width CHRYSLER CARAVAN 2002 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1219 of 2399

DESCRIPTION SPECIFICATION

Wear Limit 0.075 mm

(0.003 in.)

Bore DiameterÐPiston

Pin20.96±20.98 mm

(0.8252±0.8260 in.)

Bore DiameterÐ

Crankshaft End53.007±52.993 mm

(2.0868±2.0863 in.)

Side Clearance 0.13±0.38 mm

(0.005±0.015 in.)

Wear Limit 0.40 mm

(0.016 in.)

WeightÐTotal (Less

Bearing)565.8 grams

(19.96 oz.)

Crankshaft

Connecting Rod Journal

Diameter49.984±50.000 mm

(1.968±1.9685 in.)

Main Bearing Journal

Diameter59.992±60.008 mm

(2.362±2.3625 in.)

Journal Out-of-Round

(Max.)0.0035 mm

(0.0003 in.)

Journal Taper (Max.) 0.007 mm

(0.0001 in.)

End Play 0.09±0.24 mm

(0.0035±0.0094 in.)

Wear Limit 0.38 mm

(0.015 in.)

Main Bearing Diametrical

Clearance0.018±0.062 mm

(0.0007±0.0024 in.)

Hydraulic Lash Adjuster

Body Diameter 15.901±15.913 mm

(0.626±0.6264 in.)

Plunger Travel Minimum

(Dry)3.0 mm

(0.118 in.)

Cylinder Head Camshaft Bearing Bore Diameter

Journals No.1±6 26.020±26.041 mm

(1.024±1.025 in.)

Camshaft

Journal Diameter No. 1±6 25.951±25.970 mm

(1.021±1.022 in.)

Bearing ClearanceÐ

Diametrical0.069±0.071 mm

(0.0027±0.003 in.)

End Play 0.05±0.17 mm

(0.0019±0.0066 in.)DESCRIPTION SPECIFICATION

Lift (Zero Lash)

Intake 8.25 mm

(0.324 in.)

Exhaust 6.60 mm

(0.259 in.)

Intake Valve Timing*

Closes (ABDC) 51É

Opens (BTDC) 1É

Duration 232É

Exhaust Valve Timing*

Closes (ATDC) 7É

Opens (BBDC) 47É

Duration 234É

Valve Overlap 8É

*All readings in crankshaft degrees. Timing points @

4É from top of Ramps.

Cylinder Head

Material Cast Aluminum

Gasket Thickness

(Compressed)0.71 mm

(0.028 in.)

Valve Seat

Angle 44.5±45É

Seat DiameterÐIntake 34.37±34.63 mm

(1.353±1.363 in.)

Seat DiameterÐExhaust 27.06±27.32 mm

(1.065±1.075 in.)

Runout (Max.) 0.05 mm

(0.002 in.)

Valve Seat WidthÐIntake

and Exhaust0.9±1.3 mm

(0.035±0.051 in.)

Service LimitÐIntake 2.0 mm

(0.079 in.)

Service LimitÐExhaust 2.5 mm

(0.098 in.)

Valve Guide

Diameter I.D. 5.975±6.000 mm

(0.235±0.236 in.)

Guide Bore Diameter 11.0±11.02 mm

(0.4330±0.4338 in.)

Guide Height (spring seat

to guide tip)13.25±13.75 mm

(0.521±0.541 in.)

9 - 18 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1283 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

OIL CONSUMPTION OR SPARK

PLUGS FOULED1. PCV system malfunction. 1. Check system and repair as

necessary. (Refer to 25 -

EMISSIONS CONTROL/

EVAPORATIVE EMISSIONS/PCV

VALVE - DIAGNOSIS AND

TESTING)

2. Worn, scuffed or broken rings. 2. Hone cylinder bores. Install new

rings.

3. Carbon in oil ring slots. 3. Install new rings.

4. Rings fitted too tightly in grooves. 4. Remove rings and check

grooves. If groove is not proper

width, replace piston.

