radiator CHRYSLER CARAVAN 2002 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1340 of 2399

(9) Lower vehicle and fill crankcase with specified

type and amount of engine oil. (Refer to LUBRICA-

TION & MAINTENANCE/FLUID TYPES -

DESCRIPTION)

(10) Install oil fill cap.

(11) Start engine and inspect for leaks.

(12) Stop engine and inspect oil level.

NOTE: Care should be exercised when disposing

used engine oil after it has been drained from a

vehicle engine. Refer to the WARNING listed above.

STANDARD PROCEDURE - ENGINE OIL LEVEL

CHECK

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,

allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading (Fig. 102). Add only when the level is at or

below the ADD mark.

Fig. 102 Engine Oil Level Dipstick and Fill Locations

1 - COOLANT RECOVERY CONTAINER 3 - ENGINE OIL LEVEL DIPSTICK

2 - ENGINE OIL FILL CAP 4 - RADIATOR PRESSURE CAP

Fig. 101 Engine Oil Drain Plug and Oil Filter

1 - DRAIN PLUG

2 - OIL FILTER

RSENGINE 3.3/3.8L9 - 139

OIL (Continued)

ProCarManuals.com

Page 1351 of 2399

(11) Install air cleaner and air inlet hose assembly.

(12) Connect the inlet air temperature (IAT) sen-

sor electrical connector.

(13) Connect battery negative cable.

INTAKE MANIFOLD - LOWER

REMOVAL - LOWER INTAKE MANIFOLD

(1) Perform fuel system pressure release procedure

(before attempting any repairs).(Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE)

(2) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(3) Remove the upper intake manifold. (Refer to 9

- ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL)

(4) Remove the fuel line. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL LINES - STANDARD

PROCEDURE) (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE)

