Index CHEVROLET PLYMOUTH ACCLAIM 1993 Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 411 of 2438

GENERATOR INDEX

page page

General Information ........................ 9

Generator ReplacementÐ2.2L Turbo Engine (With 16 Valve Cylinder Head) ............. 10 Generator ReplacementÐ2.2L/2.5L Engine

...... 9

Generator ReplacementÐ3.0L Engine ......... 10

Generator ReplacementÐ3.3L/3.8L Engine ..... 11

GENERAL INFORMATION

This section will cover generator removal and instal-

lation only. Information covering generator on-vehicle

testing and diagnosis can be found in Group 8A,

Battery/Starting/Charging Systems Diagnostics. To

identify the generator, refer to the Generator Specifi-

cation chart at the rear of this section. These generators are not intended to be disas-

sembled for service. It must be replaced as an

assembly.

GENERATOR REPLACEMENTÐ2.2L/2.5L ENGINE

Removal and repositioning of A/C compressor (with-

out disconnecting refrigerant lines) is necessary on

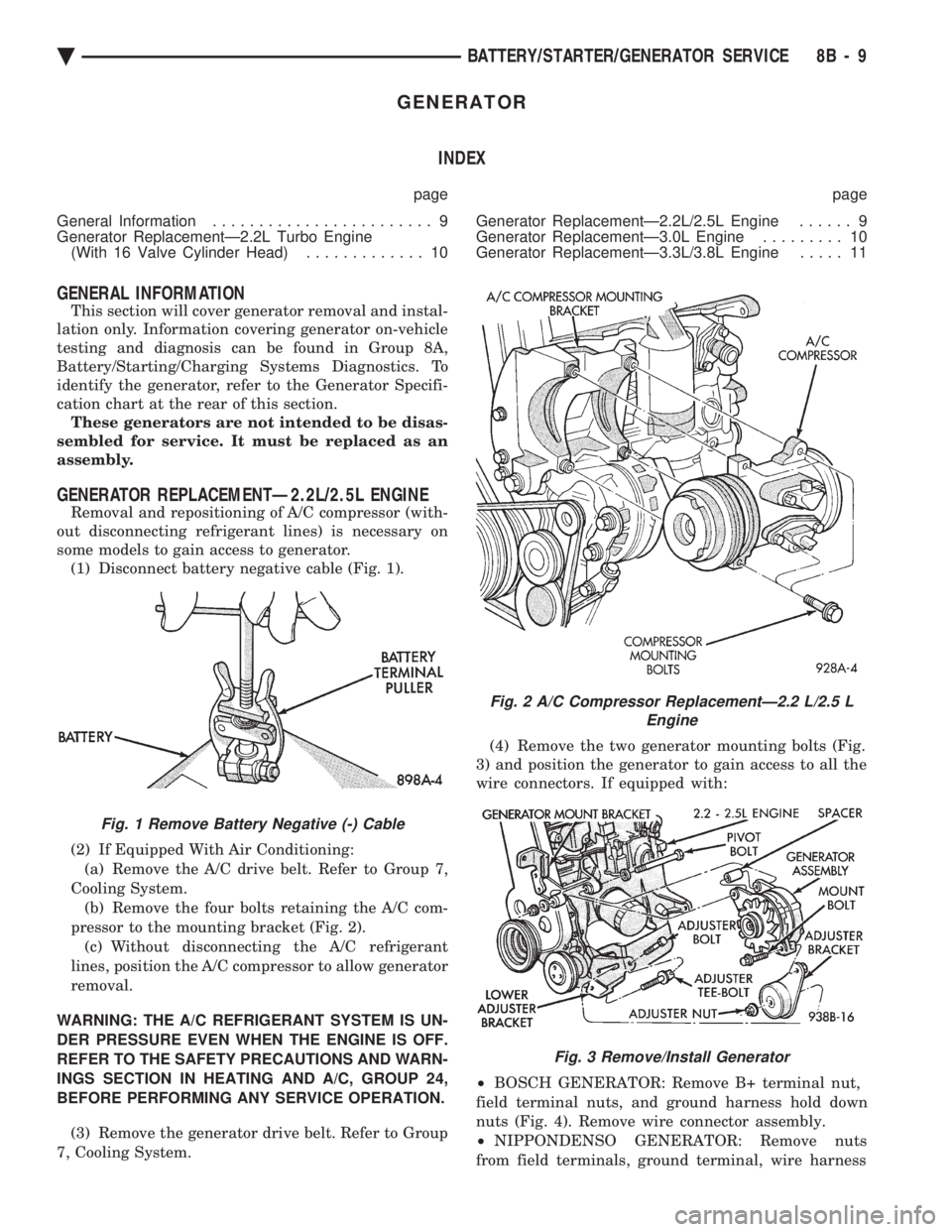

some models to gain access to generator. (1) Disconnect battery negative cable (Fig. 1).

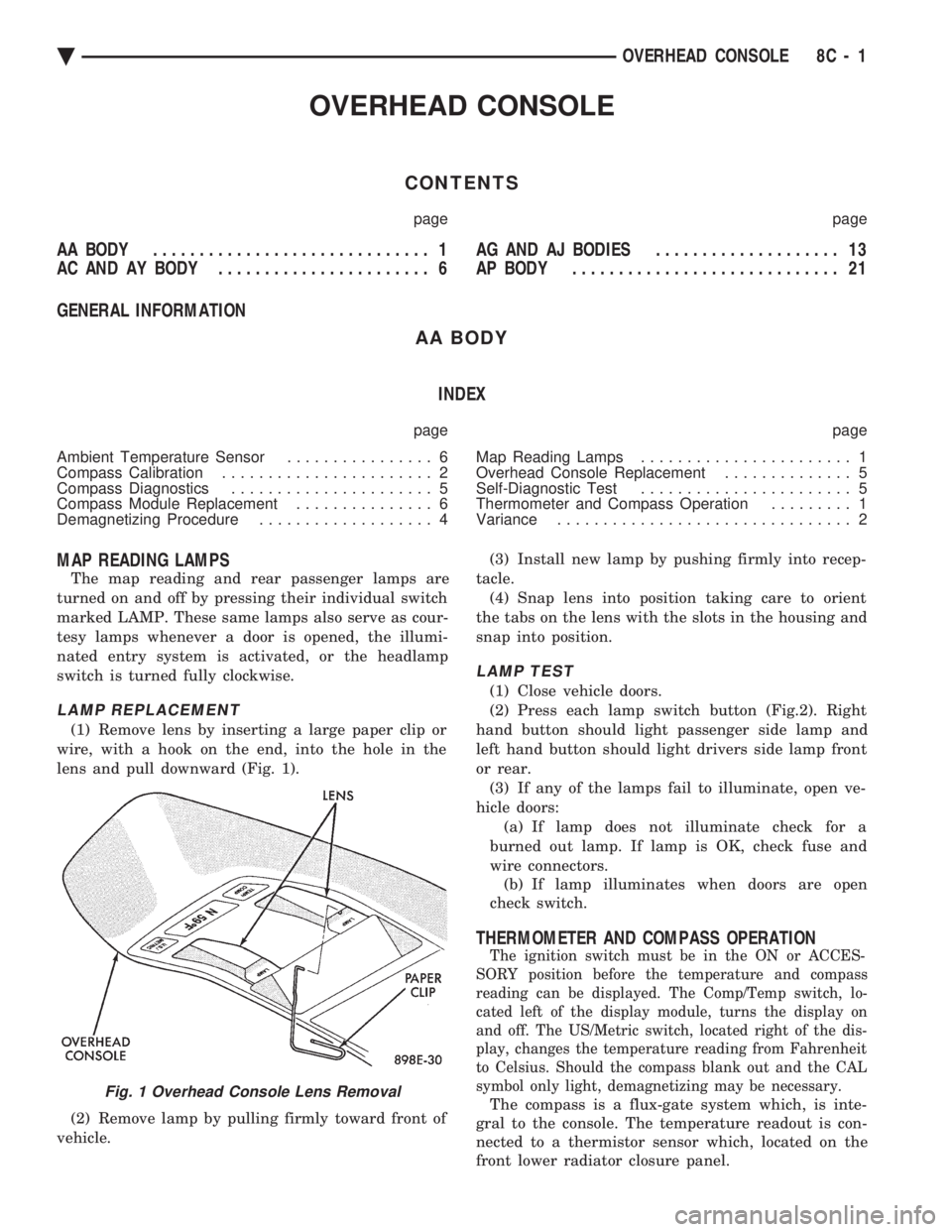

(2) If Equipped With Air Conditioning:

(a) Remove the A/C drive belt. Refer to Group 7,

Cooling System. (b) Remove the four bolts retaining the A/C com-

pressor to the mounting bracket (Fig. 2). (c) Without disconnecting the A/C refrigerant

lines, position the A/C compressor to allow generator

removal.

