roof CHRYSLER CARAVAN 2003 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1410 of 2177

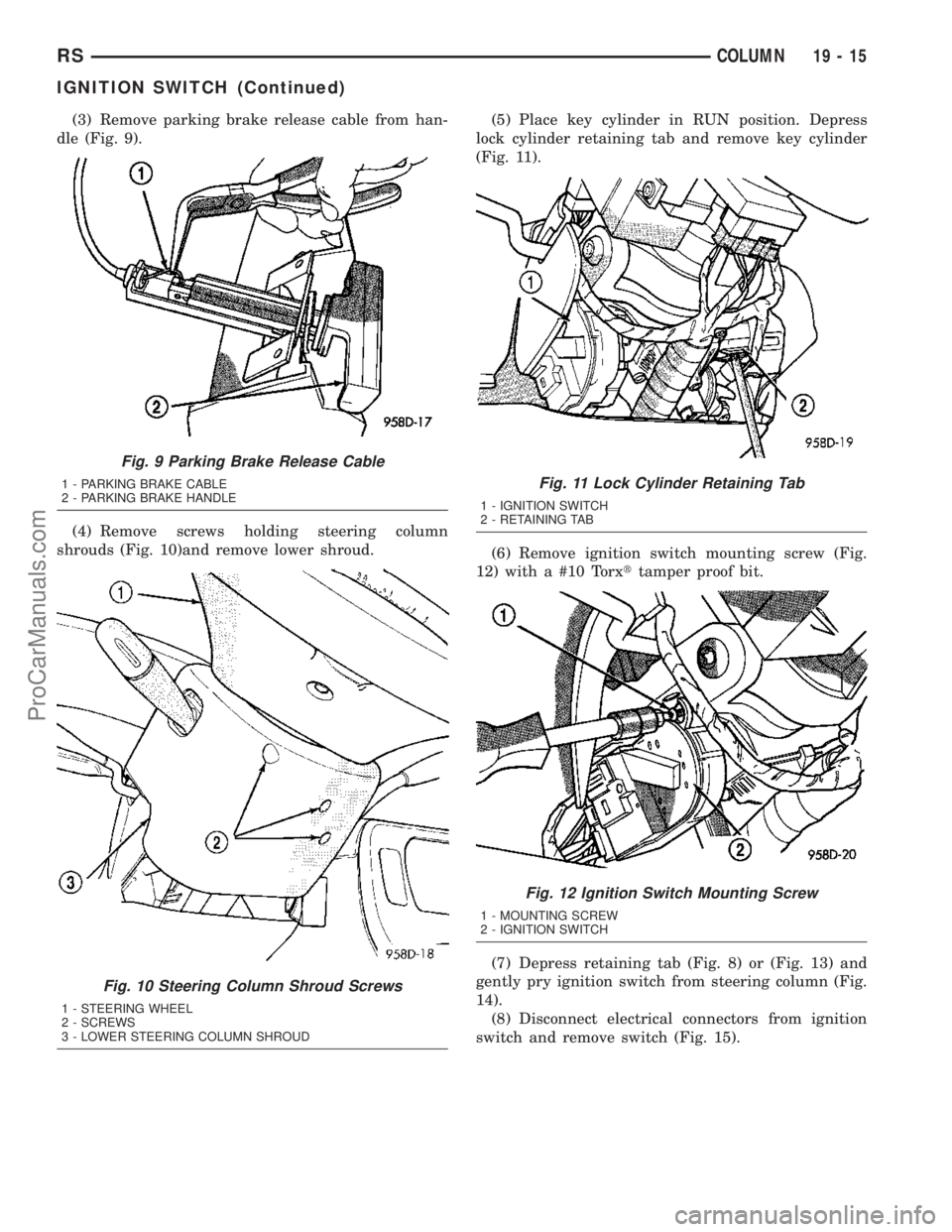

(3) Remove parking brake release cable from han-

dle (Fig. 9).

(4) Remove screws holding steering column

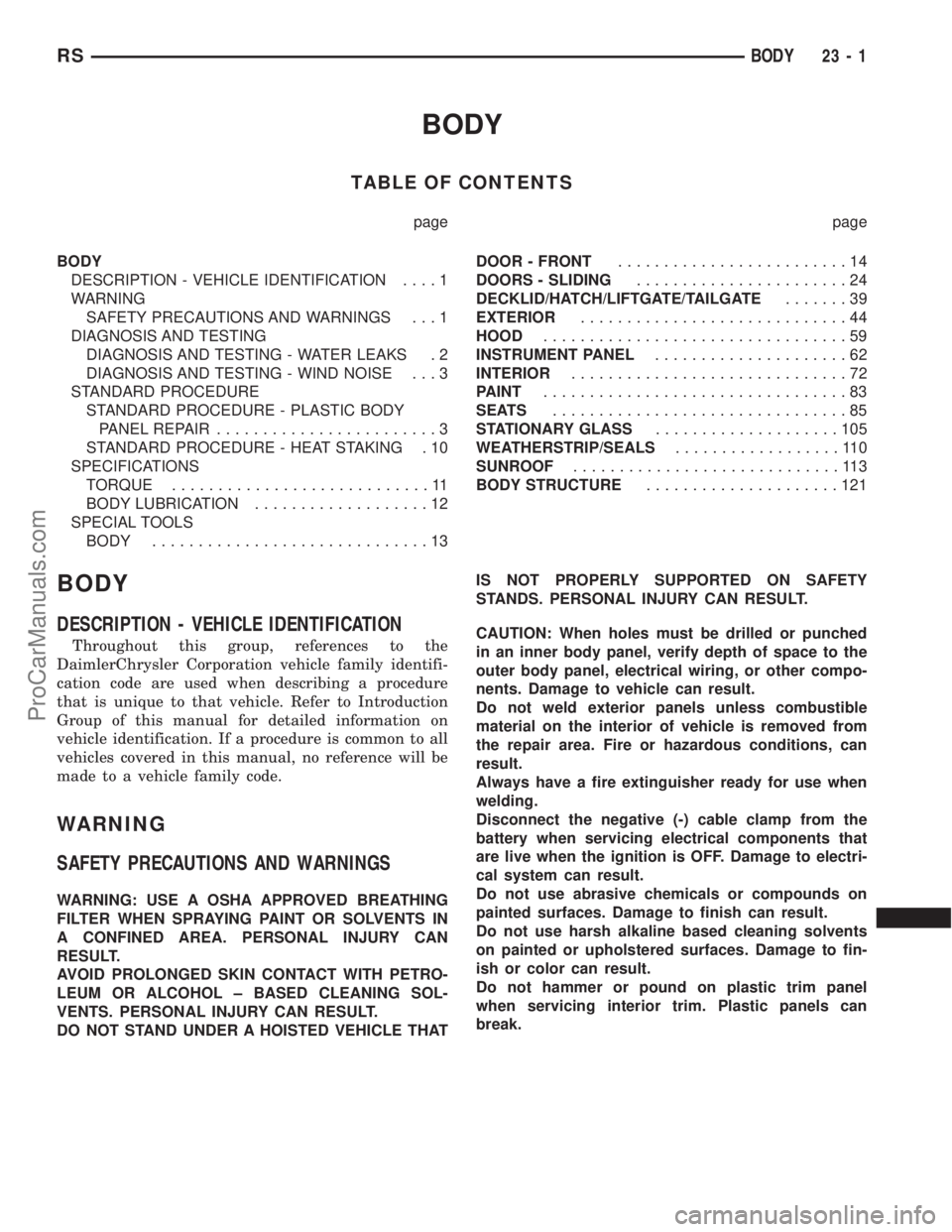

shrouds (Fig. 10)and remove lower shroud.(5) Place key cylinder in RUN position. Depress

lock cylinder retaining tab and remove key cylinder

(Fig. 11).

