check engine CHRYSLER CARAVAN 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 156 of 2339

(7) Connect the brake pedal link to the torque

shaft. Install a NEW retaining clip at the torque

shaft end of the brake pedal-to-torque shaft link.

(8) Install the HVAC housing. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION)

(9) Install the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION)

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(10) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)

(11) Road test vehicle to ensure proper operation of

the brakes.

POWER BRAKE BOOSTER

DESCRIPTION

The power brake booster mounts on the engine

compartment side of the dash panel. It is connected

to the brake pedal by the input (push) rod (Fig. 64).

The master cylinder is bolted to the front of the

booster. A vacuum line connects the power brake

booster to the intake manifold.

All Left-Hand-Drive (LHD) vehicles use a 270 mm

single diaphragm vacuum power brake booster. All

Right-Hand-Drive (RHD) vehicles use a 225/200 mm

tandem diaphragm vacuum power brake booster.

Vehicles equipped with Disc/Disc brakes use a dif-

ferent power brake booster than vehicles equipped

with Disc/Drum brakes. Differences between the two

are internal. Service is the same for all boosters.

The power brake booster can be identified by the

tag attached to the body of the booster (Fig. 65). This

tag contains the production part number, the date it

was built, and who the manufacturer of the power

brake booster is.

NOTE: The power brake booster assembly is not a

repairable component and must be replaced as a

complete assembly if found to be faulty in any way.

The check valve located on the power brake

booster face is not repairable, but it can be

replaced separately from the power brake booster.The different engine combinations used in this

vehicle require different vacuum hose routings to the

power brake booster. All vacuum hoses must be

routed from the engine to the power brake booster

without kinks or excessively tight bends.

Fig. 64 Power Brake Booster (Typical)

1 - VACUUM CHECK VALVE

2 - POWER BRAKE BOOSTER ASSEMBLY

3 - INPUT ROD

4 - POWER BOOSTER ASSEMBLY TO DASH PANEL MOUNTING

STUDS (4)

5 - MASTER CYLINDER MOUNTING STUDS (2)

6 - OUTPUT ROD

Fig. 65 MASTER CYLINDER AND BOOSTER

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

RSBRAKES - BASE5-45

PEDAL TORQUE SHAFT - RHD (Continued)

Page 157 of 2339

OPERATION

The power brake booster reduces the amount of

force required by the driver to obtain the necessary

hydraulic pressure to stop a vehicle.

The power brake booster is vacuum operated. The

vacuum is supplied from the intake manifold on the

engine through a vacuum hose and the power brake

booster check valve (Fig. 64).

As the brake pedal is depressed, the power brake

booster's input rod moves forward (Fig. 64). This

opens and closes valves in the power booster allowing

atmospheric pressure to enter on one side of a dia-

phragm. Engine vacuum is always present on the

other side. This difference in pressure forces the out-

put rod of the power brake booster out against the

primary piston of the master cylinder. As the pistons

in the master cylinder move forward this creates the

hydraulic pressure in the brake system.

DIAGNOSIS AND TESTING - POWER BRAKE

BOOSTER

BASIC TEST

(1) With engine off, depress and release the brake

pedal several times to purge all vacuum from the

power brake booster.

(2) Depress and hold the pedal with light effort (15

to 25 lbs. pressure), then start the engine.

The pedal should fall slightly, then hold. Less effort

should be needed to apply the pedal at this time. If

the pedal fell as indicated, perform the VACUUM

LEAK TEST listed after the BASIC TEST. If the

pedal did not fall, continue on with this BASIC

TEST.

(3) Disconnect the vacuum hose on the vacuum

check valve, then place a vacuum gauge in line

between the vacuum hose and the valve.

(4) Start the engine.

(5) When the engine is at warm operating temper-

ature, allow it to idle and check the vacuum at the

gauge.

If the vacuum supply is 12 inches Hg (40.5 kPa) or

more, the power brake booster is defective and must

be replaced. If the vacuum supply is below 12 inches

Hg, continue on with this BASIC TEST.

(6) Shut off the engine.

(7) Connect the vacuum gauge to the vacuum ref-

erence port on the engine intake manifold.

(8) Start the engine and observe the vacuum

gauge.

If the vacuum is still low, check the engine tune

and repair as necessary. If the vacuum is above 12

inches Hg, the hose or check valve to the booster has

a restriction or leak.

Once an adequate vacuum supply is obtained,

repeat the BASIC TEST.

