key CHRYSLER CARAVAN 2002 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 336 of 2399

ignition switch. This chime will operate for all igni-

tion positions except ON and START.

With the ignition switch in the OFF position

O N LY:

²Driver's door is open/ajar (door ajar switch is

closed to ground)

²Key is in the ignition switch (ignition is in the

LOCK position)

The chime will sound until one of the above condi-

tions is removed or until battery protection time out

(15 min.) has expired. Chime rate: 168 to 192 chimes

per minute.

To test the key-in ignition function, insert key into

the ignition and open drivers door. Do not turn igni-

tion ON. Chime should sound until key is removed

from ignition or drivers door is closed.

For diagnosis and testing of the Key-In chime for

other ignition positions, use the same testing proce-

dure as above but with the key in the accessory or

unlock position.

DIAGNOSIS AND TESTING - LOW OIL

PRESSURE CHIME

The low oil pressure chime will warn the driver

that the engine oil pressure is low. The oil pressure

switch will close to ground during a low oil pressure

condition. The oil pressure lamp will illuminate in

the message center. The PCM will monitor the oil

pressure switch and signal a low oil pressure condi-

tion. A continuous four minute warning chime will

sound and the oil pressure lamp will come ON when

the following conditions are met:

²Ignition on and engine not cranking

²Engine running at 420 to 480 rpm for 10 sec-

onds

²Oil pressure switch closed to ground for (1 sec-

ond minimum, 2 seconds maximum)

Chime rate: 168 to 192 chimes per minute.

DIAGNOSIS AND TESTING - SEAT BELT CHIME

The seat belt chime will sound for 4 to 8 seconds,

when the ignition is turned on and the driver's seat

belt is not buckled (seat belt switch is closed to

ground). This is a reminder to the driver to buckle

the seat belt. The seat belt lamp is controlled by the

ORC. The cluster will also bulb check the seat belt

warning lamp for 6 seconds. Buckling the driver's

seat belt before the time out has expired will cause

the chime to stop immediately. Chime rate: 38 to 62

chimes per minute but the lamp will remain on until

6 seconds have expired.

To test the seat belt warning system, the ignition

switch must be in the OFF position for 1 minute

before starting the test. Turn the ignition switch to

the on position with the driver's seat belt not buck-led. The seat belt warning lamp should light and the

chime should sound 4 to 8 seconds.

DIAGNOSIS AND TESTING - SEAT BELT LAMP

The seat belt lamp in the instrument cluster sig-

nals the vehicle passengers to fasten their seat belts.

The seat belt lamp is illuminated directly by the

instrument cluster for 6 seconds after the instrument

cluster receives the message from the ORC. The seat

belt lamp is therefore illuminated for 6 seconds

whenever the ignition switch is moved to run/start

position.

(1) While ignition is off, the seat belt lamp will not

be illuminated.

(2) The ignition power feed status will be updated

every 250 milliseconds or on change.

(3) This lamp will be checked by the instrument

cluster for 6 seconds with every run/start cycle of the

ignition switch.

DIAGNOSIS AND TESTING - TIRE PRESSURE

MONITOR

The Tire Pressure Warning chime, as well as the

information being displayed in the EVIC, will act as

a warning to the driver that a tire has either Low or

High pressure, or if there is a need to service the

Tire Pressure Monitor System. With the ignition

switch in the ON position and the ªLow Pressure/

High Pressureº or ªService the TPM Systemº dis-

played on the EVIC display, a single chime will

sound.

DIAGNOSIS AND TESTING - TURN SIGNAL ON

CHIME

The turn signal on chime will warn the driver that

the turn signals have been left on. When the body

control module receives a turn signal input for 1.0

mile, vehicle speed is greater than 24 km/h (15 mph),

the chime will sound continuously until the turn sig-

nal is turned OFF. If vehicle speed drops below 24

km/h (15 mph) prior to the warning being activated,

the accumulated distance traveled will be reset. The

turn signal chime is not activated when the emer-

gency flashers are turned on. Chime rate: 50 12

chimes per minute.

For the turn signal warning system to operate:

²Must have input from either the right or left

turn signal lamps. Creates a voltage change between

0 and battery voltage.

²The vehicle speed sensor sends a message to the

Powertrain Control Module that vehicle has exceeded

24 km/h (15 mph) for 1.0 mile).

²When the above two conditions are met, the

chime will sound. The chime will stop when no fur-

ther voltage change is detected.

RSCHIME/BUZZER8B-3

CHIME/BUZZER (Continued)

ProCarManuals.com

Page 338 of 2399

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ELECTRONIC CONTROL MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING.......................2

ADJUSTABLE PEDAL MODULE

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL MODULE.......................3

REMOVAL.............................3

INSTALLATION..........................3

BODY CONTROL MODULE

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................5

INSTALLATION..........................5

CONTROLLER ANTILOCK BRAKE

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................6

INSTALLATION..........................6

DATA LINK CONNECTOR

DESCRIPTION..........................7

OPERATION............................7

FRONT CONTROL MODULE

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - FRONT

CONTROL MODULE....................8

REMOVAL.............................8

INSTALLATION..........................8

HEATED SEAT MODULE

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE.............................9

REMOVAL.............................10

INSTALLATION.........................10

POWER LIFTGATE MODULE

DESCRIPTION.........................10

OPERATION...........................10

REMOVAL.............................10

INSTALLATION.........................11

POWERTRAIN CONTROL MODULE

DESCRIPTION

DESCRIPTION........................11DIAGNOSTIC TROUBLE CODE...........13

OPERATION - SENSOR RETURN - PCM

INPUT..............................25

OPERATION - SCI RECEIVE - PCM INPUT . . 25

OPERATION - IGNITION SENSE - PCM

INPUT..............................25

OPERATION - PCM GROUND............25

OPERATION

OPERATION - 8-VOLT SUPPLY - PCM

OUTPUT............................25

OPERATION - 5 VOLT SUPPLY - PCM

OUTPUT............................25

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES..........25

REMOVAL.............................26

INSTALLATION.........................26

SENTRY KEY IMMOBILIZER MODULE

DESCRIPTION.........................26

OPERATION...........................27

REMOVAL.............................27

INSTALLATION.........................27

TRANSMISSION CONTROL MODULE

DESCRIPTION.........................28

OPERATION...........................28

STANDARD PROCEDURE

STANDARD PROCEDURE - PINION

FACTOR SETTING.....................31

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE........................31

REMOVAL.............................31

INSTALLATION.........................32

MEMORY SEAT/MIRROR MODULE

DESCRIPTION.........................33

OPERATION...........................33

DIAGNOSIS AND TESTING - MEMORY

SEAT/MIRROR MODULE................33

REMOVAL.............................33

INSTALLATION.........................33

SLIDING DOOR CONTROL MODULE

DESCRIPTION.........................33

OPERATION...........................34

REMOVAL.............................34

INSTALLATION.........................34

RSELECTRONIC CONTROL MODULES8E-1

ProCarManuals.com

Page 339 of 2399

ELECTRONIC CONTROL

MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING

NOTE: Before replacing the PCM for a failed driver,

control circuit or ground circuit, be sure to check

the related component/circuit integrity for failures

not detected due to a double fault in the circuit.