WARNING: THE A/C REFRIGERANT SYSTEM IS UN-

DER PRESSURE EVEN WHEN THE ENGINE IS OFF.

REFER TO THE SAFETY PRECAUTIONS AND WARN-

INGS SECTION IN HEATING AND A/C, GROUP 24,

BEFORE PERFORMING ANY SERVICE OPERATION. (3) Remove the generator drive belt. Refer to Group

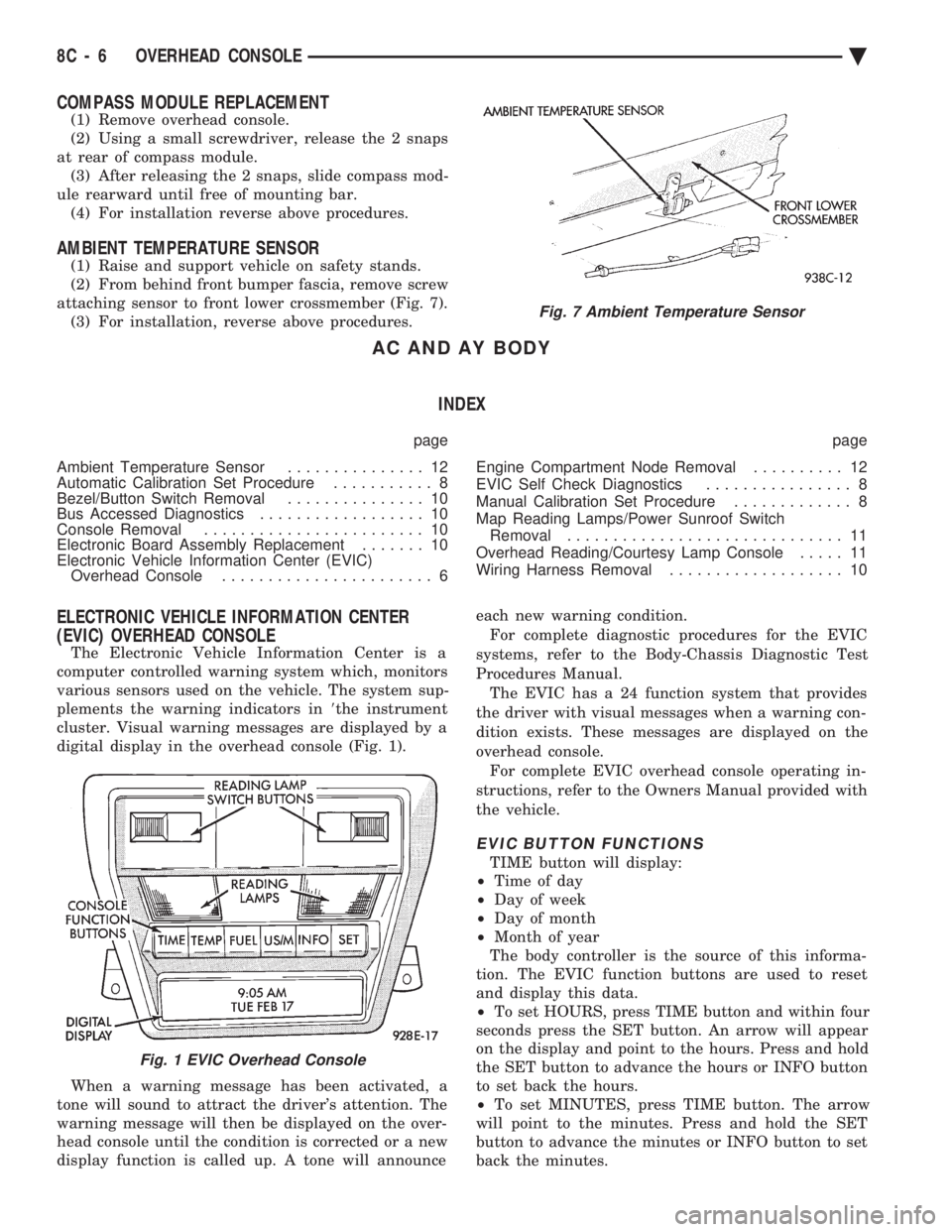

7, Cooling System. (4) Remove the two generator mounting bolts (Fig.

3) and position the generator to gain access to all the

wire connectors. If equipped with:

² BOSCH GENERATOR: Remove B+ terminal nut,

field terminal nuts, and ground harness hold down

nuts (Fig. 4). Remove wire connector assembly.

² NIPPONDENSO GENERATOR: Remove nuts

from field terminals, ground terminal, wire harness

Fig. 1 Remove Battery Negative (-) Cable

Fig. 2 A/C Compressor ReplacementÐ2.2 L/2.5 L Engine

Fig. 3 Remove/Install Generator

Ä BATTERY/STARTER/GENERATOR SERVICE 8B - 9

Page 417 of 2438

OVERHEAD CONSOLE

CONTENTS

page page

AA BODY .............................. 1

AC AND AY BODY ....................... 6 AG AND AJ BODIES

.................... 13

AP BODY ............................. 21

GENERAL INFORMATION AA BODY

INDEX

page page

Ambient Temperature Sensor ................ 6

Compass Calibration ....................... 2

Compass Diagnostics ...................... 5

Compass Module Replacement ............... 6

Demagnetizing Procedure ................... 4 Map Reading Lamps

....................... 1

Overhead Console Replacement .............. 5

Self-Diagnostic Test ....................... 5

Thermometer and Compass Operation ......... 1

Variance ................................ 2

MAP READING LAMPS

The map reading and rear passenger lamps are

turned on and off by pressing their individual switch

marked LAMP. These same lamps also serve as cour-

tesy lamps whenever a door is opened, the illumi-

nated entry system is activated, or the headlamp

switch is turned fully clockwise.

LAMP REPLACEMENT

(1) Remove lens by inserting a large paper clip or

wire, with a hook on the end, into the hole in the

lens and pull downward (Fig. 1).

(2) Remove lamp by pulling firmly toward front of

vehicle. (3) Install new lamp by pushing firmly into recep-

tacle. (4) Snap lens into position taking care to orient

the tabs on the lens with the slots in the housing and

snap into position.

LAMP TEST

(1) Close vehicle doors.

(2) Press each lamp switch button (Fig.2). Right

hand button should light passenger side lamp and

left hand button should light drivers side lamp front

or rear. (3) If any of the lamps fail to illuminate, open ve-

hicle doors: (a) If lamp does not illuminate check for a

burned out lamp. If lamp is OK, check fuse and

wire connectors. (b) If lamp illuminates when doors are open

check switch.

THERMOMETER AND COMPASS OPERATION

The ignition switch must be in the ON or ACCES-

SORY position before the temperature and compass

reading can be displayed. The Comp/Temp switch, lo-

cated left of the display module, turns the display on

and off. The US/Metric switch, located right of the dis-

play, changes the temperature reading from Fahrenheit

to Celsius. Should the compass blank out and the CAL

symbol only light, demagnetizing may be necessary.

The compass is a flux-gate system which, is inte-

gral to the console. The temperature readout is con-

nected to a thermistor sensor which, located on the

front lower radiator closure panel.Fig. 1 Overhead Console Lens Removal

Ä OVERHEAD CONSOLE 8C - 1

Page 422 of 2438

COMPASS MODULE REPLACEMENT

(1) Remove overhead console.

