airbag CHRYSLER CARAVAN 2005 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1117 of 2339

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Driver Blend Door Actuator GY On HVAC N/S

Driver Door Courtesy Lamp GY At Lamp 43

Driver Door Lock Switch BK At Switch 43

Driver Heated Seat Back LTGN At Seat N/S

Driver Heated Seat Cushion BK At Seat N/S

Driver Heated Seat Module C1 GY Driver Heated Seat N/S

Driver Heated Seat Module C2 GY Driver Heated Seat Back N/S

Driver Heated Seat Module C3 GN At Seat N/S

Driver Knee Blocker Airbag Squib YL Below Steering Column 20

Driver Power Seat Front Riser

MotorRD At Seat N/S

Driver Power Seat Front Riser

Position SensorBK At Seat N/S

Driver Power Seat Horizontal

MotorBK At Seat N/S

Driver Power Seat Horizontal

Position SensorBK At Seat N/S

Driver Power Seat Rear Riser

MotorRD At Seat N/S

Driver Power Seat Rear Riser

Position SensorBK At Seat N/S

Driver Power Seat Recliner Motor GN At Seat N/S

Driver Power Seat Recliner

Position SensorBK At Seat N/S

Driver Power Seat Switch GN At Switch N/S

Driver Power Window Motor RD At Motor 43

Driver Power Window Switch

(LHD Low Line)LTGY At Switch 43

Driver Power Window Switch

(LHD Except Low Line)LTGN At Switch N/S

Driver Power Window Switch

(RHD)NAT At Switch N/S

Driver Seat Belt Switch WT At Switch on Seat Harness N/S

Driver Seat Belt Tensioner YL On Seat Harness N/S

DVD Screen BK Headliner 50

DVD/CD Changer C1 BK Below Radio N/S

DVD/CD Changer C2 Below Radio N/S

EGR Solenoid (Diesel) LTGY Above Transmission

Right Side of Engine15

EGR Solenoid (3.3L) BK Above A/C Compressor Right Side

of Engine18

Engine Control Module C1

(Diesel)BK Right Side of Engine N/S

Engine Control Module C2

(Diesel)BK Right Side of Engine N/S

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1119 of 2339

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Hands Free Module C2 BK Instrument Panel N/S

Hands Free Module C3 Instrument Panel N/S

Headlamp Switch BK Rear of Switch 20, 21, 30

Headlamp Washer Pump Motor

(Export)BK At Motor 3

High Note Horn BK Left Frame Rail 5

Hood Ajar Switch (Export) BK Left Fender 6

Idle Air Control Motor (Gas) BK On Throttle Body 10, 11 17

Ignition Coil (2.4L) BK Top of Valve Cover 10, 11

Ignition Coil (3.3L/ 3.8L) DKGY Top of Engine 17, 18

Ignition Switch BK Rear of Switch at Steering Column 20, 21, 22, 23, 31

Inlet Air Temperature Sensor BK Top Left of Engine 9, 10, 11, 17

Input Speed Sensor GY Front of Transmission 14, 19

Instrument Cluster BK Rear of Cluster 20, 21, 28

Instrument Panel Switch Bank

(Heated Seats)BK Right Center of Instrument Panel 20, 23, 25

Instrument Panel Switch Bank

(Except Heated Seats)Right Center of Instrument Panel 20, 23, 25

Integrated Power Module C1 Left Fender Shield 7

Integrated Power Module C2 GN/BL Left Fender Shield 7

Integrated Power Module C3 Left Fender Shield 7, 11

Integrated Power Module C4 BL Left Fender Shield 7, 11

Integrated Power Module C5 BK Left Fender Shield 7

Integrated Power Module C6 NAT Left Fender Shield 7

Integrated Power Module C7 Left Fender Shield 7

Integrated Power Module C8 OR Left Fender Shield 7

Integrated Power Module C9 BK Left Fender Shield 7

Knock Sensor (Except Export) BK At Engine Block 11

Left B Pillar Switch (Power

Sliding Door)GY Left B Pillar 40

Left Cinch/Release Motor (Power

Sliding Door)GY Left Sliding Door N/S

Left Curtain Airbag Squib Rear of Left Roof Rail 47

Left Cylinder Lock Switch BK At Switch 43

Left Door Speaker BK At Speaker 43

Left Fog Lamp BK At Lamp 5

Left Front Door Ajar Switch

(Base)BK At Switch N/S

Left Front Door Lock Motor/Ajar

Switch (Except Base)BK Left Door 43

Left Front Impact Sensor BK Near T/O for C101 5

Left Front Park/Turn Signal Lamp

(Except Export)DKGY At Lamp 1

Left Front Wheel Speed Sensor GY Left Fender Side Shield 5, 11

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1121 of 2339

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Liftgate Ajar Switch (Manual

