transfer shaft CHRYSLER CARAVAN 2002 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1702 of 2399

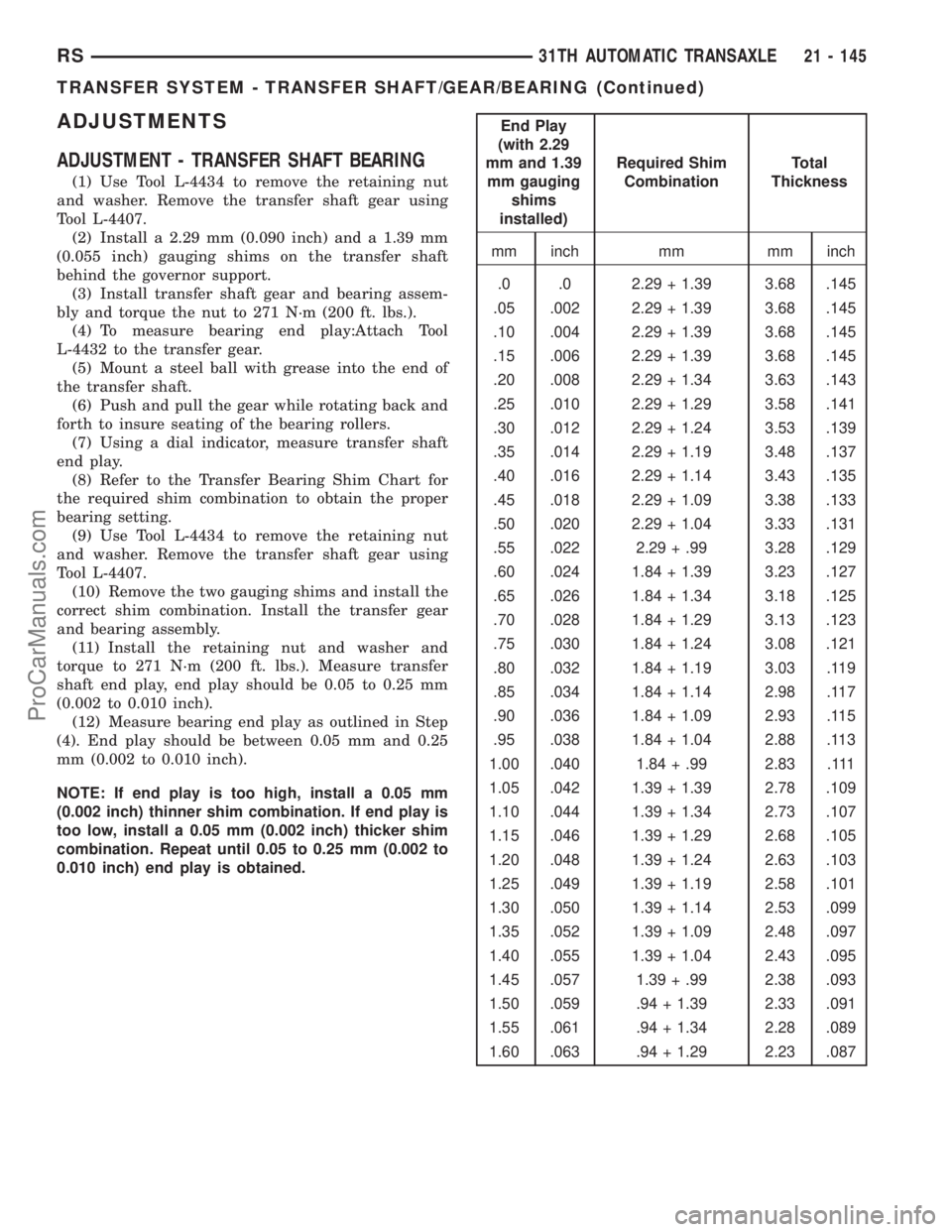

ADJUSTMENTS

ADJUSTMENT - TRANSFER SHAFT BEARING

(1) Use Tool L-4434 to remove the retaining nut

and washer. Remove the transfer shaft gear using

Tool L-4407.

(2) Install a 2.29 mm (0.090 inch) and a 1.39 mm

(0.055 inch) gauging shims on the transfer shaft

behind the governor support.

(3) Install transfer shaft gear and bearing assem-

bly and torque the nut to 271 N´m (200 ft. lbs.).

(4) To measure bearing end play:Attach Tool

L-4432 to the transfer gear.

(5) Mount a steel ball with grease into the end of

the transfer shaft.

(6) Push and pull the gear while rotating back and

forth to insure seating of the bearing rollers.

(7) Using a dial indicator, measure transfer shaft

end play.

(8) Refer to the Transfer Bearing Shim Chart for

the required shim combination to obtain the proper

bearing setting.

(9) Use Tool L-4434 to remove the retaining nut

and washer. Remove the transfer shaft gear using

Tool L-4407.

(10) Remove the two gauging shims and install the

correct shim combination. Install the transfer gear

and bearing assembly.

(11) Install the retaining nut and washer and

torque to 271 N´m (200 ft. lbs.). Measure transfer

shaft end play, end play should be 0.05 to 0.25 mm

(0.002 to 0.010 inch).

(12) Measure bearing end play as outlined in Step

(4). End play should be between 0.05 mm and 0.25

mm (0.002 to 0.010 inch).

NOTE: If end play is too high, install a 0.05 mm

(0.002 inch) thinner shim combination. If end play is

too low, install a 0.05 mm (0.002 inch) thicker shim

combination. Repeat until 0.05 to 0.25 mm (0.002 to

0.010 inch) end play is obtained.

End Play

(with 2.29

mm and 1.39

mm gauging

shims

installed)Required Shim

CombinationTotal

Thickness

mm inch mm mm inch

.0 .0 2.29 + 1.39 3.68 .145

.05 .002 2.29 + 1.39 3.68 .145

.10 .004 2.29 + 1.39 3.68 .145

.15 .006 2.29 + 1.39 3.68 .145

.20 .008 2.29 + 1.34 3.63 .143

.25 .010 2.29 + 1.29 3.58 .141

.30 .012 2.29 + 1.24 3.53 .139

.35 .014 2.29 + 1.19 3.48 .137

.40 .016 2.29 + 1.14 3.43 .135

.45 .018 2.29 + 1.09 3.38 .133

.50 .020 2.29 + 1.04 3.33 .131

.55 .022 2.29 + .99 3.28 .129

.60 .024 1.84 + 1.39 3.23 .127

.65 .026 1.84 + 1.34 3.18 .125

.70 .028 1.84 + 1.29 3.13 .123

.75 .030 1.84 + 1.24 3.08 .121

.80 .032 1.84 + 1.19 3.03 .119

.85 .034 1.84 + 1.14 2.98 .117

.90 .036 1.84 + 1.09 2.93 .115

.95 .038 1.84 + 1.04 2.88 .113

1.00 .040 1.84 + .99 2.83 .111

1.05 .042 1.39 + 1.39 2.78 .109

1.10 .044 1.39 + 1.34 2.73 .107

1.15 .046 1.39 + 1.29 2.68 .105

1.20 .048 1.39 + 1.24 2.63 .103

1.25 .049 1.39 + 1.19 2.58 .101

1.30 .050 1.39 + 1.14 2.53 .099

1.35 .052 1.39 + 1.09 2.48 .097

1.40 .055 1.39 + 1.04 2.43 .095

1.45 .057 1.39 + .99 2.38 .093

1.50 .059 .94 + 1.39 2.33 .091

1.55 .061 .94 + 1.34 2.28 .089

1.60 .063 .94 + 1.29 2.23 .087

RS31TH AUTOMATIC TRANSAXLE21 - 145

TRANSFER SYSTEM - TRANSFER SHAFT/GEAR/BEARING (Continued)

