radiator CHRYSLER CARAVAN 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1089 of 2339

RADIATOR FAN NO. 1 (DIESEL) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 N201 12DB/LG RADIATOR FAN RELAY NO. 1 OUTPUT

2 N202 12DB/OR RADIATOR FAN NO. 1 CONTROL

RADIATOR FAN NO. 1 (GAS) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 N23 12DB/DG RADIATOR FAN RELAY OUTPUT

2 Z223 12BK/DG GROUND

RADIATOR FAN NO. 2 (DIESEL) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 N112 12DB/OR RADIATOR FAN RELAY NO. 2 AND NO. 3 COMMON

OUTPUT

2 Z823 12BK/DG GROUND

RADIATOR FAN NO. 2 (GAS) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 N23 12DB/DG RADIATOR FAN RELAY OUTPUT

2 Z223 12BK/DG GROUND

8W - 80 - 120 8W-80 CONNECTOR PIN-OUTSRS

Page 1090 of 2339

RADIATOR FAN RELAY (GAS)-4WAY

CAV CIRCUIT FUNCTION

1 A112 12OR/RD FUSED B(+)

2 N23 12DB/DG RADIATOR FAN RELAY OUTPUT

3 Z723 18BK/DG GROUND

4 N173 18DB/VT RAD FAN RELAY CONTROL

RADIATOR FAN RELAY NO. 1 (DIESEL) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2 N201 12DB/LG RADIATOR FAN RELAY NO. 1 OUTPUT

3- -

4 K342 16BR/WT ECM/PCM RELAY OUTPUT

5- -

6 N210 18DB/DG LOW SPEED RADIATOR FAN RELAY CONTROL

7- -

8 A201 12RD/LG FUSED B(+)

9- -

RADIATOR FAN RELAY NO. 2 (DIESEL) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2 N112 12DB/OR RADIATOR FAN RELAY NO. 2 AND NO. 3 COMMON

OUTPUT

3- -

4 K342 16BR/WT ECM/PCM RELAY OUTPUT

5- -

6 N122 18DB/YL HIGH SPEED RADIATOR FAN DUAL RELAY CONTROL

7- -

8 A112 12OR/RD FUSED B(+)

9- -

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 121

Page 1091 of 2339

RADIATOR FAN RELAY NO. 3 (DIESEL) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2 Z823 12BK/DG GROUND

3- -

4 K342 16BR/WT ECM/PCM RELAY OUTPUT

5 N112 12DB/OR RADIATOR FAN RELAY NO. 2 AND NO. 3 COMMON

OUTPUT

6 N122 18DB/YL HIGH SPEED RADIATOR FAN DUAL RELAY CONTROL

7- -

8 N202 12DB/OR RADIATOR FAN NO. 1 CONTROL

9- -

RADIO C1 - 22 WAY

CAV CIRCUIT FUNCTION

1 A114 16GY/RD FUSED B(+) (I.O.D.)

2 F306 18DB/PK FUSED ACCESSORY RELAY OUTPUT

3 E14 20OR/TN PANEL LAMPS DRIVER

4- -

5- -

6- -

7 X54 20GY (LOWLINE) RIGHT FRONT SPEAKER (+)

8 X56 20GY/BR (LOWLINE) RIGHT FRONT SPEAKER (-)

9 X55 20DG/BR (LOWLINE) LEFT FRONT SPEAKER (-)

10 X53 20DG (LOWLINE) LEFT FRONT SPEAKER (+)

11 Z514 16BK/LG GROUND

12 A114 16GY/RD FUSED B(+) (I.O.D.)

13 X60 20GY/YL (EXPORT) RADIO 12 VOLT OUTPUT

14 D25 20WT/VT PCI BUS

15 - -

16 - -

17 - -

18 X51 22DG/DB LEFT REAR SPEAKER (+)

19 X57 22DG/OR LEFT REAR SPEAKER (-)

20 X58 22GY/OR RIGHT REAR SPEAKER (-)

21 X52 22GY/DB RIGHT REAR SPEAKER (+)

22 Z515 16BK GROUND

8W - 80 - 122 8W-80 CONNECTOR PIN-OUTSRS

Page 1114 of 2339

8W-91 CONNECTOR/GROUND/SPLICE LOCATION

TABLE OF CONTENTS

page

CONNECTOR/GROUND/SPLICE LOCATION

DESCRIPTION..........................1

CONNECTOR/GROUND/SPLICE

LOCATION

DESCRIPTION

This section provides illustrations identifying con-

nector, ground, and splice locations in the vehicle.Connector, ground, and splice indexes are provided.