(6) Remove ignition switch mounting screw (Fig.

12) with a #10 Torxttamper proof bit.

(7) Depress retaining tab (Fig. 8) or (Fig. 13) and

gently pry ignition switch from steering column (Fig.

14).

(8) Disconnect electrical connectors from ignition

switch and remove switch (Fig. 15).

Fig. 9 Parking Brake Release Cable

1 - PARKING BRAKE CABLE

2 - PARKING BRAKE HANDLE

Fig. 10 Steering Column Shroud Screws

1 - STEERING WHEEL

2 - SCREWS

3 - LOWER STEERING COLUMN SHROUD

Fig. 11 Lock Cylinder Retaining Tab

1 - IGNITION SWITCH

2 - RETAINING TAB

Fig. 12 Ignition Switch Mounting Screw

1 - MOUNTING SCREW

2 - IGNITION SWITCH

RSCOLUMN19-15

IGNITION SWITCH (Continued)

ProCarManuals.com

Page 1734 of 2177

BODY

TABLE OF CONTENTS

page page

BODY

DESCRIPTION - VEHICLE IDENTIFICATION....1

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 2

DIAGNOSIS AND TESTING - WIND NOISE . . . 3

STANDARD PROCEDURE

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR........................3

STANDARD PROCEDURE - HEAT STAKING . 10

SPECIFICATIONS

TORQUE............................11

BODY LUBRICATION...................12

SPECIAL TOOLS

BODY..............................13DOOR - FRONT.........................14

DOORS - SLIDING.......................24

DECKLID/HATCH/LIFTGATE/TAILGATE.......39

EXTERIOR.............................44

HOOD.................................59

INSTRUMENT PANEL.....................62

INTERIOR..............................72

PAINT.................................83

SEATS................................85

STATIONARY GLASS....................105

WEATHERSTRIP/SEALS..................110

SUNROOF.............................113

BODY STRUCTURE.....................121

BODY

DESCRIPTION - VEHICLE IDENTIFICATION

Throughout this group, references to the

DaimlerChrysler Corporation vehicle family identifi-

cation code are used when describing a procedure

that is unique to that vehicle. Refer to Introduction

Group of this manual for detailed information on

vehicle identification. If a procedure is common to all

vehicles covered in this manual, no reference will be

made to a vehicle family code.

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE THATIS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.

Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to fin-

ish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

RSBODY23-1

ProCarManuals.com

Page 1744 of 2177

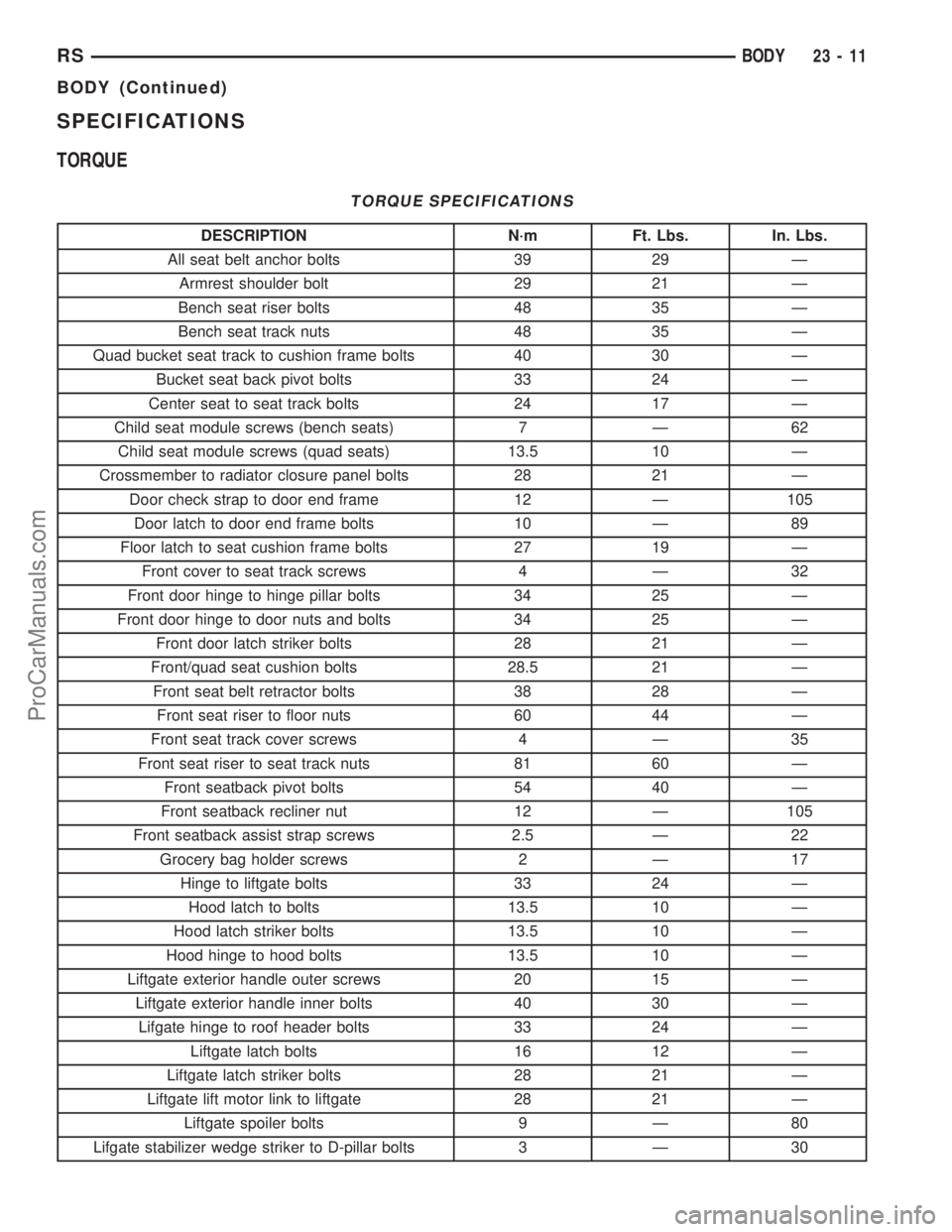

SPECIFICATIONS

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

All seat belt anchor bolts 39 29 Ð

Armrest shoulder bolt 29 21 Ð

Bench seat riser bolts 48 35 Ð

Bench seat track nuts 48 35 Ð

Quad bucket seat track to cushion frame bolts 40 30 Ð

Bucket seat back pivot bolts 33 24 Ð

Center seat to seat track bolts 24 17 Ð

Child seat module screws (bench seats) 7 Ð 62

Child seat module screws (quad seats) 13.5 10 Ð

Crossmember to radiator closure panel bolts 28 21 Ð

Door check strap to door end frame 12 Ð 105

Door latch to door end frame bolts 10 Ð 89

Floor latch to seat cushion frame bolts 27 19 Ð

Front cover to seat track screws 4 Ð 32

Front door hinge to hinge pillar bolts 34 25 Ð

Front door hinge to door nuts and bolts 34 25 Ð

Front door latch striker bolts 28 21 Ð

Front/quad seat cushion bolts 28.5 21 Ð

Front seat belt retractor bolts 38 28 Ð

Front seat riser to floor nuts 60 44 Ð

Front seat track cover screws 4 Ð 35

Front seat riser to seat track nuts 81 60 Ð

Front seatback pivot bolts 54 40 Ð

Front seatback recliner nut 12 Ð 105

Front seatback assist strap screws 2.5 Ð 22

Grocery bag holder screws 2 Ð 17

Hinge to liftgate bolts 33 24 Ð

Hood latch to bolts 13.5 10 Ð

Hood latch striker bolts 13.5 10 Ð

Hood hinge to hood bolts 13.5 10 Ð

Liftgate exterior handle outer screws 20 15 Ð

Liftgate exterior handle inner bolts 40 30 Ð

Lifgate hinge to roof header bolts 33 24 Ð

Liftgate latch bolts 16 12 Ð

Liftgate latch striker bolts 28 21 Ð

Liftgate lift motor link to liftgate 28 21 Ð

Liftgate spoiler bolts 9 Ð 80

Lifgate stabilizer wedge striker to D-pillar bolts 3 Ð 30

RSBODY23-11

BODY (Continued)

ProCarManuals.com

Page 1745 of 2177

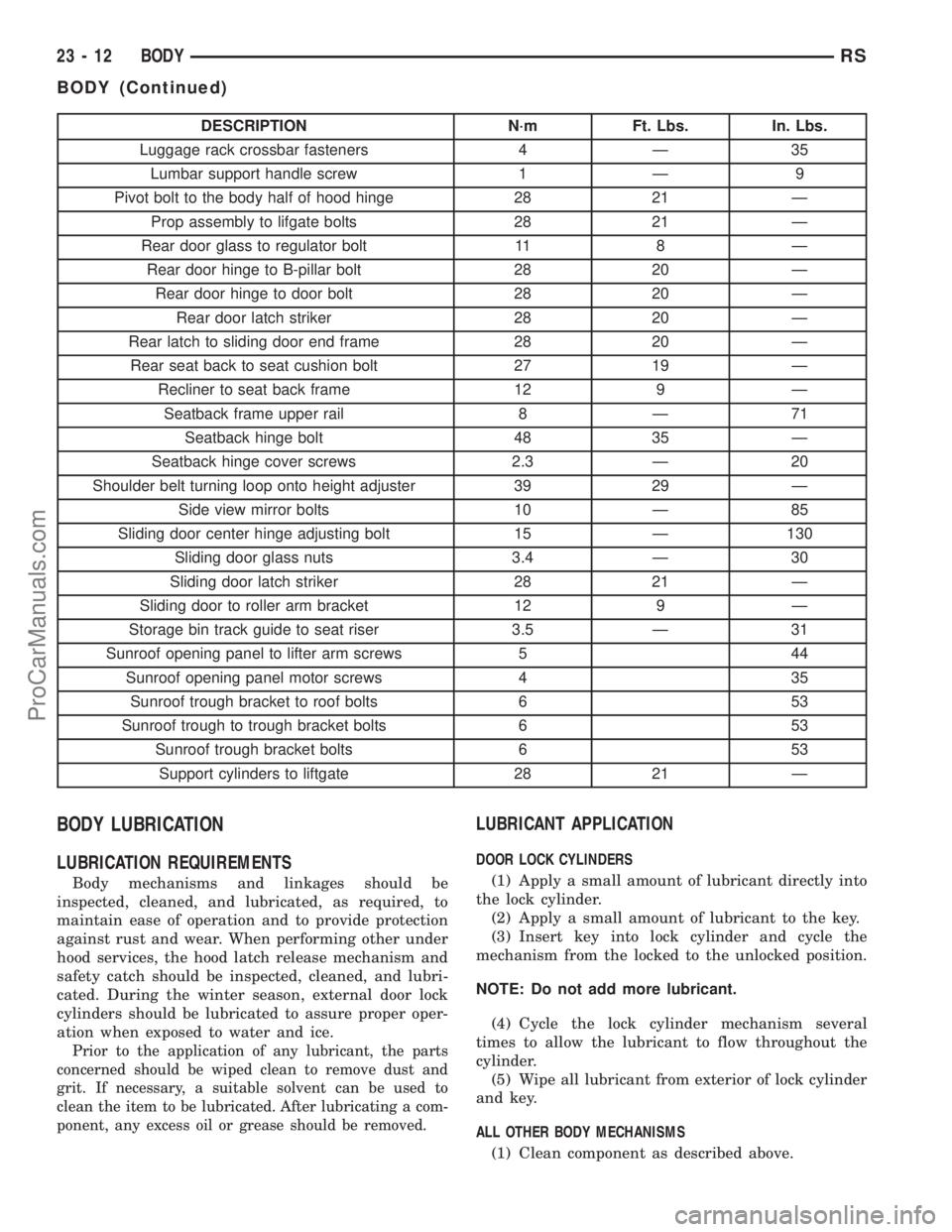

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Luggage rack crossbar fasteners 4 Ð 35

Lumbar support handle screw 1 Ð 9

Pivot bolt to the body half of hood hinge 28 21 Ð

Prop assembly to lifgate bolts 28 21 Ð

Rear door glass to regulator bolt 11 8 Ð

Rear door hinge to B-pillar bolt 28 20 Ð

Rear door hinge to door bolt 28 20 Ð

Rear door latch striker 28 20 Ð

Rear latch to sliding door end frame 28 20 Ð

Rear seat back to seat cushion bolt 27 19 Ð

Recliner to seat back frame 12 9 Ð

Seatback frame upper rail 8 Ð 71

Seatback hinge bolt 48 35 Ð

Seatback hinge cover screws 2.3 Ð 20

Shoulder belt turning loop onto height adjuster 39 29 Ð

Side view mirror bolts 10 Ð 85

Sliding door center hinge adjusting bolt 15 Ð 130

Sliding door glass nuts 3.4 Ð 30

Sliding door latch striker 28 21 Ð

Sliding door to roller arm bracket 12 9 Ð

Storage bin track guide to seat riser 3.5 Ð 31

Sunroof opening panel to lifter arm screws 5 44

Sunroof opening panel motor screws 4 35

Sunroof trough bracket to roof bolts 6 53

Sunroof trough to trough bracket bolts 6 53

Sunroof trough bracket bolts 6 53

Support cylinders to liftgate 28 21 Ð

BODY LUBRICATION

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a com-

ponent, any excess oil or grease should be removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

23 - 12 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1763 of 2177

(10) Install center stop on sliding door. (Refer to 23

- BODY/DOORS - SLIDING/STOP BUMPER -

INSTALLATION)

(11) Place upper roller stop bumper in position on

upper roller arm.