Release)BK At Latch 49

Liftgate Ajar Switch (Power

Release)BK Lower Liftgate 49

Liftgate Cinch/Release Motor

(Power Liftgate)BL Liftgate 49

Liftgate Left Pinch Sensor (Power

Liftgate)BK Left Side of Liftgate 49

Liftgate Right Pinch Sensor

(Power Liftgate)BK Right Side of Liftgate 49

Manifold Absolute Pressure

Sensor (Gas)BK On Intake N/S

Mass Air Flow Sensor (Diesel) OR Top of Engine 15, 16

Memory Seat/Mirror/Adjustable

Pedals Module C1GY Under Driver Seat N/S

Memory Seat/Mirror/ Adjustable

Pedals Module C2GY Under Driver Seat N/S

Memory Seat/Mirror/ Adjustable

Pedals Module C3WT Under Driver Seat N/S

Memory Seat/Mirror/ Adjustable

Pedals Module C4GY Under Driver Seat N/S

Memory Set Switch BK At Switch Driver Door 43

Message Center (Highline) WT Rear of Message Center 20, 21, 28

Mode Door Actuator GY Left Side of HVAC N/S

Multi Function Switch BK At Steering Column 20, 21, 22, 23, 31

Natural Vacuum Leak Detection

Assembly (Except Export)LTGY Top of Engine 12

Occupant Classification Module BK Passenger Seat N/S

Occupant Restraint Controller C1 YL Right Side Instrument Panel

Occupant Restraint Controller C2 YL Right Side Instrument Panel 20, 24, 25

Output Speed Sensor GY Front of Transmission 14, 19

Overhead Console (Except Base) BK Front of Console N/S

Oxygen Sensor 1/1 Upstream

(Gas)Rear of Engine 11, 12, 18

Oxygen Sensor 1/2 Downstream

(Gas)Rear of Engine 11, 12,18

Park Brake Switck Bottoom Left Side of Instrument

Panel20, 21

Park Sensor No.1 (Parktronics) Rear Fascia N/S

Park Sensor No.2 (Parktronics) Rear Fascia N/S

Park Sensor No.3 (Parktronics) Rear Fascia N/S

Park Sensor No.4 (Parktronics) Rear Fascia N/S

Passenger Airbag YL Passenger Side of Instrument Panel 20, 23, 24, 29

Passenger Airbag On/Off

Indicator LampRight Center of Instrument Panel 20, 23, 25

Passenger Blend Door Actuator GY On HVAC N/S

8W - 91 - 8 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1123 of 2339

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Radiator Fan Relay No. 3

(Diesel)BL Left Front Engine Compartment 2

Radio C1 Rear of Radio 20

Radio C2 (CD Changer) Rear of Radio 20

Radio C2 (DVD/CD Changer) Rear of Radio 20

Radio C2 (Hands Free) Rear of Radio 20

Rear A/C-Heater Unit (3 Zone

MTC)LTGN Right Quarter Panel NS

Rear Auto Temp Control Switch

(3 Zone ATC)BK Rear of Switch 50

Rear Blower Front Control Switch

(3 Zone MTC)BK Rear of Switch N/S

Rear Blower Motor Power Module

C1 (3 Zone ATC)RD/BK Right Quarter N/S

Rear Blower Motor Power Module

C2 (3 Zone ATC)BK Right Quarter N/S

Rear Blower Rear Control Switch

C1 (3 Zone MTC)BK Overhead 50

Rear Blower Rear Control Switch

C2 (3 Zone MTC)BK Overhead 50

Rear Dome Lamp (Except

Luxury)GY At Lamp N/S

Rear Intrusion Sensor (United

Kingdom)At Sensor N/S

Rear Mode Motor (3 Zone ATC) GY At Motor N/S

Rear Park Assist Display Module Overhead Console N/S

Rear Park Assist Module Left Quarter Panel 47

Rear Power Outlet GY Left Quarter Panel 47

Rear Temperature Motor (3 Zone

ATC)GY Right Quarter N/S

Rear View Mirror C1 BK At Mirror NS

Rear View Mirror C2 At Mirror N/S

Rear Window Defogger C1 Right Side of Liftgate 49

Rear Window Defogger C2 Left Side of Liftgate 49

Rear Wiper Motor At Motor 49

Recirculation Door Actuator GY Right Side of HVAC N/S

Right B-Pillar Switch (Power

Sliding Door)GY Right B Pillar 39

Right Cinch/Release Motor

(Power Sliding Door)GY Right Sliding Door 45

Right Curtain Airbag Squib Rear of Right Roof Rail 48

Right Cylinder Lock Switch

(Export)BK Right Front Door 44

Right Door Speaker At Speaker N/S

Right Fog Lamp WT At Lamp 3

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1176 of 2339

(5) Connect the negative and positive battery

cables.

(6) Using a scan tool, check for any stored diagnos-

tic trouble codes. Ensure that all vehicle options are

operational.

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed from its normal

cavity in the Integrated Power Module (IPM) when

the vehicle is shipped from the factory. Dealer per-

sonnel are to remove the IOD fuse from the storage

location and install it into the IPM fuse cavity

marked IOD as part of the preparation procedures

performed just prior to new vehicle delivery.

The IOD fuse is a 20 ampere blade-type mini fuse

and, when removed, it is stored in a fuse cavity adja-

cent to the washer fuse within the IPM.

OPERATION

The term ignition-off draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position.

The IOD fuse feeds the memory and sleep mode func-

tions for some of the electronic modules in the vehicle

as well as various other accessories that require bat-

tery current when the ignition switch is in the Off

position, including the clock. The only reason the

IOD fuse is removed is to reduce the normal IOD of

the vehicle electrical system during new vehicle

transportation and pre-delivery storage to reduce

battery depletion, while still allowing vehicle opera-

tion so that the vehicle can be loaded, unloaded and

moved as needed by both vehicle transportation com-

pany and dealer personnel.