VACUUM LEAK TEST

(1) Disconnect the vacuum hose on the vacuum

check valve, then place a vacuum gauge in line

between the vacuum hose and the valve.

(2) Start the engine.

(3) Allow the engine to warm up to normal operat-

ing temperature and engine idle.

(4) Using vacuum line pliers, close off the vacuum

supply hose near the booster, but before the vacuum

gauge, then observe the vacuum gauge.

If the vacuum drop exceeds 1.0 inch Hg (3.3 kPa)

in one minute, repeat the above steps to confirm the

reading. The vacuum loss should be less than 1.0

inch Hg in one minute time span. If the loss is more

than 1.0 inch Hg, replace the power brake booster. If

it is not, continue on with this test.

(5) Remove the pliers from the hose temporarily.

(6) Apply light effort (approximately 15 lbs. of

force) to the brake pedal and hold the pedal steady.

Do not move the pedal once the pressure is applied

or the test results may vary.

(7) Have an assistant reattach the vacuum line

pliers to the vacuum supply hose.

(8) Allow 5 seconds for stabilization, then observe

the vacuum gauge.

If the vacuum drop exceeds 3.0 inches Hg (10 kPa)

in 15 seconds, repeat the above steps to confirm the

reading. The vacuum loss should be less than 3.0

inches Hg in 15 seconds time span. If the loss is

more than 3.0 inches Hg, replace the power brake

booster. If it is not, the booster is not defective.

(9) Remove the pliers and vacuum gauge.

REMOVAL

REMOVAL - LHD

CAUTION: Reserve vacuum in power brake booster

must be pumped down (removed) before removing

master cylinder from booster. This is necessary to

prevent booster from sucking in any contamination

as master cylinder is removed. This can be done

simply by pumping the brake pedal, with the vehi-

cle's engine not running, until a firm feeling brake

pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes).

(2) Remove negative battery cable terminal from

battery.

(3) Remove positive battery cable terminal from

battery.

(4) Remove battery thermal guard shield.

(5) Remove battery clamp, nut and battery from

the battery tray.

5 - 46 BRAKES - BASERS

POWER BRAKE BOOSTER (Continued)

Page 158 of 2339

(6) Remove screw securing engine coolant filler

tube to battery tray.

(7) If the vehicle is equipped with speed control,

disconnect the vacuum hose at the vacuum tank built

into the battery tray.

(8) Remove the two nuts and one bolt securing bat-

tery tray in place. Remove battery tray.

(9) If vehicle is equipped with speed control:

(a) Disconnect wiring harness connector from

the speed control servo.

(b) Remove the two servo mounting nuts.

(c) Lay speed control servo off to the side, out of

the way.

(10) Remove the wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL)

(11) Disconnect wiring harness connector from

brake fluid level switch in master cylinder fluid res-

ervoir (Fig. 66).

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(12) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as MopartBrake Parts Cleaner or equivalent.(13) Disconnect primary and secondary brake

tubes from ABS integrated control unit or non-ABS

junction block (Fig. 67). Install sealing plugs in the

now open brake tube ports and install caps on ends

of tubes.

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the vacuum booster.

(14) Remove two nuts attaching master cylinder to

power brake booster (Fig. 67).

(15) Slide master cylinder straight out of power

brake booster. Remove master cylinder with primary

and secondary tubes from vehicle.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

(16) Disconnect vacuum hose from check valve

located on vacuum booster.DO NOT REMOVE

CHECK VALVE FROM POWER BRAKE

BOOSTER.

Fig. 66 Master Cylinder And Booster

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

Fig. 67 Master Cylinder Mounting

1 - MASTER CYLINDER MOUNTING NUTS

2 - MASTER CYLINDER

3 - SECONDARY TUBE NUT AT ICU

4 - PRIMARY TUBE NUT AT ICU

RSBRAKES - BASE5-47

POWER BRAKE BOOSTER (Continued)

Page 160 of 2339

(c) Lay speed control servo off to the side, out of

the way.

(9) If the vehicle is equipped with the 2.5L diesel

engine, remove the coolant recovery pressure con-

tainer and bracket. (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESS CONTAINER -

REMOVAL)

(10) Disconnect wiring harness connector from

brake fluid level switch in master cylinder fluid res-

ervoir (Fig. 71).

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(11) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as MopartBrake Parts Cleaner or equivalent.

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the booster.

