wiring CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1734 of 2177

BODY

TABLE OF CONTENTS

page page

BODY

DESCRIPTION - VEHICLE IDENTIFICATION....1

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 2

DIAGNOSIS AND TESTING - WIND NOISE . . . 3

STANDARD PROCEDURE

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR........................3

STANDARD PROCEDURE - HEAT STAKING . 10

SPECIFICATIONS

TORQUE............................11

BODY LUBRICATION...................12

SPECIAL TOOLS

BODY..............................13DOOR - FRONT.........................14

DOORS - SLIDING.......................24

DECKLID/HATCH/LIFTGATE/TAILGATE.......39

EXTERIOR.............................44

HOOD.................................59

INSTRUMENT PANEL.....................62

INTERIOR..............................72

PAINT.................................83

SEATS................................85

STATIONARY GLASS....................105

WEATHERSTRIP/SEALS..................110

SUNROOF.............................113

BODY STRUCTURE.....................121

BODY

DESCRIPTION - VEHICLE IDENTIFICATION

Throughout this group, references to the

DaimlerChrysler Corporation vehicle family identifi-

cation code are used when describing a procedure

that is unique to that vehicle. Refer to Introduction

Group of this manual for detailed information on

vehicle identification. If a procedure is common to all

vehicles covered in this manual, no reference will be

made to a vehicle family code.

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE THATIS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.

Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to fin-

ish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

RSBODY23-1

ProCarManuals.com

Page 1736 of 2177

DIAGNOSIS AND TESTING - WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

STANDARD PROCEDURE

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR

There are many different types of plastics used in

today's automotive environment. We group plastics in

three different categories: Rigid, Semi-Rigid, and

Flexible. Any of these plastics may require the use of

an adhesion promoter for repair. These types of plas-

tic are used extensively on DaimlerChrysler Motors

vehicles. Always follow repair material manufactur-

er's plastic identification and repair procedures.

Rigid Plastics:

Examples of rigid plastic use: Fascias, Hoods,

Doors, and other Body Panels, which include SMC,

ABS, and Polycarbonates.

Semi-Rigid Plastics:

Examples of semi-rigid plastic use: Interior Panels,

Under Hood Panels, and other Body Trim Panels.

Flexible Plastics:

Examples of flexible plastic use: Fascias, Body

Moldings, and upper and lower Fascia Covers.

Repair Procedure:

The repair procedure for all three categories of

plastics is basically the same. The one difference is

the material used for the repair. The materials must

be specific for each substrate, rigid repair material

for rigid plastic repair, semi-rigid repair material for

semi-rigid plastic repair and flexible repair material

for flexible plastic repair.

Adhesion Promoter/Surface Modifier:

Adhesion Promoters/Surface Modifiers are required

for certain plastics. All three categories may have

plastics that require the use of adhesion promoter/

surface modifiers. Always follow repair material man-

ufacturer's plastic identification and repair

procedures.

SAFETY PRECAUTION AND WARNINGS

WARNING:

²EYE PROTECTION SHOULD BE USED WHEN

SERVICING COMPONENTS. PERSONAL INJURY

CAN RESULT.

²USE AN OSHA APPROVED BREATHING MASK

WHEN MIXING EPOXY, GRINDING, AND SPRAYING

PAINT OR SOLVENTS IN A CONFINED AREA. PER-

SONAL INJURY CAN RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

RESIN, PETROLEUM, OR ALCOHOL BASED SOL-

VENTS. PERSONAL INJURY CAN RESULT.

²DO NOT VENTURE UNDER A HOISTED VEHI-

CLE THAT IS NOT PROPERLY SUPPORTED ON

SAFETY STANDS. PERSONAL INJURY CAN

RESULT.

NOTE:

²When holes must be drilled or cut in body pan-

els, verify locations of internal body components

and electrical wiring. Damage to vehicle can result.

²Do not use abrasive chemicals or compounds

on undamaged painted surfaces around repair

areas. Damage to finish can result.

RSBODY23-3

BODY (Continued)