ProCarManuals.com

Page 1706 of 2399

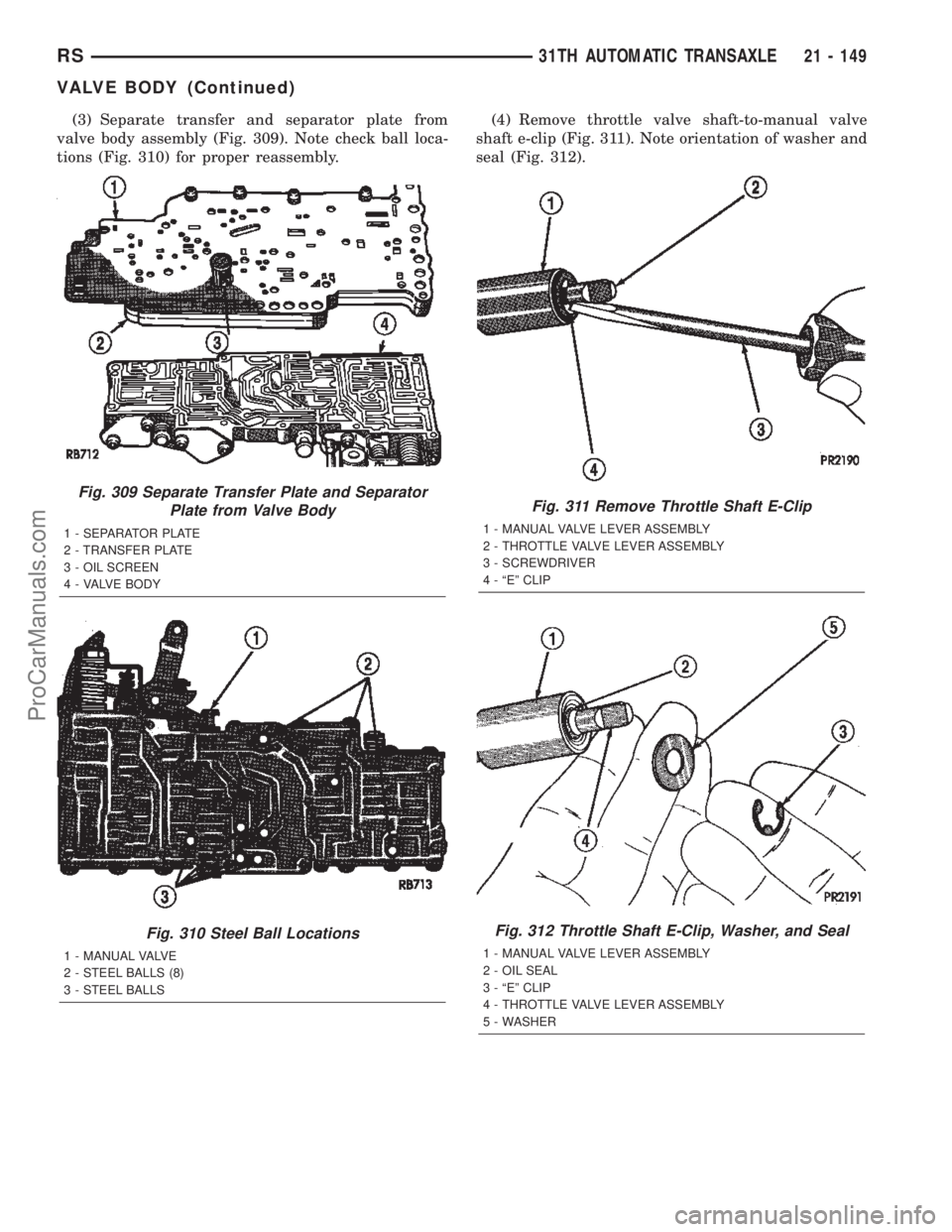

(3) Separate transfer and separator plate from

valve body assembly (Fig. 309). Note check ball loca-

tions (Fig. 310) for proper reassembly.(4) Remove throttle valve shaft-to-manual valve

shaft e-clip (Fig. 311). Note orientation of washer and

seal (Fig. 312).

Fig. 309 Separate Transfer Plate and Separator

Plate from Valve Body

1 - SEPARATOR PLATE

2 - TRANSFER PLATE

3 - OIL SCREEN

4 - VALVE BODY

Fig. 310 Steel Ball Locations

1 - MANUAL VALVE

2 - STEEL BALLS (8)

3 - STEEL BALLS

Fig. 311 Remove Throttle Shaft E-Clip

1 - MANUAL VALVE LEVER ASSEMBLY

2 - THROTTLE VALVE LEVER ASSEMBLY

3 - SCREWDRIVER

4 - ªEº CLIP

Fig. 312 Throttle Shaft E-Clip, Washer, and Seal

1 - MANUAL VALVE LEVER ASSEMBLY

2 - OIL SEAL

3 - ªEº CLIP

4 - THROTTLE VALVE LEVER ASSEMBLY

5 - WASHER

RS31TH AUTOMATIC TRANSAXLE21 - 149

VALVE BODY (Continued)