Most PCM driver/control circuit failures are caused

by internal component failures (i.e. relay and sole-

noids) and shorted circuits (i.e. pull-ups, drivers

and switched circuits). These failures are difficult to

detect when a double fault has occurred and only

one DTC has set.

When a PCM (SBEC) and the SKIM are replaced

at the same time perform the following steps in

order:

(1) Program the new PCM (SBEC)

(2) Program the new SKIM

(3) Replace all ignition keys and program them to

the new SKIM.

PROGRAMMING THE PCM (SBEC)

The SKIS Secret Key is an ID code that is unique

to each SKIM. This code is programmed and stored

in the SKIM, PCM and transponder chip (ignition

keys). When replacing the PCM it is necessary to

program the secret key into the new PCM using the

DRB III. Perform the following steps to program the

secret key into the PCM.

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRB III and select THEFT ALARM,

SKIM then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

(5) Select ENTER to update PCM VIN.

NOTE: If three attempts are made to enter secure

access mode using an incorrect PIN, secured

access mode will be locked out for one hour. To

exit this lockout mode, turn the ignition to the RUN

position for one hour then enter the correct PIN.

(Ensure all accessories are turned off. Also monitor

the battery state and connect a battery charger if

necessary).

(6) Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

(7) Press Page Back to get to the Select System

menu and select ENGINE, MISCELLANEOUS, and

SRI MEMORY CHECK.(8) The DRB III will ask, Is odometer reading

between XX and XX? Select the YES or NO button on

the DRB III. If NO is selected, the DRB III will read,

Enter odometer Reading

the odometer reading from the Instrument Panel and

press ENTER.

PROGRAMMING THE SKIM

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRB III and select THEFT ALARM,

SKIM then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Program the vehicle four-digit PIN into SKIM.

(5) Select COUNTRY CODE and enter the correct

country.

NOTE: Be sure to enter the correct country code. If

the incorrect country code is programmed into

SKIM, the SKIM must be replaced.

(6) Select YES to update VIN (the SKIM will learn

the VIN from the PCM).

(7) Press ENTER to transfer the secret key (the

PCM will send the secret key to the SKIM).

(8) Program ignition keys to SKIM.

NOTE: If the PCM and the SKIM are replaced at the

same time, all vehicle keys will need to be replaced

and programmed to the new SKIM.

PROGRAMMING IGNITION KEYS TO THE SKIM

(1) Turn the ignition switch on (transmission in

park/neutral).

(2) Use the DRB III and select THEFT ALARM,

SKIM then MISCELLANEOUS.

(3) Select PROGRAM IGNITION KEY'S.

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

NOTE: A maximum of eight keys can be learned to

each SKIM. Once a key is learned to a SKIM it (the

key) cannot be transferred to another vehicle.

If ignition key programming is unsuccessful, the

DRB III will display one of the following messages:

Programming Not Attempted - The DRB III

attempts to read the programmed key status and

there are no keys programmed into SKIM memory.

Programming Key Failed (Possible Used Key From

Wrong Vehicle) - SKIM is unable to program key due

to one of the following:

²faulty ignition key transponder

²ignition key is programmed to another vehicle.

8 Keys Already Learned, Programming Not Done -

SKIM transponder ID memory is full.

8E - 2 ELECTRONIC CONTROL MODULESRS

ProCarManuals.com

Page 340 of 2399

(5) Obtain ignition keys to be programmed from

customer (8 keys maximum).

(6) Using the DRB III, erase all ignition keys by

selecting MISCELLANEOUS and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all ignition keys.

Learned Key In Ignition - Ignition key transponder

ID is currently programmed in SKIM memory.

ADJUSTABLE PEDAL MODULE

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL MODULE

Refer to Appropriate Diagnostic Information.

