverse the preceding operation.

CAUTION: Align the blend-air door shaft to the slot

in the actuator. Be sure the shaft on blend-air door

actuator is properly engaged (when installing) to

prevent damage.

Perform system check.

MODE DOOR ACTUATOR

The mode door actuator is an electric servo motor.

It (with the use of linkages) mechanically positions

the A/C unit panel/bi-level door and the floor/defrost

door. Actuation of the servo motor will occur when

drive signals are supplied to the actuator from the

computer control. This actuator also contains a feed-

back strip which allows the computer control to know

the exact position of the mode door at all times. The

mode door actuator is not serviceable and must be re-

placed if found to be defective. The Mode Door Actuator is located on the side of

the A/C-heater case near the accelerator pedal.

CAUTION: Do not remove any of the motor actua-

tors from the heater-A/C unit assembly with any

electrical power applied. Removal should only be

done with the Ignition OFF. The actuators have no

mechanical stops to limit their travel. If the actuator

rotates and is not connected to the unit assembly,

it will become un-calibrated.

REMOVAL AND INSTALLATION

(1) Remove under panel silencer.

(2) Disconnect electrical connector from actuator.

(3) Pinch and remove the lower plastic clip from

the actuator arm (Fig. 12).

Fig. 10 Blend-Air Door ActuatorÐMode Door ActuatorÐView from bottom of A/C Housing

Figs. 11 Blend-Air Door Actuator Removal andInstallationÐView from bottom of A/C Housing

Ä HEATING AND AIR CONDITIONING 24 - 69

Page 2375 of 2438

(3) Remove the two aspirator mounting screws.

(4) Disconnect the aspirator intake hose from the

instrument panel. (5) Remove sensor/aspirator and it's wiring har-

ness from vehicle. To install, reverse the preceding operation.