The IOD fuse is removed from the Integrated

Power Module (IPM) fuse cavity when the vehicle is

shipped from the assembly plant. Dealer personnel

must install the IOD fuse when the vehicle is being

prepared for delivery in order to restore full electrical

system operation. Once the vehicle is prepared for

delivery, the IOD function of this fuse becomes trans-

parent and the fuse that has been assigned the IOD

designation becomes only another Fused B(+) circuit

fuse. The IOD fuse serves no useful purpose to the

dealer technician in the service or diagnosis of any

vehicle system or condition, other than the same pur-

pose as that of any other standard circuit protection

device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed approximately thirty days. However, it mustbe remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than thirty days,

the battery negative cable should be disconnected to

eliminate normal IOD; and, the battery should be

tested and recharged at regular intervals during the

vehicle storage period to prevent the battery from

becoming discharged or damaged.

POWER OUTLET

DESCRIPTION

Two power outlets are installed in the instrument

panel center lower bezel. Two additional power out-

lets are incorporated into the left rear C-pillar and

the center console (if equipped). The power outlets

bases are secured by a snap fit. A hinged plug flips

closed to conceal and protect the power outlet base

when not in use.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the ON position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-3

INTEGRATED POWER MODULE (Continued)

Page 1417 of 2339

COLUMN

TABLE OF CONTENTS

page page

COLUMN

DESCRIPTION - STEERING COLUMN.......10

WARNING

WARNINGS AND CAUTIONS.............10

DIAGNOSIS AND TESTING - STEERING

COLUMN............................11

REMOVAL.............................11

INSTALLATION.........................16

SPECIFICATIONS

COLUMN FASTENER TORQUE...........17

IGNITION SWITCH

REMOVAL.............................17

INSTALLATION.........................19

KEY/LOCK CYLINDER

DESCRIPTION.........................20OPERATION...........................20

REMOVAL.............................20

INSTALLATION.........................20

SHROUD - LOWER

REMOVAL.............................21

INSTALLATION.........................21

SHROUD - UPPER

REMOVAL.............................22

INSTALLATION.........................22

STEERING WHEEL

REMOVAL.............................23

INSTALLATION.........................24

COLUMN

DESCRIPTION - STEERING COLUMN

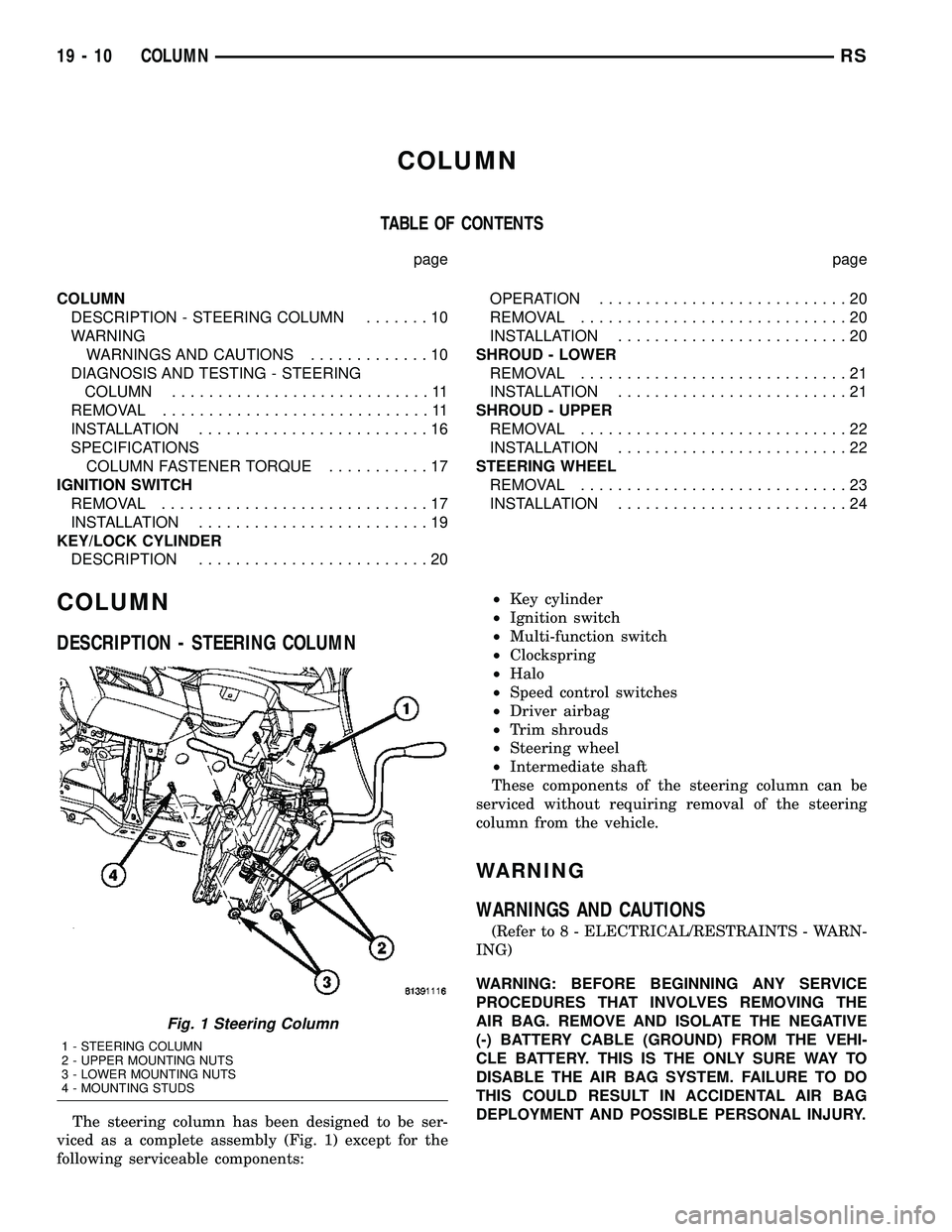

The steering column has been designed to be ser-

viced as a complete assembly (Fig. 1) except for the

following serviceable components:²Key cylinder

²Ignition switch

²Multi-function switch

²Clockspring

²Halo

²Speed control switches

²Driver airbag

²Trim shrouds

²Steering wheel

²Intermediate shaft

These components of the steering column can be

serviced without requiring removal of the steering

column from the vehicle.