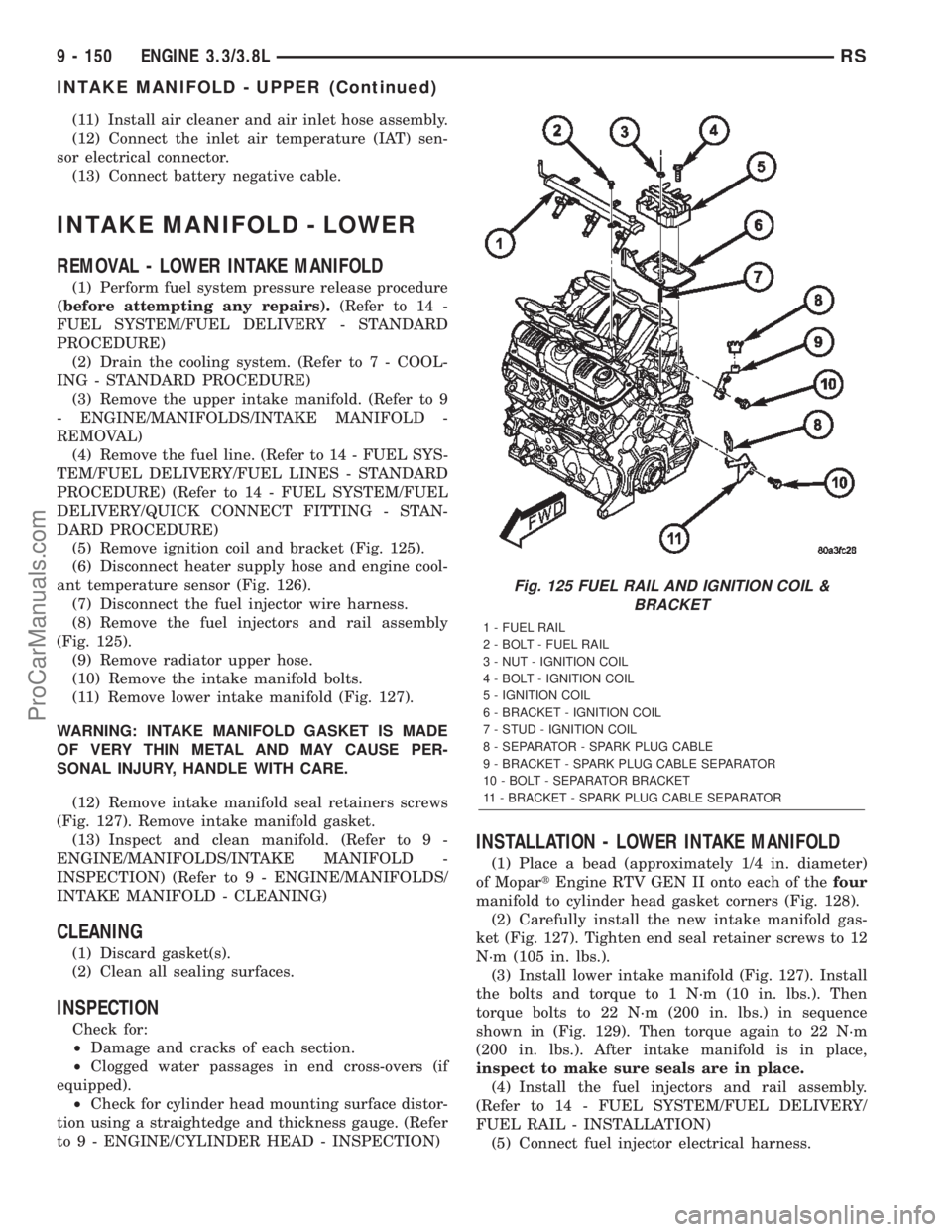

(5) Remove ignition coil and bracket (Fig. 125).

(6) Disconnect heater supply hose and engine cool-

ant temperature sensor (Fig. 126).

(7) Disconnect the fuel injector wire harness.

(8) Remove the fuel injectors and rail assembly

(Fig. 125).

(9) Remove radiator upper hose.

(10) Remove the intake manifold bolts.

(11) Remove lower intake manifold (Fig. 127).

WARNING: INTAKE MANIFOLD GASKET IS MADE

OF VERY THIN METAL AND MAY CAUSE PER-

SONAL INJURY, HANDLE WITH CARE.

(12) Remove intake manifold seal retainers screws

(Fig. 127). Remove intake manifold gasket.

(13) Inspect and clean manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSPECTION) (Refer to 9 - ENGINE/MANIFOLDS/

INTAKE MANIFOLD - CLEANING)

CLEANING

(1) Discard gasket(s).

(2) Clean all sealing surfaces.

INSPECTION

Check for:

²Damage and cracks of each section.

²Clogged water passages in end cross-overs (if

equipped).

²Check for cylinder head mounting surface distor-

tion using a straightedge and thickness gauge. (Refer

to 9 - ENGINE/CYLINDER HEAD - INSPECTION)

INSTALLATION - LOWER INTAKE MANIFOLD

(1) Place a bead (approximately 1/4 in. diameter)

of MopartEngine RTV GEN II onto each of thefour

manifold to cylinder head gasket corners (Fig. 128).

(2) Carefully install the new intake manifold gas-

ket (Fig. 127). Tighten end seal retainer screws to 12

N´m (105 in. lbs.).

(3) Install lower intake manifold (Fig. 127). Install

the bolts and torque to 1 N´m (10 in. lbs.). Then

torque bolts to 22 N´m (200 in. lbs.) in sequence

shown in (Fig. 129). Then torque again to 22 N´m

(200 in. lbs.). After intake manifold is in place,

inspect to make sure seals are in place.

(4) Install the fuel injectors and rail assembly.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL RAIL - INSTALLATION)

(5) Connect fuel injector electrical harness.

Fig. 125 FUEL RAIL AND IGNITION COIL &

BRACKET

1 - FUEL RAIL

2 - BOLT - FUEL RAIL

3 - NUT - IGNITION COIL

4 - BOLT - IGNITION COIL

5 - IGNITION COIL

6 - BRACKET - IGNITION COIL

7 - STUD - IGNITION COIL

8 - SEPARATOR - SPARK PLUG CABLE

9 - BRACKET - SPARK PLUG CABLE SEPARATOR

10 - BOLT - SEPARATOR BRACKET

11 - BRACKET - SPARK PLUG CABLE SEPARATOR

9 - 150 ENGINE 3.3/3.8LRS

INTAKE MANIFOLD - UPPER (Continued)

ProCarManuals.com

Page 1356 of 2399

(3) Position heat shield on manifold (Fig. 136).

(4) Install the remaining manifold attaching bolts.

Tighten all bolts to 23 N´m (200 in. lbs.).

(5) Install and tighten heat shield attaching nut to

12 N´m (105 in. lbs.) (Fig. 136).

(6) Connect battery negative cable.

VALVE TIMING

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVE TIMING

VERIFICATION

(1) Remove front cylinder head cover and all 6

spark plugs.

(2) Rotate engine until the #2 piston is at TDC of

the compression stroke.

(3) Install a degree wheel on the crankshaft pulley.

(4) With proper adaptor, install a dial indicator

into #2 spark plug hole. Using the indicator find TDC

on the compression stroke.

(5) Position the degree wheel to zero.

(6) Remove dial indicator from spark plug hole.

(7) Place a 5.08 mm (0.200 in.) spacer between the

valve stem tip of #2 intake valve and rocker arm pad.