(12) Remove two nuts attaching master cylinder to

power brake booster (Fig. 72).

(13) Slide master cylinder straight out of power

brake booster. Lay master cylinder with primary and

secondary tubes to the side, out of the way.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever themaster cylinder is removed from the power brake

vacuum booster.

(14) Disconnect vacuum hose from check valve

located on booster.DO NOT REMOVE CHECK

VALVE FROM POWER BRAKE BOOSTER.

(15) Under the instrument panel, remove booster

input rod trim cover.

(16) Locate the booster input rod to brake pedal

torque shaft connection under the instrument panel.

Position a small screwdriver between the center tang

on the retaining clip (Fig. 73).

Fig. 71 RHD Master Cylinder And Power Brake

Booster

1 - POWER BRAKE BOOSTER

2 - BRAKE FLUID LEVEL SWITCH

3 - FLUID RESERVOIR

4 - MASTER CYLINDER

Fig. 72 RHD Master Cylinder Mounting

1 - PRIMARY BRAKE TUBE NUT

2 - SECONDARY BRAKE TUBE NUT

3 - MASTER CYLINDER MOUNTING NUTS

Fig. 73 Booster Input Rod Pin Retaining Clip

(Typical)

1 - BRAKE PEDAL

2 - INPUT ROD

3 - SCREWDRIVER

4 - RETAINING CLIP

5 - BRAKE PEDAL PIN

RSBRAKES - BASE5-49

POWER BRAKE BOOSTER (Continued)

Page 162 of 2339

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(5) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)

(6) Install the silencer panel below the steering

column.

(7) Connect vacuum hose to check valve on power

brake booster.

CAUTION: The master cylinder (and its rear seal) is

used to create the seal for holding vacuum in the

vacuum booster. The vacuum seal on the master

cylinder MUST be replaced with a NEW seal when-

ever the master cylinder is removed from the vac-

uum booster.

CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(8) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(9) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 77).

(10) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston.(11) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 67). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

(12) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 66).

(13) Connect primary and secondary brake tubes

to ABS ICU or non-ABS junction block (Fig. 67).

Tighten the tube nuts to 17 N´m (145 in lbs.).

(14) Install wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION)

(15) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).

(16) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.).

(17) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray.

(18) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing. Securely tighten hose clamp at air cleaner hous-

ing and throttle body.

(19) Secure the engine coolant filler neck to the

battery tray with its mounting screw.

(20) Install the battery, clamp and mounting nut.

(21) Install the positive battery cable on the bat-

tery.

(22) Install the negative battery cable on the bat-

tery.

(23) Install the battery thermal guard shield.

(24) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE)

(25) Road test vehicle to ensure operation of the

brakes.

INSTALLATION - RHD

(1) Position power brake booster on dash panel

using the reverse procedure of its removal (Fig. 75).

(2) Below instrument panel, first install the two

upper nuts mounting the booster to the dash panel,

drawing it into place, then install the two lower

mounting nuts. Tighten the mounting nuts to a

torque of 29 N´m (250 in. lbs.).

(3) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod.

CAUTION: When installing the brake pedal torque

shaft pin on the power brake booster input rod, do

not re-use the old retaining clip.

Fig. 77 Vacuum Seal (Typical)

1 - MASTER CYLINDER ASSEMBLY

2 - VACUUM SEAL

RSBRAKES - BASE5-51

POWER BRAKE BOOSTER (Continued)

Page 163 of 2339

(4) Install booster input rod on brake pedal torque

shaft pin and install a NEW retaining clip (Fig. 78).

(5) Install booster input rod trim cover.

(6) Connect vacuum hose to check valve on power

brake booster.

CAUTION: The master cylinder (and its rear seal) is

used to create the seal for holding vacuum in the

vacuum booster. The vacuum seal on the master

cylinder MUST be replaced with a NEW seal when-

ever the master cylinder is removed from the vac-

uum booster.

CAUTION: When removing the vacuum seal from

the master cylinder, do not use a sharp tool.

(7) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(8) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 79).

(9) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston.

(10) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 72). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

(11) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 71).

(12) If the vehicle is equipped with the 2.5L diesel

engine, install the coolant recovery pressure con-

tainer and bracket. (Refer to 7 - COOLING/ENGINE/COOLANT RECOVERY PRESS CONTAINER -

INSTALLATION)

(13) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).

(14) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.).

(15) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray.

