airbag off CHRYSLER CARAVAN 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 494 of 2339

UNDEPLOYED AIRBAG

WARNING: The airbags must be stored in its origi-

nal special container until used for service. At no

time should a source of electricity be permitted

near the inflator on the back of an airbag. When

carrying or handling an undeployed airbag, the trim

side of the airbag should be pointing toward the

body to minimize the possibility of personal injury

or death if accidental deployment occurs. Do not

place undeployed airbag face down on a solid sur-

face, the airbag will propel into the air if accidental

deployment occurs.

STANDARD PROCEDURE - SERVICE AFTER AN

AIRBAG DEPLOYMENT

DRIVER AIRBAG

After a Driver Airbag has been deployed due to a

collision, the followingMUSTbe replaced:

²Driver Airbag

²Clockspring Assembly

²Steering Wheel

²Complete Steering Column Assembly w/Lower

Steering Column Coupler

All other airbag and vehicle components should be

closely inspected following any airbag deployment,

and should be replaced when visible damage is

incurred.

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

PASSENGER AIRBAG

After a Passenger Airbag has been deployed due to

a collision. the followingMUSTbe replaced:

²Passenger Airbag

²Instrument Panel and Pad Assembly

All other airbag and vehicle components should be

closely inspected following any airbag deployment,

and should be replaced when visible damage is

incurred.

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

KNEE BLOCKER AIRBAG

After a Knee Blocker Airbag has been deployed due

to a collision. the followingMUSTbe replaced:

²Knee Blocker Airbag

²Instrument Panel and Pad Assembly

All other airbag and vehicle components should be

closely inspected following any airbag deployment,

and should be replaced when visible damage is

incurred.

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

CURTAIN AIRBAG

After a Curtain Airbag has been deployed due to a

collision. the followingMUSTbe replaced:

²Curtain Airbag Assembly

²Headliner

²A, B, and C-Pillar Trim on deployed side.

All other airbag and vehicle components should be

closely inspected following any airbag deployment,

and should be replaced when visible damage is

incurred.

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

OCCUPANT CLASSIFICATION SYSTEM (OCS)

After an impact event, either front, rear, or side,

the OCS system components need to be inspected

and replaced if found to be damaged.

This includes:

²Belt Tension Sensor

²Occupant Classification Module (OCM)

²Passenger Airbag ON/Off Indicator

²Seat Weight Bladder and Sensor

RSRESTRAINTS8O-7

RESTRAINTS (Continued)

Page 516 of 2339

restraint system protection in case there is a loss of

battery current supply to the ORC during an impact.

Two sensors are contained within the ORC, an

electronic impact sensor and a safing sensor. The

ORC also monitors inputs from eight remote impact

sensors. Two front impact sensors are located on each

outboard side of the lower radiator support, and

three side impact sensors are located on each side of

the vehicle at the B-pillar, in the lower sliding door

opening in front of the C-pillar, and over the rear

wheel well between the C and D-pillars. The elec-

tronic impact sensors are accelerometers that sense

the rate of vehicle deceleration, which provides veri-

fication of the direction and severity of an impact.

The safing sensor is an electronic accelerometer

sensor within the ORC that provides an additional

logic input to the ORC microprocessor. The safing

sensor is used to verify the need for a supplemental

restraint deployment by detecting impact energy of a

lesser magnitude than that of the primary electronic

impact sensors, and must exceed a safing threshold

in order for the airbags to deploy. Vehicles equipped

with curtain airbags, there is a second safing sensor

within the ORC to provide confirmation to the ORC

microprocessor of side impact forces. This second saf-

ing sensor is a bi-directional unit that detects impact

forces from either side of the vehicle.

Pre-programmed decision algorithms in the ORC

microprocessor determine when the deceleration rate

as signaled by the impact sensors and the safing sen-

sors indicate an impact that is severe enough to

require supplemental restraint system protection

and, based upon the severity of the monitored

impact, determines the level of front airbag deploy-

ment force required for each front seating position.

When the programmed conditions are met, the ORC

sends the proper electrical signals to deploy the dual

multistage front airbags at the programmed force

levels, the front seat belt tensioners and, if the vehi-

cle is so equipped, either curtain airbag. For vehicles

equipped with the OCS, the passenger front airbag

and seat belt tensioner will be deployed by the ORC

only if enabled by the OCM messages (PAD indicator

OFF) at the time of the impact.

To diagnose and test the ORC and all airbag sys-

tem components, use a scan tool and the appropriate

diagnostic information.

REMOVAL

WARNING: Never replace both the Occupant

Restraint Controller (ORC) and the Occupant Clas-

sification Module (OCM) at the same time. If both

require replacement, replace one, then perform the

Airbag System test (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING - AIRBAGSYSTEM) before replacing the other. Both the ORC

and the OCM store Occupant Classification System

(OCS) calibration data, which they transfer to one

another when one of them is replaced. If both are

replaced at the same time, an irreversible fault will

be set in both modules and the OCS may malfunc-

tion and result in personal injury or death.