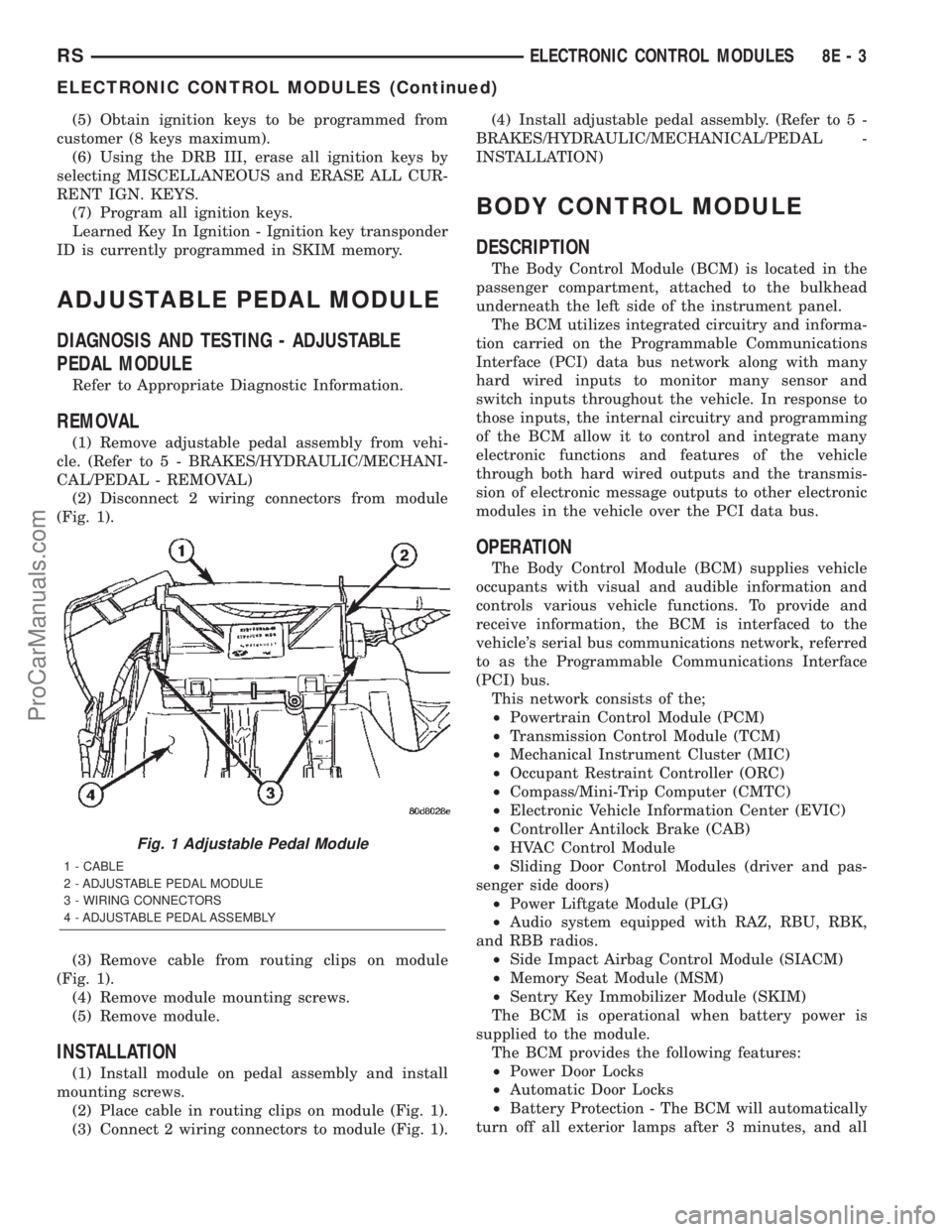

REMOVAL

(1) Remove adjustable pedal assembly from vehi-

cle. (Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/PEDAL - REMOVAL)

(2) Disconnect 2 wiring connectors from module

(Fig. 1).

(3) Remove cable from routing clips on module

(Fig. 1).

(4) Remove module mounting screws.

(5) Remove module.

INSTALLATION

(1) Install module on pedal assembly and install

mounting screws.

(2) Place cable in routing clips on module (Fig. 1).

(3) Connect 2 wiring connectors to module (Fig. 1).(4) Install adjustable pedal assembly. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/PEDAL -

INSTALLATION)

BODY CONTROL MODULE

DESCRIPTION

The Body Control Module (BCM) is located in the

passenger compartment, attached to the bulkhead

underneath the left side of the instrument panel.

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

OPERATION

The Body Control Module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the BCM is interfaced to the

vehicle's serial bus communications network, referred

to as the Programmable Communications Interface

(PCI) bus.

This network consists of the;

²Powertrain Control Module (PCM)

²Transmission Control Module (TCM)

²Mechanical Instrument Cluster (MIC)

²Occupant Restraint Controller (ORC)

²Compass/Mini-Trip Computer (CMTC)

²Electronic Vehicle Information Center (EVIC)

²Controller Antilock Brake (CAB)

²HVAC Control Module

²Sliding Door Control Modules (driver and pas-

senger side doors)

²Power Liftgate Module (PLG)

²Audio system equipped with RAZ, RBU, RBK,

and RBB radios.

²Side Impact Airbag Control Module (SIACM)

²Memory Seat Module (MSM)

²Sentry Key Immobilizer Module (SKIM)

The BCM is operational when battery power is

supplied to the module.

The BCM provides the following features:

²Power Door Locks

²Automatic Door Locks

²Battery Protection - The BCM will automatically

turn off all exterior lamps after 3 minutes, and all

Fig. 1 Adjustable Pedal Module

1 - CABLE

2 - ADJUSTABLE PEDAL MODULE

3 - WIRING CONNECTORS

4 - ADJUSTABLE PEDAL ASSEMBLY

RSELECTRONIC CONTROL MODULES8E-3

ELECTRONIC CONTROL MODULES (Continued)

ProCarManuals.com

Page 341 of 2399

interior lamps after 15 minutes after the ignition is

turned off, if they are not turned off by the driver.

²Chime Driver

²Compass/Mini-Trip support.

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Headlamp Time Delay (with/without Automatic

Headlamps)

²Illuminated Entry

²Fade to Off Interior Lamps - This feature dims

the interior lighting (courtesy lamps) gradually if theBCM does not receive any new inputs that would

cause the interior lamps to remain on.

²Pulse Width Modulated Instrument Panel Dim-

ming

²Door Lock Inhibit - This feature disables the

door lock functions if the key is in the ignition and

either front door is ajar. Pressing the Remote Keyless

Entry (RKE) lock/unlock button under these condi-

tions result in normal lock/unlock activation.