(16) Install the battery, clamp and mounting nut.

(17) Install the positive battery cable on the bat-

tery.

(18) Install the negative battery cable on the bat-

tery.

(19) Install the battery thermal guard shield.

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(20) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)

(21) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE)

(22) Road test vehicle to ensure proper operation

of the brakes.

Fig. 78 Retaining Pin Installed On Brake Pedal Pin

(Typical)

1 - BRAKE PEDAL

2 - RETAINING CLIP

3 - BOOSTER INPUT ROD

Fig. 79 Vacuum Seal (Typical)

1 - MASTER CYLINDER ASSEMBLY

2 - VACUUM SEAL

5 - 52 BRAKES - BASERS

POWER BRAKE BOOSTER (Continued)

Page 220 of 2339

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM........1

DESCRIPTION - HOSE CLAMPS...........1

OPERATION

OPERATION - COOLING SYSTEM.........2

OPERATION - HOSE CLAMPS............2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAK TEST....................2

DIAGNOSIS AND TESTING - COOLING

SYSTEM FLOW CHECK.................3

DIAGNOSIS AND TESTING - COOLING

SYSTEM AERATION....................4

DIAGNOSIS AND TESTING - COOLING

SYSTEM DEAERATION..................4

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLING

SYSTEM DRAINING....................4STANDARD PROCEDURE - COOLING

SYSTEM FILLING......................4

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................4

STANDARD PROCEDURE - COOLANT

LEVEL CHECK........................4

SPECIFICATIONS

ACCESSORY DRIVE BELT TENSION.......5

TORQUE.............................5

SPECIAL TOOLS

COOLING SYSTEM.....................6

ACCESSORY DRIVE.......................7

ENGINE...............................13

TRANSMISSION.........................38

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

The cooling system components consist of a radia-

tor, electric fan motors, shroud, pressure cap, thermo-

stat, transmission oil cooler, water pump, hoses,

clamps, coolant, and a coolant reserve system to com-

plete the circuit.

DESCRIPTION - HOSE CLAMPS

The cooling system uses spring type hose clamps.

If a spring type clamp replacement is necessary,

replace with the original Mopartequipment spring

type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 1).