ProCarManuals.com

Page 1748 of 2177

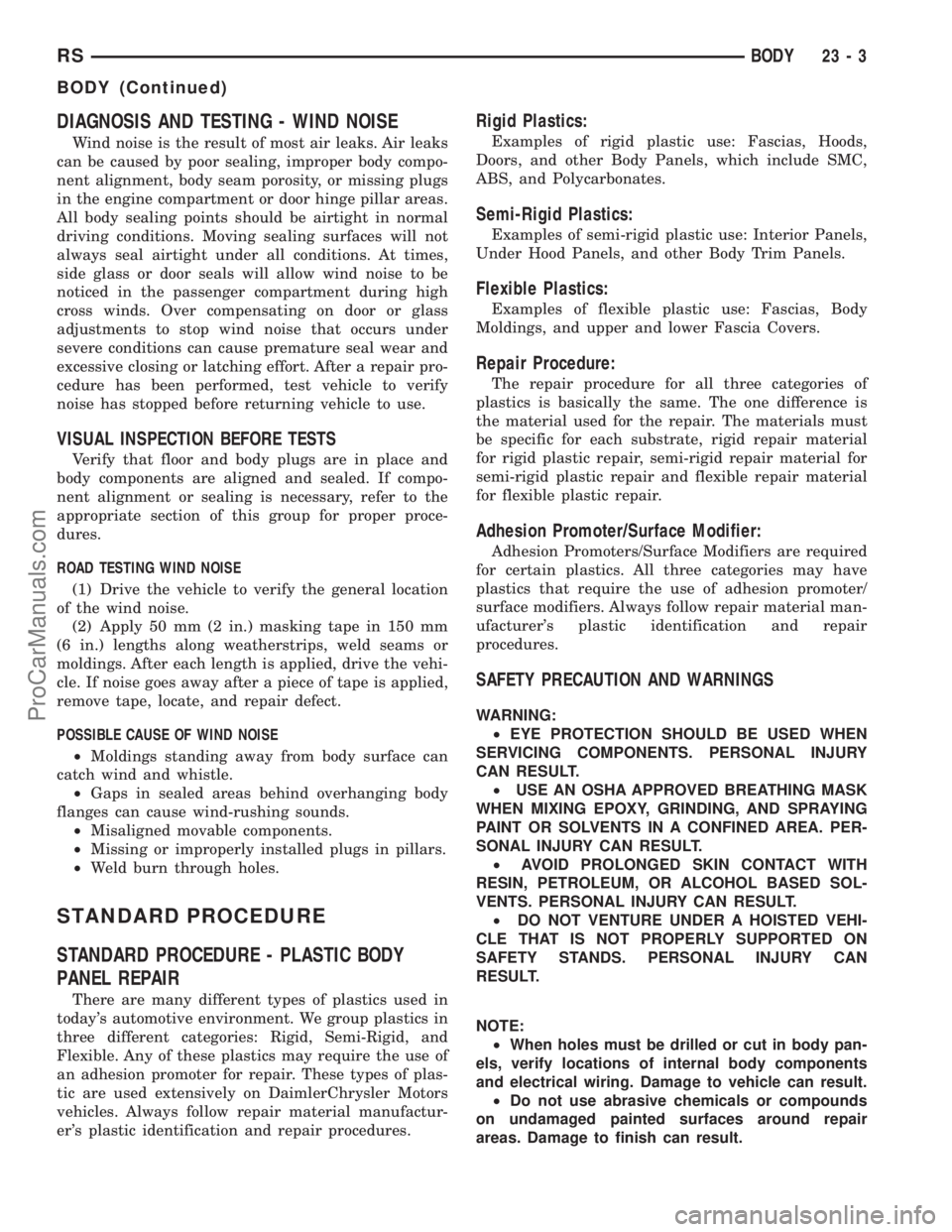

CHECK STRAP

REMOVAL

(1) Remove front door trim panel.

(2) Remove front door watershield (Refer to 23 -

BODY/DOOR - FRONT/WATERSHIELD - REMOV-

AL).

(3) Remove front door speaker, if equipped.

(4) Remove bolts attaching door check strap to

A-pillar.

(5) Remove nuts attaching check strap to door end

frame (Fig. 2).

(6) Remove check strap from door through speaker

hole.

INSTALLATION

(1) Position check strap on door through speaker

hole.

(2) Install nuts to attach check strap to door end

frame. Tighten nuts to 11 N´m (90 in. lbs.) torque.

(3) Install bolts to attach check strap to A-pillar.

Tighten bolts to 12 N´m (105 in. lbs.) torque.

(4) Install door speaker, if equipped.

(5) Install front door trim panel.

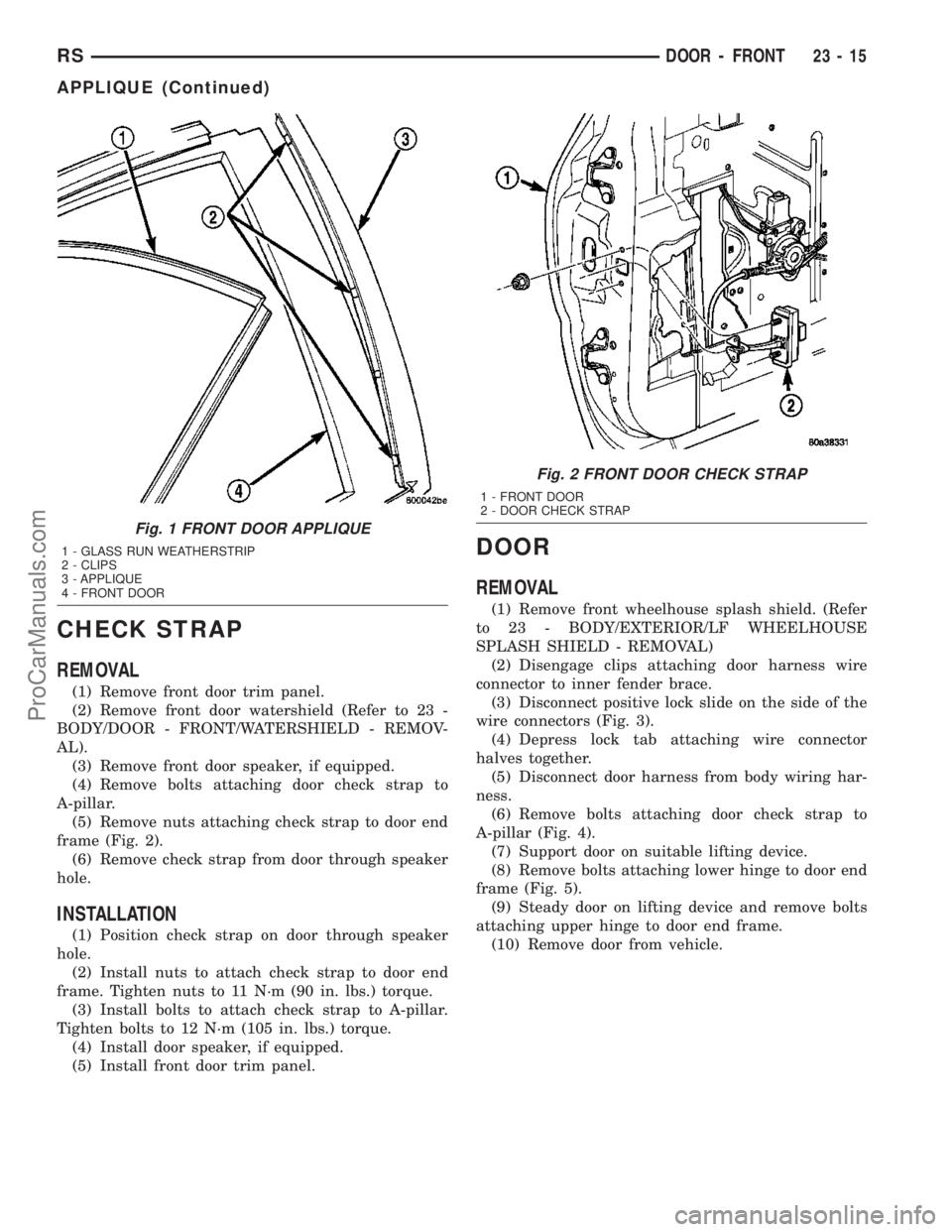

DOOR

REMOVAL

(1) Remove front wheelhouse splash shield. (Refer

to 23 - BODY/EXTERIOR/LF WHEELHOUSE

SPLASH SHIELD - REMOVAL)

(2) Disengage clips attaching door harness wire

connector to inner fender brace.