Allow tappet to bleed down to give a solid tappet

effect.

(8) Install a dial indicator so plunger contacts the

#2 intake valve spring retainer as nearly perpendic-

ular as possible. Zero the indicator.

(9) Rotate the engine clockwise until the intake

valve has lifted .254 mm (0.010 in.).

CAUTION: Do not turn crankshaft any further clock-

wise as intake valve might bottom and result in

serious damage.

(10) Degree wheel should read 6 degrees BTDC to

6 degrees ATDC.

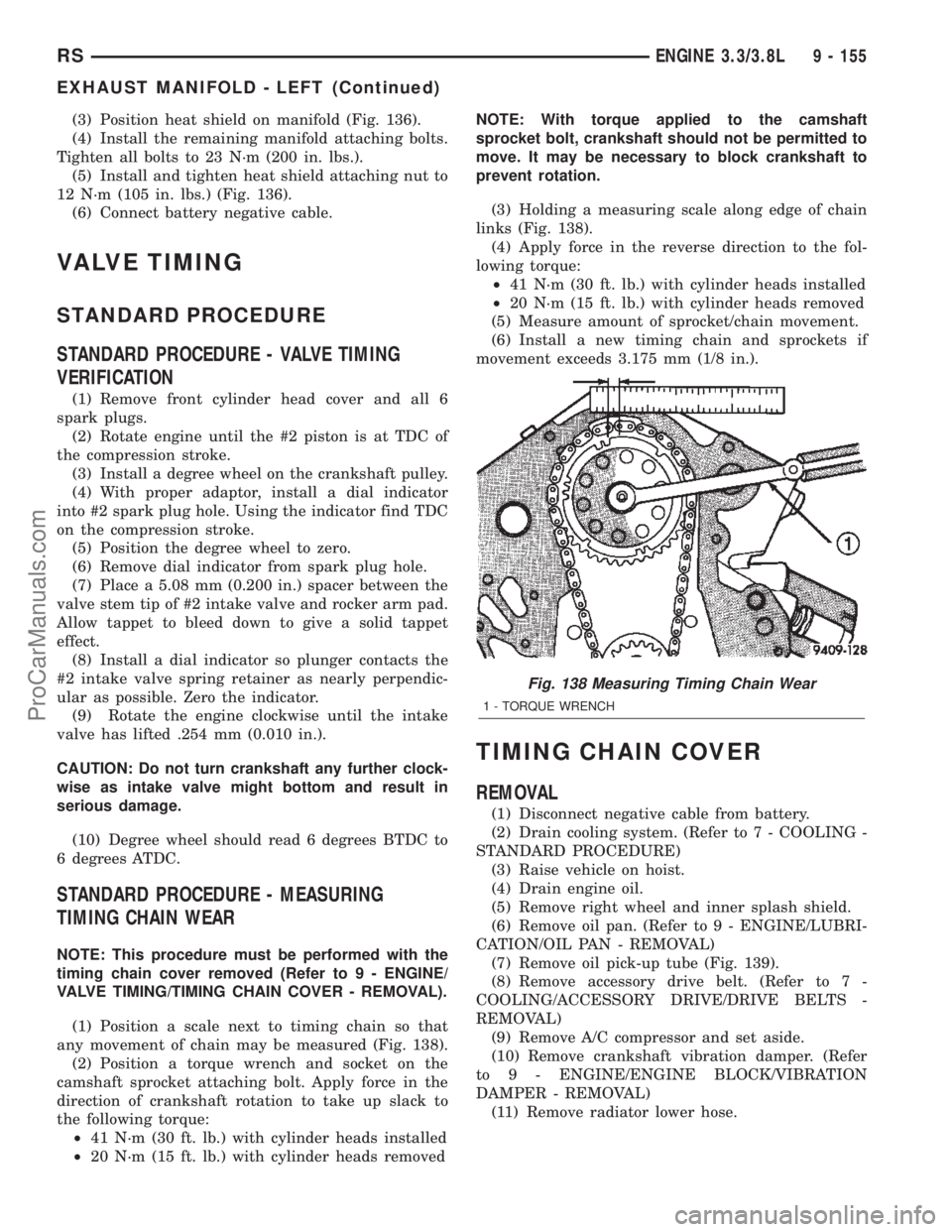

STANDARD PROCEDURE - MEASURING

TIMING CHAIN WEAR

NOTE: This procedure must be performed with the

timing chain cover removed (Refer to 9 - ENGINE/

VALVE TIMING/TIMING CHAIN COVER - REMOVAL).

(1) Position a scale next to timing chain so that

any movement of chain may be measured (Fig. 138).