ProCarManuals.com

Page 1720 of 2399

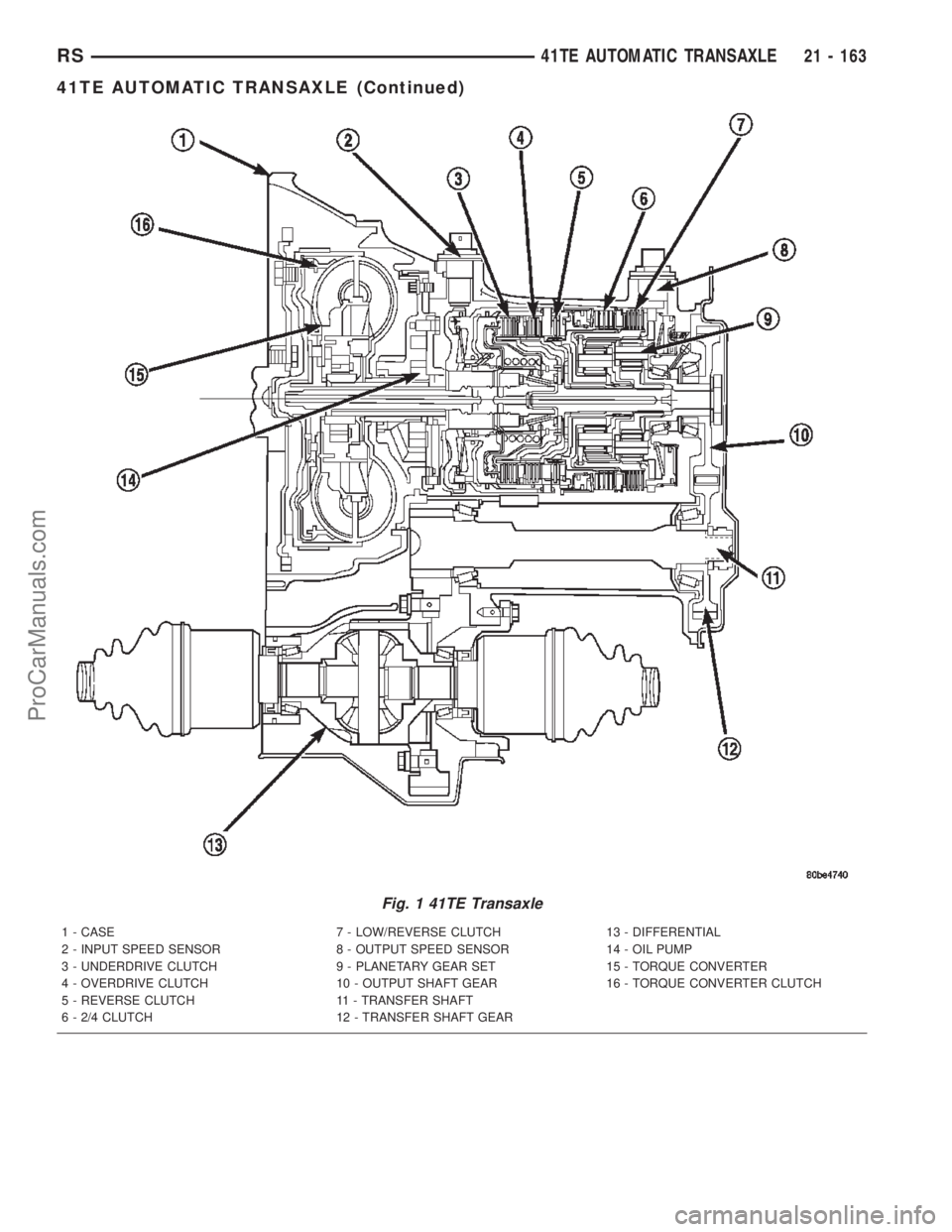

Fig. 1 41TE Transaxle

1 - CASE 7 - LOW/REVERSE CLUTCH 13 - DIFFERENTIAL

2 - INPUT SPEED SENSOR 8 - OUTPUT SPEED SENSOR 14 - OIL PUMP

3 - UNDERDRIVE CLUTCH 9 - PLANETARY GEAR SET 15 - TORQUE CONVERTER

4 - OVERDRIVE CLUTCH 10 - OUTPUT SHAFT GEAR 16 - TORQUE CONVERTER CLUTCH

5 - REVERSE CLUTCH 11 - TRANSFER SHAFT

6 - 2/4 CLUTCH 12 - TRANSFER SHAFT GEAR

RS41TE AUTOMATIC TRANSAXLE21 - 163

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1739 of 2399

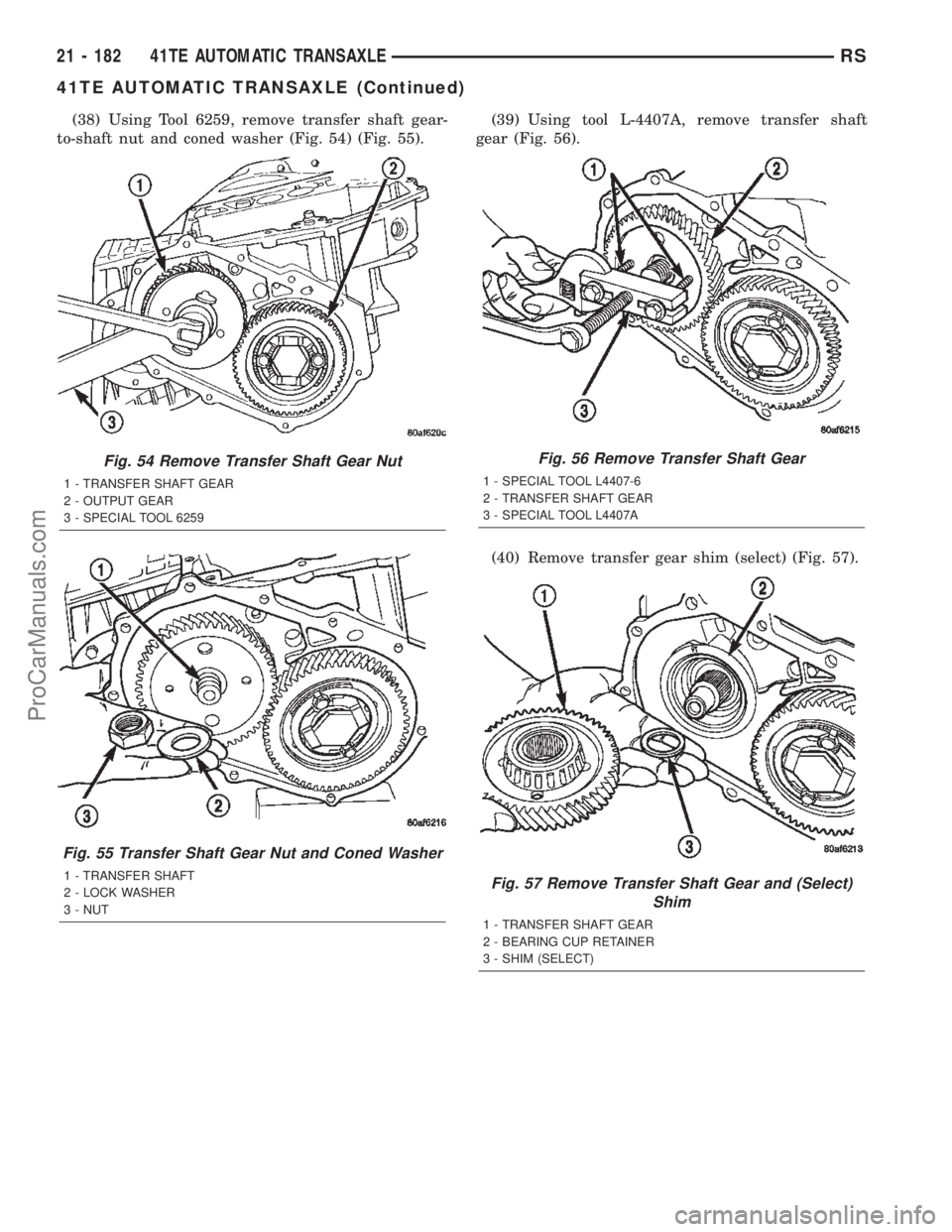

(38) Using Tool 6259, remove transfer shaft gear-

to-shaft nut and coned washer (Fig. 54) (Fig. 55).(39) Using tool L-4407A, remove transfer shaft

gear (Fig. 56).