(3) Disconnect positive lock slide on the side of the

wire connectors (Fig. 3).

(4) Depress lock tab attaching wire connector

halves together.

(5) Disconnect door harness from body wiring har-

ness.

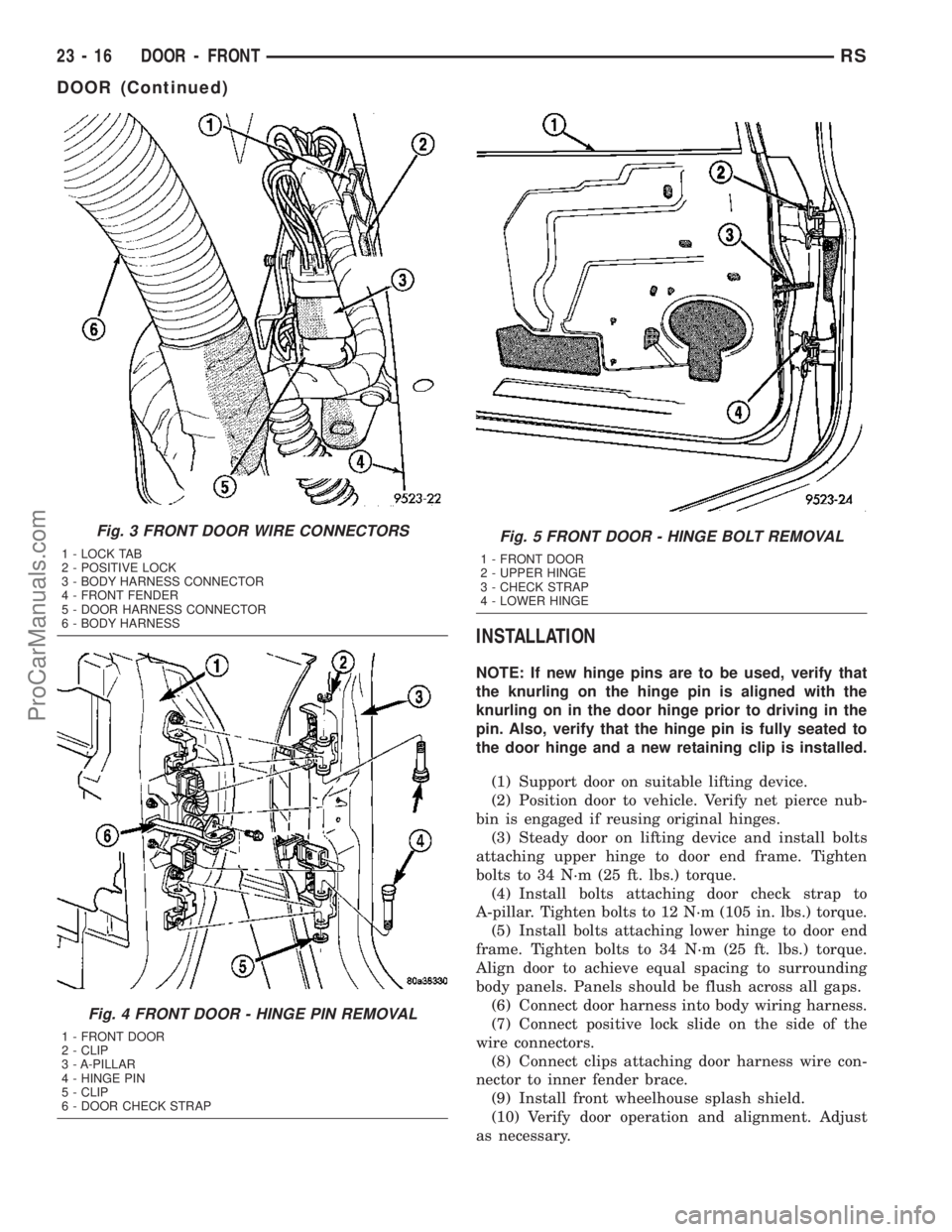

(6) Remove bolts attaching door check strap to

A-pillar (Fig. 4).

(7) Support door on suitable lifting device.

(8) Remove bolts attaching lower hinge to door end

frame (Fig. 5).

(9) Steady door on lifting device and remove bolts

attaching upper hinge to door end frame.

(10) Remove door from vehicle.

Fig. 1 FRONT DOOR APPLIQUE

1 - GLASS RUN WEATHERSTRIP

2 - CLIPS

3 - APPLIQUE

4 - FRONT DOOR

Fig. 2 FRONT DOOR CHECK STRAP

1 - FRONT DOOR

2 - DOOR CHECK STRAP

RSDOOR - FRONT23-15

APPLIQUE (Continued)

ProCarManuals.com

Page 1749 of 2177

INSTALLATION

NOTE: If new hinge pins are to be used, verify that

the knurling on the hinge pin is aligned with the

knurling on in the door hinge prior to driving in the

pin. Also, verify that the hinge pin is fully seated to

the door hinge and a new retaining clip is installed.

(1) Support door on suitable lifting device.

(2) Position door to vehicle. Verify net pierce nub-

bin is engaged if reusing original hinges.

(3) Steady door on lifting device and install bolts

attaching upper hinge to door end frame. Tighten

bolts to 34 N´m (25 ft. lbs.) torque.

(4) Install bolts attaching door check strap to

A-pillar. Tighten bolts to 12 N´m (105 in. lbs.) torque.

(5) Install bolts attaching lower hinge to door end

frame. Tighten bolts to 34 N´m (25 ft. lbs.) torque.

Align door to achieve equal spacing to surrounding

body panels. Panels should be flush across all gaps.

(6) Connect door harness into body wiring harness.

(7) Connect positive lock slide on the side of the

wire connectors.

(8) Connect clips attaching door harness wire con-

nector to inner fender brace.

(9) Install front wheelhouse splash shield.

(10) Verify door operation and alignment. Adjust

as necessary.