(2) Position a torque wrench and socket on the

camshaft sprocket attaching bolt. Apply force in the

direction of crankshaft rotation to take up slack to

the following torque:

²41 N´m (30 ft. lb.) with cylinder heads installed

²20 N´m (15 ft. lb.) with cylinder heads removedNOTE: With torque applied to the camshaft

sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block crankshaft to

prevent rotation.

(3) Holding a measuring scale along edge of chain

links (Fig. 138).

(4) Apply force in the reverse direction to the fol-

lowing torque:

²41 N´m (30 ft. lb.) with cylinder heads installed

²20 N´m (15 ft. lb.) with cylinder heads removed

(5) Measure amount of sprocket/chain movement.

(6) Install a new timing chain and sprockets if

movement exceeds 3.175 mm (1/8 in.).

TIMING CHAIN COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(3) Raise vehicle on hoist.

(4) Drain engine oil.

(5) Remove right wheel and inner splash shield.

(6) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL)

(7) Remove oil pick-up tube (Fig. 139).

(8) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(9) Remove A/C compressor and set aside.

(10) Remove crankshaft vibration damper. (Refer

to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL)

(11) Remove radiator lower hose.

Fig. 138 Measuring Timing Chain Wear

1 - TORQUE WRENCH

RSENGINE 3.3/3.8L9 - 155

EXHAUST MANIFOLD - LEFT (Continued)

ProCarManuals.com

Page 1358 of 2399

(3) Rotate crankshaft so that the oil pump drive

flats are in the vertical position.

(4) Position oil pump inner rotor so the mating

flats are in the same position as the crankshaft drive

flats (Fig. 144).CAUTION: Make sure the oil pump is engaged on

the crankshaft correctly or severe damage may

result.

(5) Install timing cover (Fig. 144).

(6) Install timing chain cover bolts. Tighten M8

bolts to 27 N´m (20 ft. lbs.) and M10 bolts to 54 N´m

(40 ft. lbs.) (Fig. 145).

(7) Install crankshaft front oil seal. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - FRONT - INSTALLATION)

(8) Install water pump and pulley. (Refer to 7 -

COOLING/ENGINE/WATER PUMP - INSTALLA-

TION)

(9) Install crankshaft vibration damper. (Refer to 9

- ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

(10) Install engine mount bracket (Fig. 142) and

tighten M10 to 54 N´m (40 ft. lbs.), M8 bolt to 28

N´m (21 ft. lb. lbs.).

(11) Install idler pulley on engine mount bracket

(Fig. 142).

(12) Install right side engine mount. (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION)

(13) Install camshaft position sensor (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/CAMSHAFT

POSITION SENSOR - INSTALLATION).

(14) Connect the heater return hose at rear of tim-

ing chain cover (Fig. 140) or at water pump inlet

tube (if engine oil cooler equipped) (Fig. 141).

(15) Connect the radiator lower hose.

(16) Install A/C compressor.

(17) Install accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

Fig. 142 Engine Mount Bracket

1 - CAMSHAFT SENSOR

2 - BOLT - CAMSHAFT SENSOR

3 - BOLT - MOUNT BRACKET (VERTICAL)

4 - BRACKET - ENGINE MOUNT

5 - BOLT - MOUNT BRACKET (HORIZONTAL)

6 - PULLEY - IDLER

7 - BOLT - IDLER PULLEY

8 - SPACER - IDLER PULLEY BOLT

9 - BOLT - MOUNT BRACKET (HORIZONTAL)

Fig. 143 Power Steering Pump Strut

1 - BOLT - LOWER

2 - STRUT - P/S PUMP

3 - BOLT - UPPER

Fig. 144 Timing Chain Cover and Gasket

1 - GASKET

2 - TIMING CHAIN COVER

RSENGINE 3.3/3.8L9 - 157

TIMING CHAIN COVER (Continued)

ProCarManuals.com

Page 1366 of 2399

(17) Remove battery shield.

(18) Remove charge air cooler outlet hose.

(19) Remove charge air cooler inlet hose (Fig. 6).

(20) Disconnect upper radiator hose at engine (Fig.

7).

(21) Disconnect lower radiator hose at engine (Fig.

7).

(22) Disconnet brake booster vacuum supply hose.

(23) Disconnect heater core return hose at engine.

(24) Disconnect egr solenoid vacuum line at brake

booster check valve.

(25) Disconnect fuel injector, cam sensor, boost

pressure/intake air temp sensor, fuel rail high pres-

sure, and egr solenoid connectors (Fig. 8).

(26) Disconnect generator electrical connectors.

(27) Disconnect coolant temp sensor and glow plug

electrical connectors.