(40) Remove transfer gear shim (select) (Fig. 57).

Fig. 54 Remove Transfer Shaft Gear Nut

1 - TRANSFER SHAFT GEAR

2 - OUTPUT GEAR

3 - SPECIAL TOOL 6259

Fig. 55 Transfer Shaft Gear Nut and Coned Washer

1 - TRANSFER SHAFT

2 - LOCK WASHER

3 - NUT

Fig. 56 Remove Transfer Shaft Gear

1 - SPECIAL TOOL L4407-6

2 - TRANSFER SHAFT GEAR

3 - SPECIAL TOOL L4407A

Fig. 57 Remove Transfer Shaft Gear and (Select)

Shim

1 - TRANSFER SHAFT GEAR

2 - BEARING CUP RETAINER

3 - SHIM (SELECT)

21 - 182 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1740 of 2399

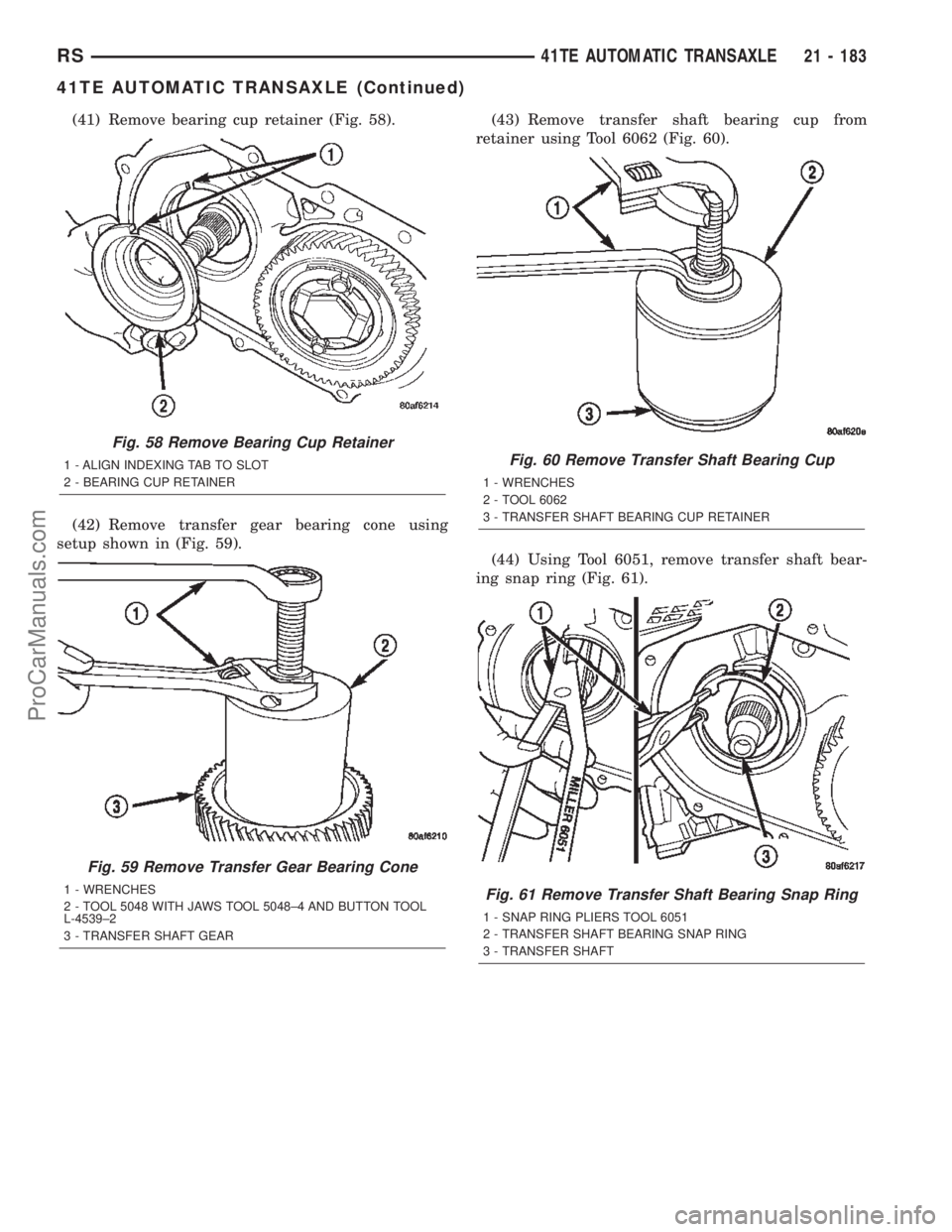

(41) Remove bearing cup retainer (Fig. 58).

(42) Remove transfer gear bearing cone using

setup shown in (Fig. 59).(43) Remove transfer shaft bearing cup from

retainer using Tool 6062 (Fig. 60).

(44) Using Tool 6051, remove transfer shaft bear-

ing snap ring (Fig. 61).