(1) Disconnect and isolate the battery negative

cable.

(2)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(3) Remove storage bin from instrument panel

(Refer to 23 - BODY/INSTRUMENT PANEL/STOR-

AGE BIN - REMOVAL).

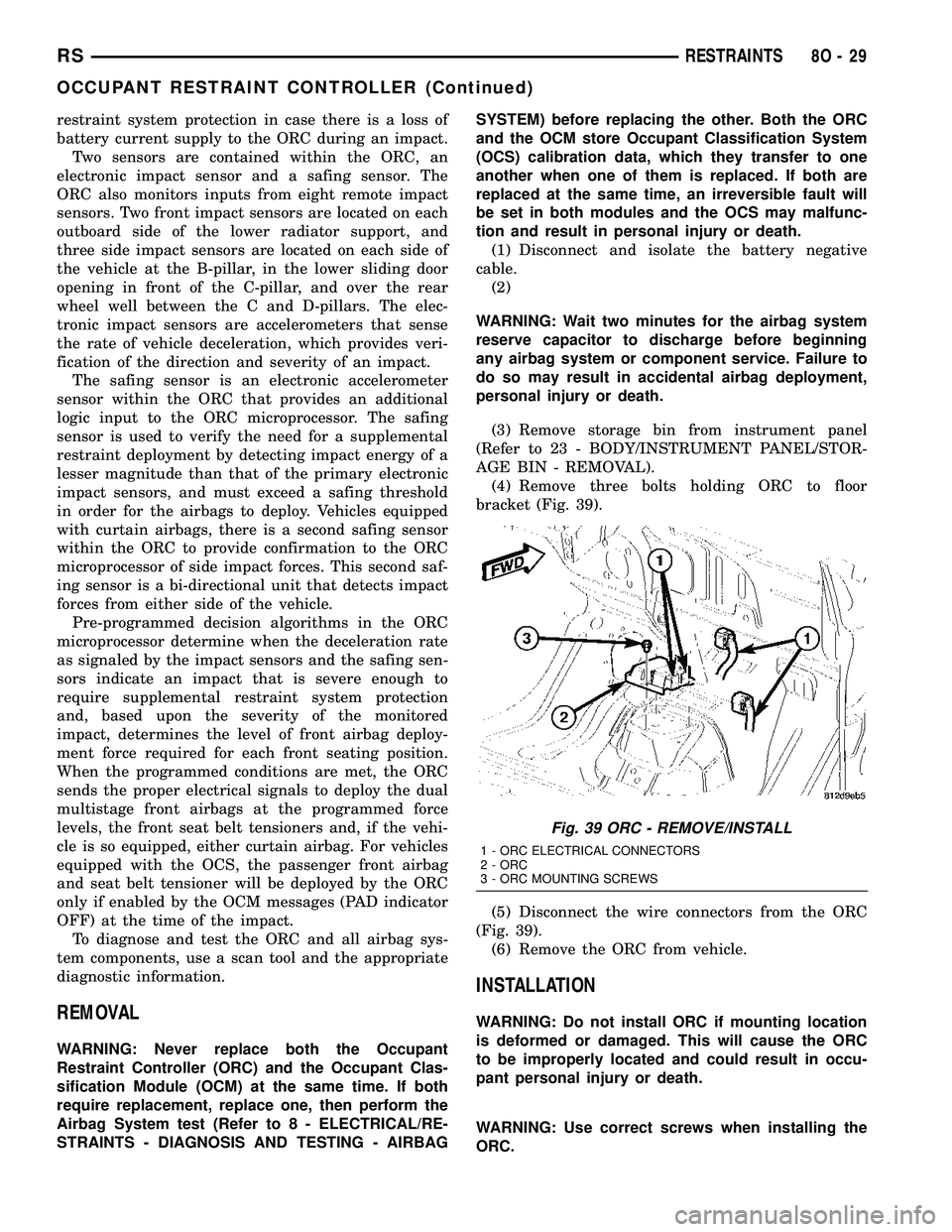

(4) Remove three bolts holding ORC to floor

bracket (Fig. 39).

(5) Disconnect the wire connectors from the ORC

(Fig. 39).

(6) Remove the ORC from vehicle.

INSTALLATION

WARNING: Do not install ORC if mounting location

is deformed or damaged. This will cause the ORC

to be improperly located and could result in occu-

pant personal injury or death.

WARNING: Use correct screws when installing the

ORC.

Fig. 39 ORC - REMOVE/INSTALL

1 - ORC ELECTRICAL CONNECTORS

2 - ORC

3 - ORC MOUNTING SCREWS

RSRESTRAINTS8O-29

OCCUPANT RESTRAINT CONTROLLER (Continued)

Page 518 of 2339

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(4) Clean powder residue from interior of vehicle

(Refer to 8 - ELECTRICAL/RESTRAINTS - STAN-

DARD PROCEDURE - SERVICE AFTER AN AIR-

BAG DEPLOYMENT).