5. Worn valve guide(s). 5. Replace cylinder head assembly.

6. Valve stem seal(s) worn or

damaged.6. Replace seal(s).

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair as necessary.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

²Disconnect the fresh air hose (make-up air) at

the cylinder head cover and plug or cap the nipple on

the cover.

²Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve nipple on the

cover.

²Attach an air hose with pressure gauge and reg-

ulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.²Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provides the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

²If the leakage occurs at the crankshaft rear oil

seal area, refer to the section, Inspection for Rear

Seal Area Leak.

(6) If no leaks are detected, turn off the air supply.

Remove the air hose, all plugs, and caps. Install the

PCV valve and fresh air hose (make-up air). Proceed

to next step.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

NOTE: If oil leakage is observed at the dipstick tube

to block location; remove the tube, clean and reseal

using MoparTStud & Bearing Mount (press fit tube

applications only), and for O-ring style tubes,

remove tube and replace the O-ring seal.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

9 - 82 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1285 of 2399

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

STANDARD PROCEDURE

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING PLASTIGAGE

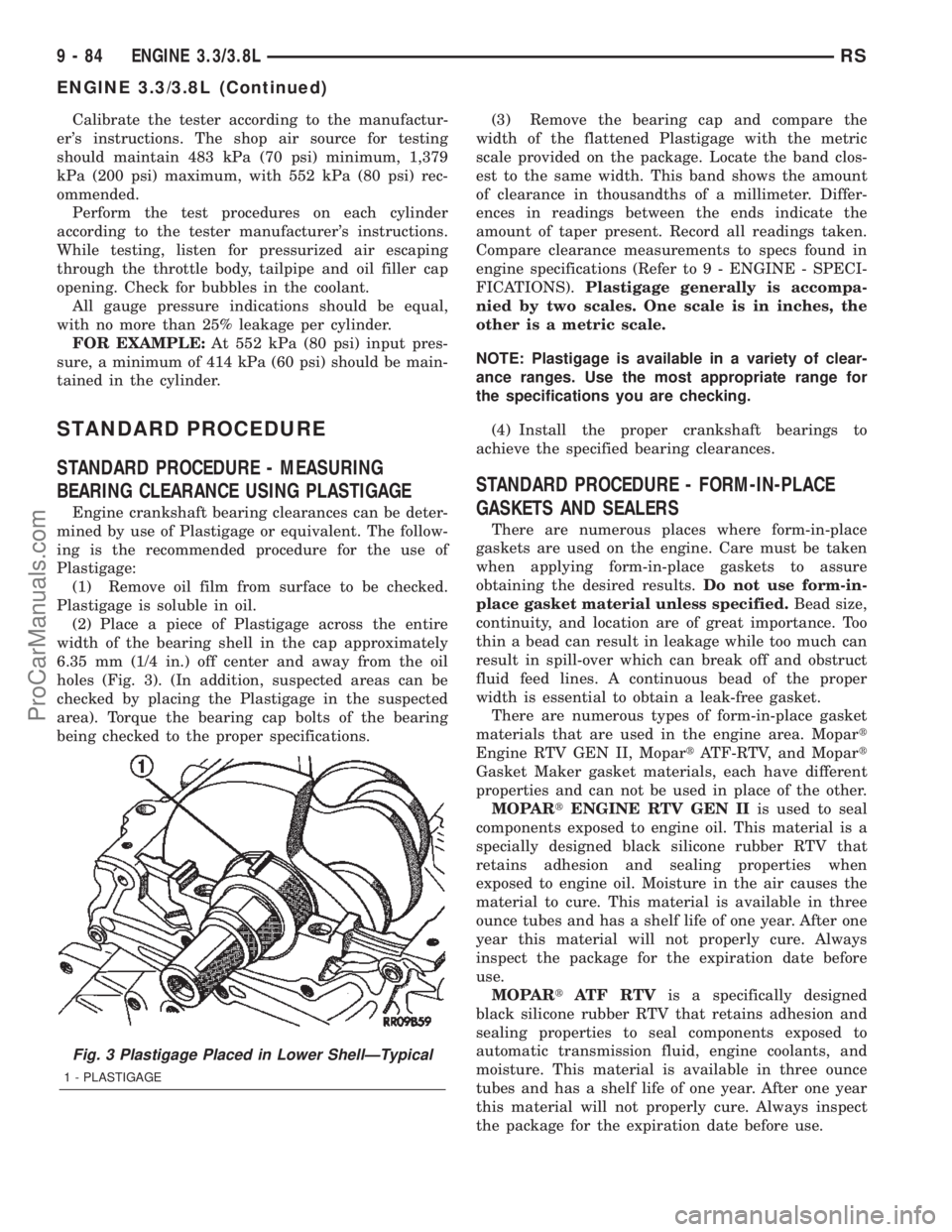

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 3). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.(3) Remove the bearing cap and compare the

width of the flattened Plastigage with the metric

scale provided on the package. Locate the band clos-