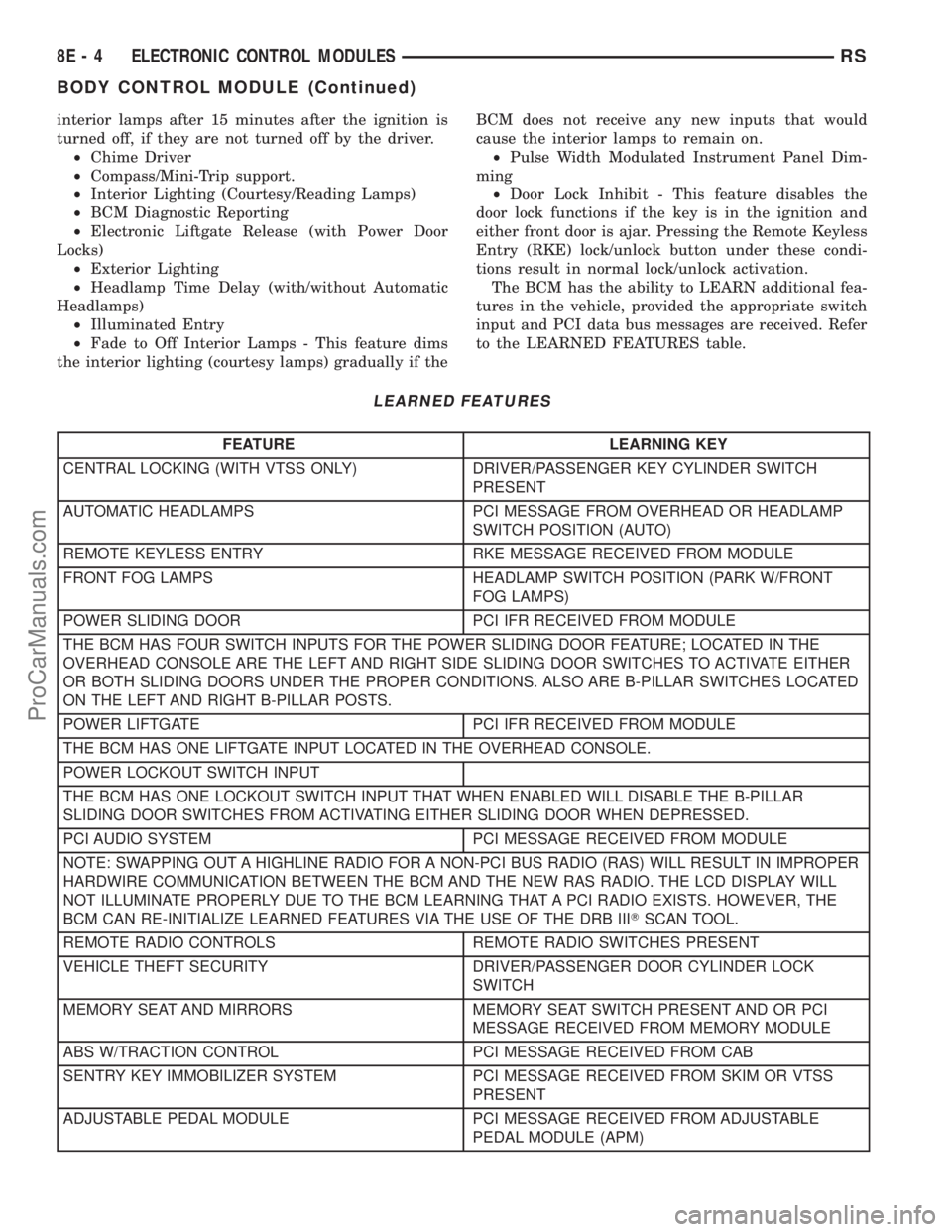

The BCM has the ability to LEARN additional fea-

tures in the vehicle, provided the appropriate switch

input and PCI data bus messages are received. Refer

to the LEARNED FEATURES table.

LEARNED FEATURES

FEATURE LEARNING KEY

CENTRAL LOCKING (WITH VTSS ONLY) DRIVER/PASSENGER KEY CYLINDER SWITCH

PRESENT

AUTOMATIC HEADLAMPS PCI MESSAGE FROM OVERHEAD OR HEADLAMP

SWITCH POSITION (AUTO)

REMOTE KEYLESS ENTRY RKE MESSAGE RECEIVED FROM MODULE

FRONT FOG LAMPS HEADLAMP SWITCH POSITION (PARK W/FRONT

FOG LAMPS)

POWER SLIDING DOOR PCI IFR RECEIVED FROM MODULE

THE BCM HAS FOUR SWITCH INPUTS FOR THE POWER SLIDING DOOR FEATURE; LOCATED IN THE

OVERHEAD CONSOLE ARE THE LEFT AND RIGHT SIDE SLIDING DOOR SWITCHES TO ACTIVATE EITHER

OR BOTH SLIDING DOORS UNDER THE PROPER CONDITIONS. ALSO ARE B-PILLAR SWITCHES LOCATED

ON THE LEFT AND RIGHT B-PILLAR POSTS.

POWER LIFTGATE PCI IFR RECEIVED FROM MODULE

THE BCM HAS ONE LIFTGATE INPUT LOCATED IN THE OVERHEAD CONSOLE.

POWER LOCKOUT SWITCH INPUT

THE BCM HAS ONE LOCKOUT SWITCH INPUT THAT WHEN ENABLED WILL DISABLE THE B-PILLAR

SLIDING DOOR SWITCHES FROM ACTIVATING EITHER SLIDING DOOR WHEN DEPRESSED.

PCI AUDIO SYSTEM PCI MESSAGE RECEIVED FROM MODULE

NOTE: SWAPPING OUT A HIGHLINE RADIO FOR A NON-PCI BUS RADIO (RAS) WILL RESULT IN IMPROPER

HARDWIRE COMMUNICATION BETWEEN THE BCM AND THE NEW RAS RADIO. THE LCD DISPLAY WILL

NOT ILLUMINATE PROPERLY DUE TO THE BCM LEARNING THAT A PCI RADIO EXISTS. HOWEVER, THE

BCM CAN RE-INITIALIZE LEARNED FEATURES VIA THE USE OF THE DRB IIITSCAN TOOL.

REMOTE RADIO CONTROLS REMOTE RADIO SWITCHES PRESENT

VEHICLE THEFT SECURITY DRIVER/PASSENGER DOOR CYLINDER LOCK

SWITCH

MEMORY SEAT AND MIRRORS MEMORY SEAT SWITCH PRESENT AND OR PCI

MESSAGE RECEIVED FROM MEMORY MODULE

ABS W/TRACTION CONTROL PCI MESSAGE RECEIVED FROM CAB

SENTRY KEY IMMOBILIZER SYSTEM PCI MESSAGE RECEIVED FROM SKIM OR VTSS

PRESENT

ADJUSTABLE PEDAL MODULE PCI MESSAGE RECEIVED FROM ADJUSTABLE

PEDAL MODULE (APM)

8E - 4 ELECTRONIC CONTROL MODULESRS

BODY CONTROL MODULE (Continued)