Use the wiring diagrams in each section for connec-

tor, ground, and splice identification. Refer to the

appropriate index for the proper figure number. For

items that are not shown in this section N/S is placed

in the Fig. column.

CONNECTORS

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

A/C Compressor Clutch LTGY Top of A/C Compressor 10, 11, 15, 17, 18

A/C Pressure Sensor GY At Throttle Body 9, 10, 15, 16, 17

A/C-Heater Control C1 (MTC) BK/RD Rear of Control 20, 23, 25

A/C-Heater Control C2 (MTC) BK/BL Rear of Control 20, 23, 25

Accelerator Pedal Position

Sensor (Diesel)At Accelerator Pedal 42

Adjustable Pedals Module

(Except Export)Near Brake Lamp Switch N/S

Adjustable Pedals Motor On Pedal Support N/S

Adjustable Pedals Relay (Except

Export)Left Side Engine Compartment 6

Adjustable Pedals Sensor On Adjustable Pedals Motor N/S

Adjustable Pedals Switch (Except

Export)Left Side Kick Panel 41

Ambient Temperature Sensor

(Except Base)BK On Radiator Closure Panel 1

Amplifier C1 NAT Right Quarter Panel 48

Amplifier C2 NAT Right Quarter Panel 48

ATC Remote Sensor Above ATC Control N/S

Auto Temp Control C1 NAT Rear of Control 20

Auto Temp Control C2 BK Rear of Control 20

Auto Temp Control C3 (MTX) Rear of Control N/S

Back-Up Lamp Switch BK On Transmission 16

Battery Temperature Sensor BK At Battery N/S

Blower Motor Resistor C1 (MTC) BK Right Side of HVAC N/S

Blower Motor Resistor C2 (MTC) BK Right Side of HVAC N/S

Body Control Module C1 BK Under Left Instrument Panel 41, 42

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-1

Page 1122 of 2339

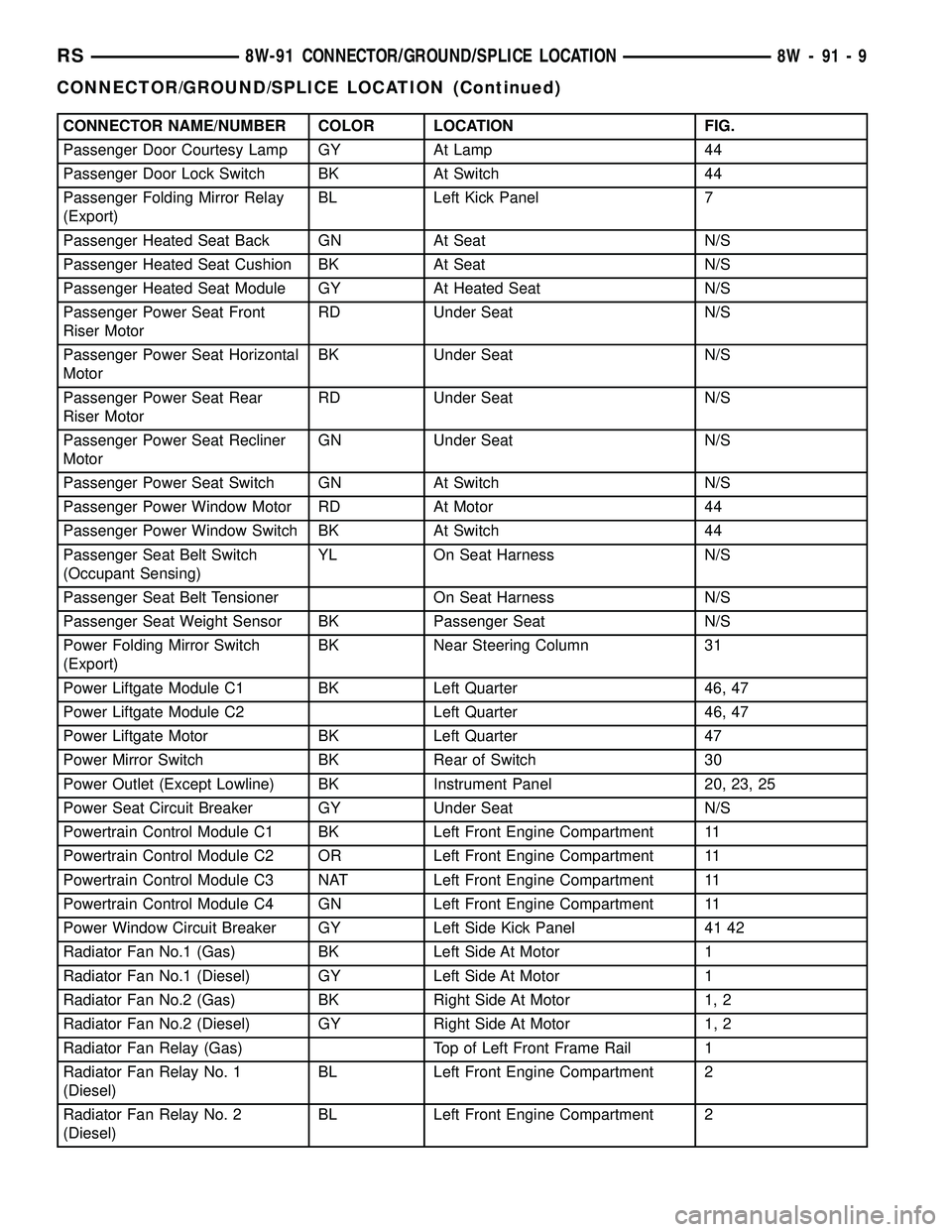

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Passenger Door Courtesy Lamp GY At Lamp 44