est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Compare clearance measurements to specs found in

engine specifications (Refer to 9 - ENGINE - SPECI-

FICATIONS).Plastigage generally is accompa-

nied by two scales. One scale is in inches, the

other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

Fig. 3 Plastigage Placed in Lower ShellÐTypical

1 - PLASTIGAGE

9 - 84 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1294 of 2399

DESCRIPTION SPECIFICATION

Ring End GapÐ2nd

Compression Ring0.28±0.57 mm

(0.011±0.022 in.)

Wear Limit 1.0 mm

(0.039 in.)

Ring End GapÐOil

Control Steel Rails0.23±0.78 mm

(0.009±0.030 in.)

Wear Limit 1.88 mm

(0.074 in.)

Ring Side ClearanceÐ

Top Compression Ring

Ð3.3L 0.030±0.080 mm

(0.0012±0.0031 in.)

Ð3.8L 0.030±0.069 mm

(0.0012±0.0027 in.)

Wear Limit 0.10 mm

(0.004 in.)

Ring Side ClearanceÐ

2nd Compression Ring

Ð3.3L 0.030±0.095 mm

(0.0012±0.0037 in.)

Ð3.8L 0.041±0.085 mm

(0.0016±0.0033 in.)

Wear Limit 0.13 mm

(0.005 in.)

Ring Side ClearanceÐOil

Ring Pack0.039±0.200 mm

(0.0015±0.0078 in.)

Wear Limit 0.266 mm

(0.009 in.)

Ring WidthÐTop

Compression Ring

Ð3.3L 1.46±1.49 mm

(0.0575±0.058 in.)

Ð3.8L 1.175±1.190 mm

(0.0462±0.0468 in.)

Ring WidthÐ2nd

Compression Ring

Ð3.3/3.8L1.46±1.49 mm

(0.0575±0.058 in.)

Ring WidthÐOil Ring

(Steel Rails)

Ð3.3L 0.435±0.490 mm

(0.017±0.019 in.)

Ð3.8L 0.435±0.510 mmDESCRIPTION SPECIFICATION

(0.017±0.020 in.)

Connecting Rod

Bearing Clearance 0.019±0.065 mm

(0.0008±0.0026 in.)

Wear Limit 0.074 mm

(0.003 in.)

Side Clearance 0.13±0.32 mm

(0.005±0.013 in.)

Wear Limit 0.38 mm

(0.015 in.)

Crankshaft

Material Nodular Iron

Connecting Rod Journal

Diameter57.979±58.005 mm

(2.2827±2.2837 in.)

Main Bearing Journal

Diameter63.993±64.013 mm

(2.5194±2.5202 in.)

Journal Out-of-Round

(Max.)0.025 mm

(0.001 in.)

Journal Taper (Max.) 0.025 mm

(0.001 in.)