ProCarManuals.com

Page 351 of 2399

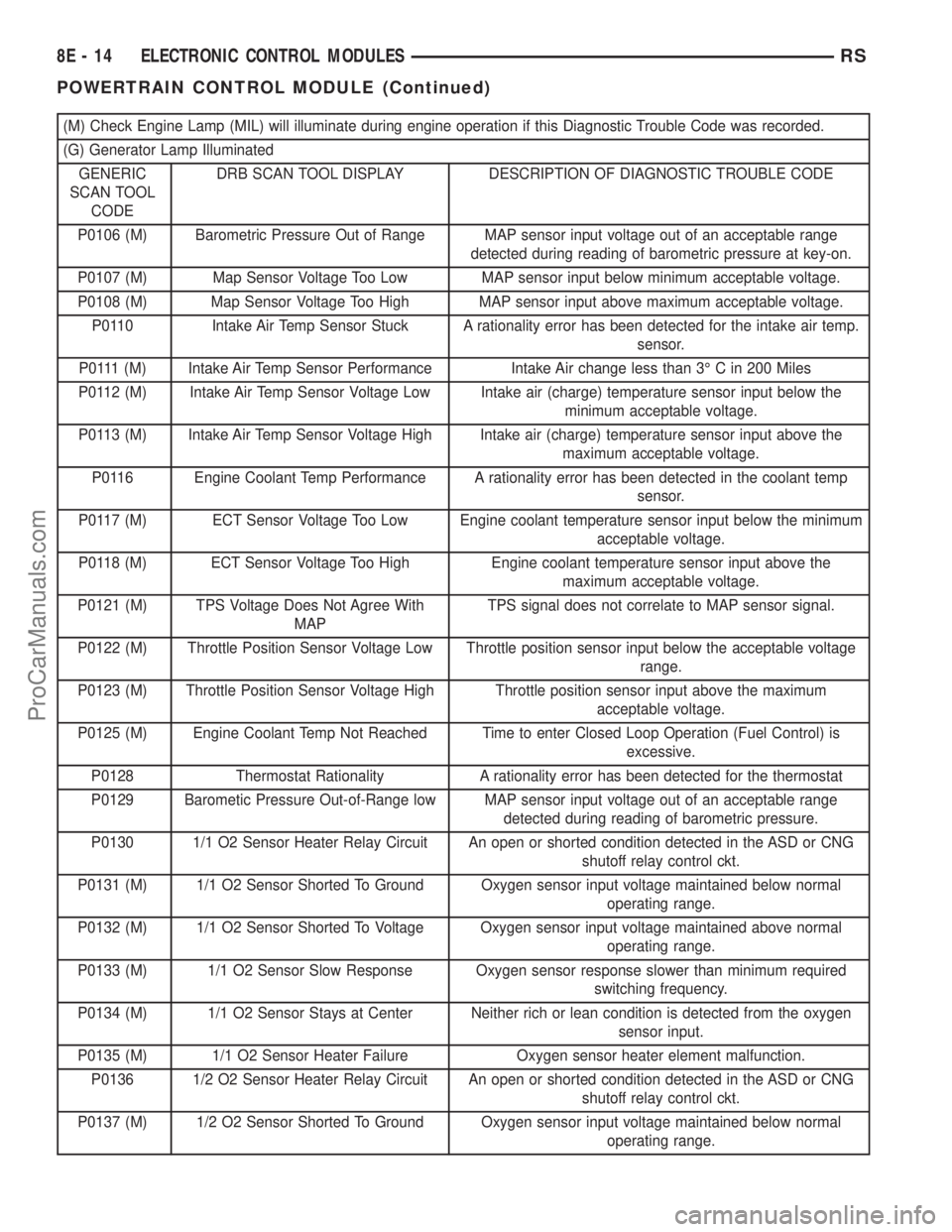

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0106 (M) Barometric Pressure Out of Range MAP sensor input voltage out of an acceptable range

detected during reading of barometric pressure at key-on.

P0107 (M) Map Sensor Voltage Too Low MAP sensor input below minimum acceptable voltage.

P0108 (M) Map Sensor Voltage Too High MAP sensor input above maximum acceptable voltage.

P0110 Intake Air Temp Sensor Stuck A rationality error has been detected for the intake air temp.

sensor.

P0111 (M) Intake Air Temp Sensor Performance Intake Air change less than 3É C in 200 Miles

P0112 (M) Intake Air Temp Sensor Voltage Low Intake air (charge) temperature sensor input below the

minimum acceptable voltage.

P0113 (M) Intake Air Temp Sensor Voltage High Intake air (charge) temperature sensor input above the

maximum acceptable voltage.

P0116 Engine Coolant Temp Performance A rationality error has been detected in the coolant temp

sensor.

P0117 (M) ECT Sensor Voltage Too Low Engine coolant temperature sensor input below the minimum

acceptable voltage.

P0118 (M) ECT Sensor Voltage Too High Engine coolant temperature sensor input above the

maximum acceptable voltage.

P0121 (M) TPS Voltage Does Not Agree With

MAPTPS signal does not correlate to MAP sensor signal.

P0122 (M) Throttle Position Sensor Voltage Low Throttle position sensor input below the acceptable voltage

range.

P0123 (M) Throttle Position Sensor Voltage High Throttle position sensor input above the maximum

acceptable voltage.

P0125 (M) Engine Coolant Temp Not Reached Time to enter Closed Loop Operation (Fuel Control) is

excessive.

P0128 Thermostat Rationality A rationality error has been detected for the thermostat

P0129 Barometic Pressure Out-of-Range low MAP sensor input voltage out of an acceptable range

detected during reading of barometric pressure.

P0130 1/1 O2 Sensor Heater Relay Circuit An open or shorted condition detected in the ASD or CNG

shutoff relay control ckt.

P0131 (M) 1/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0132 (M) 1/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0133 (M) 1/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0134 (M) 1/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor input.

P0135 (M) 1/1 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0136 1/2 O2 Sensor Heater Relay Circuit An open or shorted condition detected in the ASD or CNG

shutoff relay control ckt.

P0137 (M) 1/2 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

8E - 14 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 355 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0441 (M) Evap Purge Flow Monitor Insufficient or excessive vapor flow detected during

evaporative emission system operation.

P0442 (M) Evap Leak Monitor 0.040 Leak

DetectedA 0.040 leak has been detected in the evaporative system.

P0443 (M) Evap Purge Solenoid Circuit An open or shorted condition detected in the EVAP purge

solenoid control circuit.

P0452 NVLD Pressure Switch Stuck Closed NVLD pressure switch stuck closed.

P0453 NVLD Pressure Switch Stuck Open NVLD pressure switch stuck open.

P0455 (M) Evap Leak Monitor Large Leak

DetectedA large leak has been detected in the evaporative system.

P0456 (M) Evap Leak Monitor 0.020 Leak

DetectedA 0.020 leak has been detected in the evaporative system.

P0460 Fuel Level Unit No Change Over Miles No movement of fuel level sender detected.

P0461 Fuel Level Unit No Changeover Time No level of fuel level sender detected.

P0462 Fuel Level Sending Unit Volts Too Low Fuel level sensor input below acceptable voltage.

P0463 Fuel Level Sending Unit Volts Too

HighFuel level sensor input above acceptable voltage.

P0480 Low Speed Fan Relay Control Circuit An open or shorted condition detected in the low speed rad.

fan relay control circuit.

P0481 High Speed Fan Relay Control Circuit An open or shorted condition detected in the high speed rad.

fan relay control circuit.

P0498 NVLD Canister Vent Valve Solenoid

Circuit LowA shorted low condition detected in NVLD solenoid circuit.

P0499 NVLD Canister Vent Valve Solenoid

Circuit HighA shorted high condition detected in NVLD solenoid circuit.

P0500 (M) No Vehicle Speed Sensor Signal No vehicle speed sensor signal detected during road load

conditions.

P0501 Vehicle Speed Sensor #1 Performance A rationality error has been detected for no vehicle speed

sensor signal detected during road load conditions.

P0505 (M) Idle Air Control Motor Circuits Replace idle air control motor.