(28) Disconnect injection pump and A/C compres-

sor electrical connectors.

(29) Disconnect starter electrical connectors.

(30) Disconnect ground wires at engine block.

(31) Raise vehicle on hoist.

(32) Disconnect oil temp sensor, oil pressure sen-

sor, engine speed sensor, and vehicle speed sensor

electrical connector (Fig. 9).(33) Remove front wheels.

(34) Remove the suspension cradle assembly (Refer

to 13 - FRAME & BUMPERS/FRAME/ENGINE

CRADLE CROSSMEMBER - REMOVAL).

(35) Remove both axle shaft assemblies (Refer to 3

- DIFFERENTIAL & DRIVELINE/HALF SHAFT -

REMOVAL).

(36) Disconnect the clutch slave cylinder quick dis-

connect line (RHD only)(Refer to 6 - CLUTCH/SLAVE

CYLINDER - REMOVAL).

(37) Disconnect reverse lamp connector.

(38) Disconnect shifter cables at the tranmission

(Refer to 21 - TRANSMISSION/TRANSAXLE/MAN-

UAL/GEAR SHIFT CABLE - REMOVAL).

(39) Disconnect exhaust pipe from the turbo-

charger downpipe and reposition to right side of vehi-

cle.

(40) Disconnect cabin heater coolant line (Refer to

24 - HEATING & AIR CONDITIONING/CABIN

HEATER/HEATER UNIT - REMOVAL).

(41) Remove front engine mount bracket retaining

bolts from lower radiator support

(42) Lower vehicle. Evacuate the A/C system

(Refer to 24 - HEATING & AIR CONDITIONING/

Fig. 6 CHARGE AIR COOLER HOSES

1 - COOLING MODULE

2 - BYPASS HOSE

3 - UPPER RADIATOR HOSE

4 - CHARGE AIR COOLER OULET HOSE

5 - CHARGE AIR COOLER INLET HOSE

6 - LOWER RADIATOR HOSE

7 - CHARGE AIR COOLER

Fig. 7 UPPER AND LOWER RADIATOR HOSES

1 - COOLANT BYPASS HOSE

2 - RADIATOR ASSEMBLY

3 - UPPER RADIATOR HOSE

4 - COOLING FAN

5 - LOWER RADIATOR HOSE

6 - CHARGE AIR COOLER

7 - RADIATOR BRACKET

RGENGINE9a-5

ENGINE 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 1368 of 2399

INSTALLATION

INSTALLATION - 2.5L TURBO DIESEL ENGINE

(1) Reassembly engine and transmission assembly

and install on engine cradle.

(2) Position engine and cradle assembly under

vehicle.

(3) Slowly lower the vehicle down over the engine

and cradle assembly.

(4) Install right engine mount bolts. Torque to

54N´m (40 ft. lbs.)

(5) Install left engine mount through bolt. Torque

to 75N´m (55 ft. lbs.)

(6) Raise vehicle and engine from engine cradle.

(7) Attach front engine mount bracket to lower

radiator support. Torque to 54N´m (40 ft. lbs.)

(8) Connect cabin heater coolant hose.

(9) Connect exhaust pipe to the turbocharger

downpipe flange. Torque to 28 N´m (250 in. lbs.)

(10) Connect reverse lamp electrical connector at

transmission.

(11) Connect both shifter cables (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL/GEAR

SHIFT CABLE - INSTALLATION).

(12) Connect the clutch slave cylinder quick dis-

connect connector (RHD only)(Refer to 6 - CLUTCH/

SLAVE CYLINDER - INSTALLATION).

(13) Install engine harness into bracket on trans-

mission.

(14) Lower vehicle.

(15) Connect fuel supply and return lines.

(16) Connect A/C lines to A/C compressor. Torque

to 23N´m (17 ft. lbs.)

(17) Route engine wiring harnes to proper location.

(18) Connect engine harness ground cables to

engine block

(19) Connect starter solenoid electrical connector

and battery feed wire to starter. Torque to 10N´m (90

in. lbs.)

(20) Connect A/C compressor, injection pump, glow

plugs, and coolant temperature sensor electrical con-

nectors.

(21) Connect generator electrical connector. Torque

to 9N´m (75 in. lbs.)

(22) Connect the fuel injector, fuel pressure sensor,

boost pressure/intake air temp sensor, cam sensor,

and egr solenoid electrical connectors (Fig. 8).

(23) Connect egr solenoid vacuum supply line to

brake boost vacuum supply line.(24) Connect brake booster vacuum supply line.

(25) Connect heater core return hose to coolant

pipe.

(26) Connect lower radiator hose to engine (Fig. 7).