(12) Install screw attaching upper roller arm stop

bumper to upper roller arm (Fig. 9).

(13) Remove masking tape from body surfaces.

(14) Verify door operation and fit. Adjust as neces-

sary. (Refer to 23 - BODY/DOORS - SLIDING/SLID-

ING DOOR - ADJUSTMENTS)

ADJUSTMENTS

SLIDING DOOR ADJUSTMENTS

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

PRELIMINARY CHECKS

(1) Close the sliding door, visually checking C-post

striker alignment entry into latch. Striker at this

point must not affect alignment. Striker should go

straight into the latching mechanism.

(2) On vehicles with left sliding doors, check the

fuel door blocker striker entry into latch. Striker at

this point must not affect alignment.

(3) Check C-post and B-post for door to aperture

gaps and door to door gaps. All gaps should be 5 mm

1 mm.

(4) Check door for height using character lines as

a reference. Also check roof contour as a controlling

factor.

Using the procedures noted below, adjust the side

door in the order the individual steps are called out.

DOOR FLUSHNESS ADJUSTMENT

(1) Check sliding door flushness at the C-pillar

striker.

(2) Adjust the C-pillar striker in or out until the

door is flush.

(3) Check upper B-pillar flushness to A-pillar

cover.

(4) Loosen one nut on upper hinge and adjust door

in or out until the door is flush.

(5) Check flushness at upper C-pillar.

(6) If upper C-pillar flushness is out of specifica-

tion use a heavy rubber mallet on the door assembly

until door is in specifications.

DOOR GAP ADJUSTMENT - UP/DOWN

(1) Visually inspect the sliding door for fitting low

at the top of the door by checking the alignment of

the top contour of the door to the quarter panel.

(2) Fully open the sliding door.

(3) Verify that all center hinge bolts are tight.

(4) Adjust the rear of the sliding door up by turn-

ing the center hinge bolt clockwise (Fig. 13).

(5) Close the door and check the sliding door align-

ment.

(6) Adjust the front of the sliding door up by

adjusting lower hinge bolts.

(7) Open door half way and remove lower hinge

bolt access plug.

(8) Loosen bolts as necessary to move the front of

door up or down.