P0508 (M) Idle Air Control Motor Circuit Low Idle Air Control Motor Circuit input below acceptable current

P0509 (M) Idle Air Control Motor Circuit High Idle Air Control Motor Circuit input above acceptable current

P0511 Idle Air Control Valve Solenoid Circuit An open or shorted condition detected in the IAC control

circuit.

P0513 Invalid SKIM Key The engine controller has received an invalid key from the

Smart Key Immobilizer Module.

P0516 Battery Temperature Sensor Low Battery Temp. sensor input below minimum acceptable

voltage.

P0517 Battery Temperature Sensor High Battery Temp. sensor input above maximum acceptable

voltage.

P0519 Idle Speed Performance A rationality error has been detected for target RPM not met

during drive idle condition. Possible Vacuum leak or IAC lost

steps.

8E - 18 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 356 of 2399

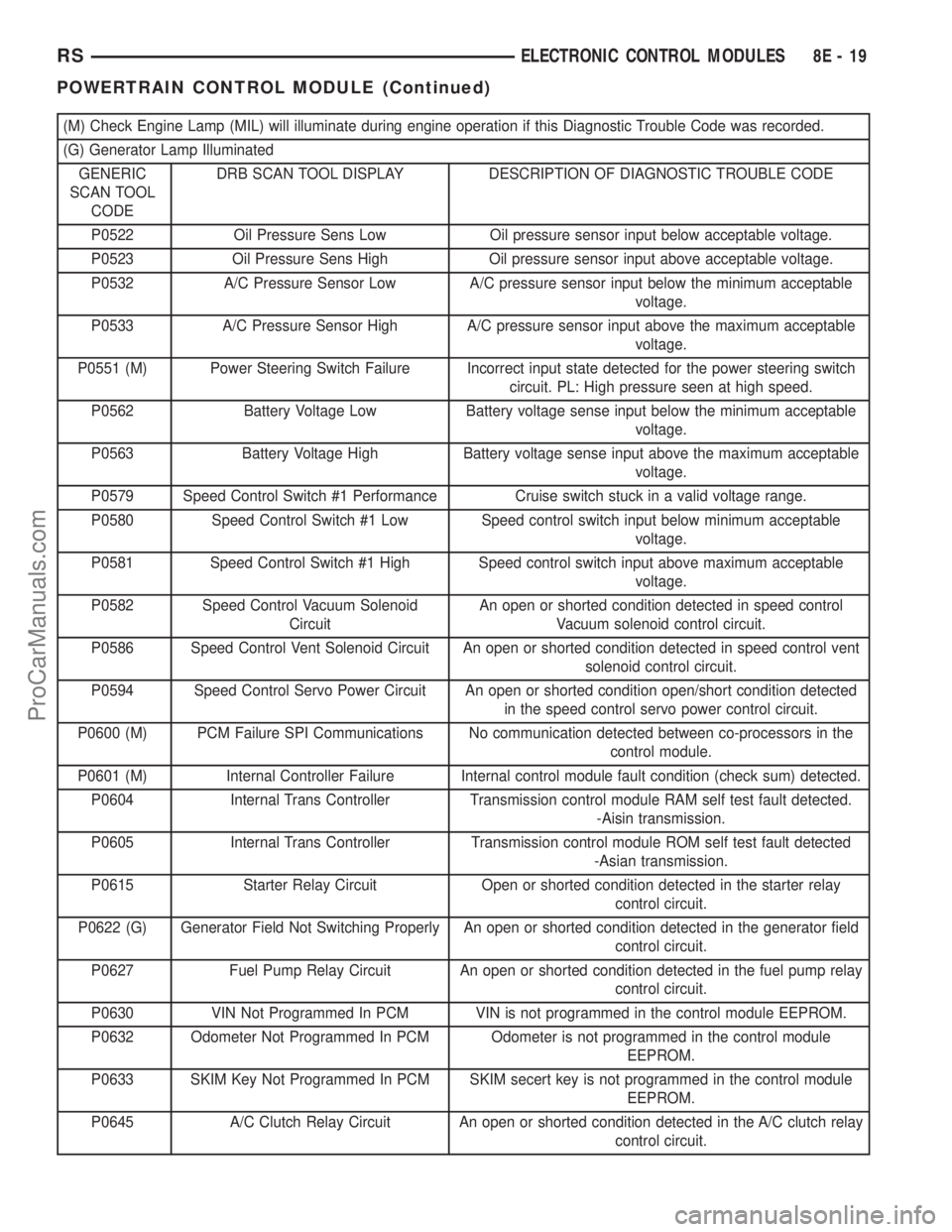

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0522 Oil Pressure Sens Low Oil pressure sensor input below acceptable voltage.

P0523 Oil Pressure Sens High Oil pressure sensor input above acceptable voltage.

P0532 A/C Pressure Sensor Low A/C pressure sensor input below the minimum acceptable

voltage.

P0533 A/C Pressure Sensor High A/C pressure sensor input above the maximum acceptable

voltage.

P0551 (M) Power Steering Switch Failure Incorrect input state detected for the power steering switch

circuit. PL: High pressure seen at high speed.

P0562 Battery Voltage Low Battery voltage sense input below the minimum acceptable

voltage.

P0563 Battery Voltage High Battery voltage sense input above the maximum acceptable

voltage.

P0579 Speed Control Switch #1 Performance Cruise switch stuck in a valid voltage range.

P0580 Speed Control Switch #1 Low Speed control switch input below minimum acceptable

voltage.

P0581 Speed Control Switch #1 High Speed control switch input above maximum acceptable

voltage.

P0582 Speed Control Vacuum Solenoid

CircuitAn open or shorted condition detected in speed control

Vacuum solenoid control circuit.

P0586 Speed Control Vent Solenoid Circuit An open or shorted condition detected in speed control vent

solenoid control circuit.

P0594 Speed Control Servo Power Circuit An open or shorted condition open/short condition detected

in the speed control servo power control circuit.

P0600 (M) PCM Failure SPI Communications No communication detected between co-processors in the

control module.

P0601 (M) Internal Controller Failure Internal control module fault condition (check sum) detected.

P0604 Internal Trans Controller Transmission control module RAM self test fault detected.

-Aisin transmission.

P0605 Internal Trans Controller Transmission control module ROM self test fault detected

-Asian transmission.

P0615 Starter Relay Circuit Open or shorted condition detected in the starter relay

control circuit.

P0622 (G) Generator Field Not Switching Properly An open or shorted condition detected in the generator field

control circuit.

P0627 Fuel Pump Relay Circuit An open or shorted condition detected in the fuel pump relay

control circuit.

P0630 VIN Not Programmed In PCM VIN is not programmed in the control module EEPROM.

P0632 Odometer Not Programmed In PCM Odometer is not programmed in the control module

EEPROM.