(2) Using a small screwdriver, release the 2 snaps

at rear of compass module. (3) After releasing the 2 snaps, slide compass mod-

ule rearward until free of mounting bar. (4) For installation reverse above procedures.

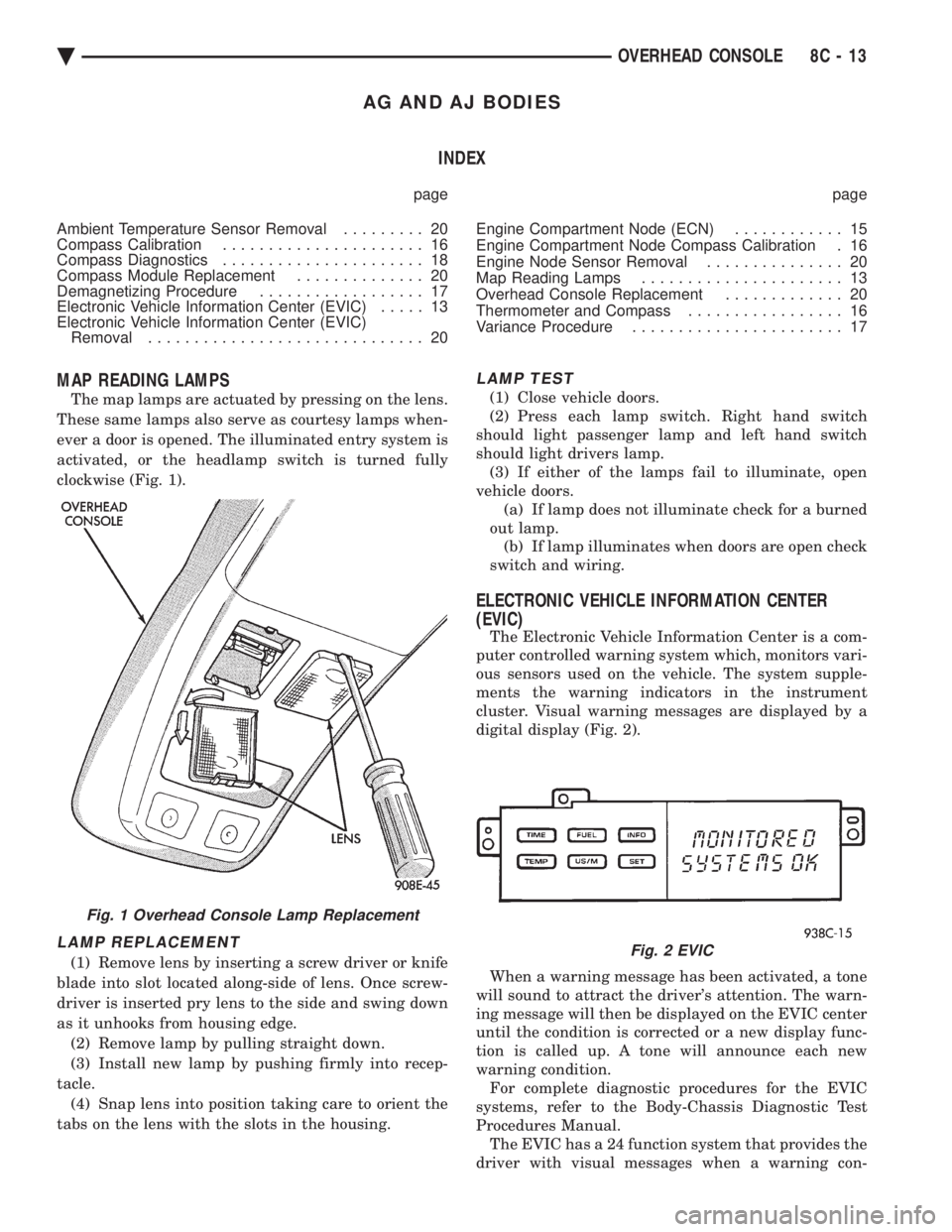

AMBIENT TEMPERATURE SENSOR

(1) Raise and support vehicle on safety stands.

(2) From behind front bumper fascia, remove screw

attaching sensor to front lower crossmember (Fig. 7). (3) For installation, reverse above procedures.

AC AND AY BODY

INDEX

page page

Ambient Temperature Sensor ............... 12

Automatic Calibration Set Procedure ........... 8

Bezel/Button Switch Removal ............... 10

Bus Accessed Diagnostics .................. 10

Console Removal ........................ 10

Electronic Board Assembly Replacement ....... 10

Electronic Vehicle Information Center (EVIC) Overhead Console ....................... 6 Engine Compartment Node Removal

.......... 12

EVIC Self Check Diagnostics ................ 8

Manual Calibration Set Procedure ............. 8

Map Reading Lamps/Power Sunroof Switch Removal .............................. 11

Overhead Reading/Courtesy Lamp Console ..... 11

Wiring Harness Removal ................... 10

ELECTRONIC VEHICLE INFORMATION CENTER

(EVIC) OVERHEAD CONSOLE

The Electronic Vehicle Information Center is a

computer controlled warning system which, monitors

various sensors used on the vehicle. The system sup-

plements the warning indicators in 8the instrument

cluster. Visual warning messages are displayed by a

digital display in the overhead console (Fig. 1).

When a warning message has been activated, a

tone will sound to attract the driver's attention. The

warning message will then be displayed on the over-

head console until the condition is corrected or a new

display function is called up. A tone will announce each new warning condition.

For complete diagnostic procedures for the EVIC

systems, refer to the Body-Chassis Diagnostic Test

Procedures Manual. The EVIC has a 24 function system that provides

the driver with visual messages when a warning con-

dition exists. These messages are displayed on the

overhead console. For complete EVIC overhead console operating in-

structions, refer to the Owners Manual provided with

the vehicle.

EVIC BUTTON FUNCTIONS

TIME button will display:

² Time of day

² Day of week

² Day of month

² Month of year

The body controller is the source of this informa-

tion. The EVIC function buttons are used to reset

and display this data.

² To set HOURS, press TIME button and within four

seconds press the SET button. An arrow will appear

on the display and point to the hours. Press and hold

the SET button to advance the hours or INFO button

to set back the hours.

² To set MINUTES, press TIME button. The arrow

will point to the minutes. Press and hold the SET

button to advance the minutes or INFO button to set

back the minutes.

Fig. 7 Ambient Temperature Sensor

Fig. 1 EVIC Overhead Console

8C - 6 OVERHEAD CONSOLE Ä

Page 429 of 2438

AG AND AJ BODIES INDEX

page page

Ambient Temperature Sensor Removal ......... 20

Compass Calibration ...................... 16

Compass Diagnostics ...................... 18

Compass Module Replacement .............. 20

Demagnetizing Procedure .................. 17

Electronic Vehicle Information Center (EVIC) ..... 13

Electronic Vehicle Information Center (EVIC) Removal .............................. 20 Engine Compartment Node (ECN)

............ 15

Engine Compartment Node Compass Calibration . 16

Engine Node Sensor Removal ............... 20

Map Reading Lamps ...................... 13

Overhead Console Replacement ............. 20

Thermometer and Compass ................. 16

Variance Procedure ....................... 17

MAP READING LAMPS

The map lamps are actuated by pressing on the lens.

These same lamps also serve as courtesy lamps when-

ever a door is opened. The illuminated entry system is

activated, or the headlamp switch is turned fully

clockwise (Fig. 1).

LAMP REPLACEMENT

(1) Remove lens by inserting a screw driver or knife

blade into slot located along-side of lens. Once screw-

driver is inserted pry lens to the side and swing down

as it unhooks from housing edge. (2) Remove lamp by pulling straight down.

(3) Install new lamp by pushing firmly into recep-

tacle. (4) Snap lens into position taking care to orient the

tabs on the lens with the slots in the housing.

LAMP TEST

(1) Close vehicle doors.

(2) Press each lamp switch. Right hand switch

should light passenger lamp and left hand switch

should light drivers lamp. (3) If either of the lamps fail to illuminate, open

vehicle doors. (a) If lamp does not illuminate check for a burned

out lamp. (b) If lamp illuminates when doors are open check

switch and wiring.