Fig. 3 FRONT DOOR WIRE CONNECTORS

1 - LOCK TAB

2 - POSITIVE LOCK

3 - BODY HARNESS CONNECTOR

4 - FRONT FENDER

5 - DOOR HARNESS CONNECTOR

6 - BODY HARNESS

Fig. 4 FRONT DOOR - HINGE PIN REMOVAL

1 - FRONT DOOR

2 - CLIP

3 - A-PILLAR

4 - HINGE PIN

5 - CLIP

6 - DOOR CHECK STRAP

Fig. 5 FRONT DOOR - HINGE BOLT REMOVAL

1 - FRONT DOOR

2 - UPPER HINGE

3 - CHECK STRAP

4 - LOWER HINGE

23 - 16 DOOR - FRONTRS

DOOR (Continued)

ProCarManuals.com

Page 1754 of 2177

(6) Install clips to attach door trim to door frame

around perimeter of panel.

(7) If equipped, install screw to attach door trim to

door panel behind inside latch release handle.

(8) If equipped, connect power switch into wire

connector.

(9) Place power accessary switch in position on

door trim.

(10) Connect wire connector into memory seat/mir-

ror switch and install switch into trim panel.

(11) Install screws to attach accessary switch

panel to door trim.

(12) Install screw cover into switch panel.

(13) If equipped, install window crank.

(14) If equipped, install screws to attach trim

panel to door inside map pocket.

(15) If equipped, install screw to attach door pull

cup to inner door panel.

(16) If equipped, install screws to attach door

assist handle to inner door panel.

(17) Connect wire connector into courtesy lamp.

(18) Install lamp in door trim.

(19) Install switch bezel.

WATERSHIELD

REMOVAL

(1) Remove door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL)

(2) Remove the front door speaker. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

INSTALLATION

(1) Insure that enough adhesive remains to

securely retain the water dam. Replace as necessary.

(2) Place the shield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(3) Install the front door speaker. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - INSTALLATION)

(4) Install door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

WINDOW CRANK

REMOVAL

(1) Using a window crank removal tool, disengage

clip attaching window crank to regulator shaft (Fig.

13).

NOTE: Wrap a shop towel around the window crank

to catch the clip when it springs out.

(2) Pull window crank from regulator shaft.

INSTALLATION

(1) Place the clip on to the window crank handle.

(2) Position window crank to regulator shaft.

(3) Push window crank onto regulator shaft to

engage retaining clip.

Fig. 12 INSIDE DOOR HANDLE LINKAGE

1 - DOOR LATCH HANDLE

2 - DOOR TRIM

3 - LATCH LINKAGE

4 - CLIP

5 - MEMORY SEAT SWITCH

Fig. 13 WINDOW CRANK - TYPICAL

1 - WINDOW CRANK REMOVAL TOOL

2 - WINDOW CRANK

RSDOOR - FRONT23-21

TRIM PANEL (Continued)

ProCarManuals.com

Page 1760 of 2177

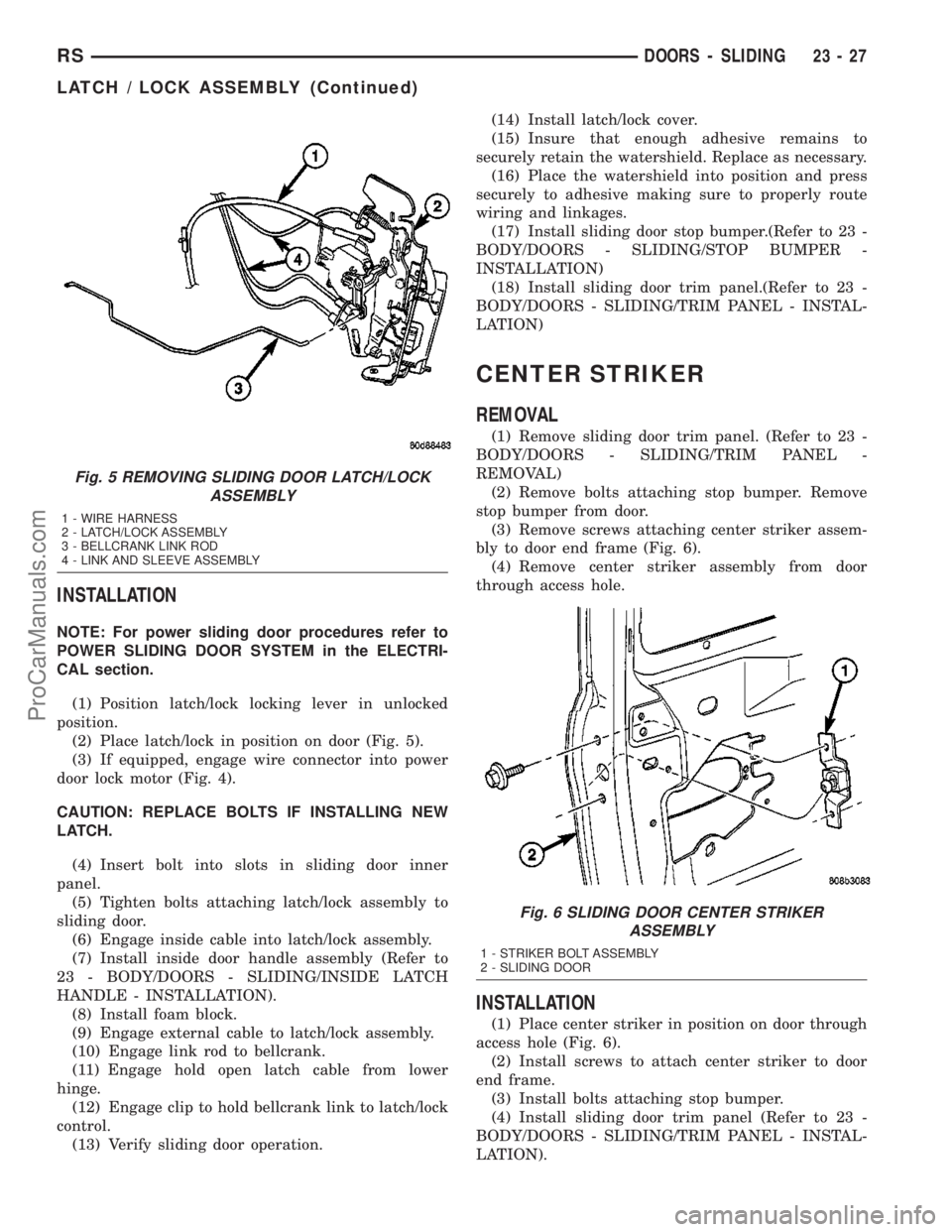

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Position latch/lock locking lever in unlocked

position.