WARNING

WARNINGS AND CAUTIONS

(Refer to 8 - ELECTRICAL/RESTRAINTS - WARN-

ING)

WARNING: BEFORE BEGINNING ANY SERVICE

PROCEDURES THAT INVOLVES REMOVING THE

AIR BAG. REMOVE AND ISOLATE THE NEGATIVE

(-) BATTERY CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

Fig. 1 Steering Column

1 - STEERING COLUMN

2 - UPPER MOUNTING NUTS

3 - LOWER MOUNTING NUTS

4 - MOUNTING STUDS

19 - 10 COLUMNRS

Page 1418 of 2339

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIR BAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIR BAG COMPONENTS, HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY DESIGNED

FOR THE AIR BAG SYSTEM. THEY MUST NEVER

BE REPLACED WITH ANY SUBSTITUTES. ANYTIME

A NEW FASTENER IS NEEDED, REPLACE WITH

THE CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR FASTENERS LISTED IN

THE PARTS BOOKS.

WARNING: SAFETY GOGGLES SHOULD BE WORN

AT ALL TIMES WHEN WORKING ON STEERING

COLUMNS.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any column compo-

nent.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

DIAGNOSIS AND TESTING - STEERING

COLUMN

For diagnosis of conditions relating to the steering

column, (Refer to 19 - STEERING - DIAGNOSIS

AND TESTING).

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING)(Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

(1) Make sure the front wheels of the vehicle are

in the STRAIGHT AHEAD position before beginning

the column removal procedure.

(2) Disconnect and isolate the negative (ground)

cable from the battery. Wait at least two minutes for

the airbag system reserve capacitor to discharge

before beginning any steering column, instrument

panel, or airbag system/component service.WARNING: WHEN AN UNDEPLOYED AIRBAG IS TO

BE REMOVED FROM THE VEHICLE, FIRST DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE. ALLOW THE AIRBAG SYSTEM

RESERVE CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE BEGINNING ANY AIRBAG SYS-

TEM OR COMPONENT SERVICE. PERSONAL

INJURY MAY RESULT IF THIS PROCEDURE IS NOT

FOLLOWED.