(5) Remove instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - REMOVAL).

(6) Remove all reusable components from the

upper instrument panel and transfer to the new

instrument panel.

UNDEPLOYED AIRBAG

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(4) Remove center console bin between front seats.

(5) Remove left front door sill plate using a trim

stick (special tool #C-4755) or equivalent, and gently

prying up on sill plate.

(6) Remove left cowl panel using a trim stick or

equivalent, and gently prying out on cowl panel.

(7) Remove four screws to lower steering column

cover and remove cover.

(8) Unsnap parking brake lever from knee blocker

reinforcement.

(9) Remove Data Link Connector (DLC) from knee

blocker.

(10) Remove screws to knee blocker.

(11) Unsnap left A-pillar lower extension trim

using a trim stick or equivalent.

(12) Remove three left side instrument panel A-pil-

lar retaining bolts and loosen the instrument panel

roll down bolt.

(13) Remove four nuts at brake pedal support

bracket to instrument panel.

(14) Using a trim stick or equivalent, gently pry

off left side upper A-pillar trim.

(15) Remove six screws and two wiring connectors

to lower instrument panel cubby bin at bottom of

center stack.

(16) Remove two left side nuts at instrument panel

center stack support to floor.(17) Remove two right side nuts at instrument

panel center stack support to floor.

(18) Remove right front door sill plate using a trim

stick or equivalent, and gently prying up on sill

plate.

(19) Remove right cowl panel using a trim stick or

equivalent, and gently prying out on cowl panel.

(20) Using a trim stick or equivalent, gently pry

out on right instrument panel end cap.

(21) Unsnap right A-pillar lower extension trim

using a trim stick or equivalent.

(22) Remove three right side instrument panel

A-pillar retaining bolts and loosen the instrument

panel roll down bolt.

(23) Using a trim stick or equivalent, gently pry

off right side upper A-pillar trim.

(24) Open glove box, pinch in sides and roll down

towards floor. With a firm pull, snap glove box door

off hinges and remove.

(25) Using a trim stick or equivalent, gently pry

up on rear of instrument panel top cover and then

pull rearward and out.

(26) Using a trim stick or equivalent, gently pry

off the filler bezel just above the cup holder to expose

the lower screws to center bezel.

(27) Remove two screws and then using a trim

stick or equivalent, gently pry off instrument panel

center bezel.

(28) Remove center bezel wiring connectors to

HVAC control and switch assembly (hazard, rear

wiper/washer, heated seats) and remove bezel.

(29) Slide cup holder assembly from instrument

panel.

(30) Remove nineteen screws to right lower instru-

ment panel trim (glove box surround), unplug glove

box lamp wire connector, and remove panel.

(31) Remove four screws and wiring connectors to

radio and remove radio.

(32) Remove one far left instrument panel speaker

retaining screw.

(33) Remove four screws along top front edge of

instrument panel cover/pad.

(34) Remove seven lower instrument panel cover/

pad retaining screws starting from right of vehicle

and only removing these seven, not all of them.

(35) Remove six upper fence line instrument panel

retaining bolts.

(36) Roll back instrument panel just enough to

increase access to the passenger airbag retaining

bolts at the reinforcement. Lift the instrument panel

up slightly so as not to damage the air distribution to

HVAC unit seal.

(37) Disconnect the passenger airbag electrical

connector. Using a trim stick or equivalent, gently

pry electrical connector off of instrument panel rein-

forcement.

RSRESTRAINTS8O-31

PASSENGER AIRBAG (Continued)

Page 520 of 2339

(28) Install two right side nuts at instrument

panel center stack support to floor.

(29) Install two left side nuts at instrument panel

center stack support to floor.

(30) Connect the two wiring connectors to lower

instrument panel cubby bin at bottom of center stack

and install six screws.

(31) Align left side upper A-pillar trim over retain-

ing slots and firmly snap into place.

(32) Install four nuts at brake pedal support

bracket to instrument panel.

(33) Align left A-pillar lower extension trim over

retaining slots and firmly snap into place.

(34) Install knee blocker and retaining screws.

(35) Install Data Link Connector (DLC) into bot-

tom of knee blocker.

(36) Align parking brake lever and snap into place

on knee blocker reinforcement.

(37) Install lower steering column cover and four

retaining screws

(38) Align left cowl panel over retaining slots and

firmly snap into place.

(39) Align left front door sill plate over retaining

slots and firmly snap into place.

(40) Install center console bin between front seats.

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(41) Close hood.

(42) Verify system and vehicle operation.

PASSENGER AIRBAG

DISABLED INDICATOR

DESCRIPTION

Vehicles equipped with the Occupant Classification

System (OCS) include a Passenger Airbag Disabled

(PAD) indicator (Fig. 40) which is located in the

instrument panel center stack, above the radio. The

PAD indicator is present only in vehicles equipped

with the OCS.The PAD indicator consists of a molded plastic

housing with an integral connector at the back. An

amber Light Emitting Diode (LED) behind the lens

causes the ªPASS AIR BAG OFFº text and icon to

appear silhouetted against an amber field through

the translucent lens when the indicator is illumi-

nated from behind by the LED. The PAD indicator is

available for separate service replacement.