(2) Place latch/lock in position on door (Fig. 5).

(3) If equipped, engage wire connector into power

door lock motor (Fig. 4).

CAUTION: REPLACE BOLTS IF INSTALLING NEW

LATCH.

(4) Insert bolt into slots in sliding door inner

panel.

(5) Tighten bolts attaching latch/lock assembly to

sliding door.

(6) Engage inside cable into latch/lock assembly.

(7) Install inside door handle assembly (Refer to

23 - BODY/DOORS - SLIDING/INSIDE LATCH

HANDLE - INSTALLATION).

(8) Install foam block.

(9) Engage external cable to latch/lock assembly.

(10) Engage link rod to bellcrank.

(11) Engage hold open latch cable from lower

hinge.

(12) Engage clip to hold bellcrank link to latch/lock

control.

(13) Verify sliding door operation.(14) Install latch/lock cover.

(15) Insure that enough adhesive remains to

securely retain the watershield. Replace as necessary.

(16) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(17) Install sliding door stop bumper.(Refer to 23 -

BODY/DOORS - SLIDING/STOP BUMPER -

INSTALLATION)

(18) Install sliding door trim panel.(Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION)

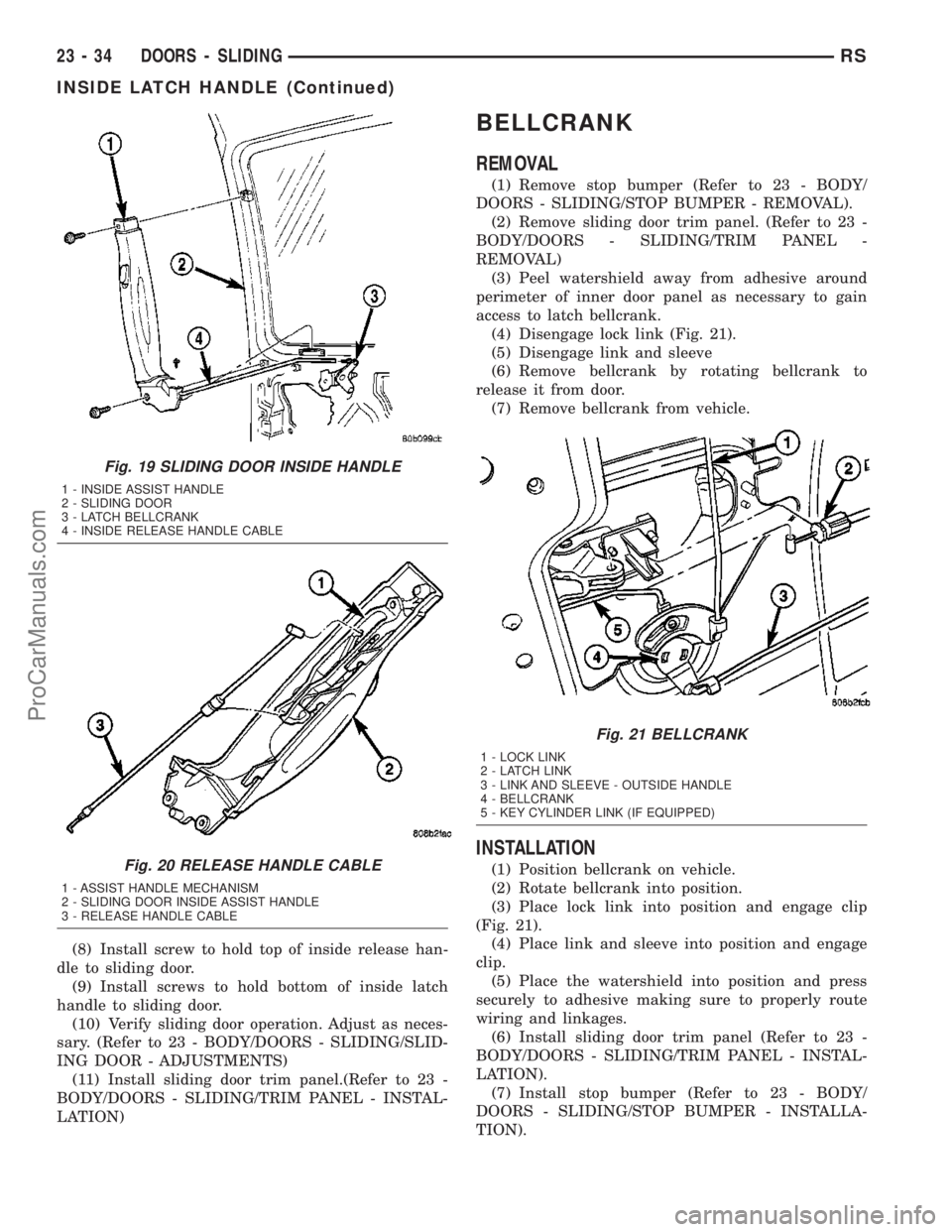

CENTER STRIKER

REMOVAL

(1) Remove sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL -

REMOVAL)

(2) Remove bolts attaching stop bumper. Remove

stop bumper from door.

(3) Remove screws attaching center striker assem-

bly to door end frame (Fig. 6).

(4) Remove center striker assembly from door

through access hole.

INSTALLATION

(1) Place center striker in position on door through

access hole (Fig. 6).

(2) Install screws to attach center striker to door

end frame.

(3) Install bolts attaching stop bumper.

(4) Install sliding door trim panel (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION).