End Play 0.09±0.24 mm

(0.0036±0.0095 in.)

Wear Limit 0.381 mm

(0.015 in.)

Main Bearing Diametrical

Clearance

ÐNo. 1, 2, 3, 4 0.011±0.055 mm

(0.0005±0.0022 in.)

Wear Limit 0.076 mm

(0.003 in.)

Camshaft

Journal Diameter

No.1 50.724±50.775 mm

(1.997±1.999 in.)

No.2 50.317±50.368 mm

(1.9809±1.9829 in.)

No.3 49.936±49.987 mm

(1.9659±1.9679 in.)

No.4 49.530±49.581 mm

(1.9499±1.9520 in.)

Bearing ClearanceÐ

Diametrical0.025±0.101 mm

(0.001±0.004 in.)

RSENGINE 3.3/3.8L9-93

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1295 of 2399

DESCRIPTION SPECIFICATION

Bearing Clearance (Max.

allowable)0.127 mm

(0.005 in.)

End Play 0.254±0.508 mm

(0.010±0.020 in.)

(Max. allowable) 0.304 mm

(0.012 in.)

Camshaft Bearing

Diameter

No. 1 50.800±50.825 mm

(1.9999±2.0009 in.)

No. 2 50.393±50.419 mm

(1.9839±1.9849 in.)

No. 3 50.013±50.038 mm

(1.9690±1.9699 in.)

No. 4 49.606±49.632 mm

(1.9529±1.954 in.)

Exhaust Valve Timing

ClosesÐ3.3L (ATDC) 13É

ClosesÐ3.8L (ATDC) 18É

OpensÐ3.3L (BBDC) 43É

OpensÐ3.8L (BBDC) 46É

DurationÐ3.3L 236É

DurationÐ3.8L 244É

Intake Valve Timing

ClosesÐ3.3L (ABDC 52É

ClosesÐ3.8L (ABDC 63É

OpensÐ3.3L (ATDC) 6É

OpensÐ3.8L (ATDC) 1É

DurationÐ3.3L 226É

DurationÐ3.8L 242É

Valve OverlapÐ3.3L 7É

Valve OverlapÐ3.8L 17É

Lifters

Type Hydraulic Roller

Diameter O.D. 22.949±22.962 mm

(0.903±0.904 in.)

Clearance In Block 0.020±0.061 mm

0.0007±0.0024 in.)

Cylinder Head

Gasket Thickness

(Compressed)0.65±0.75 mm

(0.025±0.029 in.)DESCRIPTION SPECIFICATION

Valve Seat

Angle 44.5±45É

Valve Seat Runout

(Service Limits)0.0762 mm

(0.003 in.)

Valve Seat WidthÐIntake

& Exhaust1.50±2.00 mm

(0.057±0.078 in.)

Valve Guide

Guide Bore Diameter

(Std.)6.975±7.00 mm

(0.274±0.275 in.)

Valves

Valve Lift (Zero

Lash)ÐIntake & Exhaust

Ð3.3L 9.80 mm

(0.385 in.)

Ð3.8L 11.0 mm

(0.433 in.)

Face AngleÐIntake 45±45.5É

Face AngleÐExhaust 45±45.5É

Head DiameterÐIntake 47.87±48.13 mm

(1.88±1.89 in.)

Head DiameterÐExhaust 35.37±35.63 mm

(1.39±1.40 in.)

Valve Margin

Intake 0.825±0.973 mm

(0.032±0.038 in.)

Exhaust 1.565±1.713 mm

(0.061±0.067 in.)

Valve Length (Overall)

Intake 125.84±126.6 mm

(4.95±4.98 in.)

Exhaust 127.2±127.96 mm

(5.00±5.04 in.)

Valve Stem Tip Height

Intake (valve tip to spring

seat washer)48.1±49.7 mm

(1.89±1.95 in.)

Exhaust (valve tip to

spring seat washer)48.53±50.09 mm

(1.91±1.97 in.)