Fig. 1 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

RSCOOLING7-1

Page 222 of 2339

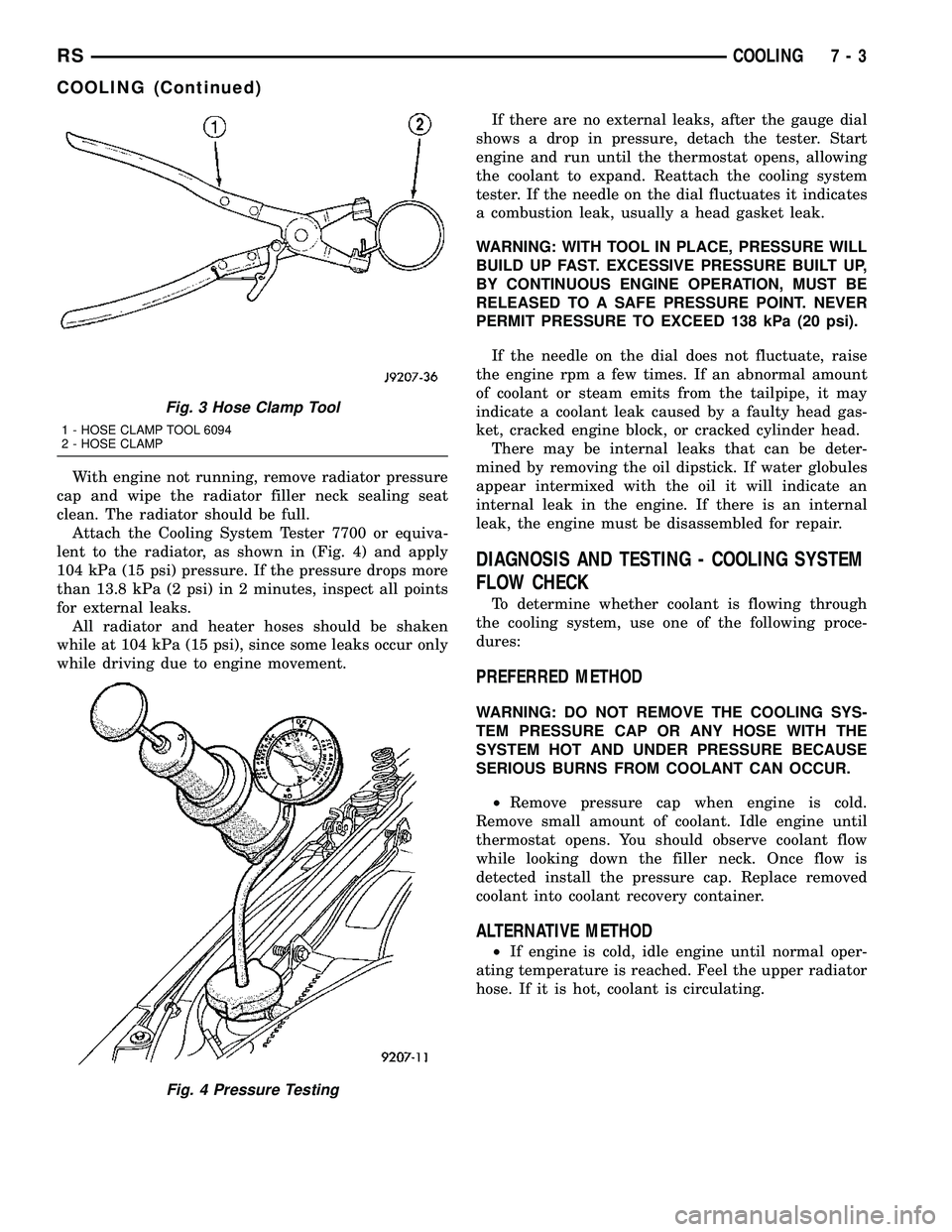

With engine not running, remove radiator pressure

cap and wipe the radiator filler neck sealing seat

clean. The radiator should be full.

Attach the Cooling System Tester 7700 or equiva-

lent to the radiator, as shown in (Fig. 4) and apply

104 kPa (15 psi) pressure. If the pressure drops more

than 13.8 kPa (2 psi) in 2 minutes, inspect all points

for external leaks.

All radiator and heater hoses should be shaken

while at 104 kPa (15 psi), since some leaks occur only

while driving due to engine movement.If there are no external leaks, after the gauge dial

shows a drop in pressure, detach the tester. Start

engine and run until the thermostat opens, allowing

the coolant to expand. Reattach the cooling system

tester. If the needle on the dial fluctuates it indicates

a combustion leak, usually a head gasket leak.

WARNING: WITH TOOL IN PLACE, PRESSURE WILL

BUILD UP FAST. EXCESSIVE PRESSURE BUILT UP,

BY CONTINUOUS ENGINE OPERATION, MUST BE

RELEASED TO A SAFE PRESSURE POINT. NEVER

PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, raise

the engine rpm a few times. If an abnormal amount

of coolant or steam emits from the tailpipe, it may

indicate a coolant leak caused by a faulty head gas-

ket, cracked engine block, or cracked cylinder head.

There may be internal leaks that can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil it will indicate an

internal leak in the engine. If there is an internal

leak, the engine must be disassembled for repair.

DIAGNOSIS AND TESTING - COOLING SYSTEM

FLOW CHECK

To determine whether coolant is flowing through

the cooling system, use one of the following proce-

dures:

PREFERRED METHOD

WARNING: DO NOT REMOVE THE COOLING SYS-

TEM PRESSURE CAP OR ANY HOSE WITH THE

SYSTEM HOT AND UNDER PRESSURE BECAUSE

SERIOUS BURNS FROM COOLANT CAN OCCUR.

²Remove pressure cap when engine is cold.

Remove small amount of coolant. Idle engine until

thermostat opens. You should observe coolant flow

while looking down the filler neck. Once flow is

detected install the pressure cap. Replace removed

coolant into coolant recovery container.

ALTERNATIVE METHOD

²If engine is cold, idle engine until normal oper-

ating temperature is reached. Feel the upper radiator

hose. If it is hot, coolant is circulating.

Fig. 3 Hose Clamp Tool

1 - HOSE CLAMP TOOL 6094

2 - HOSE CLAMP

Fig. 4 Pressure Testing

RSCOOLING7-3

COOLING (Continued)

Page 223 of 2339

DIAGNOSIS AND TESTING - COOLING SYSTEM

AERATION

Low coolant level in a cross flow radiator will

equalize in both tanks with engine off. With engine

at running and at operating temperature, the high

pressure inlet tank runs full and the low pressure

outlet tank drops, resulting in cooling system aera-

tion. Aeration will draw air into the water pump

resulting in the following:

²High reading shown on the temperature gauge.