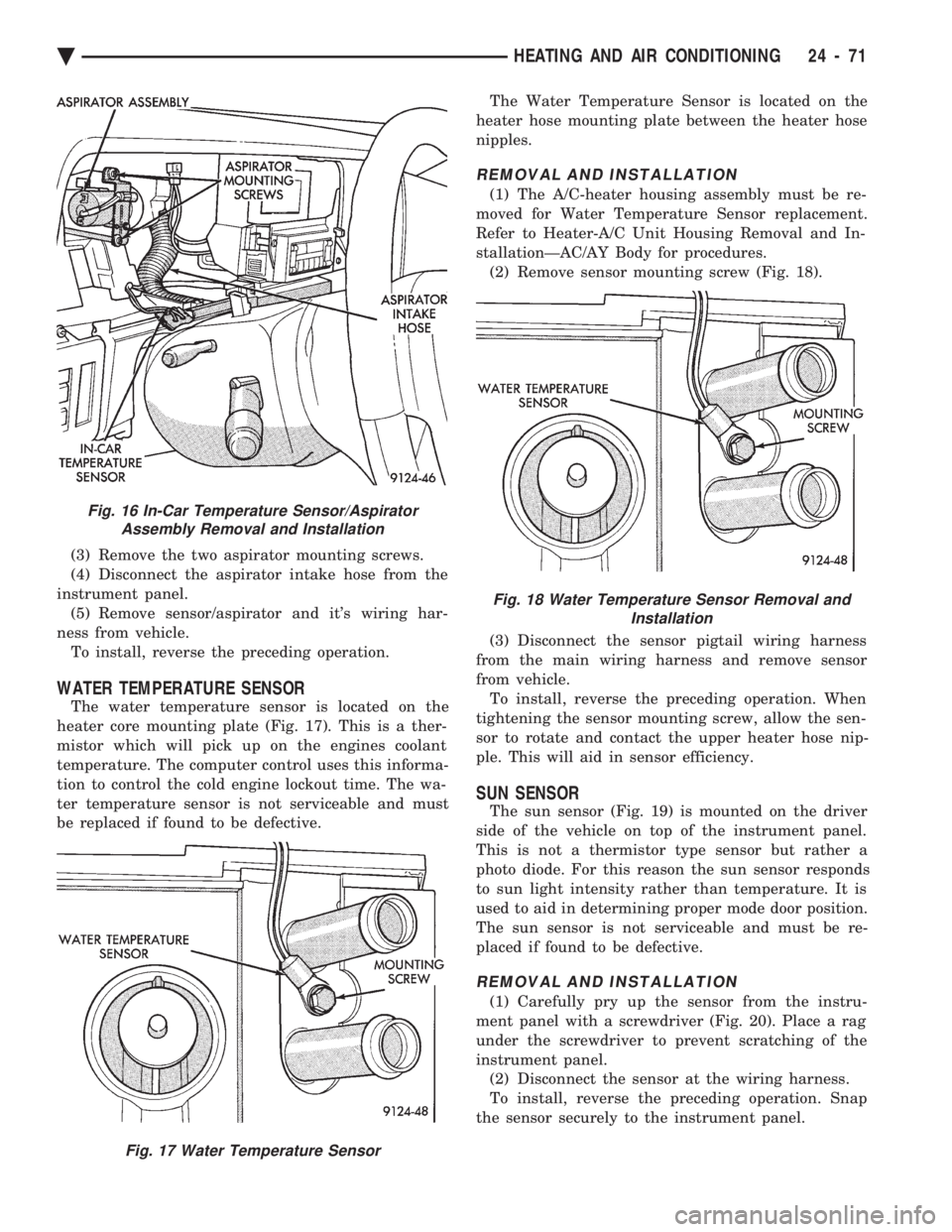

WATER TEMPERATURE SENSOR

The water temperature sensor is located on the

heater core mounting plate (Fig. 17). This is a ther-

mistor which will pick up on the engines coolant

temperature. The computer control uses this informa-

tion to control the cold engine lockout time. The wa-

ter temperature sensor is not serviceable and must

be replaced if found to be defective. The Water Temperature Sensor is located on the

heater hose mounting plate between the heater hose

nipples.

REMOVAL AND INSTALLATION

(1) The A/C-heater housing assembly must be re-

moved for Water Temperature Sensor replacement.

Refer to Heater-A/C Unit Housing Removal and In-

stallationÐAC/AY Body for procedures. (2) Remove sensor mounting screw (Fig. 18).

(3) Disconnect the sensor pigtail wiring harness

from the main wiring harness and remove sensor

from vehicle. To install, reverse the preceding operation. When

tightening the sensor mounting screw, allow the sen-

sor to rotate and contact the upper heater hose nip-

ple. This will aid in sensor efficiency.

SUN SENSOR

The sun sensor (Fig. 19) is mounted on the driver

side of the vehicle on top of the instrument panel.

This is not a thermistor type sensor but rather a

photo diode. For this reason the sun sensor responds

to sun light intensity rather than temperature. It is

used to aid in determining proper mode door position.

The sun sensor is not serviceable and must be re-

placed if found to be defective.

REMOVAL AND INSTALLATION

(1) Carefully pry up the sensor from the instru-

ment panel with a screwdriver (Fig. 20). Place a rag

under the screwdriver to prevent scratching of the

instrument panel. (2) Disconnect the sensor at the wiring harness.

To install, reverse the preceding operation. Snap

the sensor securely to the instrument panel.