Passenger Door Lock Switch BK At Switch 44

Passenger Folding Mirror Relay

(Export)BL Left Kick Panel 7

Passenger Heated Seat Back GN At Seat N/S

Passenger Heated Seat Cushion BK At Seat N/S

Passenger Heated Seat Module GY At Heated Seat N/S

Passenger Power Seat Front

Riser MotorRD Under Seat N/S

Passenger Power Seat Horizontal

MotorBK Under Seat N/S

Passenger Power Seat Rear

Riser MotorRD Under Seat N/S

Passenger Power Seat Recliner

MotorGN Under Seat N/S

Passenger Power Seat Switch GN At Switch N/S

Passenger Power Window Motor RD At Motor 44

Passenger Power Window Switch BK At Switch 44

Passenger Seat Belt Switch

(Occupant Sensing)YL On Seat Harness N/S

Passenger Seat Belt Tensioner On Seat Harness N/S

Passenger Seat Weight Sensor BK Passenger Seat N/S

Power Folding Mirror Switch

(Export)BK Near Steering Column 31

Power Liftgate Module C1 BK Left Quarter 46, 47

Power Liftgate Module C2 Left Quarter 46, 47

Power Liftgate Motor BK Left Quarter 47

Power Mirror Switch BK Rear of Switch 30

Power Outlet (Except Lowline) BK Instrument Panel 20, 23, 25

Power Seat Circuit Breaker GY Under Seat N/S

Powertrain Control Module C1 BK Left Front Engine Compartment 11

Powertrain Control Module C2 OR Left Front Engine Compartment 11

Powertrain Control Module C3 NAT Left Front Engine Compartment 11

Powertrain Control Module C4 GN Left Front Engine Compartment 11

Power Window Circuit Breaker GY Left Side Kick Panel 41 42