Fig. 5 REMOVING SLIDING DOOR LATCH/LOCK

ASSEMBLY

1 - WIRE HARNESS

2 - LATCH/LOCK ASSEMBLY

3 - BELLCRANK LINK ROD

4 - LINK AND SLEEVE ASSEMBLY

Fig. 6 SLIDING DOOR CENTER STRIKER

ASSEMBLY

1 - STRIKER BOLT ASSEMBLY

2 - SLIDING DOOR

RSDOORS - SLIDING23-27

LATCH / LOCK ASSEMBLY (Continued)

ProCarManuals.com

Page 1767 of 2177

(8) Install screw to hold top of inside release han-

dle to sliding door.

(9) Install screws to hold bottom of inside latch

handle to sliding door.

(10) Verify sliding door operation. Adjust as neces-

sary. (Refer to 23 - BODY/DOORS - SLIDING/SLID-

ING DOOR - ADJUSTMENTS)

(11) Install sliding door trim panel.(Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION)

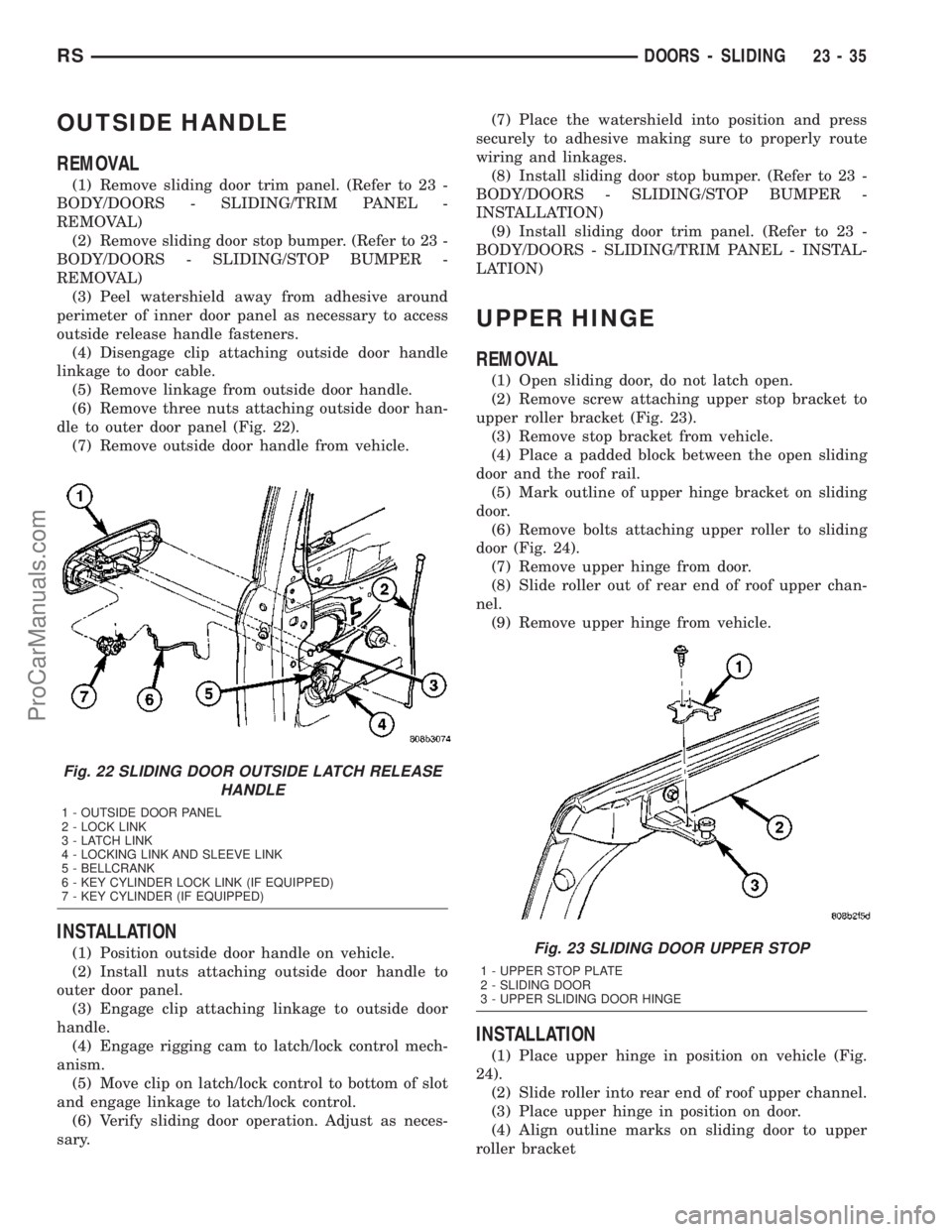

BELLCRANK

REMOVAL

(1) Remove stop bumper (Refer to 23 - BODY/

DOORS - SLIDING/STOP BUMPER - REMOVAL).

(2) Remove sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL -

REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel as necessary to gain

access to latch bellcrank.

(4) Disengage lock link (Fig. 21).

(5) Disengage link and sleeve

(6) Remove bellcrank by rotating bellcrank to

release it from door.

(7) Remove bellcrank from vehicle.

INSTALLATION

(1) Position bellcrank on vehicle.

(2) Rotate bellcrank into position.

(3) Place lock link into position and engage clip

(Fig. 21).

(4) Place link and sleeve into position and engage

clip.

(5) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(6) Install sliding door trim panel (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION).

(7) Install stop bumper (Refer to 23 - BODY/

DOORS - SLIDING/STOP BUMPER - INSTALLA-

TION).