²Loss of coolant flow through the heater core.

²Corrosion in the cooling system.

²Water pump seal may run dry, increasing the

risk of premature seal failure.

²Combustion gas leaks into the coolant can also

cause the above problems.

DIAGNOSIS AND TESTING - COOLING SYSTEM

DEAERATION

Air can only be removed from the system by gath-

ering under the pressure cap. On the next heat up it

will be pushed past the pressure cap into the coolant

recovery bottle by thermal expansion of the coolant.

It then escapes to the atmosphere in the coolant

recovery bottle and is replaced with coolant on cool

down.

To effectively deaerate the system, multiple ther-

mal cycles of the system may be required.

NOTE: Deaeration does not occur at engine idleÐ

higher engine speeds are required. Normal driving

will deaerate cooling system.

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLING SYSTEM

DRAINING

WARNING: DO NOT REMOVE OR LOOSEN THE

COOLANT PRESSURE CAP, CYLINDER BLOCK

DRAIN PLUGS, OR THE DRAINCOCK WHEN THE

SYSTEM IS HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

(1)Without removing radiator pressure cap

and with system not under pressure, using a

screwdriver, open the draincock. The draincock is

located on the lower left side of radiator.

(2) After the coolant recovery/reserve container is

empty, then remove coolant pressure cap (Fig. 5).

(3) Remove the cylinder block drain plug(s).

STANDARD PROCEDURE - COOLING SYSTEM

FILLING

Remove radiator pressure cap (Fig. 5) and fill sys-

tem, using a 50/50 mix of MopartAntifreeze/Coolant,

5 Year/100,000 Mile Formula and distilled water.

Continue filling system until full.Be careful not

to spill coolant on drive belts or the generator.

For cooling system capacity, (Refer to LUBRICATION

& MAINTENANCE/FLUID CAPACITIES - SPECIFI-

CATIONS).

Fill coolant recovery/reserve container (Fig. 5) to at

least the MAX mark with 50/50 solution. It may be

necessary to add coolant to the recovery/reserve con-

tainer after three or four warm up/cool down cycles

to maintain coolant level between the MAX and MIN

mark. This will allow trapped air to be removed from

the system.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The radiator cap should not be removed.

When additional coolant is needed to maintain this

level, it should be added to the coolant recovery/re-

serve container (Fig. 5). Use only 50/50 mix of ethyl-

ene glycol type antifreeze and distilled water. For the

recommeded antifreeze/coolant type (Refer to LUBRI-

CATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended. For the

recommeded antifreeze/coolant type (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

STANDARD PROCEDURE - COOLANT LEVEL

CHECK

NOTE: Do not remove radiator cap for routine cool-

ant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the radiator cap.With the engine cold

and not running,simply observe the level of the

coolant in the recovery/reserve container (Fig. 5). The

coolant level should be between the MIN and MAX

marks.

7 - 4 COOLINGRS

COOLING (Continued)

Page 226 of 2339

ACCESSORY DRIVE

TABLE OF CONTENTS

page page

DRIVE BELTS

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT..........................7