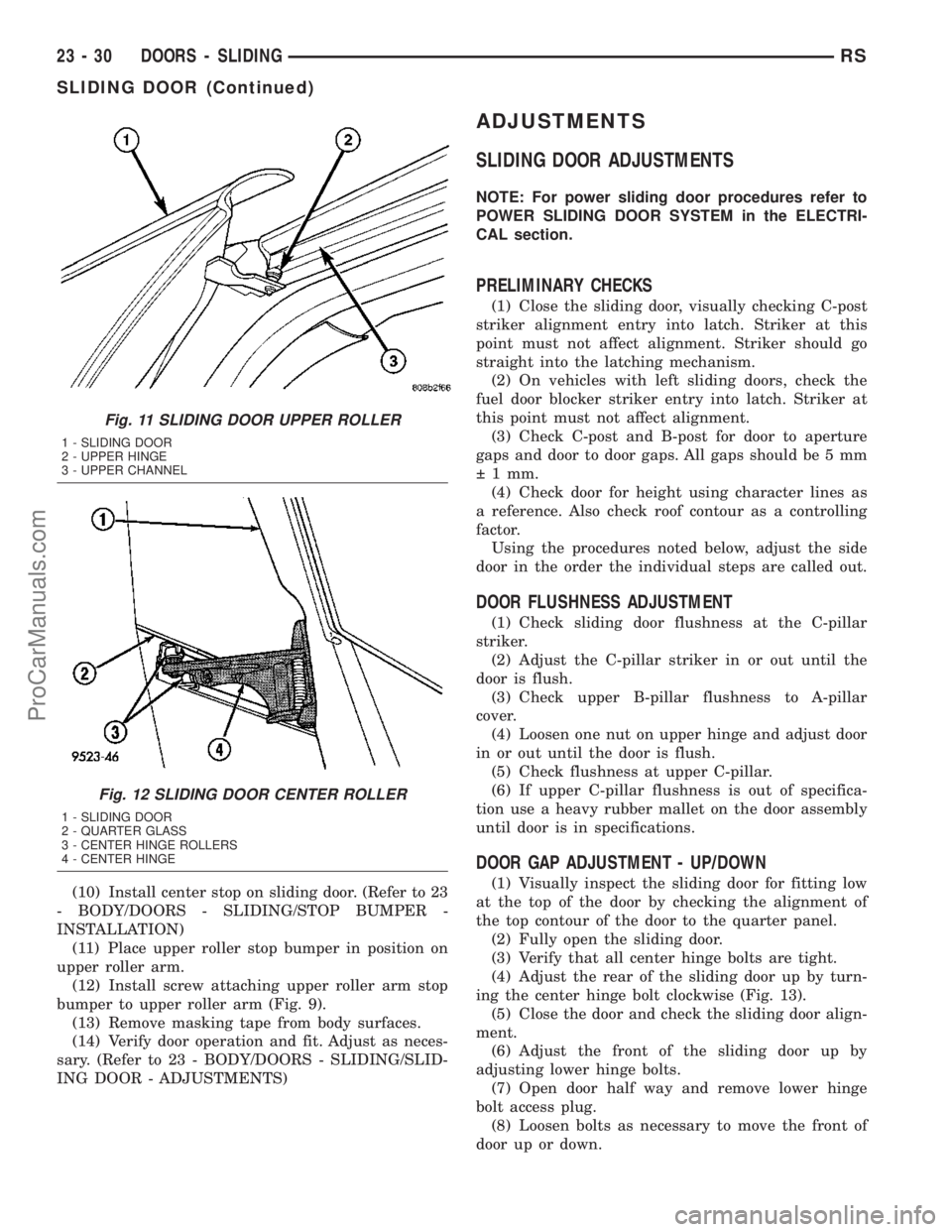

Fig. 11 SLIDING DOOR UPPER ROLLER

1 - SLIDING DOOR

2 - UPPER HINGE

3 - UPPER CHANNEL

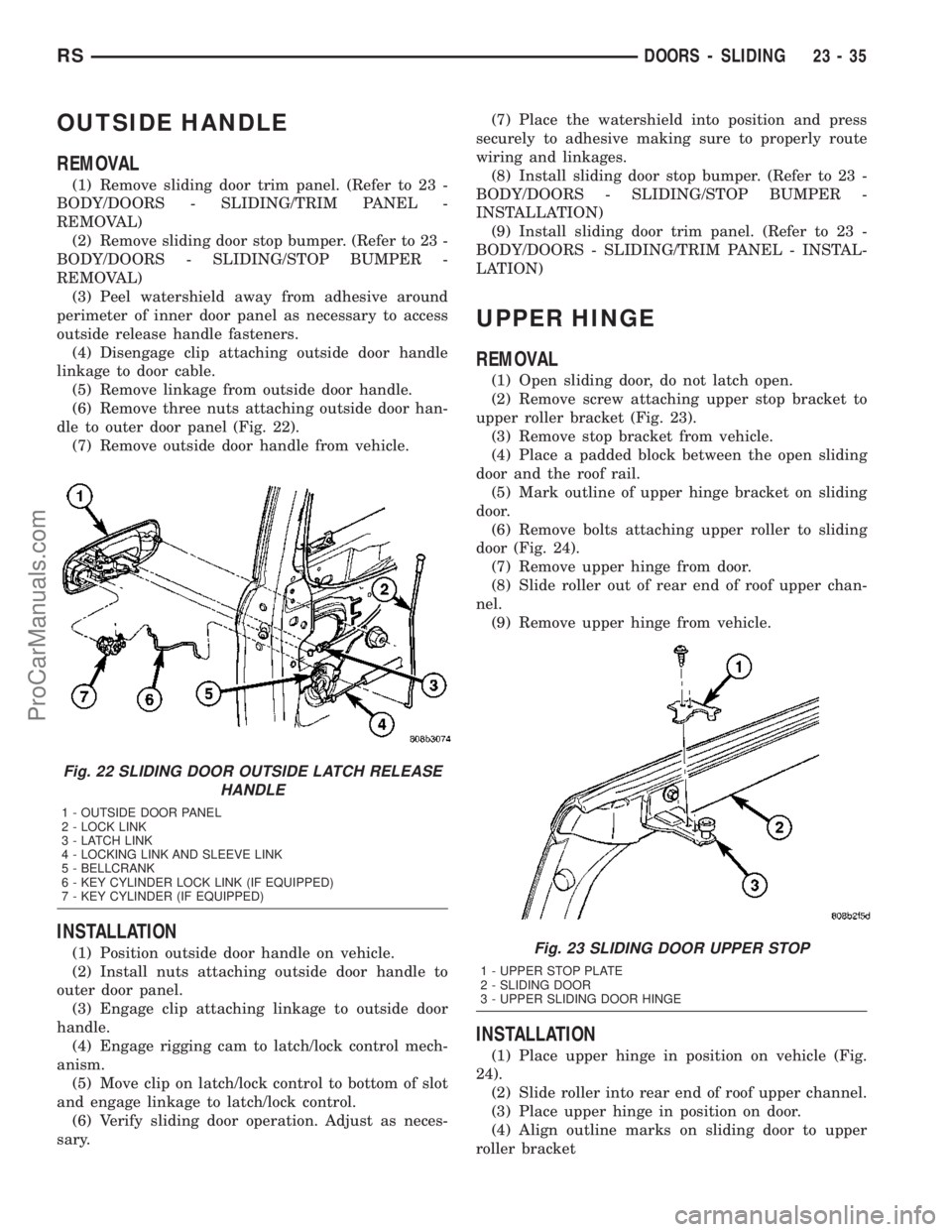

Fig. 12 SLIDING DOOR CENTER ROLLER

1 - SLIDING DOOR

2 - QUARTER GLASS

3 - CENTER HINGE ROLLERS

4 - CENTER HINGE

23 - 30 DOORS - SLIDINGRS

SLIDING DOOR (Continued)

ProCarManuals.com

Page 1768 of 2177

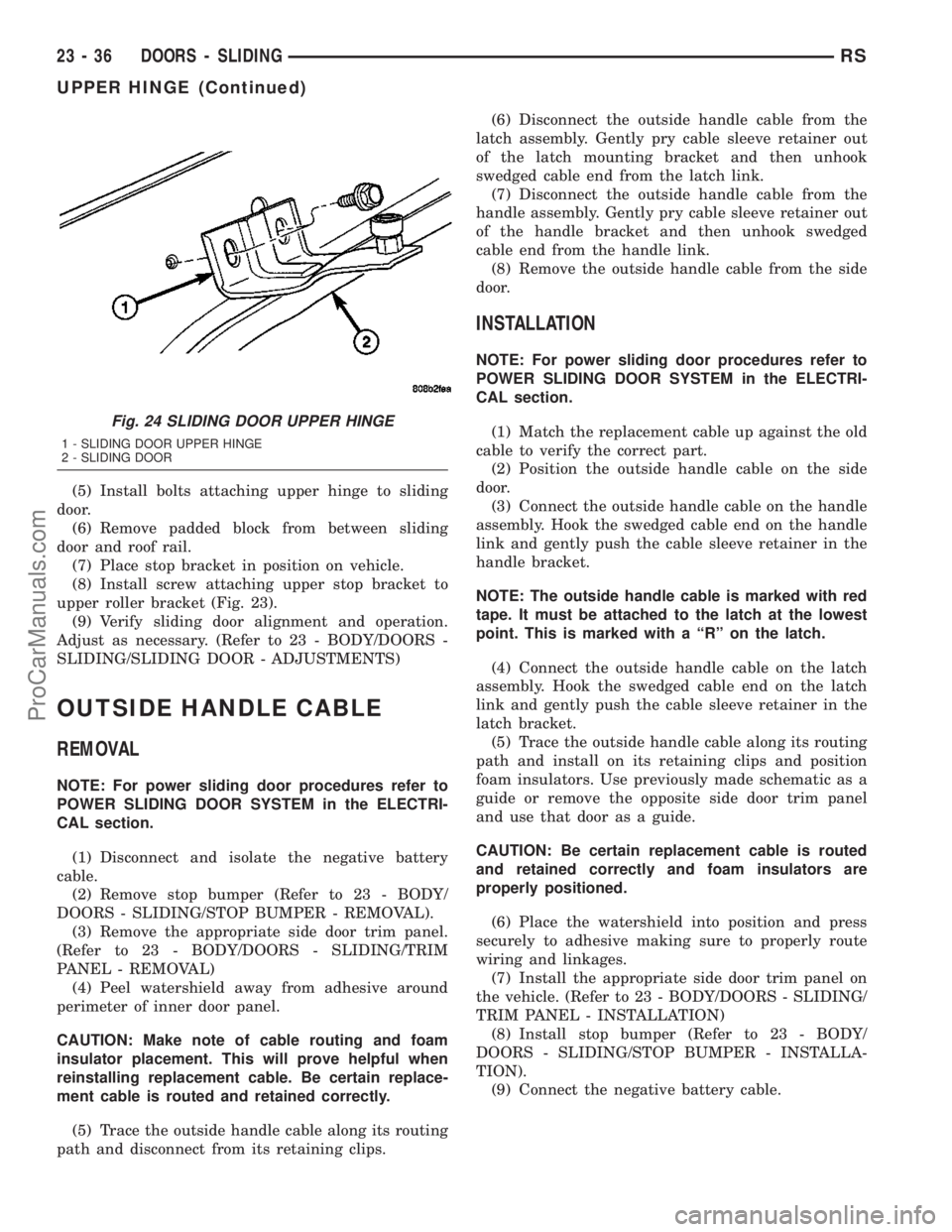

OUTSIDE HANDLE

REMOVAL

(1) Remove sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL -

REMOVAL)

(2) Remove sliding door stop bumper. (Refer to 23 -

BODY/DOORS - SLIDING/STOP BUMPER -

REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel as necessary to access

outside release handle fasteners.