Fig. 19 SLIDING DOOR INSIDE HANDLE

1 - INSIDE ASSIST HANDLE

2 - SLIDING DOOR

3 - LATCH BELLCRANK

4 - INSIDE RELEASE HANDLE CABLE

Fig. 20 RELEASE HANDLE CABLE

1 - ASSIST HANDLE MECHANISM

2 - SLIDING DOOR INSIDE ASSIST HANDLE

3 - RELEASE HANDLE CABLE

Fig. 21 BELLCRANK

1 - LOCK LINK

2 - LATCH LINK

3 - LINK AND SLEEVE - OUTSIDE HANDLE

4 - BELLCRANK

5 - KEY CYLINDER LINK (IF EQUIPPED)

23 - 34 DOORS - SLIDINGRS

INSIDE LATCH HANDLE (Continued)

ProCarManuals.com

Page 1768 of 2177

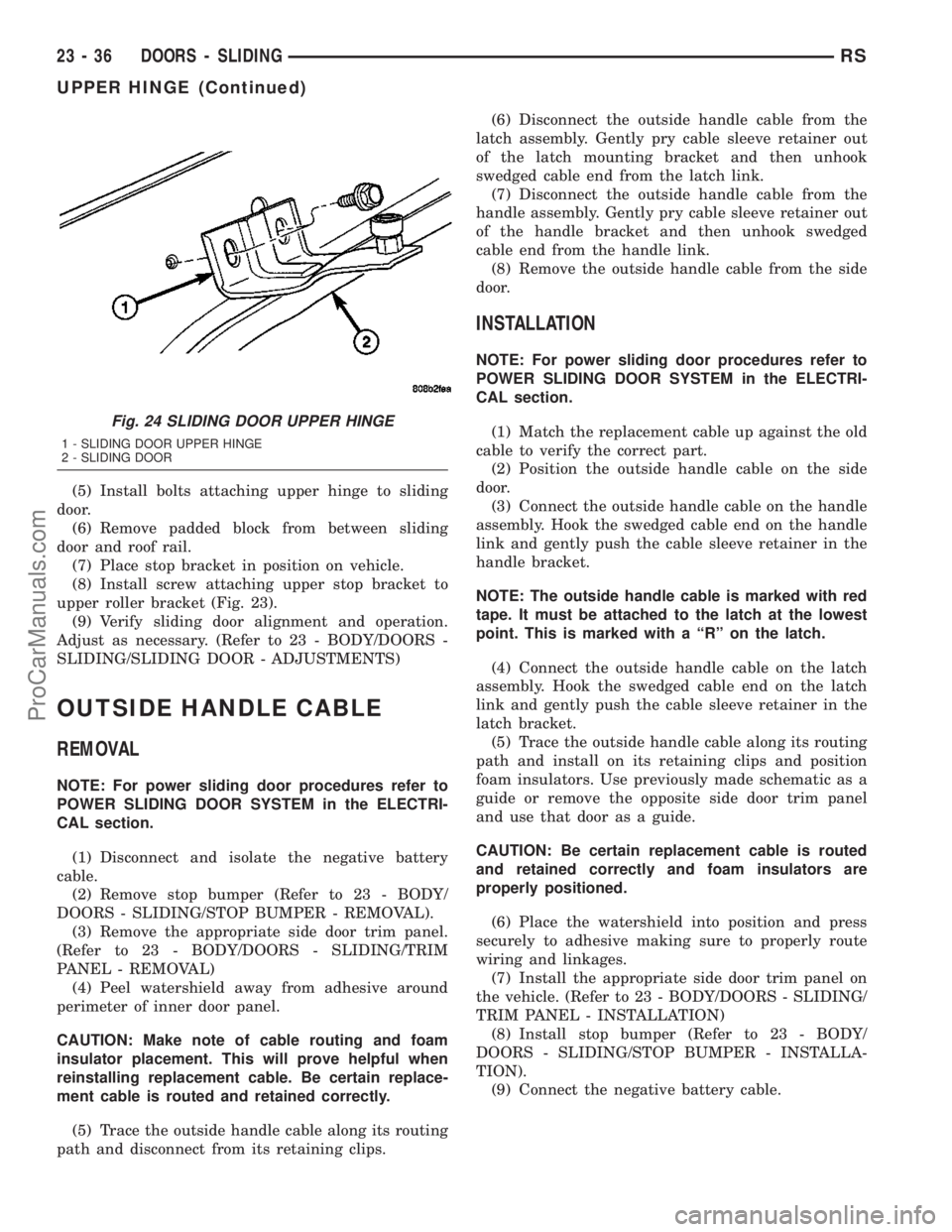

OUTSIDE HANDLE

REMOVAL

(1) Remove sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL -

REMOVAL)

(2) Remove sliding door stop bumper. (Refer to 23 -

BODY/DOORS - SLIDING/STOP BUMPER -

REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel as necessary to access

outside release handle fasteners.

(4) Disengage clip attaching outside door handle

linkage to door cable.

(5) Remove linkage from outside door handle.

(6) Remove three nuts attaching outside door han-

dle to outer door panel (Fig. 22).

(7) Remove outside door handle from vehicle.

INSTALLATION

(1) Position outside door handle on vehicle.

(2) Install nuts attaching outside door handle to

outer door panel.

(3) Engage clip attaching linkage to outside door

handle.

(4) Engage rigging cam to latch/lock control mech-

anism.

(5) Move clip on latch/lock control to bottom of slot

and engage linkage to latch/lock control.

(6) Verify sliding door operation. Adjust as neces-

sary.(7) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(8) Install sliding door stop bumper. (Refer to 23 -

BODY/DOORS - SLIDING/STOP BUMPER -

INSTALLATION)

(9) Install sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION)

UPPER HINGE

REMOVAL

(1) Open sliding door, do not latch open.

(2) Remove screw attaching upper stop bracket to

upper roller bracket (Fig. 23).

(3) Remove stop bracket from vehicle.

(4) Place a padded block between the open sliding

door and the roof rail.

(5) Mark outline of upper hinge bracket on sliding

door.

(6) Remove bolts attaching upper roller to sliding

door (Fig. 24).

(7) Remove upper hinge from door.

(8) Slide roller out of rear end of roof upper chan-

nel.

(9) Remove upper hinge from vehicle.

INSTALLATION

(1) Place upper hinge in position on vehicle (Fig.

24).

(2) Slide roller into rear end of roof upper channel.

(3) Place upper hinge in position on door.

(4) Align outline marks on sliding door to upper

roller bracket

Fig. 22 SLIDING DOOR OUTSIDE LATCH RELEASE

HANDLE

1 - OUTSIDE DOOR PANEL

2 - LOCK LINK

3 - LATCH LINK

4 - LOCKING LINK AND SLEEVE LINK

5 - BELLCRANK

6 - KEY CYLINDER LOCK LINK (IF EQUIPPED)

7 - KEY CYLINDER (IF EQUIPPED)

Fig. 23 SLIDING DOOR UPPER STOP

1 - UPPER STOP PLATE

2 - SLIDING DOOR

3 - UPPER SLIDING DOOR HINGE

RSDOORS - SLIDING23-35

ProCarManuals.com

Page 1769 of 2177

(5) Install bolts attaching upper hinge to sliding

door.