Fig. 16 In-Car Temperature Sensor/Aspirator Assembly Removal and Installation

Fig. 17 Water Temperature Sensor

Fig. 18 Water Temperature Sensor Removal and Installation

Ä HEATING AND AIR CONDITIONING 24 - 71

Page 2403 of 2438

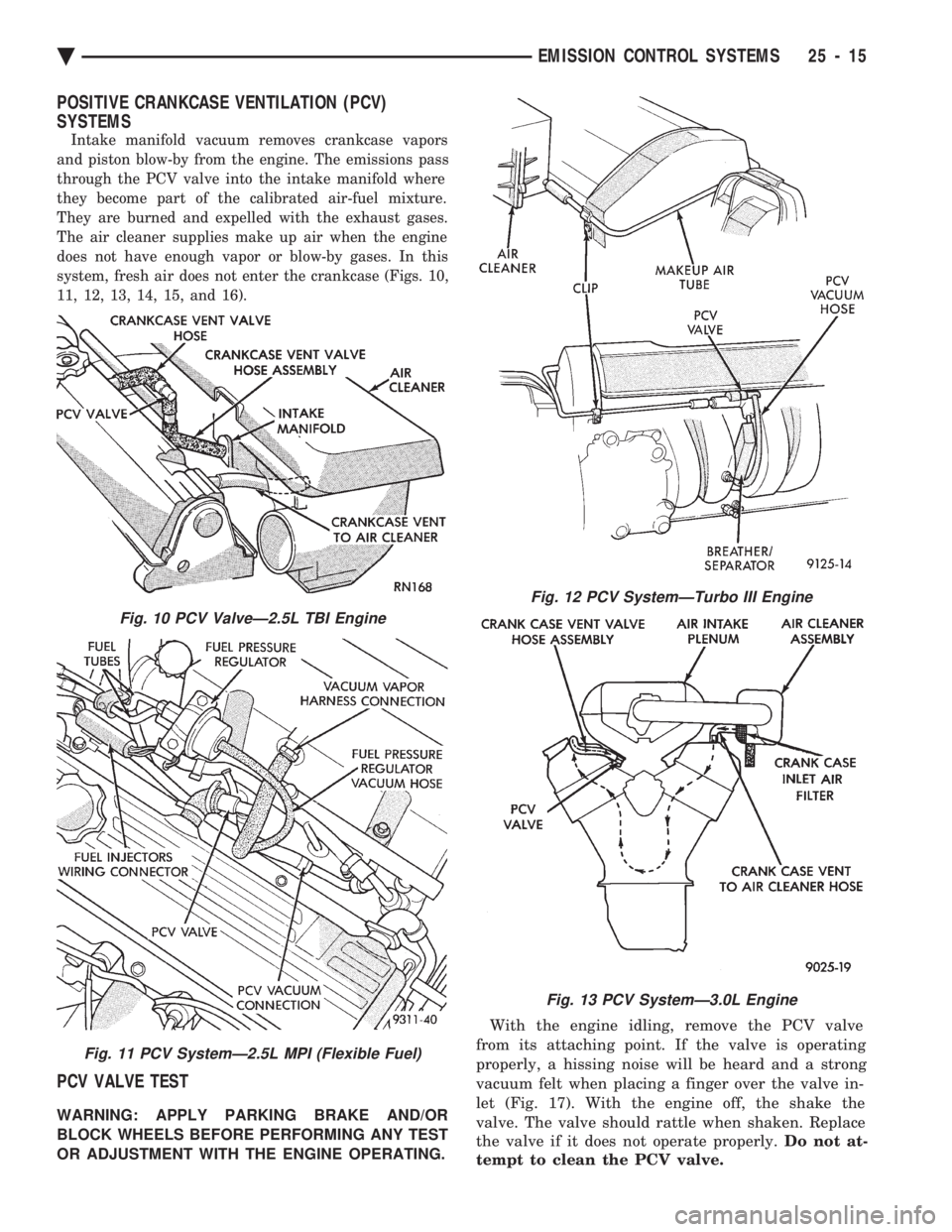

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEMS

Intake manifold vacuum removes crankcase vapors

and piston blow-by from the engine. The emissions pass

through the PCV valve into the intake manifold where

they become part of the calibrated air-fuel mixture.

They are burned and expelled with the exhaust gases.

The air cleaner supplies make up air when the engine

does not have enough vapor or blow-by gases. In this

system, fresh air does not enter the crankcase (Figs. 10,

11, 12, 13, 14, 15, and 16).