Radiator Fan No.1 (Gas) BK Left Side At Motor 1

Radiator Fan No.1 (Diesel) GY Left Side At Motor 1

Radiator Fan No.2 (Gas) BK Right Side At Motor 1, 2

Radiator Fan No.2 (Diesel) GY Right Side At Motor 1, 2

Radiator Fan Relay (Gas) Top of Left Front Frame Rail 1

Radiator Fan Relay No. 1

(Diesel)BL Left Front Engine Compartment 2

Radiator Fan Relay No. 2

(Diesel)BL Left Front Engine Compartment 2

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-9

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1123 of 2339

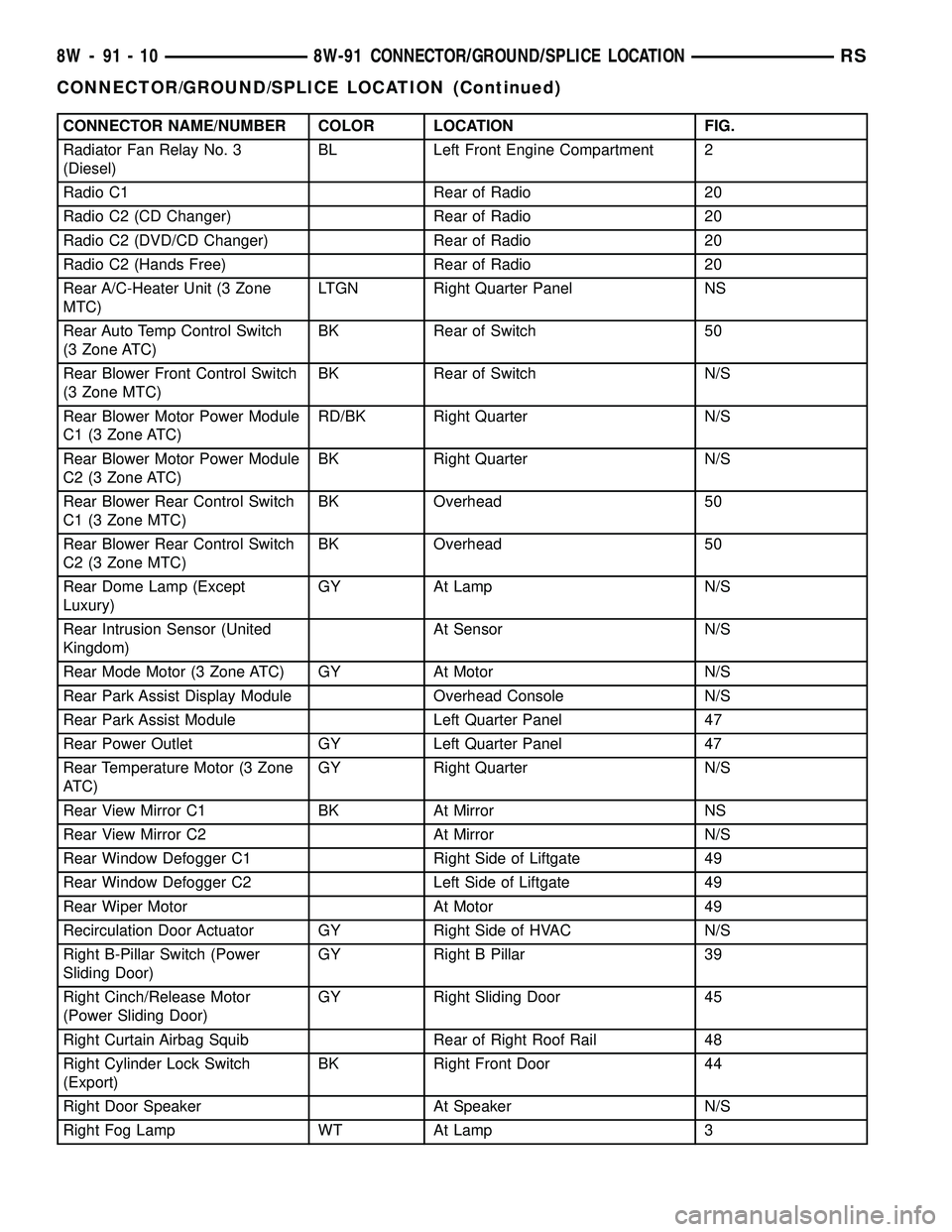

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Radiator Fan Relay No. 3

(Diesel)BL Left Front Engine Compartment 2

Radio C1 Rear of Radio 20

Radio C2 (CD Changer) Rear of Radio 20

Radio C2 (DVD/CD Changer) Rear of Radio 20

Radio C2 (Hands Free) Rear of Radio 20

Rear A/C-Heater Unit (3 Zone

MTC)LTGN Right Quarter Panel NS

Rear Auto Temp Control Switch

(3 Zone ATC)BK Rear of Switch 50

Rear Blower Front Control Switch

(3 Zone MTC)BK Rear of Switch N/S

Rear Blower Motor Power Module

C1 (3 Zone ATC)RD/BK Right Quarter N/S

Rear Blower Motor Power Module

C2 (3 Zone ATC)BK Right Quarter N/S

Rear Blower Rear Control Switch

C1 (3 Zone MTC)BK Overhead 50

Rear Blower Rear Control Switch

C2 (3 Zone MTC)BK Overhead 50

Rear Dome Lamp (Except

Luxury)GY At Lamp N/S

Rear Intrusion Sensor (United

Kingdom)At Sensor N/S

Rear Mode Motor (3 Zone ATC) GY At Motor N/S

Rear Park Assist Display Module Overhead Console N/S