OPERATION

In vehicles equipped with the Occupant Classifica-

tion System (OCS), the Passenger Airbag Disabled

(PAD) indicator gives an indication when the passen-

ger airbag and seat belt tensioner deployment cir-

cuits are disabled by the Occupant Restraint

Controller (ORC). The PAD indicator is controlled by

a transistor within the ORC through a hard wired

output based upon ORC programming and electronic

occupant classification messages received by the ORC

over the Programmable Communications Interface

(PCI) data bus from the Occupant Classification

Module (OCM). The PAD indicator Light Emitting

Diode (LED) is completely controlled by the ORC.

The LED receives a battery current input on the

fused ignition switch output (RUN/START) circuit.

Therefore, the LED will always be OFF when the

ignition switch is in any position except ON or

START. The LED only illuminates when it is pro-

vided a path to ground by the ORC transistor. The

ORC will turn on the PAD indicator for the following

reasons:

²Bulb Test- Each time the ignition switch is

turned to the ON position the PAD indicator is illu-

minated for about six seconds.

²Child Seat Detected Occupant Classifica-

tion Message- Each time the ORC receives a mes-

sage from the OCM indicating a child seat has been

detected in the passenger front seat, the passenger

airbag and seat belt tensioner deployment circuits

are deactivated and the PAD indicator will be illumi-

nated. The indicator remains illuminated until the

ORC receives an occupant classification message

indicating that:

²The passenger front seat is empty.

²The seat is occupied by a load equal to or

greater than a fifth percentile female.

²OR,Until the ignition switch is turned to the

OFF position, whichever of these three occurs first.

²Load Less Than Fifth Percentile Female

Occupant Classification Message- Each time the

ORC receives a message from the OCM indicating

that a load less than a fifth percentile female has

been detected in the passenger front seat, the pas-

senger airbag and seat belt tensioner deployment cir-

cuits are deactivated and the PAD indicator will be

illuminated. The indicator remains illuminated until:

Fig. 40 PASSENGER AIRBAG DISABLED (PAD)

INDICATOR

RSRESTRAINTS8O-33

PASSENGER AIRBAG (Continued)

Page 521 of 2339

²The ORC receives an occupant classification

message indicating that the passenger front seat is

empty.

²The seat is occupied by a load equal to or

greater than a fifth percentile female.

²OR, until the ignition switch is turned to the

OFF position, whichever of these three occurs first.

²Load Undetermined Occupant Classifica-

tion Message- Each time the ORC receives a mes-

sage from the OCM indicating that a load cannot be

determined in the passenger front seat, the passen-

ger airbag and seat belt tensioner deployment cir-

cuits are deactivated and the PAD indicator will be

illuminated. The indicator remains illuminated until:

²The ORC receives an occupant classification

message indicating that the passenger front seat is

empty.

²The seat is occupied by a load equal to or

greater than a fifth percentile female.

²OR, until the ignition switch is turned to the

OFF position, whichever of these three occurs first.

²Communication Error- If the ORC receives

invalid occupant classification messages or no mes-

sages from the OCM, the PAD indicator is illumi-

nated. The indicator remains illuminated until:

²The ORC receives an occupant classification

message indicating that the passenger front seat is

empty.

²The seat is occupied by a load equal to or

greater than a fifth percentile female.

²OR, until the ignition switch is turned to the

OFF position, whichever of these three occurs first.

The ORC continually monitors the occupant classi-

fication messages from the OCM to decide whether

the passenger airbag and seat belt tensioner deploy-

ment circuits should be activated or deactivated.

Note that there may be several seconds of delay

between changes in the detected occupant status and

PAD indications. This is a programmed feature of the

OCM used to prevent a flashing indicator condition

resulting from the normal shifting of occupant weight

on the passenger seat cushion. The ORC then pro-

vides the proper control output to turn the PAD indi-

cator ON or OFF.

The ORC will store a Diagnostic Trouble Code

(DTC) for any malfunction it detects. For proper

diagnosis of the OCM, the ORC, the PCI data bus, or

the electronic message inputs to the ORC that con-

trol the PAD indicator, use a scan tool and the appro-

priate diagnostic information.REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(4) Remove instrument panel center bezel (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL CENTER BEZEL - REMOVAL).

(5) From the back of the center bezel, depress the

two latches toward the indicator housing and push

the indicator out through the face of the center bezel.

INSTALLATION

(1) From the face of the instrument panel center

bezel, align the Passenger Airbag Disabled (PAD)

indicator housing with the mounting hole.

(2) Firmly push the indicator into the center bezel

until the two latches are fully engaged on the back of

the cap and are snapped in.