Fig. 58 Remove Bearing Cup Retainer

1 - ALIGN INDEXING TAB TO SLOT

2 - BEARING CUP RETAINER

Fig. 59 Remove Transfer Gear Bearing Cone

1 - WRENCHES

2 - TOOL 5048 WITH JAWS TOOL 5048±4 AND BUTTON TOOL

L-4539±2

3 - TRANSFER SHAFT GEAR

Fig. 60 Remove Transfer Shaft Bearing Cup

1 - WRENCHES

2 - TOOL 6062

3 - TRANSFER SHAFT BEARING CUP RETAINER

Fig. 61 Remove Transfer Shaft Bearing Snap Ring

1 - SNAP RING PLIERS TOOL 6051

2 - TRANSFER SHAFT BEARING SNAP RING

3 - TRANSFER SHAFT

RS41TE AUTOMATIC TRANSAXLE21 - 183

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1741 of 2399

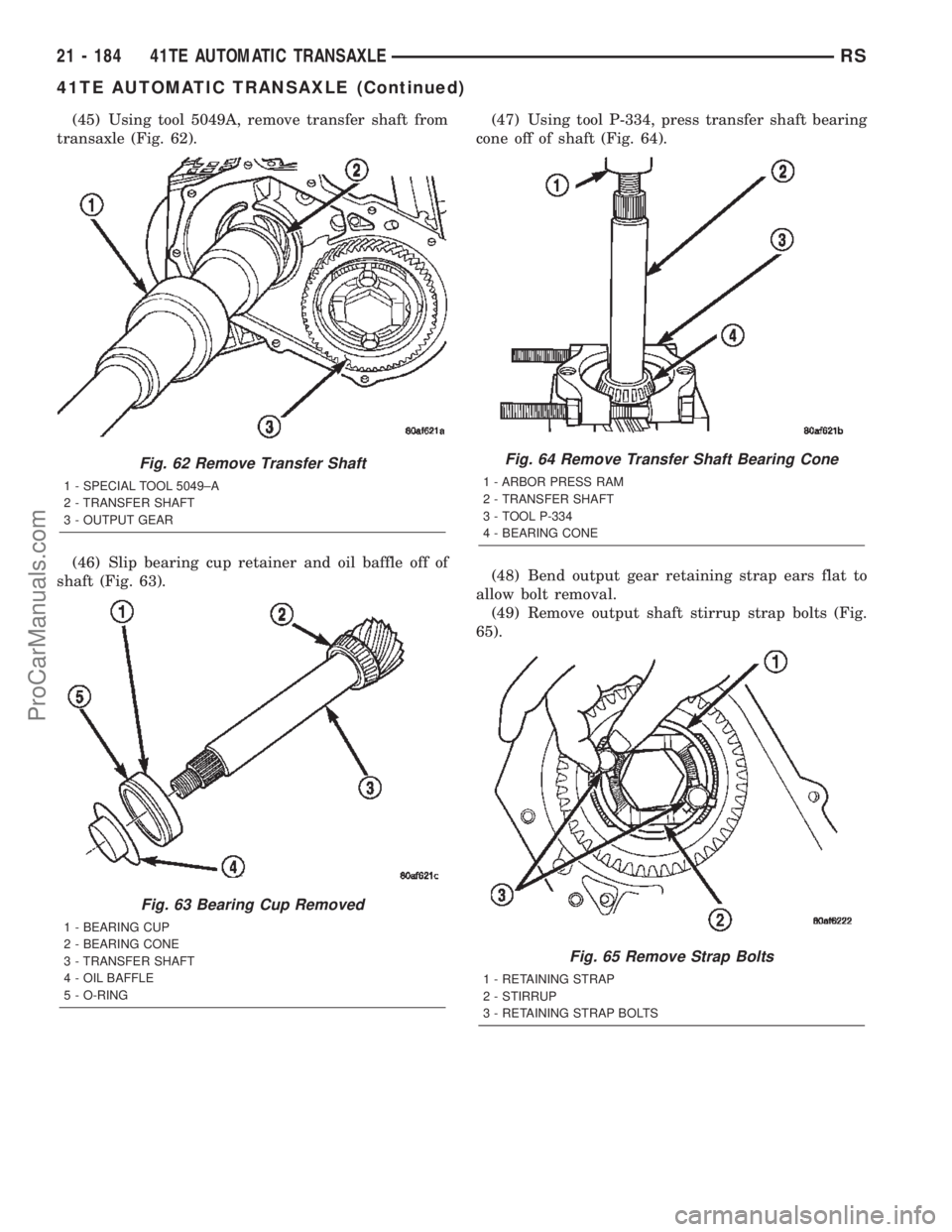

(45) Using tool 5049A, remove transfer shaft from

transaxle (Fig. 62).

(46) Slip bearing cup retainer and oil baffle off of

shaft (Fig. 63).(47) Using tool P-334, press transfer shaft bearing

cone off of shaft (Fig. 64).

(48) Bend output gear retaining strap ears flat to

allow bolt removal.

(49) Remove output shaft stirrup strap bolts (Fig.

65).