Rear Park Assist Module Left Quarter Panel 47

Rear Power Outlet GY Left Quarter Panel 47

Rear Temperature Motor (3 Zone

ATC)GY Right Quarter N/S

Rear View Mirror C1 BK At Mirror NS

Rear View Mirror C2 At Mirror N/S

Rear Window Defogger C1 Right Side of Liftgate 49

Rear Window Defogger C2 Left Side of Liftgate 49

Rear Wiper Motor At Motor 49

Recirculation Door Actuator GY Right Side of HVAC N/S

Right B-Pillar Switch (Power

Sliding Door)GY Right B Pillar 39

Right Cinch/Release Motor

(Power Sliding Door)GY Right Sliding Door 45

Right Curtain Airbag Squib Rear of Right Roof Rail 48

Right Cylinder Lock Switch

(Export)BK Right Front Door 44

Right Door Speaker At Speaker N/S

Right Fog Lamp WT At Lamp 3

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1126 of 2339

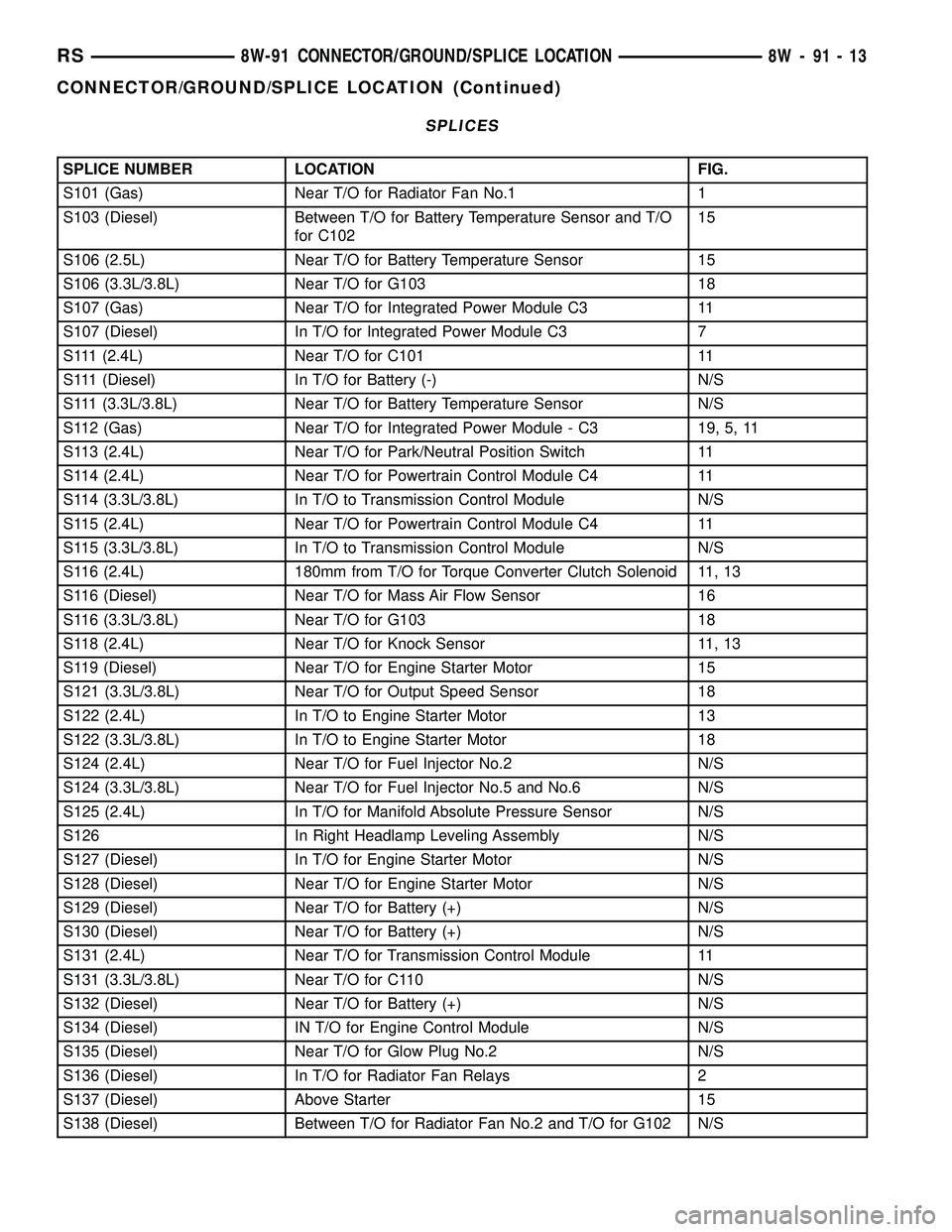

SPLICES

SPLICE NUMBER LOCATION FIG.

S101 (Gas) Near T/O for Radiator Fan No.1 1

S103 (Diesel) Between T/O for Battery Temperature Sensor and T/O

for C10215

S106 (2.5L) Near T/O for Battery Temperature Sensor 15

S106 (3.3L/3.8L) Near T/O for G103 18

S107 (Gas) Near T/O for Integrated Power Module C3 11

S107 (Diesel) In T/O for Integrated Power Module C3 7

S111 (2.4L) Near T/O for C101 11

S111 (Diesel) In T/O for Battery (-) N/S

S111 (3.3L/3.8L) Near T/O for Battery Temperature Sensor N/S

S112 (Gas) Near T/O for Integrated Power Module - C3 19, 5, 11

S113 (2.4L) Near T/O for Park/Neutral Position Switch 11