(6) Remove padded block from between sliding

door and roof rail.

(7) Place stop bracket in position on vehicle.

(8) Install screw attaching upper stop bracket to

upper roller bracket (Fig. 23).

(9) Verify sliding door alignment and operation.

Adjust as necessary. (Refer to 23 - BODY/DOORS -

SLIDING/SLIDING DOOR - ADJUSTMENTS)

OUTSIDE HANDLE CABLE

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove stop bumper (Refer to 23 - BODY/

DOORS - SLIDING/STOP BUMPER - REMOVAL).

(3) Remove the appropriate side door trim panel.

(Refer to 23 - BODY/DOORS - SLIDING/TRIM

PANEL - REMOVAL)

(4) Peel watershield away from adhesive around

perimeter of inner door panel.

CAUTION: Make note of cable routing and foam

insulator placement. This will prove helpful when

reinstalling replacement cable. Be certain replace-

ment cable is routed and retained correctly.

(5) Trace the outside handle cable along its routing

path and disconnect from its retaining clips.(6) Disconnect the outside handle cable from the

latch assembly. Gently pry cable sleeve retainer out

of the latch mounting bracket and then unhook

swedged cable end from the latch link.

(7) Disconnect the outside handle cable from the

handle assembly. Gently pry cable sleeve retainer out

of the handle bracket and then unhook swedged

cable end from the handle link.

(8) Remove the outside handle cable from the side

door.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Match the replacement cable up against the old

cable to verify the correct part.

(2) Position the outside handle cable on the side

door.

(3) Connect the outside handle cable on the handle

assembly. Hook the swedged cable end on the handle

link and gently push the cable sleeve retainer in the

handle bracket.

NOTE: The outside handle cable is marked with red

tape. It must be attached to the latch at the lowest

point. This is marked with a ªRº on the latch.

(4) Connect the outside handle cable on the latch

assembly. Hook the swedged cable end on the latch

link and gently push the cable sleeve retainer in the

latch bracket.

(5) Trace the outside handle cable along its routing

path and install on its retaining clips and position

foam insulators. Use previously made schematic as a

guide or remove the opposite side door trim panel

and use that door as a guide.

CAUTION: Be certain replacement cable is routed

and retained correctly and foam insulators are

properly positioned.

(6) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(7) Install the appropriate side door trim panel on

the vehicle. (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - INSTALLATION)

(8) Install stop bumper (Refer to 23 - BODY/

DOORS - SLIDING/STOP BUMPER - INSTALLA-

TION).

(9) Connect the negative battery cable.

Fig. 24 SLIDING DOOR UPPER HINGE

1 - SLIDING DOOR UPPER HINGE

2 - SLIDING DOOR

23 - 36 DOORS - SLIDINGRS

UPPER HINGE (Continued)

ProCarManuals.com

Page 1770 of 2177

INSIDE HANDLE CABLE

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate side door trim panel

from the vehicle. (Refer to 23 - BODY/DOORS -

SLIDING/TRIM PANEL - REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

(4) Remove the inside handle assembly from the

side door. (Refer to 23 - BODY/DOORS - SLIDING/

INSIDE LATCH HANDLE - REMOVAL)

(5) Disconnect the inside handle cable from the

handle assembly. Gently pry cable sleeve retainer out

of the handle bracket and then unhook swedged

cable end from the handle link.

(6) Open the side door and remove the latch

assembly. Refer to the Power Side Doors section for

the procedure.

CAUTION: Make note of cable routing and foam

insulator placement. This will prove helpful when

reinstalling replacement cable. Be certain replace-

ment cable is routed and retained correctly.

(7) Trace the inside handle cable along its routing

path and disconnect from its retaining clips.

(8) Disconnect the inside handle cable from the

latch assembly. Gently pry cable sleeve retainer out

of the latch mounting bracket and then unhook

swedged cable end from the latch link.

(9) Remove the inside handle cable from the side

door.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Match the replacement cable up against the old

cable to verify the correct part.

(2) Position the inside handle cable on the side

door.

(3) Connect the inside handle cable on the handle

assembly. Hook the swedged cable end on the handle

link and gently push the cable sleeve retainer in the

handle bracket.

(4) Install the inside handle assembly on the side

door. (Refer to 23 - BODY/DOORS - SLIDING/IN-

SIDE LATCH HANDLE - INSTALLATION)NOTE: The inside handle cable is marked with blue

tape and must be attached to the latch at the center

(just above the lower cable). This position is

marked with a ªBº on the latch.

(5) Connect the inside handle cable on the latch

assembly. Hook the swedged cable end on the latch

link and gently push the cable sleeve retainer in the

latch bracket.

(6) Trace the inside handle cable along its routing

path and install on its retaining clips and position

foam insulators. Use previously made schematic as a

guide or remove the opposite side door trim panel

and use that door as a guide.

CAUTION: Be certain replacement cable is routed

and retained correctly and foam insulators are

properly positioned.

(7) Install the latch assembly. Refer to the Power

Side Doors section for the procedure.

(8) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(9) Install the appropriate side door trim panel on

the vehicle. (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - INSTALLATION)

(10) Connect the negative battery cable.

HOLD OPEN LATCH CABLE

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate side door trim panel

from the vehicle. (Refer to 23 - BODY/DOORS -

SLIDING/TRIM PANEL - REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

(4) Open the side door and remove the latch

assembly. (Refer to 8 - ELECTRICAL/POWER

DOORS/LATCH - REMOVAL)

CAUTION: Make note of cable routing and foam

insulator placement. This will prove helpful when

reinstalling replacement cable. Be certain replace-

ment cable is routed and retained correctly.

(5) Trace the hold open latch cable along its rout-

ing path and disconnect from its retaining clips.

(6) Disconnect the hold open latch cable from the

latch assembly. Gently pry cable sleeve retainer out

RSDOORS - SLIDING23-37

ProCarManuals.com