(27) Install charger air cooler inlet hose (Fig. 6).

(28) Install charge air cooler outlet hose (Fig. 6).

(29) Connect upper radiator hose to engine (Fig.

7).

(30) Install battery shield.

(31) Install coolant reserve pressure container

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESS CONTAINER - INSTALLATION).

(32) Install power steering reservoir and bracket

(Fig. 4).

(33) Raise vehicle

(34) Connect oil pressure sensor, oil temperature

sensor, engine speed sensor, and vehicle speed sensor

electrical connector (Fig. 9).

(35) Install suspension cradle in vehicle (Refer to

13 - FRAME & BUMPERS/FRAME/ENGINE CRA-

DLE CROSSMEMBER - INSTALLATION).

(36) Install both axle shaft assemblies (Refer to 3 -

DIFFERENTIAL & DRIVELINE/HALF SHAFT -

INSTALLATION).

(37) Connect the power steering supply, pressure,

and return lines to power steering pump (Fig. 4).

(38) Install the power steering line brackets on oil

pan (Fig. 4).

(39) Install lower splash shield and side panels.

(40) Install both front wheel and tire assemblies.

(41) Lower vehicle.

(42) Install air cleaner housing, MAF sensor, and

air intake tube assembly (Fig. 3).

(43) Refill transmission to proper level (Refer to 21

- TRANSMISSION/TRANSAXLE/MANUAL/FLUID -

STANDARD PROCEDURE).

(44) Refill engine coolant (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(45) Recharge A/C system (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/REFRIGER-

ANT - STANDARD PROCEDURE) .

(46) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION) (Fig. 2).

(47) Connect negative battery cable.

INSTALLATION - ENGINE COVER

(1) Install engine cover on engine.

(2) Install the engine cover mounting bolts (Fig.

10).

RGENGINE9a-7

ENGINE 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 1381 of 2399

(13) Remove rocker arm and lifter assemblies from

cylinder head.

(14) Remove cylinder head cover/intake manifold

gasket from cylinder head.

(15) Disconnect glow plug and engine coolant tem-

perture electrical connectors.

(16) Remove coolant recovery pressure container

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESS CONTAINER - REMOVAL).

(17) Remove thermostat housing to upper radiator

hose pipe (Fig. 16).

(18) Remove turbocharger outlet to charge air

cooler pipe (Fig. 16).(19) Remove exhaust manifold heat shield (Fig.

17).

(20) Remove exhaust manifold retaining nuts (Fig.

17).

(21) Slide exhaust manifold and turbocharger off of

exhaust manifold studs (Fig. 17).

(22) Remove cylinder head bolts.

Fig. 16 TURBOCHARGER AND COOLANT PIPES

1 - TURBOCHARGER OUTLET PIPE RETAINING BOLT

2 - TURBOCHARGER OUTLET PIPE

3 - ADAPTER HOSE

4 - HEAT SHIELD

5 - HOSE CLAMPS

6 - TURBOCHARGER INLET PIPE RETAINING BOLT

7 - TURBOCHARGER INLET PIPE

8 - ADAPTER HOSE

9 - HOSE CLAMPS

10 - CLAMP

11 - EGR VALVE TO INTAKE AIR INLET PIPE

12 - CLAMP

13 - THERMOSTAT HOUSING TO UPPER RADIATOR HOSE

PIPE

Fig. 17 EXHAUST MANIFOLD AND

TURBOCHARGER

1 - TURBOCHARGER OIL SUPPLY BANJO BOLT

2 - COPPER WASHER

3 - EXHAUST MANIFOLD GASKET

4 - COPPER WASHER

5 - EXHAUST MANIFOLD HEAT SHIELD RETAINING BOLT

6 - TURBOCHARGER

7 - ENGINE LIFT HOOK

8 - ENGINE LIFT HOOK RETAINING BOLT

9 - SPACER

10 - EXHAUST MANIFOLD RETAINING NUT

11 - TURBOCHARGER OIL RETURN HOSE

12 - HOSE CLAMPS

13 - EXHAUST MANIFOLD STUDS

9a - 20 ENGINERG

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1383 of 2399

(5) Slide exhaust manifold and turbocharger on

exhaust manifold studs (Fig. 17).

(6) Install exhaust manifold retaining nuts. Torque

nuts to 32.4N´m.

(7) Install exhaust manifold heat shield (Fig. 17).

Torque bolts to 27.5N´m.

(8) Install turbocharger outlet to charge air cooler

pipe (Fig. 16).

(9) Install thermostat housing to upper radiator

hose pipe (Fig. 16). Install retaining bolt and torque

to 47.1N´m.