Fig. 62 Remove Transfer Shaft

1 - SPECIAL TOOL 5049±A

2 - TRANSFER SHAFT

3 - OUTPUT GEAR

Fig. 63 Bearing Cup Removed

1 - BEARING CUP

2 - BEARING CONE

3 - TRANSFER SHAFT

4 - OIL BAFFLE

5 - O-RING

Fig. 64 Remove Transfer Shaft Bearing Cone

1 - ARBOR PRESS RAM

2 - TRANSFER SHAFT

3 - TOOL P-334

4 - BEARING CONE

Fig. 65 Remove Strap Bolts

1 - RETAINING STRAP

2 - STIRRUP

3 - RETAINING STRAP BOLTS

21 - 184 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1755 of 2399

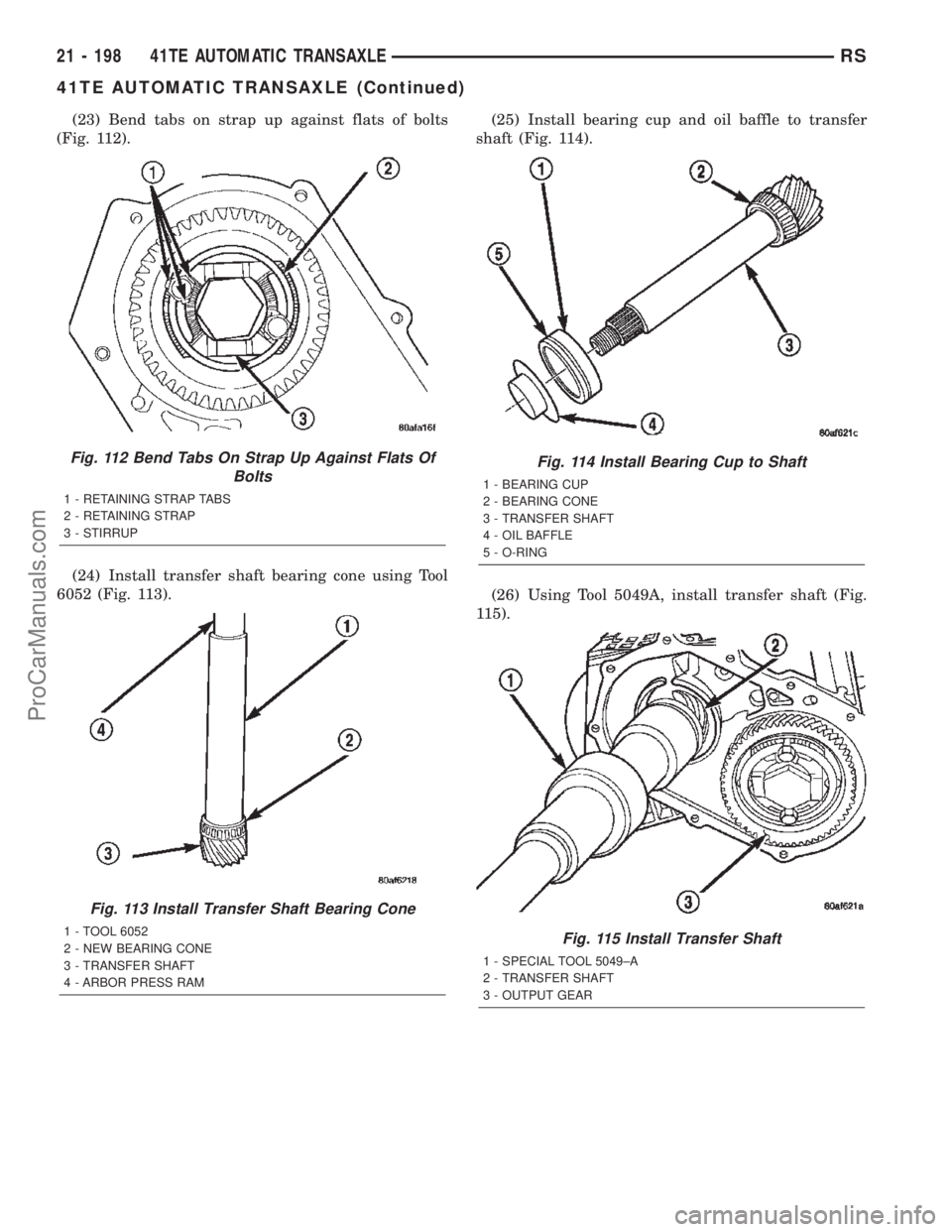

(23) Bend tabs on strap up against flats of bolts

(Fig. 112).

(24) Install transfer shaft bearing cone using Tool

6052 (Fig. 113).(25) Install bearing cup and oil baffle to transfer

shaft (Fig. 114).

(26) Using Tool 5049A, install transfer shaft (Fig.

115).

Fig. 112 Bend Tabs On Strap Up Against Flats Of

Bolts

1 - RETAINING STRAP TABS

2 - RETAINING STRAP

3 - STIRRUP

Fig. 113 Install Transfer Shaft Bearing Cone

1 - TOOL 6052

2 - NEW BEARING CONE

3 - TRANSFER SHAFT

4 - ARBOR PRESS RAM

Fig. 114 Install Bearing Cup to Shaft

1 - BEARING CUP

2 - BEARING CONE

3 - TRANSFER SHAFT

4 - OIL BAFFLE

5 - O-RING

Fig. 115 Install Transfer Shaft

1 - SPECIAL TOOL 5049±A

2 - TRANSFER SHAFT

3 - OUTPUT GEAR

21 - 198 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1756 of 2399

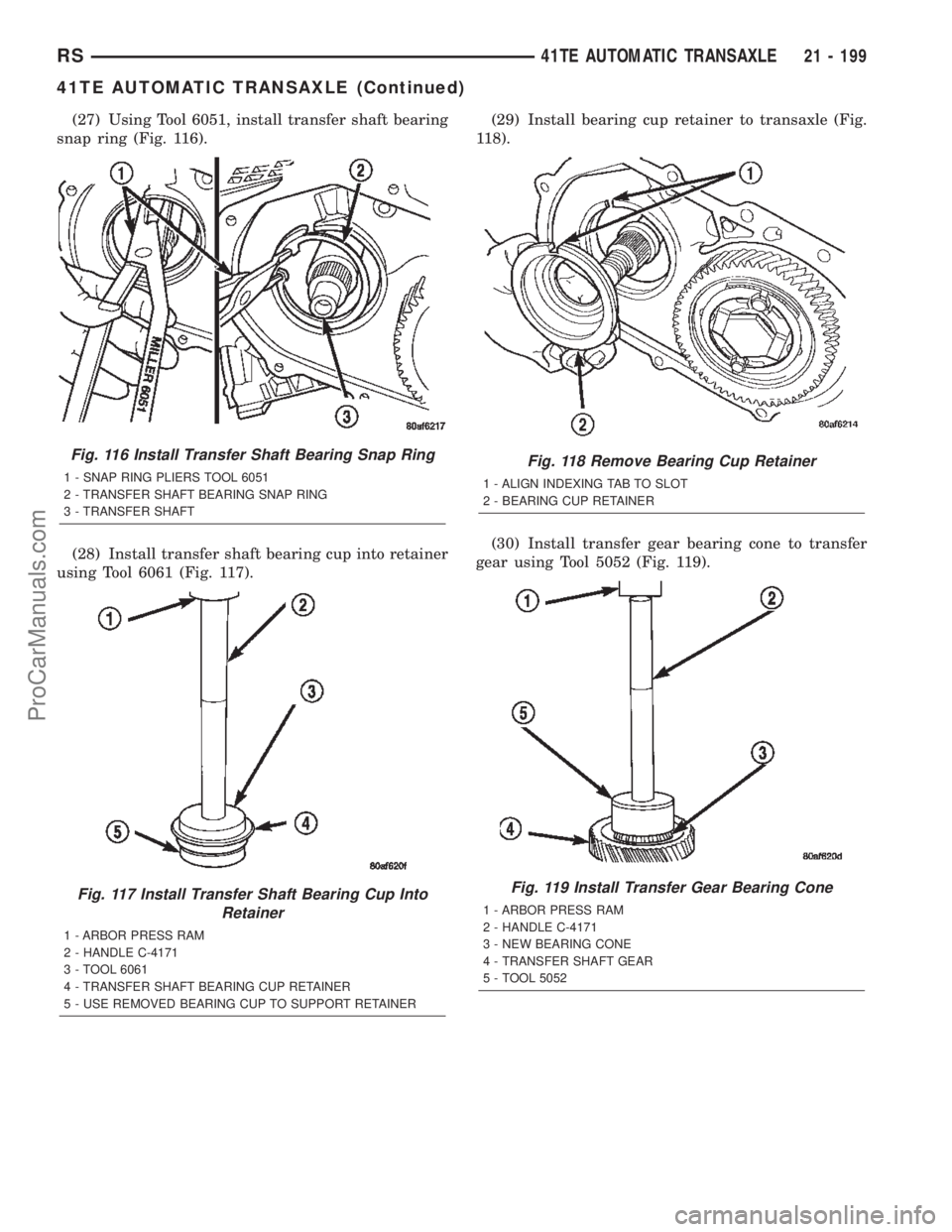

(27) Using Tool 6051, install transfer shaft bearing

snap ring (Fig. 116).

(28) Install transfer shaft bearing cup into retainer

using Tool 6061 (Fig. 117).(29) Install bearing cup retainer to transaxle (Fig.

118).

(30) Install transfer gear bearing cone to transfer

gear using Tool 5052 (Fig. 119).