(3) Install the instrument panel center bezel (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL CENTER BEZEL - INSTALLATION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

WARNING: Following successful completion of the

Airbag System test procedure, the Occupant Classi-

fication System Verification Test must be done

using a scan tool and the appropriate diagnostic

information.

(4) Close hood.

(5) Verify system and vehicle operation.

8O - 34 RESTRAINTSRS

PASSENGER AIRBAG DISABLED INDICATOR (Continued)

Page 532 of 2339

SPEED CONTROL

TABLE OF CONTENTS

page page

SPEED CONTROL

DESCRIPTION..........................1

OPERATION

OPERATION..........................1

OPERATION - INTERACTIVE SPEED

CONTROL (4 Speed EATX Only)...........2

DIAGNOSIS AND TESTING - ROAD TEST.....3

SPECIFICATIONS - TORQUE...............3

CABLE

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

SERVO

DESCRIPTION..........................4OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

SWITCH

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

VACUUM RESERVOIR

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

SPEED CONTROL

DESCRIPTION

The speed control system is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the Powertrain Control Module.

The controls are located on the steering wheel. The

ON/OFF, and SET buttons are located on the left side

of the airbag module. The RESUME/ACCEL, CAN-

CEL and COAST buttons are located on the right

side of the airbag module (Fig. 1).The system is designed to operate at speeds above

30 mph (48 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

OPERATION

When speed control is activated by depressing the

ON switch, the PCM allows a set speed to be stored

in RAM for speed control. To store a set speed,

depress and release the SET switch while the vehicle

is moving at a speed between 25 and 85 mph. In

order for the speed control to engage, the brakes can-

not be applied, nor can the gear selector be indicat-

ing the transmission is in Park or Neutral (ATX) or

1st/2nd gear (MTX). The speed control can be disen-

gaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal

²Operating in 1st or 2nd gear (autostick, if

equipped)

Fig. 1 SPEED CONTROL SWITCHES - Typical

RSSPEED CONTROL8P-1

Page 536 of 2339

(4) Connect vacuum line to speed control servo

that leads to the battery tray/vacuum reservoir.

(5) Install speed control servo and bracket.

(6) Install battery tray/vacuum reservoir, refer to

the Battery section for more information.

(7) Install speed control and throttle cable casing

to cable mount bracket.

(8) Connect the throttle and speed control cable

ends to throttle body.

(9) Connect the negative battery cable.

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system and are located on the

steering wheel.

OPERATION

The speed control system has five separate resis-

tive switches that provide a single multiplexed

(MUX) voltage inputs to the PCM.The switch names

are: ON, OFF, SET, COAST, RESUME, ACCEL, TAP-

UP, COAST, and CANCEL. Based on conditions when

the buttons are pushed (and released), the five volt-

age ranges provided to the PCM result in the follow-

ing functions: ON, OFF, SET, COAST, RESUME,

ACCEL, TAP-UP, TAP-DOWN, COAST, and CAN-

CEL. Refer to the Speed Control Section for more

information

Also the PCM receives an input from the brake

switch to sense whether the brake pedal has been

depressed. When the PCM receives the brake

depressed input, it turns off power to the speed con-

trol servo and disengages speed control. Also the

power to the servo is supplied through the brake

switch, which opens the circuit when the brake pedal

is depressed.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

REMOVAL

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

Fig. 2 Speed Control Cable End

1 - SPEED CONTROL VACUUM HOSE

2 - THROTTLE BODY

3 - SPEED CONTROL CABLE

Fig. 3 BATTERY TRAY/VACUUM RESERVOIR

Fig. 4 SPEED CONTROL SERVO

RSSPEED CONTROL8P-5

SERVO (Continued)

Page 537 of 2339

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Remove the negative battery cable.

(2) Turn off ignition.

(3) Remove the air bag, refer to the restraint sec-

tion for more information.

(4) Remove the screw from bottom of the switch.

(5) Remove switch from steering wheel.

(6) Disconnect two-way electrical connector.

(7) Repeat for the other switch.

INSTALLATION

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Connect two-way electrical connector.

(2) Install switch.

(3) Install screw for the switch.

(4) Repeat for the other switch.

(5) Install the air bag, refer to the restraint section

for more information.

(6) Install the negative battery cable.

VACUUM RESERVOIR

DESCRIPTION

The vacuum reservoir is located in the engine com-

partment. It is made of plastic.

OPERATION

The reservoir stores engine vacuum. Manifold vac-

uum is supplied from the brake booster check valve.

The speed control vacuum supply hose has a check

valve at the source (brake booster) to maintain the

highest available vacuum level in the servo, reservoir

and vacuum hoses. When engine vacuum drops, as in

climbing a grade while driving, the reservoir supplies

the vacuum needed to maintain proper speed control

operation. The vacuum reservoir cannot be repaired

and must be replaced if faulty.

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect the negative battery cable.

(3) Disconnect the vacuum line to the battery tray/

vacuum reservoir.