P0633 SKIM Key Not Programmed In PCM SKIM secert key is not programmed in the control module

EEPROM.

P0645 A/C Clutch Relay Circuit An open or shorted condition detected in the A/C clutch relay

control circuit.

RSELECTRONIC CONTROL MODULES8E-19

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 361 of 2399

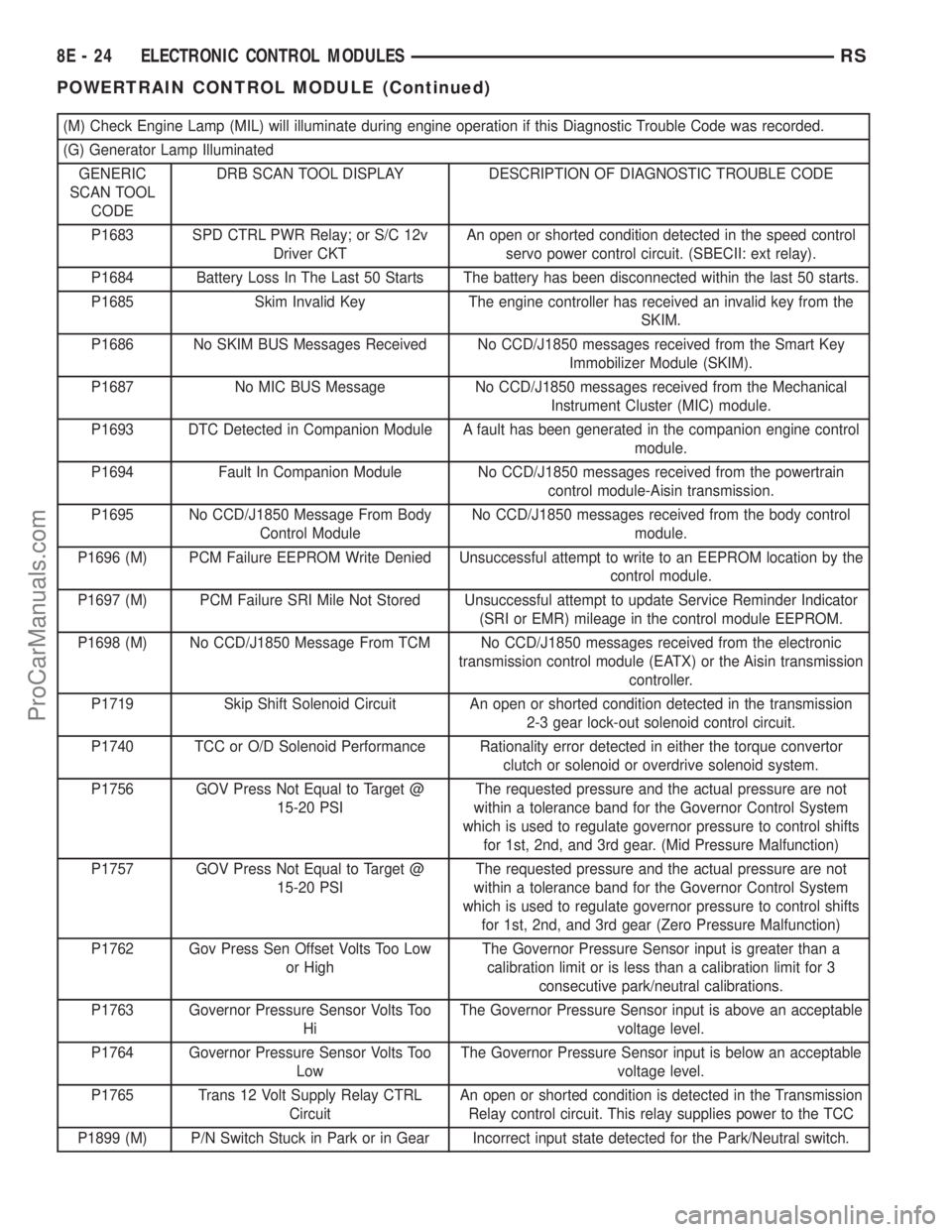

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P1683 SPD CTRL PWR Relay; or S/C 12v

Driver CKTAn open or shorted condition detected in the speed control

servo power control circuit. (SBECII: ext relay).

P1684 Battery Loss In The Last 50 Starts The battery has been disconnected within the last 50 starts.

P1685 Skim Invalid Key The engine controller has received an invalid key from the

SKIM.

P1686 No SKIM BUS Messages Received No CCD/J1850 messages received from the Smart Key

Immobilizer Module (SKIM).

P1687 No MIC BUS Message No CCD/J1850 messages received from the Mechanical

Instrument Cluster (MIC) module.

P1693 DTC Detected in Companion Module A fault has been generated in the companion engine control

module.

P1694 Fault In Companion Module No CCD/J1850 messages received from the powertrain

control module-Aisin transmission.

P1695 No CCD/J1850 Message From Body

Control ModuleNo CCD/J1850 messages received from the body control

module.

P1696 (M) PCM Failure EEPROM Write Denied Unsuccessful attempt to write to an EEPROM location by the

control module.

P1697 (M) PCM Failure SRI Mile Not Stored Unsuccessful attempt to update Service Reminder Indicator

(SRI or EMR) mileage in the control module EEPROM.

P1698 (M) No CCD/J1850 Message From TCM No CCD/J1850 messages received from the electronic

transmission control module (EATX) or the Aisin transmission

controller.

P1719 Skip Shift Solenoid Circuit An open or shorted condition detected in the transmission

2-3 gear lock-out solenoid control circuit.

P1740 TCC or O/D Solenoid Performance Rationality error detected in either the torque convertor

clutch or solenoid or overdrive solenoid system.

P1756 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear. (Mid Pressure Malfunction)

P1757 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear (Zero Pressure Malfunction)

P1762 Gov Press Sen Offset Volts Too Low

or HighThe Governor Pressure Sensor input is greater than a

calibration limit or is less than a calibration limit for 3

consecutive park/neutral calibrations.

P1763 Governor Pressure Sensor Volts Too

HiThe Governor Pressure Sensor input is above an acceptable

voltage level.

P1764 Governor Pressure Sensor Volts Too

LowThe Governor Pressure Sensor input is below an acceptable

voltage level.

P1765 Trans 12 Volt Supply Relay CTRL

CircuitAn open or shorted condition is detected in the Transmission

Relay control circuit. This relay supplies power to the TCC

P1899 (M) P/N Switch Stuck in Park or in Gear Incorrect input state detected for the Park/Neutral switch.