Fig. 116 Install Transfer Shaft Bearing Snap Ring

1 - SNAP RING PLIERS TOOL 6051

2 - TRANSFER SHAFT BEARING SNAP RING

3 - TRANSFER SHAFT

Fig. 117 Install Transfer Shaft Bearing Cup Into

Retainer

1 - ARBOR PRESS RAM

2 - HANDLE C-4171

3 - TOOL 6061

4 - TRANSFER SHAFT BEARING CUP RETAINER

5 - USE REMOVED BEARING CUP TO SUPPORT RETAINER

Fig. 118 Remove Bearing Cup Retainer

1 - ALIGN INDEXING TAB TO SLOT

2 - BEARING CUP RETAINER

Fig. 119 Install Transfer Gear Bearing Cone

1 - ARBOR PRESS RAM

2 - HANDLE C-4171

3 - NEW BEARING CONE

4 - TRANSFER SHAFT GEAR

5 - TOOL 5052

RS41TE AUTOMATIC TRANSAXLE21 - 199

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1757 of 2399

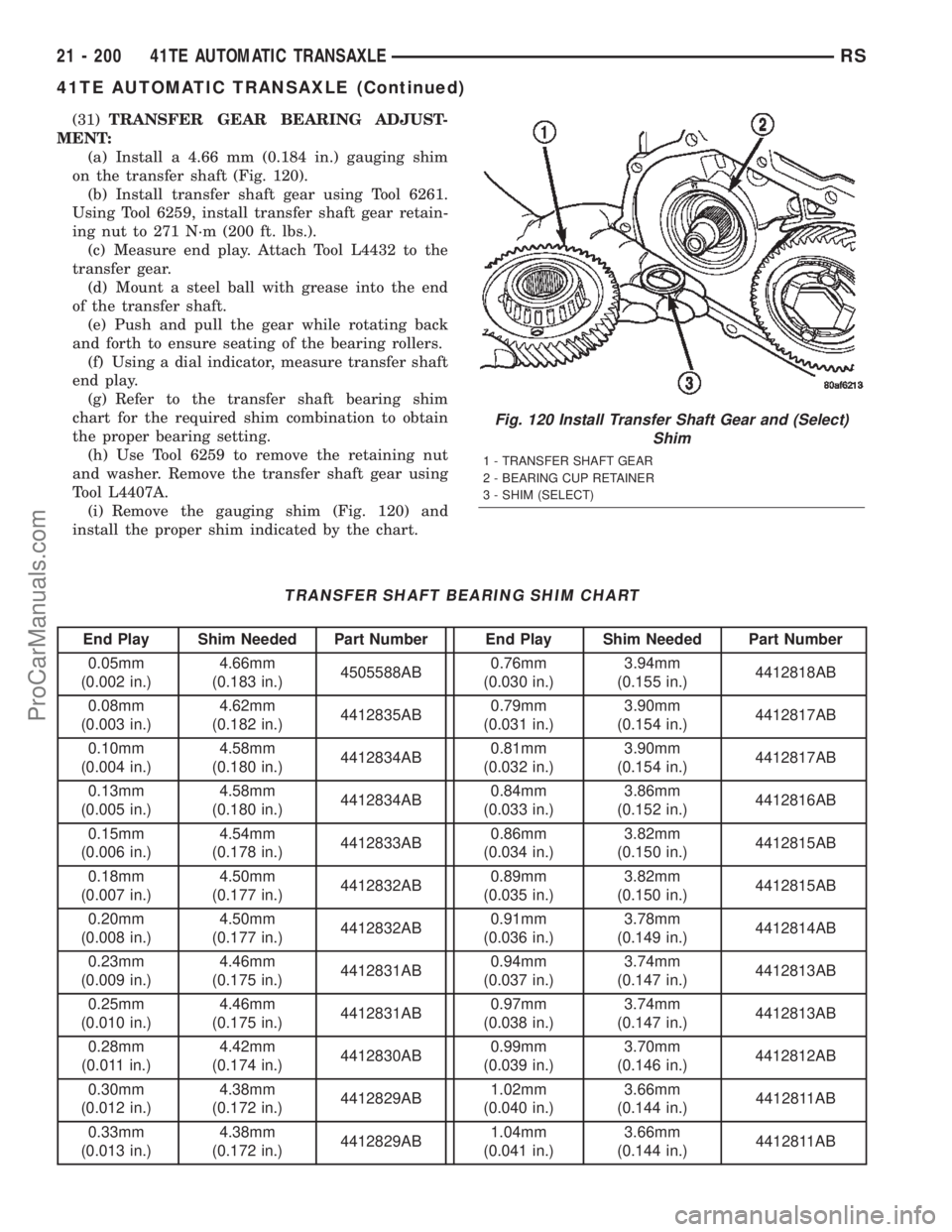

(31)TRANSFER GEAR BEARING ADJUST-

MENT:

(a) Install a 4.66 mm (0.184 in.) gauging shim

on the transfer shaft (Fig. 120).

(b) Install transfer shaft gear using Tool 6261.

Using Tool 6259, install transfer shaft gear retain-

ing nut to 271 N´m (200 ft. lbs.).

(c) Measure end play. Attach Tool L4432 to the

transfer gear.

(d) Mount a steel ball with grease into the end

of the transfer shaft.

(e) Push and pull the gear while rotating back

and forth to ensure seating of the bearing rollers.

(f) Using a dial indicator, measure transfer shaft

end play.

(g) Refer to the transfer shaft bearing shim

chart for the required shim combination to obtain

the proper bearing setting.

(h) Use Tool 6259 to remove the retaining nut

and washer. Remove the transfer shaft gear using

Tool L4407A.

(i) Remove the gauging shim (Fig. 120) and

install the proper shim indicated by the chart.