(4) Remove battery tray/vacuum reservoir, refer to

the Battery section for more information.

INSTALLATION

(1) Install battery tray/vacuum reservoir, refer to

the Battery section for more information.

(2) Connect vacuum line that leads to the battery

tray/vacuum reservoir.

(3) Connect the negative battery cable.

8P - 6 SPEED CONTROLRS

SWITCH (Continued)

Page 561 of 2339

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANELCOMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

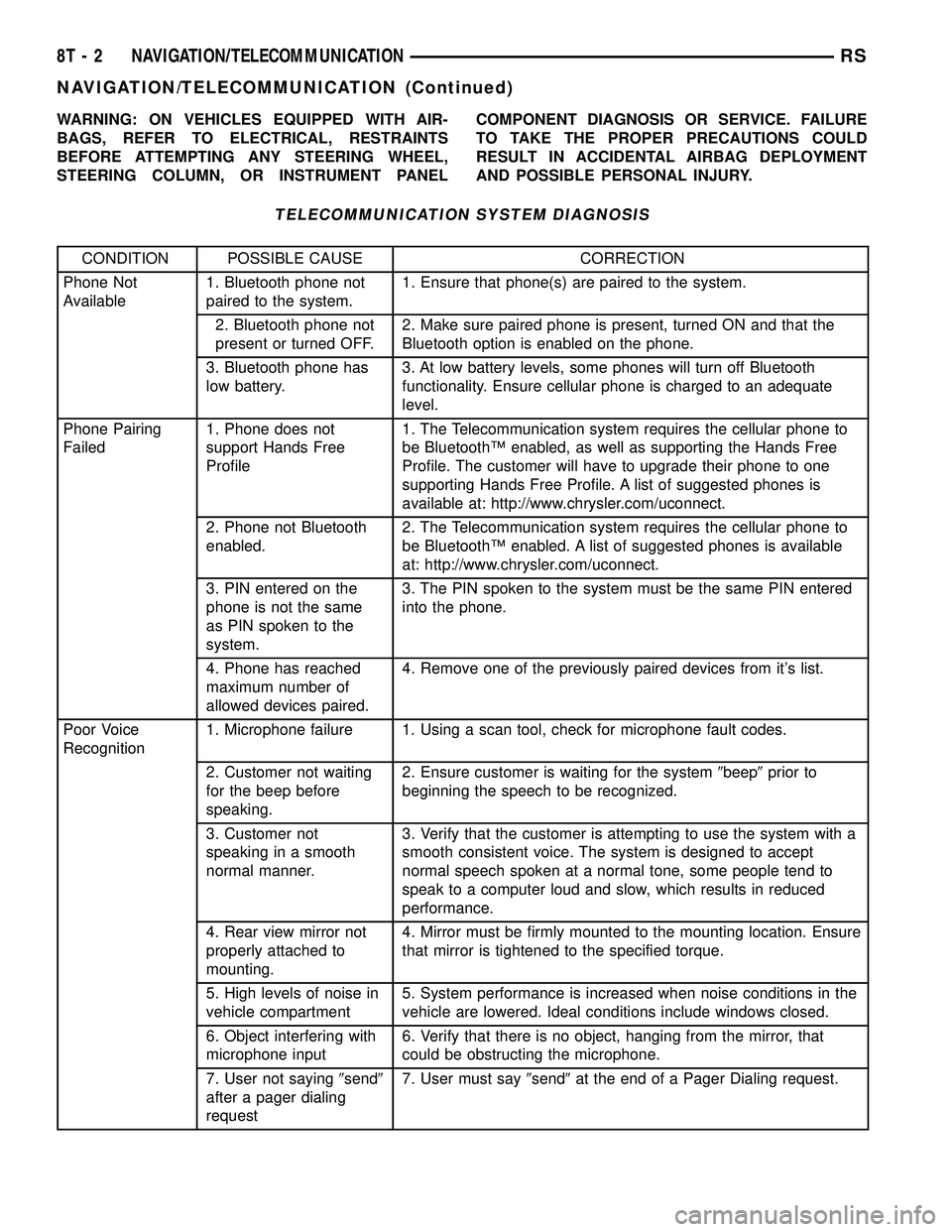

TELECOMMUNICATION SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

Phone Not

Available1. Bluetooth phone not

paired to the system.1. Ensure that phone(s) are paired to the system.

2. Bluetooth phone not

present or turned OFF.2. Make sure paired phone is present, turned ON and that the

Bluetooth option is enabled on the phone.

3. Bluetooth phone has

low battery.3. At low battery levels, some phones will turn off Bluetooth

functionality. Ensure cellular phone is charged to an adequate

level.

Phone Pairing

Failed1. Phone does not

support Hands Free

Profile1. The Telecommunication system requires the cellular phone to

be BluetoothŸ enabled, as well as supporting the Hands Free

Profile. The customer will have to upgrade their phone to one

supporting Hands Free Profile. A list of suggested phones is

available at: http://www.chrysler.com/uconnect.