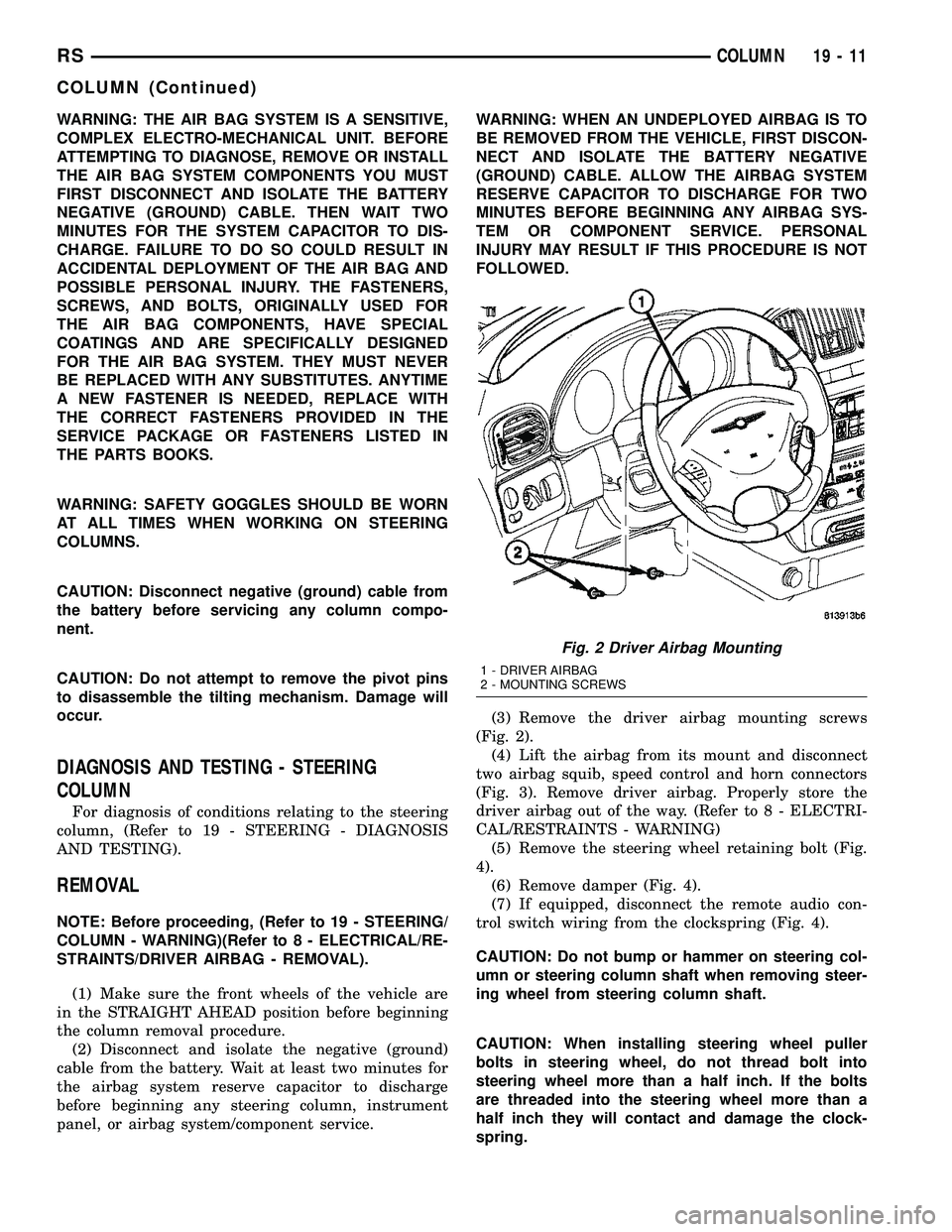

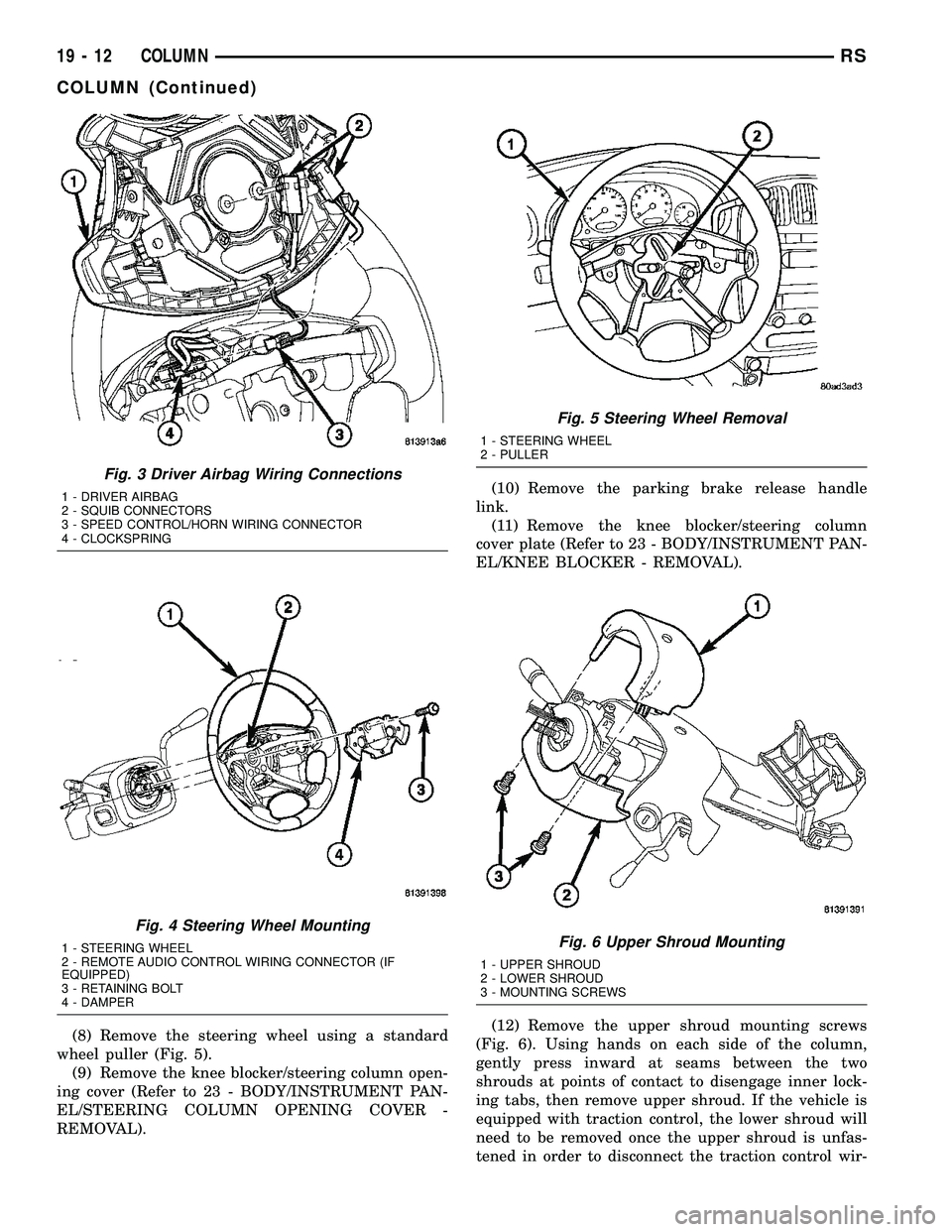

(3) Remove the driver airbag mounting screws

(Fig. 2).

(4) Lift the airbag from its mount and disconnect

two airbag squib, speed control and horn connectors

(Fig. 3). Remove driver airbag. Properly store the

driver airbag out of the way. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - WARNING)

(5) Remove the steering wheel retaining bolt (Fig.

4).

(6) Remove damper (Fig. 4).

(7) If equipped, disconnect the remote audio con-

trol switch wiring from the clockspring (Fig. 4).