(4) Disengage clip attaching outside door handle

linkage to door cable.

(5) Remove linkage from outside door handle.

(6) Remove three nuts attaching outside door han-

dle to outer door panel (Fig. 22).

(7) Remove outside door handle from vehicle.

INSTALLATION

(1) Position outside door handle on vehicle.

(2) Install nuts attaching outside door handle to

outer door panel.

(3) Engage clip attaching linkage to outside door

handle.

(4) Engage rigging cam to latch/lock control mech-

anism.

(5) Move clip on latch/lock control to bottom of slot

and engage linkage to latch/lock control.

(6) Verify sliding door operation. Adjust as neces-

sary.(7) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(8) Install sliding door stop bumper. (Refer to 23 -

BODY/DOORS - SLIDING/STOP BUMPER -

INSTALLATION)

(9) Install sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION)

UPPER HINGE

REMOVAL

(1) Open sliding door, do not latch open.

(2) Remove screw attaching upper stop bracket to

upper roller bracket (Fig. 23).

(3) Remove stop bracket from vehicle.

(4) Place a padded block between the open sliding

door and the roof rail.

(5) Mark outline of upper hinge bracket on sliding

door.

(6) Remove bolts attaching upper roller to sliding

door (Fig. 24).

(7) Remove upper hinge from door.

(8) Slide roller out of rear end of roof upper chan-

nel.

(9) Remove upper hinge from vehicle.

INSTALLATION

(1) Place upper hinge in position on vehicle (Fig.

24).

(2) Slide roller into rear end of roof upper channel.

(3) Place upper hinge in position on door.

(4) Align outline marks on sliding door to upper

roller bracket

Fig. 22 SLIDING DOOR OUTSIDE LATCH RELEASE

HANDLE

1 - OUTSIDE DOOR PANEL

2 - LOCK LINK

3 - LATCH LINK

4 - LOCKING LINK AND SLEEVE LINK

5 - BELLCRANK

6 - KEY CYLINDER LOCK LINK (IF EQUIPPED)

7 - KEY CYLINDER (IF EQUIPPED)

Fig. 23 SLIDING DOOR UPPER STOP

1 - UPPER STOP PLATE

2 - SLIDING DOOR

3 - UPPER SLIDING DOOR HINGE

RSDOORS - SLIDING23-35

ProCarManuals.com

Page 1769 of 2177

(5) Install bolts attaching upper hinge to sliding

door.

(6) Remove padded block from between sliding

door and roof rail.

(7) Place stop bracket in position on vehicle.

(8) Install screw attaching upper stop bracket to

upper roller bracket (Fig. 23).

(9) Verify sliding door alignment and operation.

Adjust as necessary. (Refer to 23 - BODY/DOORS -

SLIDING/SLIDING DOOR - ADJUSTMENTS)

OUTSIDE HANDLE CABLE

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove stop bumper (Refer to 23 - BODY/

DOORS - SLIDING/STOP BUMPER - REMOVAL).

(3) Remove the appropriate side door trim panel.

(Refer to 23 - BODY/DOORS - SLIDING/TRIM

PANEL - REMOVAL)

(4) Peel watershield away from adhesive around

perimeter of inner door panel.

CAUTION: Make note of cable routing and foam

insulator placement. This will prove helpful when

reinstalling replacement cable. Be certain replace-

ment cable is routed and retained correctly.

(5) Trace the outside handle cable along its routing

path and disconnect from its retaining clips.(6) Disconnect the outside handle cable from the

latch assembly. Gently pry cable sleeve retainer out

of the latch mounting bracket and then unhook

swedged cable end from the latch link.

(7) Disconnect the outside handle cable from the

handle assembly. Gently pry cable sleeve retainer out

of the handle bracket and then unhook swedged

cable end from the handle link.

(8) Remove the outside handle cable from the side

door.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Match the replacement cable up against the old

cable to verify the correct part.

(2) Position the outside handle cable on the side

door.

(3) Connect the outside handle cable on the handle

assembly. Hook the swedged cable end on the handle

link and gently push the cable sleeve retainer in the

handle bracket.

NOTE: The outside handle cable is marked with red

tape. It must be attached to the latch at the lowest

point. This is marked with a ªRº on the latch.

(4) Connect the outside handle cable on the latch

assembly. Hook the swedged cable end on the latch

link and gently push the cable sleeve retainer in the

latch bracket.

(5) Trace the outside handle cable along its routing

path and install on its retaining clips and position

foam insulators. Use previously made schematic as a

guide or remove the opposite side door trim panel

and use that door as a guide.

CAUTION: Be certain replacement cable is routed

and retained correctly and foam insulators are

properly positioned.

(6) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(7) Install the appropriate side door trim panel on

the vehicle. (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - INSTALLATION)

(8) Install stop bumper (Refer to 23 - BODY/

DOORS - SLIDING/STOP BUMPER - INSTALLA-

TION).

(9) Connect the negative battery cable.

Fig. 24 SLIDING DOOR UPPER HINGE

1 - SLIDING DOOR UPPER HINGE

2 - SLIDING DOOR

23 - 36 DOORS - SLIDINGRS

UPPER HINGE (Continued)

ProCarManuals.com

Page 1772 of 2177

DECKLID/HATCH/LIFTGATE/TAILGATE

TABLE OF CONTENTS

page page

EXTERIOR HANDLE

REMOVAL.............................39

INSTALLATION.........................39

HINGE

REMOVAL.............................39

INSTALLATION.........................39

LATCH

REMOVAL.............................40

INSTALLATION.........................40

LATCH STRIKER

REMOVAL.............................40

INSTALLATION.........................40

LIFTGATE

REMOVAL.............................41

INSTALLATION.........................41

LIFTGATE SPOILER

REMOVAL.............................41INSTALLATION.........................41

LOCK CYLINDER

REMOVAL.............................41

INSTALLATION.........................41

SUPPORT CYLINDER

REMOVAL.............................42

INSTALLATION.........................42

TRIM PANEL

REMOVAL.............................42

INSTALLATION.........................43

SLAM BUMPER

REMOVAL

REMOVAL...........................43

REMOVAL - LIFTGATE SIDE.............43

INSTALLATION

INSTALLATION.......................43

INSTALLATION - LIFTGATE SIDE.........43

EXTERIOR HANDLE

REMOVAL

(1) Remove liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL)

(2) Disconnect the exterior handle electrical con-

nectors.