8E - 24 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 362 of 2399

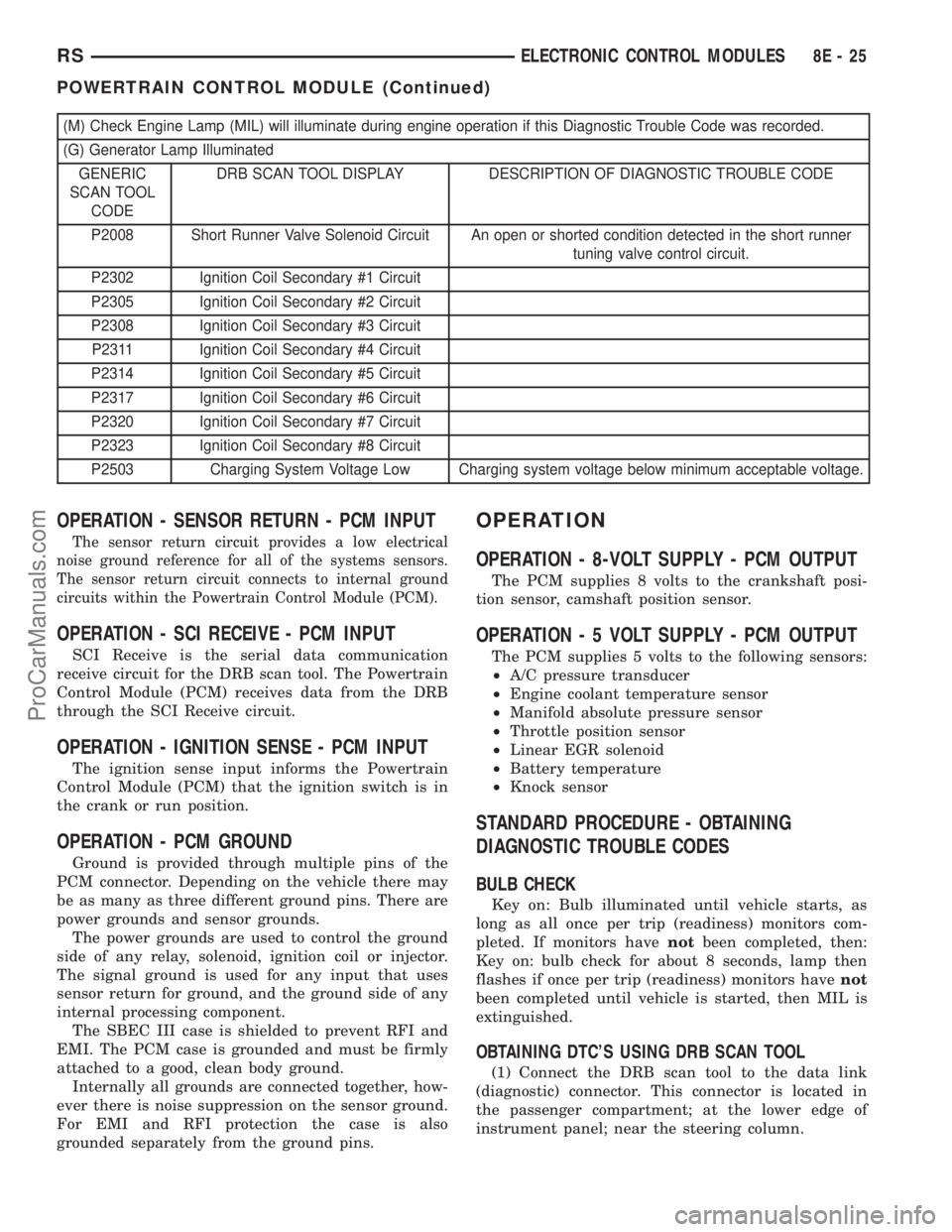

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P2008 Short Runner Valve Solenoid Circuit An open or shorted condition detected in the short runner

tuning valve control circuit.

P2302 Ignition Coil Secondary #1 Circuit

P2305 Ignition Coil Secondary #2 Circuit

P2308 Ignition Coil Secondary #3 Circuit

P2311 Ignition Coil Secondary #4 Circuit

P2314 Ignition Coil Secondary #5 Circuit

P2317 Ignition Coil Secondary #6 Circuit

P2320 Ignition Coil Secondary #7 Circuit

P2323 Ignition Coil Secondary #8 Circuit

P2503 Charging System Voltage Low Charging system voltage below minimum acceptable voltage.

OPERATION - SENSOR RETURN - PCM INPUT

The sensor return circuit provides a low electrical

noise ground reference for all of the systems sensors.

The sensor return circuit connects to internal ground

circuits within the Powertrain Control Module (PCM).

OPERATION - SCI RECEIVE - PCM INPUT

SCI Receive is the serial data communication

receive circuit for the DRB scan tool. The Powertrain

Control Module (PCM) receives data from the DRB

through the SCI Receive circuit.

OPERATION - IGNITION SENSE - PCM INPUT

The ignition sense input informs the Powertrain

Control Module (PCM) that the ignition switch is in

the crank or run position.

OPERATION - PCM GROUND

Ground is provided through multiple pins of the

PCM connector. Depending on the vehicle there may

be as many as three different ground pins. There are

power grounds and sensor grounds.

The power grounds are used to control the ground

side of any relay, solenoid, ignition coil or injector.

The signal ground is used for any input that uses

sensor return for ground, and the ground side of any

internal processing component.

The SBEC III case is shielded to prevent RFI and

EMI. The PCM case is grounded and must be firmly

attached to a good, clean body ground.

Internally all grounds are connected together, how-

ever there is noise suppression on the sensor ground.

For EMI and RFI protection the case is also

grounded separately from the ground pins.

OPERATION

OPERATION - 8-VOLT SUPPLY - PCM OUTPUT

The PCM supplies 8 volts to the crankshaft posi-

tion sensor, camshaft position sensor.

OPERATION - 5 VOLT SUPPLY - PCM OUTPUT

The PCM supplies 5 volts to the following sensors:

²A/C pressure transducer

²Engine coolant temperature sensor

²Manifold absolute pressure sensor

²Throttle position sensor

²Linear EGR solenoid

²Battery temperature

²Knock sensor

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES

BULB CHECK

Key on: Bulb illuminated until vehicle starts, as

long as all once per trip (readiness) monitors com-

pleted. If monitors havenotbeen completed, then:

Key on: bulb check for about 8 seconds, lamp then

flashes if once per trip (readiness) monitors havenot

been completed until vehicle is started, then MIL is

extinguished.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

RSELECTRONIC CONTROL MODULES8E-25

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com