ELECTRONIC VEHICLE INFORMATION CENTER

(EVIC)

The Electronic Vehicle Information Center is a com-

puter controlled warning system which, monitors vari-

ous sensors used on the vehicle. The system supple-

ments the warning indicators in the instrument

cluster. Visual warning messages are displayed by a

digital display (Fig. 2).

When a warning message has been activated, a tone

will sound to attract the driver's attention. The warn-

ing message will then be displayed on the EVIC center

until the condition is corrected or a new display func-

tion is called up. A tone will announce each new

warning condition. For complete diagnostic procedures for the EVIC

systems, refer to the Body-Chassis Diagnostic Test

Procedures Manual. The EVIC has a 24 function system that provides the

driver with visual messages when a warning con-

Fig. 1 Overhead Console Lamp Replacement

Fig. 2 EVIC

Ä OVERHEAD CONSOLE 8C - 13

Page 437 of 2438

AP BODY INDEX

page page

Ambient Temperature Sensor Removal ........ 25

Compass Calibration ...................... 21

Compass Diagnostics ..................... 23

Compass Module Replacement .............. 25

Demagnetizing Procedure .................. 22 Map Reading Lamps Operation

.............. 21

Overhead Console Replacement ............. 25

Thermometer and Compass ................ 21

Variance Procedure ....................... 22

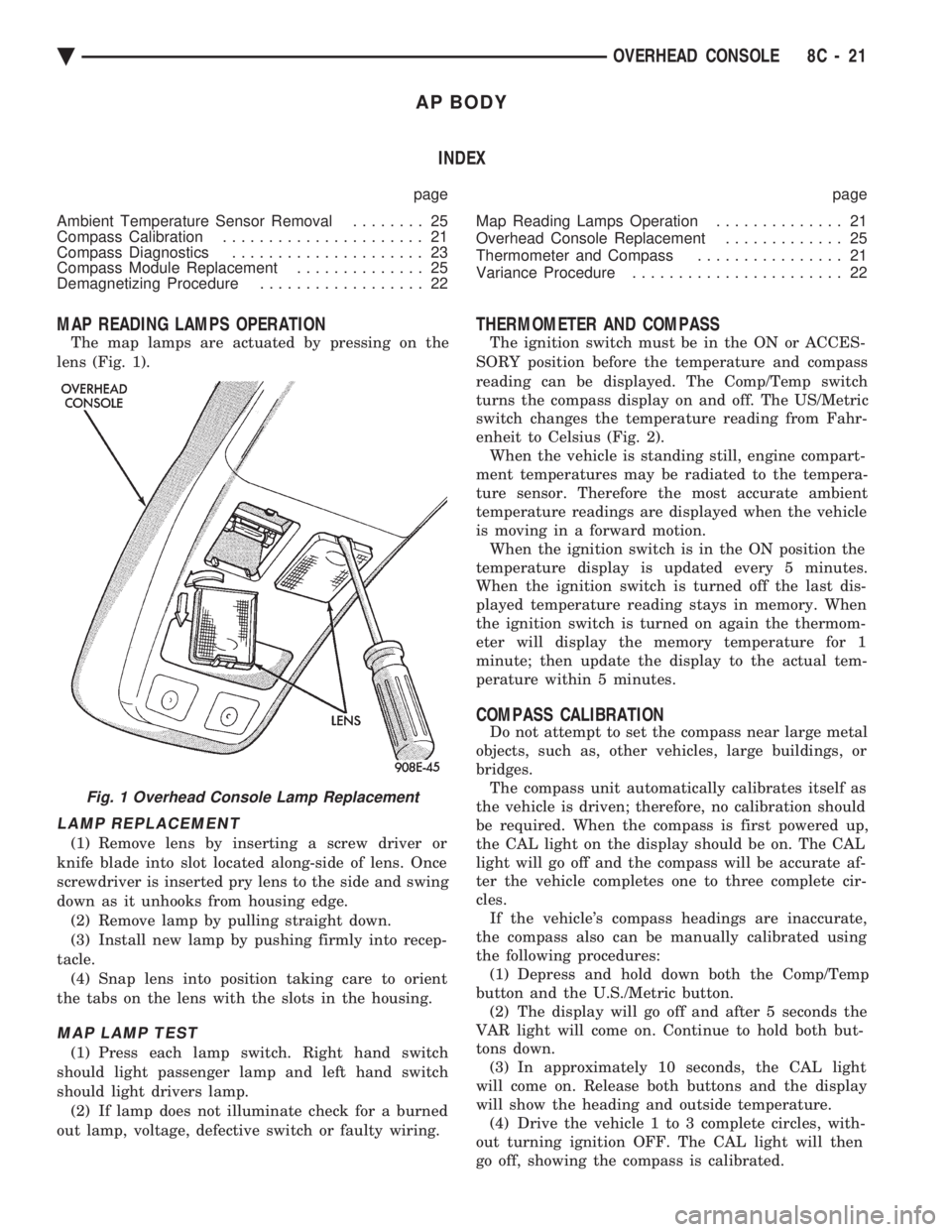

MAP READING LAMPS OPERATION

The map lamps are actuated by pressing on the

lens (Fig. 1).

LAMP REPLACEMENT

(1) Remove lens by inserting a screw driver or

knife blade into slot located along-side of lens. Once

screwdriver is inserted pry lens to the side and swing

down as it unhooks from housing edge. (2) Remove lamp by pulling straight down.

(3) Install new lamp by pushing firmly into recep-

tacle. (4) Snap lens into position taking care to orient

the tabs on the lens with the slots in the housing.

MAP LAMP TEST

(1) Press each lamp switch. Right hand switch

should light passenger lamp and left hand switch

should light drivers lamp. (2) If lamp does not illuminate check for a burned

out lamp, voltage, defective switch or faulty wiring.

THERMOMETER AND COMPASS

The ignition switch must be in the ON or ACCES-

SORY position before the temperature and compass

reading can be displayed. The Comp/Temp switch

turns the compass display on and off. The US/Metric

switch changes the temperature reading from Fahr-

enheit to Celsius (Fig. 2). When the vehicle is standing still, engine compart-

ment temperatures may be radiated to the tempera-

ture sensor. Therefore the most accurate ambient

temperature readings are displayed when the vehicle

is moving in a forward motion. When the ignition switch is in the ON position the

temperature display is updated every 5 minutes.

When the ignition switch is turned off the last dis-

played temperature reading stays in memory. When

the ignition switch is turned on again the thermom-

eter will display the memory temperature for 1

minute; then update the display to the actual tem-

perature within 5 minutes.

COMPASS CALIBRATION

Do not attempt to set the compass near large metal

objects, such as, other vehicles, large buildings, or

bridges. The compass unit automatically calibrates itself as

the vehicle is driven; therefore, no calibration should

be required. When the compass is first powered up,

the CAL light on the display should be on. The CAL

light will go off and the compass will be accurate af-

ter the vehicle completes one to three complete cir-

cles. If the vehicle's compass headings are inaccurate,

the compass also can be manually calibrated using

the following procedures: (1) Depress and hold down both the Comp/Temp

button and the U.S./Metric button. (2) The display will go off and after 5 seconds the

VAR light will come on. Continue to hold both but-

tons down. (3) In approximately 10 seconds, the CAL light

will come on. Release both buttons and the display

will show the heading and outside temperature. (4) Drive the vehicle 1 to 3 complete circles, with-

out turning ignition OFF. The CAL light will then

go off, showing the compass is calibrated.

Fig. 1 Overhead Console Lamp Replacement

Ä OVERHEAD CONSOLE 8C - 21

Page 443 of 2438

IGNITION SYSTEMS

CONTENTS

page page

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐDIAGNOSTIC PROCEDURES

..... 11

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNI- TION SYSTEMSÐSERVICE PROCEDURES . 14

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNI- TION SYSTEMSÐSYSTEM OPERATION .... 1

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐDIAGNOSTIC PROCEDURES

.... 35

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐSYSTEM OPERATION ......... 24

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMSÐSERVICE PROCEDURES ...... 39

IGNITION SWITCH ...................... 45

SPECIFICATIONS ....................... 47

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicles by letter designation. A chart ex-

plaining the designations appears in the Introduction

Section of this manual.