(10) Install coolant recovery pressure container

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESS CONTAINER - INSTALLATION).

(11) Connect glow plug and coolant temperature

sensor electrical connectors.

(12) Install new cylinder head cover/intake mani-

fold gasket.

(13) Install rocker arm and lifter assemblies.Be

sure to put rocker arm and lifter assemblies in

same location as removed.

(14) Install cylinder head cover/intake manifold

(Fig. 15)(Refer to 9 - ENGINE/CYLINDER HEAD/

CYLINDER HEAD COVER(S) - INSTALLATION).

(15) Install timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(16) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(17) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(18)Remove crankshaft and both camshaft

locking pins at this time(Refer to 9 - ENGINE/

VALVE TIMING - STANDARD PROCEDURE).

(19) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(20) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(21) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(22) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(23) Install air cleaner housing assembly.

(24) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(25) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(26) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

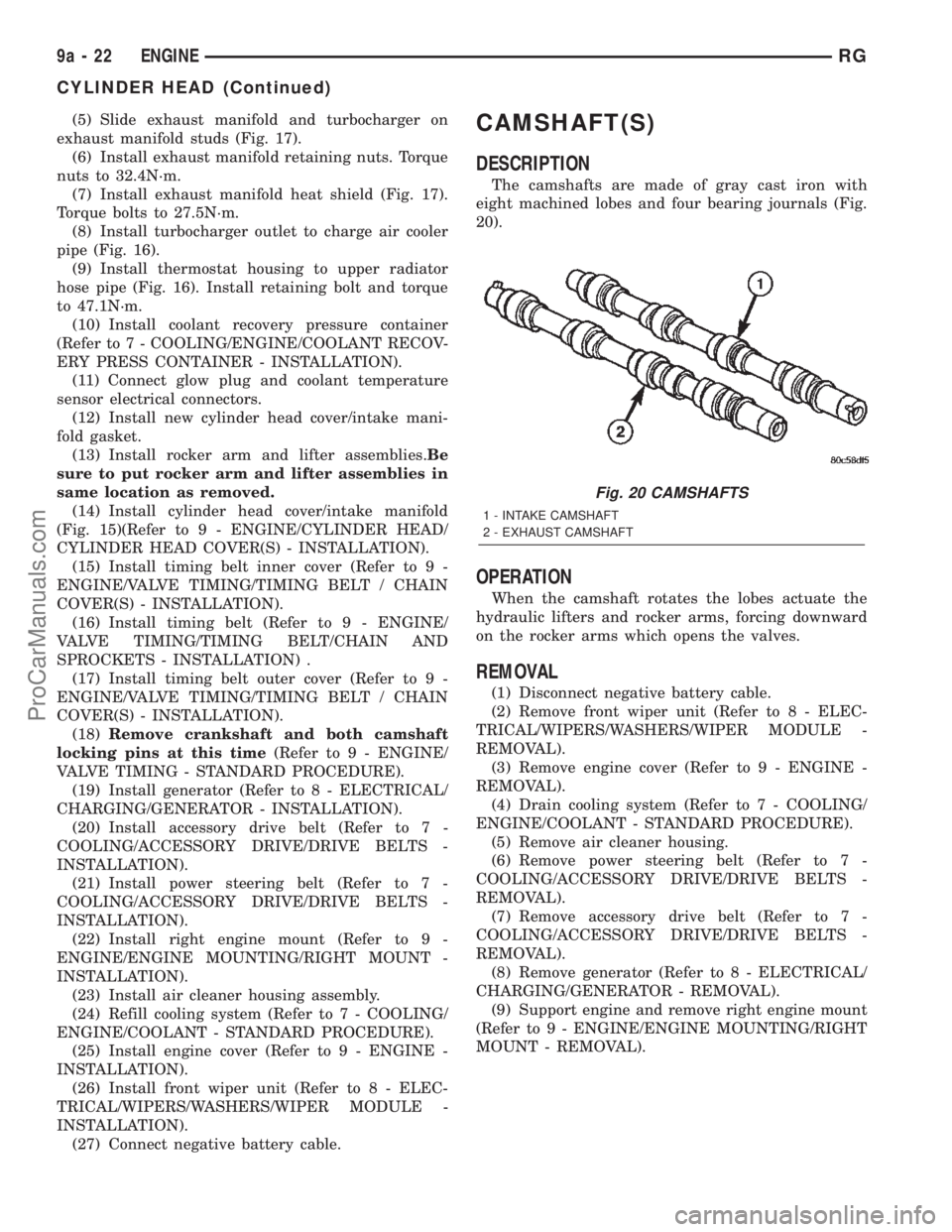

(27) Connect negative battery cable.CAMSHAFT(S)

DESCRIPTION

The camshafts are made of gray cast iron with

eight machined lobes and four bearing journals (Fig.