CAUTION: Do not bump or hammer on steering col-

umn or steering column shaft when removing steer-

ing wheel from steering column shaft.

CAUTION: When installing steering wheel puller

bolts in steering wheel, do not thread bolt into

steering wheel more than a half inch. If the bolts

are threaded into the steering wheel more than a

half inch they will contact and damage the clock-

spring.

Fig. 2 Driver Airbag Mounting

1 - DRIVER AIRBAG

2 - MOUNTING SCREWS

RSCOLUMN19-11

COLUMN (Continued)

Page 1419 of 2339

(8) Remove the steering wheel using a standard

wheel puller (Fig. 5).

(9) Remove the knee blocker/steering column open-

ing cover (Refer to 23 - BODY/INSTRUMENT PAN-

EL/STEERING COLUMN OPENING COVER -

REMOVAL).(10) Remove the parking brake release handle

link.

(11) Remove the knee blocker/steering column

cover plate (Refer to 23 - BODY/INSTRUMENT PAN-

EL/KNEE BLOCKER - REMOVAL).

(12) Remove the upper shroud mounting screws

(Fig. 6). Using hands on each side of the column,

gently press inward at seams between the two

shrouds at points of contact to disengage inner lock-

ing tabs, then remove upper shroud. If the vehicle is

equipped with traction control, the lower shroud will

need to be removed once the upper shroud is unfas-

tened in order to disconnect the traction control wir-

Fig. 3 Driver Airbag Wiring Connections

1 - DRIVER AIRBAG

2 - SQUIB CONNECTORS

3 - SPEED CONTROL/HORN WIRING CONNECTOR

4 - CLOCKSPRING

Fig. 4 Steering Wheel Mounting

1 - STEERING WHEEL

2 - REMOTE AUDIO CONTROL WIRING CONNECTOR (IF

EQUIPPED)

3 - RETAINING BOLT

4 - DAMPER

Fig. 5 Steering Wheel Removal

1 - STEERING WHEEL

2 - PULLER

Fig. 6 Upper Shroud Mounting

1 - UPPER SHROUD

2 - LOWER SHROUD

3 - MOUNTING SCREWS

19 - 12 COLUMNRS

COLUMN (Continued)

Page 1423 of 2339

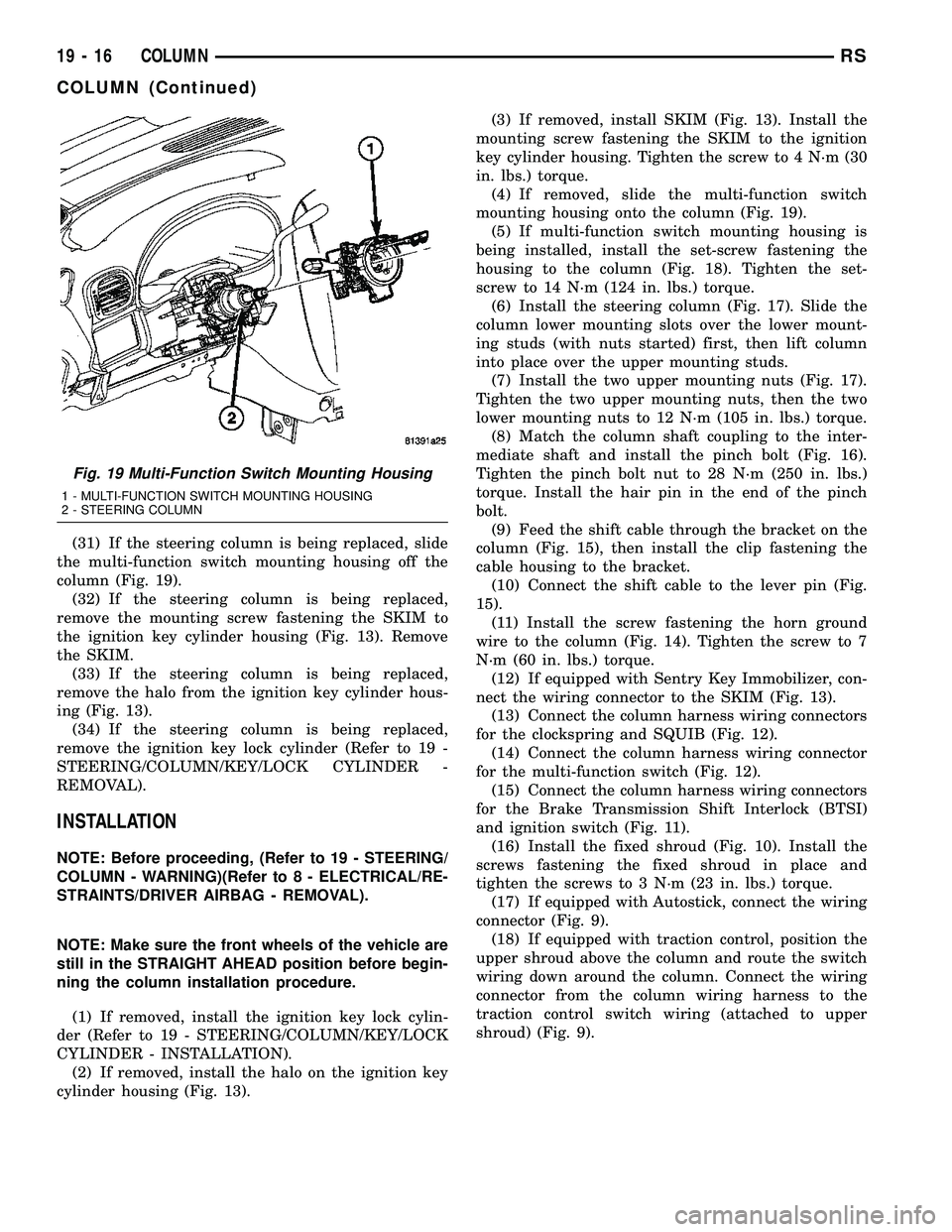

(31) If the steering column is being replaced, slide

the multi-function switch mounting housing off the

column (Fig. 19).