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐSYSTEM OPERATION

INDEX

page page

Auto Shutdown (ASD) Relay and Fuel Pump Relay . 8

Coolant Temperature Sensor ................. 7

Distributor Cap ........................... 1

Distributor Pick-UpÐ3.0L Engine .............. 7

Distributor Pick-UpÐPCM Input ............... 6

General Information ........................ 1 Ignition Coil

.............................. 9

Manifold Absolute Pressure (MAP) Sensor ...... 8

Powertrain Control Module (PCM) ............. 6

Rotor .................................. 2

Spark Plug Cables ........................ 2

Spark Plugs ............................. 3

GENERAL INFORMATION

This section describes the ignition systems of the

2.2L TBI, 2.5L TBI, 2.5L MPI (flexible fuel AA-body)

and 3.0L engines. The Fuel Injection sections of Group 14 explain On

Board Diagnostics. Group 0, Lubrication and Maintenance, contains

general maintenance information for ignition related

items. The Owner's Manual also contains mainte-

nance information.

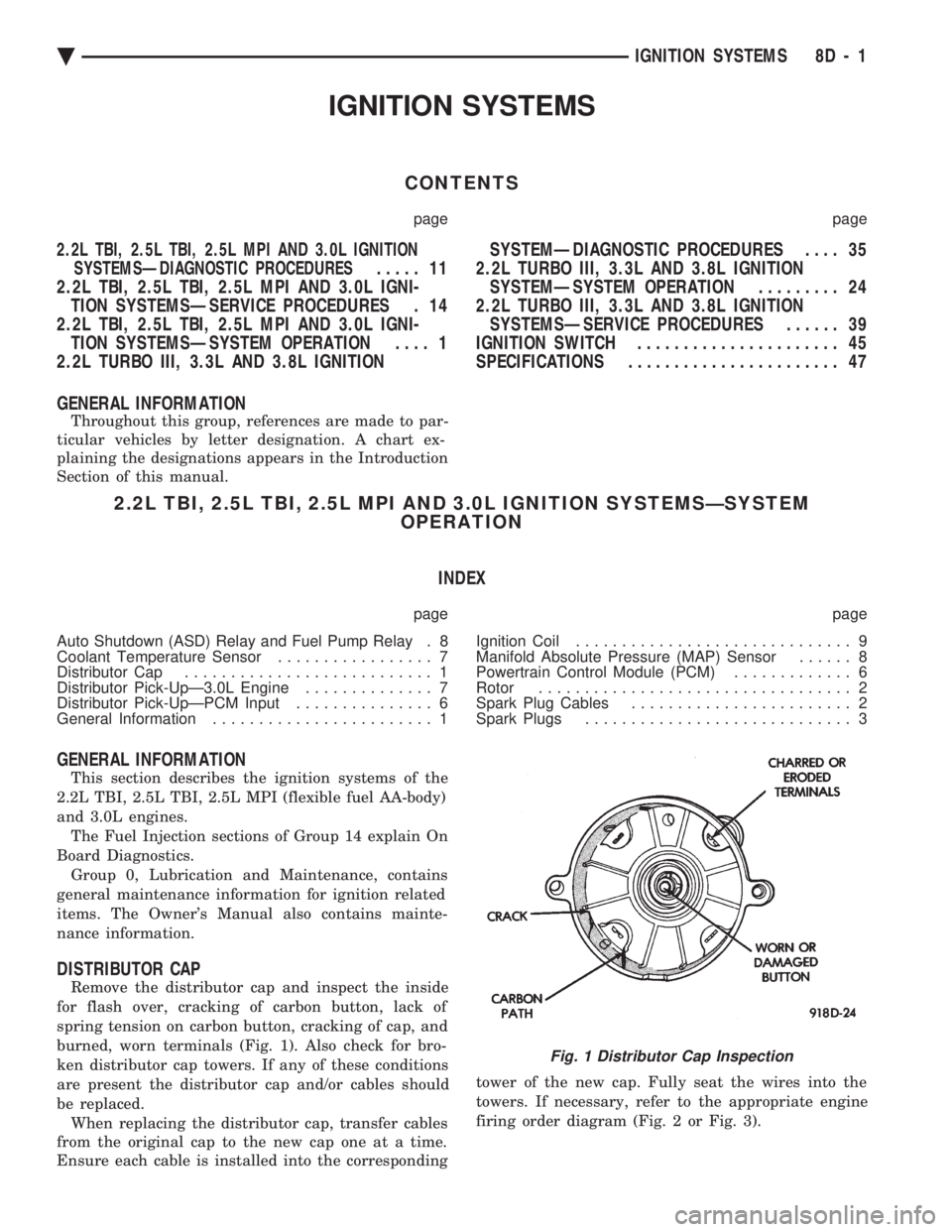

DISTRIBUTOR CAP

Remove the distributor cap and inspect the inside

for flash over, cracking of carbon button, lack of

spring tension on carbon button, cracking of cap, and

burned, worn terminals (Fig. 1). Also check for bro-

ken distributor cap towers. If any of these conditions

are present the distributor cap and/or cables should

be replaced. When replacing the distributor cap, transfer cables

from the original cap to the new cap one at a time.

Ensure each cable is installed into the corresponding tower of the new cap. Fully seat the wires into the

towers. If necessary, refer to the appropriate engine

firing order diagram (Fig. 2 or Fig. 3).

Fig. 1 Distributor Cap Inspection

Ä

IGNITION SYSTEMS 8D - 1

Page 453 of 2438

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐDIAGNOSTIC PROCEDURES

INDEX

page page

Coolant Temperature Sensor Test ............ 13

Failure to Start TestÐ2.5L TBI and 3.0L Engines . 12

General Information ....................... 11

Ignition Coil ............................. 11 Manifold Absolute Pressure (MAP) Sensor Test . 13

Poor Performance Test .................... 13

Spark Plugs ............................ 11

Testing for Spark at Coil ................... 11

GENERAL INFORMATION

For additional information, refer to On Board Di-

agnostics in the Fuel Injection General Diagnosis

sections of Group 14. Also, refer to the DRBII scan

tool and appropriate Powertrain Diagnostic Proce-

dures Manual.

SPARK PLUGS

Faulty or fouled spark plugs may perform well at

idle speed, but frequently fail at higher engine

speeds. Faulty plugs can be identified in a number of

ways: poor fuel economy, power loss, decrease in en-

gine speed, hard starting and, in general, poor en-

gine performance. Spark plugs also malfunction because of carbon

fouling, excessive electrode air gap, or a broken insu-

lator. Refer to the General Information Section of

this group for spark plug diagnosis.