20).

OPERATION

When the camshaft rotates the lobes actuate the

hydraulic lifters and rocker arms, forcing downward

on the rocker arms which opens the valves.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(3) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(4) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(5) Remove air cleaner housing.

(6) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(8) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

(9) Support engine and remove right engine mount

(Refer to 9 - ENGINE/ENGINE MOUNTING/RIGHT

MOUNT - REMOVAL).

Fig. 20 CAMSHAFTS

1 - INTAKE CAMSHAFT

2 - EXHAUST CAMSHAFT

9a - 22 ENGINERG

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1414 of 2399

VALVE TIMING

STANDARD PROCEDURE - LOCKING ENGINE

90É AFTER TDC

(1) Disconnect negative battery cable.

(2) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).

(3) Rotate engine untill notch in hub is in the fol-

lowing position (Fig. 84).

(4) Special tool VM.1068 can be install in engine

block as shown at this time (Fig. 85). This will lock

the engine at 90É after TDC.

(5) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(6) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(7) Remove plug in cylinder head cover/intake

manifold and insert VM.1053 to lock exhaust cam-

shaft in position (Fig. 86).

(8) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

Fig. 84 CRANKSHAFT HUB ALIGNMENT

1 - VIBRATION DAMPER/CRANKSHAFT PULLEY

2 - CRANKSHAFT HUB NOTCH

3 - VIBRATION DAMPER/CRANKSHAFT PULLEY TO

CRANKSHAFT HUB BOLTS

Fig. 85 TDC AND 90 DEGREES AFTER TDC

ALIGNMENT PIN LOCATION

1 - ENGINE BLOCK

2 - VM.1051 TDC PIN OR VM.1068 90 DEGREES ATDC PIN

3 - FLYWHEEL

Fig. 86 EXHAUST CAMSHAFT LOCKING PIN

VM.1053

1 - EXHAUST MANIFOLD HEAT SHIELD

2 - EXHAUST CAMSHAFT LOCKING PIN VM.1053

3 - COOLANT TUBE FROM THERMOSTAT HOUSING TO UPPER

RADIATOR HOSE

4 - CYLINDER HEAD COVER/INTAKE MANIFOLD

RGENGINE9a-53

ProCarManuals.com

Page 1437 of 2399

TURBOCHARGER

REMOVAL

The exhaust manifold and turbocharger cannot be

remove with the engine in vehicle.

(1) Remove engine from vehicle and mount on

engine stand (Refer to 9 - ENGINE - REMOVAL).

(2) Remove thermostat to upper radiator hose pipe

(Fig. 5).(3) Remove engine lift hook (Fig. 6).

(4) Remove exhaust manifold heat shield (Fig. 6).

(5) Disconnect turbocharger oil supply and return

lines at turbocharger (Fig. 6).

(6) Remove exhaust manifold retaining nuts (Fig.

6).

(7) Remove exhaust manifold and turbocharger

from engine (Fig. 6).

Fig. 5 TURBOCHARGER AND COOLANT PIPES

1 - TURBOCHARGER OUTLET PIPE RETAINING BOLT

2 - TURBOCHARGER OUTLET PIPE

3 - ADAPTER HOSE

4 - HEAT SHIELD

5 - HOSE CLAMPS

6 - TURBOCHARGER INLET PIPE RETAINING BOLT

7 - TURBOCHARGER INLET PIPE

8 - ADAPTER HOSE

9 - HOSE CLAMPS

10 - CLAMP

11 - EGR VALVE TO INTAKE AIR INLET PIPE

12 - CLAMP

13 - THERMOSTAT HOUSING TO UPPER RADIATOR HOSE

PIPE

Fig. 6 EXHAUST MANIFOLD AND TURBOCHARGER

1 - TURBOCHARGER OIL SUPPLY BANJO BOLT

2 - COPPER WASHER

3 - EXHAUST MANIFOLD GASKET

4 - COPPER WASHER

5 - EXHAUST MANIFOL HEAT SHIEL RETAINING BOLT

6 - TURBOCHARGER

7 - ENGINE LIFT HOOK

8 - ENGINE LIFT HOOK RETAINING BOLT

9 - SPACER

10 - EXHAUST MANIFOLD RETAINING NUT

11 - TURBOCHARGER OIL RETURN HOSE

12 - HOSE CLAMPS

13 - EXHAUST MANIFOLD STUDS

11a - 4 EXHAUST SYSTEM AND TURBOCHARGERRG

ProCarManuals.com