PCV VALVE TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING ANY TEST

OR ADJUSTMENT WITH THE ENGINE OPERATING. With the engine idling, remove the PCV valve

from its attaching point. If the valve is operating

properly, a hissing noise will be heard and a strong

vacuum felt when placing a finger over the valve in-

let (Fig. 17). With the engine off, the shake the

valve. The valve should rattle when shaken. Replace

the valve if it does not operate properly. Do not at-

tempt to clean the PCV valve.

Fig. 10 PCV ValveÐ2.5L TBI Engine

Fig. 11 PCV SystemÐ2.5L MPI (Flexible Fuel)

Fig. 12 PCV SystemÐTurbo III Engine

Fig. 13 PCV SystemÐ3.0L Engine

Ä EMISSION CONTROL SYSTEMS 25 - 15

Page 2409 of 2438

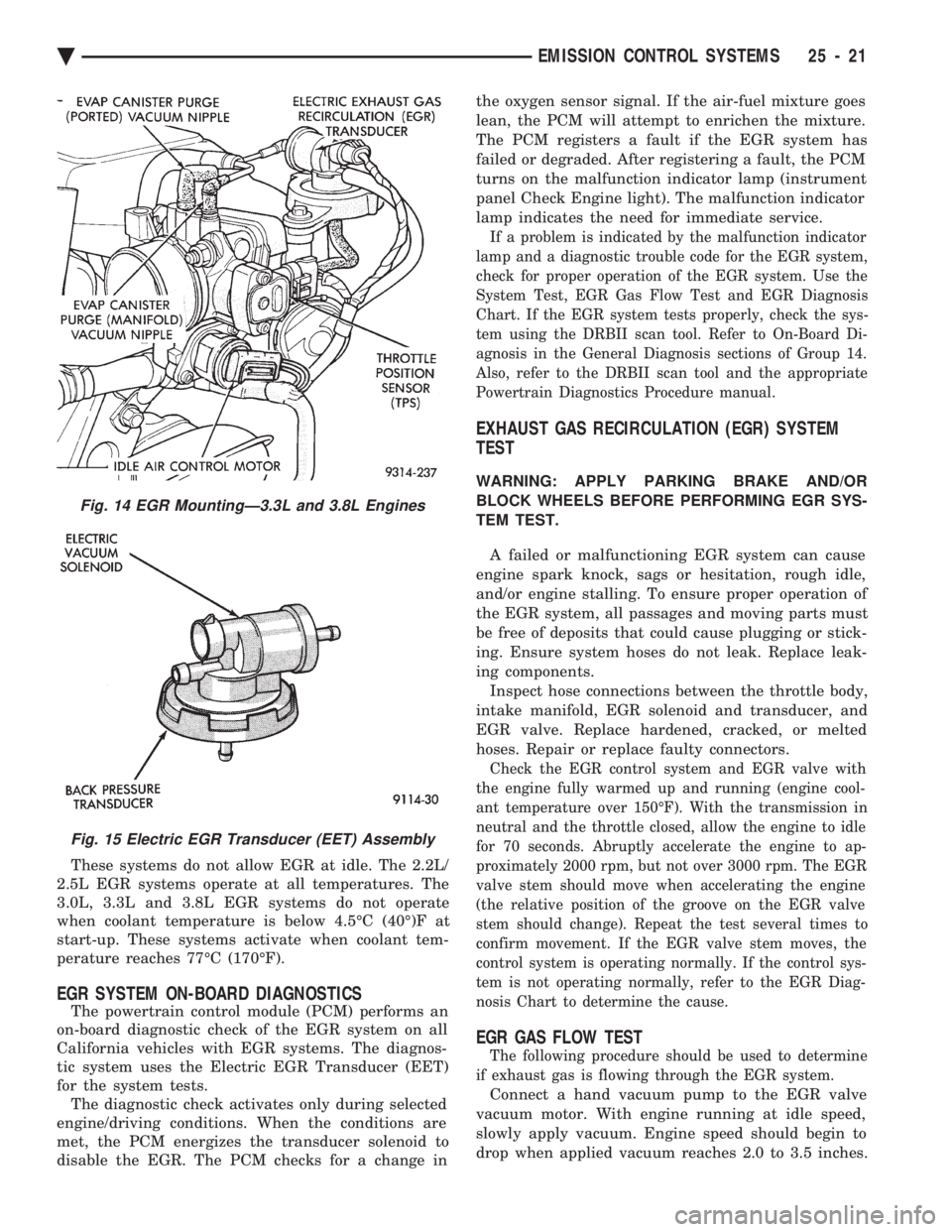

These systems do not allow EGR at idle. The 2.2L/

2.5L EGR systems operate at all temperatures. The

3.0L, 3.3L and 3.8L EGR systems do not operate

when coolant temperature is below 4.5ÉC (40É)F at

start-up. These systems activate when coolant tem-

perature reaches 77ÉC (170ÉF).

EGR SYSTEM ON-BOARD DIAGNOSTICS

The powertrain control module (PCM) performs an

on-board diagnostic check of the EGR system on all

California vehicles with EGR systems. The diagnos-

tic system uses the Electric EGR Transducer (EET)

for the system tests. The diagnostic check activates only during selected

engine/driving conditions. When the conditions are

met, the PCM energizes the transducer solenoid to

disable the EGR. The PCM checks for a change in the oxygen sensor signal. If the air-fuel mixture goes

lean, the PCM will attempt to enrichen the mixture.

The PCM registers a fault if the EGR system has

failed or degraded. After registering a fault, the PCM

turns on the malfunction indicator lamp (instrument

panel Check Engine light). The malfunction indicator

lamp indicates the need for immediate service.

If a problem is indicated by the malfunction indicator

lamp and a diagnostic trouble code for the EGR system,

check for proper operation of the EGR system. Use the