TRANSFER SHAFT BEARING SHIM CHART

End Play Shim Needed Part Number End Play Shim Needed Part Number

0.05mm

(0.002 in.)4.66mm

(0.183 in.)4505588AB0.76mm

(0.030 in.)3.94mm

(0.155 in.)4412818AB

0.08mm

(0.003 in.)4.62mm

(0.182 in.)4412835AB0.79mm

(0.031 in.)3.90mm

(0.154 in.)4412817AB

0.10mm

(0.004 in.)4.58mm

(0.180 in.)4412834AB0.81mm

(0.032 in.)3.90mm

(0.154 in.)4412817AB

0.13mm

(0.005 in.)4.58mm

(0.180 in.)4412834AB0.84mm

(0.033 in.)3.86mm

(0.152 in.)4412816AB

0.15mm

(0.006 in.)4.54mm

(0.178 in.)4412833AB0.86mm

(0.034 in.)3.82mm

(0.150 in.)4412815AB

0.18mm

(0.007 in.)4.50mm

(0.177 in.)4412832AB0.89mm

(0.035 in.)3.82mm

(0.150 in.)4412815AB

0.20mm

(0.008 in.)4.50mm

(0.177 in.)4412832AB0.91mm

(0.036 in.)3.78mm

(0.149 in.)4412814AB

0.23mm

(0.009 in.)4.46mm

(0.175 in.)4412831AB0.94mm

(0.037 in.)3.74mm

(0.147 in.)4412813AB

0.25mm

(0.010 in.)4.46mm

(0.175 in.)4412831AB0.97mm

(0.038 in.)3.74mm

(0.147 in.)4412813AB

0.28mm

(0.011 in.)4.42mm

(0.174 in.)4412830AB0.99mm

(0.039 in.)3.70mm

(0.146 in.)4412812AB

0.30mm

(0.012 in.)4.38mm

(0.172 in.)4412829AB1.02mm

(0.040 in.)3.66mm

(0.144 in.)4412811AB

0.33mm

(0.013 in.)4.38mm

(0.172 in.)4412829AB1.04mm

(0.041 in.)3.66mm

(0.144 in.)4412811AB

Fig. 120 Install Transfer Shaft Gear and (Select)

Shim

1 - TRANSFER SHAFT GEAR

2 - BEARING CUP RETAINER

3 - SHIM (SELECT)

21 - 200 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1759 of 2399

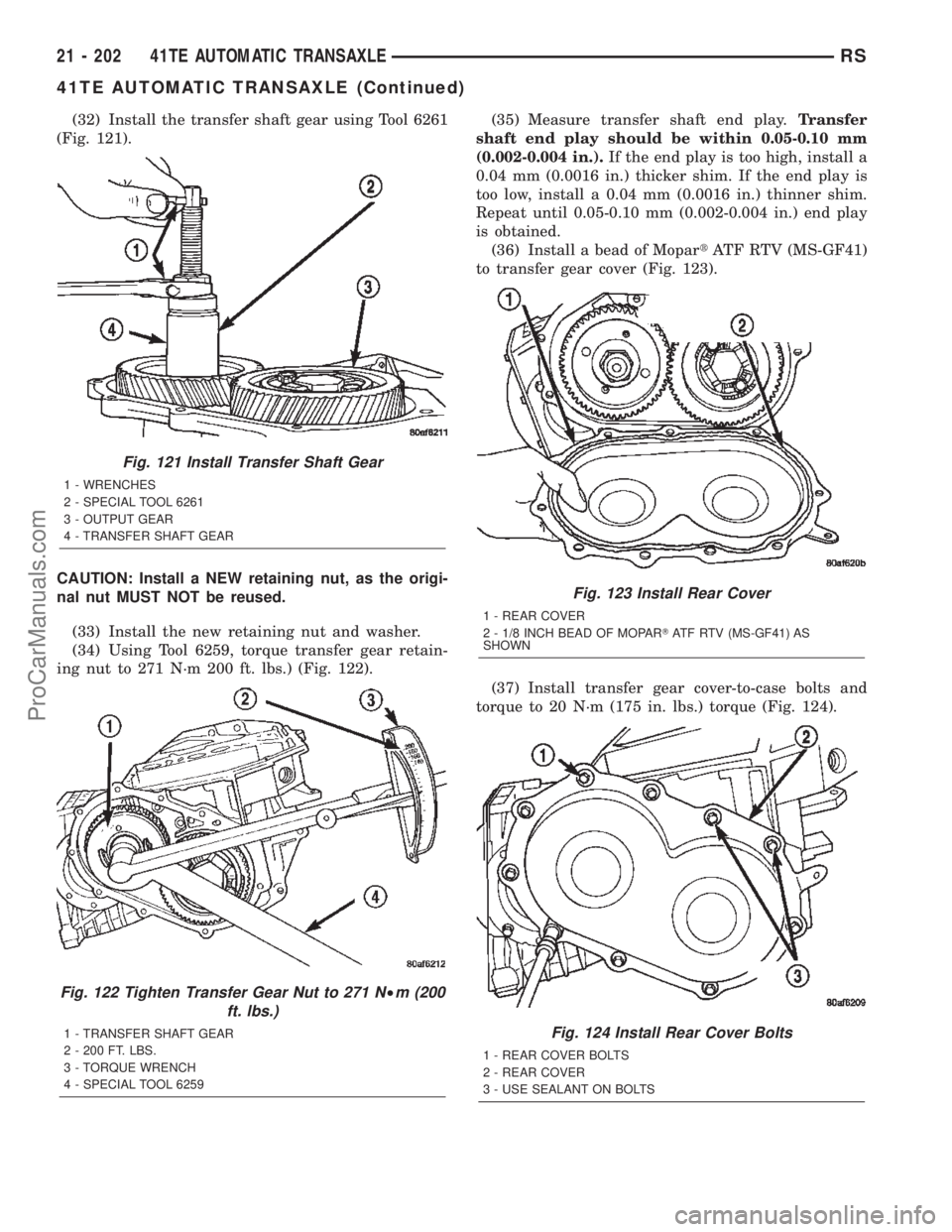

(32) Install the transfer shaft gear using Tool 6261

(Fig. 121).

CAUTION: Install a NEW retaining nut, as the origi-

nal nut MUST NOT be reused.

(33) Install the new retaining nut and washer.

(34) Using Tool 6259, torque transfer gear retain-

ing nut to 271 N´m 200 ft. lbs.) (Fig. 122).(35) Measure transfer shaft end play.Transfer

shaft end play should be within 0.05-0.10 mm

(0.002-0.004 in.).If the end play is too high, install a

0.04 mm (0.0016 in.) thicker shim. If the end play is

too low, install a 0.04 mm (0.0016 in.) thinner shim.

Repeat until 0.05-0.10 mm (0.002-0.004 in.) end play

is obtained.

(36) Install a bead of MopartATF RTV (MS-GF41)

to transfer gear cover (Fig. 123).

(37) Install transfer gear cover-to-case bolts and

torque to 20 N´m (175 in. lbs.) torque (Fig. 124).

Fig. 121 Install Transfer Shaft Gear

1 - WRENCHES

2 - SPECIAL TOOL 6261

3 - OUTPUT GEAR

4 - TRANSFER SHAFT GEAR

Fig. 122 Tighten Transfer Gear Nut to 271 N²m (200

ft. lbs.)

1 - TRANSFER SHAFT GEAR

2 - 200 FT. LBS.

3 - TORQUE WRENCH

4 - SPECIAL TOOL 6259

Fig. 123 Install Rear Cover

1 - REAR COVER

2 - 1/8 INCH BEAD OF MOPARTATF RTV (MS-GF41) AS

SHOWN

Fig. 124 Install Rear Cover Bolts

1 - REAR COVER BOLTS

2 - REAR COVER

3 - USE SEALANT ON BOLTS

21 - 202 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com