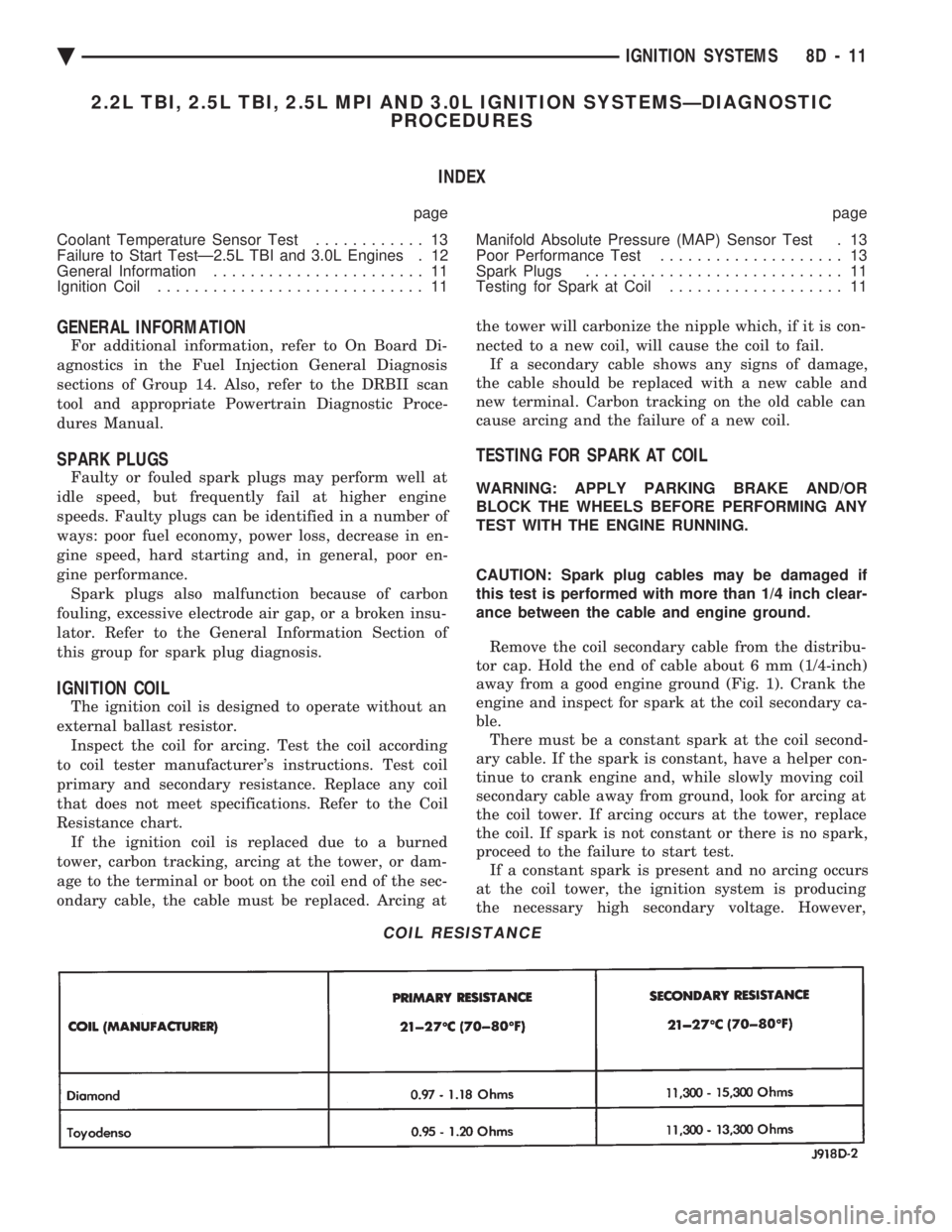

IGNITION COIL

The ignition coil is designed to operate without an

external ballast resistor. Inspect the coil for arcing. Test the coil according

to coil tester manufacturer's instructions. Test coil

primary and secondary resistance. Replace any coil

that does not meet specifications. Refer to the Coil

Resistance chart. If the ignition coil is replaced due to a burned

tower, carbon tracking, arcing at the tower, or dam-

age to the terminal or boot on the coil end of the sec-

ondary cable, the cable must be replaced. Arcing at the tower will carbonize the nipple which, if it is con-

nected to a new coil, will cause the coil to fail. If a secondary cable shows any signs of damage,

the cable should be replaced with a new cable and

new terminal. Carbon tracking on the old cable can

cause arcing and the failure of a new coil.

TESTING FOR SPARK AT COIL

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK THE WHEELS BEFORE PERFORMING ANY

TEST WITH THE ENGINE RUNNING.

CAUTION: Spark plug cables may be damaged if

this test is performed with more than 1/4 inch clear-

ance between the cable and engine ground.

Remove the coil secondary cable from the distribu-

tor cap. Hold the end of cable about 6 mm (1/4-inch)

away from a good engine ground (Fig. 1). Crank the

engine and inspect for spark at the coil secondary ca-

ble. There must be a constant spark at the coil second-

ary cable. If the spark is constant, have a helper con-

tinue to crank engine and, while slowly moving coil

secondary cable away from ground, look for arcing at

the coil tower. If arcing occurs at the tower, replace

the coil. If spark is not constant or there is no spark,

proceed to the failure to start test. If a constant spark is present and no arcing occurs

at the coil tower, the ignition system is producing

the necessary high secondary voltage. However,

COIL RESISTANCE

Ä IGNITION SYSTEMS 8D - 11

Page 456 of 2438

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐSERVICE PROCEDURES

INDEX

page page

Coolant Temperature Sensor ................ 14

Distributor Pick-UpÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines ....................... 18

Distributor ServiceÐ3.0L Engine ............. 18

DistributorÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines .............................. 17

Idle RPM TestÐ2.5L and 3.0L Engines ........ 16

Ignition CoilÐ2.2L TBI, 2.5L TBI and 2.5L MPI Engines ....................... 14 Ignition CoilÐ3.0L Engines

................. 15

Ignition Timing ProcedureÐ2.2L TBI, 2.5L TBI, 2.5L MPI, and 3.0L Engines ............... 16

Manifold Absolute Pressure (MAP) Sensor ServiceÐ2.5L TBI and 3.0L Engines ........ 22

Powertrain Control Module (PCM) ............ 14

Spark Plug Service ....................... 15

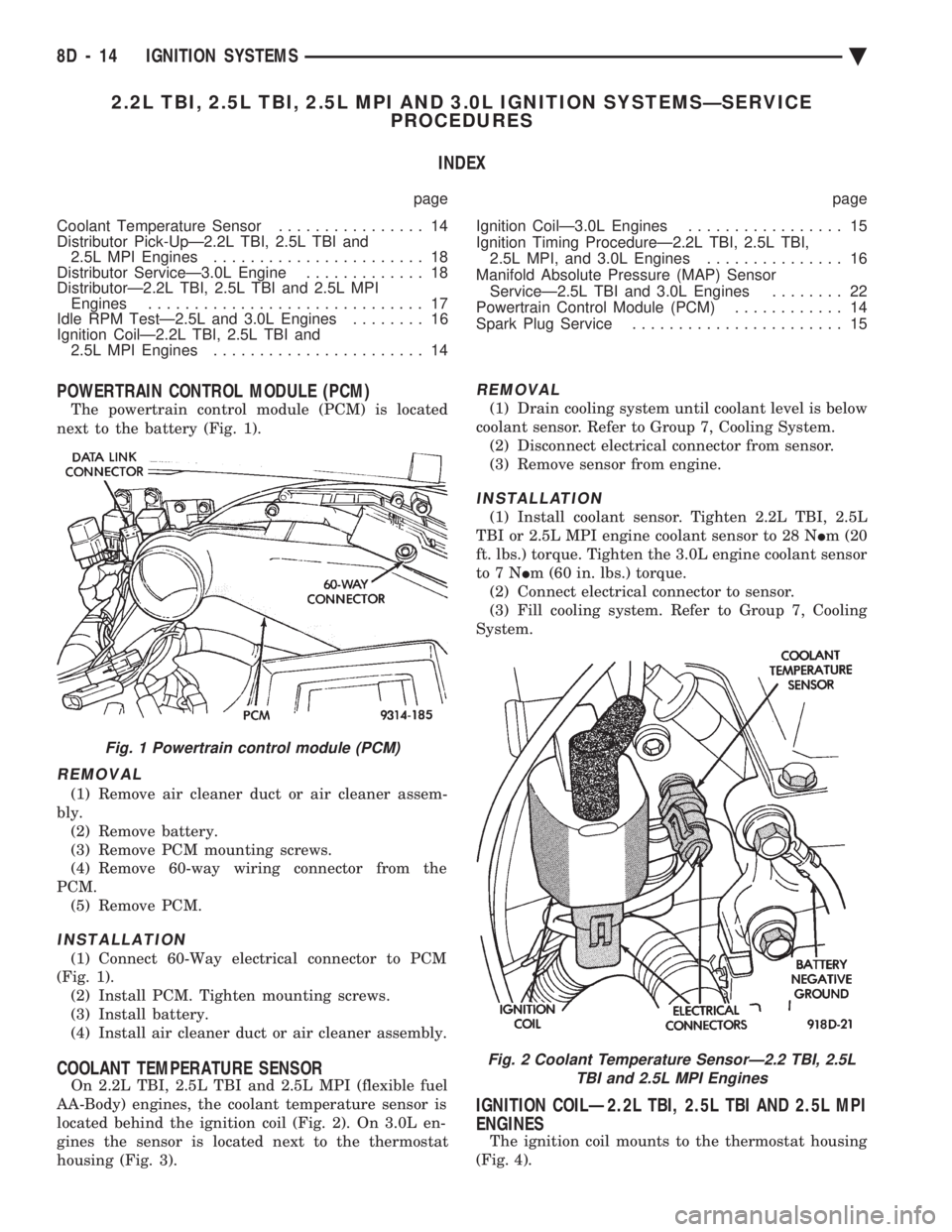

POWERTRAIN CONTROL MODULE (PCM)

The powertrain control module (PCM) is located

next to the battery (Fig. 1).