Valve Stem Diameter

Intake (Standard) 6.935±6.953 mm

(0.2730±0.2737 in.)

9 - 94 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1306 of 2399

CYLINDER HEAD COVER -

LEFT

REMOVAL

(1) Disconnect spark plug wires from spark plugs.

(2) Disconnect crankcase vent hose from cylinder

head cover.

(3) Remove cylinder head cover bolts.

(4) Remove cylinder head cover and gasket.

INSTALLATION

(1) Clean cylinder head and cover mating surfaces.

Inspect cylinder head cover surface for flatness.

Replace gasket as necessary.

(2) Assemble gasket to cylinder cover by inserting

the fasteners through each bolt hole on cover and

gasket (Fig. 26).

(3) Install the cylinder head cover and bolts (Fig.

27).

(4) Tighten cylinder head cover bolts to 12 N´m

(105 in. lbs.) (Fig. 27).

(5) Connect crankcase vent hose.

(6) Connect spark plug wires to spark plugs.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves have chrome plated valve stems with

four-bead lock grooves. The valve stem seals are

made of Viton rubber.

OPERATION

The two valves per cylinder are opened using

hydraulic lifters, push rods, and rocker arms.

STANDARD PROCEDURE - REFACING VALVES

AND VALVE SEATS

The intake and exhaust valves and seats are

machined to specific angles (Fig. 28).

VALVES

(1) Inspect the remaining margin after the valves

are refaced (Fig. 29). (Refer to 9 - ENGINE - SPEC-

IFICATIONS)

VALVE SEATS

CAUTION: Remove metal from valve seat only. Do

not remove material from cylinder head (Fig. 30).

(1)

When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseating

stones. A true and complete surface must be obtained.

Fig. 28 Valve Face and Seat

1 - SEAT WIDTH

2 - FACE ANGLE

3 - SEAT ANGLE

4 - SEAT CONTACT AREA

Fig. 29 Valve Margin

1 - VALVE FACE

2 - VALVE MARGIN

Fig. 30 Refacing Valve Seats

1 - REFACING STONE MUST NOT CUT INTO CYLINDER HEAD

2-STONE

3 - PILOT

4 - SEAT

RSENGINE 3.3/3.8L9 - 105

ProCarManuals.com

Page 1307 of 2399

(2) Measure the concentricity of valve seat using

dial indicator (Fig. 31). Total runout should not

exceed 0.051 mm (0.002 in.) total indicator reading.

(3) Inspect the valve seat using Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of valve face, lower valve seat with

a 15 degree stone. If the blue is transferred to the

bottom edge of valve face raise valve seat with a 65

degrees stone.

NOTE: Valve seats which are worn or burned can

be reworked, provided that correct angle and seat

width are maintained. Otherwise cylinder head must

be replaced.

(4) When seat is properly positioned the width of

intake and exhaust seats should be 1.50±2.00 mm

(0.059±0.078 in.) (Fig. 28).

(5) After grinding the valve seats or faces, install

the valve in cylinder head and check valve installed

height by measuring from valve tip to spring seat

(Fig. 32). Remove valve from cylinder head and grind

valve tip until within specifications. Check valve tip

for scoring. The tip chamfer should be reground (if

necessary) to prevent seal damage when the valve is

installed.

(6) Check the valve spring installed height after

refacing the valve and seat (Fig. 32).If valves

and/or seats are reground, measure the

installed height of springs (Fig. 32), make sure

measurements are taken from top of spring

seat to the bottom surface of spring retainer. If

height is greater than specifications, install a0.794 mm (0.0312 in.) spacer in head counter-

bore to bring spring height back within specifi-

cations.

REMOVAL

(1) With cylinder head removed, compress valve

springs using Valve Spring Compressor Tool

C-3422-D with adapter 8464 (Refer to 9 - ENGINE -

SPECIAL TOOLS).

(2) Remove valve retaining locks.