(3) Remove the two outer screws and the two inner

screws.

(4) Remove the exterior handle/license plate light

assembly.

INSTALLATION

(1) Route the exterior handle electrical connector

through the door and position handle.

(2) Install the two out screws and tighten to 20

N´m (15 ft. lbs.).

(3) Install the two inner bolts and tighten to 40

N´m (30 ft. lbs.).

(4) Connect the electrical connector.

(5) Install the trim panel. (Refer to 23 - BODY/

DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - INSTALLATION)

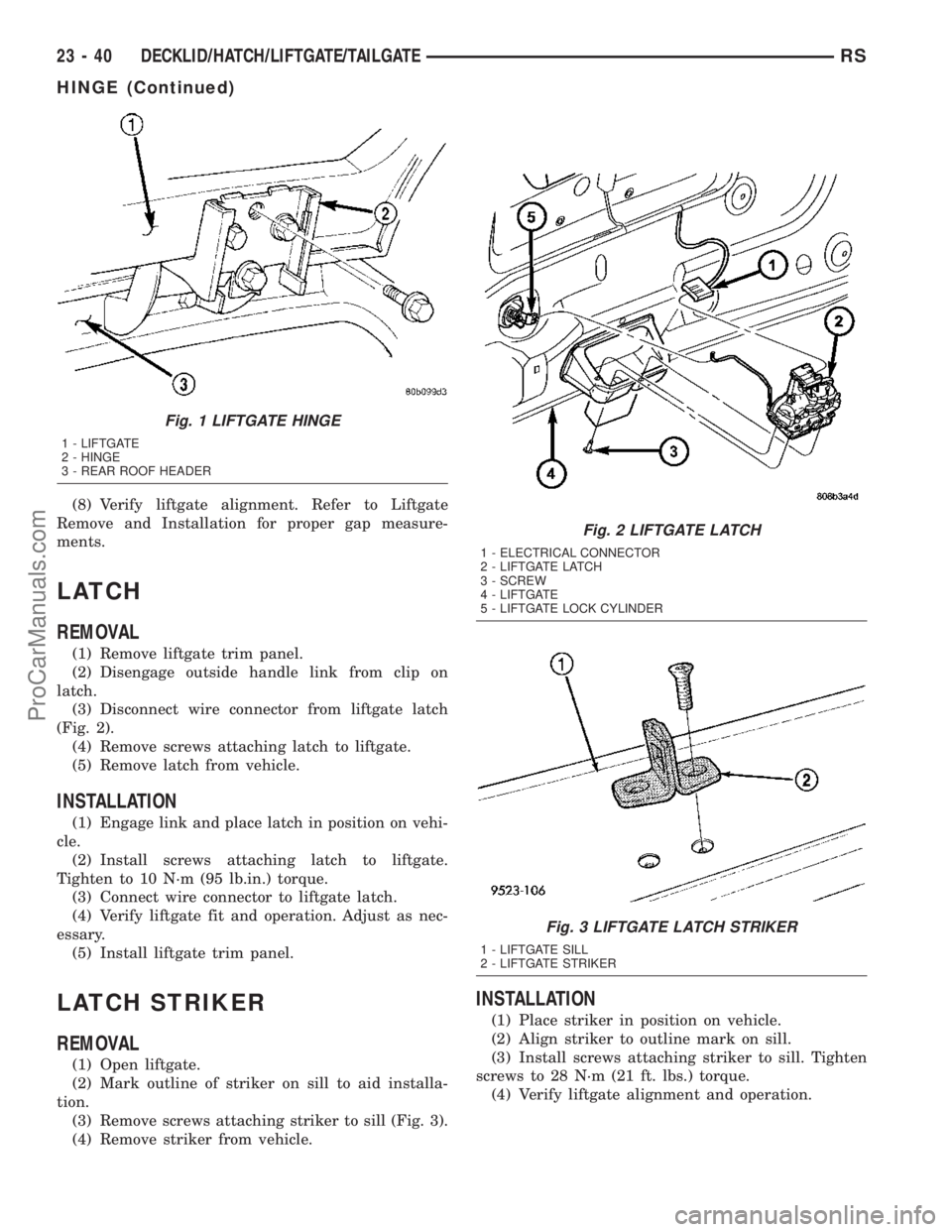

HINGE

REMOVAL

(1) Release liftgate latch and open liftgate.

(2) Support liftgate on a suitable lifting device in

the full open position.

(3) Apply several layers of duct tape on the outside

of to roof across the gap to the lift gate to hold the

liftgate in position.

(4) Remove bolts attaching liftgate hinge to roof

header.

(5) Disconnect VTSS switch from the body har-

ness.

(6) Remove bolts attaching hinge to liftgate (Fig.

1).

(7) Remove hinge from vehicle.

INSTALLATION

(1) If necessary, paint replacement hinge before

installation.

(2) Place hinge in position on vehicle.

(3) Align hinge to marks on liftgate.

(4) Install bolts attaching hinge to liftgate (Fig. 1).

Tighten bolts to 33 N´m (24 ft. lbs.) torque.

(5) Align hinge to marks on roof header.

(6) Install bolts attaching liftgate hinge to roof

header. Tighten outer two bolts to 33 N´m (24 ft. lbs.)

torque. The sheet medal screw at center 12 N´m (105

in. lbs.)

(7) Remove duct tape from roof and liftgate.

RSDECKLID/HATCH/LIFTGATE/TAILGATE23-39

ProCarManuals.com

Page 1773 of 2177

(8) Verify liftgate alignment. Refer to Liftgate

Remove and Installation for proper gap measure-

ments.