CLEANING.............................8

INSPECTION...........................8

DRIVE BELTS - 2.4L

STANDARD PROCEDURE - CHECKING

POWER STEERING BELT TENSION........8

REMOVAL.............................9

INSTALLATION..........................9ADJUSTMENTS........................10

BELT TENSIONER - 2.4L

REMOVAL.............................11

INSTALLATION.........................11

DRIVE BELTS - 3.3/3.8L

REMOVAL.............................11

INSTALLATION.........................12

BELT TENSIONER - 3.3/3.8L

REMOVAL.............................12

INSTALLATION.........................12

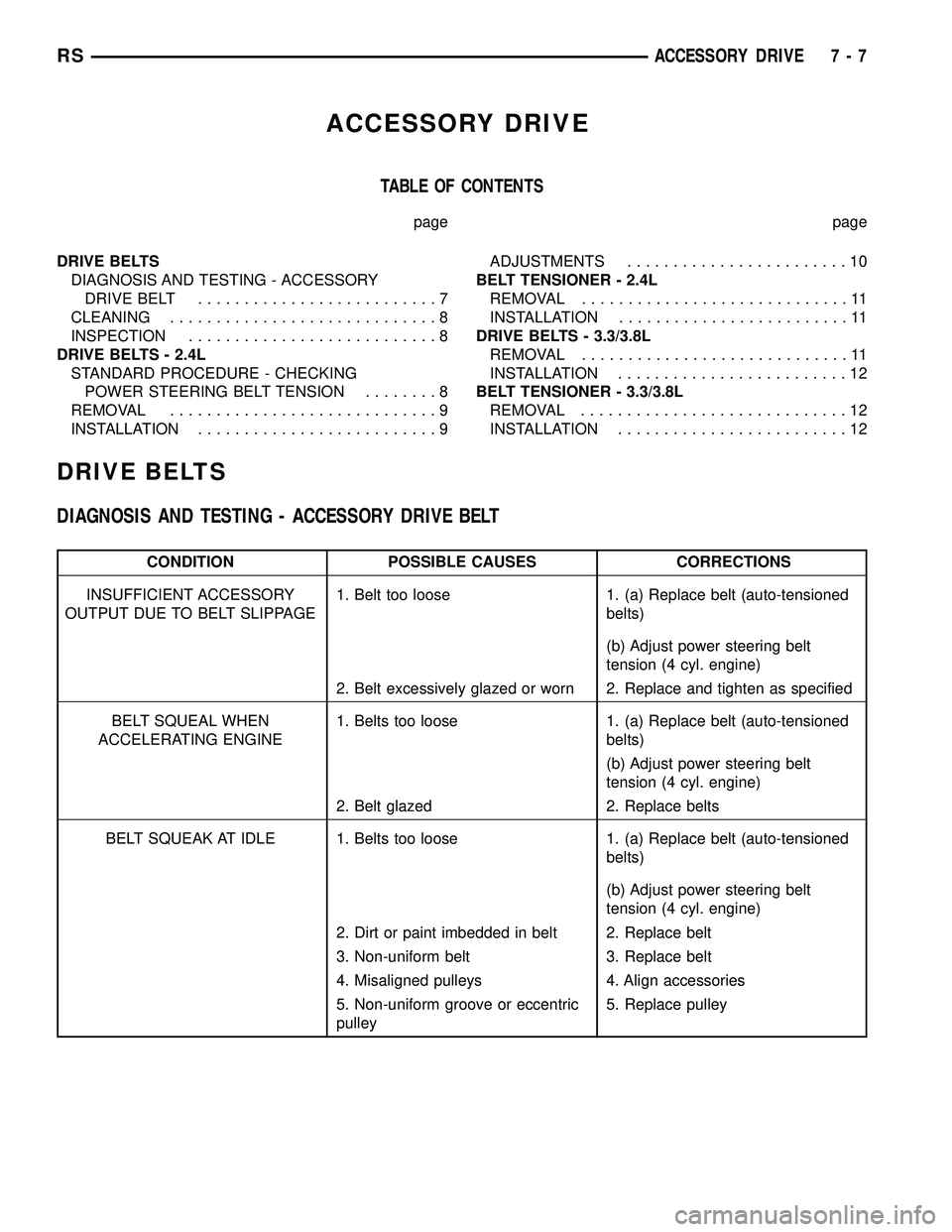

DRIVE BELTS

DIAGNOSIS AND TESTING - ACCESSORY DRIVE BELT

CONDITION POSSIBLE CAUSES CORRECTIONS

INSUFFICIENT ACCESSORY

OUTPUT DUE TO BELT SLIPPAGE1. Belt too loose 1. (a) Replace belt (auto-tensioned

belts)

(b) Adjust power steering belt

tension (4 cyl. engine)

2. Belt excessively glazed or worn 2. Replace and tighten as specified

BELT SQUEAL WHEN

ACCELERATING ENGINE1. Belts too loose 1. (a) Replace belt (auto-tensioned

belts)

(b) Adjust power steering belt

tension (4 cyl. engine)

2. Belt glazed 2. Replace belts

BELT SQUEAK AT IDLE 1. Belts too loose 1. (a) Replace belt (auto-tensioned

belts)

(b) Adjust power steering belt

tension (4 cyl. engine)

2. Dirt or paint imbedded in belt 2. Replace belt

3. Non-uniform belt 3. Replace belt

4. Misaligned pulleys 4. Align accessories

5. Non-uniform groove or eccentric

pulley5. Replace pulley

RSACCESSORY DRIVE7-7