(3) Slowly release valve spring compressor.

Remove valve spring retainer, valve spring, and valve

stem seal.

(4) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

CLEANING

(1) Clean all valves thoroughly and discard

burned, warped and cracked valves.

INSPECTION

VALVES

(1) Clean and inspect valves thoroughly. Replace

burned, warped and cracked valves.

(2) Measure valve stems for wear (Fig. 33). For

valve specifications, (Refer to 9 - ENGINE - SPECI-

FICATIONS).

NOTE: Valve stems are chrome plated and should

not be polished (Fig. 33).

Fig. 31 Measurement of Valve Seat Runout

1 - DIAL INDICATOR

Fig. 32 Checking Valve and Spring Installed Height

1 - SPRING RETAINER

2 - VALVE INSTALLED HEIGHT* - 48.1±49.7 mm (1.89±1.95 in.)

3 - CYINDER HEAD SURFACE

4 - SPRING INSTALLED HEIGHT* - 41.1±42.7 mm (1.61±1.68 in.)

*(MEASURED FROM TOP OF SPRING SEAT)

9 - 106 ENGINE 3.3/3.8LRS

INTAKE/EXHAUST VALVES & SEATS (Continued)

ProCarManuals.com

Page 1317 of 2399

(3) Place a piece of Plastigage across the entire

width of the bearing shell in the bearing cap approx-

imately 6.35 mm (1/4 in.) off center and away from

the oil hole. In addition, suspect areas can be

checked by placing Plastigage in that area.

(4) Assemble the rod cap with Plastigage in place.

Tighten the rod cap to the specified torque.Do not

rotate the crankshaft while assembling the cap

or the Plastigage may be smeared, giving inac-

curate results.

(5) Remove the bearing cap and compare the

width of the flattened Plastigage with the scale pro-

vided on the package (Fig. 50). Locate the band clos-

est to the same width. This band indicates the

amount of oil clearance. Differences in readings

between the ends indicate the amount of taper

present. Record all readings taken. Refer to Engine

Specifications (Refer to 9 - ENGINE - SPECIFICA-

TIONS).Plastigage generally is accompanied by

two scales. One scale is in inches, the other is a

metric scale. If the bearing clearance exceeds

wear limit specification, replace the bearing.CRANKSHAFT

DESCRIPTION

DESCRIPTION - 3.3L

The nodular iron crankshaft is supported by four

main bearings, with number two position the thrust

bearing (Fig. 51). Crankshaft end sealing is provided

by front and rear rubber seals.

Fig. 50 Measuring Connecting Rod Bearing

Clearance

Fig. 51 CRANKSHAFT AND ENGINE BLOCK - 3.3L

1 - MAIN BEARING CAP No. 4

2 - MAIN BEARING CAP No. 3

3 - MAIN BEARING CAP No. 2

4 - MAIN BEARING CAP BOLT (QTY. 2 PER CAP)

5 - MAIN BEARING CAP No. 1

6 - LOWER MAIN BEARING - THRUST

7 - UPPER MAIN BEARING - THRUST

8 - ENGINE BLOCK

9 - UPPER MAIN BEARINGS

10 - CRANKSHAFT

11 - LOWER MAIN BEARINGS

9 - 116 ENGINE 3.3/3.8LRS

CONNECTING ROD BEARINGS (Continued)

ProCarManuals.com

Page 1321 of 2399

Upper and lower number 2 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 59). All bearing cap bolts removed

during service procedures are to be cleaned and

lubricated with engine oil before installation. Bearing

shells are available in standard and the following

undersizes: 0.025 mm (0.001 in.) and 0.254 mm

(0.010 in). Never install an undersize bearing that

will reduce clearance below specifications.

CRANKSHAFT BEARING OIL CLEARANCE

Inspect the crankshaft bearing journals. (Refer to 9

- ENGINE/ENGINE BLOCK/CRANKSHAFT -

INSPECTION)

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or the equivalent. The fol-lowing is the recommended procedures for the use of

Plastigage with the engine in the vehicle or engine

on a repair stand.