System Test, EGR Gas Flow Test and EGR Diagnosis

Chart. If the EGR system tests properly, check the sys-

tem using the DRBII scan tool. Refer to On-Board Di-

agnosis in the General Diagnosis sections of Group 14.

Also, refer to the DRBII scan tool and the appropriate

Powertrain Diagnostics Procedure manual.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING EGR SYS-

TEM TEST.

A failed or malfunctioning EGR system can cause

engine spark knock, sags or hesitation, rough idle,

and/or engine stalling. To ensure proper operation of

the EGR system, all passages and moving parts must

be free of deposits that could cause plugging or stick-

ing. Ensure system hoses do not leak. Replace leak-

ing components. Inspect hose connections between the throttle body,

intake manifold, EGR solenoid and transducer, and

EGR valve. Replace hardened, cracked, or melted

hoses. Repair or replace faulty connectors.

Check the EGR control system and EGR valve with

the engine fully warmed up and running (engine cool-

ant temperature over 150ÉF). With the transmission in

neutral and the throttle closed, allow the engine to idle

for 70 seconds. Abruptly accelerate the engine to ap-

proximately 2000 rpm, but not over 3000 rpm. The EGR

valve stem should move when accelerating the engine

(the relative position of the groove on the EGR valve

stem should change). Repeat the test several times to

confirm movement. If the EGR valve stem moves, the

control system is operating normally. If the control sys-

tem is not operating normally, refer to the EGR Diag-

nosis Chart to determine the cause.

EGR GAS FLOW TEST

The following procedure should be used to determine

if exhaust gas is flowing through the EGR system.

Connect a hand vacuum pump to the EGR valve

vacuum motor. With engine running at idle speed,

slowly apply vacuum. Engine speed should begin to

drop when applied vacuum reaches 2.0 to 3.5 inches.

Fig. 14 EGR MountingÐ3.3L and 3.8L Engines

Fig. 15 Electric EGR Transducer (EET) Assembly

Ä EMISSION CONTROL SYSTEMS 25 - 21