2. Phone not Bluetooth

enabled.2. The Telecommunication system requires the cellular phone to

be BluetoothŸ enabled. A list of suggested phones is available

at: http://www.chrysler.com/uconnect.

3. PIN entered on the

phone is not the same

as PIN spoken to the

system.3. The PIN spoken to the system must be the same PIN entered

into the phone.

4. Phone has reached

maximum number of

allowed devices paired.4. Remove one of the previously paired devices from it's list.

Poor Voice

Recognition1. Microphone failure 1. Using a scan tool, check for microphone fault codes.

2. Customer not waiting

for the beep before

speaking.2. Ensure customer is waiting for the system9beep9prior to

beginning the speech to be recognized.

3. Customer not

speaking in a smooth

normal manner.3. Verify that the customer is attempting to use the system with a

smooth consistent voice. The system is designed to accept

normal speech spoken at a normal tone, some people tend to

speak to a computer loud and slow, which results in reduced

performance.

4. Rear view mirror not

properly attached to

mounting.4. Mirror must be firmly mounted to the mounting location. Ensure

that mirror is tightened to the specified torque.

5. High levels of noise in

vehicle compartment5. System performance is increased when noise conditions in the

vehicle are lowered. Ideal conditions include windows closed.

6. Object interfering with

microphone input6. Verify that there is no object, hanging from the mirror, that

could be obstructing the microphone.

7. User not saying9send9

after a pager dialing

request7. User must say9send9at the end of a Pager Dialing request.

8T - 2 NAVIGATION/TELECOMMUNICATIONRS

NAVIGATION/TELECOMMUNICATION (Continued)

Page 582 of 2339

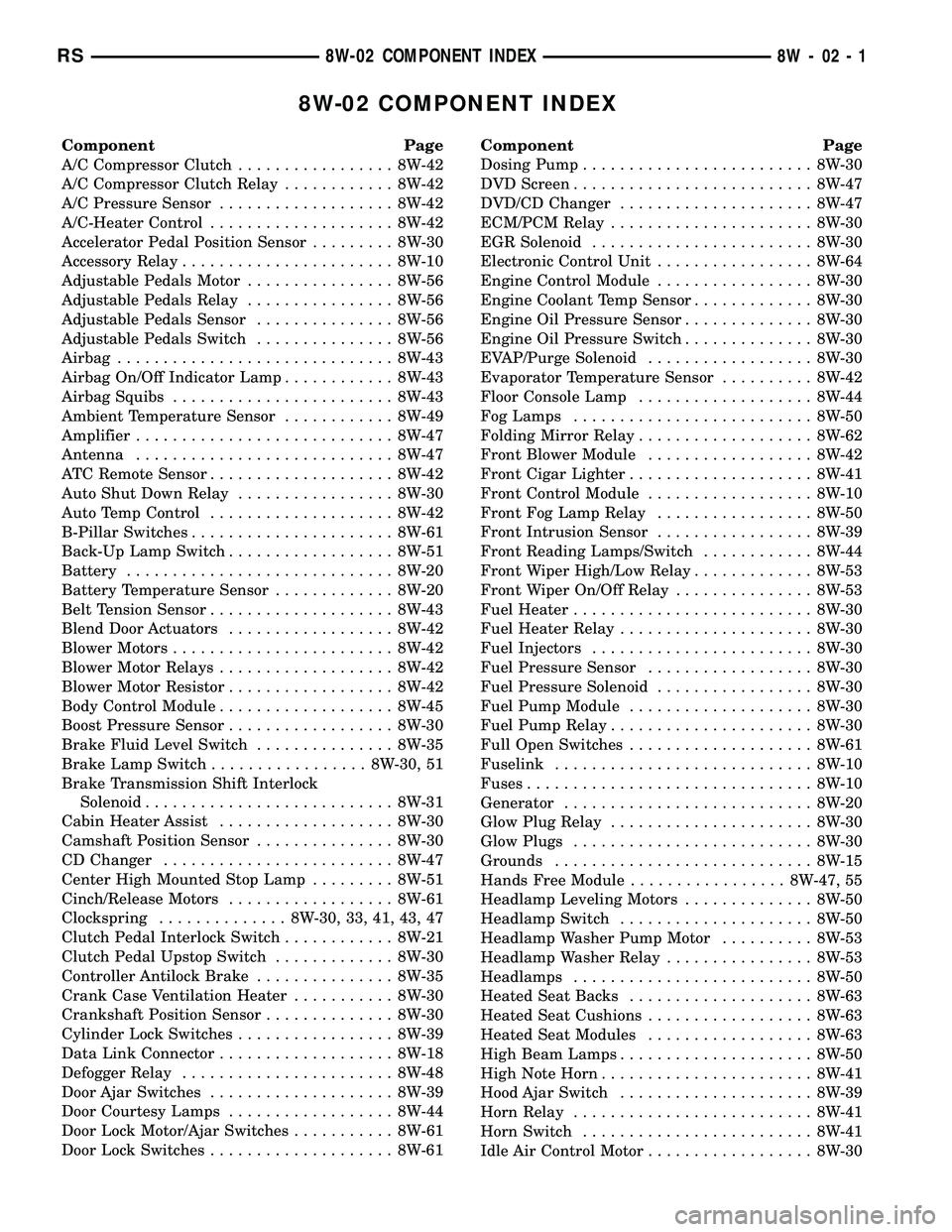

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch................. 8W-42

A/C Compressor Clutch Relay............ 8W-42

A/C Pressure Sensor................... 8W-42

A/C-Heater Control.................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Accessory Relay....................... 8W-10