(32) If the steering column is being replaced,

remove the mounting screw fastening the SKIM to

the ignition key cylinder housing (Fig. 13). Remove

the SKIM.

(33) If the steering column is being replaced,

remove the halo from the ignition key cylinder hous-

ing (Fig. 13).

(34) If the steering column is being replaced,

remove the ignition key lock cylinder (Refer to 19 -

STEERING/COLUMN/KEY/LOCK CYLINDER -

REMOVAL).

INSTALLATION

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING)(Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

NOTE: Make sure the front wheels of the vehicle are

still in the STRAIGHT AHEAD position before begin-

ning the column installation procedure.

(1) If removed, install the ignition key lock cylin-

der (Refer to 19 - STEERING/COLUMN/KEY/LOCK

CYLINDER - INSTALLATION).

(2) If removed, install the halo on the ignition key

cylinder housing (Fig. 13).(3) If removed, install SKIM (Fig. 13). Install the

mounting screw fastening the SKIM to the ignition

key cylinder housing. Tighten the screw to 4 N´m (30

in. lbs.) torque.

(4) If removed, slide the multi-function switch

mounting housing onto the column (Fig. 19).

(5) If multi-function switch mounting housing is

being installed, install the set-screw fastening the

housing to the column (Fig. 18). Tighten the set-

screw to 14 N´m (124 in. lbs.) torque.

(6) Install the steering column (Fig. 17). Slide the

column lower mounting slots over the lower mount-

ing studs (with nuts started) first, then lift column

into place over the upper mounting studs.

(7) Install the two upper mounting nuts (Fig. 17).

Tighten the two upper mounting nuts, then the two

lower mounting nuts to 12 N´m (105 in. lbs.) torque.

(8) Match the column shaft coupling to the inter-

mediate shaft and install the pinch bolt (Fig. 16).

Tighten the pinch bolt nut to 28 N´m (250 in. lbs.)

torque. Install the hair pin in the end of the pinch

bolt.

(9) Feed the shift cable through the bracket on the

column (Fig. 15), then install the clip fastening the

cable housing to the bracket.

(10) Connect the shift cable to the lever pin (Fig.

15).

(11) Install the screw fastening the horn ground

wire to the column (Fig. 14). Tighten the screw to 7

N´m (60 in. lbs.) torque.

(12) If equipped with Sentry Key Immobilizer, con-

nect the wiring connector to the SKIM (Fig. 13).

(13) Connect the column harness wiring connectors

for the clockspring and SQUIB (Fig. 12).

(14) Connect the column harness wiring connector

for the multi-function switch (Fig. 12).

(15) Connect the column harness wiring connectors

for the Brake Transmission Shift Interlock (BTSI)

and ignition switch (Fig. 11).

(16) Install the fixed shroud (Fig. 10). Install the

screws fastening the fixed shroud in place and

tighten the screws to 3 N´m (23 in. lbs.) torque.

(17) If equipped with Autostick, connect the wiring

connector (Fig. 9).

(18) If equipped with traction control, position the

upper shroud above the column and route the switch

wiring down around the column. Connect the wiring

connector from the column wiring harness to the

traction control switch wiring (attached to upper

shroud) (Fig. 9).

Fig. 19 Multi-Function Switch Mounting Housing

1 - MULTI-FUNCTION SWITCH MOUNTING HOUSING

2 - STEERING COLUMN

19 - 16 COLUMNRS

COLUMN (Continued)

Page 1424 of 2339

(19) Position the lower shroud on the column (Fig.

8). Install the lower shroud mounting screw. Tighten

the screw to 2 N´m (17 in. lbs.) torque.

(20) If equipped with adjustable pedals, Connect

the wiring connector for the switch (Fig. 7) to the col-

umn wiring harness.

(21) Position the upper shroud on top of the lower

shroud and snap it into place. Install the upper

shroud mounting screws (Fig. 6). Tighten the screws

to 2 N´m (17 in. lbs.) torque.

(22) Inspect shroud mating surfaces for excessive

gaps and correct as necessary.

(23) Install the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(24) Install the knee blocker/steering column cover

plate. (Refer to 23 - BODY/INSTRUMENT PANEL/

KNEE BLOCKER - INSTALLATION)

(25) Install the parking brake handle link.

(26) Install the knee blocker/steering column open-

ing cover. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/STEERING COLUMN OPENING COVER -

INSTALLATION)

(27) Align the splines and install the steering

wheel on the steering column shaft(Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(28) Install the damper over the steering column

shaft (Fig. 4).

(29) Install the steering wheel retaining bolt (Fig.

4). Tighten the bolt to 61 N´m (45 ft. lbs.) torque.

(30) If the steering wheel is equipped with remote

audio controls, connect the wiring connector to the

clockspring (Fig. 4).