REMOVAL

(1) Remove air cleaner duct or air cleaner assem-

bly. (2) Remove battery.

(3) Remove PCM mounting screws.

(4) Remove 60-way wiring connector from the

PCM. (5) Remove PCM.

INSTALLATION

(1) Connect 60-Way electrical connector to PCM

(Fig. 1). (2) Install PCM. Tighten mounting screws.

(3) Install battery.

(4) Install air cleaner duct or air cleaner assembly.

COOLANT TEMPERATURE SENSOR

On 2.2L TBI, 2.5L TBI and 2.5L MPI (flexible fuel

AA-Body) engines, the coolant temperature sensor is

located behind the ignition coil (Fig. 2). On 3.0L en-

gines the sensor is located next to the thermostat

housing (Fig. 3).

REMOVAL

(1) Drain cooling system until coolant level is below

coolant sensor. Refer to Group 7, Cooling System. (2) Disconnect electrical connector from sensor.

(3) Remove sensor from engine.

INSTALLATION

(1) Install coolant sensor. Tighten 2.2L TBI, 2.5L

TBI or 2.5L MPI engine coolant sensor to 28 N Im (20

ft. lbs.) torque. Tighten the 3.0L engine coolant sensor

to7N Im (60 in. lbs.) torque.

(2) Connect electrical connector to sensor.

(3) Fill cooling system. Refer to Group 7, Cooling

System.

IGNITION COILÐ2.2L TBI, 2.5L TBI AND 2.5L MPI

ENGINES

The ignition coil mounts to the thermostat housing

(Fig. 4).

Fig. 1 Powertrain control module (PCM)

Fig. 2 Coolant Temperature SensorÐ2.2 TBI, 2.5L TBI and 2.5L MPI Engines

8D - 14 IGNITION SYSTEMS Ä

Page 458 of 2438

(3) Inspect the spark plug condition. Refer to Spark

Plug Condition in this section.

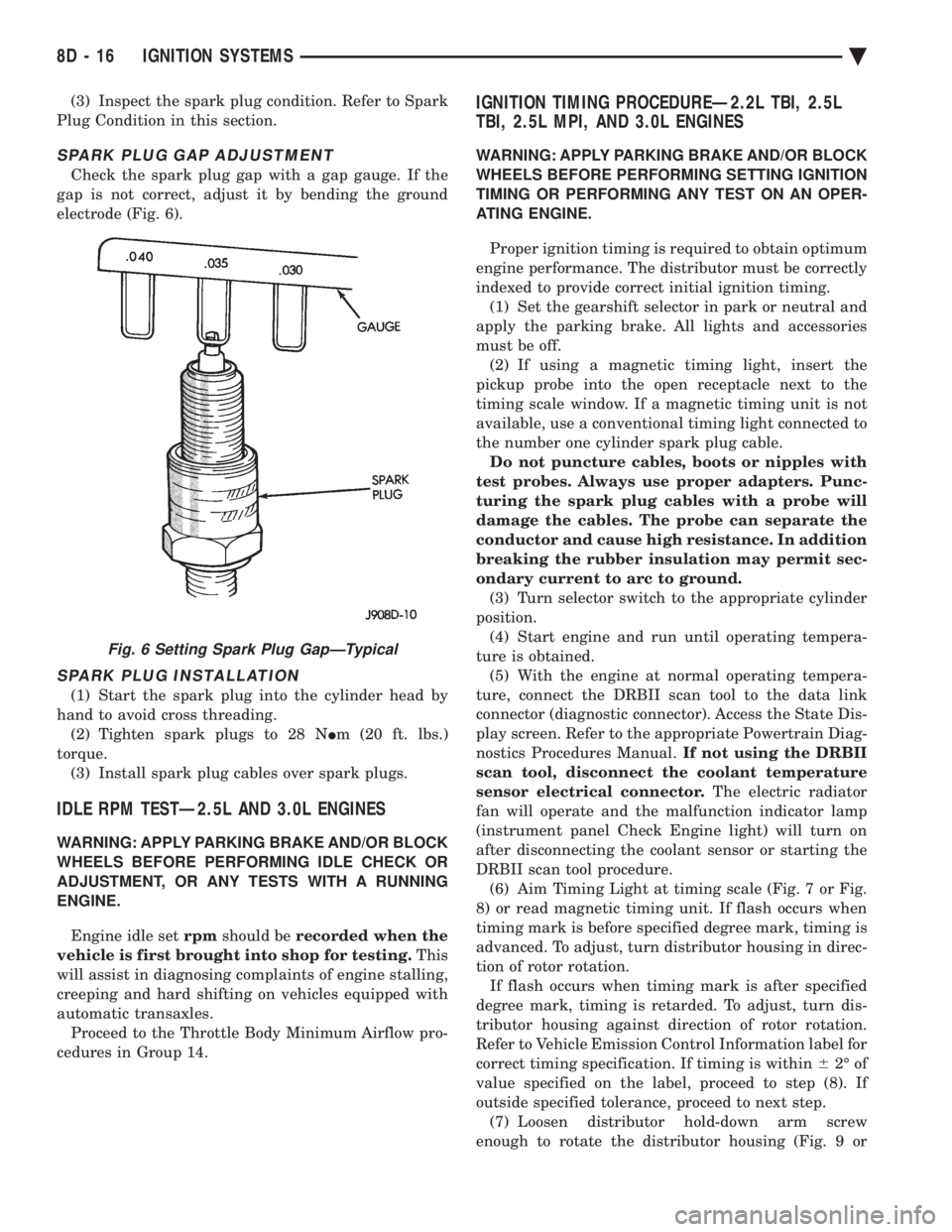

SPARK PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge. If the

gap is not correct, adjust it by bending the ground

electrode (Fig. 6).

SPARK PLUG INSTALLATION

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading. (2) Tighten spark plugs to 28 N Im (20 ft. lbs.)

torque. (3) Install spark plug cables over spark plugs.

IDLE RPM TESTÐ2.5L AND 3.0L ENGINES

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING IDLE CHECK OR

ADJUSTMENT, OR ANY TESTS WITH A RUNNING

ENGINE.

Engine idle set rpmshould be recorded when the

vehicle is first brought into shop for testing. This

will assist in diagnosing complaints of engine stalling,

creeping and hard shifting on vehicles equipped with

automatic transaxles. Proceed to the Throttle Body Minimum Airflow pro-

cedures in Group 14.

IGNITION TIMING PROCEDUREÐ2.2L TBI, 2.5L

TBI, 2.5L MPI, AND 3.0L ENGINES

WARNING: APPLY PARKING BRAKE AND/OR BLOCK

WHEELS BEFORE PERFORMING SETTING IGNITION

TIMING OR PERFORMING ANY TEST ON AN OPER-

ATING ENGINE.