PLASTIGAGE METHODÐENGINE IN-VEHICLE

NOTE: The total clearance of the main bearings can

only be determined with the engine in the vehicle

by removing the weight of the crankshaft. This can

be accomplished by either of two following meth-

ods:

(1) Preferred method:

a. Shim the bearings adjacent to the bearing to be

checked in order to remove the clearance between

upper bearing shell and the crankshaft. This can be

accomplished by placing a minimum of 0.254 mm

(0.010 in.) shim (e. g. cardboard, matchbook cover,

etc.) between the bearing shell and the bearing cap

on the adjacent bearings and tightening bolts to

14±20 N´m (10±15 ft. lbs.).

²When checking #1 main bearing shim #2 main

bearing.

²When checking #2 main bearing shim #1 & #3

main bearing.

²When checking #3 main bearing shim #2 & #4

main bearing.

²When checking #4 main bearing shim #3 main

bearing.

NOTE: Remove all shims before reassembling

engine.

(2) Alternative Method:

a. Support the weight of the crankshaft with a

jack under the counterweight adjacent to the bearing

being checked.

(3) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(4) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 60). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

(5) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 61) with the scale

provided on the package. Locate the band closest to

the same width. This band shows the amount of

clearance in thousandths. Differences in readings

between the ends indicate the amount of taper

present. Record all readings taken. (Refer to 9 -

ENGINE - SPECIFICATIONS)Plastigage gener-

ally is accompanied by two scales. One scale is

in inches, the other is a metric scale.

Fig. 58 Main Bearing Cap Identification

Fig. 59 Main Bearing Identification

1 - OIL GROOVES

2 - OIL HOLES

3 - UPPER BEARINGS

4 - LOWER BEARINGS

9 - 120 ENGINE 3.3/3.8LRS

CRANKSHAFT MAIN BEARINGS (Continued)

ProCarManuals.com

Page 1322 of 2399

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

PLASTIGAGE METHODÐENGINE OUT-OF-VEHICLE

(1) With engine in the inverted position (crank-

shaft up) and mounted on a repair stand, remove

main journal cap.

(2) Remove oil from journal and bearing shell.

(3) Cut Plastigage to same length as width of the

bearing and place it in parallel with the journal axis

(Fig. 60).

(4) Carefully install the main bearing cap and

tighten the bolts to specified torque.

CAUTION: Do not rotate crankshaft or the Plasti-

gage will be smeared.

(5) Carefully remove the bearing cap and measure

the width of the Plastigage at the widest part using

the scale on the Plastigage package (Fig. 61). Refer

to Engine Specifications for proper clearances (Refer

to 9 - ENGINE - SPECIFICATIONS). If the clearance

exceeds the specified limits, replace the main bear-

ing(s) with the appropriate size, and if necessary,

have the crankshaft machined to next undersize.REMOVAL - CRANKSHAFT MAIN BEARINGS

(1) Remove the oil pan. (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL)

(2) Identify main bearing caps before removal.

(3) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059 (Fig. 62) into the oil hole of crank-

shaft.

(4) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION - CRANKSHAFT MAIN

BEARINGS

NOTE: One main bearing should be selectively fit-

ted while all other main bearing caps are properly

tightened.

(1) For main bearing fitting procedure, (Refer to 9

- ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE)

(2) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 62).

(3) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

(4) Inspect main cap bolts for stretching (Fig. 63).

Replace bolts that are stretched.

Fig. 60 Plastigage Placed in Lower

1 - PLASTIGAGE

Fig. 61 Clearance Measurement

Fig. 62 Upper Main Bearing Removing/Installing

With Special Tool C-3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARING

RSENGINE 3.3/3.8L9 - 121

CRANKSHAFT MAIN BEARINGS (Continued)

ProCarManuals.com