(31) Connect the two squib connectors to the

driver airbag (Fig. 3). The connectors are color coded

to avoid connector mix-up.

(32) Connect the speed control and horn connector

to the clockspring (Fig. 3).

(33) Install the airbag to the steering wheel.

Install the driver airbag mounting screws (Fig. 2).

Tighten screws to 10 N´m (90 in. lbs.) torque.

(34) Connect the battery negative (ground) cable to

battery post following special Diagnosis And Testing

procedure. (Refer to 8 - ELECTRICAL/RESTRAINTS

- DIAGNOSIS AND TESTING)

(35) Check operation of all steering column

mounted components.

(36) Road test vehicle to ensure proper operation

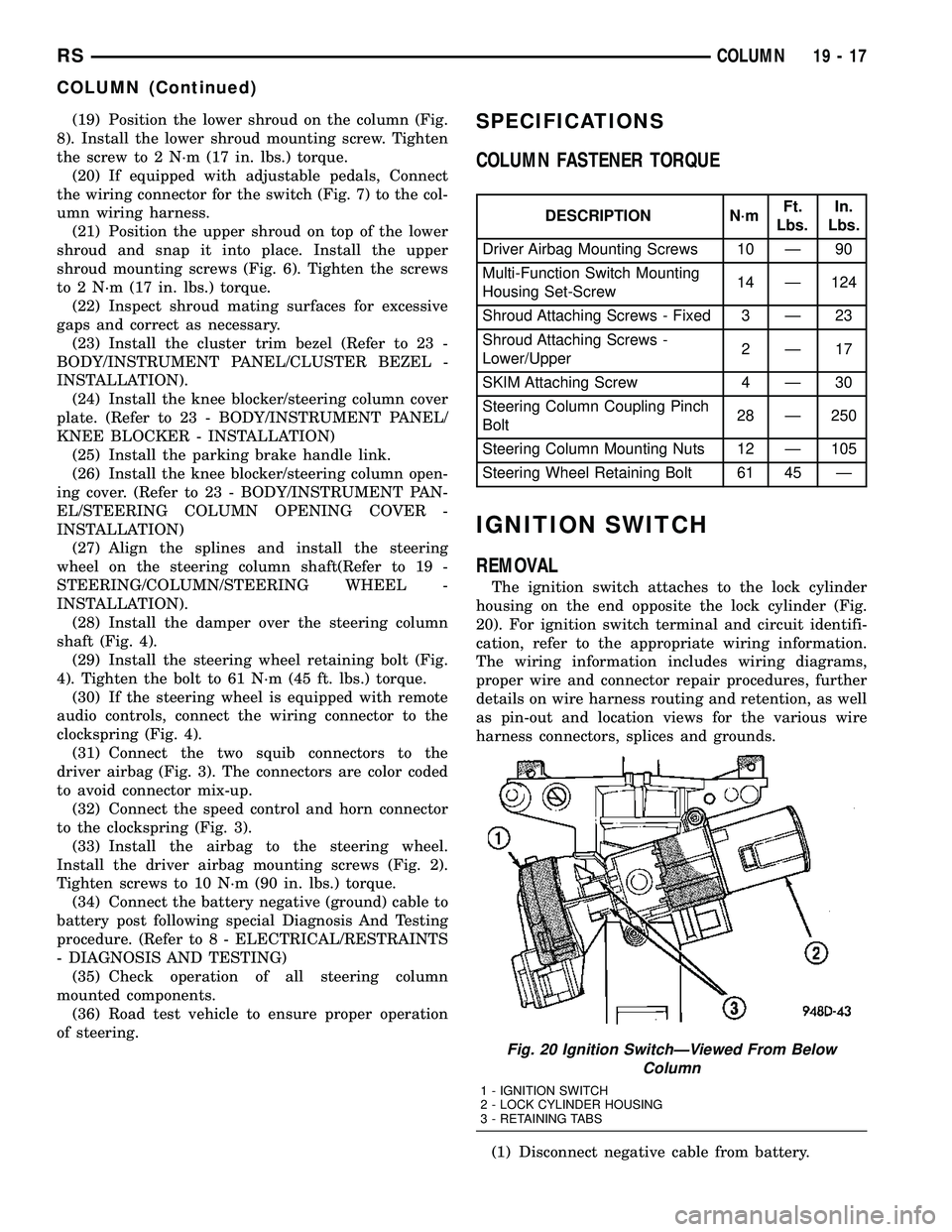

of steering.SPECIFICATIONS

COLUMN FASTENER TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Driver Airbag Mounting Screws 10 Ð 90

Multi-Function Switch Mounting

Housing Set-Screw14 Ð 124

Shroud Attaching Screws - Fixed 3 Ð 23

Shroud Attaching Screws -

Lower/Upper2Ð17

SKIM Attaching Screw 4 Ð 30

Steering Column Coupling Pinch

Bolt28 Ð 250

Steering Column Mounting Nuts 12 Ð 105

Steering Wheel Retaining Bolt 61 45 Ð

IGNITION SWITCH

REMOVAL

The ignition switch attaches to the lock cylinder

housing on the end opposite the lock cylinder (Fig.

20). For ignition switch terminal and circuit identifi-

cation, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

(1) Disconnect negative cable from battery.

Fig. 20 Ignition SwitchÐViewed From Below

Column

1 - IGNITION SWITCH

2 - LOCK CYLINDER HOUSING

3 - RETAINING TABS

RSCOLUMN19-17

COLUMN (Continued)