Proper ignition timing is required to obtain optimum

engine performance. The distributor must be correctly

indexed to provide correct initial ignition timing. (1) Set the gearshift selector in park or neutral and

apply the parking brake. All lights and accessories

must be off. (2) If using a magnetic timing light, insert the

pickup probe into the open receptacle next to the

timing scale window. If a magnetic timing unit is not

available, use a conventional timing light connected to

the number one cylinder spark plug cable. Do not puncture cables, boots or nipples with

test probes. Always use proper adapters. Punc-

turing the spark plug cables with a probe will

damage the cables. The probe can separate the

conductor and cause high resistance. In addition

breaking the rubber insulation may permit sec-

ondary current to arc to ground. (3) Turn selector switch to the appropriate cylinder

position. (4) Start engine and run until operating tempera-

ture is obtained. (5) With the engine at normal operating tempera-

ture, connect the DRBII scan tool to the data link

connector (diagnostic connector). Access the State Dis-

play screen. Refer to the appropriate Powertrain Diag-

nostics Procedures Manual. If not using the DRBII

scan tool, disconnect the coolant temperature

sensor electrical connector. The electric radiator

fan will operate and the malfunction indicator lamp

(instrument panel Check Engine light) will turn on

after disconnecting the coolant sensor or starting the

DRBII scan tool procedure. (6) Aim Timing Light at timing scale (Fig. 7 or Fig.

8) or read magnetic timing unit. If flash occurs when

timing mark is before specified degree mark, timing is

advanced. To adjust, turn distributor housing in direc-

tion of rotor rotation. If flash occurs when timing mark is after specified

degree mark, timing is retarded. To adjust, turn dis-

tributor housing against direction of rotor rotation.

Refer to Vehicle Emission Control Information label for

correct timing specification. If timing is within 62É of

value specified on the label, proceed to step (8). If

outside specified tolerance, proceed to next step. (7) Loosen distributor hold-down arm screw

enough to rotate the distributor housing (Fig. 9 or

Fig. 6 Setting Spark Plug GapÐTypical

8D - 16 IGNITION SYSTEMS Ä

Page 466 of 2438

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐSYSTEM OPERATION INDEX

page page

Auto Shutdown (ASD) Relay and Fuel Pump Relay ................................ 32

Camshaft Position Sensor .................. 28

Coolant Temperature Sensor ................ 32

Crankshaft Position Sensor ................. 29

General Information ....................... 24 Ignition Coil

............................. 31

Knock SensorÐTurbo III Engine ............. 32

Manifold Absolute Pressure (MAP) Sensor ..... 32

Powertrain Control Module (PCM) ............ 24

Spark Plug Cables ....................... 25

Spark Plugs ............................ 26

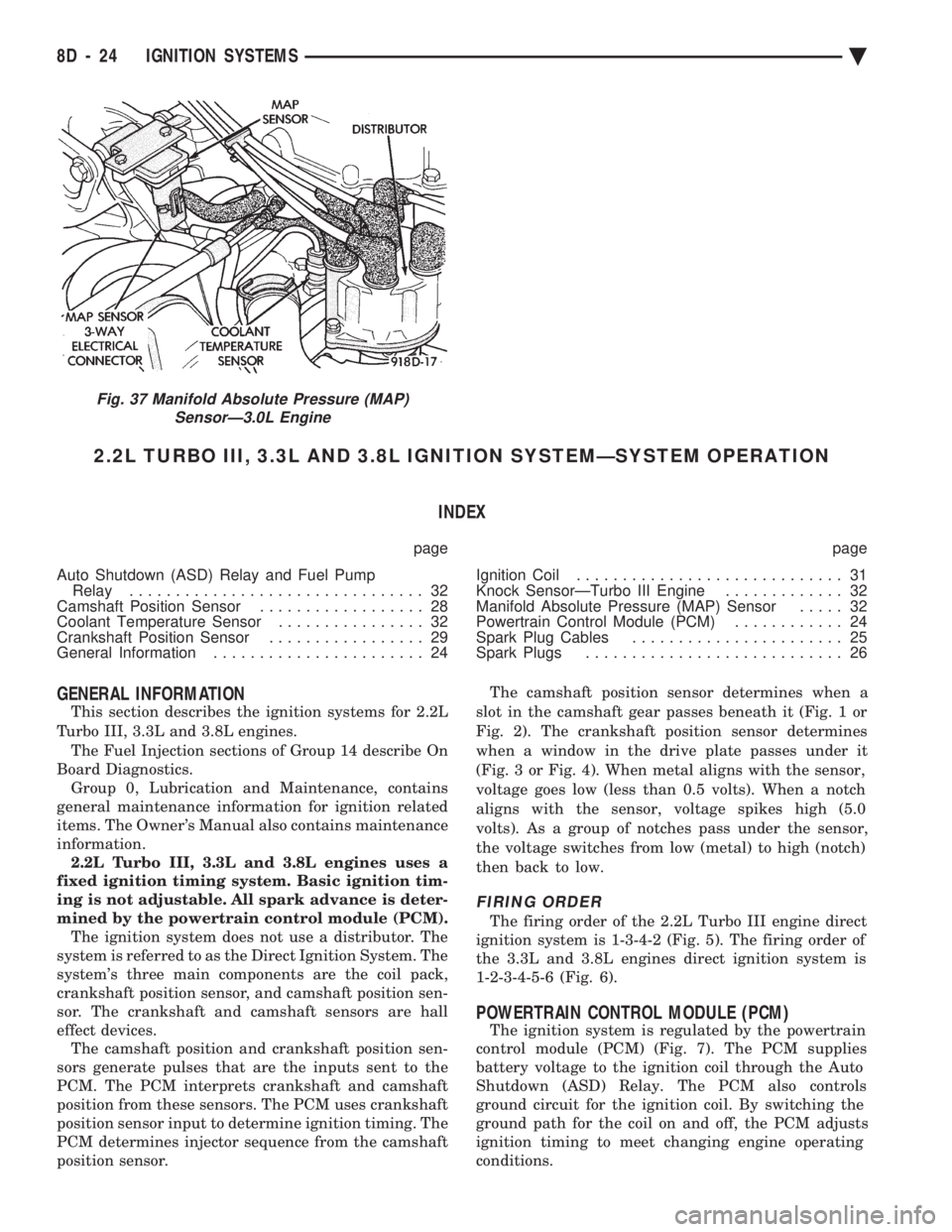

GENERAL INFORMATION

This section describes the ignition systems for 2.2L

Turbo III, 3.3L and 3.8L engines. The Fuel Injection sections of Group 14 describe On

Board Diagnostics. Group 0, Lubrication and Maintenance, contains

general maintenance information for ignition related

items. The Owner's Manual also contains maintenance

information. 2.2L Turbo III, 3.3L and 3.8L engines uses a

fixed ignition timing system. Basic ignition tim-

ing is not adjustable. All spark advance is deter-

mined by the powertrain control module (PCM). The ignition system does not use a distributor. The

system is referred to as the Direct Ignition System. The

system's three main components are the coil pack,

crankshaft position sensor, and camshaft position sen-

sor. The crankshaft and camshaft sensors are hall

effect devices. The camshaft position and crankshaft position sen-

sors generate pulses that are the inputs sent to the

PCM. The PCM interprets crankshaft and camshaft

position from these sensors. The PCM uses crankshaft

position sensor input to determine ignition timing. The

PCM determines injector sequence from the camshaft

position sensor. The camshaft position sensor determines when a

slot in the camshaft gear passes beneath it (Fig. 1 or

Fig. 2). The crankshaft position sensor determines

when a window in the drive plate passes under it

(Fig. 3 or Fig. 4). When metal aligns with the sensor,

voltage goes low (less than 0.5 volts). When a notch

aligns with the sensor, voltage spikes high (5.0

volts). As a group of notches pass under the sensor,

the voltage switches from low (metal) to high (notch)

then back to low.

FIRING ORDER

The firing order of the 2.2L Turbo III engine direct

ignition system is 1-3-4-2 (Fig. 5). The firing order of

the 3.3L and 3.8L engines direct ignition system is

1-2-3-4-5-6 (Fig. 6).

POWERTRAIN CONTROL MODULE (PCM)

The ignition system is regulated by the powertrain

control module (PCM) (Fig. 7). The PCM supplies

battery voltage to the ignition coil through the Auto

Shutdown (ASD) Relay. The PCM also controls

ground circuit for the ignition coil. By switching the

ground path for the coil on and off, the PCM adjusts

ignition timing to meet changing engine operating

conditions.

Fig. 37 Manifold Absolute Pressure (MAP) SensorÐ3.0L Engine

8D - 24 IGNITION SYSTEMS Ä