Adjustable Pedals Motor................ 8W-56

Adjustable Pedals Relay................ 8W-56

Adjustable Pedals Sensor............... 8W-56

Adjustable Pedals Switch............... 8W-56

Airbag.............................. 8W-43

Airbag On/Off Indicator Lamp............ 8W-43

Airbag Squibs........................ 8W-43

Ambient Temperature Sensor............ 8W-49

Amplifier............................ 8W-47

Antenna............................ 8W-47

ATC Remote Sensor.................... 8W-42

Auto Shut Down Relay................. 8W-30

Auto Temp Control.................... 8W-42

B-Pillar Switches...................... 8W-61

Back-Up Lamp Switch.................. 8W-51

Battery............................. 8W-20

Battery Temperature Sensor............. 8W-20

Belt Tension Sensor.................... 8W-43

Blend Door Actuators.................. 8W-42

Blower Motors........................ 8W-42

Blower Motor Relays................... 8W-42

Blower Motor Resistor.................. 8W-42

Body Control Module................... 8W-45

Boost Pressure Sensor.................. 8W-30

Brake Fluid Level Switch............... 8W-35

Brake Lamp Switch................. 8W-30, 51

Brake Transmission Shift Interlock

Solenoid........................... 8W-31

Cabin Heater Assist................... 8W-30

Camshaft Position Sensor............... 8W-30

CD Changer......................... 8W-47

Center High Mounted Stop Lamp......... 8W-51

Cinch/Release Motors.................. 8W-61

Clockspring.............. 8W-30, 33, 41, 43, 47

Clutch Pedal Interlock Switch............ 8W-21

Clutch Pedal Upstop Switch............. 8W-30

Controller Antilock Brake............... 8W-35

Crank Case Ventilation Heater........... 8W-30

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switches................. 8W-39

Data Link Connector................... 8W-18

Defogger Relay....................... 8W-48

Door Ajar Switches.................... 8W-39

Door Courtesy Lamps.................. 8W-44

Door Lock Motor/Ajar Switches........... 8W-61

Door Lock Switches.................... 8W-61Component Page

Dosing Pump......................... 8W-30

DVD Screen.......................... 8W-47

DVD/CD Changer..................... 8W-47

ECM/PCM Relay...................... 8W-30

EGR Solenoid........................ 8W-30

Electronic Control Unit................. 8W-64

Engine Control Module................. 8W-30

Engine Coolant Temp Sensor............. 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Oil Pressure Switch.............. 8W-30

EVAP/Purge Solenoid.................. 8W-30

Evaporator Temperature Sensor.......... 8W-42

Floor Console Lamp................... 8W-44

Fog Lamps.......................... 8W-50

Folding Mirror Relay................... 8W-62

Front Blower Module.................. 8W-42

Front Cigar Lighter.................... 8W-41

Front Control Module.................. 8W-10

Front Fog Lamp Relay................. 8W-50

Front Intrusion Sensor................. 8W-39

Front Reading Lamps/Switch............ 8W-44

Front Wiper High/Low Relay............. 8W-53

Front Wiper On/Off Relay............... 8W-53

Fuel Heater.......................... 8W-30

Fuel Heater Relay..................... 8W-30

Fuel Injectors........................ 8W-30

Fuel Pressure Sensor.................. 8W-30

Fuel Pressure Solenoid................. 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Relay...................... 8W-30

Full Open Switches.................... 8W-61

Fuselink............................ 8W-10

Fuses............................... 8W-10

Generator........................... 8W-20

Glow Plug Relay...................... 8W-30

Glow Plugs.......................... 8W-30

Grounds............................ 8W-15

Hands Free Module................. 8W-47, 55

Headlamp Leveling Motors.............. 8W-50

Headlamp Switch..................... 8W-50

Headlamp Washer Pump Motor.......... 8W-53

Headlamp Washer Relay................ 8W-53

Headlamps.......................... 8W-50

Heated Seat Backs.................... 8W-63

Heated Seat Cushions.................. 8W-63

Heated Seat Modules.................. 8W-63

High Beam Lamps..................... 8W-50

High Note Horn....................... 8W-41

Hood Ajar Switch..................... 8W-39

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Idle Air Control Motor.................. 8W-30

RS8W-02 COMPONENT INDEX8W-02-1