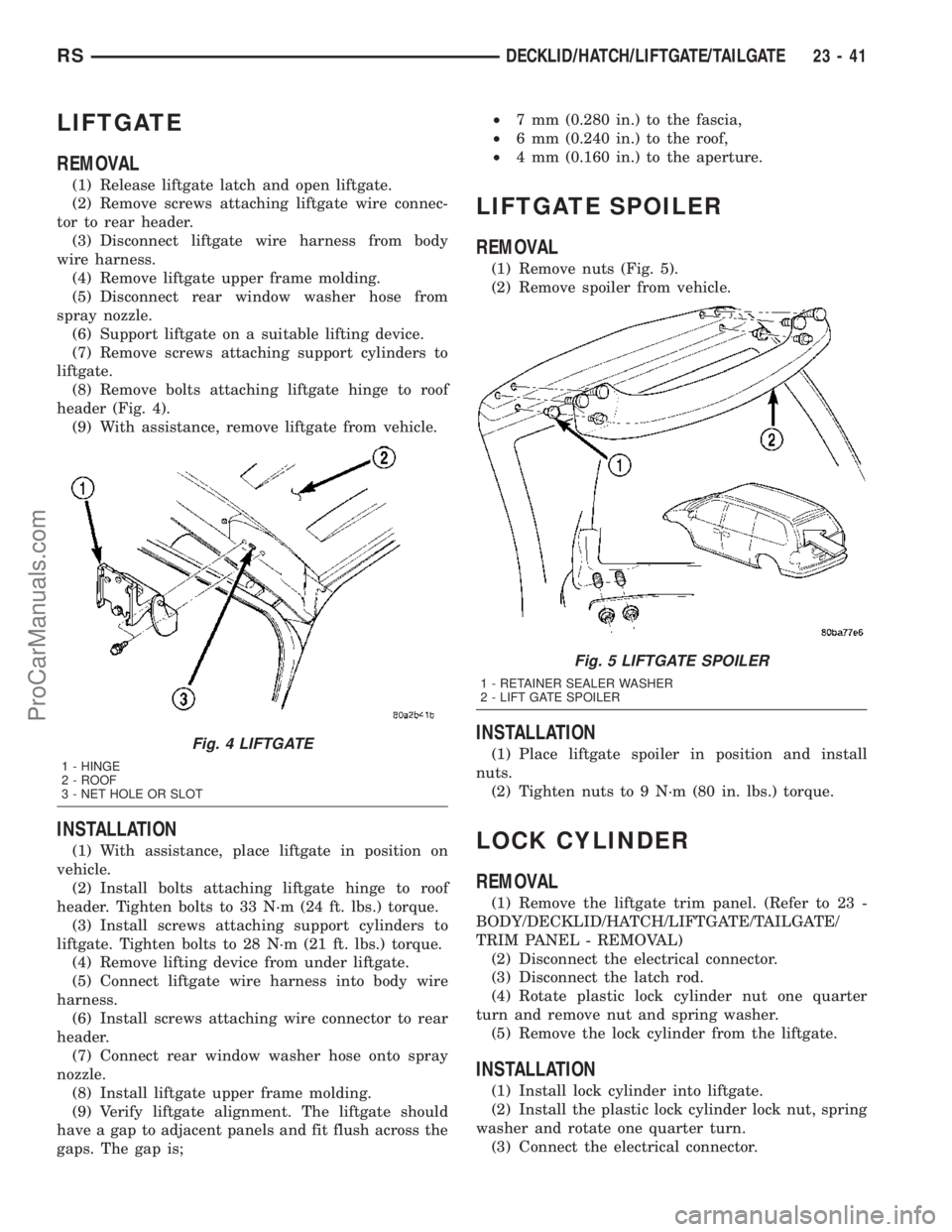

LATCH

REMOVAL

(1) Remove liftgate trim panel.

(2) Disengage outside handle link from clip on

latch.

(3) Disconnect wire connector from liftgate latch

(Fig. 2).

(4) Remove screws attaching latch to liftgate.

(5) Remove latch from vehicle.

INSTALLATION

(1) Engage link and place latch in position on vehi-

cle.

(2) Install screws attaching latch to liftgate.

Tighten to 10 N´m (95 lb.in.) torque.

(3) Connect wire connector to liftgate latch.

(4) Verify liftgate fit and operation. Adjust as nec-

essary.

(5) Install liftgate trim panel.

LATCH STRIKER

REMOVAL

(1) Open liftgate.

(2) Mark outline of striker on sill to aid installa-

tion.

(3) Remove screws attaching striker to sill (Fig. 3).

(4) Remove striker from vehicle.

INSTALLATION

(1) Place striker in position on vehicle.

(2) Align striker to outline mark on sill.

(3) Install screws attaching striker to sill. Tighten

screws to 28 N´m (21 ft. lbs.) torque.

(4) Verify liftgate alignment and operation.

Fig. 1 LIFTGATE HINGE

1 - LIFTGATE

2 - HINGE

3 - REAR ROOF HEADER

Fig. 2 LIFTGATE LATCH

1 - ELECTRICAL CONNECTOR

2 - LIFTGATE LATCH

3 - SCREW

4 - LIFTGATE

5 - LIFTGATE LOCK CYLINDER

Fig. 3 LIFTGATE LATCH STRIKER

1 - LIFTGATE SILL

2 - LIFTGATE STRIKER

23 - 40 DECKLID/HATCH/LIFTGATE/TAILGATERS

HINGE (Continued)

ProCarManuals.com

Page 1774 of 2177

LIFTGATE

REMOVAL

(1) Release liftgate latch and open liftgate.

(2) Remove screws attaching liftgate wire connec-

tor to rear header.

(3) Disconnect liftgate wire harness from body

wire harness.

(4) Remove liftgate upper frame molding.

(5) Disconnect rear window washer hose from

spray nozzle.

(6) Support liftgate on a suitable lifting device.

(7) Remove screws attaching support cylinders to

liftgate.

(8) Remove bolts attaching liftgate hinge to roof

header (Fig. 4).

(9) With assistance, remove liftgate from vehicle.

INSTALLATION

(1) With assistance, place liftgate in position on

vehicle.

(2) Install bolts attaching liftgate hinge to roof

header. Tighten bolts to 33 N´m (24 ft. lbs.) torque.

(3) Install screws attaching support cylinders to

liftgate. Tighten bolts to 28 N´m (21 ft. lbs.) torque.

(4) Remove lifting device from under liftgate.

(5) Connect liftgate wire harness into body wire

harness.

(6) Install screws attaching wire connector to rear

header.

(7) Connect rear window washer hose onto spray

nozzle.

(8) Install liftgate upper frame molding.

(9) Verify liftgate alignment. The liftgate should

have a gap to adjacent panels and fit flush across the

gaps. The gap is;²7 mm (0.280 in.) to the fascia,

²6 mm (0.240 in.) to the roof,

²4 mm (0.160 in.) to the aperture.

LIFTGATE SPOILER

REMOVAL

(1) Remove nuts (Fig. 5).

(2) Remove spoiler from vehicle.

INSTALLATION

(1) Place liftgate spoiler in position and install

nuts.

(2) Tighten nuts to 9 N´m (80 in. lbs.) torque.

LOCK CYLINDER

REMOVAL

(1) Remove the liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL)

(2) Disconnect the electrical connector.

(3) Disconnect the latch rod.

(4) Rotate plastic lock cylinder nut one quarter

turn and remove nut and spring washer.

(5) Remove the lock cylinder from the liftgate.

INSTALLATION

(1) Install lock cylinder into liftgate.

(2) Install the plastic lock cylinder lock nut, spring

washer and rotate one quarter turn.

(3) Connect the electrical connector.

Fig. 4 LIFTGATE

1 - HINGE

2 - ROOF

3 - NET HOLE OR SLOT

Fig. 5 LIFTGATE SPOILER

1 - RETAINER SEALER WASHER

2 - LIFT GATE SPOILER

RSDECKLID/HATCH/LIFTGATE/TAILGATE23-41

ProCarManuals.com