S114 (2.4L) Near T/O for Powertrain Control Module C4 11

S114 (3.3L/3.8L) In T/O to Transmission Control Module N/S

S115 (2.4L) Near T/O for Powertrain Control Module C4 11

S115 (3.3L/3.8L) In T/O to Transmission Control Module N/S

S116 (2.4L) 180mm from T/O for Torque Converter Clutch Solenoid 11, 13

S116 (Diesel) Near T/O for Mass Air Flow Sensor 16

S116 (3.3L/3.8L) Near T/O for G103 18

S118 (2.4L) Near T/O for Knock Sensor 11, 13

S119 (Diesel) Near T/O for Engine Starter Motor 15

S121 (3.3L/3.8L) Near T/O for Output Speed Sensor 18

S122 (2.4L) In T/O to Engine Starter Motor 13

S122 (3.3L/3.8L) In T/O to Engine Starter Motor 18

S124 (2.4L) Near T/O for Fuel Injector No.2 N/S

S124 (3.3L/3.8L) Near T/O for Fuel Injector No.5 and No.6 N/S

S125 (2.4L) In T/O for Manifold Absolute Pressure Sensor N/S

S126 In Right Headlamp Leveling Assembly N/S

S127 (Diesel) In T/O for Engine Starter Motor N/S

S128 (Diesel) Near T/O for Engine Starter Motor N/S

S129 (Diesel) Near T/O for Battery (+) N/S

S130 (Diesel) Near T/O for Battery (+) N/S

S131 (2.4L) Near T/O for Transmission Control Module 11

S131 (3.3L/3.8L) Near T/O for C110 N/S

S132 (Diesel) Near T/O for Battery (+) N/S

S134 (Diesel) IN T/O for Engine Control Module N/S

S135 (Diesel) Near T/O for Glow Plug No.2 N/S

S136 (Diesel) In T/O for Radiator Fan Relays 2

S137 (Diesel) Above Starter 15

S138 (Diesel) Between T/O for Radiator Fan No.2 and T/O for G102 N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-13

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1127 of 2339

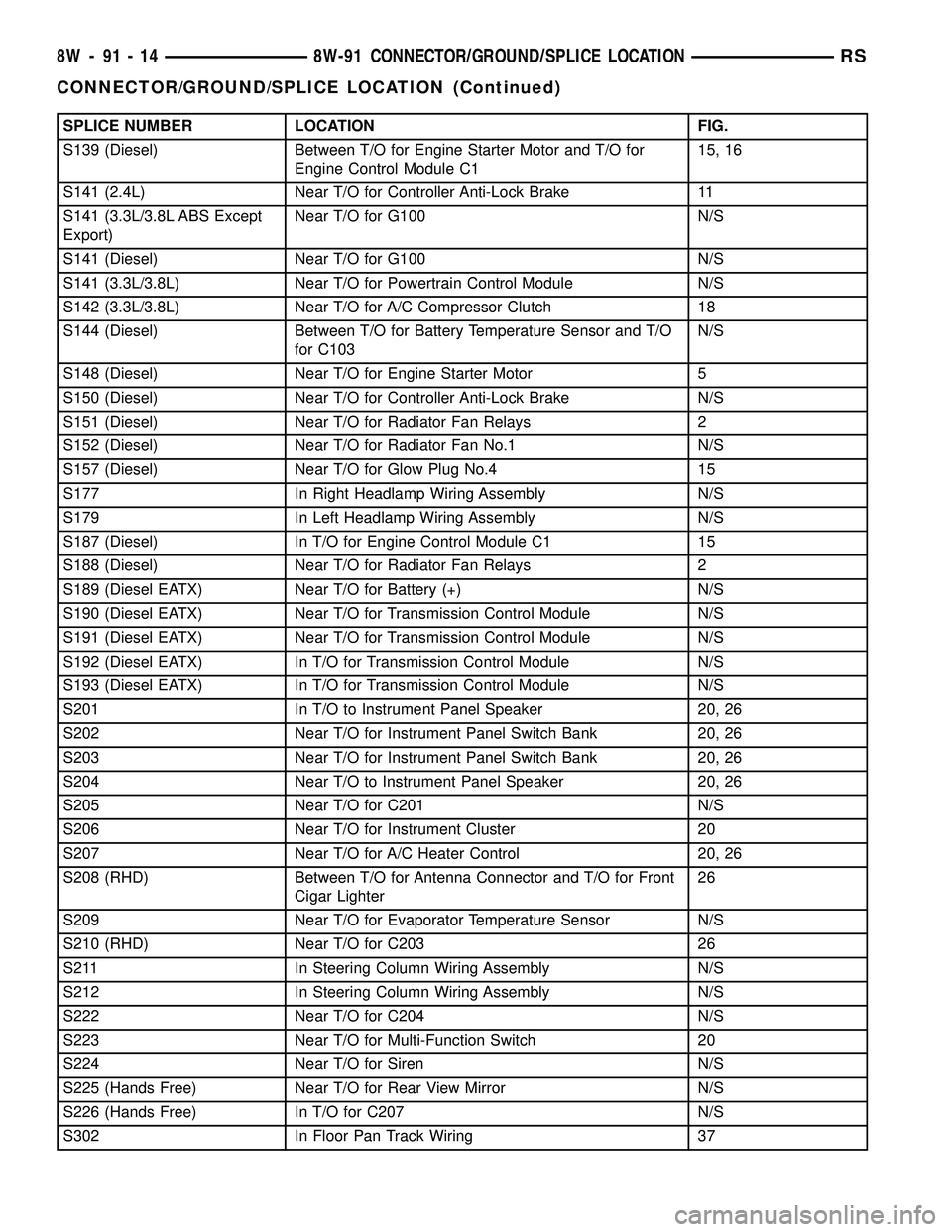

SPLICE NUMBER LOCATION FIG.

S139 (Diesel) Between T/O for Engine Starter Motor and T/O for

Engine Control Module C115, 16

S141 (2.4L) Near T/O for Controller Anti-Lock Brake 11

S141 (3.3L/3.8L ABS Except

Export)Near T/O for G100 N/S

S141 (Diesel) Near T/O for G100 N/S

S141 (3.3L/3.8L) Near T/O for Powertrain Control Module N/S

S142 (3.3L/3.8L) Near T/O for A/C Compressor Clutch 18

S144 (Diesel) Between T/O for Battery Temperature Sensor and T/O

for C103N/S

S148 (Diesel) Near T/O for Engine Starter Motor 5

S150 (Diesel) Near T/O for Controller Anti-Lock Brake N/S

S151 (Diesel) Near T/O for Radiator Fan Relays 2

S152 (Diesel) Near T/O for Radiator Fan No.1 N/S

S157 (Diesel) Near T/O for Glow Plug No.4 15

S177 In Right Headlamp Wiring Assembly N/S

S179 In Left Headlamp Wiring Assembly N/S

S187 (Diesel) In T/O for Engine Control Module C1 15

S188 (Diesel) Near T/O for Radiator Fan Relays 2

S189 (Diesel EATX) Near T/O for Battery (+) N/S

S190 (Diesel EATX) Near T/O for Transmission Control Module N/S

S191 (Diesel EATX) Near T/O for Transmission Control Module N/S

S192 (Diesel EATX) In T/O for Transmission Control Module N/S

S193 (Diesel EATX) In T/O for Transmission Control Module N/S

S201 In T/O to Instrument Panel Speaker 20, 26

S202 Near T/O for Instrument Panel Switch Bank 20, 26

S203 Near T/O for Instrument Panel Switch Bank 20, 26

S204 Near T/O to Instrument Panel Speaker 20, 26

S205 Near T/O for C201 N/S

S206 Near T/O for Instrument Cluster 20

S207 Near T/O for A/C Heater Control 20, 26

S208 (RHD) Between T/O for Antenna Connector and T/O for Front

Cigar Lighter26

S209 Near T/O for Evaporator Temperature Sensor N/S

S210 (RHD) Near T/O for C203 26

S211 In Steering Column Wiring Assembly N/S

S212 In Steering Column Wiring Assembly N/S

S222 Near T/O for C204 N/S

S223 Near T/O for Multi-Function Switch 20

S224 Near T/O for Siren N/S

S225 (Hands Free) Near T/O for Rear View Mirror N/S

S226 (Hands Free) In T/O for C207 N/S

S302 In Floor Pan Track Wiring 37

8W - 91 - 14 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1189 of 2339

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 3)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING PLASTIGAGE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 4). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap/bed plate bolts of the

bearing being checked to the proper specifications.

(3) Remove the bearing cap and compare the

width of the flattened Plastigage with the metric

scale provided on the package. Locate the band clos-

est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Compare the clearance measurements to specsifica-

tions found in the engine specifications table(Refer to9 - ENGINE - SPECIFICATIONS).Plastigage gen-

erally is accompanied by two scales. One scale

is in inches, the other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances.

REMOVAL - ENGINE ASSEMBLY

(1) Perform fuel pressure release procedure (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE)

(2) Disconnect battery negative cable.

(3) Remove air cleaner housing and inlet tube.

(4) Disconnect the fuel line from fuel rail. (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- STANDARD PROCEDURE)

(5) Disconnect all vacuum hoses.

(6) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(7) Remove radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL)

(8) Remove radiator upper and lower hoses.

NOTE: When the transaxle cooler lines are removed

from the rolled-groove type fittings at the transaxle,

damage to the inner wall of the hose will occur. To

prevent prevent potential leakage, the cooler hoses

must be cut off flush at the transaxle fitting, and a

service cooler hose splice kit must be installed

upon reassembly.

Fig. 3 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

Fig. 4 Plastigage Placed in Lower ShellÐTypical

1 - PLASTIGAGE

9 - 12 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1193 of 2339

(24) Connect all vacuum lines.

(25) Connect the throttle cables.

(26) Connect the fuel line. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(27) Connect radiator lower and upper hoses.

(28) Install radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION)

(29) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(30) Connect battery cables.

(31) Install air cleaner and inlet hose.

(32) Fill engine crankcase with proper oil to cor-

rect level.

(33) Start engine and run until operating temper-

ature is reached.

(34) Adjust transmission linkage, if necessary.

SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Type In-Line OHV, DOHC

Number of

Cylinders4

Firing Order 1-3-4-2

Compression

Ratio9.5:1

Max. Variation

Between

Cylinders25%

Metric Standard

Displacement 2.4 Liters 148 cu. in.

Bore 87.5 mm 3.445 in.

Stroke 101.0 mm 3.976 in.

Compression

Pressure1172-1551 kPa 170-225 psi

CYLINDER BLOCK

DESCRIPTION SPECIFICATIONS

Metric Standard

Cylinder Bore

Diameter87.4924 -

87.5076 mm3.4446 - 3.4452

in.

Out-of-Round

(Max.)0.051 mm 0.002 in.

Taper (Max.) 0.051 mm 0.002 in.

Fig. 9 RIGHT MOUNT TO RAIL AND ENGINE

1 - BOLT - MOUNT TO RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO ENGINE 54 N´m (40 ft. lbs.)

3 - BOLT - MOUNT TO RAIL (HORIZONTAL) 68 N´m (50 ft. lbs.)

4 - RIGHT ENGINE MOUNT

5 - RIGHT FRAME RAIL

Fig. 10 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

9 - 16 ENGINE 2.4LRS

ENGINE 2.4L (Continued)